The Ultimate Guide to Lithium Ion Battery Pack China (2025)

Introduction: Navigating the Global Market for lithium ion battery pack china

In today’s fast-evolving global market, sourcing lithium-ion battery packs from China presents a unique challenge for international B2B buyers. As industries shift towards renewable energy and electric mobility, the demand for reliable battery solutions has surged. This guide aims to equip businesses from regions such as Africa, South America, the Middle East, and Europe—including key markets like France and Kenya—with the knowledge needed to navigate this complex landscape.

Understanding the various types of lithium-ion battery packs, their applications, and the nuances of supplier vetting is critical. This comprehensive resource delves into essential factors such as production capabilities, quality assurance, and cost structures, enabling buyers to make informed purchasing decisions. It also highlights emerging trends and market dynamics that influence pricing and availability, ensuring that businesses can adapt to changing demands.

By leveraging the insights provided in this guide, international B2B buyers will be empowered to establish robust partnerships with Chinese suppliers, optimize their procurement strategies, and ultimately enhance their competitive edge in the lithium-ion battery market. Whether you are looking to power electric vehicles, renewable energy systems, or consumer electronics, this guide serves as a valuable tool to streamline your sourcing process and mitigate risks associated with global supply chains.

Understanding lithium ion battery pack china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Lithium Nickel Manganese Cobalt (NMC) | High energy density, excellent thermal stability | Electric vehicles, energy storage systems | Pros: High efficiency; Cons: Costly production. |

| Lithium Iron Phosphate (LiFePO4) | Long cycle life, enhanced safety features | Renewable energy systems, power tools | Pros: Safe; Cons: Lower energy density. |

| Lithium Cobalt Oxide (LCO) | High energy density, compact size | Smartphones, laptops, cameras | Pros: Lightweight; Cons: Shorter lifespan. |

| Lithium Polymer (LiPo) | Flexible form factor, lightweight | Drones, wearables, portable devices | Pros: Versatile; Cons: More expensive. |

| Lithium Titanate (LTO) | Fast charging capabilities, long cycle life | Electric buses, grid storage | Pros: Ultra-fast charging; Cons: Lower energy density. |

What are the Characteristics of Lithium Nickel Manganese Cobalt (NMC) Batteries?

Lithium Nickel Manganese Cobalt (NMC) batteries are distinguished by their high energy density and excellent thermal stability, making them ideal for applications requiring both power and safety. They are commonly used in electric vehicles and energy storage systems due to their ability to deliver high capacity while maintaining safety standards. When considering NMC batteries, B2B buyers should evaluate the higher production costs against the long-term efficiency benefits.

How Do Lithium Iron Phosphate (LiFePO4) Batteries Stand Out?

Lithium Iron Phosphate (LiFePO4) batteries are known for their long cycle life and enhanced safety features, making them suitable for renewable energy systems and power tools. Their ability to withstand high temperatures without risk of combustion is a significant advantage. Buyers should consider the trade-off between safety and energy density, as LiFePO4 batteries typically offer lower energy density compared to other types.

What Makes Lithium Cobalt Oxide (LCO) Batteries Popular?

Lithium Cobalt Oxide (LCO) batteries provide high energy density and compact size, which are critical for consumer electronics like smartphones, laptops, and cameras. They are favored for their lightweight nature, but buyers must be aware of their shorter lifespan and potential thermal issues. Evaluating the balance of performance and longevity is crucial for B2B buyers in tech industries.

Why Choose Lithium Polymer (LiPo) Batteries?

Lithium Polymer (LiPo) batteries are characterized by their flexible form factor and lightweight design, making them ideal for applications in drones, wearables, and portable devices. Their versatility comes at a premium price, which is a critical consideration for B2B buyers. When selecting LiPo batteries, understanding the specific application requirements and budget constraints is essential.

What are the Advantages of Lithium Titanate (LTO) Batteries?

Lithium Titanate (LTO) batteries are recognized for their ultra-fast charging capabilities and long cycle life, making them particularly suitable for electric buses and grid storage applications. Although they have a lower energy density compared to other lithium-ion batteries, their rapid charging feature can be a game-changer in specific sectors. B2B buyers should assess whether the benefits of fast charging align with their operational needs and budget limitations.

Related Video: Lithium Ion Battery Pack Architecture

Key Industrial Applications of lithium ion battery pack china

| Industry/Sector | Specific Application of lithium ion battery pack china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electric Vehicles (EVs) | Powering electric cars and buses | Reduces operational costs and enhances sustainability | Supplier reliability, compliance with international standards |

| Renewable Energy Storage | Grid energy storage systems | Stabilizes energy supply and integrates renewable sources | Capacity, cycle life, and scalability of battery packs |

| Consumer Electronics | Portable electronics (smartphones, laptops) | Improves device performance and extends battery life | Energy density, size, and weight considerations |

| Industrial Equipment | Forklifts and automated guided vehicles (AGVs) | Enhances productivity and reduces emissions | Durability, charge time, and compatibility with existing systems |

| Telecommunications | Backup power for cell towers and communication systems | Ensures uninterrupted service and reliability | Temperature tolerance, energy density, and maintenance support |

How are Lithium Ion Battery Packs Used in Electric Vehicles?

In the electric vehicle (EV) sector, lithium-ion battery packs from China are integral for powering electric cars and buses. These batteries provide a high energy density, enabling vehicles to travel longer distances on a single charge. The transition to electric vehicles not only reduces operational costs for businesses but also aligns with global sustainability goals. International buyers should consider the supplier’s reliability and adherence to international safety and quality standards to ensure the battery packs meet local regulations.

What Role Do Lithium Ion Battery Packs Play in Renewable Energy Storage?

Lithium-ion battery packs are critical in renewable energy storage systems, particularly for managing grid energy. They stabilize the energy supply by storing excess energy generated from renewable sources like solar and wind. This application is vital for businesses looking to integrate renewable energy into their operations, as it enhances energy efficiency and reduces reliance on fossil fuels. Buyers should focus on the capacity, cycle life, and scalability of the battery packs to match their energy storage needs effectively.

How Are Lithium Ion Battery Packs Enhancing Consumer Electronics?

In the consumer electronics sector, lithium-ion battery packs are used in devices such as smartphones and laptops, significantly improving their performance. These batteries allow for quicker charging times and longer usage periods, which are essential features for today’s tech-savvy consumers. For B2B buyers, factors such as energy density, size, and weight are critical considerations when sourcing battery packs to ensure compatibility with various electronic devices.

Why Are Lithium Ion Battery Packs Important for Industrial Equipment?

Lithium-ion battery packs are increasingly utilized in industrial equipment, including forklifts and automated guided vehicles (AGVs). These batteries enhance productivity by providing reliable power and reducing emissions compared to traditional lead-acid batteries. Businesses looking to upgrade their equipment should prioritize durability, charge time, and compatibility with existing systems to maximize efficiency and minimize downtime.

How Do Lithium Ion Battery Packs Support Telecommunications?

In the telecommunications industry, lithium-ion battery packs serve as backup power sources for cell towers and communication systems. They ensure uninterrupted service during power outages, which is crucial for maintaining connectivity in both urban and remote areas. When sourcing these battery packs, businesses must consider temperature tolerance, energy density, and the availability of maintenance support to ensure reliable operation in varying environmental conditions.

3 Common User Pain Points for ‘lithium ion battery pack china’ & Their Solutions

Scenario 1: Difficulty in Assessing Supplier Quality and Reliability

The Problem:

B2B buyers often face significant challenges when evaluating the quality and reliability of lithium-ion battery pack suppliers in China. With numerous manufacturers offering similar products, distinguishing between reputable suppliers and those that may deliver subpar products can be overwhelming. For instance, a buyer from Kenya might be tempted by low prices but later discover that the batteries have a high failure rate, leading to increased operational costs and potential damage to their brand reputation.

The Solution:

To effectively assess supplier quality, international buyers should conduct thorough due diligence. Start by requesting detailed product specifications and certifications, such as ISO 9001 and UN38.3 for safe transport. Additionally, leverage platforms like Alibaba or Global Sources to read customer reviews and ratings. Engaging with third-party inspection services before placing large orders can also mitigate risks. Consider establishing a trial order to evaluate the performance and reliability of the battery packs firsthand. This proactive approach not only builds trust but also ensures that the supplier meets your specific quality standards before committing to larger contracts.

Scenario 2: Navigating Compliance and Regulatory Challenges

The Problem:

International buyers often encounter complex regulatory requirements when importing lithium-ion battery packs from China. For example, a company in South America may struggle with understanding the specific safety and environmental regulations related to battery imports, leading to costly delays and potential fines if compliance is not met. The lack of clarity in regulations can create a daunting barrier to entry, particularly for businesses new to sourcing from overseas markets.

The Solution:

To navigate these compliance challenges, buyers should invest time in understanding the regulatory landscape of their target market. Start by consulting local regulatory agencies or industry associations for guidance on necessary certifications and import procedures. Collaborating with a logistics partner experienced in international shipping of hazardous materials can also provide valuable insights into compliance requirements. Additionally, consider working with a legal advisor familiar with trade laws to ensure that all aspects of the import process are covered. By prioritizing compliance, you can avoid costly disruptions and ensure a smoother entry into your market.

Scenario 3: Managing Supply Chain Disruptions

The Problem:

Supply chain disruptions, such as delays in shipping or shortages of raw materials, can severely impact the availability of lithium-ion battery packs. Buyers in Europe, for instance, may find themselves facing unexpected lead times that hinder production schedules, especially as demand for electric vehicles and renewable energy solutions rises. Such disruptions not only affect project timelines but can also lead to lost business opportunities and increased costs.

The Solution:

To mitigate the risks associated with supply chain disruptions, B2B buyers should implement a diversified sourcing strategy. Rather than relying solely on a single supplier, consider establishing relationships with multiple manufacturers across different regions. This approach provides flexibility and options in the event of disruptions. Additionally, maintaining open lines of communication with suppliers can help you stay informed about potential delays or issues. Employing inventory management software can also facilitate better forecasting and planning, allowing you to keep sufficient stock on hand to buffer against unforeseen disruptions. By proactively managing your supply chain, you can enhance resilience and ensure continuity in your operations.

Strategic Material Selection Guide for lithium ion battery pack china

When selecting materials for lithium-ion battery packs manufactured in China, it is crucial for international B2B buyers to consider various factors that affect performance, cost, and compliance. Below is an analysis of four common materials used in lithium-ion battery packs, focusing on their properties, advantages and disadvantages, and specific considerations for buyers from regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Lithium-Ion Battery Pack Materials?

1. Lithium Cobalt Oxide (LCO)

Lithium cobalt oxide is widely used as a cathode material in lithium-ion batteries. It offers a high energy density, making it suitable for applications requiring compact power sources, such as smartphones and laptops.

- Key Properties: High energy density, good thermal stability, and a voltage rating of about 3.7V.

- Pros: Excellent performance in terms of energy capacity, relatively simple manufacturing process.

- Cons: High cost and limited thermal stability at elevated temperatures, leading to potential safety issues.

- Impact on Application: Best suited for consumer electronics but may not perform well in high-temperature environments.

- Considerations for Buyers: Compliance with international safety standards (e.g., UL, IEC) is essential, especially for markets in Europe and North America.

2. Lithium Iron Phosphate (LFP)

Lithium iron phosphate is known for its safety and long cycle life, making it a popular choice for electric vehicles and energy storage systems.

- Key Properties: Lower energy density compared to LCO, excellent thermal stability, and a voltage rating of about 3.2V.

- Pros: High safety profile, long lifespan, and cost-effective in large-scale applications.

- Cons: Lower energy density leads to larger battery sizes, which may not be suitable for compact devices.

- Impact on Application: Ideal for applications where safety and longevity are prioritized, such as electric buses or stationary storage.

- Considerations for Buyers: Buyers should ensure compliance with regional standards like ASTM and JIS, particularly in South America and Africa.

3. Nickel Manganese Cobalt (NMC)

NMC is a versatile cathode material that balances performance, cost, and safety, making it suitable for a wide range of applications.

- Key Properties: High energy density, good thermal stability, and a voltage rating of about 3.6V.

- Pros: Versatile application across consumer electronics, EVs, and industrial storage; relatively lower cost than LCO.

- Cons: More complex manufacturing process compared to LFP, potential for thermal runaway if not managed properly.

- Impact on Application: Suitable for high-performance applications like electric vehicles and power tools.

- Considerations for Buyers: Buyers should be aware of the supply chain for nickel and cobalt, which may involve ethical sourcing concerns, particularly in Europe.

4. Graphite

Graphite is commonly used as an anode material in lithium-ion batteries due to its excellent conductivity and stability.

- Key Properties: High conductivity, good thermal stability, and a typical voltage rating of about 0.1V.

- Pros: Cost-effective, abundant, and well-established supply chains.

- Cons: Limited capacity compared to silicon-based alternatives, and potential for dendrite formation.

- Impact on Application: Suitable for a wide range of applications but may require enhancements for high-capacity needs.

- Considerations for Buyers: Buyers should consider sourcing from suppliers that adhere to environmental regulations, especially in regions like Africa and South America.

Summary Table of Material Selection for Lithium-Ion Battery Packs

| Material | Typical Use Case for lithium ion battery pack china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Lithium Cobalt Oxide (LCO) | Consumer electronics (smartphones, laptops) | High energy density | High cost, limited thermal stability | High |

| Lithium Iron Phosphate (LFP) | Electric vehicles, energy storage systems | Excellent safety and long cycle life | Lower energy density | Medium |

| Nickel Manganese Cobalt (NMC) | Electric vehicles, power tools | Balanced performance and cost | Complex manufacturing process | Medium |

| Graphite | General applications, batteries | Cost-effective and abundant | Limited capacity compared to alternatives | Low |

This guide provides essential insights for B2B buyers looking to make informed decisions when selecting materials for lithium-ion battery packs in China. Understanding the properties, advantages, and limitations of each material will aid in aligning product specifications with market demands and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for lithium ion battery pack china

What Are the Key Manufacturing Processes for Lithium Ion Battery Packs in China?

The manufacturing of lithium ion battery packs in China is a complex process that involves several stages, each critical for ensuring the final product’s performance and safety. The primary stages include material preparation, cell formation, assembly, and finishing.

How Is Material Prepared in Lithium Ion Battery Manufacturing?

Material preparation is the first step in the lithium ion battery pack manufacturing process. This stage involves sourcing high-quality raw materials, including lithium, cobalt, nickel, and graphite.

- Sourcing: International B2B buyers should prioritize suppliers with reliable sourcing channels, particularly from regions rich in lithium reserves, such as South America and Australia. This is essential for ensuring the sustainability and availability of materials.

- Quality Control: Buyers should inquire about the supplier’s material verification processes, ensuring that all materials meet international standards before entering production.

What Techniques Are Used in Cell Formation?

Once materials are prepared, the next stage is cell formation, where individual battery cells are created.

- Coating: The electrodes are coated with active materials, often using a slurry coating process. This technique is critical as it determines the energy density of the batteries.

- Drying and Pressing: After coating, the electrodes are dried and compressed to enhance their structural integrity. This step is vital to ensure the longevity and reliability of the battery cells.

- Electrolyte Filling: The cells are then filled with electrolyte, which facilitates ion transfer. The choice of electrolyte can significantly impact the battery’s performance and safety.

How Is Assembly Conducted in Lithium Ion Battery Pack Manufacturing?

The assembly stage combines multiple battery cells into a complete battery pack.

- Cell Arrangement: Cells are arranged in series and parallel configurations based on the desired voltage and capacity. Buyers should discuss with suppliers the flexibility in configurations to meet specific application needs.

- Connection: Cells are interconnected using busbars or tabs, which are welded or soldered to ensure a secure connection. Proper connection techniques are crucial for minimizing resistance and heat generation during operation.

- Integration of Battery Management System (BMS): The BMS is integrated to monitor cell voltages, temperatures, and overall performance. Buyers should ensure that the BMS complies with international safety standards.

What Are the Finishing Touches in Lithium Ion Battery Manufacturing?

The finishing stage involves finalizing the battery packs for delivery.

- Encapsulation: Battery packs are encapsulated in protective casings to prevent physical damage and chemical leakage. Discussing casing materials and designs with suppliers can help buyers select products best suited for their environmental conditions.

- Labeling and Packaging: Proper labeling, including safety warnings and specifications, is critical for compliance and user safety. Buyers should verify that labeling meets international regulations.

What Quality Assurance Measures Are Implemented in Lithium Ion Battery Manufacturing?

Quality assurance (QA) is paramount in lithium ion battery production, ensuring that products meet international standards and customer expectations.

Which International Standards Are Relevant for Lithium Ion Battery Quality Assurance?

B2B buyers should be aware of various international standards that govern lithium ion battery production:

- ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent product quality. Suppliers should provide documentation proving their compliance with ISO 9001.

- CE Marking: This indicates compliance with European health, safety, and environmental protection standards. Buyers from Europe, particularly, should ensure that their suppliers have CE certification.

- API Standards: For specific applications, especially in energy sectors, adherence to American Petroleum Institute (API) standards may be necessary.

What Are the Quality Control Checkpoints in Battery Manufacturing?

Quality control (QC) checkpoints are critical in maintaining product integrity throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This step verifies the quality of raw materials before production begins. Buyers should request IQC reports to ensure materials meet specified standards.

- In-Process Quality Control (IPQC): During production, regular checks are conducted to monitor the manufacturing process, ensuring adherence to specifications.

- Final Quality Control (FQC): After production, the final product undergoes rigorous testing to validate performance and safety before shipment.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control measures is crucial for B2B buyers, especially when dealing with international suppliers. Here are some actionable steps:

- Conduct Audits: Regular audits of suppliers can help buyers assess compliance with quality standards. Buyers should request audit reports to understand how suppliers maintain quality.

- Request Quality Reports: Suppliers should provide documentation of QC processes and results, including testing methods used and outcomes.

- Engage Third-Party Inspectors: Utilizing third-party inspectors can provide an unbiased evaluation of the manufacturing process and product quality. Buyers should consider this option to enhance trust in supplier capabilities.

What Common Testing Methods Are Used in Lithium Ion Battery Quality Assurance?

Various testing methods ensure that lithium ion batteries meet performance and safety standards:

- Capacity Testing: Measures the energy capacity of the battery to ensure it meets specified requirements.

- Cycle Life Testing: Evaluates how many charge/discharge cycles the battery can undergo before significant capacity loss occurs.

- Safety Testing: Includes thermal runaway tests, short-circuit tests, and drop tests to assess safety under various conditions.

What Are the Quality Control and Certification Nuances for International Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of QC and certification is essential:

- Regulatory Compliance: Different regions have unique regulations governing battery imports. Buyers should familiarize themselves with local regulations to ensure compliance.

- Cultural Considerations: Cultural differences may affect communication and expectations regarding quality. Building strong relationships with suppliers can help navigate these nuances.

- Market Trends: Staying updated on trends in battery technology and regulations can help buyers make informed decisions about their suppliers and products.

By understanding these key manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions when sourcing lithium ion battery packs from China, ensuring they receive high-quality products that meet their specific needs.

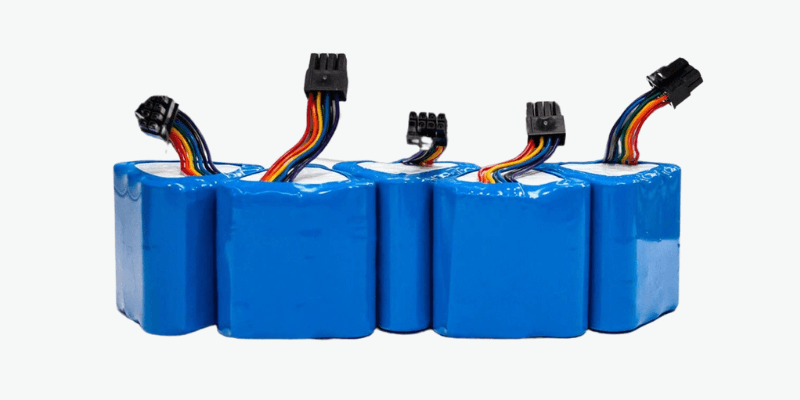

A stock image related to lithium ion battery pack china.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘lithium ion battery pack china’

In the competitive landscape of lithium-ion battery procurement, especially from China, international B2B buyers must navigate a series of critical steps to ensure they make informed and strategic sourcing decisions. This guide provides a practical checklist to streamline the process of sourcing lithium-ion battery packs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful procurement process. Identify the exact requirements such as capacity, size, weight, voltage, and intended application. This step ensures that you align your needs with the capabilities of potential suppliers, minimizing the risk of receiving unsuitable products.

- Capacity: Determine the energy storage capacity required for your applications.

- Application: Specify whether the batteries are for electric vehicles, consumer electronics, or renewable energy storage.

Step 2: Research the Market Landscape

Understanding the market dynamics is vital for identifying potential suppliers. Research the top lithium-ion battery manufacturers in China, focusing on their production capabilities, technology advancements, and market reputation. This step helps you shortlist suppliers that are capable of meeting your specifications.

- Market Leaders: Look for established manufacturers with a proven track record.

- Emerging Players: Consider innovative companies that may offer competitive pricing or unique technologies.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; look for reviews and testimonials that can provide insights into their reliability and product quality.

- Certifications: Ensure suppliers hold relevant certifications such as ISO, UL, or CE.

- Production Capacity: Assess whether the supplier can meet your volume requirements consistently.

Step 4: Request Samples and Conduct Quality Testing

Before placing a large order, request samples to evaluate the product quality. Conduct rigorous testing to ensure that the samples meet your specifications and performance criteria. This hands-on approach can prevent costly errors down the line.

- Testing Parameters: Evaluate samples for performance metrics such as charge cycles, discharge rates, and safety features.

- Long-term Reliability: Consider the lifespan and warranty offered by the supplier.

Step 5: Negotiate Terms and Pricing

Once you have identified a suitable supplier, it’s time to negotiate pricing, payment terms, and delivery schedules. Be clear about your budget constraints and seek flexibility in payment options, especially if you are ordering large quantities.

- Bulk Discounts: Inquire about discounts for larger orders.

- Payment Terms: Aim for favorable terms that protect your cash flow, such as staggered payments or letters of credit.

Step 6: Confirm Compliance with International Standards

Ensure that the lithium-ion battery packs comply with international safety and environmental standards. This is particularly important for markets in Europe and North America, where regulations are stringent. Confirm that your supplier adheres to these regulations to avoid potential legal issues.

- Safety Standards: Check for compliance with standards such as UN 38.3 for transportation safety.

- Environmental Regulations: Verify adherence to RoHS and WEEE directives if applicable.

Step 7: Establish a Clear Communication Channel

Finally, set up a reliable communication channel with your supplier. Regular updates on production status, shipping schedules, and potential issues can help foster a strong partnership and mitigate risks associated with sourcing.

- Point of Contact: Designate a specific person for communication to streamline processes.

- Feedback Loop: Encourage open lines of communication for ongoing improvements and adjustments.

By following this step-by-step checklist, international B2B buyers can effectively navigate the complexities of sourcing lithium-ion battery packs from China, ensuring that they secure high-quality products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for lithium ion battery pack china Sourcing

What Are the Key Cost Components for Sourcing Lithium Ion Battery Packs from China?

When evaluating the cost structure for lithium ion battery packs sourced from China, several components need to be considered:

-

Materials: The cost of lithium and other essential materials (such as cobalt, nickel, and graphite) significantly impacts the overall pricing. As global demand rises, prices for these raw materials can fluctuate. Sourcing from reputable suppliers who ensure quality can mitigate risks related to material shortages or price spikes.

-

Labor: Labor costs in China are generally lower than in many Western countries, but they can vary by region and manufacturer. Skilled labor is essential for quality assembly and production, so buyers should consider the balance between cost and expertise.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and administrative expenses. Efficient manufacturing processes can help reduce overhead, which can be a negotiable point when discussing pricing with suppliers.

-

Tooling: Initial tooling costs can be significant, especially for customized battery packs. These costs are typically amortized over the production run, so higher volumes can lower the per-unit tooling expense.

-

Quality Control (QC): Investing in robust QC processes is vital to ensure product reliability. This may involve additional costs, but it can prevent costly defects and returns, thus impacting the Total Cost of Ownership (TCO).

-

Logistics: Shipping costs can vary significantly based on the shipping method, distance, and current freight rates. Understanding Incoterms is crucial, as they define who bears the cost and risk during transportation.

-

Margin: Suppliers will include a profit margin in their pricing. This margin can vary based on market competition and the supplier’s positioning, so it’s worth negotiating.

How Do Price Influencers Affect Lithium Ion Battery Pack Costs?

Several factors influence the pricing of lithium ion battery packs:

-

Volume/MOQ: The Minimum Order Quantity (MOQ) can greatly affect pricing. Larger orders typically yield lower per-unit costs due to economies of scale. Buyers should assess their demand to negotiate favorable terms.

-

Specifications and Customization: Customized battery packs tailored to specific applications or performance criteria may incur additional costs. It’s important to clarify specifications upfront to avoid unexpected charges.

-

Material Quality and Certifications: Higher quality materials and certifications (like ISO or UL) can increase costs but also enhance product reliability and marketability. Buyers should weigh the benefits against the added expense.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a track record may offer better quality assurance but at a premium price. Researching and vetting suppliers is essential.

What Tips Can Help International B2B Buyers Negotiate Better Prices?

-

Understand Total Cost of Ownership (TCO): Beyond just the purchase price, consider logistics, maintenance, and potential warranty costs. A lower upfront cost may lead to higher long-term expenses.

-

Leverage Volume Discounts: If feasible, consolidating orders can help achieve better pricing. Discussing future orders may provide leverage in negotiations.

-

Negotiate Terms: Don’t hesitate to negotiate payment terms, delivery schedules, and warranty options. Flexibility can lead to cost savings.

-

Consider Incoterms: Understanding the implications of various Incoterms (like FOB, CIF, etc.) can help in assessing shipping costs and responsibilities, impacting overall pricing.

-

Stay Informed on Market Trends: Keeping an eye on global lithium prices and trade policies can provide insights into timing your purchases effectively.

Disclaimer on Pricing

It is crucial to note that prices for lithium ion battery packs can vary widely based on market conditions, supplier relationships, and other factors mentioned above. The pricing insights provided are indicative and should be validated through direct quotes from suppliers. Always conduct thorough due diligence before making purchasing decisions.

Alternatives Analysis: Comparing lithium ion battery pack china With Other Solutions

Understanding the Importance of Alternative Solutions in Battery Technology

As the demand for energy storage solutions continues to rise globally, particularly in regions like Africa, South America, the Middle East, and Europe, B2B buyers must explore various alternatives to the widely used lithium-ion battery packs produced in China. This analysis will compare lithium-ion technology against other viable solutions, helping international buyers make informed decisions tailored to their unique operational needs.

Comparative Analysis of Lithium-Ion Battery Pack and Alternatives

| Comparison Aspect | Lithium-Ion Battery Pack China | Solid-State Batteries | Nickel-Metal Hydride (NiMH) Batteries |

|---|---|---|---|

| Performance | High energy density, good cycle life | Higher energy density, longer lifespan | Moderate energy density, decent cycle life |

| Cost | Competitive, but varies by supplier | Currently high, but decreasing | Generally lower than lithium-ion but higher than lead-acid |

| Ease of Implementation | Established supply chains, well-understood technology | Emerging technology, limited suppliers | Widely available, established manufacturing processes |

| Maintenance | Low maintenance, robust design | Low maintenance, but technology still evolving | Moderate maintenance, susceptible to temperature variations |

| Best Use Case | Electric vehicles, consumer electronics | Electric vehicles, renewable energy storage | Hybrid vehicles, power tools |

Exploring Solid-State Batteries: A High-Performance Alternative

Solid-state batteries represent an innovative leap in battery technology, offering higher energy density and improved safety compared to traditional lithium-ion batteries. They replace the liquid electrolyte with a solid electrolyte, which not only enhances performance but also mitigates the risk of leaks and fires. However, the primary drawback is the current high cost and limited availability, which may pose challenges for B2B buyers looking for immediate solutions. As production scales and technology matures, costs are expected to decrease, making them a more viable option in the near future.

Evaluating Nickel-Metal Hydride Batteries: A Cost-Effective Solution

Nickel-metal hydride (NiMH) batteries have been a reliable alternative for many applications, particularly in hybrid vehicles and portable electronics. They are generally less expensive than lithium-ion batteries and have a good cycle life. However, their energy density is lower, meaning they take up more space for the same amount of power. Additionally, NiMH batteries are sensitive to temperature fluctuations, which can affect their performance and lifespan. For B2B buyers in sectors where cost is a primary concern and space is not a critical issue, NiMH batteries can be an attractive option.

Conclusion: Choosing the Right Battery Solution for Your Business Needs

Selecting the right battery solution involves a careful assessment of your specific operational requirements, including performance needs, budget constraints, and application environments. While lithium-ion battery packs from China offer robust performance and established supply chains, alternatives like solid-state and nickel-metal hydride batteries may provide unique advantages in certain contexts. B2B buyers should conduct a thorough analysis of these factors, potentially consulting with industry experts, to determine which battery technology aligns best with their strategic objectives. By taking a comprehensive approach to battery selection, businesses can enhance their operational efficiency and future-proof their energy storage solutions.

Essential Technical Properties and Trade Terminology for lithium ion battery pack china

What Are the Essential Technical Properties of Lithium Ion Battery Packs?

When sourcing lithium ion battery packs from China, understanding key technical properties is crucial for making informed purchasing decisions. Here are some essential specifications that international B2B buyers should consider:

-

Material Grade

– The material grade of lithium ion battery packs often includes lithium carbonate and lithium hydroxide, which significantly influence performance. Higher-grade materials usually offer better energy density and longevity. For buyers, ensuring the right material grade can lead to more efficient energy storage solutions. -

Energy Density

– Measured in watt-hours per kilogram (Wh/kg), energy density indicates how much energy a battery can store relative to its weight. Higher energy densities are essential for applications like electric vehicles and portable electronics. For B2B buyers, selecting battery packs with optimal energy density can enhance the overall performance of their products. -

Cycle Life

– This specification refers to the number of complete charge and discharge cycles a battery can undergo before its capacity significantly diminishes (often defined as 80% of its original capacity). A longer cycle life translates to lower replacement costs and reduced waste, which is particularly important for businesses focused on sustainability. -

Temperature Range

– Lithium ion batteries operate effectively within specific temperature ranges. Understanding the operational temperature limits is vital for applications in extreme environments. Buyers should ensure that the batteries meet the temperature requirements of their intended applications to avoid performance issues. -

Charging Time

– The time it takes to fully charge a battery pack can vary significantly. Fast-charging capabilities can be a key selling point for many end-users. B2B buyers should inquire about charging times to align with their product requirements and customer expectations. -

Tolerance Levels

– Tolerance refers to the permissible variation in dimensions and specifications. It is crucial for ensuring that battery packs fit correctly within devices and perform reliably. Buyers should discuss tolerance levels with suppliers to ensure compatibility with their designs.

What Are Common Trade Terms in the Lithium Ion Battery Market?

Familiarity with industry-specific terminology can greatly facilitate negotiations and purchasing processes. Here are some common terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce products that are marketed under another company’s brand. Understanding OEM relationships is essential for buyers looking to source battery packs that align with their product lines. -

MOQ (Minimum Order Quantity)

– MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This is crucial for B2B buyers to know, as it can impact inventory management and cash flow. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to solicit price quotes for specific products. For buyers, crafting a detailed RFQ can streamline the procurement process and ensure they receive competitive pricing. -

Incoterms (International Commercial Terms)

– These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risks, and delivery obligations, which is vital for budgeting and logistics planning. -

Lead Time

– This term refers to the time it takes from placing an order to receiving the goods. Understanding lead times is crucial for effective supply chain management, especially for businesses that depend on timely delivery for production schedules. -

Certification Standards

– Various certification standards (such as ISO, UL, CE) ensure that battery packs meet safety and quality regulations. Buyers should verify that their suppliers adhere to relevant certification standards to mitigate risks related to product quality and compliance.

By grasping these technical properties and trade terminologies, B2B buyers from regions such as Africa, South America, the Middle East, and Europe can make more informed decisions when sourcing lithium ion battery packs from China.

Navigating Market Dynamics and Sourcing Trends in the lithium ion battery pack china Sector

What Are the Current Market Dynamics and Key Trends in the Lithium Ion Battery Pack Sector?

The lithium ion battery pack sector is witnessing a surge driven by the global transition to renewable energy and the electrification of transportation. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of several key trends shaping this market. Firstly, the increasing demand for electric vehicles (EVs) and energy storage systems is propelling lithium ion battery production. Countries like China, Australia, and Chile are leading in lithium production, making it essential for buyers to consider the geographical sourcing implications.

Moreover, advancements in battery technology, such as solid-state batteries and enhanced recycling processes, are emerging trends that can significantly affect procurement strategies. Buyers should also monitor the rising importance of local supply chains to mitigate risks associated with geopolitical tensions and trade policies. As a result, forming strategic partnerships with manufacturers in China or investing in local suppliers can enhance supply chain resilience.

Lastly, the focus on digital transformation in supply chain management is becoming vital. B2B buyers can leverage data analytics and IoT technologies to optimize sourcing decisions and improve inventory management, thus reducing costs and increasing efficiency.

How Does Sustainability and Ethical Sourcing Impact the Lithium Ion Battery Pack Market?

Sustainability is becoming a cornerstone of the lithium ion battery pack industry, especially for international B2B buyers. The environmental impact of lithium extraction and battery production is significant, raising concerns about water usage and ecosystem disruption. Buyers must prioritize ethical sourcing practices to ensure that materials are obtained responsibly.

Certifications such as ISO 14001 (Environmental Management) and adherence to guidelines from organizations like the Responsible Business Alliance (RBA) can help buyers identify suppliers committed to sustainability. Furthermore, the demand for “green” materials is on the rise, with companies increasingly seeking batteries made from recycled materials or those that utilize less harmful chemicals in production.

Investing in suppliers who adhere to these sustainability practices not only meets regulatory requirements but also enhances brand reputation. Buyers can also benefit from government incentives aimed at promoting sustainable practices in battery production, which can lead to cost savings and improved market positioning.

What Is the Historical Context of Lithium Ion Battery Development?

The evolution of lithium ion battery technology dates back to the early 1990s when Sony commercialized the first lithium ion battery. This innovation revolutionized portable electronics and laid the foundation for subsequent advancements. Over the decades, improvements in energy density, charge cycles, and safety features have propelled lithium ion batteries into various sectors, including renewable energy storage and electric vehicles.

Today, the lithium ion battery market is characterized by rapid technological advancements and increasing demand, resulting in significant investments from major players worldwide. Understanding this historical context is crucial for B2B buyers as it highlights the ongoing innovation and the competitive landscape, allowing them to make informed sourcing decisions that align with future trends.

In summary, by staying informed about market dynamics, prioritizing sustainability, and understanding the historical development of lithium ion technology, international B2B buyers can navigate the complexities of sourcing lithium ion battery packs effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of lithium ion battery pack china

-

How do I ensure the quality of lithium ion battery packs sourced from China?

To ensure quality, conduct thorough due diligence on potential suppliers. Request certifications such as ISO 9001 and UL certification, which demonstrate compliance with international quality standards. Additionally, consider visiting the manufacturing facility or using third-party inspection services to assess quality control processes. Establish a clear quality assurance agreement before placing orders, detailing your specifications and expectations. -

What are the typical minimum order quantities (MOQ) for lithium ion battery packs from Chinese suppliers?

MOQs for lithium ion battery packs can vary significantly based on the supplier and product specifications. Generally, MOQs range from 100 to 1,000 units. Suppliers may offer flexibility on MOQs for repeat customers or larger contracts. When negotiating, clearly communicate your needs and explore options for sample orders to test quality before committing to larger quantities. -

What payment terms should I expect when sourcing lithium ion battery packs from China?

Payment terms often depend on the supplier’s policies and the size of your order. Common arrangements include a 30% deposit upfront with the remaining 70% due before shipment. Some suppliers may offer credit terms or payment through secure platforms like Alibaba Trade Assurance. Always clarify payment terms in advance to avoid misunderstandings and protect your investment. -

How can I customize lithium ion battery packs for my specific application?

Customization options typically include changes to capacity, size, shape, and connector types. Discuss your specific requirements with potential suppliers early in the negotiation process. Many manufacturers in China are equipped to handle custom projects, but ensure they have experience with similar modifications. Request prototypes to validate functionality and performance before full-scale production. -

What logistics considerations should I keep in mind when importing lithium ion battery packs from China?

Logistics for importing battery packs involve several factors, including shipping methods, customs clearance, and compliance with international regulations. Choose a reliable freight forwarder familiar with hazardous materials regulations, as lithium ion batteries are classified as dangerous goods. Ensure you have all necessary documentation, such as commercial invoices and packing lists, to facilitate smooth customs processing. -

What are the key factors to consider when vetting suppliers for lithium ion battery packs?

When vetting suppliers, consider their industry experience, production capacity, and customer reviews. Look for suppliers with a proven track record in producing lithium ion batteries and a strong understanding of your market needs. Verify their compliance with international safety standards and ask for references from previous clients to gauge reliability and service quality.

-

How can I protect myself against potential scams when sourcing from China?

To protect against scams, use reputable platforms like Alibaba or Global Sources, which offer buyer protection services. Conduct background checks on suppliers and request documentation of their business licenses and certifications. Avoid suppliers that demand full payment upfront without providing a detailed contract. Establishing a payment plan and using escrow services can also add layers of security to your transactions. -

What are the environmental regulations I need to be aware of when importing lithium ion batteries?

When importing lithium ion batteries, familiarize yourself with both your country’s regulations and international standards regarding hazardous materials. Many regions have specific guidelines for the disposal and recycling of batteries. Ensure your supplier provides compliant products and that you have the necessary documentation for safe transportation and disposal. This not only avoids legal issues but also aligns your business with sustainability practices.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for lithium ion battery pack china

What are the Key Takeaways for B2B Buyers in Lithium Ion Battery Packs?

In navigating the competitive landscape of lithium-ion battery packs from China, international B2B buyers must prioritize strategic sourcing to leverage cost efficiencies and high-quality products. Understanding the supply chain dynamics, from raw material sourcing to manufacturing capabilities, is crucial. Buyers from Africa, South America, the Middle East, and Europe should focus on establishing long-term partnerships with reputable suppliers who demonstrate transparency and reliability.

How Can Strategic Sourcing Enhance Your Business?

Strategic sourcing not only minimizes procurement risks but also aligns with evolving sustainability practices that are increasingly important in global markets. As lithium production intensifies, particularly in regions like Latin America, buyers should consider diversifying their supplier base to mitigate potential disruptions. This approach fosters resilience and ensures access to innovative technologies that enhance battery performance.

What Does the Future Hold for Lithium Ion Battery Pack Procurement?

Looking ahead, the demand for lithium-ion battery packs is poised to grow exponentially, driven by the global push towards renewable energy and electric vehicles. International B2B buyers are encouraged to stay informed about market trends and technological advancements. Engaging with industry leaders and participating in trade shows can provide valuable insights and networking opportunities. By embracing strategic sourcing today, businesses can secure a competitive edge in the rapidly evolving energy landscape.