The Ultimate Guide to Injection Molding Manufacturer (2025)

Introduction: Navigating the Global Market for injection molding manufacturer

Navigating the complexities of the global market for injection molding manufacturers can present significant challenges for international B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, including countries like France and Egypt. As businesses seek to enhance their production capabilities, sourcing reliable injection molding partners becomes critical. This guide aims to equip buyers with essential insights into the various types of injection molding processes, applications across industries, and the intricacies of supplier vetting.

With a focus on actionable strategies, the guide delves into the key factors influencing cost, quality, and delivery timelines. Buyers will learn how to identify reputable manufacturers, assess their capabilities, and negotiate favorable terms to ensure optimal outcomes. Additionally, the guide covers emerging trends in the injection molding sector, including sustainable practices and technological advancements that can enhance efficiency and reduce waste.

By providing a comprehensive overview, this resource empowers B2B buyers to make informed purchasing decisions that align with their operational goals. Whether you are a startup looking to develop a new product line or an established company aiming to optimize your supply chain, this guide serves as a valuable tool in navigating the intricate landscape of injection molding manufacturing.

Understanding injection molding manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Injection Molding | Tailored designs for specific client requirements | Automotive, Consumer Products | Pros: Highly specialized; Cons: Longer lead times. |

| High-Volume Injection Molding | Optimized for mass production with efficient cycles | Electronics, Toys | Pros: Cost-effective for large runs; Cons: Less flexibility. |

| Micro Injection Molding | Precision molding for small parts | Medical Devices, Aerospace | Pros: High precision; Cons: Requires specialized machinery. |

| Insert Molding | Combines multiple materials in a single process | Automotive, Electronics | Pros: Reduces assembly time; Cons: Complex design requirements. |

| Two-Shot Injection Molding | Uses two materials in one cycle for multi-material parts | Consumer Goods, Medical Devices | Pros: Improved part performance; Cons: Higher initial setup costs. |

What Are the Characteristics of Custom Injection Molding?

Custom injection molding is characterized by its ability to produce parts that meet specific client needs. This variation allows for unique designs and specifications, making it ideal for industries such as automotive and consumer products. B2B buyers should consider the manufacturer‘s capability to adapt to their unique requirements, as well as the potential for longer lead times due to the tailored nature of production.

How Does High-Volume Injection Molding Benefit Businesses?

High-volume injection molding is designed for mass production, utilizing efficient cycle times to create large quantities of identical parts. This method is commonly used in electronics and toy manufacturing, where cost efficiency is crucial. Buyers should evaluate the manufacturer‘s production capabilities, as this type is best suited for businesses with consistent demand for large volumes, despite its reduced flexibility for customization.

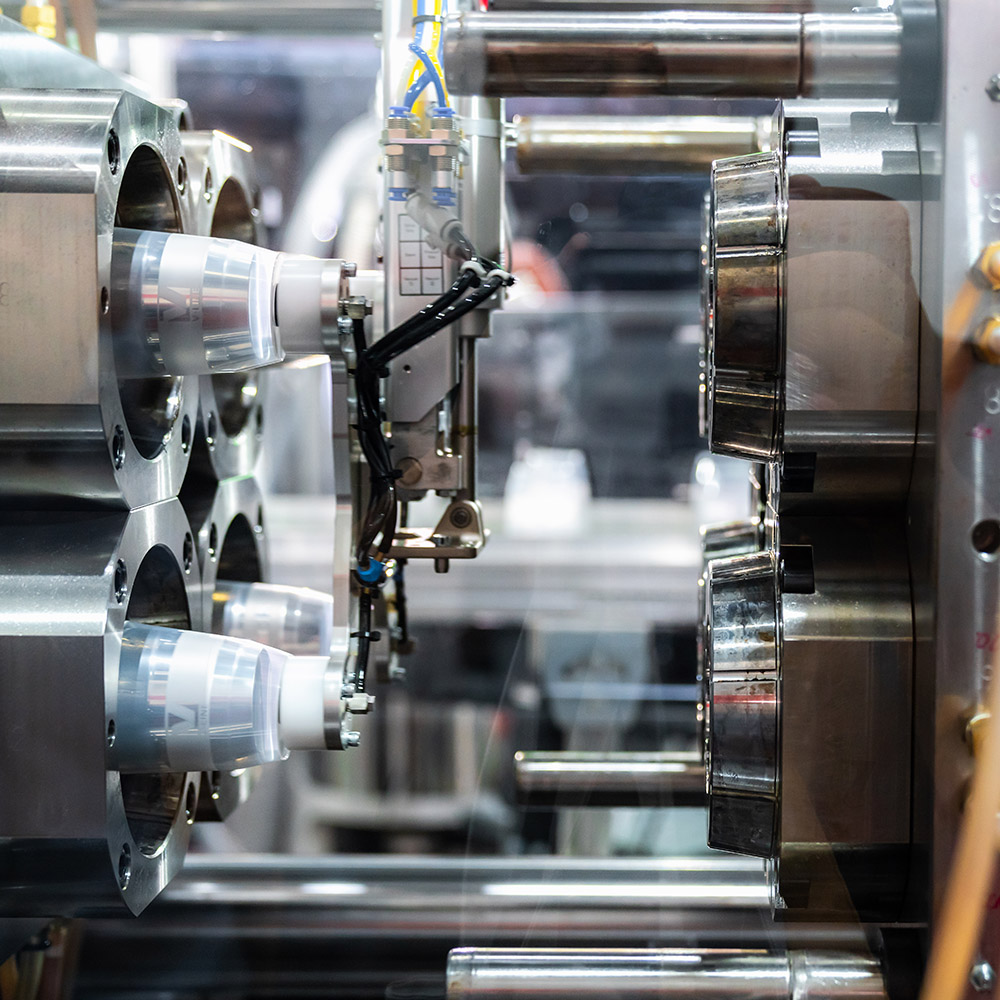

A stock image related to injection molding manufacturer.

What Makes Micro Injection Molding Suitable for Precision Parts?

Micro injection molding focuses on the production of very small and intricate parts, often used in medical devices and aerospace applications. This method requires specialized machinery to achieve the high precision needed for these components. B2B buyers should assess the manufacturer’s expertise and technology in micro molding, as the complexity of these parts may lead to higher costs and longer production times.

Why Choose Insert Molding for Complex Assemblies?

Insert molding integrates multiple materials in a single molding process, which is beneficial in applications such as automotive and electronics. This approach not only reduces assembly time but also enhances the functionality of the final product. Buyers need to consider the complexity of their design and the manufacturer’s capability to execute insert molding effectively, as it often requires advanced tooling and design considerations.

What Are the Advantages of Two-Shot Injection Molding?

Two-shot injection molding allows manufacturers to use two different materials in one cycle, resulting in parts that combine various properties. This technique is especially useful in consumer goods and medical devices, where performance and aesthetics are critical. B2B buyers should weigh the benefits of improved product performance against the potentially higher initial setup costs, which may be justified by the long-term advantages of enhanced product functionality.

Related Video: What is Injection Molding and How Does it Work?

Key Industrial Applications of injection molding manufacturer

| Industry/Sector | Specific Application of Injection Molding Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Production of complex interior and exterior components | Enhanced design flexibility and reduced weight | Supplier reliability, material specifications, and lead times |

| Consumer Electronics | Manufacturing of housings and connectors | Improved durability and aesthetic appeal | Compliance with safety standards and customization options |

| Medical Devices | Creation of precision parts for devices | Ensured sterility and compliance with regulations | Certification requirements and material biocompatibility |

| Packaging | Development of custom packaging solutions | Cost efficiency and enhanced product protection | Sustainability of materials and scalability of production |

| Construction | Fabrication of structural components and fixtures | Increased strength and reduced construction time | Quality control measures and adherence to local regulations |

How is Injection Molding Used in the Automotive Industry?

In the automotive sector, injection molding is pivotal for producing intricate interior and exterior components such as dashboards, bumpers, and trim pieces. This manufacturing process allows for lightweight designs that enhance fuel efficiency without compromising safety. B2B buyers must consider the supplier’s ability to meet stringent quality standards and provide materials that withstand automotive conditions, such as UV exposure and temperature variations. Additionally, lead times are crucial, especially for just-in-time manufacturing processes common in the industry.

What Are the Applications of Injection Molding in Consumer Electronics?

Injection molding is extensively used in consumer electronics for creating durable housings, connectors, and other intricate parts. The ability to produce high-quality, aesthetically pleasing components at scale helps companies maintain a competitive edge. Buyers should focus on suppliers that comply with international safety standards, as well as those that offer customization options to meet specific design requirements. Material selection is also vital, as it affects the product’s durability and longevity.

How Does Injection Molding Benefit the Medical Device Industry?

In the medical device industry, injection molding is essential for producing precision parts, such as syringes, surgical instruments, and diagnostic equipment. This process ensures that components can be manufactured with high accuracy, which is crucial for patient safety and regulatory compliance. Buyers from Africa, South America, the Middle East, and Europe must prioritize suppliers with relevant certifications and experience in biocompatible materials to ensure product safety and efficacy.

What Role Does Injection Molding Play in Packaging Solutions?

Injection molding is integral to the packaging industry, allowing for the development of custom packaging solutions that protect products while optimizing cost. This method provides significant advantages in terms of durability and design flexibility, which can enhance brand visibility. B2B buyers should consider the sustainability of materials used in packaging, as well as the supplier’s ability to scale production to meet varying demand levels.

How is Injection Molding Applied in the Construction Sector?

In construction, injection molding is used for fabricating structural components, fixtures, and fittings that require strength and precision. This method offers significant time savings during installation and contributes to the overall structural integrity of projects. Buyers must ensure that suppliers adhere to local building codes and quality control measures to mitigate risks associated with structural failures. The choice of materials is also critical, as it impacts durability and maintenance costs over time.

Related Video: Injection Molding Animation

3 Common User Pain Points for ‘injection molding manufacturer’ & Their Solutions

Scenario 1: Navigating Quality Control Challenges in Injection Molding

The Problem:

One of the primary pain points for B2B buyers in the injection molding sector is ensuring consistent quality in manufactured parts. In regions like Africa and South America, where manufacturing standards may vary significantly, buyers often face difficulties in sourcing injection molding manufacturers that adhere to rigorous quality protocols. This inconsistency can lead to costly production delays, increased waste, and ultimately, dissatisfaction from end customers.

The Solution:

To mitigate quality control issues, B2B buyers should prioritize manufacturers that have established quality assurance systems. Begin by conducting thorough research on potential suppliers, focusing on their certifications such as ISO 9001 or ISO/TS 16949, which indicate adherence to international quality standards. Moreover, request samples of previous work to assess the quality firsthand. During negotiations, insist on a detailed quality control plan that outlines the processes and checks the manufacturer will implement throughout production. Additionally, consider establishing a regular review mechanism, such as quarterly audits or on-site inspections, to ensure ongoing compliance with agreed-upon standards. By choosing partners who prioritize quality, buyers can reduce the risk of defects and enhance overall production efficiency.

Scenario 2: Managing Lead Times and Delivery Delays

The Problem:

For many international B2B buyers, especially in the Middle East and Europe, managing lead times and delivery schedules is crucial. Injection molding projects can be derailed by unexpected delays, whether due to logistical challenges, material shortages, or inefficient communication with manufacturers. Such disruptions not only affect production schedules but can also result in missed market opportunities and financial losses.

The Solution:

To address lead time concerns, B2B buyers should implement a proactive supply chain management strategy. Start by clearly defining expectations regarding timelines and delivery schedules during the initial discussions with manufacturers. Utilize project management tools to track progress and set up regular check-ins with suppliers to monitor production status. Additionally, consider diversifying your supplier base to include manufacturers from different geographic locations. This not only mitigates risks associated with single-source dependency but also allows for quicker responses to supply chain disruptions. Establishing contingency plans, such as alternative logistics partners or expedited shipping options, can further enhance your ability to meet tight deadlines.

Scenario 3: Overcoming Communication Barriers with Injection Molding Manufacturers

The Problem:

Communication barriers can significantly hinder the collaboration between B2B buyers and injection molding manufacturers, particularly when dealing with suppliers in different countries. Misunderstandings regarding specifications, timelines, or production capabilities can lead to costly mistakes and project setbacks, which are particularly concerning for buyers in diverse markets like Europe and Africa.

The Solution:

To improve communication, B2B buyers should adopt a multi-faceted approach. First, ensure that all technical specifications and requirements are documented in clear, unambiguous language. Utilize visual aids such as drawings, diagrams, and prototypes to convey complex ideas effectively. It’s also beneficial to establish a single point of contact within the manufacturer’s organization who can facilitate communication and address any queries swiftly. Additionally, consider using project management software that allows for real-time updates and feedback, ensuring both parties are aligned throughout the production process. Finally, investing in cultural training for teams can enhance mutual understanding and foster stronger relationships, leading to a smoother collaboration. By prioritizing clear communication, buyers can significantly reduce the risk of errors and improve project outcomes.

Strategic Material Selection Guide for injection molding manufacturer

What Are the Key Properties of Common Injection Molding Materials?

When selecting materials for injection molding, understanding the properties of each option is crucial for ensuring optimal product performance. Here are four common materials used in the injection molding process, along with their key properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Polypropylene (PP)

Key Properties: Polypropylene is known for its excellent chemical resistance, low density, and high melting point (around 160°C). It is also resistant to moisture and has good fatigue resistance.

Pros & Cons: The advantages of polypropylene include its lightweight nature, cost-effectiveness, and versatility in applications ranging from automotive parts to consumer goods. However, it has a lower tensile strength compared to some other plastics and can become brittle at low temperatures.

Impact on Application: Polypropylene is compatible with a wide range of media, making it suitable for packaging, automotive components, and household items. Its chemical resistance allows it to be used in environments where exposure to solvents or acids may occur.

Considerations for International Buyers: B2B buyers from regions like Africa and South America should consider local regulations regarding plastic use and recycling. Compliance with standards such as ASTM D4101 is essential, especially in Europe, where environmental regulations are stringent.

2. Acrylonitrile Butadiene Styrene (ABS)

Key Properties: ABS is characterized by its high impact resistance, toughness, and good dimensional stability. It has a melting point around 105°C and offers good resistance to chemicals and heat.

Pros & Cons: The main advantages of ABS are its strength and durability, making it ideal for products that require impact resistance, such as electronic housings and automotive parts. However, it can be more expensive than other materials and may require specific processing conditions to avoid warping.

Impact on Application: ABS is widely used in the automotive and consumer electronics industries due to its ability to withstand stress and impact. Its compatibility with various coatings and finishes enhances its aesthetic appeal.

Considerations for International Buyers: Buyers in the Middle East and Europe should ensure that the ABS materials meet the relevant safety and environmental standards, such as EN 71 for toys. Understanding the supply chain for ABS in these regions is also crucial, as sourcing can affect lead times and costs.

3. Polyethylene Terephthalate (PET)

Key Properties: PET is known for its excellent tensile strength, chemical resistance, and clarity. It has a melting point of approximately 260°C and is highly resistant to moisture.

Pros & Cons: The advantages of PET include its recyclability and strength, making it a popular choice for packaging applications, particularly in the beverage industry. However, it can be more expensive than other thermoplastics and may require specific processing conditions.

Impact on Application: PET is particularly suitable for food and beverage packaging due to its safety and barrier properties. It is also used in textiles and automotive applications due to its durability.

Considerations for International Buyers: Compliance with food safety standards is critical for buyers in Europe and Africa. Understanding local recycling regulations and consumer preferences for sustainable materials can also influence purchasing decisions.

4. Polystyrene (PS)

Key Properties: Polystyrene is a versatile plastic with good rigidity and clarity. It has a melting point of around 100°C and is easily molded, making it suitable for a variety of applications.

Pros & Cons: The key advantages of polystyrene include its low cost and ease of processing. However, it is less durable than other materials and has poor resistance to heat and chemicals, which can limit its applications.

Impact on Application: Polystyrene is commonly used for disposable cutlery, packaging materials, and insulation. Its clarity makes it suitable for applications where visibility is important.

Considerations for International Buyers: Buyers in South America and the Middle East should be aware of the environmental impact of polystyrene, especially in regions with strict regulations on single-use plastics. Compliance with local standards and consumer sentiment regarding sustainability can affect market acceptance.

Summary Table of Injection Molding Materials

| Material | Typical Use Case for injection molding manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene (PP) | Packaging, automotive parts, consumer goods | Lightweight and cost-effective | Lower tensile strength, brittle at low temperatures | Low |

| Acrylonitrile Butadiene Styrene (ABS) | Electronic housings, automotive components | High impact resistance and toughness | More expensive, specific processing conditions needed | Medium |

| Polyethylene Terephthalate (PET) | Food and beverage packaging, textiles | Excellent strength and recyclability | Higher cost, specific processing conditions | High |

| Polystyrene (PS) | Disposable cutlery, packaging materials | Low cost and easy to process | Poor heat and chemical resistance | Low |

This strategic material selection guide provides essential insights for international B2B buyers, enabling them to make informed decisions based on material properties, application suitability, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for injection molding manufacturer

What Are the Key Stages in the Manufacturing Process of Injection Molding?

The manufacturing process for injection molding is a complex yet systematic operation that involves several crucial stages. Understanding these stages is vital for international B2B buyers looking to source high-quality injection molded products.

-

Material Preparation

– The first stage involves selecting and preparing the right materials, typically thermoplastics or thermosetting plastics. Buyers should be aware that the quality of raw materials significantly influences the final product. Manufacturers often use pellets, which are melted down for the injection process.

– The preparation phase may also include drying the material to remove moisture, which can affect the performance and appearance of the molded parts. -

Injection Molding

– This stage involves feeding the prepared material into a heated barrel, where it is melted and injected into a mold under high pressure. Key techniques include:- Single Shot Injection: The most common method, where a single amount of material is injected in one go.

- Multi-Shot Injection: Involves injecting multiple materials into the same mold to create multi-material products, allowing for varied properties and colors.

- Buyers should inquire about the machines used (e.g., hydraulic vs. electric) as they affect precision, speed, and energy consumption.

-

Cooling and Solidification

– After injection, the material needs to cool and solidify within the mold. The cooling time can vary based on the material and part thickness. Efficient cooling systems are essential to reduce cycle times and improve productivity. -

Ejection

– Once solidified, the molded part is ejected from the mold using ejector pins. This stage is critical to ensure the integrity of the product and minimize defects. Buyers should check if manufacturers conduct post-ejection inspections to catch any potential issues. -

Finishing and Assembly

– The final stage may include secondary processes such as trimming, painting, or assembling parts. Manufacturers might employ techniques like ultrasonic welding or adhesive bonding for assembly. Buyers should assess the capabilities of suppliers in these areas to ensure they meet specific requirements.

How Do Manufacturers Ensure Quality Assurance in Injection Molding?

Quality assurance is a critical component of the injection molding process, ensuring that products meet international standards and customer expectations. Here’s how manufacturers typically ensure quality:

-

Adherence to International Standards

– Most reputable injection molding manufacturers comply with international quality standards such as ISO 9001, which emphasizes a quality management system. Buyers should verify if their suppliers hold relevant certifications as these reflect a commitment to quality.

– Additionally, industry-specific certifications like CE marking for products sold in Europe or API for oil and gas applications are crucial for compliance in specific markets. -

Quality Control Checkpoints

– Quality control is integrated at various checkpoints throughout the manufacturing process:- Incoming Quality Control (IQC): Raw materials are inspected before use to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing checks during production monitor for defects and process consistency.

- Final Quality Control (FQC): Finished products undergo thorough inspections to confirm they meet design specifications and functional requirements.

-

Common Testing Methods

– Testing methods such as dimensional checks, visual inspections, and performance testing are standard. Additionally, buyers should inquire about the use of advanced techniques like:- X-ray Inspection: For internal defects.

- Spectroscopy: To verify material composition.

- Mechanical Testing: To assess strength and durability.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to mitigate risks.

-

Conducting Audits

– Regular audits of the manufacturing facility can provide insights into the operational processes and adherence to quality standards. Buyers should consider both pre-qualification audits and ongoing assessments to ensure continuous compliance. -

Requesting Quality Reports

– Suppliers should provide detailed quality reports, including inspection and testing results, as part of their documentation. This transparency builds trust and allows buyers to make informed decisions. -

Third-Party Inspections

– Engaging third-party inspection services can further validate supplier claims. These independent entities can assess compliance with international standards and provide unbiased evaluations of product quality. -

Understanding Quality Control Nuances for International Buyers

– Buyers from different regions should be aware of the specific quality standards and regulations applicable in their markets. For instance, European buyers may prioritize CE marking, while Middle Eastern buyers might focus on local certifications. It’s crucial to communicate these requirements clearly to suppliers.

What Challenges Do International Buyers Face in Quality Assurance?

International B2B buyers often encounter challenges related to quality assurance in injection molding. These may include:

-

Language and Cultural Barriers: Miscommunication can lead to misunderstandings regarding quality expectations. Establishing clear communication channels and using translation services when necessary can mitigate this risk.

-

Regulatory Compliance: Varying regulations across regions can complicate the sourcing process. Buyers should conduct thorough research on local standards and ensure their suppliers are compliant.

-

Supply Chain Variability: Fluctuations in supply chain quality can affect the consistency of products. Building strong relationships with suppliers and conducting regular evaluations can help maintain quality standards.

A stock image related to injection molding manufacturer.

In conclusion, understanding the manufacturing processes and quality assurance measures in injection molding is crucial for international B2B buyers. By focusing on these elements, buyers can make informed decisions, ensuring they partner with manufacturers that meet their quality and operational standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘injection molding manufacturer’

In the competitive landscape of B2B procurement, securing a reliable injection molding manufacturer is crucial for product development and supply chain efficiency. This checklist serves as a practical guide for international buyers—particularly from Africa, South America, the Middle East, and Europe—helping you navigate the sourcing process effectively.

Step 1: Define Your Technical Specifications

Clearly outline your project requirements, including material types, production volume, and tolerances. This step is essential because it sets the foundation for your search, ensuring that potential manufacturers can meet your specific needs. Be as detailed as possible, as this will help in getting accurate quotes and timelines.

- Material Considerations: Specify whether you need thermoplastics, thermosets, or elastomers.

- Volume Requirements: Indicate if this is a one-time order or ongoing production.

Step 2: Conduct Market Research

Engage in thorough market research to identify potential suppliers. This includes understanding the landscape of injection molding manufacturers in your target regions and assessing their capabilities. Research helps you find companies with the necessary expertise and technological capabilities.

- Industry Reports: Utilize resources such as industry reports and trade publications to identify top manufacturers.

- Online Platforms: Explore platforms like Alibaba or ThomasNet for reviews and ratings.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This evaluation will help you gauge their reliability and quality standards.

- Certifications: Check for ISO certifications or other industry-specific credentials that ensure quality.

- Client Testimonials: Ask for references and speak to previous clients about their experiences.

Step 4: Request Quotes and Proposals

Once you have shortlisted potential suppliers, request detailed quotes and proposals. This step is vital as it provides insight into pricing structures, lead times, and payment terms, allowing for informed comparisons.

- Comparative Analysis: Create a comparison table to evaluate quotes based on price, delivery time, and payment terms.

- Clarification: Don’t hesitate to ask for clarifications on any ambiguous terms or conditions.

Step 5: Assess Manufacturing Capabilities

Visit the manufacturing facilities if possible, or request a virtual tour. This assessment is crucial to ensure that the manufacturer has the necessary equipment and processes in place to meet your specifications.

- Technology Used: Inquire about the types of injection molding machines and technology they employ.

- Quality Control Processes: Understand their quality control measures to ensure product consistency.

Step 6: Negotiate Terms and Conditions

Once you’ve identified a preferred supplier, negotiate the terms and conditions of the contract. This step is important to protect your interests and ensure clarity in the business relationship.

- Payment Terms: Discuss upfront costs, payment schedules, and any potential penalties for late deliveries.

- Warranties and Support: Ensure that warranties for defects and post-production support are clearly outlined.

Step 7: Establish a Communication Plan

Finally, set up a clear communication plan with your chosen supplier. Effective communication is key to a successful partnership and helps in addressing any issues promptly.

- Regular Updates: Schedule regular check-ins to discuss progress and any potential challenges.

- Point of Contact: Designate a primary contact person on both sides to streamline communication.

By following this checklist, B2B buyers can enhance their sourcing process for injection molding manufacturers, ensuring they partner with a supplier that meets their operational needs and quality standards.

Comprehensive Cost and Pricing Analysis for injection molding manufacturer Sourcing

What Are the Key Cost Components in Injection Molding Manufacturing?

Understanding the cost structure of injection molding is crucial for international B2B buyers looking to source effectively. The primary cost components include:

-

Materials: The choice of raw materials significantly impacts the overall cost. Common materials like polypropylene or ABS vary in price and quality. Buyers should evaluate material specifications based on their product requirements.

-

Labor: Labor costs can fluctuate based on geographic location and skill level of workers. In regions like Africa and South America, labor may be less expensive, but the trade-off can be in the expertise required for high-quality production.

-

Manufacturing Overhead: This includes utilities, facility costs, and equipment maintenance. Understanding the overhead structure can help buyers assess the competitiveness of a supplier’s pricing.

-

Tooling: Tooling is a significant upfront cost that can vary widely based on the complexity of the part design. Buyers should consider the tooling cost as part of the Total Cost of Ownership (TCO) when evaluating suppliers.

-

Quality Control (QC): Effective QC measures are essential for ensuring product reliability. Suppliers with stringent QC processes may charge higher prices, but this can result in lower defect rates and better long-term value.

-

Logistics: Transportation costs can add significantly to the final price, especially for international shipments. Incoterms play a vital role in determining who bears these costs, influencing the overall budget.

-

Margin: Manufacturers typically include a profit margin in their pricing. Understanding typical margins in different markets can aid in negotiations.

How Do Price Influencers Affect Injection Molding Costs?

Several factors can influence the final price of injection molded products:

-

Volume/MOQ: Higher order volumes often lead to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) to optimize pricing.

-

Specifications and Customization: Custom designs or specifications can increase costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Materials: The choice of material not only affects the price but also the product’s performance and compliance with regulatory standards, especially in Europe and the Middle East.

-

Quality and Certifications: Suppliers that meet international quality standards (ISO, ASTM) may command higher prices. However, these certifications can provide assurance of product quality.

-

Supplier Factors: The supplier’s reputation, experience, and geographic location can influence pricing. Established suppliers may offer more reliable service but at a premium.

-

Incoterms: The chosen Incoterms can affect shipping costs and responsibilities, impacting the overall pricing strategy. Buyers should understand the implications of terms like FOB or CIF.

What Are Some Effective Buyer Tips for Negotiating Injection Molding Prices?

International B2B buyers can employ various strategies to enhance cost-efficiency:

-

Conduct Thorough Research: Understand market rates and supplier capabilities. This knowledge empowers you during negotiations.

-

Negotiate Volume Discounts: If you anticipate future orders, negotiate bulk pricing upfront to secure better rates.

-

Evaluate Total Cost of Ownership: Consider not only the upfront costs but also long-term costs associated with quality, logistics, and support services.

-

Leverage Multiple Quotes: Obtain quotes from various suppliers to compare pricing structures and negotiate better deals.

-

Understand Regional Pricing Nuances: Be aware of specific market conditions in regions like Africa or Europe, where economic factors may influence pricing.

-

Build Long-term Relationships: Establishing a good rapport with suppliers can lead to better pricing and service over time.

Disclaimer on Indicative Prices

Prices in injection molding can vary widely based on market conditions, supplier capabilities, and specific project requirements. It is advisable for buyers to request detailed quotes and conduct due diligence before making sourcing decisions.

Alternatives Analysis: Comparing injection molding manufacturer With Other Solutions

Understanding the Alternatives to Injection Molding Manufacturing

When considering manufacturing solutions, international B2B buyers often encounter multiple technologies that can meet their needs. Among these, injection molding stands out for its efficiency and scalability. However, it’s vital to explore alternatives to ensure the best fit for your specific requirements. This analysis compares injection molding with two viable alternatives: 3D Printing and Blow Molding.

Comparison Table

| Comparison Aspect | Injection Molding Manufacturer | 3D Printing | Blow Molding |

|---|---|---|---|

| Performance | High-volume production, precision | Good for prototyping, lower volume | High-speed production for hollow objects |

| Cost | High initial setup cost, lower per unit cost at scale | Lower initial cost, higher per unit cost at scale | Moderate initial investment, cost-effective for large runs |

| Ease of Implementation | Complex setup, requires specialized molds | Simple setup, no molds needed | Requires specific molds, but simpler than injection molding |

| Maintenance | Requires regular maintenance of molds and machines | Minimal maintenance required | Moderate maintenance, depending on equipment |

| Best Use Case | Large-scale production of complex parts | Prototyping, custom parts, low-volume production | Bottles, containers, and other hollow parts |

In-Depth Analysis of Alternatives

How Does 3D Printing Compare to Injection Molding?

3D printing offers a flexible manufacturing process that enables the production of complex geometries without the need for expensive molds. This method is particularly advantageous for prototyping and custom parts, allowing businesses to quickly iterate designs. However, while the initial investment is lower, the cost per unit increases with production volume, making it less suitable for high-volume manufacturing. Moreover, the speed of production can lag behind injection molding, especially for larger parts.

What Are the Benefits of Blow Molding as an Alternative?

Blow molding is an excellent alternative for producing hollow objects such as bottles and containers. It operates at high speeds and can be cost-effective for larger production runs. The initial setup cost is moderate, and while it requires specific molds, the complexity is less than that of injection molding. However, blow molding is limited to hollow shapes, which may not suit all projects. Additionally, the precision and finish might not match that of injection molded parts, particularly for intricate designs.

Conclusion: How Should B2B Buyers Choose the Right Manufacturing Solution?

For international B2B buyers, selecting the right manufacturing solution hinges on understanding the specific requirements of their projects. Injection molding excels in high-volume production of complex parts, but alternatives like 3D printing and blow molding offer unique advantages for different applications. When evaluating options, consider factors such as production volume, part complexity, initial investment, and maintenance needs. By aligning these elements with your business goals, you can make an informed decision that optimizes both cost and efficiency.

Essential Technical Properties and Trade Terminology for injection molding manufacturer

What Are the Essential Technical Properties for Injection Molding?

When considering injection molding manufacturing, understanding the technical properties is crucial for making informed decisions. Here are some key specifications to be aware of:

-

Material Grade

– Definition: This refers to the specific type of plastic or resin used in the injection molding process. Common materials include ABS, polypropylene, and polycarbonate.

– Importance: The choice of material impacts the strength, flexibility, and durability of the final product. B2B buyers must select a grade that aligns with their product requirements and performance expectations. -

Tolerance

– Definition: Tolerance is the allowable variation in the dimensions of a molded part. It is often expressed in millimeters or inches.

– Importance: Precise tolerances ensure that parts fit together correctly and function as intended. For industries like automotive or aerospace, where precision is critical, understanding tolerance specifications can prevent costly reworks and delays. -

Cycle Time

– Definition: Cycle time is the total time taken to complete one injection molding process, from the injection of material to the ejection of the molded part.

– Importance: Shorter cycle times enhance production efficiency and reduce costs. International buyers should evaluate manufacturers based on their ability to optimize cycle times without compromising quality. -

Shrinkage Rate

– Definition: This is the percentage decrease in size of the part as it cools and solidifies post-molding.

– Importance: Understanding the shrinkage rate is essential for achieving the desired final dimensions. It is particularly important for high-volume production runs where consistency is key. -

Surface Finish

– Definition: This refers to the texture and appearance of the molded part’s surface, which can vary from matte to glossy.

– Importance: The surface finish can affect the aesthetic appeal and functionality of a product. Buyers should specify their finish requirements to ensure the end product meets market expectations. -

Impact Resistance

– Definition: This property measures a material’s ability to withstand sudden force or shock without breaking.

– Importance: For applications that require durability, such as consumer electronics or automotive parts, impact resistance is critical. Buyers should inquire about the impact ratings of materials used by manufacturers.

Which Trade Terms Should B2B Buyers Understand in Injection Molding?

Familiarity with industry jargon can facilitate smoother negotiations and operations. Here are some common terms that every B2B buyer should know:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships helps buyers identify quality suppliers who can meet specific production needs while maintaining brand integrity. -

MOQ (Minimum Order Quantity)

– Definition: This is the smallest number of units a supplier is willing to produce for a single order.

– Importance: Knowing the MOQ can influence purchasing decisions, especially for small to mid-sized businesses that may have limited budgets or storage capacity. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document used to invite suppliers to submit price proposals for a specific quantity of goods or services.

– Importance: Utilizing RFQs helps buyers compare pricing and terms from multiple manufacturers, ensuring they secure the best deal for their needs. -

Incoterms (International Commercial Terms)

– Definition: These are predefined commercial terms that clarify the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms can help buyers understand their obligations regarding shipping, insurance, and tariffs, which is vital for cost management and risk mitigation.

-

Lead Time

– Definition: This refers to the time taken from placing an order to the delivery of the final product.

– Importance: Understanding lead times is essential for effective inventory management and production planning, particularly in industries with tight deadlines. -

Prototype

– Definition: A prototype is an initial model of a product used to test and validate concepts before full-scale production.

– Importance: Prototyping allows buyers to assess design feasibility and functionality, significantly reducing the risk of costly errors in the production phase.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when selecting an injection molding manufacturer, ultimately leading to successful partnerships and products.

Navigating Market Dynamics and Sourcing Trends in the injection molding manufacturer Sector

What Are the Current Market Dynamics and Sourcing Trends in the Injection Molding Sector?

The injection molding manufacturing sector is experiencing transformative changes driven by several global trends. One of the most significant drivers is the increasing demand for lightweight and high-performance materials, particularly in automotive, consumer goods, and medical applications. This demand is spurred by industries seeking to enhance product durability while reducing weight and material costs. Additionally, the growing emphasis on automation and Industry 4.0 technologies is reshaping sourcing strategies. International B2B buyers are now leveraging advanced manufacturing technologies such as robotics, AI, and IoT to enhance production efficiency, reduce lead times, and improve product quality.

Moreover, globalization continues to play a crucial role in the market dynamics, with many manufacturers expanding their operations to emerging markets in Africa and South America. This trend is fueled by lower labor costs and the availability of raw materials, making it more cost-effective for companies to source injection-molded products from these regions. However, international buyers must remain vigilant about potential supply chain disruptions due to geopolitical tensions and trade regulations, particularly between major markets like Europe and Asia.

How Is Sustainability Influencing Sourcing Decisions in the Injection Molding Industry?

Sustainability has emerged as a pivotal factor influencing sourcing decisions in the injection molding sector. The environmental impact of plastic production has prompted businesses to adopt more sustainable practices. As a result, companies are increasingly prioritizing ethical sourcing and the use of recyclable or biodegradable materials in their manufacturing processes. B2B buyers, especially those in Europe and North America, are demanding transparency in the supply chain to ensure that materials are sourced responsibly.

Furthermore, obtaining certifications such as ISO 14001 for environmental management and using ‘green’ materials can significantly enhance a manufacturer’s credibility in the marketplace. Buyers are encouraged to seek suppliers who demonstrate a commitment to sustainability through their production methods and material choices. This shift not only helps mitigate environmental impact but also aligns with the growing consumer preference for eco-friendly products, thereby enhancing brand loyalty and marketability.

What Is the Historical Context of Injection Molding and Its Evolution?

The evolution of injection molding can be traced back to the early 19th century when the first injection molding machine was patented. Over the decades, advancements in materials science and machinery technology have significantly improved the efficiency and versatility of injection molding. Initially used for simple items like buttons, the process has expanded to manufacture complex components used in various industries, including automotive, electronics, and healthcare.

In recent years, the integration of computer-aided design (CAD) and 3D printing technology has further revolutionized the injection molding landscape, enabling faster prototyping and more intricate designs. This evolution reflects the industry’s adaptability to changing market demands and technological advancements, positioning injection molding as a critical manufacturing process in today’s global economy. B2B buyers must consider this historical context to better understand current capabilities and future trends in the injection molding sector.

Frequently Asked Questions (FAQs) for B2B Buyers of injection molding manufacturer

-

How do I choose the right injection molding manufacturer for my business?

Selecting the right injection molding manufacturer involves evaluating several key factors. Start by assessing their experience in your industry and the complexity of the parts you require. Look for manufacturers with advanced technology and certifications, such as ISO 9001, which indicates a commitment to quality management. Additionally, consider their production capacity and lead times to ensure they can meet your demand. Finally, request samples of their previous work to gauge the quality and precision of their products. -

What are the most important quality assurance practices in injection molding?

Quality assurance in injection molding is critical to ensuring that the final products meet specifications and standards. Key practices include regular inspections throughout the production process, utilizing Statistical Process Control (SPC) to monitor variations, and conducting thorough testing on finished parts. Implementing a robust feedback loop allows manufacturers to address any issues promptly. Additionally, certifications like ISO 9001 can further assure buyers of consistent quality. -

What should I know about minimum order quantities (MOQ) when sourcing injection molded parts?

Minimum order quantities (MOQ) can vary significantly among injection molding manufacturers. It’s essential to discuss your specific needs upfront. Some manufacturers may have flexible MOQs for new clients or smaller projects, while others may require higher quantities to justify setup costs. Understanding the MOQ will help you plan your inventory and budget accordingly. Always negotiate terms that align with your business model to avoid excess stock or high upfront costs. -

How can I ensure the customization of my injection molded products?

To ensure customization of your injection molded products, communicate your specific design requirements clearly to the manufacturer. Provide detailed CAD drawings and specifications, and discuss any unique materials or finishes you need. Most manufacturers will offer prototyping services, allowing you to review a sample before full production. Collaborating closely during the design phase can help you achieve the desired functionality and aesthetics in your custom parts. -

What payment terms should I expect from injection molding manufacturers?

Payment terms can vary widely among injection molding manufacturers, especially for international orders. Typically, manufacturers may request a deposit upfront (often 30-50%) with the remaining balance due upon completion or shipment of the order. It’s important to discuss payment methods, such as wire transfers or letters of credit, and consider any additional fees for international transactions. Establishing clear payment terms in your contract can help prevent misunderstandings later. -

How can I vet an injection molding supplier for reliability?

Vetting an injection molding supplier requires thorough research and due diligence. Start by checking their industry reputation through online reviews and testimonials. Request references from past clients to gain insights into their reliability and quality. Additionally, visit their facility if possible to assess their operations and quality control processes. Certifications such as ISO or other industry-specific standards can also indicate a supplier’s commitment to excellence. -

What logistics considerations should I take into account when importing injection molded parts?

Logistics are crucial when importing injection molded parts, especially for international transactions. Consider factors such as shipping methods, customs regulations, and potential tariffs that may affect delivery times and costs. It’s beneficial to work with a logistics partner familiar with your destination country’s regulations. Ensure that the manufacturer can provide the necessary documentation, such as invoices and packing lists, to facilitate smooth customs clearance. -

How do I handle communication and time zone differences with international suppliers?

Effective communication with international suppliers can be challenging due to time zone differences. Establish a clear communication schedule that accommodates both parties, possibly setting specific times for regular updates. Utilize digital tools like email, instant messaging, and video calls to enhance communication. It’s also helpful to document all discussions and agreements in writing to avoid misunderstandings. Building a strong relationship with your supplier will facilitate smoother interactions over time.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for injection molding manufacturer

How Can Strategic Sourcing Enhance Your Injection Molding Operations?

In conclusion, strategic sourcing plays a pivotal role in optimizing the operations of injection molding manufacturers. By focusing on supplier relationships, cost management, and quality assurance, international B2B buyers can significantly enhance their production efficiency and product quality. Understanding the local market dynamics in regions such as Africa, South America, the Middle East, and Europe is essential for selecting the right partners who can meet specific needs while offering competitive advantages.

Moreover, leveraging technology and data analytics can streamline sourcing processes, allowing businesses to make informed decisions that align with their long-term strategic goals. As global supply chains continue to evolve, staying abreast of industry trends and potential disruptions will be crucial for maintaining a resilient sourcing strategy.

What’s Next for International Buyers in Injection Molding?

Looking ahead, B2B buyers are encouraged to take proactive steps in refining their sourcing strategies. Engage with local suppliers to foster collaboration and innovation, and consider diversifying your supplier base to mitigate risks. By investing in strong partnerships and embracing technological advancements, you can position your business for sustainable growth in the competitive landscape of injection molding. The future is bright for those who are ready to adapt and seize opportunities in this dynamic industry.