The Ultimate Guide to Lan Cable Manufacturer (2025)

Introduction: Navigating the Global Market for lan cable manufacturer

In an increasingly interconnected world, sourcing the right LAN cable manufacturer is crucial for businesses aiming to enhance their network infrastructure. However, navigating the complexities of global supply chains can pose significant challenges, particularly for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe. With varying standards, quality assurance practices, and market dynamics, making an informed choice is paramount to ensure reliable connectivity and operational efficiency.

This comprehensive guide delves into the diverse landscape of LAN cable manufacturers, covering essential aspects such as types of cables, their applications across different industries, and best practices for supplier vetting. By understanding the intricacies of product specifications and compliance standards, buyers can better assess the value propositions of potential suppliers. Moreover, we will explore cost considerations and market trends that impact pricing, helping you to budget effectively while ensuring quality.

Empowering international B2B buyers with actionable insights, this guide aims to simplify the procurement process, enabling you to make informed purchasing decisions. Whether you are based in bustling cities like Jakarta or Dubai, or emerging markets across Africa, our objective is to equip you with the knowledge necessary to secure high-quality LAN cables that meet your specific business needs.

Understanding lan cable manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Unshielded Twisted Pair (UTP) | Cost-effective, lightweight, no shielding | Office networks, small businesses | Pros: Affordable, easy to install. Cons: Susceptible to interference. |

| Shielded Twisted Pair (STP) | Shielding to reduce electromagnetic interference | Industrial settings, data centers | Pros: Better performance in noisy environments. Cons: Higher cost, more complex installation. |

| Fiber Optic Cables | High-speed data transmission, immune to interference | Large enterprises, telecom companies | Pros: Extremely high bandwidth, long-distance capability. Cons: More expensive, requires specialized installation. |

| Category 6 (Cat 6) | Supports up to 10 Gbps, enhanced shielding | High-speed networks, data centers | Pros: Excellent performance for modern applications. Cons: Bulkier than lower categories. |

| Category 5e (Cat 5e) | Improved version of Cat 5, supports up to 1 Gbps | General office use, basic networking | Pros: Cost-effective for standard applications. Cons: Limited future-proofing compared to higher categories. |

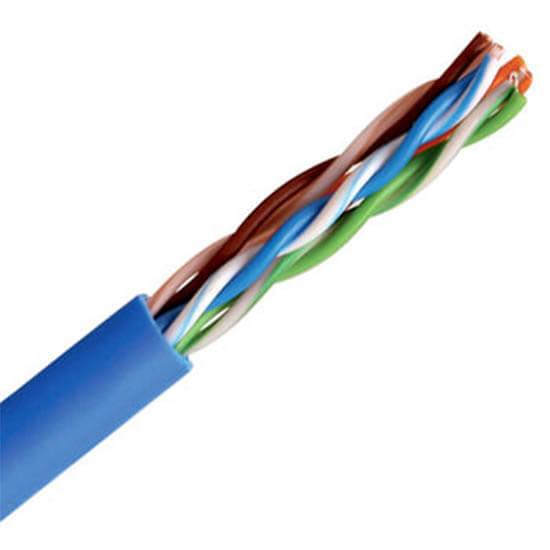

What Are the Characteristics of Unshielded Twisted Pair (UTP) Cables?

Unshielded Twisted Pair (UTP) cables are the most common type of LAN cable used in office and small business environments. They are lightweight, cost-effective, and easy to install, making them suitable for general networking needs. However, UTP cables are susceptible to electromagnetic interference, which can affect performance in environments with heavy machinery or wireless devices. B2B buyers should consider the specific networking demands of their operations when opting for UTP cables, particularly in terms of distance and potential interference.

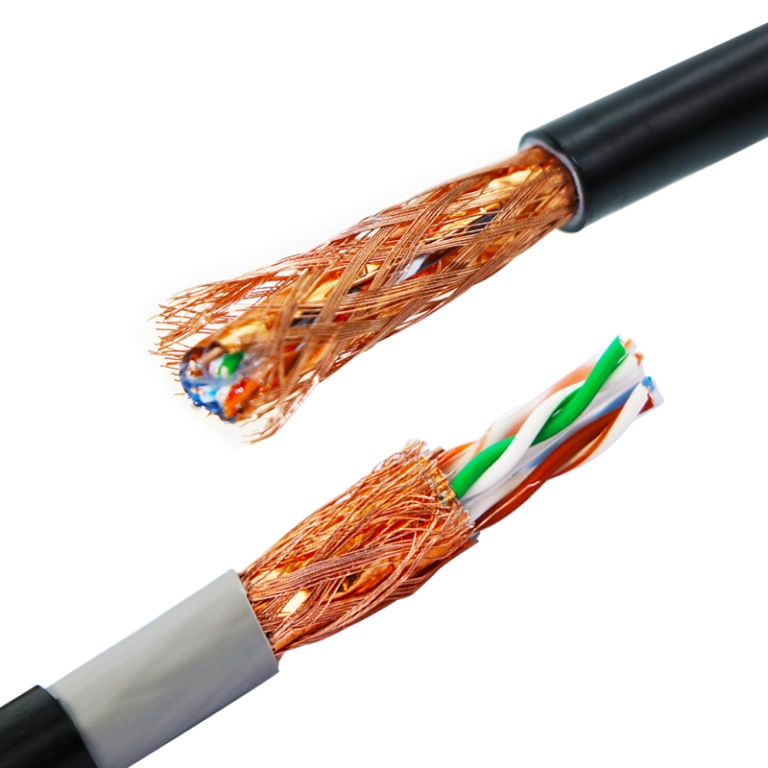

How Do Shielded Twisted Pair (STP) Cables Enhance Network Performance?

Shielded Twisted Pair (STP) cables incorporate additional shielding to protect against electromagnetic interference, making them ideal for industrial settings and data centers where equipment generates significant noise. They offer improved performance compared to UTP cables, particularly in environments with high interference. However, STP cables come at a higher cost and require more complex installation processes. B2B buyers should evaluate the operational environment and budget constraints when deciding on STP cables to ensure optimal performance.

What Advantages Do Fiber Optic Cables Offer for Large Enterprises?

Fiber optic cables are known for their ability to transmit data at extremely high speeds over long distances without the interference issues common in copper cables. They are particularly suitable for large enterprises and telecom companies that require robust, high-bandwidth connections. While fiber optic cables offer unmatched performance, they are also more expensive and necessitate specialized installation. B2B buyers should weigh the long-term benefits of fiber optics against initial costs, especially if their networking demands are expected to grow significantly.

Why Choose Category 6 (Cat 6) Cables for High-Speed Networks?

Category 6 (Cat 6) cables support data transmission speeds of up to 10 Gbps, making them an excellent choice for high-speed networks and data centers. They feature enhanced shielding to reduce interference, ensuring reliable performance for modern applications. While they are bulkier and more expensive than lower categories, the investment is often justified by the superior performance and future-proofing capabilities. B2B buyers should assess their current and anticipated networking needs to determine if Cat 6 is the right fit for their organization.

What Makes Category 5e (Cat 5e) Cables a Cost-Effective Solution?

Category 5e (Cat 5e) cables are an enhanced version of the original Cat 5, supporting data transmission speeds of up to 1 Gbps. They are widely used for general office applications and basic networking needs due to their cost-effectiveness. However, while Cat 5e cables provide satisfactory performance for most standard applications, they may not offer the same future-proofing as higher categories like Cat 6. B2B buyers should consider their current networking requirements and future growth when selecting Cat 5e cables, ensuring they align with their overall technology strategy.

Related Video: What Ethernet Cable to Use? Cat5? Cat6? Cat7?

Key Industrial Applications of lan cable manufacturer

| Industry/Sector | Specific Application of lan cable manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Network Infrastructure for Telecom Providers | Enhanced data transmission speeds and reliability | Quality certifications, compliance with local regulations |

| Manufacturing | Automation and Control Systems | Improved operational efficiency and reduced downtime | Ruggedness, temperature tolerance, and installation ease |

| Healthcare | Medical Device Connectivity | Real-time patient monitoring and data accuracy | Compliance with health regulations, data security features |

| Education | Campus Network Solutions | High-speed internet access for students and staff | Scalability, ease of installation, and long-term support |

| Smart Cities | IoT Integration for Urban Infrastructure | Enhanced service delivery and resource management | Compatibility with existing systems, future-proofing, and cost-effectiveness |

How Are LAN Cables Used in Telecommunications?

In the telecommunications sector, LAN cables are crucial for building robust network infrastructures. They facilitate high-speed data transmission, which is vital for service providers operating in competitive markets. By investing in quality LAN cables, telecom companies can ensure minimal downtime and maximize customer satisfaction. International buyers should prioritize sourcing cables that meet local quality certifications and are compliant with regional regulations to avoid connectivity issues.

What Role Do LAN Cables Play in Manufacturing?

Manufacturers leverage LAN cables for automation and control systems, which are essential for streamlining operations. These cables connect machines and systems, enabling real-time data exchange that enhances operational efficiency and reduces downtime. Buyers in this sector should consider the ruggedness and temperature tolerance of LAN cables, especially in environments with heavy machinery. Additionally, ease of installation can significantly impact project timelines and costs.

How Are LAN Cables Essential in Healthcare Settings?

In healthcare, LAN cables are instrumental for connecting medical devices, ensuring real-time monitoring of patients. This connectivity is crucial for accurate data collection and timely medical interventions. For international buyers in the healthcare sector, it is essential to source LAN cables that comply with health regulations and have strong data security features. This ensures that patient data remains confidential and secure while maintaining operational integrity.

Why Are LAN Cables Important for Educational Institutions?

Educational institutions utilize LAN cables for campus network solutions, which provide high-speed internet access to students and staff. This connectivity is vital for modern learning environments that rely on digital resources. B2B buyers in this sector should look for scalable solutions that can grow with the institution’s needs. Additionally, ease of installation and long-term support are critical factors to consider when sourcing LAN cables for educational applications.

How Do LAN Cables Contribute to Smart City Initiatives?

In the context of smart cities, LAN cables enable the integration of Internet of Things (IoT) devices, which enhance service delivery and resource management. These cables support the connectivity needed for smart traffic systems, public safety networks, and environmental monitoring. For international buyers, it is crucial to source cables that are compatible with existing systems and offer future-proofing capabilities. Cost-effectiveness is also a key consideration, as smart city projects often involve significant investments.

Related Video: Introduction to LAN – Networking Basics

3 Common User Pain Points for ‘lan cable manufacturer’ & Their Solutions

Scenario 1: Sourcing Quality LAN Cables in Diverse Markets

The Problem: B2B buyers often struggle to source high-quality LAN cables that meet international standards, especially when dealing with manufacturers from different regions. For instance, a company in South America may find it challenging to ensure that the LAN cables they procure from a manufacturer in Asia comply with local regulations and standards. This can lead to issues such as network inefficiencies, increased downtime, and potential damage to connected equipment due to poor-quality cables.

The Solution: To effectively source quality LAN cables, buyers should prioritize suppliers that provide comprehensive product specifications and certifications. Engage in thorough due diligence by verifying the manufacturer’s compliance with international standards such as ISO/IEC 11801 and TIA/EIA 568. Request samples before placing bulk orders to test the cables under your specific operating conditions. Additionally, building a relationship with local distributors can facilitate access to products that are compliant with regional standards, reducing the risk of incompatibility and ensuring reliable performance.

Scenario 2: Understanding Technical Specifications and Requirements

The Problem: Another common challenge faced by international B2B buyers is the complexity of technical specifications associated with LAN cables. Buyers may not fully understand terms like Cat5e, Cat6, or shielding types, leading to the procurement of cables that do not meet their specific networking needs. For example, a company in the UAE may purchase Cat5e cables thinking they are sufficient for their operations, only to realize later that they require the higher bandwidth capabilities of Cat6 cables for optimal performance.

The Solution: To overcome this knowledge gap, it’s crucial for buyers to invest time in understanding the technical specifications of LAN cables. Manufacturers should provide clear, detailed guides that outline the differences between cable types and their respective use cases. Additionally, buyers can benefit from consulting with network engineers or IT professionals who can assess their needs and recommend the appropriate cable type. Engaging in webinars or training sessions hosted by manufacturers can also provide valuable insights and help ensure that buyers make informed purchasing decisions.

Scenario 3: Managing Supply Chain and Delivery Challenges

The Problem: Supply chain disruptions can pose significant challenges for B2B buyers in securing timely delivery of LAN cables. Buyers in Africa or South America may experience delays due to shipping logistics, customs regulations, or unexpected demand fluctuations. These delays can hinder project timelines, lead to lost revenue, and damage relationships with clients relying on timely installations.

The Solution: To mitigate supply chain risks, buyers should establish strong communication channels with manufacturers and logistics partners. Implementing a just-in-time inventory strategy can help manage stock levels effectively, reducing the impact of delays. Additionally, buyers should inquire about the manufacturer’s inventory management practices and lead times during the sourcing process. Consider diversifying suppliers to reduce dependency on a single source, which can buffer against localized disruptions. By proactively managing supply chain relationships and expectations, B2B buyers can enhance their operational resilience and ensure timely access to essential LAN cables.

Strategic Material Selection Guide for lan cable manufacturer

When selecting materials for LAN cable manufacturing, international B2B buyers must consider various factors that impact performance, compliance, and suitability for specific applications. Below is an analysis of four common materials used in the production of LAN cables, focusing on their properties, advantages, disadvantages, and considerations for buyers from diverse regions, including Africa, South America, the Middle East, and Europe.

What are the Key Properties of Copper in LAN Cable Manufacturing?

Copper is the most widely used material for LAN cables, particularly in twisted pair and coaxial cables. Its excellent electrical conductivity (approximately 59.6 x 10^6 S/m) ensures minimal signal loss over distances, making it ideal for high-speed data transmission. Copper also has a high melting point (around 1,984°F or 1,085°C), which contributes to its durability under varying temperature conditions.

Pros & Cons of Copper:

– Pros: High durability, excellent conductivity, and flexibility in manufacturing.

– Cons: Higher cost compared to alternatives like aluminum, and susceptibility to corrosion if not properly insulated.

Impact on Application:

Copper cables are compatible with various media, including Ethernet and video transmission, making them versatile for different networking needs.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM and IEC, particularly regarding electrical safety and performance metrics. In regions with high humidity, the choice of copper alloy may also influence corrosion resistance.

How Does Aluminum Compare as a Material for LAN Cables?

Aluminum is often used as a cost-effective alternative to copper in LAN cables. While it has lower conductivity (approximately 37 x 10^6 S/m), it is significantly lighter and less expensive, which can reduce overall manufacturing costs.

Pros & Cons of Aluminum:

– Pros: Lower cost and weight, making it easier to install and transport.

– Cons: Lower conductivity and potential for higher signal loss over longer distances.

Impact on Application:

Aluminum is suitable for applications where cost is a primary concern, but it may not be ideal for high-performance networking environments.

Considerations for International Buyers:

Buyers should be aware of local regulations regarding the use of aluminum in electrical applications, as some regions may have specific standards governing its use.

What Role Does Polyethylene Play in LAN Cable Insulation?

Polyethylene (PE) is commonly used as an insulating material in LAN cables due to its excellent dielectric properties and resistance to moisture. It can withstand temperatures ranging from -40°F to 185°F (-40°C to 85°C), making it suitable for various environmental conditions.

Pros & Cons of Polyethylene:

– Pros: Excellent moisture resistance, lightweight, and good electrical insulation properties.

– Cons: Limited resistance to UV radiation, which can lead to degradation if exposed to sunlight.

Impact on Application:

PE insulation is ideal for outdoor cables and environments where moisture is a concern, ensuring reliable performance in adverse conditions.

Considerations for International Buyers:

Buyers should check for compliance with local environmental regulations, especially in regions with high UV exposure, as this may affect the longevity of the cables.

Why is PVC a Popular Choice for LAN Cable Jackets?

Polyvinyl Chloride (PVC) is frequently used for the outer jackets of LAN cables due to its durability and flame-retardant properties. It offers a good balance between performance and cost, with a temperature range of -13°F to 158°F (-25°C to 70°C).

Pros & Cons of PVC:

– Pros: Cost-effective, durable, and flame-resistant.

– Cons: Less environmentally friendly than alternatives like low-smoke zero-halogen (LSZH) materials.

Impact on Application:

PVC jackets are suitable for indoor applications where fire safety is a concern, making them a popular choice for commercial buildings.

Considerations for International Buyers:

Buyers in regions with stringent fire safety regulations should ensure that PVC cables meet local standards, such as those set by the European Union or the Middle East.

Summary Table of Material Selection for LAN Cable Manufacturing

| Material | Typical Use Case for LAN Cable Manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | High-speed data transmission | Excellent conductivity | Higher cost | High |

| Aluminum | Cost-sensitive applications | Lightweight and cost-effective | Lower conductivity | Low |

| Polyethylene | Outdoor and moisture-prone environments | Excellent moisture resistance | Limited UV resistance | Medium |

| PVC | Indoor commercial applications | Durable and flame-resistant | Less environmentally friendly | Medium |

This strategic material selection guide aims to empower international B2B buyers with the insights needed to make informed decisions when sourcing materials for LAN cable manufacturing.

In-depth Look: Manufacturing Processes and Quality Assurance for lan cable manufacturer

What Are the Main Stages of Manufacturing LAN Cables?

The manufacturing process of LAN cables involves several critical stages that ensure the final product meets both performance and quality standards. Understanding these stages is essential for international B2B buyers, particularly those sourcing from regions like Africa, South America, the Middle East, and Europe.

-

Material Preparation: The first step in manufacturing LAN cables is sourcing high-quality raw materials, including copper or fiber optic wires, insulation materials, and protective sheathing. Suppliers should provide certifications for their materials, such as RoHS compliance, to ensure they meet environmental standards.

-

Forming: This stage involves shaping the wires and insulation into the desired configuration. Techniques such as extrusion are commonly used for applying insulation around the wires. The precision of this process is crucial, as any imperfections can lead to signal loss or interference.

-

Assembly: The assembly process includes twisting the pairs of wires together, which is essential for reducing electromagnetic interference. Automated machines often perform this task to ensure consistency and efficiency. Additionally, connectors are attached during this stage, and the assembly must be done in a clean environment to avoid contamination.

-

Finishing: The final stage involves testing the assembled cables and applying protective outer sheathing. Quality checks are performed to ensure that the cables meet industry standards, such as Category 5e, 6, or 6a specifications. This stage also includes labeling and packaging the cables for distribution.

How Is Quality Assurance Implemented in LAN Cable Manufacturing?

Quality assurance (QA) is integral to the manufacturing process of LAN cables, ensuring that products meet international standards and customer specifications. B2B buyers should pay close attention to the quality assurance practices of potential suppliers.

-

International Standards Compliance: Manufacturers often adhere to international quality management standards, such as ISO 9001. Compliance with these standards indicates that a manufacturer has a robust quality management system in place, focusing on continuous improvement and customer satisfaction.

-

Industry-Specific Certifications: In addition to ISO, LAN cable manufacturers may need to obtain certifications specific to the telecommunications industry, such as CE marking in Europe and UL certification in the United States. These certifications ensure that the products meet specific safety and performance criteria.

-

Quality Control Checkpoints: Various checkpoints throughout the manufacturing process help maintain quality standards:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival at the manufacturing facility to ensure they meet specifications.

– In-Process Quality Control (IPQC): This step includes monitoring the production process in real-time, ensuring that any deviations from standards are corrected immediately.

– Final Quality Control (FQC): At this stage, finished products undergo rigorous testing to verify they meet performance standards before packaging and shipping.

What Testing Methods Are Commonly Used in LAN Cable Manufacturing?

B2B buyers should be aware of the testing methods employed by LAN cable manufacturers to ensure product quality. Common testing methods include:

-

Electrical Testing: This involves checking for continuity, resistance, and capacitance. Electrical tests ensure that the cables can carry signals effectively without degradation.

-

Transmission Testing: LAN cables undergo tests to measure performance parameters, such as insertion loss and crosstalk, which are critical for data transmission quality.

-

Environmental Testing: Cables may also be subjected to environmental conditions, including temperature variations and humidity, to assess their durability and reliability in various settings.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial for ensuring product reliability. Here are several strategies:

-

Conduct Supplier Audits: Regular audits help assess a supplier’s adherence to quality standards and manufacturing processes. Buyers should request audit reports to gain insights into the supplier’s operations.

-

Review Quality Control Reports: Manufacturers should provide detailed quality control reports, outlining testing methodologies, results, and any corrective actions taken. These documents provide transparency and reassurance about the product quality.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased evaluation of the manufacturer’s quality control practices. This step is particularly valuable for buyers unfamiliar with local suppliers.

What Are the Quality Control Nuances for International B2B Buyers?

Understanding the nuances of quality control is essential for international B2B buyers, especially when navigating different regulatory environments across regions like Africa, South America, the Middle East, and Europe.

-

Regulatory Compliance: Different regions have unique regulatory requirements for LAN cables. Buyers should familiarize themselves with local standards, such as the National Electrical Code (NEC) in the U.S. or IEC standards in Europe, to ensure compliance.

-

Cultural and Regional Considerations: Variations in manufacturing practices and quality perceptions may exist across different regions. Buyers should consider these differences when evaluating potential suppliers and their quality control measures.

-

Supplier Relationships: Building strong relationships with suppliers can facilitate better communication regarding quality expectations and standards. Engaging in regular discussions about quality control can lead to improved product offerings and partnerships.

By understanding the manufacturing processes and quality assurance practices of LAN cable manufacturers, international B2B buyers can make informed decisions, ensuring they select reliable suppliers that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘lan cable manufacturer’

In the competitive landscape of global sourcing, procuring LAN cables requires a strategic approach to ensure quality, reliability, and cost-effectiveness. This step-by-step checklist is designed to assist international B2B buyers—especially those from Africa, South America, the Middle East, and Europe—in identifying and selecting the right LAN cable manufacturers.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is vital for effective sourcing. Consider factors such as cable type (e.g., Cat5e, Cat6, Cat6a), length, shielding type, and performance standards. Providing detailed specifications helps manufacturers understand your needs and enables you to compare offerings accurately.

Step 2: Research Potential Manufacturers

Conduct comprehensive research to identify manufacturers that specialize in LAN cables. Utilize industry directories, trade shows, and online platforms to compile a list of potential suppliers. Pay attention to their market presence and reputation, as these factors can indicate reliability and quality.

Step 3: Verify Supplier Certifications

It’s essential to ensure that the manufacturers adhere to international standards and certifications such as ISO 9001 or UL certification. These certifications demonstrate a commitment to quality management and product safety. Request documentation to verify their compliance, which can help mitigate risks associated with subpar products.

Step 4: Request Samples for Quality Assessment

Before making a bulk order, request samples to evaluate the product quality firsthand. Examine the materials, construction, and overall performance of the cables. Testing samples in real-world applications can help you assess whether they meet your specific needs and expectations.

Step 5: Evaluate Pricing and Payment Terms

Compare pricing structures among shortlisted manufacturers, keeping in mind that the cheapest option may not always provide the best value. Consider the total cost of ownership, which includes shipping, taxes, and potential tariffs. Additionally, clarify payment terms to ensure they align with your budget and cash flow requirements.

Step 6: Assess Customer Support and Communication

Effective communication is crucial for a successful partnership. Evaluate how responsive and supportive potential suppliers are during your initial interactions. A supplier that provides clear answers and timely updates can significantly enhance your sourcing experience and help resolve any issues that may arise.

Step 7: Check References and Reviews

Finally, ask for references from other clients, particularly those in your region or industry. Reading reviews and testimonials can provide insights into the supplier’s reliability, delivery timelines, and after-sales service. This step is critical in ensuring that you are choosing a manufacturer with a proven track record.

By following this structured approach, B2B buyers can navigate the complexities of sourcing LAN cables effectively, ensuring they partner with manufacturers that meet their quality standards and business needs.

Comprehensive Cost and Pricing Analysis for lan cable manufacturer Sourcing

What Are the Key Cost Components in LAN Cable Manufacturing?

Understanding the cost structure of LAN cable manufacturing is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. Copper and fiber optics are common materials used in LAN cables. The fluctuating prices of these raw materials can influence overall manufacturing costs. Buyers should consider suppliers that offer competitive pricing for high-quality materials.

-

Labor: Labor costs vary by region. In countries with lower labor costs, manufacturers may offer more competitive pricing. However, it’s essential to balance cost with the skill level and expertise of the workforce, as this directly affects product quality.

-

Manufacturing Overhead: This includes the costs of utilities, factory rent, and equipment maintenance. Manufacturers with modern facilities and efficient processes typically have lower overhead costs, which can be passed on to buyers.

-

Tooling: Initial tooling costs can be significant, especially for custom or specialized cables. Buyers should inquire about tooling fees and whether they can be amortized over large orders, reducing the per-unit cost.

-

Quality Control (QC): Rigorous QC processes are vital for ensuring product reliability. While enhanced QC measures may increase initial costs, they help prevent defects and returns, ultimately leading to cost savings over time.

-

Logistics: Shipping and handling costs can vary dramatically based on the destination, volume of goods, and chosen Incoterms. It’s crucial for buyers to factor in these costs when evaluating pricing.

-

Margin: Manufacturers typically add a profit margin to their costs. Understanding the average margins in different regions can help buyers negotiate better deals.

How Do Price Influencers Affect LAN Cable Sourcing?

Several factors can influence the pricing of LAN cables:

-

Volume/MOQ: Larger orders generally lead to lower unit prices due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) that align with their needs.

-

Specifications and Customization: Custom cables tailored to specific requirements often come with higher costs. Buyers should clearly define their specifications to avoid unnecessary expenses.

-

Materials and Quality Certifications: Premium materials and certifications (like ISO or RoHS) can raise costs. Buyers should evaluate the necessity of these certifications based on their market requirements.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more but often provide better quality and service.

-

Incoterms: The chosen Incoterms can significantly affect landed costs. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for budgeting.

What Are Some Effective Buyer Tips for Sourcing LAN Cables?

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, consider the following tips:

-

Negotiate Wisely: Always be prepared to negotiate terms and pricing. Leverage multiple quotes to create competitive pressure among suppliers.

-

Focus on Cost-Efficiency: Look beyond the sticker price. Assess the Total Cost of Ownership (TCO), which includes initial costs, maintenance, and potential downtime.

-

Understand Pricing Nuances: Be aware that prices may vary due to regional factors such as import duties, currency fluctuations, and local economic conditions. Buyers should conduct market research to understand these variables.

-

Build Long-term Relationships: Developing strong relationships with suppliers can lead to better pricing and service over time. Consider establishing strategic partnerships rather than one-off transactions.

Conclusion: Navigating Pricing in LAN Cable Sourcing

Navigating the complex landscape of LAN cable sourcing requires a thorough understanding of cost structures and pricing influencers. By strategically evaluating materials, labor, logistics, and supplier capabilities, international B2B buyers can make informed decisions that align with their business objectives. Always keep in mind that prices are indicative and can fluctuate based on market conditions and specific supplier circumstances.

Alternatives Analysis: Comparing lan cable manufacturer With Other Solutions

Understanding Alternatives in LAN Cable Manufacturing

In the realm of networking solutions, choosing the right technology is crucial for ensuring optimal performance and cost efficiency. LAN cables are a fundamental part of establishing reliable network infrastructure, but international B2B buyers should be aware of viable alternatives that may offer unique advantages. This section compares LAN cable manufacturers with two alternative solutions: fiber optic cables and wireless networking technologies.

Comparison Table of LAN Cable Manufacturer and Alternatives

| Comparison Aspect | LAN Cable Manufacturer | Fiber Optic Cables | Wireless Networking Technologies |

|---|---|---|---|

| Performance | High-speed data transmission, reliable up to 100 meters | Superior speed and bandwidth over long distances, minimal signal loss | Varied speeds, dependent on environment and technology (Wi-Fi 6, etc.) |

| Cost | Generally lower upfront costs | Higher initial investment, but lower long-term costs | Lower initial setup costs, but potential for higher maintenance and upgrade costs |

| Ease of Implementation | Relatively straightforward installation | Requires specialized installation and equipment | Quick setup, no physical cabling required |

| Maintenance | Low maintenance if properly installed | Requires periodic checks, but generally durable | Regular updates and potential troubleshooting needed |

| Best Use Case | Ideal for local area networks (LANs) in office settings | Best for high-bandwidth applications (data centers, long distances) | Suitable for flexible environments, temporary setups, or areas with physical constraints |

What Are the Pros and Cons of Fiber Optic Cables?

Fiber optic cables offer remarkable advantages, particularly in terms of performance. They can transmit data over much longer distances without signal degradation, making them ideal for connecting multiple buildings or expansive campuses. However, the initial investment can be significantly higher than traditional LAN cables, and the installation process is more complex, requiring specialized knowledge. Maintenance is generally low, but periodic inspections are necessary to ensure optimal functionality.

How Do Wireless Networking Technologies Compare?

Wireless networking technologies provide unparalleled flexibility, allowing businesses to set up networks without the constraints of physical cabling. They are especially useful in environments where cabling is impractical or where mobility is a priority. While installation is straightforward, performance can be affected by environmental factors such as interference and distance from access points. Costs can vary based on the technology used (e.g., Wi-Fi 6) and may include ongoing expenses for maintenance and upgrades.

Conclusion: How Should International B2B Buyers Choose the Right Solution?

When selecting the right networking solution, international B2B buyers should consider their specific operational needs, budget constraints, and long-term goals. For businesses focused on high-speed, reliable connections over long distances, fiber optic cables may be the best option despite their higher initial costs. Conversely, for organizations needing flexible and quick-to-deploy solutions, wireless networking technologies could be more suitable. Ultimately, understanding the unique advantages and limitations of each alternative will empower buyers to make informed decisions that align with their business objectives.

Essential Technical Properties and Trade Terminology for lan cable manufacturer

What Are the Key Technical Properties of LAN Cables That B2B Buyers Should Know?

When selecting LAN cables, understanding the technical properties is crucial for ensuring optimal performance in various applications. Here are some essential specifications that buyers should consider:

-

Material Grade

– The grade of materials used in LAN cables significantly impacts their performance and durability. Common materials include copper (for its conductivity) and aluminum (for cost-effectiveness). Copper cables, such as Cat 6 and Cat 7, offer better transmission speeds and lower attenuation, making them ideal for high-speed networks. -

Cable Category

– LAN cables are categorized (e.g., Cat 5e, Cat 6, Cat 6a, Cat 7) based on their performance capabilities, particularly in terms of bandwidth and data transmission rates. Understanding these categories helps buyers choose the right cable for specific applications, such as standard office networking or high-speed data centers. -

Attenuation

– Attenuation refers to the loss of signal strength as it travels through the cable. It is measured in decibels (dB) per 100 meters. Lower attenuation values indicate better performance and longer distances without signal degradation. Buyers should consider attenuation specifications to ensure reliable communication over extended distances. -

Twist Rate

– The twist rate of the pairs within the cable is critical for reducing electromagnetic interference (EMI) and crosstalk. A higher twist rate generally enhances performance, especially in environments with significant electronic noise. Buyers should assess this property to ensure the cable will operate effectively in their specific settings. -

Jacket Material

– The outer jacket of the LAN cable protects it from physical damage and environmental factors. Common materials include PVC (Polyvinyl Chloride) and LSZH (Low Smoke Zero Halogen). Selecting the appropriate jacket material is essential for ensuring the cable’s longevity and safety, particularly in sensitive environments. -

Shielding Type

– Shielding can be unshielded (UTP), shielded twisted pair (STP), or foiled twisted pair (FTP). Shielded cables provide additional protection against interference, making them suitable for industrial or high-density environments. Buyers should evaluate the shielding type based on the potential for interference in their installation area.

What Are Common Trade Terms Used in the LAN Cable Industry?

Understanding industry terminology is vital for navigating negotiations and ensuring clarity in transactions. Here are some key terms that B2B buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the LAN cable industry, knowing OEM partners can help buyers ensure they are sourcing high-quality components that meet specific standards. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest quantity of products that a supplier is willing to sell. Understanding MOQ is crucial for buyers, especially when budgeting for projects or determining inventory needs. It can also influence pricing and negotiation strategies. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to solicit price bids for specific products or services. It helps buyers compare offers and negotiate better terms. Crafting a clear RFQ can streamline the procurement process and ensure all necessary specifications are covered. -

Incoterms (International Commercial Terms)

– Incoterms define the responsibilities of buyers and sellers in international trade. They clarify who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms can help buyers avoid unexpected costs and ensure smooth logistics when importing LAN cables. -

Lead Time

– Lead time is the amount of time it takes from placing an order to receiving the goods. Understanding lead times is essential for project planning and inventory management. Buyers should factor in lead time to ensure they have the necessary materials when needed. -

Certification Standards

– Certification standards, such as ISO or UL, indicate that a product meets specific quality and safety requirements. Buyers should look for certifications to ensure they are purchasing reliable and compliant LAN cables that meet international standards.

By familiarizing themselves with these essential technical properties and trade terms, B2B buyers can make informed decisions, optimize their procurement strategies, and ultimately enhance their networking capabilities.

Navigating Market Dynamics and Sourcing Trends in the lan cable manufacturer Sector

What Are the Current Market Dynamics in the LAN Cable Manufacturing Sector?

The LAN cable manufacturing sector is witnessing significant transformation driven by globalization, technological advancements, and increasing demand for robust networking solutions. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe must stay attuned to these dynamics to make informed sourcing decisions.

One of the key drivers is the surge in data consumption and the subsequent demand for high-speed internet connectivity. With the expansion of IoT (Internet of Things) and smart city initiatives, the need for reliable LAN cabling solutions has never been greater. Moreover, the increasing rollout of 5G technology across various regions is fueling a corresponding growth in demand for high-quality, high-performance cabling systems.

Emerging trends include the shift towards fiber optic LAN cables, which offer higher bandwidth and lower signal degradation over longer distances compared to traditional copper cables. Additionally, there is a notable trend towards modular and scalable networking solutions, allowing businesses to adapt their infrastructure as they grow. International buyers should also consider the impact of regional trade policies, which can affect pricing and availability.

How Is Sustainability Influencing B2B Sourcing in LAN Cable Manufacturing?

Sustainability is becoming a cornerstone of sourcing strategies in the LAN cable manufacturing sector. International buyers are increasingly prioritizing suppliers who demonstrate a commitment to environmental responsibility and ethical sourcing practices. The environmental impact of LAN cable production can be significant, particularly concerning the use of hazardous materials and energy consumption during manufacturing.

A stock image related to lan cable manufacturer.

A growing number of manufacturers are adopting ‘green’ certifications, such as RoHS (Restriction of Hazardous Substances) and ISO 14001, which signal their commitment to sustainable practices. These certifications ensure that products are made with minimal environmental impact and that waste is managed responsibly. Furthermore, buyers are encouraged to seek out manufacturers who utilize recycled materials in their products, thereby reducing the ecological footprint of their supply chains.

Ethical supply chains are also gaining traction, with buyers increasingly demanding transparency regarding labor practices and sourcing. This shift not only enhances brand reputation but also aligns with the growing consumer preference for sustainable and ethically produced goods. By prioritizing suppliers with strong sustainability credentials, businesses can mitigate risks and enhance their corporate social responsibility (CSR) initiatives.

What Is the Historical Context of LAN Cable Manufacturing?

The LAN cable manufacturing sector has evolved significantly since its inception in the late 20th century. Initially dominated by copper cabling, advancements in technology and the demand for higher bandwidth led to the introduction of fiber optic cables in the 1990s. This shift allowed for faster data transmission and greater reliability, paving the way for modern networking.

As the internet expanded and the digital landscape transformed, the need for more sophisticated networking solutions emerged. Over the years, manufacturers have adapted to these changes, focusing on innovation and quality to meet the demands of both commercial and residential markets. Today, the sector is characterized by a diverse range of products, including Category 5e, 6, and 7 cables, each catering to specific networking needs.

A stock image related to lan cable manufacturer.

Understanding this historical context is crucial for B2B buyers, as it highlights the evolution of technology and the importance of selecting suppliers that are not only innovative but also capable of meeting the current and future demands of the market.

Frequently Asked Questions (FAQs) for B2B Buyers of lan cable manufacturer

-

How do I choose the right LAN cable manufacturer for my business needs?

Selecting the right LAN cable manufacturer requires a thorough evaluation of several factors. Start by assessing the manufacturer’s reputation in the industry, focusing on their experience and client testimonials. Consider their product range, ensuring they offer various types of LAN cables suited to your specific requirements, such as Cat5e, Cat6, or fiber optic. Additionally, inquire about their certifications and compliance with international standards, as this can affect product quality and reliability. Finally, assess their ability to offer customization options, which can be crucial for meeting unique project specifications. -

What are the key certifications to look for in a LAN cable manufacturer?

When sourcing LAN cables, it’s vital to check for specific certifications that ensure product quality and compliance with international standards. Look for certifications such as ISO 9001 for quality management systems, ISO/IEC 11801 for structured cabling standards, and RoHS compliance to ensure environmental safety. Additionally, UL certification indicates that the cables meet safety standards in the U.S., while CE marking is essential for European markets. These certifications not only guarantee product reliability but also enhance your credibility when reselling or using these products in your projects. -

What is the minimum order quantity (MOQ) typically required by LAN cable manufacturers?

Minimum order quantities (MOQs) can vary significantly between LAN cable manufacturers, often depending on the type of cable, the materials used, and the manufacturer’s production capabilities. Generally, MOQs for standard cables can range from 100 to 1,000 units, while specialized or custom cables may require higher MOQs. It’s advisable to negotiate terms with potential suppliers, especially if you’re a smaller business or just starting. Building a strong relationship with the manufacturer can sometimes lead to more flexible MOQ arrangements, allowing you to better manage your inventory and cash flow. -

What payment terms should I expect when dealing with LAN cable manufacturers?

Payment terms can vary widely among LAN cable manufacturers, influenced by factors such as the supplier’s location and your business relationship. Common payment terms include a 30% deposit upfront with the balance due upon shipment, or net 30 days after delivery. Some manufacturers may offer more favorable terms for larger orders or established clients. It’s essential to clarify payment options and methods early in negotiations, as this can impact your cash flow. Additionally, consider using secure payment methods like letters of credit or escrow services to protect your financial interests. -

How can I ensure quality assurance in LAN cable manufacturing?

To ensure quality assurance, request detailed information about the manufacturer’s quality control processes. This includes in-house testing protocols, third-party certifications, and adherence to international standards. Ask for samples to evaluate cable performance, including factors such as signal integrity and durability. It’s also beneficial to visit the manufacturing facility if possible, or to engage third-party inspection services to validate the quality before shipment. Establishing a clear quality assurance agreement can help mitigate risks and ensure that the cables meet your specifications consistently. -

What are the logistics considerations when importing LAN cables from international manufacturers?

When importing LAN cables, logistics plays a critical role in ensuring timely delivery and cost-effectiveness. Start by understanding the shipping methods available, such as air freight for faster delivery or sea freight for larger shipments. Factor in customs duties, taxes, and any import regulations specific to your country, as these can affect overall costs. Collaborate with a reliable freight forwarder who can assist with documentation and compliance. Additionally, consider the manufacturer’s location and proximity to shipping ports, as this can influence lead times and shipping costs. -

Can LAN cables be customized to meet specific project requirements?

Yes, many LAN cable manufacturers offer customization options to cater to specific project needs. This can include variations in cable length, color coding, shielding types, and connector types. When discussing customization, clearly outline your requirements and ensure the manufacturer has the capability to deliver. Custom cables might also involve additional costs and longer lead times, so it’s important to plan accordingly. Establishing a strong line of communication with the manufacturer will facilitate a smoother customization process and help you achieve the desired specifications. -

What should I consider when vetting LAN cable suppliers from different regions?

When vetting LAN cable suppliers from regions like Africa, South America, the Middle East, and Europe, consider several key factors. First, evaluate the supplier’s reputation and reliability by researching customer reviews and industry feedback. Understand the regulatory environment in their region, as this may impact product quality and compliance. Assess their logistics capabilities and experience with international shipping, which is crucial for timely delivery. Additionally, consider cultural differences and communication styles that may affect your working relationship. Establishing a clear, open line of communication can lead to more effective collaboration and problem-solving.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for lan cable manufacturer

In today’s competitive landscape, effective strategic sourcing for LAN cable manufacturers is essential for international B2B buyers. By prioritizing quality, understanding supplier capabilities, and leveraging regional advantages, companies can secure the best products at optimal prices. Buyers from Africa, South America, the Middle East, and Europe should focus on forming long-term partnerships with manufacturers who demonstrate reliability, innovation, and responsiveness to market changes.

How Can Strategic Sourcing Enhance Your Procurement Process?

Strategic sourcing not only minimizes costs but also enhances supply chain resilience. By investing time in understanding market trends and supplier networks, businesses can mitigate risks associated with supply disruptions, particularly in volatile regions. This approach allows buyers to adapt quickly to evolving technological demands and customer preferences, ensuring they remain competitive.

What Should International Buyers Consider Moving Forward?

As you explore sourcing options, consider the increasing importance of sustainability and ethical practices in the manufacturing process. Collaborating with manufacturers who prioritize environmentally friendly production methods can enhance your brand’s reputation and align with global standards.

In conclusion, the future of LAN cable procurement is bright for those who embrace strategic sourcing. Now is the time to act—evaluate your sourcing strategies, foster meaningful partnerships, and position your business for sustained growth in a dynamic market.