The Ultimate Guide to Electrical Component Supplier (2025)

Introduction: Navigating the Global Market for electrical component supplier

In today’s rapidly evolving global market, sourcing electrical components presents a unique set of challenges for international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe. The complexity of identifying reliable suppliers who offer quality products at competitive prices can be daunting. This guide aims to alleviate these concerns by providing a comprehensive overview of the electrical component supplier landscape.

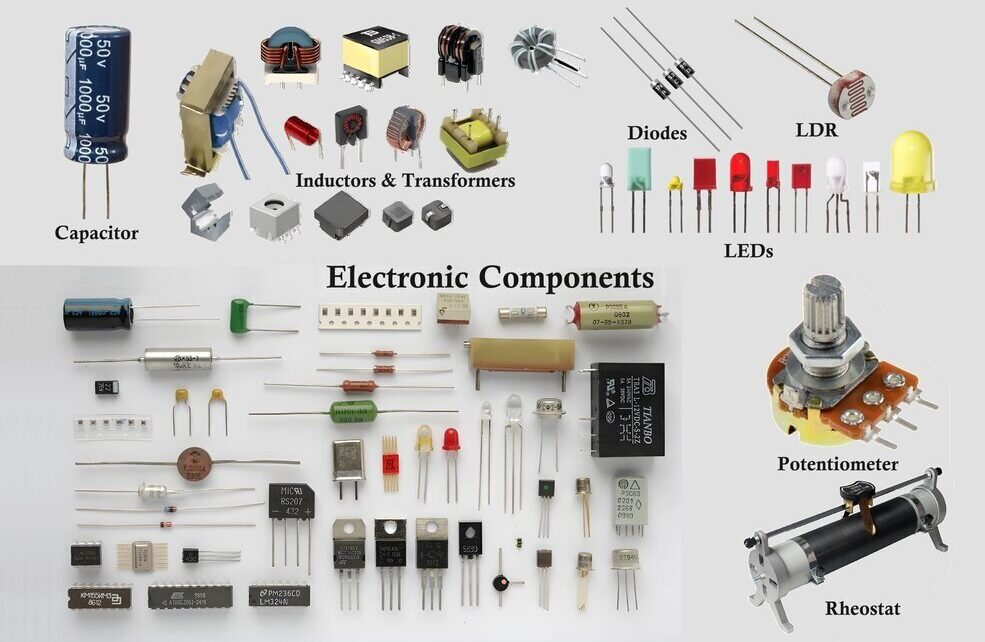

What Types of Electrical Components Should You Consider?

From connectors and circuit breakers to transformers and capacitors, understanding the various types of electrical components is crucial. Each component serves specific applications across industries, such as manufacturing, renewable energy, and telecommunications. By familiarizing yourself with these components, you can make informed decisions that align with your operational needs.

How to Vet Electrical Component Suppliers Effectively?

Supplier vetting is a critical step in ensuring the reliability and quality of your electrical components. This guide will delve into best practices for evaluating suppliers, including assessing certifications, reviewing customer feedback, and understanding delivery timelines. These insights will empower you to establish partnerships that foster business growth and innovation.

What Are the Cost Considerations in Sourcing Electrical Components?

Cost is always a significant factor in procurement. This guide will explore various pricing models, helping you to identify the best value for your investment. By equipping yourself with knowledge about market trends and cost factors, you can negotiate better terms and optimize your purchasing strategy.

Ultimately, this guide serves as a valuable resource for international B2B buyers, enabling you to navigate the complexities of sourcing electrical components with confidence. Whether you are based in Colombia or Poland, the insights provided will help you make strategic purchasing decisions that contribute to your business success.

Understanding electrical component supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wholesale Electrical Suppliers | Bulk purchasing, wide range of products, competitive pricing | Construction, manufacturing, and industrial sectors | Pros: Cost-effective, large inventory. Cons: May require minimum order quantities. |

| Specialized Component Suppliers | Focus on specific electrical components (e.g., semiconductors, connectors) | High-tech industries, automotive, aerospace | Pros: Expertise in niche markets, tailored solutions. Cons: Potentially higher prices. |

| Local Electrical Distributors | Regional availability, faster delivery, personalized service | Small to medium enterprises, local contractors | Pros: Quick access to products, local support. Cons: Limited product range compared to wholesalers. |

| Online Electrical Component Suppliers | E-commerce platforms, extensive catalogs, user-friendly interfaces | All sectors needing quick access to parts | Pros: Convenience, easy comparison shopping. Cons: Shipping times may vary, potential for miscommunication. |

| OEM (Original Equipment Manufacturer) Suppliers | Custom manufacturing, brand-specific components, long-term partnerships | Electronics, automotive, and appliance industries | Pros: High-quality, brand assurance. Cons: Longer lead times, less flexibility in orders. |

What Are the Key Characteristics of Wholesale Electrical Suppliers?

Wholesale electrical suppliers are pivotal for B2B buyers looking for bulk purchasing options. They typically offer a vast array of electrical components at competitive prices, making them ideal for large-scale projects in construction and manufacturing. Buyers should consider minimum order quantities and shipping costs, as these can impact overall savings. Establishing a relationship with a wholesale supplier can also lead to better pricing and terms over time.

How Do Specialized Component Suppliers Differ from Others?

Specialized component suppliers focus on niche markets by providing specific electrical components, such as semiconductors and connectors. These suppliers are crucial for industries like automotive and aerospace, where precision and reliability are paramount. B2B buyers should assess the supplier’s expertise and product certifications, as these factors can influence the quality and performance of components in critical applications. While prices may be higher, the tailored solutions offered can justify the investment.

Why Choose Local Electrical Distributors for Your Business Needs?

Local electrical distributors are advantageous for small to medium enterprises that require fast access to components. Their regional presence allows for quicker delivery times and personalized service, which can be essential for ongoing projects. Buyers should evaluate the distributor’s inventory and support capabilities, as a limited range might require additional sourcing from other suppliers. However, the convenience of local sourcing often outweighs these limitations.

What Benefits Do Online Electrical Component Suppliers Provide?

Online electrical component suppliers have transformed the purchasing landscape by offering extensive catalogs and user-friendly interfaces. They cater to businesses that need quick access to parts, making them suitable for various sectors. B2B buyers should take advantage of the convenience and ability to compare products easily. However, it’s crucial to be aware of potential shipping delays and the need for clear communication about product specifications to avoid errors in orders.

How Do OEM Suppliers Support Specific Industry Needs?

OEM suppliers are essential for businesses requiring custom-manufactured components that meet specific brand requirements. They often have long-term partnerships with industries such as electronics and automotive, ensuring high quality and brand assurance. B2B buyers should consider the lead times and flexibility in order quantities, as OEM suppliers may not accommodate smaller or urgent requests. However, the investment in OEM components can lead to enhanced product reliability and performance in the long run.

Related Video: Schematic Diagrams & Symbols, Electrical Circuits – Resistors, Capacitors, Inductors, Diodes, & LEDs

Key Industrial Applications of electrical component supplier

| Industry/Sector | Specific Application of electrical component supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Supply of electrical components for automation systems | Increases operational efficiency and reduces labor costs | Quality certifications, compliance with international standards |

| Renewable Energy | Provision of electrical components for solar panels | Enhances energy production and sustainability goals | Supplier reliability, availability of technical support |

| Transportation | Electrical components for electric vehicles (EVs) | Supports innovation in eco-friendly transport solutions | Compatibility with existing systems, warranty and service terms |

| Construction | Electrical wiring and components for building projects | Ensures safety and compliance with regulations | Local regulations, availability of materials, lead times |

| Telecommunications | Electrical components for communication networks | Improves connectivity and service reliability | Scalability of supply, technical specifications, pricing |

How is Electrical Component Supplier Used in Manufacturing?

In the manufacturing sector, electrical component suppliers provide essential parts for automation systems, such as sensors, relays, and PLCs (Programmable Logic Controllers). These components are crucial for streamlining production processes, enhancing operational efficiency, and reducing labor costs. International buyers, especially from regions like Africa and South America, should prioritize suppliers that offer quality certifications and compliance with international standards to ensure reliability and safety in their operations.

What Role Do Electrical Components Play in Renewable Energy?

In the renewable energy sector, particularly solar energy, electrical component suppliers deliver critical components such as inverters, connectors, and cabling. These components facilitate the conversion of solar energy into usable electricity, thereby enhancing energy production and helping businesses meet sustainability goals. Buyers from Europe and the Middle East should focus on supplier reliability and the availability of technical support to address any operational challenges that may arise during installation and maintenance.

How Are Electrical Components Essential for Transportation?

The transportation industry increasingly relies on electrical component suppliers for the development of electric vehicles (EVs). Components such as batteries, charging systems, and control units are integral to the functionality and efficiency of EVs. As international buyers, particularly from Poland and Colombia, seek to innovate in eco-friendly transport solutions, they must consider compatibility with existing systems, warranty, and service terms when selecting suppliers.

Why Are Electrical Components Important in Construction?

In the construction industry, electrical component suppliers provide wiring, circuit breakers, and safety devices that are essential for building projects. These components ensure the safety and compliance of electrical installations with local regulations. Buyers should be aware of local regulations and the availability of materials when sourcing these components to avoid delays and ensure compliance with safety standards.

How Do Electrical Components Enhance Telecommunications?

Electrical component suppliers play a vital role in the telecommunications sector by providing components for communication networks, such as routers, switches, and signal amplifiers. These components improve connectivity and service reliability, which are critical for businesses in today’s digital age. Buyers should evaluate the scalability of supply and technical specifications to ensure they meet the demands of their growing networks.

Related Video: Introduction to UL 508A Industrial Electrical Control Panels with PLC

3 Common User Pain Points for ‘electrical component supplier’ & Their Solutions

Scenario 1: Navigating Supply Chain Disruptions

The Problem:

International B2B buyers, particularly in regions like Africa and South America, often face significant challenges due to supply chain disruptions. Factors such as political instability, natural disasters, and pandemics can lead to delays in receiving essential electrical components. This not only affects production schedules but can also lead to increased costs and strained relationships with clients who rely on timely deliveries. The uncertainty surrounding lead times and the availability of components can create a frustrating environment for procurement teams trying to meet project deadlines.

The Solution:

To mitigate these supply chain risks, B2B buyers should diversify their supplier base by sourcing electrical components from multiple suppliers across different regions. This strategy helps to reduce dependency on a single source and provides alternative options in case of disruptions. Additionally, establishing strong relationships with suppliers can lead to better communication and more favorable terms during crises. Investing in a robust supply chain management system can also provide real-time data on inventory levels and lead times, allowing businesses to anticipate shortages and plan accordingly. Regularly reviewing and updating contingency plans will further ensure that buyers are prepared for any unforeseen circumstances.

Scenario 2: Ensuring Compliance with International Standards

The Problem:

B2B buyers in Europe and the Middle East often encounter difficulties ensuring that the electrical components they purchase comply with local and international regulations. Non-compliance can lead to costly penalties, project delays, and damage to a company’s reputation. The varying standards across regions can complicate the procurement process, as buyers must navigate a complex landscape of certifications and quality assurance requirements.

The Solution:

To overcome compliance challenges, buyers should prioritize working with suppliers who have a proven track record of meeting international standards. Before making a purchase, it’s crucial to request documentation that verifies compliance with relevant certifications (such as ISO, CE, or UL). Engaging in thorough due diligence by conducting audits of suppliers’ facilities can also provide peace of mind regarding their adherence to quality standards. Additionally, staying informed about changes in regulations and participating in industry associations can equip buyers with the knowledge necessary to ensure ongoing compliance.

Scenario 3: Managing Quality Assurance and Testing Procedures

The Problem:

Quality assurance is a critical concern for B2B buyers of electrical components, especially when sourcing from international suppliers. Inconsistent product quality can lead to malfunctioning systems, increased warranty claims, and heightened operational costs. Buyers may struggle to implement effective testing procedures when they lack direct access to suppliers or when they are unfamiliar with the manufacturing processes used.

The Solution:

To address quality assurance issues, buyers should establish clear quality specifications and testing protocols with their suppliers before placing orders. This includes defining acceptable tolerances, performance metrics, and testing methods. Engaging third-party inspection services can also provide unbiased assessments of product quality before shipment. Furthermore, implementing a feedback loop where buyers report quality issues back to suppliers can foster continuous improvement and accountability. Training procurement teams on quality management principles will ensure that they are well-equipped to evaluate supplier performance and product quality effectively.

Strategic Material Selection Guide for electrical component supplier

When selecting materials for electrical components, international B2B buyers must consider a variety of factors that influence product performance, durability, and compliance with regional standards. Below, we analyze four common materials used in electrical components, focusing on their properties, advantages, disadvantages, and specific considerations for buyers in Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Copper in Electrical Components?

Copper is widely regarded as one of the best conductors of electricity, making it a popular choice for wiring and connectors. Key properties include excellent electrical conductivity (around 59.6 x 10^6 S/m), good thermal conductivity, and resistance to corrosion when properly treated.

Pros: Copper’s high conductivity leads to minimal energy loss, making it suitable for high-performance applications. It is also relatively easy to work with and can be soldered or welded.

Cons: The primary drawback is its cost, which can be higher than alternatives like aluminum. Additionally, copper is susceptible to oxidation, which can affect performance if not adequately protected.

Impact on Application: Copper is ideal for applications requiring efficient power transmission, such as in electrical motors and transformers. However, buyers must ensure compliance with local standards such as ASTM B170 for copper wire.

How Does Aluminum Compare as a Material for Electrical Components?

Aluminum is another common material used in electrical components, particularly in applications where weight is a critical factor. It has a lower electrical conductivity than copper (approximately 37.7 x 10^6 S/m) but is much lighter.

Pros: Aluminum is less expensive than copper and offers good corrosion resistance, especially when anodized. Its lightweight nature makes it suitable for applications in aerospace and automotive sectors.

Cons: The lower conductivity means that aluminum wires must be thicker to carry the same current as copper, which can complicate design and increase material costs.

Impact on Application: Aluminum is often used in overhead power lines and large-scale electrical distribution. Buyers should consider compliance with standards like ASTM B231 for aluminum conductors.

What Are the Benefits of Using Thermoplastics in Electrical Components?

Thermoplastics, such as polyvinyl chloride (PVC) and polyethylene (PE), are frequently used as insulating materials in electrical components. They offer excellent dielectric properties and resistance to moisture and chemicals.

Pros: Thermoplastics are versatile, lightweight, and can be molded into complex shapes, making them ideal for various applications. They also provide good thermal stability and are relatively inexpensive.

Cons: While thermoplastics are durable, they can degrade under high temperatures or exposure to certain chemicals. This limits their use in high-heat applications.

Impact on Application: Thermoplastics are commonly used for cable insulation and connectors. Buyers should ensure that the materials meet relevant standards, such as UL 94 for flammability.

Why Are Ceramics Important in Electrical Component Manufacturing?

Ceramics are used in specific electrical components, particularly insulators and capacitors, due to their excellent dielectric properties and high-temperature resistance.

Pros: Ceramics are highly durable, resistant to heat and corrosion, and provide excellent insulation. They can operate effectively in extreme environments.

Cons: The brittleness of ceramics can be a drawback, making them susceptible to cracking under mechanical stress. Additionally, they can be more expensive to manufacture.

Impact on Application: Ceramics are essential in high-voltage applications, such as insulators for power lines. Buyers should consider compliance with standards like IEC 60233 for ceramic insulators.

Summary of Material Selection for Electrical Components

| Material | Typical Use Case for electrical component supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Wiring and connectors in electrical motors | High electrical conductivity | Higher cost and oxidation susceptibility | High |

| Aluminum | Overhead power lines and electrical distribution | Lightweight and cost-effective | Lower conductivity requires thicker wires | Medium |

| Thermoplastics | Cable insulation and connectors | Versatile and inexpensive | Degradation under high temperatures | Low |

| Ceramics | Insulators and capacitors in high-voltage systems | Excellent durability and insulation | Brittleness and higher manufacturing cost | Medium |

In conclusion, selecting the right material for electrical components involves balancing performance, cost, and compliance with regional standards. Buyers from diverse regions should carefully evaluate these factors to ensure optimal product performance and regulatory adherence.

In-depth Look: Manufacturing Processes and Quality Assurance for electrical component supplier

What Are the Main Stages of Manufacturing Electrical Components?

The manufacturing process for electrical components is intricate and involves several crucial stages. Each stage is designed to ensure that the final product meets quality standards and performs reliably in its intended applications.

Material Preparation

The manufacturing process begins with material preparation, which involves sourcing high-quality raw materials such as metals, plastics, and semiconductors. Buyers should verify that suppliers use materials that meet international standards, such as ASTM or ISO specifications. For example, copper is often used for wiring due to its excellent conductivity, while plastics may be selected based on thermal and electrical insulation properties.

Forming Processes

Once materials are prepared, the next step is forming, which includes various techniques such as stamping, molding, and extrusion. Stamping is typically used for creating flat components, while molding is essential for producing complex shapes in plastics. Extrusion is often employed for producing wires and cables. B2B buyers should inquire about the specific forming techniques utilized by suppliers, as these can significantly impact the performance and durability of the electrical components.

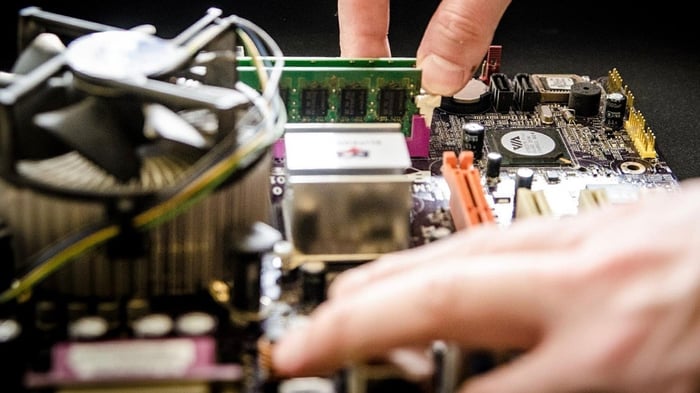

Assembly Techniques

After forming, components move to the assembly stage, where they are integrated into final products. This may involve soldering, welding, or using adhesive methods. Automated assembly lines are increasingly common, enhancing precision and efficiency. Buyers should assess a supplier’s assembly capabilities, especially for complex products like circuit boards, where precision is paramount.

Finishing Processes

Finishing processes such as plating, painting, or coating are applied to enhance the appearance and durability of the components. For instance, electroplating can improve corrosion resistance, while coatings can provide insulation. It is important for buyers to understand the finishing techniques employed by suppliers to ensure that products can withstand environmental conditions in their specific markets.

A stock image related to electrical component supplier.

How Is Quality Assurance Implemented in Electrical Component Manufacturing?

Quality assurance (QA) is a critical aspect of manufacturing electrical components. It encompasses various practices and standards designed to ensure that products meet specific performance and safety criteria.

What International Standards Should B2B Buyers Consider?

International standards such as ISO 9001 play a significant role in quality assurance. ISO 9001 focuses on quality management systems and is applicable across various industries, including electrical components. Compliance with this standard indicates that a supplier has processes in place to consistently produce products that meet customer and regulatory requirements.

In addition to ISO standards, industry-specific certifications such as CE marking for electrical products in Europe and API certification for certain industrial components are crucial. These certifications assure buyers that products have been tested for safety and efficiency.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are essential for maintaining product quality throughout the manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified requirements.

-

In-Process Quality Control (IPQC): During the manufacturing process, periodic inspections are conducted to identify and address any deviations from quality standards.

-

Final Quality Control (FQC): This final inspection stage ensures that the completed product meets all specifications before shipment.

B2B buyers should inquire about the QC practices at each stage and request documentation of these processes to ensure transparency.

What Common Testing Methods Are Used in Electrical Component Manufacturing?

Testing is a vital component of quality assurance in electrical manufacturing. Various methods are employed to assess the performance and reliability of components, including:

-

Electrical Testing: This involves checking the electrical properties of components, such as resistance, capacitance, and inductance.

-

Environmental Testing: Components may undergo tests for temperature, humidity, and vibration to ensure they can perform under varying conditions.

-

Safety Testing: Compliance with safety standards is critical, especially for components used in consumer electronics. Tests may include dielectric strength and insulation resistance checks.

Buyers should request test reports from suppliers, ensuring that tests are conducted in accredited laboratories to validate results.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Verifying a supplier’s quality control processes is crucial for B2B buyers, particularly when sourcing from international suppliers. Here are some effective strategies:

Conducting Supplier Audits

One of the most effective methods for verifying QC processes is conducting supplier audits. These audits can be performed by the buyer or third-party organizations. During an audit, buyers can review the manufacturing facilities, processes, and documentation related to quality management systems.

Requesting Quality Reports

Buyers should also ask suppliers for quality reports, including inspection and testing results. These reports provide insights into the supplier’s adherence to quality standards and their ability to produce consistent products.

Utilizing Third-Party Inspection Services

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control processes. These services can conduct inspections at various stages of the manufacturing process, ensuring that products meet specified standards before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate specific challenges related to quality control that may differ from domestic sourcing. Key considerations include:

-

Understanding Local Standards: Different regions may have varying quality and safety standards. For instance, products sold in Europe must comply with CE marking requirements, while those in the U.S. may need UL certification.

-

Cultural Differences in Quality Expectations: Quality perceptions can vary significantly across cultures. Buyers should communicate their quality expectations clearly to suppliers to avoid misunderstandings.

-

Logistical Challenges: Delays in shipping and customs can affect the timing of inspections and product delivery. Buyers should plan for these potential issues and establish clear timelines with suppliers.

By understanding these nuances, B2B buyers can make informed decisions and establish strong partnerships with electrical component suppliers across different regions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electrical component supplier’

In today’s fast-paced global market, sourcing electrical components requires a strategic approach. This guide provides B2B buyers with a practical checklist to streamline the procurement process, ensuring that you select the right suppliers for your business needs.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is the first step in the sourcing process. This includes understanding the voltage, current ratings, and compatibility with existing systems. Precise specifications help prevent miscommunications and ensure that the components meet your operational requirements.

- Voltage and Current Ratings: Specify the necessary voltage and current ratings for your application.

- Environmental Conditions: Consider factors like temperature, humidity, and potential exposure to chemicals.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers. Look for companies with a proven track record in the electrical components industry and those that cater to your geographical region.

- Industry Reputation: Utilize online platforms, forums, and trade associations to gauge supplier reputation.

- Experience and Expertise: Prioritize suppliers with experience in your specific sector or application.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with international standards. This step is vital to ensure the components are safe and reliable.

- ISO Certifications: Check for ISO 9001 certification, which indicates quality management practices.

- Product Certifications: Look for certifications like CE, UL, or RoHS that affirm adherence to safety and environmental regulations.

Step 4: Request Samples and Prototypes

Asking for samples or prototypes is essential to assess the quality and compatibility of the electrical components. This hands-on evaluation can prevent costly mistakes down the line.

- Quality Assurance: Ensure the samples meet your specifications and quality standards.

- Compatibility Testing: Conduct tests to verify that the components work seamlessly with your existing systems.

Step 5: Negotiate Terms and Conditions

Effective negotiation of terms and conditions can significantly impact your procurement process. Ensure that you cover pricing, payment terms, delivery schedules, and warranty conditions.

- Volume Discounts: Inquire about discounts for bulk purchases to optimize costs.

- Delivery and Lead Times: Clarify delivery timelines to align with your project schedules.

Step 6: Establish Clear Communication Channels

Setting up effective communication channels is crucial for maintaining a good relationship with your supplier. Clear communication can help resolve issues quickly and facilitate smoother transactions.

- Regular Updates: Schedule regular check-ins to discuss order status and address any concerns.

- Point of Contact: Designate a specific contact person on both sides for streamlined communication.

Step 7: Monitor Performance and Quality

After procurement, continuously monitor the supplier’s performance and the quality of the components received. This practice ensures that you maintain high standards and can make informed decisions for future sourcing.

- Feedback Mechanism: Implement a feedback system to report any quality issues or performance concerns.

- Supplier Evaluation: Regularly assess supplier performance against agreed metrics to ensure ongoing compliance.

By following this comprehensive checklist, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe can enhance their sourcing strategies for electrical components, leading to better operational efficiency and business growth.

Comprehensive Cost and Pricing Analysis for electrical component supplier Sourcing

What Are the Key Cost Components for Electrical Component Suppliers?

When sourcing electrical components, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The quality and type of raw materials significantly impact pricing. For instance, high-purity metals and specialized plastics can elevate costs. Buyers should consider sourcing materials locally to mitigate import costs.

-

Labor: Labor costs vary by region. In countries with higher labor costs, such as those in Western Europe, suppliers may charge more. Buyers from Africa or South America might find competitive pricing in regions with lower labor costs, but they should also evaluate the skill level and expertise of the workforce.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses that suppliers incur during production. Understanding how much overhead contributes to the final price can help buyers negotiate better.

-

Tooling: Initial setup costs for manufacturing tools and molds can be substantial, especially for customized components. Buyers should inquire about tooling costs upfront, as they can significantly influence the overall price.

-

Quality Control (QC): Ensuring that components meet specific quality standards requires investment in QC processes. Buyers should assess the supplier’s quality certifications, as these can affect pricing and reliability.

-

Logistics: Transportation and shipping costs can vary based on the Incoterms agreed upon. Buyers should analyze shipping routes and methods to minimize logistics costs.

-

Margin: Suppliers typically add a markup to cover their risks and profit. Understanding standard margins in the electrical component industry can help buyers gauge whether prices are fair.

How Do Price Influencers Affect Electrical Component Sourcing?

Several factors influence the pricing of electrical components, including:

-

Volume and Minimum Order Quantity (MOQ): Ordering in bulk often results in lower per-unit costs. Buyers should negotiate MOQs with suppliers to optimize pricing.

-

Specifications and Customization: Customized components tend to be more expensive due to the additional engineering and tooling required. Buyers must clearly define their specifications to avoid unexpected costs.

-

Material Quality and Certifications: Higher quality materials and certifications (like ISO or CE) can raise costs but may ensure better performance and longevity. Buyers should weigh the benefits of quality against budget constraints.

-

Supplier Factors: The supplier’s reputation, experience, and location can impact pricing. Established suppliers with a track record of reliability may charge more but can provide peace of mind.

-

Incoterms: The agreed-upon Incoterms dictate the responsibilities of buyers and sellers in terms of shipping, insurance, and customs duties. Understanding these terms can help buyers avoid hidden costs.

What Are Some Effective Buyer Tips for Negotiating Electrical Component Prices?

International B2B buyers can adopt several strategies to enhance their sourcing experience:

-

Negotiate Effectively: Use detailed cost breakdowns to negotiate better terms. Highlighting specific components that can be adjusted (like MOQ or payment terms) can lead to mutually beneficial agreements.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership (TCO) rather than just the purchase price. This includes installation, maintenance, and potential downtime costs.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations and their impact on pricing. Establishing contracts in a stable currency can mitigate risks.

-

Research Local Market Conditions: Understanding regional market trends, particularly in target areas like Africa, South America, the Middle East, and Europe, can provide leverage during negotiations.

-

Request Sample Orders: Before committing to large orders, request sample components to evaluate quality. This can prevent costly mistakes and ensure the components meet expectations.

Conclusion: Navigating the Cost Landscape for Electrical Components

By thoroughly understanding the cost components, pricing influencers, and effective negotiation strategies, B2B buyers can make informed decisions when sourcing electrical components. This approach not only enhances cost-efficiency but also builds long-term relationships with suppliers across regions. Always remember to consider the total cost of ownership and remain adaptable to market dynamics.

Alternatives Analysis: Comparing electrical component supplier With Other Solutions

Exploring Alternatives to Electrical Component Suppliers

In the evolving landscape of international trade, particularly for B2B buyers from regions like Africa, South America, the Middle East, and Europe, understanding the available alternatives to traditional electrical component suppliers is vital. This analysis provides a comparative view of the conventional electrical component supplier against two alternative solutions: Direct Manufacturer Relationships and Wholesale Distributors.

Comparison Table of Alternatives

| Comparison Aspect | Electrical Component Supplier | Direct Manufacturer Relationships | Wholesale Distributors |

|---|---|---|---|

| Performance | High quality, consistent supply | Tailored solutions, potential for innovation | Moderate quality, bulk availability |

| Cost | Higher due to branding and service | Potentially lower, especially with bulk orders | Competitive pricing, but markups may apply |

| Ease of Implementation | Often requires extensive vetting | May require more effort to establish | Generally straightforward; established networks |

| Maintenance | Reliable support services | Direct support, potentially better customization | Limited support; may depend on third-party services |

| Best Use Case | Standardized components for diverse applications | Specialized projects needing custom solutions | Large volume orders for standard components |

Understanding Direct Manufacturer Relationships

Pros: Establishing a direct relationship with manufacturers can yield significant advantages for B2B buyers. This approach often allows for customized components tailored to specific project needs. Moreover, manufacturers may offer better pricing structures for bulk orders, reducing overall procurement costs.

Cons: However, the initial setup can be time-consuming and may require extensive research to find reliable manufacturers. Additionally, buyers must be prepared to manage logistics and quality assurance directly, which can add complexity to the procurement process.

Evaluating Wholesale Distributors

Pros: Wholesale distributors are an attractive alternative for B2B buyers seeking convenience and competitive pricing. They provide quick access to a wide range of electrical components, allowing for fast turnaround times on orders. Distributors often have established logistics and supply chains, which can streamline the purchasing process.

Cons: On the downside, the quality of components may vary, as distributors may not have the same level of quality control as direct manufacturers. Additionally, while prices can be competitive, there may be hidden costs or markups that could impact the overall budget. Support may also be limited, depending on the distributor’s policies and resources.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right solution for sourcing electrical components requires a thorough understanding of your specific needs and operational capabilities. For B2B buyers in Africa, South America, the Middle East, and Europe, weighing the benefits of traditional electrical component suppliers against alternatives like direct manufacturer relationships and wholesale distributors is essential. Consider factors such as performance, cost, ease of implementation, and maintenance when making your decision. Ultimately, the right choice will align with your project requirements, budget constraints, and long-term business goals.

Essential Technical Properties and Trade Terminology for electrical component supplier

What Are the Essential Technical Properties for Electrical Components?

When sourcing electrical components, understanding the critical technical properties is vital for making informed purchasing decisions. Here are some key specifications that B2B buyers should consider:

-

Material Grade

– The material grade indicates the quality and suitability of the component for specific applications. Common materials include copper, aluminum, and various plastics. Higher-grade materials typically offer better conductivity, durability, and resistance to environmental factors, which can lead to improved product performance and longevity. -

Tolerance Levels

– Tolerance specifies the acceptable deviation from a specified dimension or performance metric. It is crucial in ensuring components fit correctly and function as intended within a system. High tolerance levels reduce the likelihood of failures and compatibility issues, which can be costly in the long run. -

Voltage Rating

– The voltage rating indicates the maximum voltage the component can handle safely. Selecting components with appropriate voltage ratings is essential to prevent electrical failures or hazards. This is particularly important in high-voltage applications common in industrial settings. -

Current Rating

– Similar to voltage rating, the current rating specifies the maximum current the component can carry without overheating or failing. Understanding the current requirements of your application can help in selecting the right components that maintain operational efficiency and safety. -

Operating Temperature Range

– This property defines the temperature limits within which the component can operate effectively. Components exposed to extreme temperatures may degrade faster or fail prematurely. Knowing the operating temperature range helps ensure reliability and longevity in various environments. -

Insulation Resistance

– Insulation resistance measures the effectiveness of insulation within a component. High insulation resistance is critical for preventing electrical leakage and ensuring safety. This is particularly important in applications where moisture or contaminants may be present.

What Are Common Trade Terms in the Electrical Components Industry?

Familiarizing yourself with industry jargon can enhance communication with suppliers and help streamline procurement processes. Here are several essential terms:

-

OEM (Original Equipment Manufacturer)

– An OEM produces components that are used in the manufacturing of another company’s products. B2B buyers often engage with OEMs to ensure quality and compatibility with existing systems. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management, as it impacts purchasing decisions and overall cost. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing and availability for specific components. This is an essential step in the procurement process, allowing buyers to compare costs and negotiate terms effectively. -

Incoterms (International Commercial Terms)

– These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for managing shipping costs, insurance, and risk during transit. -

Lead Time

– Lead time is the period between placing an order and receiving the goods. Knowing the lead time helps in planning production schedules and managing customer expectations. -

Certification Standards

– Certification standards ensure that components meet specific safety, quality, and environmental criteria. Familiarity with relevant certifications, such as ISO or CE, can aid in compliance and enhance product credibility.

By understanding these technical properties and trade terms, international B2B buyers can make informed purchasing decisions, ensuring they select the right electrical components for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the electrical component supplier Sector

What Are the Current Market Dynamics and Key Trends in the Electrical Component Supplier Sector?

The electrical component supplier sector is experiencing significant transformation driven by a combination of technological advancements, geopolitical changes, and evolving customer demands. Key global drivers include the rapid adoption of renewable energy sources, increased digitalization, and the Internet of Things (IoT). These trends are reshaping sourcing strategies, particularly for international B2B buyers from regions like Africa, South America, the Middle East, and Europe.

A stock image related to electrical component supplier.

Emerging B2B technologies such as artificial intelligence (AI) and machine learning are enhancing predictive analytics for inventory management and demand forecasting. Buyers are increasingly leveraging these technologies to optimize their supply chains, reduce costs, and improve service levels. Additionally, the rise of e-commerce platforms tailored for B2B transactions is making it easier for buyers in remote markets to access a broader range of suppliers and products.

Market dynamics are also influenced by geopolitical factors, including trade policies and tariffs, which can impact sourcing strategies. For instance, companies in Poland may face different challenges compared to those in Colombia when it comes to sourcing electrical components. Understanding these regional nuances is crucial for international buyers to navigate the complexities of global supply chains effectively.

How Important Is Sustainability and Ethical Sourcing in the Electrical Component Supplier Sector?

Sustainability and ethical sourcing have emerged as critical considerations for international B2B buyers in the electrical component sector. The environmental impact of electrical components, particularly in terms of resource extraction and waste management, is under increasing scrutiny. Companies are now expected to demonstrate a commitment to sustainability through the use of eco-friendly materials and responsible manufacturing practices.

For B2B buyers, the importance of ethical supply chains cannot be overstated. Suppliers that prioritize sustainability often hold certifications such as ISO 14001 for environmental management or RoHS compliance for hazardous substances. These certifications not only enhance a supplier’s credibility but also align with the growing consumer demand for responsible sourcing practices.

Moreover, adopting ‘green’ materials—such as recyclable plastics and energy-efficient components—can significantly reduce the overall carbon footprint of products. Buyers in regions like South America and Africa are particularly focused on sustainability, as these markets are often more vulnerable to the effects of climate change. By prioritizing suppliers that adhere to sustainable practices, B2B buyers can contribute to a more resilient global supply chain while also satisfying regulatory requirements and consumer expectations.

What Has Been the Evolution of the Electrical Component Supplier Sector?

The electrical component supplier sector has evolved significantly over the past few decades, influenced by technological advancements and changing market demands. Initially dominated by traditional manufacturing processes, the industry has seen a shift towards automation and digitalization, particularly with the rise of smart technologies and IoT devices.

In the early 2000s, globalization played a critical role in expanding the supply chain networks, allowing suppliers to source materials from various regions, including Asia and Europe. This era also witnessed the introduction of electronic components that enabled the development of more sophisticated products, such as smart appliances and industrial automation systems.

Today, the focus has shifted towards sustainability and ethical sourcing, as buyers increasingly seek suppliers that demonstrate responsible practices. This evolution reflects a broader trend within the B2B landscape, where transparency, sustainability, and technological integration are becoming essential criteria for supplier selection. Understanding this historical context can help international buyers make informed decisions when sourcing electrical components.

Frequently Asked Questions (FAQs) for B2B Buyers of electrical component supplier

-

How do I ensure the quality of electrical components from suppliers?

To ensure quality, begin by verifying the supplier’s certifications, such as ISO 9001 or industry-specific standards. Request product samples to assess their performance and durability. Additionally, consider conducting factory audits or third-party inspections, especially if sourcing from regions with varying quality standards. Establishing a clear quality assurance process, including detailed specifications and testing requirements, can further mitigate risks. -

What are the common payment terms when sourcing electrical components internationally?

Payment terms can vary significantly by supplier and region. Common options include advance payment, letters of credit, or payment upon delivery. It’s crucial to negotiate terms that align with your cash flow while ensuring supplier trust. Consider using escrow services for larger orders to protect both parties. Understanding local banking practices can also help streamline transactions, especially in regions like Africa and South America. -

How can I vet suppliers for electrical components effectively?

Start by researching potential suppliers online, focusing on reviews and ratings from other international buyers. Request references and contact them to gain insights into the supplier’s reliability and service quality. Additionally, consider visiting the supplier’s facility or engaging a local representative to conduct on-site evaluations. Utilizing platforms like Alibaba or ThomasNet can also provide insights into supplier credibility through verified trade history. -

What is the significance of Minimum Order Quantity (MOQ) in international sourcing?

MOQ is a critical factor as it determines the smallest quantity a supplier is willing to sell. Understanding MOQ can help in budgeting and managing inventory effectively. Suppliers may set higher MOQs for custom products or lower for standard items. If the MOQ is too high, consider negotiating or exploring alternative suppliers. Keep in mind that lower MOQs may come with increased costs per unit. -

How do I handle logistics when importing electrical components?

Effective logistics management involves selecting the right shipping method based on cost, speed, and reliability. Collaborate with freight forwarders who specialize in international shipping to navigate customs regulations and ensure timely delivery. It’s also essential to understand the incoterms (International Commercial Terms) to clarify responsibility for shipping costs, risks, and insurance. Establishing a robust tracking system will help monitor shipments and manage any potential delays. -

What customization options should I consider when sourcing electrical components?

Customization can enhance product fit for specific applications. Discuss options such as tailored dimensions, colors, or unique features with your supplier. It’s important to communicate your requirements clearly and request prototypes for testing before bulk orders. Customization may lead to higher costs or longer lead times, so balance these factors against your project needs. Ensure that the supplier has experience in producing customized components. -

What are the best practices for maintaining relationships with electrical component suppliers?

Building strong supplier relationships is vital for long-term success. Maintain open lines of communication and provide constructive feedback to foster collaboration. Regularly review performance metrics and address any concerns promptly. Consider arranging periodic visits to strengthen ties and discuss future projects. Establishing a partnership mentality can lead to better pricing, priority service, and access to new products.

- How can I stay informed about the latest trends in electrical components?

To stay updated, subscribe to industry newsletters, attend trade shows, and participate in relevant online forums. Engaging with professional organizations and networks can provide insights into emerging technologies and market shifts. Following leading manufacturers and suppliers on social media can also offer valuable information about product launches and innovations. Regularly conducting market research can help you anticipate changes and adapt your sourcing strategy accordingly.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for electrical component supplier

In today’s rapidly evolving electrical components market, international B2B buyers must prioritize strategic sourcing to enhance their operational efficiency and reduce costs. Understanding the distinctions between electric, electrical, and electronic components is crucial for making informed purchasing decisions. By aligning with reliable suppliers who offer quality certifications and robust support, businesses can mitigate risks associated with supply chain disruptions and ensure compliance with regional standards, particularly in diverse markets such as Africa, South America, the Middle East, and Europe.

What are the key benefits of strategic sourcing for international buyers?

Strategic sourcing not only enables buyers to negotiate better pricing but also fosters long-term partnerships that can lead to innovation and improved product offerings. As global demand for advanced electrical components continues to rise, staying ahead of market trends and technological advancements is essential.

Looking ahead, B2B buyers are encouraged to leverage digital tools and platforms to streamline procurement processes and enhance visibility across their supply chains. Engaging with forward-thinking suppliers will position your business to thrive in an increasingly competitive landscape. Embrace strategic sourcing today to unlock new opportunities and drive sustainable growth in your operations.