The Ultimate Guide to Induction Cooker Manufacturer (2025)

Introduction: Navigating the Global Market for induction cooker manufacturer

As international B2B buyers seek to enhance their culinary offerings, sourcing the right induction cooker manufacturer can be a daunting challenge. The rapid evolution of kitchen technology, combined with diverse regional preferences and standards, requires a nuanced understanding of the global market landscape. This guide is designed to streamline your decision-making process by providing comprehensive insights into the various types of induction cookers, their applications across different sectors, and effective supplier vetting strategies.

In the ever-competitive markets of Africa, South America, the Middle East, and Europe—countries like Kenya and Mexico included—understanding local consumer behaviors and regulatory requirements is essential for successful procurement. This guide will delve into the essential factors influencing cost, quality, and performance, enabling you to make informed purchasing decisions.

You will also find actionable insights on evaluating potential suppliers, including key criteria such as certifications, production capabilities, and after-sales support. By navigating through this resource, you will be better equipped to choose the right induction cooker manufacturer that aligns with your business goals, ensuring both customer satisfaction and operational efficiency. Empower yourself with the knowledge to make strategic investments that drive growth and innovation in your market.

Understanding induction cooker manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Commercial Induction Cookers | High power output, durable construction | Restaurants, catering services | Pros: Fast cooking, energy-efficient. Cons: Higher upfront cost. |

| Portable Induction Cookers | Lightweight, compact design | Food trucks, pop-up restaurants | Pros: Easy to transport, versatile. Cons: Limited cooking capacity. |

| Built-in Induction Cooktops | Integrated design, customizable features | Residential kitchens, high-end restaurants | Pros: Aesthetic appeal, space-saving. Cons: Installation complexity. |

| Induction Ranges | All-in-one cooking solution, multiple burners | Large-scale kitchens, culinary schools | Pros: Comprehensive cooking options, even heat distribution. Cons: Expensive, requires professional installation. |

| Induction Cookware Sets | Includes compatible pots and pans | Retail, kitchen supply stores | Pros: Complete cooking solution, ensures compatibility. Cons: Limited to included cookware types. |

What Are the Characteristics of Commercial Induction Cookers?

Commercial induction cookers are designed for high-demand environments such as restaurants and catering services. They typically feature a high power output, allowing for rapid heating and cooking, which is essential in busy kitchens. Their durable construction ensures longevity, making them a worthwhile investment for B2B buyers focused on efficiency and reliability. When purchasing, consider the wattage, size, and whether the model can accommodate the specific cooking needs of your establishment.

How Do Portable Induction Cookers Benefit B2B Buyers?

Portable induction cookers are ideal for mobile food businesses, such as food trucks and pop-up restaurants, due to their lightweight and compact design. They offer the flexibility to cook in various locations, making them a popular choice for chefs on the go. Buyers should evaluate the power settings and size to ensure they meet their cooking requirements while also considering how they will transport and store the units when not in use.

Why Choose Built-in Induction Cooktops for B2B Applications?

Built-in induction cooktops provide a sleek, integrated design that enhances the aesthetic appeal of both residential kitchens and high-end restaurant settings. Their customizable features allow for a tailored cooking experience, which can be a significant selling point for upscale establishments. Buyers should consider the installation complexity, as professional installation may be required, and assess the available customization options to match their kitchen layout.

What Are the Advantages of Induction Ranges for Large-Scale Kitchens?

Induction ranges serve as an all-in-one cooking solution, featuring multiple burners and comprehensive cooking capabilities, making them suitable for large-scale kitchens and culinary schools. They provide even heat distribution and rapid cooking times, which can significantly enhance kitchen productivity. When purchasing, it is crucial to consider the total number of burners needed and the overall size of the range to ensure it fits within the available kitchen space.

How Do Induction Cookware Sets Enhance Cooking Efficiency?

Induction cookware sets are designed to be compatible with induction cooktops, ensuring optimal cooking performance. These sets typically include various pots and pans, making them a complete cooking solution for retail and kitchen supply stores. Buyers should assess the quality of the materials and the variety of cookware included, as this can affect cooking efficiency and customer satisfaction. Consideration of brand reputation and warranty options can also play a role in the purchasing decision.

Related Video: Induction vs Infrared cooker | Difference between Infrared and Induction cooker in detail.

Key Industrial Applications of induction cooker manufacturer

| Industry/Sector | Specific Application of Induction Cooker Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service & Catering | Commercial kitchens in restaurants and hotels | Faster cooking times, energy efficiency, improved safety | Certification compliance, energy ratings, after-sales support |

| Healthcare | Hospital food preparation units | Consistent cooking quality, reduced contamination risks | Hygiene standards, ease of use, energy efficiency |

| Education | Institutional cafeterias and school kitchens | Cost savings, quicker meal preparation, enhanced safety | Durability, warranty terms, service agreements |

| Food Processing | Large-scale food manufacturing plants | Increased productivity, precise temperature control | Customization options, maintenance services, energy consumption |

| Retail | Food courts and quick-service restaurants | Enhanced customer experience, reduced cooking odors | Brand reputation, customer service, product availability |

How Are Induction Cookers Used in Food Service & Catering?

In the food service and catering industry, induction cookers are extensively utilized in commercial kitchens of restaurants and hotels. They facilitate faster cooking times while being energy efficient, which is crucial for high-volume meal preparation. Induction cookers also enhance safety by minimizing burn risks due to their cool-to-touch surfaces. International buyers, especially from regions like Africa and South America, should consider sourcing induction cookers that comply with local certification standards and energy ratings to optimize operational efficiency.

What Role Do Induction Cookers Play in Healthcare?

Induction cookers are increasingly being adopted in healthcare settings, particularly in hospital food preparation units. Their ability to provide consistent cooking quality while reducing contamination risks is paramount in maintaining food safety standards. Buyers from the Middle East and Europe should prioritize suppliers that adhere to stringent hygiene standards and offer user-friendly equipment, ensuring that staff can operate them efficiently in a high-pressure environment.

How Are Induction Cookers Beneficial in Educational Institutions?

In educational settings, such as institutional cafeterias and school kitchens, induction cookers are valuable for their cost-saving potential and quicker meal preparation times. They also enhance safety, a vital consideration when catering to large groups of students. Buyers should focus on the durability of the equipment and favorable warranty terms, ensuring long-term reliability and support, especially in regions like Africa and South America where service infrastructure may vary.

What Advantages Do Induction Cookers Provide in Food Processing?

In food processing industries, induction cookers are employed in large-scale manufacturing plants to increase productivity and provide precise temperature control. This level of control is essential for maintaining product consistency and quality. International buyers should look for induction cookers that offer customization options tailored to specific production needs, along with maintenance services to minimize downtime and ensure operational efficiency.

How Do Induction Cookers Enhance Retail Experiences?

In retail environments, such as food courts and quick-service restaurants, induction cookers significantly enhance the customer experience by providing quick meal preparation with minimal cooking odors. This is particularly important in high-traffic areas where ambiance matters. Buyers should consider the reputation of the brand, customer service reliability, and product availability to ensure they receive a solution that meets their operational demands effectively.

3 Common User Pain Points for ‘induction cooker manufacturer’ & Their Solutions

Scenario 1: Navigating High Initial Costs of Induction Cookers

The Problem: Many B2B buyers, especially in regions like Africa and South America, often face the challenge of high initial costs associated with purchasing induction cookers. This can deter businesses, particularly small to medium-sized enterprises, from adopting this efficient cooking technology. The perception that induction cookers are a premium product can lead to hesitance in investment, especially when budgets are tight.

The Solution: To mitigate this challenge, buyers should consider exploring financing options and bulk purchase agreements. Manufacturers often provide tiered pricing for larger orders, enabling businesses to negotiate better rates. Additionally, buyers should evaluate the long-term cost savings associated with induction cookers, such as reduced energy consumption and lower operational costs. Engaging with manufacturers who offer warranties and after-sales support can further enhance the value proposition, making the initial investment more palatable.

Scenario 2: Limited Understanding of Induction Cooking Technology

The Problem: A significant pain point for B2B buyers is the lack of knowledge surrounding induction cooking technology. This includes understanding the specific benefits and requirements of induction cookers compared to traditional gas or electric options. Buyers may struggle to educate their staff or customers on how to utilize these cookers effectively, which can hinder adoption and lead to operational inefficiencies.

The Solution: Induction cooker manufacturers should provide comprehensive training and resources to their buyers. This could include detailed user manuals, online training modules, and in-person demonstrations. Additionally, suppliers can create educational content such as webinars or video tutorials that explain the technology and its advantages. B2B buyers should also seek manufacturers that offer customizable training programs tailored to their specific operations, ensuring that all personnel are well-equipped to maximize the benefits of induction cooking.

Scenario 3: Compatibility Issues with Cookware

The Problem: A common issue faced by international B2B buyers is compatibility between induction cookers and existing cookware. Many businesses, especially in emerging markets, have invested in traditional cookware that may not work with induction technology. This can lead to unexpected additional costs for purchasing new cookware, creating frustration and hesitation in adopting induction solutions.

The Solution: Buyers should conduct a thorough inventory assessment of their existing cookware before making a purchase decision. Engaging with induction cooker manufacturers that provide clear guidelines on compatible cookware can save time and costs. Manufacturers should also consider offering starter packages that include induction-compatible cookware as part of the purchase. This not only simplifies the transition but also enhances customer satisfaction by providing a complete solution. Additionally, B2B buyers can explore local options for affordable induction-compatible cookware, which can help mitigate the impact of this compatibility issue.

Strategic Material Selection Guide for induction cooker manufacturer

When selecting materials for induction cookers, manufacturers must consider various factors that impact performance, durability, and compliance with international standards. Here, we analyze four common materials used in induction cooker manufacturing, providing actionable insights tailored for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe.

What are the Key Properties of Stainless Steel for Induction Cookers?

Stainless steel is a popular choice for induction cookers due to its excellent corrosion resistance and high-temperature tolerance. It typically withstands temperatures up to 500°F (260°C) and is compatible with high-pressure environments. The material’s non-reactive nature ensures that it does not alter the taste of food, making it suitable for culinary applications.

Pros and Cons:

– Pros: Durable, easy to clean, and resistant to rust and staining. It also has a sleek appearance that appeals to consumers.

– Cons: Higher manufacturing costs compared to other materials, and it may not distribute heat as evenly unless combined with a conductive layer.

Impact on Application:

Stainless steel is compatible with a wide range of cooking media, including water, oils, and acidic foods. However, its performance can be impacted by the quality of the induction coil used.

Considerations for International Buyers:

Buyers from regions like Kenya and Mexico should ensure compliance with local standards such as ASTM or DIN for food safety and material quality. The preference for aesthetic appeal in European markets may also influence the choice of stainless steel finishes.

How Does Cast Iron Perform in Induction Cookers?

Cast iron is renowned for its exceptional heat retention and even heating properties, making it a favored material for induction cookers designed for high-performance cooking.

Pros and Cons:

– Pros: Excellent heat retention, durability, and compatibility with high-temperature cooking.

– Cons: Heavy and can be prone to rust if not properly maintained. It also requires a more complex manufacturing process.

Impact on Application:

Cast iron is particularly suitable for slow cooking and frying, but its weight can be a disadvantage in portable induction cookers. It is also less suitable for rapid heating applications.

Considerations for International Buyers:

Manufacturers should consider local preferences for cookware weight and ease of use. Compliance with safety standards is crucial, especially in regions like the Middle East, where consumers may prioritize durability and longevity.

What are the Advantages of Aluminum in Induction Cookers?

Aluminum is lightweight and offers excellent thermal conductivity, making it a practical choice for induction cookers that require quick heating.

Pros and Cons:

– Pros: Lightweight, affordable, and heats up quickly, reducing cooking times.

– Cons: Less durable than stainless steel or cast iron and can warp at high temperatures.

Impact on Application:

Aluminum is well-suited for applications requiring rapid heating and is often used in commercial induction cookers. However, its lower durability may limit its use in high-end residential models.

Considerations for International Buyers:

Buyers in South America and Africa should be aware of the potential for aluminum to react with acidic foods. Ensuring compliance with local food safety regulations is essential, as is considering the cost-effectiveness of aluminum in comparison to more durable materials.

Why is Glass Ceramic a Good Option for Induction Cookers?

Glass ceramic is increasingly popular for induction cookers due to its aesthetic appeal and ability to withstand high temperatures.

Pros and Cons:

– Pros: Attractive appearance, easy to clean, and resistant to thermal shock.

– Cons: Fragile compared to metals and can be more expensive.

Impact on Application:

Glass ceramic is ideal for modern kitchen designs and can handle various cooking media. However, its fragility may limit its use in commercial settings.

Considerations for International Buyers:

In Europe, where design aesthetics are critical, glass ceramic may be favored. Buyers should ensure compliance with EU regulations regarding material safety and durability.

Summary Table of Material Selection for Induction Cookers

| Material | Typical Use Case for induction cooker manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Residential and commercial cookers | Corrosion resistant and durable | Higher manufacturing cost | High |

| Cast Iron | High-performance cooking applications | Excellent heat retention | Heavy and prone to rust | Medium |

| Aluminum | Commercial induction cookers | Lightweight and quick heating | Less durable and can warp | Low |

| Glass Ceramic | Modern residential cookers | Aesthetic appeal and easy to clean | Fragile and more expensive | High |

This strategic material selection guide provides insights into the properties, advantages, and limitations of various materials used in induction cookers, helping international B2B buyers make informed decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for induction cooker manufacturer

What Are the Main Stages of Manufacturing Induction Cookers?

Manufacturing induction cookers involves several critical stages that ensure both efficiency and quality. Understanding these stages is crucial for international B2B buyers looking for reliable suppliers.

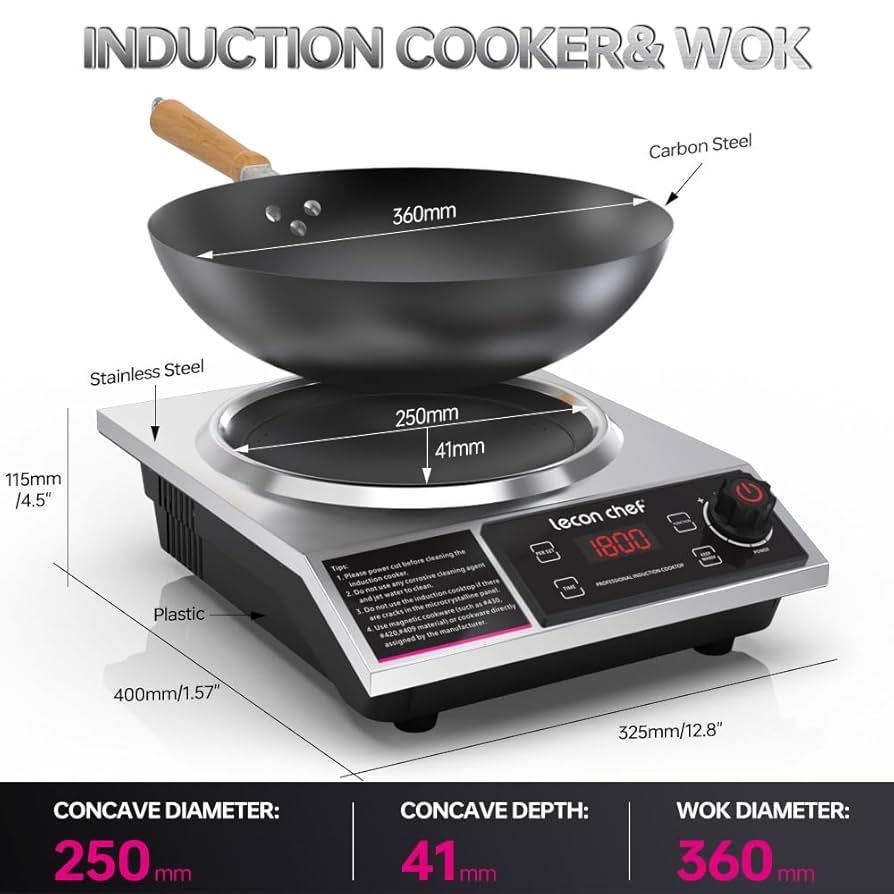

A stock image related to induction cooker manufacturer.

-

Material Preparation

The first step involves sourcing high-quality materials, including stainless steel, copper, and aluminum for the cooktop, and durable plastics or metals for the casing. Suppliers often conduct rigorous testing on raw materials to ensure they meet international standards. Buyers should look for manufacturers who provide material certifications, which can help verify the quality and source of materials used. -

Forming

In this stage, raw materials are shaped into the desired form. Techniques such as stamping, molding, and die-casting are commonly used to create components like the cooktop and housing. Advanced technologies like CNC machining may also be employed for precision. B2B buyers should inquire about the manufacturing techniques used, as this can impact the durability and performance of the final product. -

Assembly

The assembly process is where individual components come together. This stage often employs automated assembly lines to enhance efficiency. Experienced technicians oversee the process to ensure that each component is correctly fitted and that the assembly meets design specifications. Buyers should assess the manufacturer’s assembly capabilities, including labor skills and technology, to ensure high-quality products. -

Finishing

After assembly, induction cookers undergo finishing processes, such as polishing, coating, and quality checks. This step not only improves aesthetics but also adds protective layers that can enhance durability. It is advisable for buyers to request samples of the finishing processes to evaluate the quality before making bulk orders.

How Do Manufacturers Ensure Quality Control for Induction Cookers?

Quality assurance is a vital aspect of the manufacturing process for induction cookers. B2B buyers must understand the quality control measures in place to ensure product reliability.

-

International Standards Compliance

Many manufacturers adhere to international quality management systems like ISO 9001, which provides a framework for consistent quality improvement. Additionally, certifications such as CE mark indicate compliance with European safety standards, while API standards may apply to specific components. Buyers should request documentation of these certifications to ensure adherence to recognized quality benchmarks. -

Quality Control Checkpoints

The quality control process typically involves several checkpoints:

– Incoming Quality Control (IQC): This initial check evaluates the quality of raw materials before they enter the production line.

– In-Process Quality Control (IPQC): During manufacturing, components are inspected at various stages to catch any defects early.

– Final Quality Control (FQC): Before products are packaged and shipped, a comprehensive assessment is conducted to ensure they meet all specifications. -

Common Testing Methods

Manufacturers often employ several testing methods, including:

– Electrical Testing: Ensures the induction cookers function correctly under electrical load.

– Thermal Testing: Assesses how efficiently the cookers generate heat and maintain temperature.

– Durability Testing: Evaluates the product’s resilience to wear and tear over time.

B2B buyers should inquire about the specific testing methods employed by manufacturers and request test reports to validate results.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a manufacturer’s quality control processes is essential for international buyers. Here are effective strategies to ensure your supplier adheres to quality standards:

-

Supplier Audits

Conducting a supplier audit is one of the most effective ways to assess a manufacturer’s quality control. This involves a systematic review of their processes, quality management systems, and compliance with international standards. Buyers from regions like Africa and South America may consider engaging third-party audit services for an impartial evaluation. -

Requesting Quality Control Reports

Regular quality control reports can provide insights into a manufacturer’s performance over time. These documents should detail compliance with quality standards, results of quality checks, and any corrective actions taken. Buyers should insist on receiving these reports periodically, especially before placing large orders. -

Third-Party Inspections

Engaging third-party inspection services can further ensure product quality. These services can perform inspections during various stages of production and before shipment. This is particularly crucial for buyers in Europe and the Middle East, where regulatory compliance is strict, and the demand for high-quality products is paramount.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

Navigating the complexities of quality control and certification can be challenging for international buyers. Here are some nuances to consider:

-

Regional Compliance Requirements

Different regions have unique compliance requirements for induction cookers. For example, buyers in Europe need to ensure that products meet CE certification, while those in the Middle East may require specific local certifications. Understanding these requirements can help buyers avoid costly compliance issues. -

Language Barriers and Documentation

Language differences can complicate communication regarding quality control. It is advisable for buyers to work with suppliers who provide documentation in a language they are comfortable with. This can help clarify compliance standards and quality assurance processes. -

Cultural Differences in Quality Perception

Cultural perceptions of quality can vary significantly. For instance, buyers in Africa may prioritize cost-effectiveness, while European buyers might focus on durability and brand reputation. Understanding these differences can aid in selecting the right supplier that aligns with specific quality expectations.

By thoroughly understanding the manufacturing processes and quality assurance mechanisms in place, international B2B buyers can make informed decisions when sourcing induction cookers. This knowledge not only enhances product reliability but also fosters long-term partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘induction cooker manufacturer’

Introduction

Sourcing an induction cooker manufacturer requires careful consideration and a structured approach. This guide provides a comprehensive checklist to help international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, navigate the complexities of finding reliable manufacturers. Each step is designed to ensure that you make informed decisions, mitigate risks, and ultimately secure the best supplier for your needs.

Step 1: Define Your Technical Specifications

Before starting your search, clearly outline your technical requirements for the induction cookers. This includes the desired power output, size, materials, and safety features. Defining these specifications helps narrow down potential manufacturers who can meet your precise needs, ensuring compatibility with your market demands.

- Power Output: Specify wattage to ensure efficiency in cooking.

- Size and Design: Consider the dimensions that fit your target market’s preferences.

Step 2: Research Potential Suppliers

Invest time in researching potential suppliers to build a list of credible candidates. Utilize online platforms such as trade directories and industry forums, and leverage social media to gather insights. A thorough research phase enables you to identify manufacturers with a solid reputation and relevant experience.

- Online Reviews: Check feedback from previous clients to gauge reliability.

- Industry Reputation: Look for manufacturers recognized in trade shows or industry publications.

Step 3: Evaluate Supplier Certifications and Compliance

Verify that your potential suppliers hold the necessary certifications and comply with international quality standards. Certifications like ISO 9001 or specific safety certifications (e.g., CE, UL) indicate a commitment to quality and safety, which is crucial for consumer products.

- Quality Management Systems: Ensure they have robust processes in place.

- Safety Standards: Confirm compliance with regional regulations applicable in your target markets.

Step 4: Request Samples and Prototypes

Always request samples or prototypes of the induction cookers before finalizing your order. This step allows you to evaluate the product’s quality, functionality, and design firsthand. It also helps identify any modifications needed to meet your specifications.

- Testing for Functionality: Ensure the product performs as expected.

- Assessing Build Quality: Look for durability and design flaws.

Step 5: Negotiate Terms and Pricing

Once you have identified a suitable manufacturer, engage in negotiations to discuss pricing, payment terms, and delivery schedules. Clear communication during this phase can prevent misunderstandings and ensure both parties are aligned on expectations.

- Pricing Structure: Understand how pricing varies with order volume.

- Payment Terms: Establish favorable terms that protect your cash flow.

Step 6: Establish a Communication Plan

Set up a robust communication plan to maintain regular contact with your supplier throughout the production process. Effective communication helps address issues promptly, ensures transparency, and fosters a strong working relationship.

- Regular Updates: Schedule check-ins during production stages.

- Crisis Management: Have a strategy in place for addressing potential delays.

Step 7: Assess Logistics and Shipping Options

Finally, consider logistics and shipping arrangements to ensure timely delivery of your products. Evaluate different shipping methods, costs, and timelines to find the most efficient solution for your needs.

- Customs Regulations: Be aware of import regulations in your country.

- Shipping Partners: Collaborate with logistics companies experienced in handling international shipments.

By following these steps, B2B buyers can ensure a comprehensive and effective sourcing process when selecting an induction cooker manufacturer.

Comprehensive Cost and Pricing Analysis for induction cooker manufacturer Sourcing

What Are the Key Cost Components in Induction Cooker Manufacturing?

Understanding the cost structure of induction cooker manufacturing is crucial for B2B buyers looking to optimize their sourcing strategies. The primary cost components include:

-

Materials: The cost of raw materials, such as stainless steel, aluminum, and electronic components, is a significant factor. Prices can fluctuate based on global market conditions, so buyers should keep abreast of material trends.

-

Labor: Labor costs vary widely by region. For instance, manufacturing in countries with lower labor costs, such as certain parts of Africa or South America, may lead to significant savings. However, it’s essential to consider the skill level required for the assembly of induction cookers.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses associated with running a manufacturing facility. Efficient management of overhead can impact the final pricing of the products.

-

Tooling: The initial investment in tooling and molds can be substantial, especially for custom designs. Buyers should inquire about tooling costs upfront, particularly when ordering specialized or high-volume products.

-

Quality Control (QC): Ensuring product quality through rigorous testing and inspection processes incurs additional costs. Buyers should weigh these costs against the potential for returns or warranty claims.

-

Logistics: Shipping costs can vary significantly depending on the destination and shipping method. Incoterms play a crucial role in determining who bears these costs, making it essential for buyers to clarify terms with suppliers.

-

Margin: Manufacturers typically add a profit margin to their costs, which can vary based on the supplier’s business model and market competition.

How Do Price Influencers Affect Induction Cooker Sourcing?

Several factors influence the pricing of induction cookers that international buyers must consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs. Buyers should negotiate MOQs that fit their needs while maximizing cost efficiency.

-

Specifications and Customization: Tailored solutions may incur additional costs. Buyers should balance the desire for customization against potential price increases.

-

Material Quality and Certifications: Higher-quality materials and certifications (like energy efficiency ratings) can raise costs but may lead to better performance and lower long-term operational costs.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established manufacturers might charge a premium for their products due to brand trust and quality assurance.

-

Incoterms: Understanding Incoterms is vital for cost management. Different terms can significantly affect the total landed cost of products, impacting overall budgeting.

What Are Effective Buyer Tips for Sourcing Induction Cookers?

To navigate the complexities of sourcing induction cookers, international buyers should consider the following strategies:

-

Negotiation: Engage in open discussions with suppliers about pricing, payment terms, and potential discounts for larger orders. Building a relationship can lead to better deals.

-

Cost-Efficiency: Evaluate total cost of ownership (TCO) rather than just the purchase price. Consider factors like energy efficiency, maintenance costs, and potential resale value.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, tariffs, and trade regulations that could affect pricing. Staying informed can help mitigate unexpected costs.

-

Build a Diverse Supplier Base: Relying on multiple suppliers can reduce risk and provide leverage during negotiations. This approach also allows for comparison of costs and quality.

-

Leverage Technology: Utilize online platforms and sourcing tools to compare prices and suppliers globally. This can help identify competitive pricing and innovative products.

Disclaimer on Pricing

Prices for induction cookers can vary significantly based on market conditions, supplier negotiations, and specific buyer requirements. It is advisable to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing induction cooker manufacturer With Other Solutions

Introduction: Understanding Alternatives in Induction Cooking Solutions

When considering induction cooking solutions, B2B buyers must evaluate various alternatives to determine the most suitable option for their specific needs. Each solution offers unique benefits and drawbacks, making it essential to conduct a thorough comparison. This analysis will focus on the induction cooker manufacturer against two viable alternatives: traditional gas cookers and electric coil cookers. Understanding these alternatives can help buyers make informed decisions that align with their operational requirements, budget constraints, and sustainability goals.

Comparison Table

| Comparison Aspect | Induction Cooker Manufacturer | Traditional Gas Cooker | Electric Coil Cooker |

|---|---|---|---|

| Performance | High efficiency; rapid heating and precise temperature control | Good heating; slower response time | Moderate efficiency; uneven heating |

| Cost | Higher upfront cost, but energy-efficient | Lower initial cost, but higher long-term fuel expenses | Affordable upfront cost, higher electricity costs |

| Ease of Implementation | Requires specialized electrical infrastructure | Easy installation; widely available | Simple installation; standard electrical outlets |

| Maintenance | Low maintenance; durable and easy to clean | Moderate maintenance; requires regular cleaning and safety checks | Higher maintenance; coil replacement needed |

| Best Use Case | Commercial kitchens seeking efficiency and speed | Restaurants and homes prioritizing traditional cooking | Budget-conscious users or small kitchens |

What Are the Pros and Cons of Traditional Gas Cookers?

Traditional gas cookers are a widely recognized alternative, especially in regions where gas supply is reliable and cost-effective. They offer excellent performance with immediate heat and a traditional cooking experience. However, gas cookers can lead to higher fuel costs over time, and safety concerns related to gas leaks must be managed. Additionally, they require regular maintenance to ensure efficiency and safety, making them less appealing for some commercial applications.

How Do Electric Coil Cookers Compare in Terms of Functionality?

Electric coil cookers are another alternative, often chosen for their affordability and ease of use. They can be installed quickly in most kitchens with standard electrical outlets. However, they are less efficient than induction cookers and can produce uneven heating, which may affect cooking results. Maintenance is also a consideration, as the coils can wear out and need replacement. While they serve well in budget-conscious environments, they may not meet the performance standards required in high-volume commercial kitchens.

Conclusion: Choosing the Right Cooking Solution for Your Needs

Selecting the right cooking solution is critical for B2B buyers, particularly in diverse markets across Africa, South America, the Middle East, and Europe. When deciding between an induction cooker manufacturer and alternatives like traditional gas or electric coil cookers, buyers should assess their specific operational needs, budget limitations, and long-term goals. Induction cookers may present a higher initial investment but offer unparalleled efficiency and low maintenance, making them ideal for commercial applications. In contrast, gas and electric options may suit smaller operations or those prioritizing upfront costs. Conducting a detailed analysis of these factors will ultimately guide buyers to the most appropriate cooking solution for their business.

Essential Technical Properties and Trade Terminology for induction cooker manufacturer

Understanding the technical properties and trade terminology specific to induction cookers is vital for international B2B buyers looking to make informed purchasing decisions. This guide outlines essential specifications and jargon that will enhance your comprehension and negotiation capabilities when dealing with manufacturers.

What Are the Key Technical Properties of Induction Cookers?

1. Material Grade

The material grade of an induction cooker typically refers to the type of metals and alloys used in its construction, such as stainless steel or cast iron. A high-grade material not only ensures durability but also enhances the performance of the cooker. For buyers, understanding material grades is crucial for assessing product longevity and suitability for various cooking environments.

2. Power Rating

Power rating, measured in watts, indicates the energy consumption and efficiency of the induction cooker. Higher wattage means faster heating times and better performance, which can be a significant selling point. Buyers should evaluate power ratings to ensure that the induction cookers meet the demands of their target market, particularly in regions with varying energy availability.

3. Cooking Zone Size

The cooking zone size determines the area on the cooktop that can be used for heating. Induction cookers often come with multiple zones of different sizes. Understanding this specification helps buyers match the product to their customers’ cooking habits and kitchen designs, which can influence overall satisfaction and sales.

4. Temperature Control Precision

Temperature control precision refers to the accuracy and responsiveness of the cooker’s temperature settings. A precise control system allows for better cooking outcomes, which is particularly important for professional kitchens. Buyers should consider this property to meet the expectations of culinary professionals who require exact temperature management.

5. Safety Features

Safety features, such as automatic shut-off, child lock, and overheating protection, are essential for induction cookers. These features not only enhance user safety but also comply with various international safety standards. Understanding safety specifications is vital for buyers to ensure compliance and to appeal to safety-conscious consumers.

Which Trade Terminology Should B2B Buyers Understand?

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For B2B buyers, working with OEMs can often lead to better pricing and customization options. It’s essential to establish relationships with reputable OEMs to ensure quality and reliability.

2. MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory planning. Buyers should negotiate MOQs that align with their purchasing capabilities to avoid excess stock or missed opportunities.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers use to solicit price quotes from suppliers. It typically includes specifications, quantities, and delivery timelines. Crafting a comprehensive RFQ ensures that buyers receive accurate and competitive pricing, enabling informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping, insurance, and liability, which can significantly impact total costs and delivery timelines.

5. Lead Time

Lead time refers to the time it takes from placing an order until the product is delivered. Understanding lead times is crucial for inventory management and meeting customer expectations. Buyers should factor in lead times when planning their supply chains to ensure timely delivery of products.

By familiarizing yourself with these technical properties and trade terms, you will be better equipped to navigate the complexities of purchasing induction cookers in the international B2B market. This knowledge not only streamlines the procurement process but also empowers you to build stronger relationships with manufacturers.

Navigating Market Dynamics and Sourcing Trends in the induction cooker manufacturer Sector

What Are the Current Market Dynamics in the Induction Cooker Manufacturing Sector?

The induction cooker manufacturing sector is experiencing significant growth driven by rising energy efficiency concerns, increasing urbanization, and a shift towards modern cooking solutions. In markets like Africa and South America, where energy costs can be high, the demand for energy-efficient appliances is particularly strong. In Europe and the Middle East, regulatory frameworks favoring sustainable energy solutions are propelling the adoption of induction cookers, which are often seen as a safer and more efficient alternative to traditional gas cooking.

Emerging technologies such as smart induction cookers with IoT capabilities are also influencing sourcing trends. These devices allow for remote operation and integration with smart home systems, appealing to tech-savvy consumers. For international B2B buyers, understanding these technological advancements is crucial for selecting suppliers who can meet evolving consumer preferences. Additionally, the growth of e-commerce platforms has streamlined sourcing processes, enabling buyers from diverse regions to access a wider range of manufacturers and products than ever before.

How Important Is Sustainability and Ethical Sourcing in the Induction Cooker Manufacturing Industry?

Sustainability and ethical sourcing are becoming increasingly critical in the induction cooker manufacturing sector. Buyers are not just looking for high-quality products but are also considering the environmental impact of their choices. Manufacturers that prioritize eco-friendly practices, such as using recyclable materials and reducing carbon footprints, are gaining a competitive edge.

Incorporating ‘green’ certifications into the supply chain is essential for manufacturers aiming to attract international buyers. Certifications such as Energy Star, RoHS, and ISO 14001 demonstrate a commitment to environmental standards and can significantly enhance a manufacturer’s marketability. Moreover, ethical sourcing practices—ensuring that materials are sourced responsibly and labor practices are fair—are becoming a key consideration for B2B buyers, particularly in regions like Europe, where consumers are increasingly conscious of the origins of their products.

What Is the Historical Context of Induction Cooker Manufacturing?

Induction cooking technology has evolved significantly since its inception in the early 20th century. Initially, induction cookers were primarily used in commercial settings due to their high cost and specialized technology. However, advancements in manufacturing processes and a growing awareness of energy efficiency have led to their rise in popularity among residential consumers.

In recent decades, the market has shifted towards more affordable and user-friendly induction cookers, making them accessible to a broader audience. This evolution has been marked by increased competition among manufacturers, driving innovation and enhancing product features. For B2B buyers, understanding this historical context can provide insights into the reliability and reputation of different manufacturers, ultimately aiding in informed sourcing decisions.

How Can International Buyers Navigate the Induction Cooker Market?

For international B2B buyers, navigating the induction cooker market requires a strategic approach. It is vital to conduct thorough research on potential suppliers, focusing on their technological capabilities, sustainability practices, and compliance with international standards. Engaging in direct communication with manufacturers to inquire about their sourcing practices, certifications, and product warranties can further ensure a successful partnership.

Additionally, staying updated on market trends and consumer preferences in specific regions can help buyers make informed decisions. As the induction cooker market continues to evolve, those who adapt their sourcing strategies to align with these dynamics will be well-positioned to capitalize on growth opportunities.

Frequently Asked Questions (FAQs) for B2B Buyers of induction cooker manufacturer

-

How do I solve the problem of finding a reliable induction cooker manufacturer?

To find a reliable induction cooker manufacturer, start by conducting thorough research online. Look for manufacturers with established reputations in the industry, and read customer reviews and testimonials. Networking at trade shows and industry events can also provide valuable insights. Consider utilizing platforms like Alibaba or Global Sources to connect with verified suppliers. Always request references and verify their business credentials before entering negotiations. -

What is the best induction cooker for commercial use in Africa?

The best induction cooker for commercial use in Africa should prioritize durability and energy efficiency. Models with high wattage (over 3000W) can handle large cooking volumes and are ideal for busy kitchens. Look for units that come with multiple cooking zones to accommodate various pots and pans. Additionally, consider local support and availability of spare parts, as this can significantly reduce downtime in operations. -

What factors should I consider when vetting an induction cooker supplier?

When vetting an induction cooker supplier, consider their production capacity, quality control processes, and certifications (e.g., ISO, CE). Investigate their history in the industry, including years of operation and past client relationships. Ask about their manufacturing methods and materials used. It’s also wise to inquire about their ability to provide after-sales support and warranty terms, ensuring you have recourse if issues arise post-purchase. -

What are the typical minimum order quantities (MOQs) for induction cookers?

Minimum order quantities (MOQs) for induction cookers can vary significantly by manufacturer and product specifications. Generally, MOQs range from 50 to 500 units. Some manufacturers may offer flexibility for first-time buyers or smaller companies, while others might require higher quantities to ensure cost-efficiency in production. Always discuss MOQs upfront and consider negotiating terms based on your business needs and purchasing plans. -

What payment terms should I expect when sourcing induction cookers internationally?

Payment terms for international procurement of induction cookers usually include options such as advance payment, letter of credit, or payment upon delivery. Many suppliers may require a deposit (typically 30-50%) before production begins, with the balance due upon shipment. Familiarize yourself with the supplier’s payment policies and ensure they align with your cash flow capabilities. Using secure payment methods can also mitigate risks associated with international transactions. -

How can I ensure quality assurance (QA) for induction cookers?

To ensure quality assurance for induction cookers, request a detailed QA plan from your supplier. This should include inspection processes and testing standards they adhere to during production. Ask if they conduct third-party inspections and if you can receive pre-shipment samples for evaluation. It’s also beneficial to visit the manufacturing facility if possible, or hire a local inspection service to verify product quality before shipment. -

What logistics considerations should I keep in mind when importing induction cookers?

Logistics considerations for importing induction cookers include shipping methods, customs regulations, and local delivery options. Determine the best shipping route and method (air vs. sea) based on urgency and cost-effectiveness. Familiarize yourself with import duties and taxes applicable in your country. Engage a reliable freight forwarder to assist with documentation and ensure compliance with international shipping standards to avoid delays. -

Are there customization options available when sourcing induction cookers?

Yes, many manufacturers offer customization options for induction cookers to meet specific business needs. This can include branding, design alterations, and feature enhancements such as additional cooking zones or integrated safety features. Discuss your requirements during the initial negotiations and obtain samples or prototypes if possible. Customization may affect lead times and pricing, so factor these into your procurement strategy.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for induction cooker manufacturer

In the evolving landscape of the induction cooker market, strategic sourcing emerges as a pivotal strategy for international B2B buyers. By prioritizing quality, sustainability, and supplier reliability, companies can ensure they meet consumer demands while optimizing costs. Key takeaways include the importance of establishing strong relationships with manufacturers, focusing on innovation and technology, and understanding regional market dynamics—particularly in Africa, South America, the Middle East, and Europe.

A stock image related to induction cooker manufacturer.

How can B2B buyers leverage strategic sourcing for competitive advantage? It is essential to engage with suppliers that not only provide high-quality products but also align with your company’s values and sustainability goals. Implementing a robust sourcing strategy can lead to significant cost savings and improved operational efficiencies.

As we look to the future, the induction cooker market is poised for growth. International buyers should remain vigilant in monitoring market trends and supplier capabilities, adapting their sourcing strategies to stay ahead of the competition. Take the initiative today to explore partnerships that not only fulfill your immediate needs but also position your business for long-term success in this dynamic industry. Embrace the potential of strategic sourcing to transform your procurement process and drive innovation.