The Ultimate Guide to Kitchen Knife Supplier (2025)

Introduction: Navigating the Global Market for kitchen knife supplier

In an increasingly competitive global marketplace, sourcing high-quality kitchen knives can pose significant challenges for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The variety of materials, designs, and functionalities available can overwhelm even the most seasoned procurement professionals. This guide addresses these complexities by providing a comprehensive exploration of kitchen knife suppliers. From understanding the different types of kitchen knives to their specific applications in both commercial and domestic settings, our aim is to equip international buyers with the knowledge necessary to make informed purchasing decisions.

This resource will delve into critical aspects such as supplier vetting processes, essential quality assurance standards, and strategies for negotiating favorable terms. We will also analyze cost factors, helping you understand pricing structures and how to balance quality with budget constraints. Whether you are a small restaurant owner in South America seeking reliable kitchen tools or a large distributor in Europe looking to expand your product range, this guide is designed to empower you with actionable insights.

By navigating the global market for kitchen knife suppliers effectively, you can ensure that your business remains competitive while meeting the diverse culinary needs of your clientele. Let this guide be your trusted companion in mastering the art of sourcing kitchen knives that elevate culinary experiences and enhance operational efficiency.

Understanding kitchen knife supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Artisan Knife Suppliers | Handmade, unique designs, often using high-quality materials | High-end restaurants, gourmet shops | Pros: Unique offerings, superior craftsmanship. Cons: Higher costs, longer lead times. |

| Mass-Produced Knife Suppliers | Standardized designs, large-scale production | Retail chains, food service | Pros: Cost-effective, consistent quality. Cons: Limited customization, may lack uniqueness. |

| Specialty Knife Suppliers | Focused on specific knife types (e.g., sushi, chef, utility) | Culinary schools, specialized markets | Pros: Expertise in niche products, tailored solutions. Cons: Limited range of other knife types. |

| OEM/Private Label Suppliers | Custom branding on existing knife models | Distributors, retailers | Pros: Brand differentiation, lower investment in R&D. Cons: Potential quality variability, dependency on supplier quality. |

| Eco-Friendly Knife Suppliers | Sustainable materials and production practices | Health-conscious businesses, eco-friendly retailers | Pros: Appeal to eco-conscious consumers, innovative materials. Cons: May be pricier, limited availability. |

What are the Characteristics of Artisan Knife Suppliers?

Artisan knife suppliers focus on handmade products, often characterized by unique designs and the use of high-quality materials. These suppliers cater primarily to high-end restaurants and gourmet shops, where the demand for distinctive and superior craftsmanship is paramount. When considering B2B purchases from artisan suppliers, buyers should evaluate the supplier’s reputation, the artisans’ skill level, and the potential for longer lead times due to the handcrafted nature of the products. While the prices may be higher, the uniqueness of each piece can justify the investment for businesses aiming to enhance their culinary offerings.

How do Mass-Produced Knife Suppliers Operate?

Mass-produced knife suppliers specialize in standardized designs and large-scale production, making them ideal for retail chains and food service companies looking for cost-effective solutions. These suppliers focus on consistency and reliability, providing knives that meet industry standards without the premium prices associated with artisan products. B2B buyers should consider factors such as the supplier’s production capacity, quality control measures, and shipping logistics. While mass-produced knives offer affordability, they often lack the unique features that could appeal to niche markets.

What Makes Specialty Knife Suppliers Valuable?

Specialty knife suppliers concentrate on specific types of knives, such as sushi knives or chef’s knives, and are often sought after by culinary schools and specialized markets. Their expertise allows them to provide tailored solutions that meet the precise needs of their clientele. When purchasing from specialty suppliers, buyers should assess the range of products offered and the supplier’s knowledge of the specific knife type. Although these suppliers may have a limited range of other knife types, their focus on quality and performance in their niche can be a significant advantage for buyers looking for specific culinary applications.

How Can OEM/Private Label Suppliers Benefit Your Business?

OEM (Original Equipment Manufacturer) and private label suppliers offer the opportunity for businesses to customize branding on existing knife models. This is particularly beneficial for distributors and retailers looking to differentiate their products in a competitive market. When considering these suppliers, B2B buyers should evaluate the quality of the base products, the supplier’s ability to meet branding requirements, and potential lead times. While this option can lower investment costs in research and development, buyers must be cautious of potential quality variability, as the end product will heavily rely on the supplier’s manufacturing standards.

Why Choose Eco-Friendly Knife Suppliers?

Eco-friendly knife suppliers focus on sustainable materials and production practices, appealing to health-conscious businesses and eco-friendly retailers. As sustainability becomes increasingly important to consumers, these suppliers can help businesses align with market trends. B2B buyers should investigate the materials used, the supplier’s production processes, and any certifications that demonstrate their commitment to sustainability. Although eco-friendly knives may come at a higher price point, the growing consumer demand for sustainable products can offer a competitive edge in the marketplace.

Related Video: The BEST Japanese kitchen knife? Learn all about it.

Key Industrial Applications of kitchen knife supplier

| Industry/Sector | Specific Application of Kitchen Knife Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service Industry | Culinary Preparation in Restaurants | Enhanced efficiency in food preparation, consistent quality of cuts | Supplier reliability, knife material quality, and ergonomic design |

| Retail & Wholesale | Kitchen Knife Sales in Consumer Goods Stores | Increased product range, customer satisfaction through quality offerings | Packaging options, brand reputation, and price competitiveness |

| Food Processing | Precision Cutting in Food Manufacturing Facilities | Improved production speed, reduced waste from accurate cuts | Compliance with health standards, bulk purchasing options, and custom designs |

| Culinary Education | Training Programs in Culinary Schools | Provision of high-quality tools for student learning, fostering skill development | Affordability for bulk orders, durability, and safety features |

| Hospitality & Catering | Event Catering Knife Supplies | Flexibility in menu offerings, ability to cater to diverse cuisines | Customization options, delivery timelines, and after-sales support |

How is Kitchen Knife Supplier Used in the Food Service Industry?

In the food service industry, kitchen knife suppliers play a crucial role in culinary preparation within restaurants. High-quality knives are essential for chefs to perform various cutting techniques, which enhances efficiency and ensures consistent food presentation. For international B2B buyers, especially those from Africa and South America, sourcing knives that meet local culinary standards and preferences is vital. Buyers should prioritize suppliers that provide durable knives tailored for heavy usage and ergonomic designs to reduce hand fatigue during peak hours.

What are the Applications of Kitchen Knives in Retail & Wholesale?

Kitchen knife suppliers are integral to the retail and wholesale sectors, where they provide a diverse range of kitchen knives to consumer goods stores. Retailers benefit from offering high-quality knives that meet customer expectations for performance and longevity. For buyers in Europe and the Middle East, sourcing from suppliers with established brand reputations can enhance customer trust. It is important to consider packaging options that appeal to consumers and competitive pricing to ensure profitability in a crowded market.

How Do Kitchen Knives Benefit Food Processing Industries?

In food processing facilities, kitchen knife suppliers provide precision cutting tools that streamline operations. Accurate cuts lead to reduced food waste and improved production speed, which are critical for maintaining profit margins. Buyers in this sector, particularly from Africa and South America, must ensure that suppliers comply with local health and safety standards. Bulk purchasing options and custom knife designs tailored to specific processing tasks can provide additional value and efficiency.

Why are Kitchen Knives Important in Culinary Education?

Culinary schools rely on kitchen knife suppliers to equip students with the tools necessary for skill development. High-quality knives are essential for teaching various culinary techniques and ensuring students can practice safely. For international B2B buyers in Europe and Australia, affordability for bulk orders is a key consideration, alongside the durability of the knives. Suppliers that offer training support or instructional materials can further enhance their appeal to educational institutions.

How are Kitchen Knife Suppliers Used in Hospitality & Catering?

In the hospitality and catering sectors, kitchen knife suppliers provide essential tools for event catering. Chefs require a variety of knives to prepare diverse menus, making flexibility in knife offerings crucial. Buyers in the Middle East and South America should look for suppliers that offer customization options to meet specific event needs. Timely delivery and robust after-sales support are also important factors to ensure smooth operations during high-demand periods.

Related Video: Types of Kitchen Knives and Their Uses

3 Common User Pain Points for ‘kitchen knife supplier’ & Their Solutions

Scenario 1: Inconsistent Quality Across Suppliers

The Problem: One of the significant challenges faced by B2B buyers in the kitchen knife sector is the inconsistency in quality across different suppliers. A buyer in Africa may find that while one supplier offers high-quality stainless steel knives, another may provide blades that chip or rust easily. This inconsistency can lead to operational disruptions, customer dissatisfaction, and ultimately harm the brand’s reputation. Buyers may feel hesitant to switch suppliers due to past investments or relationships, creating a dilemma.

The Solution: To combat this issue, B2B buyers should implement a rigorous supplier evaluation process. This includes requesting samples and conducting quality assessments before making bulk purchases. Establishing a clear set of quality standards and communicating them to potential suppliers is essential. Additionally, consider forming long-term partnerships with suppliers who demonstrate a consistent track record of quality and reliability. Regular audits and feedback loops can help ensure that standards are maintained over time. Utilizing third-party testing services can further guarantee that the knives meet international quality standards.

Scenario 2: Complicated Import and Compliance Regulations

The Problem: B2B buyers in regions such as South America and the Middle East often face the complex web of import regulations and compliance requirements when sourcing kitchen knives from international suppliers. These regulations can vary significantly from one country to another, leading to delays in shipments, unexpected tariffs, and even the risk of confiscation at customs. Buyers can become overwhelmed by the paperwork and legalities involved, which can significantly impact their supply chain efficiency.

The Solution: To navigate these complexities, buyers should engage with logistics partners who specialize in international trade and customs regulations. Investing in a comprehensive compliance management system can streamline the import process and keep buyers informed of changing regulations. Additionally, it is beneficial to work closely with suppliers who have experience exporting to the buyer’s country, as they can provide valuable insights and assistance with documentation. Establishing a clear communication channel with local customs authorities can also help clarify requirements, ensuring that all necessary paperwork is in order before shipments arrive.

Scenario 3: Difficulty in Finding a Diverse Range of Products

The Problem: Many B2B buyers encounter challenges when searching for suppliers that offer a diverse range of kitchen knives to meet varying customer needs. For instance, a buyer in Europe might require specialty knives for professional chefs, while another buyer in Africa may need more general-purpose knives for home use. This lack of variety can limit market potential and hinder the ability to satisfy a broad customer base.

The Solution: To address this pain point, buyers should prioritize suppliers that offer a comprehensive catalog of products, including specialty knives, different blade materials, and ergonomic designs. Conducting thorough market research to identify suppliers who cater specifically to diverse culinary needs is crucial. Additionally, buyers can benefit from establishing partnerships with manufacturers willing to customize products to meet specific requirements. Engaging in trade shows and industry events can also help buyers discover innovative suppliers and expand their product offerings. Utilizing online platforms and marketplaces that aggregate various suppliers can simplify the sourcing process and provide access to a wider array of kitchen knives.

Strategic Material Selection Guide for kitchen knife supplier

What Are the Key Properties of Stainless Steel for Kitchen Knives?

Stainless steel is one of the most popular materials for kitchen knives due to its excellent balance of durability, corrosion resistance, and ease of maintenance. It typically contains chromium, which enhances its resistance to rust and staining, making it suitable for various kitchen environments. The temperature and pressure ratings for stainless steel are generally high, allowing it to withstand rigorous use without deforming.

Pros and Cons of Stainless Steel

The primary advantage of stainless steel is its durability and resistance to corrosion, which is crucial for kitchen environments where moisture is prevalent. However, it can be more expensive than other materials, and its manufacturing process can be complex, impacting production timelines. Additionally, while stainless steel knives can maintain a sharp edge, they may require regular honing to retain their performance.

Impact on Application

Stainless steel is compatible with a wide range of food products, making it versatile for various culinary tasks. However, international buyers should be aware of the specific grades of stainless steel used, as not all grades offer the same level of performance. Compliance with standards such as ASTM or DIN is essential for ensuring product quality.

How Does Carbon Steel Compare for Kitchen Knives?

Carbon steel is known for its exceptional sharpness and edge retention, making it a favored choice among professional chefs. This material can achieve a sharper edge than stainless steel, which is beneficial for precision cutting tasks. However, carbon steel is more susceptible to rust and requires regular maintenance to prevent corrosion.

Pros and Cons of Carbon Steel

The key advantage of carbon steel knives is their ability to hold a sharp edge longer than stainless steel, providing excellent cutting performance. However, the downside is that they require more care and maintenance, as they can rust if not properly dried and oiled after use. This increased maintenance may not be suitable for all buyers, particularly those in humid climates.

Impact on Application

Carbon steel is ideal for cutting softer foods but may not perform as well with acidic ingredients, which can accelerate corrosion. Buyers from regions with high humidity, such as parts of Africa and South America, should consider the environmental impact on the longevity of carbon steel knives.

What Are the Benefits of Ceramic Knives for Kitchen Use?

Ceramic knives are made from zirconia, which is a hard, non-metallic material. They are known for their lightweight nature and ability to maintain a sharp edge for an extended period. The non-reactive properties of ceramic make these knives suitable for cutting fruits and vegetables without altering their flavors.

Pros and Cons of Ceramic Knives

The primary advantage of ceramic knives is their sharpness and low weight, which reduces fatigue during prolonged use. However, they are brittle and can chip or break if dropped or used on hard surfaces. This fragility makes them less suitable for heavy-duty tasks, which may limit their appeal for certain buyers.

Impact on Application

Ceramic knives are best used for slicing and dicing softer foods. International buyers should consider the limitations of ceramic knives in terms of versatility, as they may not be suitable for all kitchen tasks, particularly in commercial settings.

How Does Damascus Steel Stand Out in Kitchen Knife Manufacturing?

Damascus steel is renowned for its unique patterns and exceptional sharpness. It is made by layering different types of steel, which not only enhances its aesthetic appeal but also its performance. The resulting blades are often strong, durable, and resistant to wear.

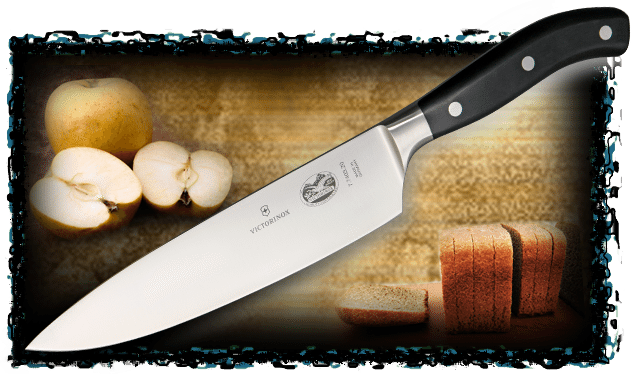

A stock image related to kitchen knife supplier.

Pros and Cons of Damascus Steel

The key advantage of Damascus steel is its combination of beauty and functionality. The layered structure provides excellent edge retention and durability. However, the manufacturing process is more complex and can lead to higher costs, which may be a consideration for B2B buyers looking for cost-effective solutions.

Impact on Application

Damascus steel knives are versatile and can handle a variety of cutting tasks. However, international buyers should ensure that the knives meet local standards for food safety and quality, as the production methods can vary significantly.

Summary Table of Material Properties for Kitchen Knives

| Material | Typical Use Case for kitchen knife supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | General kitchen use, versatile applications | Corrosion resistance, durability | Higher cost, requires honing | Medium |

| Carbon Steel | Professional chef knives, precision cutting | Excellent edge retention | Susceptible to rust, requires care | Medium |

| Ceramic | Slicing fruits and vegetables | Lightweight, maintains sharpness | Brittle, limited versatility | Low |

| Damascus Steel | High-end culinary applications | Aesthetic appeal, strong performance | Complex manufacturing, higher cost | High |

This comprehensive guide to material selection will aid international B2B buyers in making informed decisions when sourcing kitchen knives, ensuring they choose the right material for their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for kitchen knife supplier

What Are the Main Stages of Kitchen Knife Manufacturing?

The manufacturing process of kitchen knives is intricate and involves several critical stages that ensure both functionality and durability. Here’s a breakdown of the primary stages:

-

Material Preparation: The choice of materials is paramount in knife manufacturing. High-carbon stainless steel is commonly used due to its balance of hardness and corrosion resistance. The steel is cut into sheets and undergoes heat treatment to enhance its properties. Alternative materials like ceramic and Damascus steel are also gaining popularity, particularly for specialty knives.

-

Forming: This stage involves shaping the knife. Techniques such as forging and stamping are prevalent. Forging entails heating the steel and shaping it with hammers, resulting in a blade with superior strength and edge retention. Stamping, on the other hand, uses a die to cut the blade shape from a flat sheet of steel, which is often more cost-effective for mass production.

-

Assembly: Once the blade is formed, it is attached to the handle. Handles can be made from various materials, including wood, plastic, or metal, each offering different aesthetics and ergonomics. The assembly process often includes fitting, fastening, and ensuring that the blade is securely attached to the handle.

-

Finishing: This final stage involves polishing and sharpening the knife. The blade is ground to achieve the desired edge angle, and the surface is polished to ensure a smooth finish. Additional processes like coating with non-stick materials or adding decorative elements may also occur during this stage.

What Quality Control Standards Should B2B Buyers Be Aware Of?

Quality assurance is critical in the kitchen knife manufacturing process. Adhering to international standards ensures that products meet safety and performance expectations. Here are some key standards and checkpoints:

-

International Standards:

– ISO 9001: This standard outlines the criteria for a quality management system. Suppliers adhering to ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

– CE Marking: Particularly relevant for suppliers in Europe, CE marking indicates compliance with EU safety, health, and environmental protection standards. -

Industry-Specific Standards:

– API (American Petroleum Institute): While primarily focused on the oil and gas industry, some knife manufacturers may comply with API standards, particularly if they produce specialty knives for industrial applications.

How Are Quality Control Checkpoints Established in Knife Manufacturing?

Quality control (QC) involves systematic checks at various stages of the manufacturing process to identify and rectify defects. Here are the key checkpoints:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon delivery. Suppliers should verify the quality of steel, handle materials, and other components to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During manufacturing, various inspections are conducted to monitor processes and identify defects early. This includes checking dimensions, blade hardness, and the integrity of the assembly.

-

Final Quality Control (FQC): After production, a comprehensive inspection is performed on the finished products. This includes testing the sharpness, balance, and overall quality of the knives. Any knives that do not meet the established criteria are rejected.

What Common Testing Methods Are Used in Kitchen Knife Quality Assurance?

Several testing methods are utilized to ensure the quality and safety of kitchen knives:

- Edge Retention Testing: This assesses how well a knife maintains its sharpness after a specified number of cuts on various materials.

- Corrosion Resistance Testing: Knives are subjected to conditions that simulate prolonged exposure to moisture and acidic substances to ensure they do not corrode.

- Drop Tests: These tests evaluate the durability of the knife handle and blade under impact conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, it’s essential to ensure that suppliers maintain rigorous QC practices. Here are actionable steps to verify supplier quality control:

-

Conduct Supplier Audits: Regular audits of potential suppliers can help assess their manufacturing processes and quality assurance measures. Look for suppliers who are open to audits and provide transparency in their operations.

-

Request Quality Assurance Reports: Suppliers should be able to provide documentation of their quality control processes, including IQC, IPQC, and FQC results. These reports should detail any issues encountered and corrective actions taken.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing capabilities and quality assurance practices. This is particularly useful for international transactions where buyers cannot be present.

-

Review Certifications and Compliance: Confirm that suppliers possess relevant certifications, such as ISO 9001 or CE marking. This not only verifies their commitment to quality but also ensures compliance with international standards.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

B2B buyers from diverse regions must be aware of specific nuances in quality control and certification:

- Regional Regulations: Different countries may have varying regulations regarding kitchen knife safety and quality. Buyers should familiarize themselves with local regulations in their target markets to ensure compliance.

- Cultural Expectations: Understanding cultural preferences for knife design and functionality can influence quality expectations. For instance, buyers in Europe may prioritize ergonomic designs, while those in Africa may value durability for varied cooking methods.

- Import Regulations: Buyers should consider import regulations and tariffs that may affect the cost and feasibility of sourcing knives from certain regions. Staying informed about trade agreements can also provide advantages.

Conclusion

The manufacturing processes and quality assurance practices of kitchen knife suppliers are vital for ensuring product reliability and safety. By understanding these processes and actively engaging in quality verification, international B2B buyers can secure high-quality kitchen knives that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘kitchen knife supplier’

This guide serves as a practical checklist for international B2B buyers seeking reliable kitchen knife suppliers. By following these steps, you can streamline your sourcing process, ensuring you partner with suppliers who meet your quality, compliance, and logistical needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial to ensure the kitchen knives meet your operational requirements. Consider factors such as blade material, handle design, and intended use (e.g., culinary, industrial). This clarity helps potential suppliers understand your needs and reduces the risk of miscommunication during production.

Step 2: Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers in your target regions—Africa, South America, the Middle East, and Europe. Use platforms like Alibaba, Global Sources, and industry-specific directories. Look for suppliers with a strong reputation, positive reviews, and a history of exporting to your region, which can indicate reliability.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, perform a comprehensive evaluation. Request company profiles, product catalogs, and case studies that demonstrate their capabilities. It’s also beneficial to ask for references from other buyers in similar markets to gauge their reliability and product quality. This step can prevent costly mistakes later in the procurement process.

Step 4: Verify Supplier Certifications

Ensure that the suppliers you consider hold relevant certifications, such as ISO 9001 for quality management systems or other industry-specific certifications. These credentials indicate that the supplier adheres to international quality standards and regulatory compliance. Verification can usually be done through official certification bodies or directly with the supplier.

Step 5: Request Samples and Conduct Quality Checks

Always request product samples before placing a bulk order. This allows you to assess the quality of the kitchen knives firsthand, ensuring they meet your specifications and expectations. During this phase, evaluate the craftsmanship, materials used, and overall functionality. It’s also wise to conduct quality checks based on your defined criteria.

Step 6: Discuss Payment Terms and Shipping Logistics

Negotiate payment terms and shipping logistics to align with your financial planning and operational timelines. Common payment methods include letters of credit, advance payments, or net payment terms. Additionally, clarify shipping responsibilities, including costs, insurance, and delivery timelines, to avoid misunderstandings later.

Step 7: Establish Communication Protocols

Maintain clear and consistent communication with your selected supplier throughout the sourcing process. Establish regular check-ins to monitor production status and address any issues promptly. This proactive approach helps build a strong partnership and ensures that both parties are aligned on expectations.

By following this comprehensive checklist, B2B buyers can effectively navigate the complexities of sourcing kitchen knives, ensuring they partner with suppliers who deliver quality products and reliable service.

Comprehensive Cost and Pricing Analysis for kitchen knife supplier Sourcing

What Are the Key Cost Components for Sourcing Kitchen Knives?

Understanding the cost structure of kitchen knife suppliers is essential for B2B buyers looking to optimize their sourcing strategies. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality stainless steel or carbon steel will incur higher initial costs but may offer better durability and performance, which can be critical for professional kitchens.

-

Labor: Labor costs vary depending on the region and the complexity of the manufacturing process. Countries with lower labor costs may offer competitive pricing, but this could affect quality and craftsmanship.

-

Manufacturing Overhead: This encompasses the operational costs associated with running a manufacturing facility, including utilities, equipment maintenance, and facility leasing. Efficient production processes can help in reducing these overheads.

-

Tooling: The investment in tooling and machinery is a significant factor. Suppliers who have invested in advanced technology may produce knives more efficiently, impacting both cost and quality.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability but can add to costs. Buyers should assess the level of QC employed by suppliers to avoid future issues.

-

Logistics: Transportation costs can vary widely based on distance, shipping method, and local tariffs. Understanding the logistics involved in shipping knives to your location is crucial for calculating total costs.

-

Margin: Finally, suppliers will add their profit margin to the total cost structure, which can vary based on brand reputation and market demand.

How Do Price Influencers Affect Kitchen Knife Sourcing?

Several factors influence the pricing of kitchen knives, and understanding these can help buyers negotiate better deals:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs. Buyers should consider their inventory needs to leverage bulk pricing.

-

Specifications and Customization: Customized knives or those with specific features will typically be priced higher. Buyers should weigh the benefits of customization against their budget constraints.

-

Materials and Quality Certifications: Knives made from premium materials or those certified by industry standards (e.g., ISO, ANSI) may command higher prices. Buyers should evaluate the necessity of these features based on their target market.

-

Supplier Factors: The reputation, reliability, and experience of the supplier can influence pricing. Established suppliers may charge a premium for their expertise and service.

-

Incoterms: Understanding Incoterms is essential for international buyers. These terms dictate who bears the responsibility for shipping costs, insurance, and tariffs, directly impacting the total landed cost.

What Buyer Tips Can Enhance Cost-Efficiency in Kitchen Knife Procurement?

To maximize cost efficiency when sourcing kitchen knives, consider the following strategies:

-

Negotiate with Suppliers: Always be prepared to negotiate terms, including price, payment terms, and delivery schedules. Building a good relationship with suppliers can lead to better deals over time.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the long-term costs associated with the product, including maintenance, durability, and replacement frequency. A higher upfront cost may be justified if the product lasts longer.

-

Understand Pricing Nuances for International Sourcing: Be aware of additional costs such as customs duties, tariffs, and local taxes that can impact the final price. Research these factors specific to your region, especially when importing from countries in Africa, South America, the Middle East, and Europe.

-

Conduct Market Research: Understanding current market trends and price ranges can provide leverage during negotiations. Regularly review competitor pricing and product offerings to stay informed.

Disclaimer on Indicative Prices

Pricing for kitchen knives can vary significantly based on the factors discussed above. Buyers should seek updated quotes from suppliers to obtain accurate pricing tailored to their specific needs and circumstances. Always conduct thorough due diligence to ensure that the prices reflect the current market conditions.

Alternatives Analysis: Comparing kitchen knife supplier With Other Solutions

Understanding the Importance of Alternative Solutions for Kitchen Knife Suppliers

In the competitive landscape of kitchen equipment sourcing, B2B buyers need to evaluate various solutions beyond traditional kitchen knife suppliers. This analysis provides insights into alternative approaches that can fulfill similar needs, helping international buyers from Africa, South America, the Middle East, and Europe make informed decisions.

Comparison Table: Kitchen Knife Supplier vs. Alternative Solutions

| Comparison Aspect | Kitchen Knife Supplier | Custom Knife Manufacturer | Electric Knife Sharpener |

|---|---|---|---|

| Performance | High-quality, durable knives suitable for various culinary tasks | Tailored knives with specific design and performance features | Provides consistent sharpening but limited to knife maintenance |

| Cost | Moderate to high, depending on brand and material | Typically higher due to customization | Low to moderate, one-time purchase with minimal ongoing costs |

| Ease of Implementation | Straightforward sourcing process, established suppliers available | Longer lead times due to production and customization | Easy to use, minimal setup required |

| Maintenance | Requires regular sharpening and care | Minimal maintenance needed if high-quality materials are used | Regular blade replacement may be necessary |

| Best Use Case | General commercial kitchens needing reliable knife options | Specialized culinary businesses requiring unique knife designs | Establishments focusing on knife maintenance and longevity |

What Are the Advantages and Disadvantages of Custom Knife Manufacturers?

Custom knife manufacturers offer tailored solutions that meet specific culinary requirements. The primary advantage of this alternative is the ability to design knives that cater to unique cooking styles or specific cuisines. However, the downside is the typically higher cost and longer lead times, which may not align with the needs of businesses requiring immediate supply.

How Do Electric Knife Sharpeners Compare for B2B Buyers?

Electric knife sharpeners provide a practical solution for maintaining the sharpness of kitchen knives. They are user-friendly and require little training, making them accessible for various staff members in a kitchen. The initial investment is generally low, but ongoing costs may arise from the need for replacement blades. This option is best suited for businesses that already have a knife supply and are looking to extend the life of their existing tools, rather than those seeking new knives.

Making the Right Choice: Which Solution Fits Your Business Needs?

When evaluating kitchen knife suppliers and their alternatives, B2B buyers should consider their specific operational needs and budget constraints. For businesses seeking reliable and versatile knives, traditional suppliers may be the best choice. Conversely, those with specialized requirements or a focus on maintenance might benefit from custom manufacturers or electric sharpeners. Ultimately, the decision should reflect the unique culinary demands of the business while balancing quality, cost, and practicality.

Essential Technical Properties and Trade Terminology for kitchen knife supplier

What Are the Essential Technical Properties of Kitchen Knives for B2B Buyers?

A stock image related to kitchen knife supplier.

Understanding the technical properties of kitchen knives is crucial for international B2B buyers, especially when sourcing high-quality products that meet specific culinary needs. Here are some key specifications to consider:

1. Material Grade

The material used in kitchen knives significantly influences their performance and durability. Common materials include stainless steel, carbon steel, and high-carbon stainless steel. Stainless steel offers corrosion resistance and ease of maintenance, while carbon steel provides sharpness and edge retention. Buyers should assess material grades, often denoted by standards such as AISI (American Iron and Steel Institute) or JIS (Japanese Industrial Standards), to ensure they are sourcing knives that will withstand their intended use.

2. Blade Hardness

Blade hardness is measured on the Rockwell scale (HRC) and indicates how well a knife can retain its edge. A higher HRC (typically between 56-62 for kitchen knives) means better edge retention but can also lead to brittleness. For B2B buyers, understanding the balance between hardness and brittleness is essential to select knives that meet operational demands without compromising safety.

3. Tolerance and Precision

Tolerance refers to the allowable deviation from a specified dimension, which is critical in knife manufacturing. Precision in manufacturing ensures uniformity in blade thickness and sharpness, directly affecting performance. B2B buyers should inquire about the manufacturer’s tolerance levels to ensure consistent product quality, which is essential for professional kitchens that rely on precision.

4. Edge Geometry

The edge geometry of a knife affects how it performs during cutting tasks. Common edge types include straight, serrated, and granton edges. Each design serves different culinary purposes—straight edges are ideal for slicing, while serrated edges excel at cutting through crusty surfaces. Understanding edge geometry helps buyers choose the right knife for specific culinary tasks, ensuring efficiency in food preparation.

5. Handle Ergonomics

The handle design plays a vital role in user comfort and safety. Ergonomic handles provide better grip and reduce fatigue during prolonged use. Materials such as wood, plastic, or composite are commonly used. B2B buyers should evaluate handle ergonomics to ensure that their staff can work efficiently without discomfort, which can impact productivity.

What Are Common Trade Terms Every Kitchen Knife Supplier Should Know?

Familiarity with industry terminology is essential for effective communication and negotiation in the kitchen knife supply chain. Here are some critical trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce goods under another company’s brand name. For kitchen knife suppliers, understanding OEM relationships can facilitate sourcing and branding opportunities. Buyers should clarify whether suppliers offer OEM services to enhance product customization.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory and cash flow. Buyers should negotiate MOQs based on their purchasing capacity to avoid overstocking or supply shortages.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. This term is vital for buyers looking to compare costs and terms from multiple suppliers. A well-prepared RFQ can lead to better pricing and more favorable terms, making it a key tool for procurement.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help B2B buyers understand their obligations and minimize risks during international transactions.

5. Lead Time

Lead time is the period from placing an order to receiving the goods. For kitchen knife suppliers, understanding lead times is crucial for inventory planning and meeting customer demands. Buyers should discuss lead times upfront to ensure timely delivery and avoid disruptions in their operations.

By grasping these essential properties and trade terms, international B2B buyers can make informed decisions when sourcing kitchen knives, ultimately leading to better product quality and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the kitchen knife supplier Sector

What Are the Key Market Dynamics and Trends Influencing the Kitchen Knife Supplier Sector?

The kitchen knife supplier sector is currently experiencing significant transformations driven by globalization, technological advancements, and shifting consumer preferences. For international B2B buyers from Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions. Key trends include the rise of e-commerce platforms that facilitate direct access to manufacturers, enabling buyers to compare prices and quality seamlessly. Additionally, advancements in manufacturing technologies, such as automation and precision engineering, have improved product consistency and reduced lead times, making it easier for businesses to meet consumer demand efficiently.

Moreover, the demand for high-quality, durable kitchen knives is on the rise, propelled by a growing interest in culinary arts and home cooking. Buyers should be aware of the increasing importance of branding and product differentiation, as suppliers enhance their offerings through unique designs, materials, and features. Sustainability is also becoming a vital consideration, with many consumers preferring products that align with eco-friendly practices. Therefore, B2B buyers need to evaluate suppliers not only on the quality and price of their knives but also on their ability to adapt to these evolving market demands.

How Is Sustainability Shaping Sourcing Decisions for Kitchen Knife Suppliers?

Sustainability and ethical sourcing have emerged as paramount considerations for B2B buyers in the kitchen knife sector. The environmental impact of production processes, from sourcing raw materials to manufacturing and distribution, is under increasing scrutiny. Buyers are now expected to prioritize suppliers who demonstrate a commitment to sustainable practices, such as using responsibly sourced metals and eco-friendly packaging.

Ethical supply chains are vital for maintaining brand reputation and consumer trust. Suppliers that hold certifications, such as ISO 14001 for environmental management or Fair Trade certifications, are often preferred by buyers who are conscious of their own corporate social responsibility. Additionally, the shift towards using ‘green’ materials, such as recycled stainless steel and sustainable wood for handles, is gaining traction. By choosing suppliers that align with these principles, B2B buyers can enhance their own sustainability credentials while meeting the growing demand for eco-friendly products.

What Is the Historical Context of the Kitchen Knife Supplier Sector?

The kitchen knife supplier sector has evolved significantly over the past few centuries. Initially, knives were handcrafted by blacksmiths, focusing primarily on functionality and durability. As culinary practices advanced and the global trade network expanded, the production of kitchen knives transitioned to industrial manufacturing, particularly in regions renowned for their craftsmanship, such as Japan and Germany. The introduction of stainless steel in the early 20th century revolutionized the industry, offering improved corrosion resistance and ease of maintenance.

In recent decades, globalization has further transformed the sector, allowing for the exchange of ideas, techniques, and materials across borders. This evolution has led to a more competitive market landscape, where B2B buyers now have access to a diverse range of products from various suppliers worldwide. Understanding this historical context can provide valuable insights into current sourcing strategies and the importance of innovation in meeting modern consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of kitchen knife supplier

-

How do I identify a reliable kitchen knife supplier for my business needs?

To identify a reliable kitchen knife supplier, conduct thorough research by checking their reputation in the industry. Look for reviews and testimonials from previous clients, and assess their experience in exporting to your region, especially if you are in Africa, South America, the Middle East, or Europe. Request samples to evaluate product quality, and ensure they comply with international standards. Establish communication to gauge their responsiveness and willingness to address your queries. Lastly, verify their certifications, such as ISO or other relevant quality assurance standards. -

What factors should I consider when evaluating kitchen knife quality?

When evaluating kitchen knife quality, consider the materials used (such as stainless steel or carbon steel), the blade’s edge retention, and the handle’s ergonomics. Check for certifications that indicate compliance with safety and quality standards. Additionally, inquire about the manufacturing processes, including heat treatment and sharpening techniques. The warranty offered can also be a significant indicator of quality, as reputable suppliers typically stand behind their products with robust guarantees. -

What customization options are available when sourcing kitchen knives?

Many suppliers offer customization options, including blade size, handle design, and engraving. You can also request specific finishes or materials that align with your brand identity. When discussing customization, ensure the supplier can meet your minimum order quantities (MOQs) and delivery timelines. It’s essential to provide detailed specifications to avoid misunderstandings and to request prototypes before placing a bulk order to assess the final product quality. -

What are the typical minimum order quantities (MOQs) for kitchen knives?

Minimum order quantities for kitchen knives can vary significantly based on the supplier and the type of knives. Generally, MOQs may range from 100 to 1,000 units for standard designs. Custom designs often come with higher MOQs due to the additional costs involved in production setup. Always clarify MOQs with potential suppliers to ensure they align with your purchasing capabilities, especially if you are starting a new business or expanding your product line. -

What payment terms should I expect from international kitchen knife suppliers?

Payment terms can vary widely among suppliers, but common practices include upfront deposits (typically 30-50%) with the balance due before shipment. Some suppliers may offer payment through letters of credit or escrow services for larger orders. It’s crucial to discuss and agree on payment terms upfront to avoid any financial misunderstandings. Consider using secure payment methods to protect your transaction, especially when dealing with suppliers in different countries. -

How can I ensure quality assurance during the kitchen knife sourcing process?

To ensure quality assurance, request detailed documentation of the supplier’s quality control processes. This can include inspection reports, certifications, and compliance with international standards. Consider conducting a factory audit if feasible, or hiring third-party inspection services to verify product quality before shipment. Establish clear communication regarding your quality expectations and ensure the supplier understands your requirements to minimize issues during delivery. -

What logistics considerations should I keep in mind when importing kitchen knives?

When importing kitchen knives, consider shipping methods, customs duties, and import regulations specific to your country. Air freight is faster but more expensive, while sea freight is more economical for larger orders. Understand the lead times associated with each method and factor in potential delays at customs. Partnering with a freight forwarder who specializes in international trade can help navigate the complexities of logistics and ensure timely delivery of your products. -

How do trade regulations affect sourcing kitchen knives from international suppliers?

Trade regulations can significantly impact your ability to source kitchen knives. Different countries may have specific tariffs, import quotas, and safety standards that must be adhered to. Research the regulations in both your country and the supplier’s country to ensure compliance. Additionally, consider any trade agreements that may facilitate smoother transactions. Consulting with a trade expert can help navigate these complexities and ensure that your imports meet all legal requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for kitchen knife supplier

In today’s competitive landscape, strategic sourcing is pivotal for international B2B buyers seeking reliable kitchen knife suppliers. By prioritizing quality, sustainability, and supplier relationships, businesses can enhance their product offerings and operational efficiency. Engaging with suppliers who understand local market dynamics can help mitigate risks associated with supply chain disruptions, especially for buyers in Africa, South America, the Middle East, and Europe.

What are the key benefits of strategic sourcing for kitchen knife suppliers? First, it facilitates access to innovative designs and materials, ensuring that your products stand out in the market. Second, it encourages cost savings through bulk purchasing and long-term agreements, enhancing your bottom line. Lastly, fostering partnerships with ethical suppliers contributes to a positive brand image, appealing to increasingly conscientious consumers.

Looking ahead, the demand for high-quality kitchen knives will continue to rise. B2B buyers are encouraged to leverage this opportunity by adopting a proactive sourcing strategy that emphasizes collaboration and sustainability. As the market evolves, embracing technological advancements and consumer trends will be essential. Take the next step: evaluate your sourcing strategies and align them with the best suppliers to position your business for future success.