The Ultimate Guide to Dental Products Manufacturers (2025)

Introduction: Navigating the Global Market for dental products manufacturers

Navigating the intricate landscape of dental products manufacturers can be a daunting challenge for international B2B buyers. With a vast array of suppliers and products available, sourcing high-quality dental equipment and materials tailored to specific market needs—whether for clinics in Saudi Arabia or dental labs in Brazil—requires a strategic approach. This guide aims to demystify the global dental products market, providing insights into various types of products, their applications, and essential criteria for supplier vetting.

As buyers from Africa, South America, the Middle East, and Europe seek reliable partners in their procurement processes, understanding the nuances of cost structures, regulatory compliance, and product quality becomes paramount. This comprehensive resource will equip you with the knowledge to make informed purchasing decisions, ensuring that you select manufacturers who not only meet your operational requirements but also align with your business values.

From the latest innovations in dental technology to the foundational materials needed for everyday procedures, this guide covers it all. Expect actionable insights on how to evaluate suppliers effectively, negotiate favorable terms, and leverage market trends to your advantage. By empowering B2B buyers with critical information and practical strategies, we aim to streamline your sourcing journey and enhance your competitive edge in the ever-evolving dental landscape.

Understanding dental products manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Dental Equipment Manufacturers | Specialize in large equipment like chairs and x-ray machines | Dental clinics, hospitals, educational institutions | Pros: High durability, advanced technology; Cons: High initial investment, maintenance costs |

| Dental Consumables Manufacturers | Produce everyday items like dental crowns and fillings | Dental practices, laboratories | Pros: Cost-effective, essential for daily operations; Cons: Quality variability, short shelf life |

| Dental Instrument Manufacturers | Focus on hand tools such as scalers and mirrors | Dental surgeries, orthodontics | Pros: Precision tools, diverse options; Cons: Risk of obsolescence, may require frequent replacement |

| Dental Lab Manufacturers | Provide custom products like dentures and implants | Dental labs, cosmetic dentistry | Pros: Customization options, specialized products; Cons: Longer lead times, potential for higher costs |

| Digital Dental Technology Providers | Offer software and digital solutions for design and imaging | Dental practices, educational institutions | Pros: Enhanced efficiency, improved accuracy; Cons: Technology learning curve, ongoing software costs |

What Are the Characteristics of Dental Equipment Manufacturers?

Dental Equipment Manufacturers specialize in creating large-scale equipment essential for dental practices, such as dental chairs, sterilizers, and x-ray machines. These manufacturers focus on durability and advanced technology, making their products a long-term investment for clinics and hospitals. When considering B2B purchases, buyers should evaluate the total cost of ownership, including installation, maintenance, and potential upgrades, to ensure that the equipment meets their operational needs without exceeding budget constraints.

How Do Dental Consumables Manufacturers Differ?

Dental Consumables Manufacturers focus on everyday dental products like crowns, fillings, and impression materials. These products are essential for the daily operations of dental practices and are often cost-effective. However, buyers must consider factors such as quality consistency and shelf life when making purchasing decisions. Establishing relationships with reputable manufacturers can mitigate risks associated with product variability and ensure that dental professionals have reliable supplies for patient care.

What Should B2B Buyers Know About Dental Instrument Manufacturers?

Dental Instrument Manufacturers produce hand tools like scalers, mirrors, and forceps that are vital for dental procedures. These instruments are characterized by their precision and variety, allowing dental professionals to select tools that best fit their specific needs. For B2B buyers, it is crucial to assess the durability and ergonomics of instruments, as well as the manufacturer’s reputation for quality. Regular updates and replacements may be necessary, so establishing a reliable supply chain is essential for ongoing practice operations.

Why Consider Dental Lab Manufacturers?

Dental Lab Manufacturers provide custom products such as dentures, crowns, and implants tailored to individual patient needs. Their focus on customization makes them a critical partner for dental labs and cosmetic dentistry practices. When evaluating these manufacturers, B2B buyers should consider lead times and the potential for higher costs associated with bespoke products. It is beneficial to seek manufacturers that offer transparent communication and reliable delivery schedules to enhance workflow efficiency.

What Are the Benefits of Digital Dental Technology Providers?

Digital Dental Technology Providers offer innovative software and imaging solutions that streamline dental design and diagnostic processes. These technologies enhance operational efficiency and improve accuracy in treatment planning. For B2B buyers, understanding the learning curve associated with new technologies is essential, as well as considering the ongoing costs related to software updates and training. Investing in digital solutions can significantly elevate practice capabilities, making it a worthy consideration for modern dental practices.

Related Video: Gypsum Products | Dental Plaster Dental Stone | Dental Materials

Key Industrial Applications of dental products manufacturers

| Industry/Sector | Specific Application of dental products manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dental Clinics | Supply of dental instruments and consumables | Enhanced patient care and operational efficiency | Quality certifications, supplier reliability, and lead times |

| Dental Laboratories | Production of dental prosthetics and restorations | Improved accuracy in dental solutions and patient outcomes | Material specifications, customization options, and delivery timelines |

| Educational Institutions | Training kits for dental students | Comprehensive training, ensuring future workforce readiness | Cost-effectiveness, educational alignment, and product quality |

| Pharmaceutical Companies | Development of dental medications and treatments | Expansion of product lines and market competitiveness | Regulatory compliance, formulation expertise, and sourcing of active ingredients |

| Research Institutions | Development of innovative dental materials | Advancements in dental technology and research outputs | Collaboration opportunities, intellectual property, and funding sources |

How Are Dental Instruments and Consumables Used in Dental Clinics?

Dental clinics rely heavily on dental instruments and consumables, such as drills, scalers, and sterilization supplies, to provide quality care. These products enable dentists to perform various procedures efficiently, thus enhancing patient satisfaction and clinic productivity. International buyers, particularly from Africa, South America, the Middle East, and Europe, must ensure that the suppliers adhere to high-quality standards and certifications to maintain safety and efficacy in their practices.

What Role Do Dental Laboratories Play in Producing Prosthetics and Restorations?

Dental laboratories utilize dental products manufacturers to create custom prosthetics and restorations, such as crowns, bridges, and dentures. This application is crucial for delivering tailored solutions that meet specific patient needs, improving overall dental outcomes. B2B buyers in this sector should focus on the material specifications and customization options offered by manufacturers to ensure compatibility with their existing processes and technologies.

Why Are Training Kits Important for Educational Institutions?

Educational institutions use dental training kits to equip students with the necessary hands-on experience in dental procedures. These kits typically include models, instruments, and materials that simulate real-world scenarios, fostering a comprehensive learning environment. Buyers from international markets should prioritize cost-effectiveness and alignment with educational standards to ensure that they are investing in products that enhance the learning experience while also preparing students for the workforce.

How Do Pharmaceutical Companies Benefit from Dental Medications?

Pharmaceutical companies partner with dental products manufacturers to develop innovative dental medications and treatments, such as anesthetics and antibacterial agents. This collaboration allows for the expansion of product lines and strengthens their competitive edge in the market. When sourcing dental medications, companies must consider regulatory compliance and the formulation expertise of their suppliers to ensure the safety and effectiveness of their products.

What Innovations Are Being Developed in Research Institutions?

Research institutions are at the forefront of developing innovative dental materials, such as biocompatible composites and advanced ceramics. These materials are essential for pushing the boundaries of dental technology and improving treatment options. International buyers looking to collaborate with research institutions should focus on potential partnerships, intellectual property rights, and available funding sources to support their innovation efforts in the dental sector.

Related Video: Uses and Gratifications Theory

3 Common User Pain Points for ‘dental products manufacturers’ & Their Solutions

Scenario 1: Navigating Regulatory Compliance in Dental Products

The Problem:

International B2B buyers often face significant hurdles when it comes to regulatory compliance for dental products. Each country has its own set of regulations, which can be particularly challenging for buyers in regions like Africa and the Middle East, where guidelines may be less transparent or frequently changing. For instance, a dental practice in Saudi Arabia may struggle to understand the specific certifications required for importing dental materials, leading to potential delays in product availability and the risk of incurring fines or penalties.

The Solution:

To effectively navigate these regulatory complexities, B2B buyers should prioritize partnering with dental product manufacturers that have a robust understanding of international regulations. Start by requesting documentation that outlines compliance with local and international standards, such as ISO certifications or CE marking for products intended for the European market.

Engage with manufacturers that have experience exporting to your specific region and can provide insights into local regulations. Additionally, consider using third-party compliance consultants who specialize in the dental industry to help interpret regulations and ensure that all products meet necessary standards before shipment. This proactive approach will minimize delays and enhance your supply chain’s reliability.

Scenario 2: Ensuring Product Quality and Consistency

The Problem:

Quality control is a persistent issue for B2B buyers in the dental sector. Importing dental products from manufacturers can lead to variations in quality, which is particularly concerning when the products in question are critical to patient care. For example, a dental clinic in South America may receive inconsistent batches of dental composites, impacting treatment outcomes and client satisfaction.

The Solution:

To address concerns about product quality and consistency, buyers should establish clear quality criteria and communicate these expectations directly to manufacturers. Consider implementing a quality assurance program that includes regular audits and product testing.

Additionally, building long-term relationships with manufacturers known for their commitment to quality can also prove beneficial. Engage in discussions about their manufacturing processes and quality control measures to understand how they ensure product consistency. Lastly, leverage technology by utilizing supply chain management software that tracks quality metrics and product performance over time, allowing for more informed purchasing decisions.

Scenario 3: Managing Supply Chain Disruptions

The Problem:

Supply chain disruptions can significantly impact the availability of dental products. This issue has become increasingly pronounced in recent years, with global events causing delays and shortages. For instance, a dental supplier in Europe might find that their usual source for dental tools is suddenly unavailable, leading to treatment delays and lost revenue.

The Solution:

To mitigate the risks associated with supply chain disruptions, B2B buyers should diversify their supplier base. Rather than relying on a single manufacturer, identify multiple sources for essential dental products, including local manufacturers in emerging markets. This strategy not only enhances resilience but may also uncover cost-effective alternatives.

Additionally, maintaining open lines of communication with suppliers can provide early warnings of potential disruptions. Establishing agreements with manufacturers that include contingency plans for supply chain interruptions will also be beneficial. Finally, consider leveraging local inventory solutions, such as warehousing partnerships, to ensure that critical dental supplies are readily available, even during times of global uncertainty. This proactive supply chain management will help sustain operations and maintain service levels for clients.

Strategic Material Selection Guide for dental products manufacturers

When selecting materials for dental products, manufacturers must consider a variety of factors that impact product performance, compliance, and market suitability. This guide analyzes four common materials used in the dental industry: stainless steel, dental ceramics, thermoplastics, and composite resins. Each material presents unique properties, advantages, and limitations that can significantly influence the final product and its acceptance in various international markets.

What Are the Key Properties of Stainless Steel for Dental Products?

Stainless steel is a popular choice for dental instruments and components due to its excellent mechanical properties, including high tensile strength and resistance to deformation. It typically withstands temperatures up to 300°C and exhibits good corrosion resistance, making it suitable for sterilization processes.

Pros & Cons: The durability of stainless steel is a significant advantage, ensuring long-lasting performance in clinical settings. However, its higher cost compared to some alternatives can be a drawback for budget-sensitive buyers. Additionally, the manufacturing complexity may lead to increased lead times.

Impact on Application: Stainless steel is compatible with various dental applications, including surgical instruments and orthodontic appliances. Its ability to withstand repeated sterilization cycles without degradation is crucial for maintaining hygiene standards.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local health regulations and standards such as ASTM and ISO. The preference for stainless steel may vary based on regional availability and pricing.

How Do Dental Ceramics Compare in Terms of Performance?

Dental ceramics, particularly zirconia and porcelain, are renowned for their aesthetic appeal and biocompatibility. These materials can withstand high temperatures and exhibit excellent wear resistance, making them ideal for crowns, bridges, and veneers.

Pros & Cons: The primary advantage of dental ceramics is their superior aesthetic qualities, closely mimicking natural teeth. However, they can be brittle, leading to potential failure under excessive stress. Additionally, the manufacturing process can be complex and costly.

Impact on Application: Ceramics are particularly suitable for applications requiring high aesthetic standards, such as cosmetic dentistry. Their compatibility with dental cements and adhesives is essential for ensuring long-term success in restorations.

Considerations for International Buyers: Buyers in Europe may prioritize ceramics due to aesthetic preferences, while those in South America might focus on cost-effectiveness. Understanding local market trends and consumer preferences is vital for successful product positioning.

What Are the Advantages of Using Thermoplastics in Dental Manufacturing?

Thermoplastics, such as polyether ether ketone (PEEK) and polyamide (nylon), are increasingly used in dental applications due to their lightweight nature and flexibility. These materials can withstand moderate temperatures and exhibit good chemical resistance.

Pros & Cons: The key advantage of thermoplastics is their versatility and ease of processing, allowing for rapid prototyping and production. However, their mechanical properties may not match those of metals, limiting their use in load-bearing applications.

Impact on Application: Thermoplastics are often used in removable dentures and orthodontic appliances, where flexibility and comfort are paramount. Their compatibility with various dental adhesives enhances their usability.

Considerations for International Buyers: Buyers from regions like Saudi Arabia should consider the local acceptance of thermoplastics in dental applications, as traditional materials may still dominate the market. Compliance with regional standards is also crucial.

Why Are Composite Resins Important for Dental Applications?

Composite resins are widely used for restorative procedures due to their aesthetic qualities and bonding capabilities. These materials typically perform well under varying temperatures and exhibit good wear resistance.

Pros & Cons: The primary advantage of composite resins is their ability to blend seamlessly with natural teeth, making them ideal for fillings and cosmetic repairs. However, they may require careful handling during application to avoid issues like shrinkage.

Impact on Application: Composite resins are suitable for anterior and posterior restorations, providing both functional and aesthetic benefits. Their compatibility with dental bonding agents is critical for ensuring durability.

Considerations for International Buyers: Buyers in Europe and South America may favor composite resins due to their aesthetic advantages. Understanding the local regulations regarding dental materials and their performance standards is essential for compliance.

Summary Table of Material Selection for Dental Products

| Material | Typical Use Case for dental products manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Surgical instruments, orthodontic appliances | High durability and sterilization resistance | Higher cost, manufacturing complexity | Medium |

| Dental Ceramics | Crowns, bridges, veneers | Superior aesthetics and biocompatibility | Brittle, complex manufacturing | High |

| Thermoplastics | Removable dentures, orthodontic appliances | Lightweight and flexible | Limited mechanical properties | Medium |

| Composite Resins | Restorative fillings, cosmetic repairs | Excellent aesthetic blending | Potential shrinkage issues | Medium |

In conclusion, selecting the right material for dental products involves a careful evaluation of performance properties, application suitability, and compliance with regional standards. Understanding these factors will empower international B2B buyers to make informed decisions that align with their market needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for dental products manufacturers

What Are the Key Stages in Manufacturing Dental Products?

Manufacturing dental products involves several critical stages, each designed to ensure high-quality outputs that meet stringent industry standards. The main stages of the manufacturing process include material preparation, forming, assembly, and finishing.

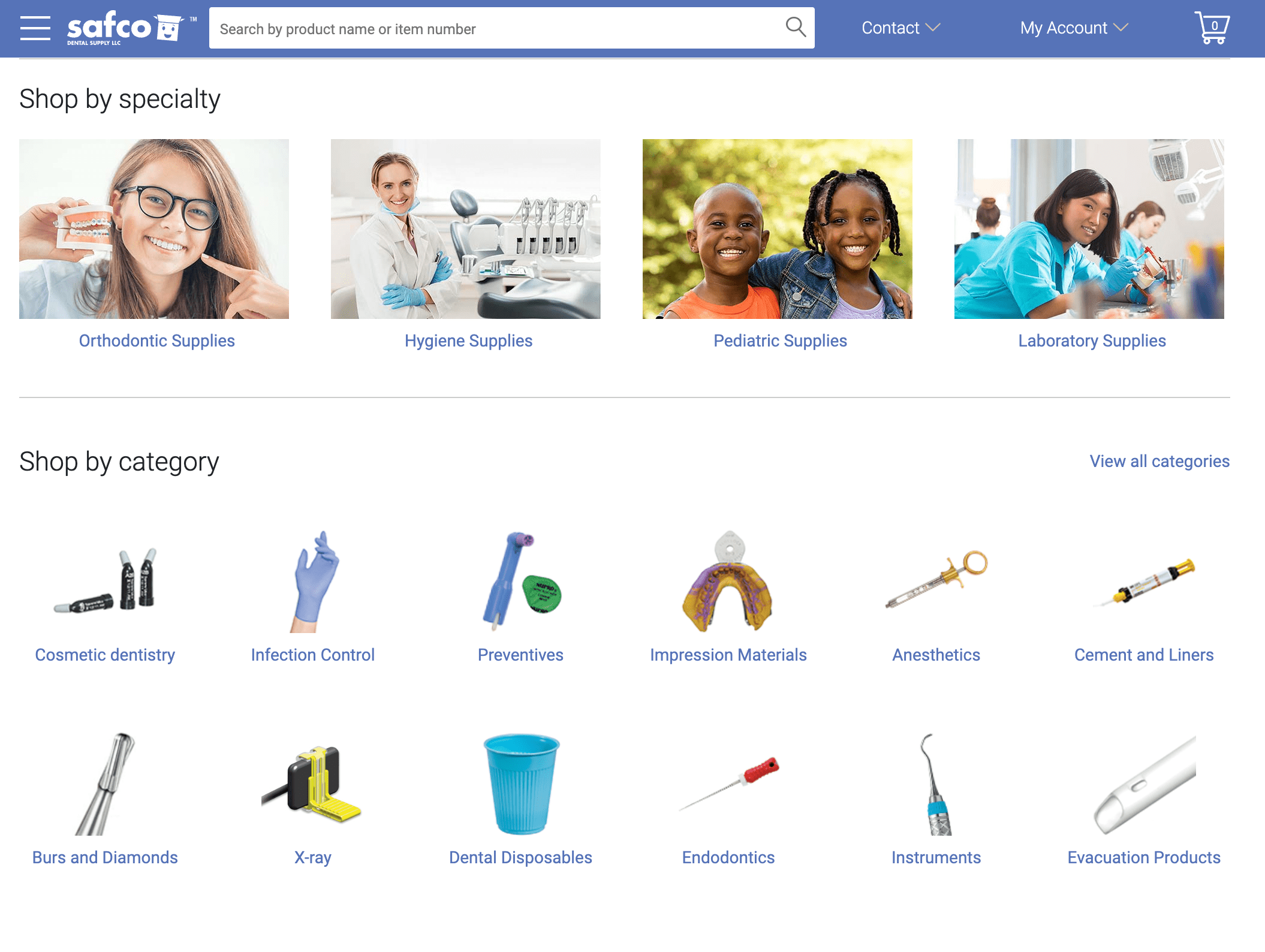

A stock image related to dental products manufacturers.

-

Material Preparation: This initial stage involves sourcing high-quality raw materials, which can include metals, plastics, ceramics, and composites. Suppliers must ensure that these materials comply with international standards such as ISO 13485, which is specific to medical devices. B2B buyers should inquire about the origin of materials and their certifications, as this can impact product quality and regulatory compliance.

-

Forming: During the forming stage, raw materials are shaped into the desired product forms. Common techniques include injection molding, extrusion, and CNC machining. Each technique has its advantages; for example, injection molding is favored for producing complex shapes with high precision. Buyers should assess the manufacturing capabilities of suppliers to ensure they can meet specific design requirements.

-

Assembly: This stage involves the integration of various components to create the final product. For dental products, assembly may include attaching handles to instruments or assembling multi-part devices like dental chairs. It’s crucial for manufacturers to maintain a clean environment during assembly to prevent contamination. Buyers should evaluate suppliers’ assembly processes, including labor skills and the use of automation.

-

Finishing: The final stage focuses on refining the product’s surface and ensuring it meets aesthetic and functional specifications. This may involve polishing, coating, or sterilization processes. B2B buyers should verify that suppliers use appropriate finishing techniques that comply with health regulations, especially in regions with strict hygiene standards.

How Do Quality Control Measures Ensure Product Integrity?

Quality control (QC) is an essential aspect of manufacturing dental products. Robust QC processes help guarantee that products meet both industry standards and customer expectations. Key international standards relevant to dental product manufacturers include ISO 9001 for quality management systems and specific certifications like CE marking in Europe and FDA approval in the U.S.

What Are the Key QC Checkpoints in Dental Product Manufacturing?

-

Incoming Quality Control (IQC): This checkpoint assesses the quality of incoming materials before production begins. Effective IQC procedures include material inspections and testing for compliance with specifications. Buyers should request information on IQC practices to understand how suppliers ensure material quality from the outset.

-

In-Process Quality Control (IPQC): During manufacturing, IPQC monitors production processes to identify and address issues in real time. This could involve checking machinery calibration, monitoring environmental conditions, and conducting random product sampling. Buyers should inquire about the frequency and methods of IPQC to ensure ongoing quality during production.

-

Final Quality Control (FQC): The FQC stage evaluates the finished product against pre-defined criteria. This includes functional testing, dimensional checks, and aesthetic inspections. B2B buyers should ask for documentation of FQC results to verify that the products meet the required standards before shipment.

What Testing Methods Are Commonly Used in Dental Product Manufacturing?

Testing methods play a crucial role in quality assurance for dental products. Common testing techniques include:

-

Mechanical Testing: This involves assessing the strength and durability of materials and components under various conditions. Tensile strength tests, fatigue tests, and impact tests are often conducted.

-

Biocompatibility Testing: Given that dental products often come into contact with human tissues, it’s vital to conduct biocompatibility tests. These tests evaluate the safety of materials used in dental products.

-

Sterilization Validation: Manufacturers must demonstrate that their sterilization processes effectively eliminate pathogens. This is particularly important for products intended for surgical use.

B2B buyers should ensure that suppliers have validated testing protocols and can provide evidence of compliance with relevant standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are several actionable strategies:

-

Supplier Audits: Conducting regular audits of potential suppliers allows buyers to assess their manufacturing processes and QC measures firsthand. During audits, buyers should evaluate the supplier’s adherence to quality standards, staff training, and equipment maintenance.

-

Quality Assurance Reports: Requesting detailed quality assurance reports from suppliers can provide insights into their QC processes. These reports should include information on testing methods, results, and any corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can offer an impartial assessment of a supplier’s capabilities and compliance with international standards. This is particularly beneficial for buyers who may not have the resources to conduct comprehensive audits themselves.

-

Certifications and Compliance Documents: Buyers should request copies of relevant certifications, such as ISO 9001 or CE marks, to verify that suppliers meet industry standards. Understanding the nuances of these certifications can help buyers make informed decisions.

What Are the Regulatory Nuances for International B2B Buyers in Dental Product Manufacturing?

Navigating the regulatory landscape is vital for B2B buyers sourcing dental products internationally. Different regions have distinct regulations that must be adhered to:

-

Africa: Many African countries are developing their regulatory frameworks for medical devices. Buyers should familiarize themselves with local regulations to ensure compliance.

-

South America: In countries like Brazil, ANVISA regulates medical devices. Buyers should ensure that suppliers are compliant with local registration processes.

-

Middle East: The GCC countries have adopted specific regulations for medical devices. Buyers should verify that suppliers meet these standards to avoid import issues.

-

Europe: The EU has stringent regulations for medical devices, including the Medical Device Regulation (MDR). Buyers must ensure suppliers are compliant with CE marking requirements.

By understanding these regulatory nuances, B2B buyers can mitigate risks associated with compliance and ensure that the products they purchase are safe and effective.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dental products manufacturers’

This guide serves as a comprehensive checklist for international B2B buyers seeking to source dental products from manufacturers. With the growing demand for dental supplies globally, particularly in regions like Africa, South America, the Middle East, and Europe, it is essential to follow a structured approach to ensure quality, compliance, and reliability in your procurement process.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for sourcing dental products that meet your needs. This includes determining the types of products required, such as dental instruments, materials, or equipment. Additionally, consider factors like dimensions, materials, and performance standards that align with industry regulations and best practices.

Step 2: Conduct Market Research

Before reaching out to suppliers, invest time in market research to understand the landscape of dental products manufacturers. Identify key players in the market and analyze their offerings, pricing structures, and reputations. Utilize industry reports, trade shows, and online directories to compile a list of potential suppliers that cater to your specific region and requirements.

Step 3: Verify Supplier Certifications

Ensure that potential suppliers possess the necessary certifications and licenses to operate in the dental products sector. Look for ISO certifications, CE markings (for European markets), and FDA approvals (for the U.S. market). These certifications indicate compliance with quality standards and regulations, which is vital for ensuring product safety and efficacy.

Step 4: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation of their capabilities. Request company profiles, case studies, and references from other buyers in similar industries or regions. Pay attention to their production capacity, lead times, and customer service reputation, as these factors can significantly impact your supply chain efficiency.

Step 5: Request Samples and Conduct Quality Testing

Always request samples of the products you intend to purchase to assess their quality firsthand. Conduct rigorous quality testing to ensure that the products meet your specifications and industry standards. This step not only helps in verifying the product quality but also gives you a chance to evaluate the supplier’s responsiveness and willingness to accommodate your needs.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, negotiate terms and conditions that are mutually beneficial. Discuss pricing, payment terms, delivery schedules, and warranty policies. Be clear about your expectations to avoid misunderstandings later. A well-negotiated agreement can foster a strong long-term partnership.

Step 7: Establish a Communication Plan

Effective communication is key to a successful sourcing relationship. Establish a clear communication plan that outlines how often you will check in with the supplier and through which channels (e.g., email, phone, or video calls). Regular updates can help you stay informed about production progress and any potential issues that may arise.

By following this step-by-step checklist, B2B buyers can streamline their sourcing process for dental products, ensuring they partner with reputable manufacturers that meet their specific needs and quality standards.

Comprehensive Cost and Pricing Analysis for dental products manufacturers Sourcing

What Are the Key Cost Components in Dental Products Manufacturing?

Understanding the cost structure of dental products manufacturing is crucial for international B2B buyers. The primary components include:

-

Materials: Raw materials such as plastics, metals, and ceramics constitute a significant portion of the total cost. Prices can fluctuate based on global supply chain conditions and material availability.

-

Labor: Labor costs vary significantly by region. In emerging markets, labor may be cheaper, but this can also correlate with varying skill levels and productivity rates.

-

Manufacturing Overhead: This includes utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: The costs associated with the equipment and molds needed for production can be substantial, especially for custom products. Investment in high-quality tooling can lead to better long-term cost efficiency.

-

Quality Control (QC): Implementing rigorous QC processes is essential in the dental industry to ensure product safety and efficacy. While this adds to the upfront costs, it can prevent expensive recalls and legal issues down the line.

-

Logistics: Shipping and handling costs, including warehousing and freight charges, play a critical role in overall pricing. International buyers must consider the implications of customs duties and taxes.

-

Margin: Manufacturers typically build in a profit margin to cover their costs and ensure sustainability. This margin can vary based on market dynamics and competition.

How Do Price Influencers Affect Dental Products Costs?

Several factors influence pricing strategies for dental products:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchasing often leads to lower per-unit costs. Negotiating favorable terms can yield significant savings.

-

Specifications and Customization: Customized products may incur additional costs due to specialized manufacturing processes. Clearly defining your specifications can help avoid unexpected expenses.

-

Materials: The choice of materials directly impacts pricing. High-quality or specialized materials will increase costs but can also enhance product performance and longevity.

-

Quality Certifications: Compliance with international quality standards (e.g., ISO, CE) may involve additional costs for testing and certification, which can affect pricing.

-

Supplier Factors: The supplier’s reputation, reliability, and capacity can influence pricing. Established suppliers may charge a premium for their experience and quality assurance.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for determining responsibilities in shipping and logistics, impacting the total cost.

What Are the Best Negotiation Tips for B2B Buyers in the Dental Products Sector?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation is key to cost savings:

-

Conduct a Total Cost of Ownership Analysis: Look beyond the initial price. Consider factors like maintenance, durability, and warranty services to assess the true cost of a product.

-

Leverage Market Knowledge: Familiarize yourself with regional market conditions and competitor pricing. This knowledge can strengthen your negotiating position.

-

Build Long-term Relationships: Establishing rapport with suppliers can lead to better pricing and terms over time. Suppliers may be more willing to negotiate with buyers who demonstrate loyalty.

-

Request Multiple Quotes: Solicit bids from several manufacturers to compare prices and services. This competitive approach can help you secure more favorable terms.

-

Be Clear About Expectations: Clearly communicating your needs and expectations can minimize misunderstandings and lead to more accurate pricing.

Are There Pricing Nuances for International Buyers to Consider?

International buyers must navigate additional complexities when sourcing dental products:

-

Currency Fluctuations: Exchange rate variations can affect pricing, especially for long-term contracts. Consider pricing in a stable currency to mitigate risks.

-

Import Duties and Taxes: Be aware of tariffs and taxes that may apply when importing dental products. These can significantly alter the total cost.

-

Cultural Differences in Business Practices: Understanding regional negotiation styles and business etiquette can facilitate smoother transactions.

Disclaimer on Indicative Prices

Prices for dental products can vary widely based on the factors mentioned above. It’s essential to conduct thorough market research and engage in direct negotiations with manufacturers to obtain accurate and current pricing information tailored to your specific needs.

Alternatives Analysis: Comparing dental products manufacturers With Other Solutions

Understanding Alternative Solutions in Dental Products

In the ever-evolving landscape of dental care, B2B buyers often face the challenge of selecting the most effective solutions for their practices or distribution needs. While traditional dental products manufacturers offer a wide array of tools and supplies, exploring alternative solutions can yield significant benefits. This section compares dental products manufacturers with two viable alternatives: digital dentistry technologies and outsourcing dental supplies.

Comparison Table of Dental Products Manufacturers and Alternatives

| Comparison Aspect | Dental Products Manufacturers | Digital Dentistry Technologies | Outsourcing Dental Supplies |

|---|---|---|---|

| Performance | High quality and reliability | High precision and efficiency | Varies widely |

| Cost | Moderate to high | Can be high initial investment | Typically lower |

| Ease of Implementation | Straightforward | Requires training and adaptation | Simple, but depends on provider |

| Maintenance | Regular maintenance needed | Software updates and hardware checks | Minimal, dependent on supplier |

| Best Use Case | General dental practices | Advanced procedures, efficiency | Cost-effective bulk purchasing |

What Are the Benefits and Drawbacks of Digital Dentistry Technologies?

Digital dentistry technologies, including CAD/CAM systems and 3D printing, offer innovative solutions for dental practices looking to enhance precision and efficiency. The primary advantages include reduced turnaround times for dental restorations and the ability to create highly customized products. However, the initial investment can be substantial, and practices may require additional training to fully leverage the technology. This option is best suited for dental practices focusing on advanced procedures and those that want to streamline their workflows.

How Does Outsourcing Dental Supplies Compare to Traditional Manufacturing?

Outsourcing dental supplies involves partnering with third-party suppliers who handle the procurement of dental products. This method can significantly lower costs, especially for practices or distributors looking to purchase in bulk. Outsourcing also simplifies inventory management and reduces the overhead associated with maintaining stock. However, the quality of products may vary depending on the supplier, and buyers must conduct thorough due diligence to ensure reliability. This solution is ideal for businesses focused on cost savings and efficient supply chain management.

How Should B2B Buyers Choose Between These Solutions?

When selecting the right solution, B2B buyers should assess their specific needs, budget, and operational goals. For practices emphasizing advanced dental techniques and patient customization, digital dentistry technologies may offer the most significant return on investment despite their higher initial costs. Conversely, for those prioritizing cost-efficiency and simplified logistics, outsourcing dental supplies can be a smart choice. Ultimately, understanding the unique demands of your business and aligning them with the strengths of each alternative will lead to a more informed decision.

Essential Technical Properties and Trade Terminology for dental products manufacturers

What Are the Key Technical Properties of Dental Products?

When sourcing dental products, understanding the technical properties is crucial for ensuring quality and compliance. Here are some of the essential specifications that international B2B buyers should consider:

1. Material Grade

Material grade refers to the quality and composition of the materials used in dental products. Common grades include high-grade stainless steel for instruments and biocompatible polymers for dental prosthetics. The choice of material affects durability, safety, and patient comfort. Buyers must verify material certifications to ensure compliance with local and international standards.

2. Tolerance

Tolerance indicates the allowable deviation from a specified dimension in dental products. For example, a dental crown must fit precisely to avoid discomfort and complications. A tighter tolerance often translates to higher manufacturing costs but is essential for patient safety and satisfaction. Understanding tolerance levels helps buyers assess product quality and suitability for specific applications.

3. Sterilization Method

Different dental products require specific sterilization methods to ensure they are safe for use. Common methods include autoclaving, ethylene oxide gas, and gamma radiation. Each method has implications for product integrity and longevity. Buyers should inquire about the sterilization process used by manufacturers to ensure that products meet safety regulations in their region.

4. Biocompatibility

Biocompatibility refers to the ability of a material to perform safely within the human body without eliciting an adverse reaction. This property is particularly important for dental implants and prosthetics. Buyers should request biocompatibility testing data to ensure that the products will not cause allergies or other health issues for patients.

5. Shelf Life

Shelf life indicates how long a dental product can be stored before it becomes ineffective or unsafe. Understanding shelf life is crucial for inventory management and ensuring that products remain viable for use. Buyers should check expiration dates and storage conditions to optimize stock rotation and minimize waste.

What Are Common Trade Terms Used in Dental Products Manufacturing?

Familiarity with trade terminology is essential for effective communication and negotiation in the dental products industry. Here are some common terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are branded and sold by another company. In the dental industry, this often involves producing instruments or devices that are later marketed under a different label. Understanding OEM relationships can help buyers identify potential partners and ensure product quality.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier requires for an order. This term is crucial for buyers to understand, as it affects purchasing decisions and inventory management. A lower MOQ can facilitate smaller purchases, especially for new or growing businesses, while higher MOQs might offer cost savings per unit.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing information for specific products. This process allows buyers to compare offers and negotiate terms. When submitting an RFQ, it’s important to provide detailed specifications to ensure accurate quotes.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping costs and risk transfer. Familiarity with these terms helps buyers understand their obligations and negotiate better terms. Common Incoterms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight).

5. CE Marking

CE marking indicates that a product meets European safety, health, and environmental protection standards. This certification is vital for dental products sold in Europe, ensuring compliance with regulations. Buyers should verify CE marking to ensure that products are legally marketable in their regions.

Understanding these technical properties and trade terms can significantly enhance the purchasing process for international B2B buyers in the dental products sector, leading to informed decisions that meet both business and patient needs.

Navigating Market Dynamics and Sourcing Trends in the dental products manufacturers Sector

What Are the Current Market Dynamics and Key Trends in Dental Products Manufacturing?

The dental products manufacturing sector is witnessing significant changes driven by global factors such as technological advancements, evolving consumer preferences, and regulatory shifts. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, it is crucial to understand these dynamics.

One of the major drivers is the increasing demand for advanced dental solutions, such as digital dentistry tools and tele-dentistry services. These technologies not only enhance patient care but also streamline operations for dental practices. Moreover, the rise of e-commerce platforms has transformed how dental products are sourced, allowing manufacturers to reach international markets with greater ease. B2B buyers should leverage these platforms to find competitive pricing and unique products.

Another notable trend is the growing emphasis on personalized dental care. Customization in dental products, such as tailored orthodontic devices and 3D-printed dental implants, is becoming a key differentiator. This trend aligns with the rising consumer expectation for personalized healthcare solutions, presenting opportunities for international buyers to source innovative products that meet these demands.

Additionally, the impact of global events such as the COVID-19 pandemic has led to a heightened focus on supply chain resilience. Buyers should prioritize manufacturers that demonstrate flexibility and reliability in their sourcing strategies, as well as those who have adopted advanced inventory management systems to mitigate disruptions.

How Is Sustainability and Ethical Sourcing Impacting the Dental Products Sector?

Sustainability is no longer just a trend; it has become a vital consideration for B2B buyers in the dental products sector. The environmental impact of manufacturing processes, including waste generation and resource depletion, is under scrutiny. Buyers are encouraged to seek out manufacturers who prioritize sustainability in their operations.

Ethical sourcing is also paramount. This involves ensuring that materials used in dental products are obtained responsibly, without harming communities or ecosystems. Buyers should inquire about a manufacturer’s supply chain practices and look for certifications such as ISO 14001 for environmental management and Fair Trade certifications.

Moreover, the demand for “green” materials—such as biodegradable composites and sustainably sourced metals—has surged. International buyers should actively search for products that meet these environmental standards, as they not only align with global sustainability goals but also appeal to an increasingly eco-conscious consumer base.

Investing in sustainable and ethically sourced dental products can enhance a company’s reputation and appeal to clients who prioritize corporate social responsibility. Therefore, understanding these factors is essential for making informed purchasing decisions.

What Has Been the Evolution of the Dental Products Manufacturing Sector?

The dental products manufacturing sector has evolved significantly over the past few decades. Initially dominated by traditional methods and materials, the industry has transitioned to embrace cutting-edge technologies and innovative materials. The introduction of digital technologies, such as CAD/CAM systems and 3D printing, has revolutionized product development, allowing for greater precision and customization.

This evolution is not only about technology but also reflects a shift in consumer expectations. Patients today are more informed and demand higher-quality, personalized care. As a result, manufacturers have had to adapt their offerings to meet these changing needs, ensuring that they remain competitive in a rapidly evolving marketplace.

For international B2B buyers, understanding this historical context is essential. It provides insights into how manufacturers have responded to market demands and highlights the importance of innovation in selecting reliable partners.

Frequently Asked Questions (FAQs) for B2B Buyers of dental products manufacturers

-

How do I evaluate the quality of dental products from manufacturers?

To assess the quality of dental products, international B2B buyers should request certifications such as ISO, CE, or FDA approvals that indicate compliance with international standards. It’s also beneficial to ask for product samples to conduct firsthand evaluations. Consider visiting the manufacturing facility, if feasible, or utilizing third-party inspection services to verify quality. Additionally, reviewing customer testimonials and case studies can provide insights into the manufacturer’s reputation and reliability. -

What are the key factors to consider when selecting a dental products manufacturer?

When choosing a dental products manufacturer, consider their industry experience, product range, and technological capabilities. Evaluate their customer service and responsiveness to inquiries, as this reflects their commitment to collaboration. Additionally, investigate their supply chain logistics and ability to meet delivery timelines. Understanding their pricing structure and flexibility regarding minimum order quantities (MOQ) will also help determine if they align with your business needs. -

What is the minimum order quantity (MOQ) for dental products?

Minimum order quantities can vary significantly among dental product manufacturers. Typically, MOQs are influenced by the type of product, production costs, and the manufacturer’s business model. For international buyers, it’s essential to negotiate MOQs that suit your purchasing capacity, especially when entering new markets. Discussing potential bulk order discounts or trial orders can also provide an opportunity to establish a relationship without committing to large quantities initially. -

What payment terms should I expect when sourcing dental products internationally?

Payment terms can vary widely based on the manufacturer and the country of origin. Common terms include advance payment, letter of credit, or payment upon delivery. It’s crucial to clarify these terms before finalizing an agreement. Buyers should consider negotiating terms that mitigate risk, such as partial payments upon order confirmation and balance upon shipment. Understanding currency exchange rates and potential transaction fees is also essential to ensure clear budgeting. -

How can I ensure timely delivery of dental products from manufacturers?

To ensure timely delivery, establish clear communication with the manufacturer regarding lead times and shipping schedules. Utilizing reliable logistics partners and discussing freight options can optimize delivery efficiency. It’s advisable to factor in potential delays due to customs clearance or other logistical challenges, especially for international shipments. Regular follow-ups during the production and shipping process can also help in managing timelines effectively. -

What customization options are available for dental products?

Many dental products manufacturers offer customization options to meet specific buyer requirements. This may include product design, branding, packaging, and even formulation for certain products. To explore customization, initiate discussions early in the sourcing process and provide detailed specifications of your needs. Understanding the associated costs and lead times for custom orders is also crucial, as these can differ from standard offerings. -

How do I vet potential dental products manufacturers effectively?

Effective vetting of dental products manufacturers involves thorough research and due diligence. Start by checking the manufacturer’s credentials, including certifications and industry memberships. Request references from previous clients and investigate online reviews. Conducting factory audits or third-party inspections can also provide deeper insights into their operational capabilities. Utilizing platforms that specialize in supplier verification can further enhance your vetting process.

A stock image related to dental products manufacturers.

- What are the common logistics challenges when importing dental products?

Common logistics challenges include customs regulations, tariffs, and potential delays in shipping. Understanding the import regulations specific to your country is vital to ensure compliance and avoid penalties. Additionally, coordinating with freight forwarders who specialize in medical and dental products can alleviate some of these challenges. Preparing accurate documentation and selecting reliable shipping methods will also help streamline the logistics process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for dental products manufacturers

The strategic sourcing of dental products is vital for international B2B buyers aiming to enhance operational efficiency and competitiveness. By prioritizing supplier relationships, buyers can ensure consistent quality and innovation, which are essential in the rapidly evolving dental market. Additionally, leveraging data analytics and market insights can significantly optimize procurement strategies, enabling buyers to make informed decisions that align with their specific regional needs, whether in Africa, South America, the Middle East, or Europe.

How can B2B buyers capitalize on emerging trends in dental product sourcing? By staying abreast of technological advancements and regulatory changes, buyers can better anticipate market demands and adjust their sourcing strategies accordingly. This proactive approach not only mitigates risks but also opens up new avenues for growth and collaboration.

As we look to the future, it is crucial for international B2B buyers to engage with reliable manufacturers and suppliers who are committed to quality and sustainability. By fostering these relationships, buyers can position themselves as leaders in the dental industry. The time to act is now—embrace strategic sourcing as a pathway to innovation and success in your dental product procurement journey.