The Ultimate Guide to Electronic Component Manufacturer (2025)

Introduction: Navigating the Global Market for electronic component manufacturer

In today’s interconnected world, sourcing electronic components from global manufacturers poses both opportunities and challenges for international B2B buyers. The rapid pace of technological advancement necessitates a strategic approach to procurement, especially for companies in regions like Africa, South America, the Middle East, and Europe. Buyers often grapple with ensuring product quality, managing costs, and navigating the complexities of international supply chains. This guide is designed to empower you in making informed decisions about electronic component manufacturers, providing you with the essential knowledge to thrive in the global market.

What Types of Electronic Components Should You Consider?

This comprehensive guide will delve into the various types of electronic components, from semiconductors and capacitors to connectors and sensors. Understanding the specific applications of these components in your industry is crucial for effective sourcing.

How Can You Vet Suppliers Effectively?

Moreover, we will explore supplier vetting techniques to help you identify reliable manufacturers that meet your quality and compliance standards. This includes assessing their production capabilities, certifications, and customer feedback, ensuring you partner with reputable suppliers.

What Cost Factors Should You Consider?

Cost management is another critical aspect we will address, helping you understand pricing structures, potential hidden costs, and negotiation strategies that can lead to better deals.

By equipping yourself with this knowledge, you can navigate the global market with confidence, ensuring that your business remains competitive and responsive to market demands. Whether you are sourcing for a startup in Brazil or a large enterprise in Egypt, this guide will serve as your roadmap to successful procurement in the electronic components sector.

Understanding electronic component manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Original Equipment Manufacturers (OEMs) | Produce components for integration into larger systems. | Consumer electronics, automotive, medical devices | Pros: High-quality standards; tailored solutions. Cons: Potentially higher costs; longer lead times. |

| Contract Manufacturers (CMs) | Provide manufacturing services based on client designs. | Telecommunications, industrial equipment | Pros: Cost-effective; scalability; flexibility. Cons: Quality control challenges; potential IP risks. |

| Electronic Manufacturing Services (EMS) | Offer comprehensive services including design, assembly, and testing. | Aerospace, defense, consumer products | Pros: Full-service solutions; rapid prototyping. Cons: Complexity in communication; possible hidden costs. |

| Distributors | Act as intermediaries, stocking various components from multiple manufacturers. | Retail, small-scale manufacturing | Pros: Quick access to a wide range of products; lower minimum order quantities. Cons: Markup on prices; limited customization. |

| Specialty Manufacturers | Focus on niche markets or specific component types. | Medical devices, automotive sensors | Pros: Expertise in specific areas; innovative solutions. Cons: Limited product range; may not meet bulk needs. |

What Are the Characteristics of Original Equipment Manufacturers (OEMs)?

OEMs are pivotal in the electronics supply chain, creating components that are integrated into end products. They often maintain stringent quality control and offer tailored solutions to meet specific client requirements. For B2B buyers, the key consideration when working with OEMs is the balance between quality and cost. While OEMs provide high-quality components, the associated costs can be higher, and lead times may be extended, particularly for customized orders.

How Do Contract Manufacturers (CMs) Operate in the B2B Space?

Contract manufacturers specialize in producing goods based on client specifications. They are particularly appealing to companies looking to reduce production costs while maintaining flexibility in their manufacturing processes. CMs can scale operations up or down based on demand, making them suitable for businesses with fluctuating needs. However, buyers should be cautious about quality control, as outsourcing production can sometimes lead to inconsistencies, and there may be intellectual property risks involved.

What Services Do Electronic Manufacturing Services (EMS) Provide?

EMS companies offer a comprehensive suite of services that encompass everything from design and engineering to assembly and testing of electronic components. This makes them a one-stop solution for businesses in sectors such as aerospace and defense, where reliability is paramount. The complexity of these services requires clear communication between buyers and EMS providers. While EMS can facilitate rapid prototyping and streamline the production process, potential hidden costs and the need for diligent project management can pose challenges for buyers.

Why Choose Distributors for Electronic Components?

Distributors serve as vital intermediaries in the electronics market, providing quick access to a wide array of components from various manufacturers. They cater to small-scale manufacturers and retailers who may not need large quantities of components. The key advantage of working with distributors is their ability to fulfill orders with lower minimum quantities and faster delivery times. However, buyers should be aware of potential markups on prices and the limitations in customization that may not align with specific project requirements.

What Makes Specialty Manufacturers Unique?

Specialty manufacturers focus on producing specific types of electronic components for niche markets, such as medical devices or automotive sensors. Their deep expertise allows them to innovate and provide tailored solutions that meet unique industry needs. B2B buyers looking for specialized products may find these manufacturers invaluable; however, they should also consider the limited product range and the potential challenges in meeting bulk order requirements.

Related Video: A simple guide to electronic components.

Key Industrial Applications of electronic component manufacturer

| Industry/Sector | Specific Application of electronic component manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Advanced Driver-Assistance Systems (ADAS) | Enhances safety and efficiency, reduces accident rates | Compliance with local regulations and standards, reliability of components |

| Telecommunications | Network Infrastructure | Supports high-speed data transfer, improves connectivity | Quality assurance, scalability, and compatibility with existing systems |

| Consumer Electronics | Smart Home Devices | Increases energy efficiency and convenience for users | Innovation in design, energy ratings, and supply chain reliability |

| Industrial Automation | Robotics and Automation Systems | Boosts productivity and reduces labor costs | Customization options, technical support, and after-sales service |

| Medical Devices | Diagnostic Equipment | Improves patient care and operational efficiency | Certification compliance, precision manufacturing, and timely delivery |

How Are Electronic Components Used in the Automotive Industry?

In the automotive sector, electronic component manufacturers play a crucial role in the development of Advanced Driver-Assistance Systems (ADAS). These components include sensors, cameras, and control units that enhance vehicle safety and performance. For international B2B buyers, particularly in Africa and Europe, sourcing high-quality, reliable components is essential to meet stringent safety standards and regulations. Additionally, manufacturers must ensure that their products are compatible with various vehicle models to facilitate seamless integration.

What Role Do Electronic Components Play in Telecommunications?

In telecommunications, electronic components are pivotal in building robust network infrastructures. They enable high-speed data transfer and reliable connectivity, which are vital for modern communication systems. For buyers in South America and the Middle East, it is important to consider sourcing components that not only meet technical specifications but also offer scalability to accommodate future growth. Quality assurance is a critical factor, as any failure in components can lead to significant operational disruptions.

How Are Electronic Components Transforming Consumer Electronics?

The consumer electronics industry increasingly relies on electronic components to create innovative smart home devices. These components help improve energy efficiency and enhance user convenience through automation and connectivity. Buyers from regions like Europe and Africa should focus on sourcing components that prioritize innovation and energy ratings, as these factors significantly impact market competitiveness. Additionally, a reliable supply chain is essential to ensure timely product launches.

What Are the Applications of Electronic Components in Industrial Automation?

In industrial automation, electronic components are integral to the functionality of robotics and automation systems. They enable enhanced productivity and reduced labor costs by automating repetitive tasks. For B2B buyers in South America and the Middle East, it is crucial to seek manufacturers that offer customization options to meet specific operational needs. Technical support and after-sales service are also important considerations, as they can significantly affect the efficiency of the systems in the long run.

How Are Electronic Components Used in Medical Devices?

In the medical field, electronic components are essential for the development of diagnostic equipment that improves patient care. These components must meet stringent certification requirements to ensure safety and efficacy. Buyers in regions like Africa and Europe should prioritize suppliers that specialize in precision manufacturing and timely delivery, as delays or defects can have serious implications for patient outcomes. Understanding the regulatory landscape is also vital for successful sourcing in this sector.

3 Common User Pain Points for ‘electronic component manufacturer’ & Their Solutions

Scenario 1: Navigating Supply Chain Disruptions in Electronics Manufacturing

The Problem: One of the most pressing challenges B2B buyers face is the unpredictability of supply chain disruptions. For manufacturers in regions like Africa and South America, sourcing electronic components can become a logistical nightmare due to delays caused by geopolitical tensions, natural disasters, or even pandemics. Buyers often find themselves grappling with lead times that extend beyond acceptable limits, affecting production schedules and ultimately customer satisfaction.

The Solution: To mitigate these disruptions, buyers should adopt a proactive supply chain management strategy. This includes establishing strong relationships with multiple suppliers across different geographical regions. By diversifying the supplier base, businesses can ensure they have alternative sources for critical components, reducing reliance on any single supplier. Additionally, implementing just-in-time inventory practices can help maintain optimal stock levels without overcommitting capital. Leveraging technology, such as supply chain management software, can provide real-time visibility into inventory levels and supplier performance, enabling timely decision-making.

Scenario 2: Ensuring Quality and Compliance in Electronic Components

The Problem: Quality assurance is a significant concern when sourcing electronic components, especially for buyers in Europe and the Middle East. Many manufacturers face issues with components that do not meet required specifications or regulatory standards, leading to costly reworks or product failures. This challenge is compounded by the complexity of international regulations and standards that vary by region, making it difficult for buyers to ensure compliance.

The Solution: To address quality and compliance issues, B2B buyers should implement a rigorous vendor evaluation process that includes quality certifications and compliance documentation. Requesting samples before placing large orders can help verify the quality of components. Additionally, buyers should stay informed about relevant standards such as ISO, RoHS, and REACH by engaging with industry bodies and attending relevant trade shows. Establishing a collaborative relationship with manufacturers can also facilitate open communication about quality expectations and regulatory updates, ensuring that both parties are aligned on compliance requirements.

Scenario 3: Managing Cost Fluctuations in Component Sourcing

The Problem: Fluctuating prices of electronic components can create significant budgeting challenges for businesses, particularly for those operating in volatile economic environments like Brazil or Egypt. Unexpected increases in material costs or exchange rate variations can dramatically impact overall project budgets, leading to strained financial resources and project delays.

The Solution: To effectively manage cost fluctuations, B2B buyers should consider adopting long-term contracts with suppliers that include fixed pricing agreements. This strategy can help mitigate the impact of market volatility and provide predictability in budgeting. Additionally, conducting thorough market research to understand pricing trends can empower buyers to make informed purchasing decisions. Engaging in strategic sourcing practices—such as bulk buying or joining procurement cooperatives—can also offer leverage to negotiate better rates. Finally, continuously analyzing total cost of ownership (TCO) instead of just upfront costs can help buyers make more economically sound decisions in the long run.

Strategic Material Selection Guide for electronic component manufacturer

When selecting materials for electronic components, manufacturers must consider various factors that influence performance, durability, and cost-effectiveness. Below is an analysis of four common materials used in the industry, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Polycarbonate in Electronic Components?

Polycarbonate is a thermoplastic polymer known for its high impact resistance and transparency. It has a temperature rating of approximately -40°C to 120°C, making it suitable for various electronic applications. Polycarbonate is also resistant to UV radiation, which enhances its longevity in outdoor applications.

Pros and Cons:

The primary advantage of polycarbonate is its durability, which helps protect sensitive electronic components from physical damage. However, it can be more expensive than other plastics, and its manufacturing process is complex, requiring precise molding techniques. This can lead to increased production costs.

Impact on Application:

Polycarbonate is ideal for applications that require transparency and toughness, such as protective housings for electronic devices. It is compatible with various media, including oils and some solvents, but not all.

Considerations for International Buyers:

Buyers in regions like Brazil and Egypt should ensure that their suppliers comply with international standards such as ASTM and ISO for material quality and safety. Additionally, understanding local regulations regarding plastic use is crucial.

How Does Aluminum Benefit Electronic Component Manufacturing?

Aluminum is a lightweight metal with excellent thermal and electrical conductivity, making it a popular choice for heat sinks and housings in electronic devices. It has a high corrosion resistance, especially when anodized, and can withstand temperatures up to 600°C.

Pros and Cons:

The key advantage of aluminum is its lightweight nature combined with strength, which reduces the overall weight of electronic assemblies. However, aluminum can be more expensive than some plastics and may require additional treatments to enhance its corrosion resistance, complicating the manufacturing process.

Impact on Application:

Aluminum is particularly effective in applications where heat dissipation is critical, such as in power electronics. Its compatibility with various media is generally good, but it can corrode in highly acidic or alkaline environments.

Considerations for International Buyers:

Buyers should be aware of the common standards for aluminum, such as ASTM and JIS, and ensure that their suppliers can provide certified materials. Additionally, understanding the local supply chain for aluminum can help mitigate costs.

What Are the Advantages of Using FR-4 in Electronic Components?

FR-4 is a composite material made from woven fiberglass cloth and epoxy resin, widely used as a substrate for printed circuit boards (PCBs). It has excellent electrical insulation properties and can operate at temperatures up to 130°C.

Pros and Cons:

FR-4 is cost-effective and provides good mechanical strength, making it suitable for a wide range of electronic applications. However, it has limitations in high-frequency applications due to signal loss and can be less environmentally friendly due to its epoxy content.

Impact on Application:

FR-4 is ideal for PCBs in consumer electronics, automotive, and industrial applications. It is compatible with various media but may degrade in extreme environments.

Considerations for International Buyers:

Buyers should verify compliance with international standards such as IPC and UL for PCB materials. Understanding local environmental regulations regarding the disposal of FR-4 is also essential, particularly in regions with strict e-waste laws.

How Does Copper Contribute to Electronic Component Performance?

Copper is a highly conductive metal, making it essential in electronic components, especially for wiring and circuit traces. It has excellent thermal and electrical conductivity, with a melting point of around 1,085°C.

Pros and Cons:

The primary advantage of copper is its superior conductivity, which enhances the performance of electronic components. However, copper is prone to oxidation, which can affect its performance over time, and it is generally more expensive than aluminum.

Impact on Application:

Copper is crucial in applications requiring efficient electrical connections, such as in connectors and circuit boards. Its compatibility with various media is excellent, but it can corrode in certain environments.

Considerations for International Buyers:

Buyers should ensure that copper materials meet standards such as ASTM B170 and JIS H3250. Additionally, understanding the local market for copper can help in negotiating better prices.

Summary Table of Material Selection for Electronic Components

| Material | Typical Use Case for electronic component manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Protective housings for electronic devices | High impact resistance | Higher cost and complex manufacturing | Medium |

| Aluminum | Heat sinks and housings in electronic devices | Lightweight and strong | Higher cost and corrosion treatment | High |

| FR-4 | Substrate for printed circuit boards (PCBs) | Cost-effective with good strength | Limited in high-frequency applications | Low |

| Copper | Wiring and circuit traces in electronic components | Superior electrical conductivity | Prone to oxidation | High |

In-depth Look: Manufacturing Processes and Quality Assurance for electronic component manufacturer

What Are the Main Stages of Manufacturing Processes for Electronic Components?

The manufacturing of electronic components involves several critical stages that ensure the final product meets quality and performance standards. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: What Raw Materials Are Used?

The first step in the manufacturing process is material preparation. This stage involves sourcing high-quality raw materials such as silicon wafers, copper, and various polymers. Suppliers must adhere to strict specifications, as the quality of these materials directly influences the performance of the final electronic components. Buyers should inquire about the origin of these materials and the supplier’s adherence to international sourcing standards to ensure compliance and reliability.

How Are Electronic Components Formed?

Once the raw materials are prepared, the next stage is forming. This process typically involves techniques such as photolithography, etching, and deposition. For example, photolithography is used to transfer patterns onto semiconductor wafers, while etching removes unwanted material to create circuit designs. B2B buyers should assess suppliers’ capabilities in these techniques, as advanced methods can lead to better precision and lower defect rates.

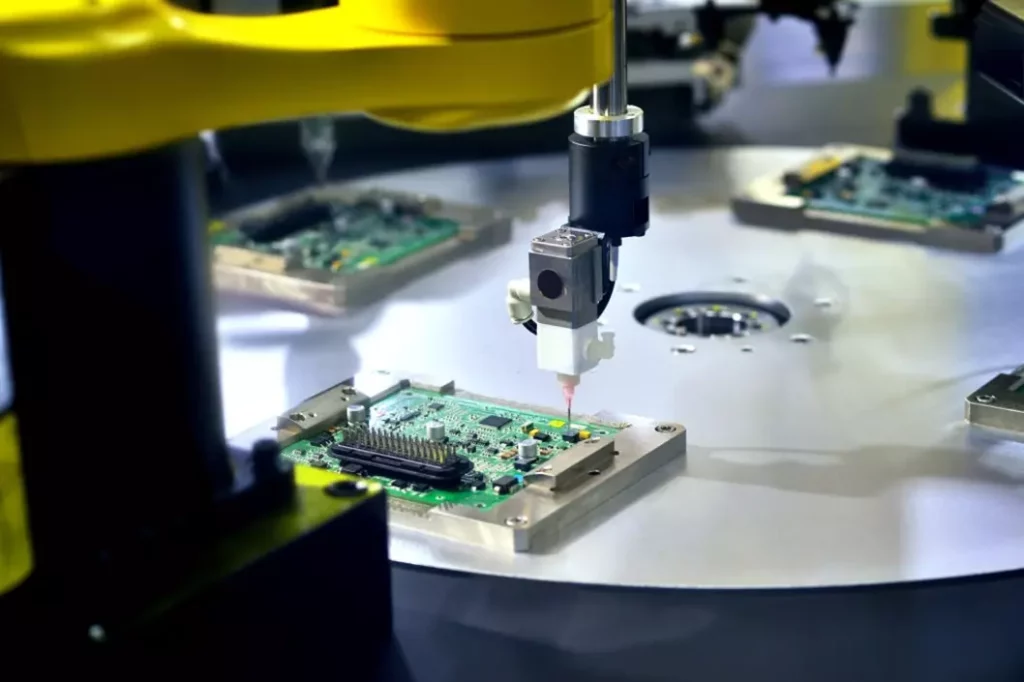

What Does the Assembly Process Entail?

Following the forming stage, components are assembled. This can involve placing components onto printed circuit boards (PCBs) through surface mount technology (SMT) or through-hole technology. Automated assembly lines are common in modern manufacturing, enhancing speed and reducing human error. Buyers should look for suppliers that utilize the latest assembly technologies, as this can significantly impact production efficiency and product quality.

How Is the Finishing Process Conducted?

The final stage in the manufacturing process is finishing, which includes soldering, coating, and packaging. Proper finishing protects components from environmental factors and ensures they are ready for shipment. B2B buyers should inquire about the finishing techniques employed by their suppliers, as this can affect the durability and longevity of the components.

What Quality Assurance Measures Are Essential for Electronic Component Manufacturers?

Quality assurance (QA) is a crucial aspect of electronic component manufacturing. It ensures that products meet specified standards and regulations. Buyers should be familiar with the key QA processes and certifications that affect their purchasing decisions.

Which International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 are essential for ensuring quality management systems in manufacturing. Compliance with ISO 9001 indicates that a manufacturer has established processes for quality assurance and continuous improvement. In addition, industry-specific certifications like CE for European markets or API for certain applications provide additional assurance of quality and safety. Buyers should prioritize suppliers that hold these certifications, as they demonstrate a commitment to maintaining high standards.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process, typically categorized into three main types:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards. Buyers should confirm that suppliers conduct thorough IQC to prevent defects from the outset.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are necessary to monitor production processes and detect issues early. Buyers should inquire about the frequency and methods of IPQC performed by their suppliers.

-

Final Quality Control (FQC): After production, FQC ensures that the finished products meet all specifications and performance criteria. This stage typically includes testing and inspection procedures. Buyers should request FQC reports to validate that the products are ready for delivery.

What Common Testing Methods Are Used in Quality Assurance?

To ensure that electronic components meet quality standards, various testing methods are utilized. Common approaches include:

- Functional Testing: Verifies that the component performs as intended under normal operating conditions.

- Environmental Testing: Assesses how components behave under extreme conditions, including temperature fluctuations and humidity.

- Electrical Testing: Measures electrical parameters to ensure they fall within acceptable ranges.

B2B buyers should ask suppliers about their testing protocols and how they ensure compliance with relevant standards.

How Can B2B Buyers Verify Supplier Quality Control?

Verification of a supplier’s quality control processes is vital for international B2B buyers. Here are several actionable steps buyers can take:

-

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and adherence to quality standards. Buyers should establish a schedule for audits and ensure they cover all critical aspects of manufacturing and QC.

-

Request Reports: Suppliers should provide detailed QC reports that outline their testing methods, results, and any corrective actions taken. Buyers should review these documents to assess the supplier’s commitment to quality.

-

Engage Third-Party Inspectors: Utilizing independent third-party inspection services can provide an unbiased evaluation of a supplier’s quality control processes. This can be particularly useful for buyers operating in regions where they cannot physically inspect the manufacturing facilities.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

For B2B buyers from Africa, South America, the Middle East, and Europe, understanding local regulations and market expectations is crucial. Different regions may have specific compliance requirements that suppliers must meet. Buyers should familiarize themselves with these regulations and ensure that their suppliers can demonstrate compliance.

Furthermore, cultural differences in business practices may influence communication and expectations regarding quality. Establishing clear guidelines and maintaining open lines of communication with suppliers can help mitigate misunderstandings and ensure that quality expectations are met consistently.

In conclusion, a thorough understanding of manufacturing processes and quality assurance practices is essential for B2B buyers in the electronic components sector. By focusing on these aspects, buyers can make informed decisions that enhance product quality and reliability, ultimately leading to successful partnerships with manufacturers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electronic component manufacturer’

This guide provides a structured approach for international B2B buyers seeking to procure electronic components. With the growing demand for electronic devices, understanding how to effectively source components can help ensure you select the right manufacturer, maintain quality, and optimize costs. The following checklist outlines essential steps to streamline your sourcing process.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing strategy. This includes defining the required electrical characteristics, physical dimensions, and performance criteria of the electronic components you need. Ensure that these specifications align with industry standards and your project’s requirements to avoid compatibility issues later on.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify potential manufacturers. Utilize industry directories, trade shows, and online marketplaces to compile a list of suppliers who specialize in the electronic components relevant to your needs. Pay special attention to suppliers with a solid reputation in your target markets—such as Africa, South America, the Middle East, and Europe—to ensure they can meet regional compliance standards.

Step 3: Evaluate Supplier Capabilities and Experience

Before committing to a supplier, it’s crucial to assess their capabilities and experience in the industry. Request detailed company profiles that include information on their production capacity, technology used, and previous projects. Look for suppliers that have experience working with companies in your specific sector, as this can be indicative of their ability to meet your unique requirements.

Step 4: Verify Supplier Certifications and Compliance

Ensuring that your supplier meets industry certifications and regulatory compliance is vital for quality assurance. Request copies of relevant certifications such as ISO 9001, RoHS, or CE marking, depending on your region and industry. Compliance with these standards not only assures quality but also mitigates risks associated with legal and operational challenges.

Step 5: Request Samples and Conduct Testing

Before finalizing your order, request samples of the electronic components to evaluate their quality and performance. Conduct thorough testing to ensure they meet your specifications and function effectively within your application. This step is crucial for identifying potential issues before bulk ordering and can save time and costs associated with returns or replacements.

Step 6: Understand Pricing Structures and Terms

Discuss pricing structures and payment terms with potential suppliers to avoid unexpected costs. Inquire about minimum order quantities, bulk pricing, and shipping costs. Ensure that you are clear on payment terms—whether upfront, upon delivery, or through credit arrangements—so you can manage your budget effectively.

Step 7: Establish Clear Communication Channels

Effective communication is key to a successful partnership with your supplier. Establish clear communication channels and protocols for regular updates, inquiries, and problem-solving. This will help you maintain a good relationship and ensure that any issues can be addressed promptly, minimizing disruptions in your supply chain.

By following these steps, international B2B buyers can streamline their sourcing process for electronic components, ensuring they select the right manufacturers and achieve successful procurement outcomes.

Comprehensive Cost and Pricing Analysis for electronic component manufacturer Sourcing

What Are the Key Cost Components in Electronic Component Manufacturing?

When sourcing electronic components, understanding the cost structure is critical for international B2B buyers. The primary cost components include:

-

Materials: The quality and type of raw materials significantly influence the price. High-grade materials may incur higher costs but can also enhance product reliability and lifespan.

-

Labor: Labor costs vary by region. Countries with lower wage rates may offer cost advantages, but this can impact quality and efficiency. Consider the skill level of labor in the manufacturing region, as this can affect both production speed and defect rates.

-

Manufacturing Overhead: This encompasses costs related to facilities, utilities, and administrative expenses. Efficient manufacturing processes can minimize overhead, which is a crucial factor in competitive pricing.

-

Tooling: Initial tooling investments can be substantial. Custom tools for specific components can drive up costs, so it’s essential to factor this into your total budget, especially for low-volume orders.

-

Quality Control (QC): Implementing rigorous QC processes is vital for ensuring product reliability. However, these processes also add to the cost. Buyers should assess the supplier’s QC standards and how they align with their own quality requirements.

-

Logistics: Shipping, handling, and customs duties are significant considerations, particularly for international buyers. The choice of shipping methods (air vs. sea) can dramatically influence overall costs and delivery times.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding industry standards for margins can help buyers gauge whether a quoted price is reasonable.

How Do Pricing Influencers Affect Costs for International Buyers?

Several factors influence the pricing of electronic components, impacting the total cost for buyers:

-

Volume/MOQ: Minimum Order Quantities (MOQs) can lead to bulk pricing advantages. Larger orders often result in lower per-unit costs, but buyers should balance inventory management with cost savings.

-

Specifications and Customization: Custom components often come at a premium. Clearly defining specifications can help prevent misunderstandings and additional costs during production.

-

Materials and Quality Certifications: Components that require certifications (like ISO or RoHS compliance) may carry higher costs. Buyers should prioritize suppliers who can provide the necessary documentation to avoid future compliance issues.

-

Supplier Factors: The reputation, reliability, and financial stability of suppliers can impact pricing. Engaging with well-established manufacturers may come at a premium but can reduce risks associated with quality and delivery.

-

Incoterms: The agreed-upon Incoterms determine who bears the costs and risks during transportation. Selecting the right Incoterms can optimize logistics costs and clarify responsibilities.

What Tips Can Help B2B Buyers Negotiate Better Prices?

Navigating pricing nuances is essential for international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe. Here are some actionable tips:

-

Effective Negotiation: Develop a clear understanding of your sourcing needs and market prices. Leverage multiple quotes to create a competitive bidding environment.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, shipping, tariffs, and maintenance costs. A lower initial price may not always equate to the best value.

-

Understand Pricing Nuances: Be aware that pricing can fluctuate based on geopolitical factors, currency exchange rates, and supply chain disruptions. Staying informed about these variables can provide leverage during negotiations.

-

Build Strong Relationships: Establishing a long-term partnership with suppliers can lead to better pricing and service. Suppliers may be more willing to negotiate if they see you as a committed customer.

Conclusion and Disclaimer

It’s important to note that prices for electronic components can vary widely based on market conditions and specific requirements. The insights provided here serve as a guide for B2B buyers, particularly those sourcing from diverse global markets. Always conduct thorough research and seek professional advice to obtain the most accurate and relevant pricing for your specific needs.

Alternatives Analysis: Comparing electronic component manufacturer With Other Solutions

In the realm of sourcing electronic components, international B2B buyers often encounter various solutions that can meet their needs. Understanding the available alternatives allows companies to make informed decisions that align with their operational goals. This section provides a comparative analysis between traditional electronic component manufacturers and two viable alternatives: 3D Printing of Components and Open-Source Hardware Solutions. Each option has distinct features that can cater to different business requirements.

Comparison Table of Electronic Component Solutions

| Comparison Aspect | Electronic Component Manufacturer | 3D Printing of Components | Open-Source Hardware Solutions |

|---|---|---|---|

| Performance | High precision and reliability | Variable; dependent on technology used | Moderate; design quality varies |

| Cost | Generally high upfront costs | Lower initial investment; material costs vary | Typically low-cost; community-driven |

| Ease of Implementation | Requires established supply chains | Moderate; requires specialized knowledge | Easy for tech-savvy users; community support available |

| Maintenance | Established support and warranty | Self-managed; requires ongoing expertise | Community-based support; variable reliability |

| Best Use Case | Large-scale production with consistent quality | Prototyping and low-volume production | Rapid prototyping and educational projects |

What Are the Pros and Cons of 3D Printing of Components?

3D printing technology offers significant advantages for businesses seeking flexibility and rapid prototyping capabilities. One of the main benefits is the ability to produce custom components quickly, which is ideal for companies needing unique solutions or small batches. Additionally, the initial investment can be lower than traditional manufacturing methods, as it eliminates the need for extensive tooling.

However, the performance can be inconsistent, particularly with lower-end printers or less experienced operators. The material costs can also add up, and while 3D printing is excellent for prototypes, it may not match the precision and reliability of components manufactured through traditional methods for high-volume production.

How Do Open-Source Hardware Solutions Compare?

Open-source hardware solutions provide a cost-effective alternative, especially for startups and educational institutions. The primary advantage lies in the accessibility of designs and community support, which allows users to modify and adapt existing projects to their specific needs. This collaborative approach fosters innovation and rapid iteration.

A stock image related to electronic component manufacturer.

On the downside, the quality of components can vary significantly since they are often produced by different manufacturers or hobbyists. Additionally, while community support exists, it may lack the robustness and reliability of dedicated customer service from traditional manufacturers, leading to potential challenges in maintenance and troubleshooting.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting the right electronic component solution, B2B buyers should consider their specific operational needs and long-term goals. Factors such as production scale, budget constraints, and the importance of precision should guide their decision-making process. For companies focused on high-volume production with a need for reliability, traditional electronic component manufacturers may be the best choice. Conversely, those in need of rapid prototyping and flexibility might find 3D printing or open-source hardware more aligned with their objectives. Evaluating these alternatives against their business requirements will empower buyers to make strategic decisions that enhance efficiency and innovation.

Essential Technical Properties and Trade Terminology for electronic component manufacturer

What Are the Key Technical Properties for Electronic Components?

When sourcing electronic components, understanding their technical specifications is essential for making informed purchasing decisions. Here are some critical properties to consider:

-

Material Grade

Material grade refers to the type and quality of materials used in the manufacturing of electronic components. For instance, components made from high-grade metals or polymers are generally more reliable and durable. Buyers should assess material grades to ensure that the components will withstand specific environmental conditions, which is crucial for applications in diverse climates across Africa and South America. -

Tolerance

Tolerance indicates the permissible limit or limits of variation in a physical dimension. In electronic components, tight tolerances are often necessary for performance and reliability. For example, a tolerance of ±0.01mm may be critical in applications requiring high precision. Understanding tolerance levels helps buyers ensure compatibility with existing systems and reduces the risk of costly errors in production. -

Voltage Rating

The voltage rating defines the maximum voltage that an electronic component can handle without failure. This specification is vital for ensuring that components operate safely within their intended application. Buyers must consider voltage ratings to prevent component damage and system failures, especially in regions with variable electrical standards. -

Operating Temperature Range

This property specifies the temperature limits within which the component can operate effectively. Components designed for extreme temperatures are essential for applications in harsh environments, such as industrial settings in the Middle East or high-altitude areas in Europe. Selecting components with appropriate operating temperature ranges can enhance reliability and longevity. -

Power Rating

Power rating refers to the maximum amount of power a component can handle before failing. This is particularly important for components like resistors and capacitors, as exceeding the power rating can lead to overheating and failure. Buyers should ensure that the power ratings align with their application requirements to maintain optimal performance.

What Are Common Trade Terms in the Electronic Component Industry?

Familiarity with industry terminology is crucial for effective communication and negotiation with suppliers. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding the OEM status of a supplier can help buyers gauge the quality and reliability of components, as reputable OEMs typically adhere to strict manufacturing standards. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. This term is particularly important for B2B buyers, as it affects inventory management and cost efficiency. Knowing the MOQ can help buyers negotiate better terms and align orders with their production needs. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific quantities of components. This process allows buyers to compare pricing and terms effectively. Crafting a detailed RFQ can lead to better supplier responses and more competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in shipping and freight. Understanding these terms helps B2B buyers manage logistics effectively, ensuring clarity on who bears the risk and costs during transportation. This is particularly important for international transactions across diverse regions. -

Lead Time

Lead time refers to the time it takes from placing an order until the goods are delivered. This term is critical for supply chain management, as longer lead times can disrupt production schedules. Buyers should discuss lead times upfront to ensure alignment with project timelines.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions, reduce risks, and enhance their procurement processes in the electronic components market.

Navigating Market Dynamics and Sourcing Trends in the electronic component manufacturer Sector

What Are the Key Market Dynamics and Sourcing Trends in the Electronic Component Manufacturing Sector?

The electronic component manufacturing sector is undergoing significant transformation driven by globalization, technological advancements, and evolving consumer demands. For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. The increasing adoption of Internet of Things (IoT) devices and smart technologies is propelling demand for a variety of electronic components, including semiconductors, capacitors, and connectors. Furthermore, the rise of automation in manufacturing processes is leading to more efficient production cycles, which can translate into cost savings for buyers.

Emerging trends such as Industry 4.0 are reshaping sourcing strategies. Companies are now leveraging data analytics and AI for better inventory management and demand forecasting. For buyers in regions like Brazil and Egypt, this means that suppliers who adopt these technologies can offer more reliable lead times and lower prices. Additionally, the push towards localized sourcing is becoming prominent, as businesses seek to mitigate risks associated with long supply chains. B2B buyers should explore partnerships with local manufacturers to enhance supply chain resilience and responsiveness.

How Is Sustainability and Ethical Sourcing Reshaping the Electronic Component Manufacturing Sector?

Sustainability has become a focal point for electronic component manufacturers, driven by both regulatory pressures and consumer preferences. The environmental impact of electronic waste is significant, making it imperative for B2B buyers to consider ethical sourcing practices. Suppliers who prioritize sustainability not only contribute to environmental conservation but can also enhance their marketability. Certifications like ISO 14001 for environmental management and RoHS compliance for hazardous substances are becoming essential benchmarks for buyers evaluating suppliers.

Incorporating sustainable practices into sourcing strategies can yield long-term benefits. For instance, manufacturers who utilize recycled materials or renewable energy sources can reduce production costs and appeal to eco-conscious customers. B2B buyers from regions such as South America and Africa should prioritize suppliers that demonstrate a commitment to sustainability, as this can also align with their own corporate social responsibility goals. By fostering relationships with ethically minded suppliers, buyers can not only enhance their brand image but also contribute to a more sustainable future.

What Is the Historical Context of the Electronic Component Manufacturing Sector?

A stock image related to electronic component manufacturer.

The electronic component manufacturing sector has evolved significantly over the past few decades. Initially dominated by a few key players, the industry has expanded as technological advancements have democratized access to manufacturing capabilities. The rise of digital technologies in the late 20th century catalyzed a shift towards miniaturization and higher functionality of components, paving the way for the modern electronics era.

As international trade barriers have lowered, manufacturers from emerging markets have increasingly entered the global supply chain. This shift has provided B2B buyers in regions like the Middle East and Europe access to a broader range of products at competitive prices. Understanding this historical context allows buyers to appreciate the complexities of the current market and make informed sourcing decisions that align with both their operational needs and strategic objectives.

Frequently Asked Questions (FAQs) for B2B Buyers of electronic component manufacturer

-

How do I solve quality assurance issues when sourcing electronic components?

To address quality assurance concerns, start by establishing clear quality standards and specifications with your manufacturer. Request samples and conduct rigorous testing before placing large orders. Additionally, consider implementing third-party quality audits to verify compliance with international standards. Engage in regular communication with the supplier to address any discrepancies promptly. Utilizing certifications like ISO 9001 can also help ensure that the manufacturer adheres to recognized quality management practices. -

What is the best way to vet an electronic component manufacturer?

The best way to vet an electronic component manufacturer involves a multi-step process. Begin by researching their reputation through industry reviews and testimonials. Request references from previous clients and verify their experience in your specific sector. Conduct site visits, if possible, to assess their manufacturing capabilities and quality control processes. Additionally, check for compliance with international standards and certifications, which can indicate reliability and commitment to quality. -

How can I negotiate favorable payment terms with electronic component manufacturers?

Negotiating favorable payment terms requires a clear understanding of your cash flow needs and the manufacturer’s policies. Start by proposing terms that align with your financial capabilities, such as extended payment periods or partial upfront payments. Building a strong relationship with the supplier can enhance your negotiating power, so consider discussing your long-term purchasing plans. Always ensure that the terms are documented in the contract to avoid misunderstandings. -

What are the typical minimum order quantities (MOQs) for electronic components?

Minimum order quantities (MOQs) for electronic components can vary significantly based on the manufacturer and the specific component. Generally, MOQs may range from a few hundred to several thousand units. For niche or custom components, MOQs might be higher due to setup costs. It’s essential to discuss your requirements with potential suppliers to negotiate MOQs that align with your production needs while considering cost implications. -

How do I ensure timely logistics and shipping of electronic components?

To ensure timely logistics and shipping, establish a robust supply chain management strategy. Collaborate closely with your manufacturer to agree on realistic production timelines and shipping schedules. Use reliable logistics partners experienced in international shipping to minimize delays. Additionally, consider incorporating buffer time in your planning to accommodate potential customs clearance issues, especially when sourcing from regions with complex regulations. -

What customization options should I consider when sourcing electronic components?

When sourcing electronic components, consider customization options that can enhance your product’s performance and market fit. Discuss your specific requirements with manufacturers, such as tailored specifications, packaging, or branding. Explore design modifications that can improve functionality or reduce costs. Be aware that customized components may come with higher MOQs and longer lead times, so plan accordingly to align with your project timelines. -

How can I mitigate risks when sourcing electronic components internationally?

Mitigating risks in international sourcing involves thorough due diligence and strategic planning. Start by assessing the political and economic stability of the supplier’s country. Implement contracts that include terms for quality assurance, delivery timelines, and penalties for non-compliance. Diversifying your supplier base can also reduce dependency on a single manufacturer. Finally, consider obtaining insurance for shipments to protect against loss or damage during transit. -

What certifications should I look for in electronic component manufacturers?

When evaluating electronic component manufacturers, look for certifications that demonstrate their commitment to quality and compliance. Key certifications include ISO 9001 for quality management systems, ISO 14001 for environmental management, and IPC standards for electronic manufacturing. Additionally, certifications specific to your industry, such as UL or CE markings, can indicate adherence to safety and regulatory requirements. These certifications not only ensure quality but also enhance your credibility when marketing your products.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for electronic component manufacturer

As we conclude our exploration of strategic sourcing in the electronic component manufacturing sector, it is clear that a proactive approach to supplier selection and relationship management is crucial for B2B buyers. By leveraging data analytics and market insights, international buyers can navigate the complexities of global supply chains, ensuring a consistent flow of high-quality components.

How Can Strategic Sourcing Enhance Competitive Advantage?

Strategic sourcing not only reduces costs but also fosters innovation and enhances the resilience of supply chains. For buyers in Africa, South America, the Middle East, and Europe, understanding regional market dynamics and supplier capabilities is vital. Engaging in partnerships with manufacturers who prioritize sustainability and technological advancement can lead to significant long-term benefits.

What Should International B2B Buyers Do Next?

As the electronic component market continues to evolve, it is imperative for buyers to stay informed about emerging trends and shifts in demand. Establishing robust supplier relationships and investing in technology for supply chain visibility will empower companies to adapt swiftly to market changes.

In closing, we encourage international B2B buyers to take decisive action by reassessing their sourcing strategies. Embrace the opportunities that arise from strategic partnerships and innovative sourcing solutions, positioning your business for sustainable growth in an increasingly competitive landscape.