The Ultimate Guide to Drilling Machine Manufacturer (2025)

Introduction: Navigating the Global Market for drilling machine manufacturer

In an increasingly competitive global marketplace, sourcing reliable drilling machines can be a daunting challenge for B2B buyers, especially those operating in resource-rich regions like Africa, South America, the Middle East, and Europe. The demand for high-performance drilling equipment is rising, driven by the need for efficient extraction in industries such as oil and gas, mining, and construction. This comprehensive guide delves into the complexities of navigating the global market for drilling machine manufacturers, equipping buyers with the knowledge to make informed purchasing decisions.

The guide covers a wide array of topics crucial for international buyers, including various types of drilling machines, their applications across different sectors, and essential criteria for supplier vetting. Moreover, it addresses cost considerations and highlights best practices for negotiating contracts with manufacturers. By providing actionable insights and expert recommendations, this resource empowers B2B buyers to identify reputable suppliers, ensuring they invest in machinery that meets their operational needs and budget constraints.

As you explore this guide, you will gain valuable perspectives on how to effectively source drilling machines that align with your specific requirements, ultimately enhancing your operational efficiency and competitive edge in the market. Whether you are a seasoned professional or new to the industry, understanding these key elements will pave the way for successful procurement strategies in the dynamic global landscape.

Understanding drilling machine manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rotary Drilling Rigs | Utilizes a rotating drill bit; ideal for deep drilling applications. | Oil and gas exploration, mineral extraction | Pros: High penetration rate. Cons: Higher operational costs. |

| Directional Drilling Equipment | Allows for angled drilling; enhances access to hard-to-reach areas. | Geothermal energy, horizontal drilling | Pros: Increased resource access. Cons: Complex technology requires skilled operators. |

| Cable Tool Drilling Machines | Uses a heavy drill bit attached to a cable; suitable for shallow wells. | Water well drilling, environmental projects | Pros: Cost-effective for shallow depths. Cons: Slower drilling speed. |

| Auger Drilling Equipment | Employs a helical screw to remove soil; effective in soft ground. | Foundation drilling, geotechnical surveys | Pros: Minimal disturbance to surrounding soil. Cons: Limited to softer materials. |

| Sonic Drilling Rigs | Utilizes high-frequency vibrations to enhance penetration. | Environmental sampling, mineral exploration | Pros: Rapid drilling with minimal waste. Cons: More expensive initial investment. |

What Are the Characteristics of Rotary Drilling Rigs?

Rotary drilling rigs are prominent in the oil and gas industry due to their ability to drill deep into the earth. They operate by rotating a drill bit, which can penetrate various geological formations. Buyers should consider their operational costs, as these rigs typically require significant investment and maintenance. However, their high penetration rates make them ideal for large-scale projects where time is of the essence.

How Does Directional Drilling Equipment Enhance Resource Access?

Directional drilling equipment is engineered for drilling at various angles, allowing access to resources that are not directly beneath the rig. This technology is particularly beneficial in urban settings or when drilling for geothermal energy. B2B buyers should evaluate the complexity of the technology and ensure that their team is adequately trained, as it requires specialized skills. The potential for accessing multiple wells from a single drilling site can offset the initial investment.

In What Situations Are Cable Tool Drilling Machines Most Effective?

Cable tool drilling machines are typically used for shallow well applications, such as water well drilling. They operate by dropping a heavy bit on the surface and then lifting it, which makes them suitable for softer ground conditions. Buyers appreciate their cost-effectiveness, but should be aware that their slower drilling speed may not meet the demands of larger projects. Thus, they are best suited for smaller, localized tasks.

Why Choose Auger Drilling Equipment for Geotechnical Surveys?

Auger drilling equipment is particularly useful in environments with soft soil. It employs a helical screw to extract soil, which minimizes disturbance and is ideal for foundation drilling and geotechnical surveys. Buyers should consider the limitations of auger drilling, as it is not effective in hard or rocky conditions. However, its efficiency in soft ground can lead to significant cost savings in the right applications.

What Advantages Does Sonic Drilling Offer for Environmental Sampling?

Sonic drilling rigs utilize high-frequency vibrations to facilitate rapid penetration into various materials, making them an excellent choice for environmental sampling and mineral exploration. The technology results in minimal waste and disturbance to the surrounding area, which is a significant advantage for environmentally sensitive projects. Buyers should weigh the higher initial investment against the long-term benefits of efficiency and reduced environmental impact.

Related Video: Design and Fabrication Of Multi Spindle Drilling Machine | Mechanical project

Key Industrial Applications of drilling machine manufacturer

| Industry/Sector | Specific Application of Drilling Machine Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Exploration and Production Drilling | Enhanced efficiency and safety in resource extraction | Equipment reliability, local regulations, and service support |

| Construction | Foundation Drilling | Improved structural integrity and project timelines | Soil conditions, depth requirements, and project scale |

| Mining | Mineral Exploration and Extraction | Increased yield and reduced operational costs | Equipment durability, maintenance services, and local expertise |

| Geothermal Energy | Well Drilling for Geothermal Systems | Sustainable energy production and reduced emissions | Temperature tolerance, depth capabilities, and environmental impact |

| Water Well Drilling | Borehole Drilling for Water Supply | Reliable access to clean water for communities | Local geology, drilling techniques, and permit processes |

How is Drilling Machine Manufacturing Applied in the Oil & Gas Industry?

Drilling machines are pivotal in the oil and gas industry, specifically for exploration and production drilling. These machines enable companies to efficiently reach hydrocarbon deposits while minimizing environmental impact. International buyers must consider equipment reliability, adherence to local regulations, and the availability of service support to ensure operational continuity. In regions like Africa and the Middle East, where oil reserves are significant, advanced drilling technologies can enhance safety and reduce the risk of blowouts, ultimately optimizing resource extraction.

What Role Do Drilling Machines Play in Construction Projects?

In construction, drilling machines are essential for foundation drilling. They ensure that structures have the necessary support by penetrating various soil layers to create stable foundations. This application is crucial for maintaining project timelines and structural integrity. Buyers should assess soil conditions, depth requirements, and the scale of their projects when sourcing drilling equipment. In Europe, especially in urban areas, drilling machines must comply with strict environmental and noise regulations, making local expertise invaluable.

How is Drilling Equipment Used in Mining Operations?

Mining operations leverage drilling machines for both mineral exploration and extraction. These machines facilitate the identification of mineral deposits and enhance extraction processes, leading to increased yield and reduced operational costs. Buyers from South America, known for its rich mineral resources, should prioritize equipment durability and the availability of maintenance services. Understanding local geological conditions and securing partnerships with local experts can significantly impact the success of mining operations.

Why is Drilling Important for Geothermal Energy Development?

Drilling machines are critical in the geothermal energy sector for well drilling, which is necessary to access geothermal reservoirs. This application supports sustainable energy production, contributing to reduced emissions and energy independence. Buyers must consider the temperature tolerance of the equipment, depth capabilities, and the potential environmental impact of drilling activities. In regions like Europe, where renewable energy initiatives are prioritized, sourcing advanced drilling technologies can enhance project viability and compliance with regulatory frameworks.

How Do Drilling Machines Facilitate Water Supply Solutions?

In water well drilling, drilling machines are employed to create boreholes that provide reliable access to clean water for communities. This application is vital in regions facing water scarcity, particularly in parts of Africa and South America. Buyers should focus on local geology, appropriate drilling techniques, and the necessary permit processes when sourcing equipment. Ensuring compliance with local regulations and understanding community needs can enhance the effectiveness and sustainability of water supply initiatives.

Related Video: Drilling Machine | Construction ,Parts , Working , Animation

3 Common User Pain Points for ‘drilling machine manufacturer’ & Their Solutions

Scenario 1: Navigating High Equipment Costs in Drilling Projects

The Problem:

B2B buyers often face the daunting challenge of high initial costs when procuring drilling machines. This is particularly true in regions like Africa and South America, where budget constraints are a significant concern for many companies. The financial burden of acquiring advanced drilling technology can deter buyers from investing in machinery that could enhance their operational efficiency. Buyers worry about the return on investment (ROI) and whether the capabilities of the drilling equipment will justify the costs, especially in competitive markets with slim margins.

The Solution:

To mitigate these financial concerns, international buyers should consider leveraging financing options or leasing agreements offered by drilling machine manufacturers. This approach allows companies to access high-quality equipment without the immediate capital outlay associated with outright purchases. Additionally, conducting thorough market research to identify manufacturers that provide flexible financing terms can lead to significant savings.

Another actionable step is to perform a cost-benefit analysis of different drilling machines based on their features, efficiency ratings, and durability. By comparing the total cost of ownership—including maintenance and operational costs—buyers can make informed decisions that align with their budget constraints. Engaging in discussions with manufacturers about customized packages or bundled services can also yield favorable pricing, ensuring buyers maximize their investment while minimizing financial risk.

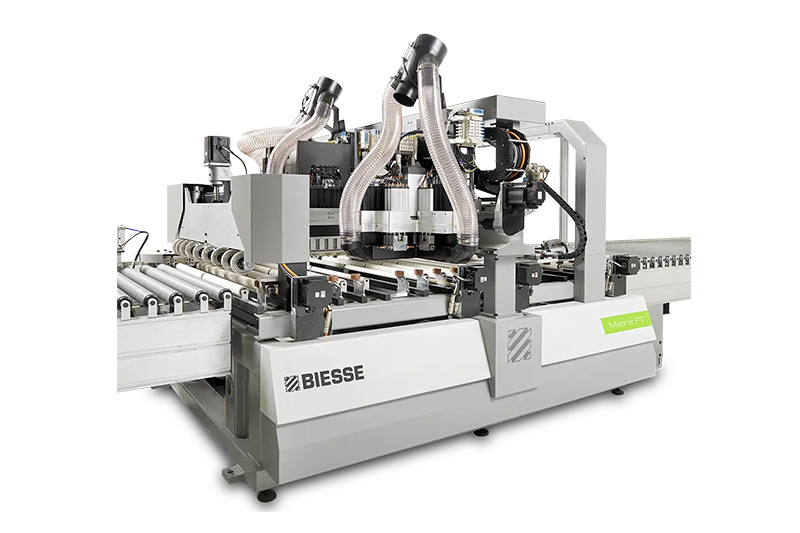

A stock image related to drilling machine manufacturer.

Scenario 2: Ensuring Equipment Reliability in Diverse Environments

The Problem:

B2B buyers often encounter issues with equipment reliability, particularly in challenging environments like those found in the Middle East or remote areas of South America. Drilling machines can be subjected to extreme temperatures, varying geological conditions, and unpredictable weather patterns. Such challenges can lead to equipment failures or breakdowns, resulting in costly downtime and delayed project timelines. This uncertainty creates frustration for buyers who depend on consistent performance to meet project deadlines and contractual obligations.

The Solution:

To address reliability concerns, buyers should prioritize working with drilling machine manufacturers known for their rigorous testing and quality assurance processes. It is advisable to request detailed information on the equipment’s performance in various environmental conditions, including case studies or testimonials from previous clients operating in similar settings.

Furthermore, establishing a robust maintenance and support plan with the manufacturer can significantly enhance equipment reliability. Buyers should seek manufacturers who offer comprehensive after-sales support, including regular maintenance schedules and quick-response repair services. Investing in training for operators on best practices for equipment use and maintenance can also extend the lifespan of drilling machines and improve operational efficiency.

Scenario 3: Difficulty in Finding Suitable Spare Parts and Support

The Problem:

An ongoing pain point for B2B buyers in the drilling sector is the challenge of sourcing spare parts and technical support for their machinery. This is particularly prevalent in regions where manufacturers have limited distribution networks or in emerging markets with less established supply chains. Delays in obtaining spare parts can halt operations, resulting in financial losses and damage to client relationships. Buyers often feel anxious about the long-term support they will receive after making a significant investment in drilling equipment.

The Solution:

To combat these issues, buyers should prioritize manufacturers that have a robust global supply chain and local partnerships for spare parts distribution. When evaluating potential suppliers, inquire about their logistical capabilities and the availability of parts in the buyer’s region. Establishing a proactive relationship with the manufacturer can also facilitate quicker access to necessary components, as well as technical support.

Buyers should also consider entering into service agreements that include guaranteed parts availability and maintenance support. This approach not only ensures timely access to spare parts but also fosters a collaborative partnership with the manufacturer, enhancing overall service quality. Additionally, investing in training for in-house technicians can empower teams to perform minor repairs and maintenance, further reducing downtime and reliance on external support.

Strategic Material Selection Guide for drilling machine manufacturer

What Are the Key Materials for Drilling Machine Manufacturing?

Selecting the right materials for drilling machines is crucial for ensuring performance, durability, and cost-effectiveness. Here, we analyze four common materials used in drilling machine manufacturing, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

Steel: The Backbone of Drilling Machines

Steel is a primary material in drilling machine construction due to its excellent mechanical properties. It boasts high tensile strength, making it suitable for high-pressure applications. Steel can withstand temperatures up to 500°C, depending on the alloy used, and offers moderate corrosion resistance, which can be enhanced with coatings.

Pros: Steel is durable and widely available, making it a cost-effective option. Its strength allows for the creation of robust components that can handle extreme conditions.

Cons: The weight of steel can be a disadvantage in mobile drilling applications. Additionally, it may require protective coatings to prevent corrosion, increasing manufacturing complexity.

Impact on Application: Steel’s compatibility with various drilling media makes it versatile. However, international buyers must ensure compliance with standards such as ASTM A36 or DIN 17100, particularly in regions like Europe and the Middle East.

Aluminum: Lightweight and Corrosion-Resistant

Aluminum is increasingly used in drilling machines due to its lightweight properties and excellent corrosion resistance. It can perform well in temperatures up to 200°C and is often used in components where weight reduction is critical.

Pros: The lightweight nature of aluminum enhances mobility and reduces energy consumption. Its natural resistance to corrosion makes it suitable for environments with high humidity or exposure to chemicals.

Cons: Aluminum is less durable than steel and can be more expensive. It may also require specialized welding techniques, complicating the manufacturing process.

Impact on Application: Aluminum is particularly favored in offshore drilling operations due to its resistance to saltwater corrosion. Buyers in Africa and South America should consider local availability and compliance with standards such as ASTM B221.

Composite Materials: The Future of Drilling Technology?

Composite materials, such as carbon fiber reinforced polymers (CFRP), are emerging in drilling machine applications due to their high strength-to-weight ratio and excellent fatigue resistance. These materials can operate effectively at temperatures up to 150°C.

Pros: Composites are lightweight and provide excellent resistance to corrosion and wear, making them ideal for high-performance applications.

Cons: The primary drawback is the higher cost and complexity of manufacturing processes. Additionally, composites may not be suitable for all drilling environments, particularly where high temperatures are involved.

Impact on Application: Composites can enhance the performance of drilling machines in specific applications, such as geothermal drilling. Buyers in Europe, particularly in countries like Germany, should be aware of the evolving regulations surrounding composite materials.

High-Strength Alloys: Performance Under Pressure

High-strength alloys, including nickel-based and titanium alloys, are used in drilling machines that operate in extreme environments. These materials can withstand high temperatures (up to 800°C) and pressures, making them suitable for deep drilling applications.

Pros: Alloys offer superior strength and durability, ensuring reliability in challenging conditions. Their performance can significantly reduce the risk of equipment failure.

Cons: The cost of high-strength alloys is significantly higher than that of conventional materials. Additionally, their manufacturing processes can be complex and require specialized equipment.

Impact on Application: High-strength alloys are essential for drilling operations in harsh environments, such as deep-sea drilling. Buyers in the Middle East and Africa should consider the availability of these materials and compliance with international standards like ASTM B637.

Summary Table of Material Selection

| Material | Typical Use Case for drilling machine manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components, drill bits | High strength and durability | Heavy weight, corrosion risk | Medium |

| Aluminum | Lightweight components, portable drilling machines | Lightweight, corrosion-resistant | Less durable, higher cost | Medium |

| Composite Materials | High-performance applications, offshore drilling | Excellent strength-to-weight ratio | High cost, complex manufacturing | High |

| High-Strength Alloys | Deep drilling applications, extreme environments | Superior strength and durability | Very high cost, complex processing | High |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for drilling machines, ensuring informed decisions that align with their operational needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for drilling machine manufacturer

What Are the Key Stages in the Manufacturing Process of Drilling Machines?

The manufacturing of drilling machines involves several critical stages that ensure the final product meets the required specifications and quality standards. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial phase involves selecting high-quality raw materials, often steel alloys, which provide the necessary strength and durability for drilling applications. Suppliers must ensure that materials meet industry specifications, which can include certifications for material grade and properties. Conducting thorough inspections at this stage is crucial to avoid issues later in the manufacturing process.

-

Forming: The forming stage utilizes various techniques such as casting, forging, and machining to shape the raw materials into components. Advanced CNC (Computer Numerical Control) machines are commonly employed for precision in machining parts like drill bits, housings, and other critical components. This stage is vital for achieving the dimensional accuracy required for effective drilling operations.

-

Assembly: In the assembly phase, the individual components are brought together to create the final product. This process often involves both manual and automated assembly techniques. Quality control measures, including torque tests and alignment checks, are essential during assembly to ensure that all components fit correctly and function as intended.

-

Finishing: The finishing stage includes surface treatments such as coating, painting, or plating to enhance corrosion resistance and aesthetics. Techniques like anodizing or powder coating may also be used to prolong the life of the drilling machines. Additionally, this stage often involves final inspections to ensure that the machine meets all quality and performance standards.

What Quality Assurance Practices Are Essential for Drilling Machine Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process for drilling machines. It ensures that products not only meet customer expectations but also comply with relevant international standards.

-

International Standards: Compliance with international standards, such as ISO 9001, is essential for manufacturers targeting global markets. ISO 9001 focuses on quality management systems and requires companies to demonstrate their ability to consistently provide products that meet customer and regulatory requirements. Additionally, industry-specific certifications such as CE marking in Europe and API (American Petroleum Institute) standards for drilling equipment are often mandatory.

-

Quality Control Checkpoints: Implementing robust quality control checkpoints throughout the manufacturing process is vital. These checkpoints typically include:

– Incoming Quality Control (IQC): Inspecting raw materials and components upon arrival to ensure they meet specifications.

– In-Process Quality Control (IPQC): Monitoring the manufacturing process to identify defects early. This can involve regular checks on machining tolerances and assembly accuracy.

– Final Quality Control (FQC): Conducting comprehensive testing of the finished product to verify it meets all performance and safety standards before shipment. -

Common Testing Methods: Various testing methods are employed to ensure the quality and performance of drilling machines. These can include:

– Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or magnetic particle inspection are used to detect internal flaws without damaging the components.

– Functional Testing: This assesses the performance of the drilling machine under simulated operating conditions to ensure it meets operational requirements.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying the quality control practices of drilling machine manufacturers is essential to mitigate risks associated with procurement.

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their quality management systems and manufacturing processes. Auditors should assess compliance with international standards and the effectiveness of the supplier’s quality control measures.

-

Reviewing Quality Reports: Requesting access to quality reports, including inspection records, test results, and certification documents, can help buyers understand the supplier’s commitment to quality. These documents should detail the procedures followed and any issues encountered during manufacturing.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing process and quality assurance practices. This can include pre-shipment inspections, where independent inspectors assess the final products against specified criteria before they are dispatched.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers must navigate various nuances in quality control when sourcing drilling machines from manufacturers across different regions.

-

Understanding Regional Standards: Different regions may have specific quality standards that manufacturers must comply with. For instance, European buyers must ensure products meet CE marking requirements, while North American buyers may require compliance with API standards. Understanding these differences is crucial for ensuring product compliance and safety.

-

Cultural Considerations in Quality Assurance: Cultural attitudes towards quality can vary significantly between regions. For example, some countries may have a more relaxed approach to quality control, while others may have stringent practices. B2B buyers should consider these cultural differences when assessing potential suppliers and their quality management systems.

-

Communication and Transparency: Establishing clear communication channels with suppliers is essential for effective quality control. B2B buyers should seek suppliers willing to provide transparency in their processes, including sharing their quality assurance protocols and any challenges they face in maintaining quality.

Conclusion

Understanding the manufacturing processes and quality assurance practices of drilling machine manufacturers is crucial for international B2B buyers. By focusing on the key stages of manufacturing, relevant quality standards, and effective verification methods, buyers can make informed decisions that ensure they procure high-quality, reliable drilling machines tailored to their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘drilling machine manufacturer’

In today’s competitive landscape, sourcing drilling machines requires a systematic approach to ensure quality, efficiency, and cost-effectiveness. This step-by-step checklist is designed to guide international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, through the sourcing process, ensuring a thorough evaluation of potential manufacturers.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical requirements of the drilling machines you need. Consider factors such as the type of drilling (e.g., oil, gas, mineral), depth, and specific features like automation or energy efficiency.

– Why it matters: Clear specifications help streamline the selection process and ensure that potential suppliers can meet your operational needs.

Step 2: Conduct Market Research

Investigate the current market landscape for drilling machine manufacturers. Utilize online platforms, industry reports, and trade publications to identify reputable suppliers.

– What to look for: Focus on manufacturers with a strong presence in your target region and check for innovations they offer that could enhance your operations.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Key considerations: Look for suppliers with proven track records in delivering reliable equipment and excellent after-sales support. Confirm their experience with specific types of drilling machines that align with your needs.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers hold relevant certifications and adhere to international standards, such as ISO 9001 for quality management.

– Why this is important: Certifications are indicators of a supplier’s commitment to quality and safety, which is crucial for high-stakes operations in drilling.

Step 5: Request Detailed Quotations

Once you have shortlisted suppliers, request detailed quotations that include pricing, lead times, and warranty conditions.

– What to include in your request: Ensure that the quotes specify the model, features, and any additional costs (e.g., shipping, taxes). This transparency helps in comparing offers effectively.

Step 6: Assess After-Sales Support and Service

Evaluate the after-sales support provided by the manufacturers. This includes warranty terms, maintenance services, and availability of spare parts.

– Importance: Reliable after-sales support can significantly reduce downtime in operations, which is vital for productivity in the drilling industry.

Step 7: Negotiate Terms and Finalize Contracts

Once you have selected a supplier, engage in negotiations to finalize terms. Ensure that all aspects, including payment terms, delivery schedules, and penalties for non-compliance, are clearly defined in the contract.

– Why it matters: A well-negotiated contract protects your interests and clarifies expectations, minimizing potential disputes in the future.

By following this comprehensive checklist, B2B buyers can streamline their sourcing process, ensuring they partner with the right drilling machine manufacturer that meets their technical and operational needs.

Comprehensive Cost and Pricing Analysis for drilling machine manufacturer Sourcing

What Are the Key Cost Components in Drilling Machine Manufacturing?

Understanding the cost structure of drilling machine manufacturing is crucial for international B2B buyers. The primary cost components include:

-

Materials: Raw materials account for a significant portion of the total cost. High-grade steel, aluminum, and advanced composites are commonly used, and fluctuations in the global commodity market can directly impact pricing.

-

Labor: Skilled labor is essential for manufacturing precision drilling machines. Labor costs can vary widely by region; for instance, labor in Europe may be more expensive compared to South America or Africa.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and administrative expenses. Efficient overhead management can significantly influence the final price.

-

Tooling: The cost of specialized tools required for production can add to the overall expenses. Custom tooling designed for specific projects may increase initial costs but can lead to better efficiency and quality in the long run.

-

Quality Control (QC): Implementing stringent QC processes ensures product reliability and safety, but it also adds to the cost. Certifications, such as ISO, can raise production costs but are often necessary for compliance in international markets.

-

Logistics: Transportation and warehousing expenses can vary greatly depending on the location of the supplier and the buyer. Buyers should consider these costs when evaluating total expenses.

-

Margin: Manufacturers typically include a profit margin that reflects the risk and investment involved in the production process. Understanding this can aid buyers in negotiating better deals.

How Do Pricing Influencers Affect Drilling Machine Costs?

Several factors influence the pricing of drilling machines, making it essential for buyers to understand them:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit costs. Buyers should assess their needs and consider negotiating bulk purchases for better rates.

-

Specifications and Customization: Custom-built machines tailored to specific requirements may incur higher costs due to additional design and manufacturing complexities. Standardized machines generally offer more competitive pricing.

-

Materials Quality and Certifications: Premium materials and necessary certifications can elevate costs. Buyers should weigh the benefits of higher-quality materials against their budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established manufacturers may charge more but offer better warranties and after-sales support, which can lead to long-term savings.

-

Incoterms: The chosen Incoterm can significantly impact total costs. Buyers should understand terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) to better manage their logistics and cost exposure.

What Are the Best Negotiation Tips for International B2B Buyers?

Effective negotiation strategies can lead to significant cost savings for international buyers:

-

Research and Benchmarking: Conduct thorough market research to understand standard pricing for drilling machines. Use this information to negotiate from a position of knowledge.

-

Focus on Total Cost of Ownership (TCO): Emphasize the total cost of ownership rather than just the purchase price. This includes maintenance, operation, and potential resale value, which can justify higher initial costs.

-

Leverage Relationships: Building strong relationships with suppliers can facilitate better deals. Regular communication and trust can lead to more favorable terms.

-

Be Flexible with Specifications: If possible, consider slight adjustments to specifications that could lower costs. Flexibility can open avenues for better pricing.

-

Consider Payment Terms: Negotiating favorable payment terms can alleviate upfront cost burdens. Options like staggered payments or extended payment periods can improve cash flow.

Conclusion: Why Are Indicative Prices Important for Buyers?

While it’s essential to understand cost components and pricing influencers, indicative prices should be viewed as a reference rather than fixed figures. Prices can fluctuate based on market conditions, supplier capabilities, and specific buyer requirements. Therefore, buyers should engage in thorough discussions with suppliers to obtain accurate and tailored pricing information that reflects their unique needs.

Alternatives Analysis: Comparing drilling machine manufacturer With Other Solutions

Understanding the Importance of Evaluating Alternatives in Drilling Solutions

In the competitive landscape of drilling operations, B2B buyers must carefully evaluate various solutions to determine the most effective and cost-efficient choice for their projects. While traditional drilling machine manufacturers provide robust and reliable equipment, alternative technologies and methods may offer distinct advantages depending on the specific requirements of the drilling operation. This section compares drilling machines with two viable alternatives: Directional Drilling Technology and Rotary Steerable Systems (RSS).

Comparison Table of Drilling Solutions

| Comparison Aspect | Drilling Machine Manufacturer | Directional Drilling Technology | Rotary Steerable Systems (RSS) |

|---|---|---|---|

| Performance | High torque and depth capacity; suitable for vertical drilling | Offers flexibility in trajectory; ideal for complex well paths | Real-time control of wellbore trajectory; high precision |

| Cost | Generally high initial investment and operational costs | Moderate costs; savings on time and resources | Higher costs due to advanced technology and equipment |

| Ease of Implementation | Requires significant setup and training | Moderate; may need specialized training | Complex setup; requires skilled personnel |

| Maintenance | Regular maintenance required; parts can be costly | Lower frequency of maintenance; simpler technology | High maintenance; specialized parts can be expensive |

| Best Use Case | Conventional vertical wells in stable formations | Complex well designs, offshore drilling, and resource recovery | High-precision drilling in challenging formations or environments |

Detailed Breakdown of Alternatives

Directional Drilling Technology

Directional drilling technology allows operators to drill non-linear paths, optimizing the placement of the wellbore in relation to the target resource. This method is particularly beneficial for accessing resources in complex geological formations or when multiple wells are drilled from a single surface location. The primary advantage is its ability to minimize environmental impact and surface disturbance. However, the technology demands moderate upfront investment and may necessitate specialized training for personnel, making it less accessible for all operators.

Rotary Steerable Systems (RSS)

Rotary steerable systems represent an advanced drilling technology that provides real-time control of the drilling trajectory. This technology allows for high precision in wellbore placement, significantly improving drilling efficiency and reducing the risk of costly drilling errors. RSS is particularly effective in challenging formations where traditional methods may struggle. However, the initial investment and operational costs can be considerably higher compared to conventional drilling machines, and maintenance requires specialized knowledge and parts, which may not be readily available in all regions.

Conclusion: Choosing the Right Drilling Solution for Your Needs

When evaluating drilling solutions, B2B buyers must consider multiple factors, including performance requirements, cost constraints, and the specific geological challenges of their projects. While traditional drilling machine manufacturers offer dependable equipment for straightforward drilling operations, alternatives like directional drilling technology and rotary steerable systems provide unique advantages for complex drilling scenarios. By thoroughly assessing the capabilities, costs, and operational demands of each option, international buyers can make informed decisions that align with their strategic objectives and operational efficiencies.

Essential Technical Properties and Trade Terminology for drilling machine manufacturer

What Are the Key Technical Properties of Drilling Machines?

When evaluating drilling machines for purchase, B2B buyers must consider several critical technical specifications that directly impact performance, efficiency, and cost-effectiveness. Here are some essential properties to keep in mind:

1. Material Grade

Material grade refers to the quality and type of materials used in the construction of drilling machines. Common materials include high-strength steel and specialized alloys designed to withstand extreme conditions. A higher material grade often leads to increased durability and reduced maintenance costs, which is crucial for operations in challenging environments found in Africa, South America, and the Middle East.

2. Tolerance Levels

Tolerance levels indicate the permissible limits of variation in a physical dimension or measured value of the drilling equipment. For example, tight tolerances in the manufacturing process enhance precision in drilling operations, reducing the likelihood of errors that could lead to costly downtime. Understanding the tolerance specifications is vital for ensuring compatibility with existing equipment and achieving optimal drilling performance.

3. Weight and Size Specifications

The weight and size of drilling machines can significantly affect transportation costs and ease of setup. Lightweight and compact models are often preferred for remote locations, reducing logistical challenges. Buyers should assess these specifications in relation to their project sites to avoid unexpected complications during deployment.

4. Power Requirements

Power requirements include the type and amount of energy needed to operate the drilling machine effectively. Machines may operate on diesel, electricity, or hybrid systems. Understanding these requirements helps buyers evaluate operational costs and the feasibility of using specific machines in various geographic regions.

5. Performance Metrics

Performance metrics such as drilling speed, depth capacity, and torque are essential for assessing a machine’s suitability for specific projects. Machines with higher performance ratings can lead to increased productivity, which is crucial for competitive bidding in international markets.

What Are Common Trade Terms Used in the Drilling Machine Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are some common terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding the OEM relationship is crucial for buyers seeking reliable suppliers, as it often reflects the quality and design standards of the equipment.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is essential for buyers to understand as it can affect purchasing strategies, especially when budgeting for large-scale projects.

3. RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit price quotes from suppliers for specific products or services. Crafting a clear RFQ can lead to better pricing and terms, making it a vital tool for buyers looking to optimize procurement processes.

4. Incoterms

Incoterms (International Commercial Terms) are standardized terms used in international trade that define the responsibilities of buyers and sellers. Familiarity with these terms helps buyers understand shipping costs, insurance responsibilities, and risk management during transport, which is particularly important for international transactions.

5. Lead Time

Lead time refers to the amount of time between placing an order and receiving the product. Understanding lead times can help buyers plan their project timelines more effectively, ensuring that drilling operations commence as scheduled without unnecessary delays.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when selecting drilling machine manufacturers, ultimately leading to enhanced operational efficiency and profitability.

Navigating Market Dynamics and Sourcing Trends in the drilling machine manufacturer Sector

What Are the Key Market Dynamics and Trends in the Drilling Machine Manufacturing Sector?

The global drilling machine manufacturing market is witnessing significant transformations driven by technological advancements, increased demand for efficient drilling operations, and a growing emphasis on sustainability. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, navigate this evolving landscape, it’s crucial to understand these dynamics.

One of the primary drivers in the sector is the rising demand for advanced drilling technologies that enhance efficiency and reduce operational costs. Automation and smart technologies, such as IoT-enabled drilling equipment, are becoming increasingly prevalent. These innovations not only improve the precision of drilling operations but also facilitate real-time data analysis, enabling better decision-making.

Emerging trends include the shift toward integrated solutions that combine drilling with completion and well management services. This holistic approach offers buyers a streamlined procurement process, reducing the complexity and time involved in sourcing multiple suppliers. Moreover, the increasing focus on energy efficiency and renewable energy sources is prompting manufacturers to innovate, leading to the development of eco-friendly drilling machines designed to minimize environmental impact.

Regional dynamics also play a significant role. In Africa and South America, the exploration of untapped resources is driving demand for reliable drilling equipment, while in Europe and the Middle East, stringent regulations and a push for sustainable practices are influencing purchasing decisions. As a result, international buyers must stay informed about local regulations and market demands to make strategic sourcing decisions.

How Is Sustainability Shaping B2B Sourcing in the Drilling Machine Manufacturing Sector?

Sustainability is increasingly becoming a focal point in the drilling machine manufacturing sector, reflecting the broader global commitment to environmental responsibility. International B2B buyers must recognize the environmental impact of drilling operations and the importance of ethical sourcing practices.

The extraction and production processes involved in drilling can have significant ecological consequences. As such, manufacturers are under pressure to adopt sustainable practices that minimize waste and reduce carbon footprints. Buyers should prioritize suppliers that demonstrate a commitment to sustainability through certifications such as ISO 14001 for environmental management and the use of eco-friendly materials.

Ethical supply chains are also critical. Companies that source materials responsibly not only mitigate risks associated with environmental degradation but also enhance their brand reputation. For example, using recycled or sustainably sourced components can appeal to environmentally conscious consumers and stakeholders.

A stock image related to drilling machine manufacturer.

In addition, manufacturers are increasingly developing ‘green’ drilling technologies, including machines that utilize alternative energy sources or are designed to operate with reduced emissions. By aligning sourcing strategies with sustainability goals, B2B buyers can contribute to a more responsible industry while ensuring compliance with regulatory standards.

What Is the Evolution of the Drilling Machine Manufacturing Sector?

The drilling machine manufacturing sector has evolved significantly over the last few decades, influenced by technological advancements and changing market needs. Initially, the industry relied on traditional mechanical drilling methods, which were labor-intensive and less efficient. However, the introduction of hydraulic and rotary drilling techniques revolutionized the field, enabling deeper and more precise drilling.

In recent years, the focus has shifted towards automation and smart technologies. The advent of digitalization has transformed drilling operations, allowing for real-time monitoring and data-driven decision-making. This evolution not only enhances operational efficiency but also addresses the growing need for sustainable practices in the industry.

As the sector continues to advance, international B2B buyers must stay informed about these historical shifts to understand the current market landscape better. The interplay between technology, sustainability, and market demands will shape the future of drilling machine manufacturing, making it essential for buyers to adapt their sourcing strategies accordingly.

Frequently Asked Questions (FAQs) for B2B Buyers of drilling machine manufacturer

-

How do I choose the right drilling machine manufacturer for my needs?

Selecting the right drilling machine manufacturer involves evaluating several factors. Start by assessing the manufacturer’s expertise in your specific drilling requirements, such as depth, type of material, and operational environment. Request case studies or references from similar projects to gauge their experience. Additionally, consider their production capabilities, technological innovations, and certifications. It’s also vital to communicate clearly about your needs and expectations to ensure they can deliver a tailored solution. -

What are the key specifications to look for in a drilling machine?

When sourcing a drilling machine, focus on specifications such as drilling depth, torque capacity, weight, and power requirements. Assess the machine’s adaptability to different terrains and its compatibility with various drilling techniques (e.g., rotary, percussion). Additionally, inquire about the availability of spare parts and maintenance services, which can significantly impact your operational efficiency. Understanding these specifications will help you make an informed decision that aligns with your project needs. -

What are the typical payment terms when purchasing drilling machines internationally?

Payment terms can vary significantly among manufacturers, but common practices include advance payments, letters of credit, or staggered payments based on milestones. It’s essential to negotiate terms that protect your interests while ensuring the manufacturer has confidence in the transaction. Be aware of currency fluctuations and international banking fees, especially when dealing with suppliers from Africa, South America, the Middle East, or Europe. Clear communication about payment expectations can prevent misunderstandings. -

What is the minimum order quantity (MOQ) for drilling machines?

The minimum order quantity (MOQ) can differ widely among manufacturers and may depend on the complexity of the drilling machine and the supplier’s production capabilities. Generally, MOQs for specialized equipment like drilling machines can range from a single unit to several units. For international buyers, it’s crucial to discuss the MOQ upfront, as this can impact your budgeting and project timelines. Some manufacturers may offer flexibility for first-time buyers or smaller projects. -

How can I ensure quality assurance when sourcing drilling machines?

To ensure quality assurance, request detailed quality control processes from the manufacturer. Look for certifications such as ISO 9001, which indicates adherence to international quality management standards. Additionally, consider arranging for third-party inspections during production and before shipment. Establishing a clear contract that includes quality benchmarks and penalties for non-compliance can also safeguard your investment. Regular communication with the manufacturer throughout the process is key to maintaining quality standards. -

What are the logistics considerations for importing drilling machines?

Importing drilling machines involves several logistical considerations, including shipping methods, customs regulations, and handling procedures. Choose a reliable logistics partner experienced in heavy machinery transport to ensure safe and timely delivery. Familiarize yourself with the customs requirements of your country, as this can affect delivery timelines and costs. Additionally, consider insurance for the shipment to mitigate risks associated with damage during transport. -

How can I verify the credibility of a drilling machine supplier?

To verify a supplier’s credibility, conduct thorough background checks, including reviewing their business history, customer testimonials, and industry certifications. Utilize platforms like LinkedIn or industry-specific forums to gather insights from other buyers. Request references and follow up with past clients to understand their experiences. Additionally, consider visiting the manufacturer’s facility, if feasible, to evaluate their operations and quality control processes firsthand. -

What customization options are available for drilling machines?

Many drilling machine manufacturers offer customization options to meet specific operational needs. Common customizations include modifications to drilling depth, torque settings, and added features like automated controls or enhanced safety mechanisms. When discussing customization, be clear about your requirements and any specific challenges you face in your drilling projects. Collaborating closely with the manufacturer during the design phase can lead to a more effective and tailored solution that enhances your operational efficiency.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for drilling machine manufacturer

What Are the Key Takeaways for B2B Buyers in Strategic Sourcing?

In the competitive landscape of drilling machine manufacturing, strategic sourcing emerges as a vital component for international buyers. By understanding supplier capabilities and leveraging global supply chains, organizations can enhance their procurement processes, reduce costs, and ensure timely delivery of high-quality equipment. For buyers from Africa, South America, the Middle East, and Europe, particularly in countries like France and Germany, the ability to establish strong relationships with reliable manufacturers can lead to improved operational efficiency and innovation in drilling technologies.

How Can B2B Buyers Prepare for Future Trends in Drilling Machine Procurement?

Looking ahead, the integration of advanced technologies and sustainable practices in drilling operations will reshape the industry. B2B buyers should proactively seek suppliers who prioritize innovation and environmental responsibility, as these factors will increasingly influence purchasing decisions. Engaging with manufacturers that offer cutting-edge solutions, such as automated drilling systems and eco-friendly machinery, can provide a competitive edge.

What Steps Should International Buyers Take Next?

To capitalize on these insights, international B2B buyers are encouraged to conduct thorough market research, attend industry conferences, and network with potential suppliers. By adopting a forward-thinking approach and embracing strategic sourcing, companies can position themselves for success in the evolving drilling sector. Take action now to explore partnerships that will drive your operational excellence and sustainability goals forward.