The Ultimate Guide to Fluorescent Manufacturer (2025)

Introduction: Navigating the Global Market for fluorescent manufacturer

In an increasingly interconnected world, sourcing fluorescent manufacturers that meet specific quality standards and regulatory requirements can pose a significant challenge for international B2B buyers. Whether you are seeking energy-efficient lighting solutions for industrial applications or innovative designs for commercial spaces, the need for reliable suppliers is paramount. This comprehensive guide is designed to empower you with actionable insights into the global market for fluorescent manufacturers, addressing key factors such as types of fluorescent products, their diverse applications, and essential criteria for vetting potential suppliers.

As a B2B buyer from regions like Africa, South America, the Middle East, or Europe, understanding the nuances of the fluorescent manufacturing landscape is crucial. This guide will delve into the intricacies of sourcing, providing a detailed analysis of pricing structures, quality assurance practices, and logistics considerations. Furthermore, it will highlight the importance of establishing long-term partnerships with manufacturers who align with your business values and operational goals.

By navigating the complexities of the fluorescent manufacturing market, you will be equipped to make informed purchasing decisions that drive efficiency and profitability for your organization. This guide serves not only as a resource for identifying potential suppliers but also as a strategic tool for optimizing your procurement process in the global arena.

Understanding fluorescent manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Fluorescent | Traditional tube design, available in various lengths and diameters | Warehouses, offices, retail spaces | Pros: Cost-effective; easy to replace. Cons: Lower energy efficiency compared to LED. |

| High-Output Fluorescent | Higher lumen output; typically used in industrial settings | Factories, gymnasiums, large retail spaces | Pros: Bright light output; suitable for high ceilings. Cons: Shorter lifespan than LED alternatives. |

| Compact Fluorescent | Smaller size, spiral or bulb shape; energy-efficient | Residential, small offices, task lighting | Pros: Energy-saving; versatile. Cons: More expensive upfront than incandescent bulbs. |

| Fluorescent High Bay | Designed for high ceilings; robust housing for durability | Warehouses, manufacturing plants, parking lots | Pros: Excellent light distribution; durable. Cons: Higher initial investment; installation complexity. |

| Specialty Fluorescent | Unique spectrums for specific applications (e.g., horticultural, black light) | Laboratories, art galleries, horticulture | Pros: Tailored lighting solutions; enhances specific tasks. Cons: Limited general applicability; often higher cost. |

What Are the Characteristics of Standard Fluorescent Manufacturers?

Standard fluorescent manufacturers produce traditional tube lights available in various lengths and diameters. These lights are widely used in commercial settings such as offices and retail spaces due to their cost-effectiveness and ease of replacement. When considering B2B purchases, buyers should evaluate the compatibility of these lights with existing fixtures and the overall energy efficiency compared to newer technologies.

How Do High-Output Fluorescent Manufacturers Stand Out?

High-output fluorescent lights provide a significantly higher lumen output, making them ideal for industrial applications like factories and gymnasiums. These lights excel in environments with high ceilings where bright illumination is necessary. Buyers should consider the specific lighting requirements of their space and be aware that while these bulbs offer intense brightness, they may have a shorter lifespan compared to LED options.

What Makes Compact Fluorescent Manufacturers Unique?

Compact fluorescent lights (CFLs) are smaller, often designed in a spiral or bulb shape, and are celebrated for their energy efficiency. They are commonly used in residential settings and small offices for task lighting. B2B buyers should weigh the initial higher cost against long-term energy savings, as well as the versatility of these bulbs in various applications.

Why Choose Fluorescent High Bay Manufacturers?

Fluorescent high bay lights are specifically engineered for high-ceiling installations, providing robust housing for durability. They are commonly found in warehouses, manufacturing plants, and parking lots. When considering a purchase, buyers should evaluate the installation complexity and upfront costs, as these fixtures tend to require a larger investment but offer excellent light distribution.

What Are the Benefits of Specialty Fluorescent Manufacturers?

Specialty fluorescent manufacturers create lights with unique spectrums tailored for specific applications, such as horticultural growth or black light effects. These lights serve niche markets including laboratories and art galleries. B2B buyers should assess the specific needs of their operations and understand that while these solutions can enhance performance, they often come with a higher cost and limited general applicability.

Related Video: Fluorescent Dyes

Key Industrial Applications of fluorescent manufacturer

| Industry/Sector | Specific Application of fluorescent manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Fluorescent lighting in surgical and examination rooms | Enhances visibility and accuracy during procedures | Compliance with health regulations; energy efficiency; durability under high usage |

| Manufacturing | Fluorescent lamps in production lines | Improves worker productivity and safety | Customization for specific environments; robust supply chain; maintenance requirements |

| Retail | In-store fluorescent displays for product highlighting | Attracts customers and enhances product visibility | Color temperature consistency; energy-saving options; fixture compatibility |

| Education | Fluorescent lighting in classrooms and labs | Supports better learning environments through bright, even lighting | Compliance with educational standards; long lifespan; low maintenance needs |

| Transportation | Fluorescent signals and signage in transportation hubs | Increases safety and navigability for passengers | Weather resistance; visibility in low light; compliance with transportation regulations |

How is Fluorescent Lighting Used in Healthcare Settings?

In healthcare, fluorescent lighting is critical in surgical and examination rooms. The bright, even illumination allows medical professionals to see details clearly, which is essential for accurate diagnoses and procedures. This application not only enhances visibility but also reduces eye strain during long hours of work. International buyers in the healthcare sector must ensure compliance with local health regulations and focus on energy-efficient options to minimize operational costs.

What Role Does Fluorescent Lighting Play in Manufacturing?

In manufacturing environments, fluorescent lamps are commonly used along production lines to provide consistent and high-quality lighting. This enhanced visibility contributes to increased worker productivity and safety by reducing accidents and errors. B2B buyers should consider the customization of lighting solutions to fit specific production needs and ensure that the chosen products can withstand the rigors of industrial use, including temperature variations and vibrations.

How Can Retailers Benefit from Fluorescent Displays?

Retailers utilize fluorescent lighting to create eye-catching displays that highlight products and attract customers. This application significantly enhances product visibility, which can lead to increased sales. When sourcing fluorescent lighting for retail, buyers should focus on color temperature consistency and energy-saving options to reduce long-term costs while ensuring compatibility with existing fixtures.

Why is Fluorescent Lighting Important in Educational Institutions?

Educational institutions often rely on fluorescent lighting in classrooms and laboratories to create a conducive learning environment. Bright, even lighting supports better concentration and engagement among students. Buyers in this sector should prioritize compliance with educational standards, as well as long lifespan and low maintenance requirements to keep operational disruptions to a minimum.

What are the Benefits of Fluorescent Lighting in Transportation Hubs?

In transportation hubs, fluorescent lighting is essential for signals and signage, increasing safety and navigability for passengers. This application ensures that information is visible even in low-light conditions, which is crucial for effective crowd management. Buyers in this sector need to consider weather-resistant options and compliance with transportation regulations to ensure longevity and reliability in various environmental conditions.

Related Video: Microscopy: Fluorescent Probes (Timothy Mitchison)

3 Common User Pain Points for ‘fluorescent manufacturer’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Fluorescent Tubes for Specific Applications

The Problem: B2B buyers often struggle to identify the appropriate fluorescent tubes for their specific applications, such as in industrial settings, retail spaces, or office environments. With a plethora of options available, including different color temperatures, wattages, and lengths, the choice can be overwhelming. This confusion can lead to purchasing products that do not meet their needs, resulting in inadequate lighting quality, increased operational costs, and wasted time on returns and replacements.

The Solution: To effectively source the right fluorescent tubes, buyers should start by conducting a thorough assessment of their lighting requirements. This includes understanding the purpose of the lighting (e.g., for visibility, ambiance, or energy efficiency), determining the desired color temperature (e.g., warm white for hospitality or cool white for industrial use), and noting any space constraints. Once these factors are established, buyers can collaborate with reputable fluorescent manufacturers who provide detailed product specifications and application guides. Requesting samples or trial installations can also be beneficial, allowing buyers to evaluate how different tubes perform in their specific environments before making a larger commitment.

Scenario 2: Managing Energy Efficiency and Cost-Effectiveness

The Problem: Many businesses are increasingly focused on reducing energy costs and minimizing their carbon footprint, yet they may not realize how much energy their fluorescent lighting systems consume. Traditional fluorescent lights can often be inefficient, leading to higher electricity bills and a larger environmental impact. Buyers may find themselves in a dilemma: how to maintain adequate lighting while also pursuing cost-saving measures.

The Solution: One effective approach is to transition to energy-efficient fluorescent options, such as T5 or T8 tubes that offer better lumen output per watt. B2B buyers should consult with fluorescent manufacturers who can provide insights into the latest energy-efficient technologies and products. Additionally, integrating smart lighting controls, such as dimmers or occupancy sensors, can significantly reduce energy consumption. Buyers should also consider bulk purchasing agreements with manufacturers to lower costs further and negotiate for warranties or service agreements that ensure long-term support and maintenance, thereby maximizing their investment.

Scenario 3: Ensuring Compliance with Local Regulations and Standards

The Problem: Navigating local regulations and compliance standards regarding lighting can be a significant hurdle for B2B buyers. Different regions have various mandates for energy efficiency, light pollution reduction, and hazardous material disposal (such as the proper handling of fluorescent tubes due to mercury content). Failure to comply can lead to fines, project delays, or even legal issues, adding layers of stress to the procurement process.

The Solution: To mitigate these challenges, buyers must stay informed about the regulations that affect their specific industries and locations. Engaging with a knowledgeable fluorescent manufacturer who understands local compliance requirements can be invaluable. Manufacturers can offer guidance on the most compliant products, assist with documentation, and provide resources for proper disposal and recycling of old fluorescent tubes. Additionally, buyers should consider joining industry associations or forums that focus on lighting standards, as these platforms often provide updates and best practices that can help businesses remain compliant while optimizing their lighting solutions.

Strategic Material Selection Guide for fluorescent manufacturer

What Are the Key Materials Used in Fluorescent Manufacturing?

When considering the manufacturing of fluorescent products, selecting the right materials is paramount. Each material offers unique properties that can significantly influence performance, cost, and suitability for specific applications. Below are analyses of common materials used in fluorescent manufacturing.

What Are the Key Properties of Glass in Fluorescent Manufacturing?

Key Properties: Glass is a primary material in fluorescent tubes, known for its excellent transparency to UV light and good thermal stability. It can withstand high temperatures and has a low thermal expansion coefficient, which is crucial for maintaining structural integrity under varying conditions.

Pros & Cons: The durability of glass is a significant advantage, as it is resistant to corrosion and chemical exposure. However, it can be fragile, making it susceptible to breakage during handling or installation. The manufacturing complexity is moderate, as it requires specialized techniques for shaping and sealing.

Impact on Application: Glass is compatible with various gases used in fluorescent lamps, such as argon and mercury. However, international buyers should consider the environmental regulations regarding mercury usage in their respective regions.

Considerations for International Buyers: Compliance with standards like ASTM and EN is essential, especially in Europe, where regulations on hazardous materials are stringent. Buyers from Africa and South America should also consider local regulations regarding waste management and recycling of glass products.

How Does Polycarbonate Compare in Fluorescent Applications?

Key Properties: Polycarbonate is a lightweight, impact-resistant plastic that offers good optical clarity. It can withstand high temperatures and has a high degree of UV resistance, making it suitable for outdoor applications.

Pros & Cons: The primary advantage of polycarbonate is its durability and resistance to shattering, which reduces the risk of injury during installation. However, it can be more expensive than glass and may yellow over time when exposed to UV light.

Impact on Application: Polycarbonate is often used in protective covers for fluorescent fixtures, enhancing safety without sacrificing light quality. Its compatibility with various fluorescent technologies makes it a versatile choice.

Considerations for International Buyers: Buyers should ensure that polycarbonate products meet relevant standards like ISO and DIN, particularly in Europe. In regions like the Middle East, where temperatures can be extreme, confirming the material’s heat resistance is critical.

What Role Does Aluminum Play in Fluorescent Manufacturing?

Key Properties: Aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity. Its ability to dissipate heat effectively is crucial for maintaining the efficiency of fluorescent lamps.

Pros & Cons: The advantages of aluminum include its durability and lightweight nature, which simplifies installation. However, it can be more expensive than other metals and may require additional coatings to enhance its corrosion resistance.

Impact on Application: Aluminum is commonly used in the housing and reflectors of fluorescent fixtures, improving light output and efficiency. Its compatibility with various environmental conditions makes it suitable for both indoor and outdoor applications.

Considerations for International Buyers: Compliance with industry standards such as JIS in Japan or ASTM in the U.S. is essential. Buyers from Africa and South America should also be aware of local sourcing options to minimize costs and support regional industries.

How Is Steel Utilized in Fluorescent Manufacturing?

Key Properties: Steel is known for its strength and durability. It can withstand high pressure and is often used in structural components of fluorescent fixtures.

Pros & Cons: The primary advantage of steel is its robustness, making it suitable for heavy-duty applications. However, it is prone to corrosion if not properly treated, which can lead to reduced lifespan.

Impact on Application: Steel is often used in the framework of fluorescent fixtures, providing stability and support. Its compatibility with various coatings can enhance its performance in different environments.

Considerations for International Buyers: Buyers should ensure that the steel used complies with local and international standards, particularly regarding corrosion resistance. In regions with high humidity, such as parts of Africa and South America, selecting galvanized or stainless steel may be advisable.

Summary Table of Material Selection

| Material | Typical Use Case for fluorescent manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | Tubes for fluorescent lamps | Excellent transparency and thermal stability | Fragile and susceptible to breakage | Medium |

| Polycarbonate | Protective covers for fixtures | Impact-resistant and lightweight | More expensive and may yellow over time | High |

| Aluminum | Housing and reflectors | Lightweight and corrosion-resistant | More expensive, requires coatings | Medium |

| Steel | Structural components of fixtures | Strong and durable | Prone to corrosion without treatment | Low |

This guide provides international B2B buyers with crucial insights into material selection for fluorescent manufacturing, ensuring informed decisions that align with regional standards and application requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for fluorescent manufacturer

What Are the Main Stages in the Manufacturing Process of Fluorescent Products?

The manufacturing process for fluorescent products encompasses several critical stages, each contributing to the quality and performance of the final product. Understanding these stages can empower B2B buyers to make informed decisions when selecting suppliers.

Material Preparation: How Are Raw Materials Selected and Processed?

The first stage involves sourcing high-quality raw materials, such as phosphor powders, glass tubes, and gases like argon and mercury. Suppliers typically conduct thorough evaluations of their material vendors to ensure compliance with international standards. The materials are then prepared through processes like milling and mixing, which ensure uniformity and optimal performance. Buyers should verify that suppliers adhere to stringent quality control measures during this phase, ensuring materials meet specifications and are free from defects.

Forming: What Techniques Are Used to Shape Fluorescent Components?

In the forming stage, the prepared materials are transformed into the desired shapes. This may involve glass blowing for tubes, where precise temperatures and techniques are crucial to achieving uniform thickness and strength. For phosphor coatings, techniques such as spraying or dipping are employed to ensure even application. B2B buyers should inquire about the technologies and machinery used in this stage, as advanced equipment can significantly enhance product quality and consistency.

Assembly: How Are Fluorescent Products Assembled?

The assembly process integrates various components, including the glass tubes, phosphor coatings, and electronic ballasts. This stage often employs automated assembly lines to enhance efficiency and reduce human error. The assembly process must be meticulously controlled to avoid contamination and ensure proper functioning of the final product. Buyers should assess the supplier‘s assembly practices, including workforce training and equipment maintenance, to ensure high standards are maintained.

Finishing: What Final Touches Ensure Quality and Performance?

Finishing processes, such as sealing and testing, are crucial to ensuring the durability and reliability of fluorescent products. This stage may involve applying protective coatings and conducting electrical and performance tests. B2B buyers should look for suppliers that implement thorough finishing protocols, including visual inspections and functional testing, to guarantee that every product meets quality standards before shipment.

How Is Quality Assurance Implemented Throughout the Manufacturing Process?

Quality assurance (QA) is integral to the manufacturing of fluorescent products. It involves systematic processes to monitor and improve product quality at every stage of production.

What International Standards Should B2B Buyers Be Aware Of?

International standards like ISO 9001 set the framework for quality management systems. Compliance with these standards ensures that suppliers maintain consistent quality throughout their operations. Additionally, industry-specific certifications, such as CE marking for European markets or API standards for specific applications, can further assure buyers of product reliability. B2B buyers should request documentation of these certifications to verify compliance.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are established at various stages to catch defects early and ensure compliance with specifications. The main checkpoints include:

- Incoming Quality Control (IQC): Inspects raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitors production processes to detect and correct any deviations in real-time.

- Final Quality Control (FQC): Conducts comprehensive testing on finished products to validate performance and safety before shipment.

B2B buyers should inquire about the frequency and rigor of these QC checkpoints, as they directly impact the quality of the final product.

What Common Testing Methods Are Used in Quality Control?

Testing methods for fluorescent products typically include:

- Electrical Testing: Ensures that the electrical components function correctly.

- Performance Testing: Measures brightness, energy efficiency, and lifespan under various conditions.

- Safety Testing: Assesses compliance with safety regulations, including potential hazards associated with mercury and other materials.

B2B buyers should request detailed reports on these testing methodologies to understand how the supplier ensures product quality and safety.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers have several avenues to verify a supplier’s quality control practices:

- Conducting Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality assurance measures. Buyers should establish a schedule for audits, particularly for new suppliers.

- Requesting Quality Reports: Suppliers should be willing to provide quality reports detailing testing results and compliance with international standards.

- Utilizing Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control practices. This is particularly important for buyers in regions with stringent import regulations.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

- Regulatory Compliance: Different regions may have unique regulations concerning product safety and environmental impact. B2B buyers should ensure that suppliers comply with local and international regulations applicable to their markets.

- Cultural Differences in Quality Expectations: Understanding cultural variations in quality perception can help in setting realistic expectations. Buyers should communicate their quality requirements clearly and ensure that suppliers understand the significance of these standards.

- Logistical Challenges: Importing fluorescent products can involve additional quality assurance steps, such as inspections during transit. Buyers should work closely with suppliers to ensure that products remain compliant throughout the shipping process.

In conclusion, understanding the manufacturing processes and quality assurance protocols for fluorescent products is crucial for B2B buyers. By focusing on material preparation, forming, assembly, finishing, and quality control, buyers can make informed decisions and establish partnerships with suppliers that prioritize quality and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fluorescent manufacturer’

In the competitive landscape of fluorescent manufacturing, sourcing the right supplier is essential for international B2B buyers. This guide provides a structured checklist to help you navigate the procurement process efficiently, ensuring you partner with a reliable manufacturer that meets your specific needs.

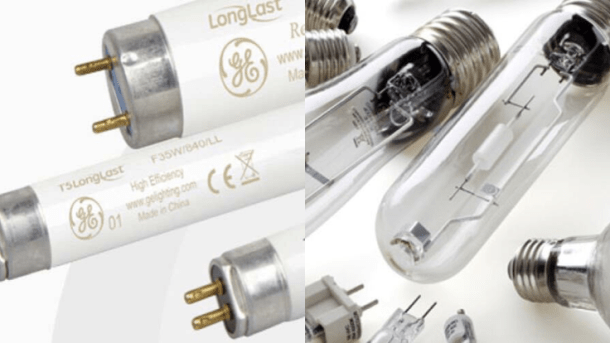

A stock image related to fluorescent manufacturer.

Step 1: Define Your Technical Specifications

Before beginning your search for a fluorescent manufacturer, it’s crucial to outline your technical requirements. Consider factors such as the type of fluorescent products needed (e.g., tubes, lamps), performance standards (lumens, color temperature), and compliance with international regulations. Clearly defined specifications will streamline your selection process and help avoid miscommunication with potential suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify manufacturers that specialize in fluorescent lighting. Utilize industry directories, trade shows, and online platforms to compile a list of potential suppliers. Pay special attention to their market reputation and experience in your region—this will be vital in ensuring they understand local regulations and customer preferences.

Step 3: Verify Supplier Certifications

It’s imperative to confirm that your shortlisted suppliers possess the necessary certifications and compliance with international quality standards, such as ISO 9001 or other relevant industry-specific certifications. These credentials ensure that the manufacturer adheres to strict quality control measures and can deliver reliable products. Always request copies of these certifications for verification.

Step 4: Evaluate Supplier Capabilities

Assess the manufacturing capabilities of each supplier on your list. Consider factors such as production capacity, technology used, and the range of products offered. A supplier with advanced manufacturing techniques and the ability to scale production will be more likely to meet fluctuating demands and support your growth strategy.

Step 5: Request Samples and Conduct Tests

Once you have narrowed down your options, request product samples to evaluate quality and performance. Conduct rigorous testing to ensure the products meet your specifications and industry standards. This step is vital for verifying that the manufacturer can deliver products that meet your expectations consistently.

Step 6: Review Pricing and Payment Terms

Compare pricing structures and payment terms from different suppliers. Be cautious of prices that seem too good to be true, as they may indicate compromised quality. Look for transparent pricing models that include all potential costs, such as shipping, taxes, and duties, to avoid unexpected expenses.

Step 7: Establish Clear Communication Channels

Effective communication is crucial in any B2B relationship. Establish clear lines of communication with your selected supplier to facilitate a smooth procurement process. Discuss expectations regarding lead times, order tracking, and customer support. A supplier that values communication will be more responsive to your needs and concerns.

By following this practical sourcing checklist, international B2B buyers can confidently navigate the process of procuring fluorescent manufacturers, ensuring they make informed decisions that align with their business goals.

Comprehensive Cost and Pricing Analysis for fluorescent manufacturer Sourcing

What Are the Key Cost Components in Fluorescent Manufacturing?

When sourcing from fluorescent manufacturers, international B2B buyers must understand the various cost components that contribute to the final pricing. The primary cost elements include:

-

Materials: This is often the largest component of the cost structure. The type and quality of raw materials, such as phosphor powders, glass tubing, and electronic components, significantly influence the overall price. Buyers should inquire about the sourcing of materials and any potential fluctuations in pricing based on market conditions.

-

Labor: Labor costs vary significantly based on the region of manufacturing. Countries with lower labor costs can provide more competitive pricing, but this may come at the expense of quality. Understanding the labor market in the manufacturer’s location can offer insights into the cost structure.

-

Manufacturing Overhead: This includes utilities, facility maintenance, and other indirect costs associated with production. Efficient manufacturing processes can help reduce overhead costs, which can be a point of negotiation for buyers.

-

Tooling: Tooling costs are associated with the equipment required to produce fluorescent lighting products. High-quality tooling can improve product quality but may also increase initial costs. Buyers should assess whether these costs are included in the quoted price.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes incurs costs. Buyers should inquire about the QC measures in place and how they impact pricing.

-

Logistics: This includes shipping, handling, and any tariffs or duties applicable to international shipments. Logistics costs can fluctuate based on global shipping rates, making it essential for buyers to consider these when evaluating total costs.

-

Margin: Manufacturers typically add a profit margin to cover their costs and ensure sustainability. Understanding the typical margin in the industry can help buyers assess whether a quote is reasonable.

How Do Price Influencers Impact Fluorescent Manufacturer Pricing?

Several factors influence the pricing strategy of fluorescent manufacturers, particularly for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to discounted pricing. Buyers should negotiate to achieve the best possible MOQ to maximize cost savings.

-

Specifications and Customization: Customized products may incur additional costs due to the need for specialized materials or processes. Buyers should clearly communicate their specifications to avoid unexpected price increases.

-

Materials and Quality Certifications: The quality of materials used can significantly influence pricing. Products with higher quality certifications, such as ISO or RoHS compliance, may come at a premium. Buyers should weigh the cost against the benefits of enhanced quality and compliance.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established manufacturers may charge higher prices due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for determining who bears the costs and risks during shipping. Buyers should specify the terms clearly to avoid misunderstandings that could lead to additional costs.

What Are the Best Buyer Tips for Cost-Efficiency in Fluorescent Sourcing?

To optimize purchasing decisions, international B2B buyers should consider the following strategies:

-

Negotiate Pricing: Always approach negotiations with a clear understanding of market rates and your budget. Leverage multiple quotes to enhance your bargaining position.

-

Consider Total Cost of Ownership (TCO): Evaluate not only the purchase price but also long-term costs associated with maintenance, energy consumption, and disposal. This holistic view can lead to better purchasing decisions.

-

Pricing Nuances for Different Regions: Be aware that pricing structures can vary across regions due to economic conditions, tariffs, and local competition. For instance, buyers from Africa may encounter different challenges compared to those in Europe or the Middle East.

-

Stay Informed: Keep abreast of market trends and material costs. An informed buyer can make better decisions and potentially negotiate more favorable terms.

Disclaimer

Prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific project requirements. Always conduct thorough research and due diligence before finalizing any sourcing decisions.

Alternatives Analysis: Comparing fluorescent manufacturer With Other Solutions

Understanding Alternative Solutions to Fluorescent Manufacturing

In the quest for effective lighting solutions, fluorescent manufacturing has long been a staple in various industries. However, with advancements in technology and growing environmental concerns, B2B buyers are increasingly exploring alternative solutions. This section provides a comprehensive comparison of fluorescent manufacturing against viable alternatives, helping businesses make informed decisions that align with their operational goals and sustainability commitments.

Comparison Table: Fluorescent Manufacturer vs. Alternative Solutions

| Comparison Aspect | Fluorescent Manufacturer | LED Lighting | Halogen Lighting |

|---|---|---|---|

| Performance | Good color rendering and efficiency | Excellent efficiency and longevity | High color rendering but lower efficiency |

| Cost | Moderate initial cost, lower energy costs | Higher initial investment, lower long-term costs | Lower initial cost, higher energy costs |

| Ease of Implementation | Simple installation process | Requires more planning for installation | Straightforward installation, similar to fluorescent |

| Maintenance | Moderate, requires regular replacement | Low, long lifespan reduces frequency | High, frequent bulb replacements needed |

| Best Use Case | General office and retail lighting | Commercial spaces and residential applications | Accent and display lighting |

What Are the Benefits and Drawbacks of LED Lighting?

LED lighting has emerged as a leading alternative to fluorescent manufacturing due to its superior energy efficiency and longer lifespan. LEDs consume significantly less power, resulting in lower electricity bills and reduced carbon footprints. Moreover, they have a lifespan of up to 25,000 hours, minimizing the frequency of replacements. However, the initial investment is considerably higher than fluorescent systems, which may deter some businesses. Additionally, LED installations may require more careful planning to ensure optimal performance, especially in larger setups.

How Does Halogen Lighting Compare?

A stock image related to fluorescent manufacturer.

Halogen lighting offers an alternative that provides high-quality illumination with excellent color rendering. It is often used in settings that require precise lighting, such as galleries or retail displays. While the initial costs are generally lower than LEDs, halogen bulbs have a shorter lifespan and consume more energy, leading to higher operational costs over time. Maintenance can also be a burden, as these bulbs need to be replaced more frequently than both fluorescent and LED options. Despite these drawbacks, halogen lighting remains a popular choice for its brightness and quality.

How to Choose the Right Lighting Solution for Your Business?

When deciding between fluorescent manufacturing and its alternatives, B2B buyers should evaluate their specific needs, including energy efficiency, budget constraints, and the intended application of the lighting solution. For businesses focused on reducing operational costs in the long term, investing in LED lighting may be the most beneficial, despite the higher upfront costs. Conversely, for applications that demand high-quality light output and minimal initial investment, halogen lighting may be more suitable. Ultimately, the choice hinges on balancing upfront costs with long-term savings and performance requirements.

In summary, understanding the strengths and weaknesses of fluorescent manufacturing in comparison to LED and halogen lighting can empower B2B buyers to make informed decisions that enhance their operational efficiency and sustainability. Each option has unique advantages and challenges, and careful consideration of these factors will lead to the best choice for any business’s specific lighting needs.

Essential Technical Properties and Trade Terminology for fluorescent manufacturer

What Are the Key Technical Properties of Fluorescent Products?

Understanding the essential technical properties of fluorescent products is crucial for international B2B buyers seeking quality and reliability in their purchases. Here are some critical specifications to consider:

1. Material Grade

Material grade refers to the quality and type of materials used in manufacturing fluorescent lighting products. Common materials include glass, phosphors, and metals. Buyers should ensure that the materials meet industry standards, as higher grades typically offer better durability and performance.

2. Lumens Output

Lumens output measures the total amount of visible light emitted by a fluorescent lamp. This specification is vital for determining the brightness of the lighting solution. For B2B buyers, understanding lumens helps in selecting products that meet specific lighting needs for various applications, from industrial to commercial settings.

3. Color Temperature

Color temperature, measured in Kelvin (K), indicates the hue of the light emitted. For instance, a color temperature of 3000K produces warm white light, while 5000K yields a cool daylight effect. Knowing the appropriate color temperature is essential for creating the desired ambiance in workplaces, enhancing productivity, and ensuring comfort for employees.

4. Energy Efficiency Rating

Energy efficiency ratings, often denoted by the Energy Star label or similar certifications, indicate how effectively a fluorescent lamp converts energy into light. High-efficiency products consume less electricity, leading to lower operational costs over time. B2B buyers should prioritize energy-efficient options to reduce long-term expenses and meet sustainability goals.

5. Life Span

The life span of fluorescent lamps is typically measured in hours of operation before failure. Standard life spans range from 7,000 to 20,000 hours. Understanding this property is vital for planning maintenance schedules and minimizing downtime in commercial or industrial environments.

What Are Common Trade Terms in the Fluorescent Manufacturing Industry?

Familiarity with industry jargon can facilitate smoother transactions and better communication with suppliers. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce products that are rebranded and sold by another company. In the fluorescent lighting industry, many manufacturers produce lamps for retailers or other brands. Understanding OEM relationships can help buyers identify the quality and reliability of products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This is particularly relevant in the fluorescent lighting industry, where manufacturers may set MOQs to ensure cost-effectiveness. Buyers should assess their needs to negotiate favorable terms without overcommitting.

3. RFQ (Request for Quotation)

An RFQ is a document issued by potential buyers to solicit price quotes from suppliers. Including specific requirements, such as technical specifications and quantities, allows for accurate comparisons. Utilizing RFQs can streamline the procurement process for fluorescent products.

4. Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international trade. They specify who is responsible for shipping, insurance, and tariffs. Familiarity with these terms is essential for B2B buyers to avoid misunderstandings and ensure smooth logistics.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. In the fluorescent manufacturing sector, lead times can vary significantly based on production schedules and shipping logistics. Understanding lead times helps buyers plan their inventory and project timelines effectively.

By grasping these technical properties and trade terms, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe can make informed decisions when sourcing fluorescent products, ensuring they meet both operational needs and budget considerations.

Navigating Market Dynamics and Sourcing Trends in the fluorescent manufacturer Sector

What Are the Key Market Trends Impacting the Fluorescent Manufacturing Sector?

The fluorescent manufacturing sector is undergoing significant transformation driven by technological advancements and changing consumer preferences. A major global driver is the push for energy efficiency, with fluorescent lighting being favored for its lower energy consumption compared to traditional incandescent bulbs. This trend is particularly relevant for international B2B buyers from regions like Africa and South America, where energy costs can be a significant operational expense.

Emerging technologies such as smart lighting systems are also reshaping the market. These systems allow for remote control and automation, which can enhance energy savings and operational efficiency. Buyers from Europe, particularly in countries like France, are increasingly looking for suppliers that offer smart, integrated solutions. Moreover, the rise of e-commerce platforms is changing sourcing dynamics, enabling buyers to access a wider range of suppliers and products, fostering competitive pricing and innovation.

Another notable trend is the growing demand for custom solutions tailored to specific industrial needs. B2B buyers are seeking manufacturers who can provide bespoke fluorescent lighting solutions that fit unique operational requirements. This demand is particularly evident in sectors like agriculture, where specialized lighting can enhance plant growth.

How Is Sustainability Shaping the Fluorescent Manufacturing Sector?

Sustainability is becoming a critical consideration in the fluorescent manufacturing sector. The environmental impact of fluorescent lights, particularly regarding the disposal of mercury-containing bulbs, necessitates a focus on sustainable practices. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainability through responsible sourcing and waste management practices.

Ethical supply chains are also gaining traction, as buyers seek to partner with manufacturers that uphold social responsibility. This includes ensuring fair labor practices and minimizing environmental footprints throughout the production process. Certifications such as ISO 14001 for environmental management systems and the use of eco-friendly materials can serve as indicators of a manufacturer’s commitment to sustainability.

Additionally, the demand for ‘green’ fluorescent products is on the rise. Buyers are looking for options that are free from hazardous materials and compliant with international environmental standards. By choosing suppliers that prioritize sustainability, B2B buyers not only enhance their corporate social responsibility initiatives but also appeal to environmentally-conscious consumers.

How Has the Fluorescent Manufacturing Sector Evolved?

The fluorescent manufacturing sector has evolved significantly since its inception in the early 20th century. Initially celebrated for its energy efficiency compared to incandescent lighting, fluorescent technology gained popularity in commercial and industrial applications. Over the decades, advancements in materials and production processes have improved the performance and lifespan of fluorescent lights, making them a staple in various settings, from offices to retail spaces.

In recent years, the introduction of LED technology has posed challenges for the fluorescent market, driving manufacturers to innovate and adapt. Today, many manufacturers are focusing on hybrid solutions that incorporate both fluorescent and LED technologies, appealing to a broader range of applications and customer needs. This evolution underscores the importance of continuous innovation in maintaining competitive advantage in the ever-changing B2B landscape.

By understanding these market dynamics and trends, international B2B buyers can make informed decisions, ensuring they partner with manufacturers that align with their operational goals and sustainability objectives.

Frequently Asked Questions (FAQs) for B2B Buyers of fluorescent manufacturer

-

How do I solve the issue of finding a reliable fluorescent manufacturer?

To find a reliable fluorescent manufacturer, start by researching potential suppliers through industry directories, trade shows, and online platforms like Alibaba. Assess their reputation by reading reviews and seeking referrals from other businesses. Request product samples to evaluate quality, and ensure they comply with international standards. Additionally, consider their manufacturing capabilities, responsiveness, and willingness to accommodate your specific needs. Establishing a clear communication channel will help you gauge their reliability before committing to a partnership. -

What is the best fluorescent lighting solution for commercial spaces?

The best fluorescent lighting solution for commercial spaces depends on factors such as the size of the area, the type of activities conducted, and energy efficiency requirements. For larger spaces, high-output fluorescent tubes or LED retrofits can provide sufficient illumination while minimizing energy costs. Consider using daylight-balanced tubes to enhance productivity and comfort. Additionally, consult with your manufacturer about customizable options, including color temperature and fixture design, to ensure the lighting meets your specific commercial needs. -

What are the minimum order quantities (MOQ) I should expect from fluorescent manufacturers?

Minimum order quantities (MOQ) vary significantly among fluorescent manufacturers based on their production capabilities and market strategy. Typically, MOQs can range from 100 to 1,000 units for bulk orders. However, many manufacturers may be flexible for new clients or smaller businesses, especially if you express a commitment to future orders. Always clarify the MOQ during negotiations and consider how it aligns with your inventory needs and budget constraints. -

How can I ensure quality control when sourcing fluorescent products?

Ensuring quality control when sourcing fluorescent products involves several steps. First, request certifications and compliance documents to verify that the products meet international quality standards. Conduct factory audits, if feasible, to inspect manufacturing processes and equipment. Additionally, establish a quality assurance plan that includes regular inspections of samples, batch testing, and adherence to safety regulations. Building a strong relationship with your supplier can also facilitate better communication regarding quality expectations. -

What payment terms should I negotiate with fluorescent manufacturers?

When negotiating payment terms with fluorescent manufacturers, aim for conditions that protect your cash flow while fostering a good relationship. Common terms include a 30% deposit upon order confirmation and the remaining 70% before shipment. Explore options for letters of credit, which can offer security for both parties. Be clear about currency preferences and any potential fees associated with international transactions. Ensure that the payment terms are documented in the contract to avoid misunderstandings. -

What logistics considerations should I keep in mind when importing fluorescent products?

Logistics considerations for importing fluorescent products include shipping methods, customs regulations, and lead times. Choose a reliable freight forwarder who understands the complexities of international shipping and can assist with customs clearance. Factor in the shipping method that best suits your budget and urgency—air freight is faster but more expensive than sea freight. Additionally, familiarize yourself with the import duties and taxes applicable in your country to avoid unexpected costs. -

How can I customize fluorescent products to meet my specific needs?

Customizing fluorescent products typically involves discussing your requirements directly with the manufacturer. Many manufacturers offer options such as custom lengths, wattages, color temperatures, and fixture designs. Prepare a detailed specification sheet outlining your needs, and inquire about the feasibility and associated costs. Allow ample time for design and production adjustments, as custom orders may require longer lead times compared to standard products. -

What are the common challenges faced when sourcing fluorescent lighting internationally?

Common challenges in sourcing fluorescent lighting internationally include language barriers, cultural differences, and varying regulatory standards. Ensure clear communication by using precise language and confirming understanding at each step. Familiarize yourself with the regulatory requirements in both the exporting and importing countries to prevent compliance issues. Additionally, be prepared for potential delays in shipping and customs clearance, and maintain flexibility in your timelines to accommodate these uncertainties.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for fluorescent manufacturer

What Are the Key Takeaways for B2B Buyers in the Fluorescent Manufacturing Sector?

In conclusion, strategic sourcing plays a pivotal role in optimizing procurement processes for fluorescent manufacturers. By leveraging insights into supplier capabilities, market trends, and regional demands, international B2B buyers can enhance their supply chain resilience. Key takeaways include the importance of establishing long-term relationships with reliable suppliers, understanding local regulations, and adapting to varying market needs across regions such as Africa, South America, the Middle East, and Europe.

How Can Buyers Prepare for Future Opportunities in Fluorescent Manufacturing?

As we look to the future, buyers should focus on sustainability and innovation within the fluorescent manufacturing landscape. Emphasizing energy-efficient products and environmentally friendly practices will not only meet increasing regulatory demands but also cater to the growing consumer preference for sustainable solutions.

We encourage B2B buyers to actively engage with manufacturers to explore tailored solutions that align with their business goals. By prioritizing strategic sourcing now, you position your business to thrive in a competitive market, ensuring access to quality products that meet your operational needs. Engage with suppliers today to secure your place in the evolving fluorescent manufacturing landscape.