The Ultimate Guide to Measuring Instruments Supplier (2025)

Introduction: Navigating the Global Market for measuring instruments supplier

Navigating the complexities of the global market for measuring instruments can be daunting for international B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe, including countries like Germany and Poland. The challenge lies not just in sourcing high-quality measuring instruments but also in ensuring compliance with local regulations, understanding market demands, and evaluating supplier credibility. This comprehensive guide aims to demystify the process of sourcing measuring instruments by providing insights into various types, applications, and the critical aspects of supplier vetting.

Throughout this guide, we will explore the different categories of measuring instruments available in the market, their specific applications across industries, and the crucial factors that influence pricing. We will also delve into strategies for assessing supplier reliability, including quality certifications and customer testimonials, to empower you to make informed purchasing decisions.

By equipping B2B buyers with the necessary knowledge and actionable insights, this guide seeks to streamline the procurement process, reduce risks, and ultimately enhance operational efficiency. As businesses navigate the competitive landscape of global trade, understanding how to effectively source measuring instruments will not only support compliance and quality assurance but also drive growth and innovation in their respective markets.

Understanding measuring instruments supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Calibration Equipment Suppliers | Provide instruments for calibrating measuring devices. | Manufacturing, Aerospace, Automotive | Pros: Ensures accuracy; Cons: Can be costly. |

| Industrial Measuring Tools | Focus on tools like calipers, micrometers, and gauges. | Manufacturing, Construction | Pros: Versatile; Cons: Requires skilled use. |

| Testing Instrument Suppliers | Offer devices for testing physical properties (e.g., pressure). | Oil & Gas, Construction | Pros: Reliable data; Cons: Maintenance needed. |

| Electronic Measurement Suppliers | Supply digital measuring devices (e.g., multimeters). | Electronics, Telecommunications | Pros: High precision; Cons: May require training. |

| Environmental Measurement Tools | Specialize in monitoring environmental parameters (e.g., pH). | Environmental Management, Agriculture | Pros: Vital for compliance; Cons: Can be complex. |

What Are Calibration Equipment Suppliers and Their Importance in B2B?

Calibration equipment suppliers are pivotal in ensuring that measuring devices operate accurately and reliably. They provide specialized instruments designed to calibrate various equipment, which is essential in sectors like manufacturing and aerospace where precision is non-negotiable. When purchasing, B2B buyers should consider the supplier’s certification and the range of calibration services offered. Investing in quality calibration equipment can help avoid costly errors in production and enhance product quality.

How Do Industrial Measuring Tools Benefit B2B Buyers?

Industrial measuring tools encompass a broad range of devices including calipers, micrometers, and gauges. These tools are essential for ensuring that components meet specified tolerances in manufacturing and construction. B2B buyers should assess the durability and precision of these tools, as well as the availability of calibration services. While they offer versatility and are crucial for quality control, buyers must ensure that their staff is trained in using these tools effectively to maximize their benefits.

What Are the Key Features of Testing Instrument Suppliers?

Testing instrument suppliers provide devices that measure physical properties such as pressure, temperature, and flow. These instruments are vital in industries like oil and gas and construction, where safety and efficiency depend on accurate measurements. Buyers should look for suppliers that offer comprehensive testing solutions and consider the reliability and ease of use of the instruments. Although these tools provide reliable data, they often require regular maintenance to ensure continued accuracy.

Why Choose Electronic Measurement Suppliers for Your Business?

Electronic measurement suppliers focus on digital devices like multimeters, oscilloscopes, and data loggers. These instruments are known for their high precision and are widely used in electronics and telecommunications. B2B buyers should consider the technological advancements of these devices, as well as their compatibility with existing systems. While electronic measurement tools can provide high accuracy, they may also necessitate additional training for staff to utilize them effectively.

How Do Environmental Measurement Tools Support Compliance in B2B Operations?

Environmental measurement tools are designed to monitor various environmental parameters, including air quality, water quality, and soil conditions. These tools play a crucial role in sectors like environmental management and agriculture, helping businesses comply with regulations and improve sustainability practices. When selecting suppliers, B2B buyers should evaluate the range of parameters measured and the complexity of the tools. Although these instruments are vital for compliance, their use can be complex and may require specialized training for effective operation.

Related Video: STATIC AND DYNAMIC CHARACTERISTICS OF MEASURING INSTRUMENTS | Static vs Dynamic characteristics

Key Industrial Applications of measuring instruments supplier

| Industry/Sector | Specific Application of measuring instruments supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Precision Measurement Tools for Quality Control | Ensures product consistency and reduces defects | Calibration standards, supplier certifications, support services |

| Oil & Gas | Flow Meters for Resource Management | Optimizes resource extraction and minimizes waste | Environmental compliance, measurement accuracy, maintenance support |

| Pharmaceuticals | Analytical Instruments for Drug Testing | Ensures compliance with regulatory standards | Validation processes, supplier reliability, technical support |

| Agriculture | Soil Moisture Sensors for Crop Management | Enhances yield and resource efficiency | Durability in harsh environments, data integration capabilities, support services |

| Construction | Surveying Instruments for Project Management | Improves accuracy in project planning and execution | Calibration, portability, user training, and support |

How Are Measuring Instruments Used in Manufacturing for Quality Control?

In the manufacturing sector, precision measurement tools are critical for quality control. These instruments, such as calipers and micrometers, help ensure that products meet specified tolerances and standards. By using precise measurements, businesses can significantly reduce defects and improve overall product quality, which is essential for maintaining customer satisfaction and competitiveness in global markets. International B2B buyers should consider sourcing suppliers who offer calibration standards and reliable after-sales support to maintain measurement accuracy.

What Role Do Flow Meters Play in the Oil & Gas Industry?

Flow meters are essential in the oil and gas industry for effective resource management. They measure the flow of liquids and gases, enabling companies to optimize extraction processes and minimize waste. Accurate flow measurement can lead to significant cost savings and improved operational efficiency. Buyers from regions like Africa and the Middle East should prioritize suppliers who comply with environmental regulations and provide maintenance support to ensure long-term reliability.

How Do Analytical Instruments Benefit the Pharmaceutical Sector?

In the pharmaceutical industry, analytical instruments are crucial for drug testing and ensuring compliance with stringent regulatory standards. These instruments, including spectrometers and chromatographs, help in the accurate analysis of chemical compositions, ensuring the safety and efficacy of medications. International buyers should focus on suppliers with robust validation processes and a proven track record to guarantee the reliability of these critical instruments.

How Can Soil Moisture Sensors Enhance Agricultural Practices?

Soil moisture sensors are invaluable for crop management in agriculture, allowing farmers to monitor soil conditions accurately. By utilizing these sensors, businesses can enhance yield and resource efficiency, ensuring optimal irrigation practices. Buyers should seek durable products capable of withstanding harsh environmental conditions and those that offer data integration capabilities for comprehensive farm management.

Why Are Surveying Instruments Important for Construction Projects?

Surveying instruments, such as total stations and GPS equipment, are essential for effective project management in construction. They improve accuracy in project planning and execution, reducing the likelihood of costly errors. B2B buyers in the construction sector should consider the portability of these instruments, as well as the availability of user training and technical support, to ensure they can be effectively utilized on-site.

Related Video: Types Of Flowmeters And Their Industrial Applications.

3 Common User Pain Points for ‘measuring instruments supplier’ & Their Solutions

Scenario 1: Difficulty in Ensuring Measurement Accuracy Across Diverse Environments

The Problem:

B2B buyers often face challenges in ensuring the accuracy of measuring instruments in varying environmental conditions. For instance, a construction firm operating in both humid coastal regions and arid deserts may experience discrepancies in measurement readings due to temperature fluctuations and humidity levels. Such inaccuracies can lead to costly mistakes in project specifications, affecting both safety and compliance with regulations. This scenario is particularly acute for buyers who lack expertise in selecting instruments suitable for specific environmental conditions.

The Solution:

To mitigate accuracy issues, buyers should first conduct a thorough environmental analysis before selecting measuring instruments. This includes assessing temperature ranges, humidity levels, and potential exposure to dust or corrosive elements. When sourcing measuring instruments, opt for those with environmental ratings that match the operational conditions. Suppliers often provide detailed specifications regarding the performance of their instruments under various conditions; leverage this information to guide your selection. Additionally, consider investing in calibration services offered by suppliers to ensure ongoing accuracy over time. Regularly scheduled recalibrations can be pivotal in maintaining precision, especially in fluctuating environments.

Scenario 2: Complexity in Integrating New Measuring Instruments with Existing Systems

The Problem:

Another significant pain point for B2B buyers is the complexity involved in integrating new measuring instruments with existing technological systems. Companies often rely on a combination of legacy systems and new technologies, and integrating these can pose significant hurdles. For instance, a manufacturing company may need to integrate new digital measuring tools with older manual systems, creating compatibility issues that can disrupt operations and lead to data discrepancies.

The Solution:

To address integration challenges, begin by conducting a comprehensive audit of your current systems to identify compatibility requirements. When engaging with suppliers, explicitly communicate your existing infrastructure and ask for detailed information about how their instruments can interface with your systems. Seek suppliers that offer customization options or have a history of successful integrations in similar environments. Additionally, consider using middleware solutions that can bridge compatibility gaps. Engaging IT professionals early in the selection process can also streamline integration efforts, ensuring that both hardware and software work seamlessly together.

Scenario 3: Insufficient Training and Support for Personnel Using Measuring Instruments

The Problem:

A common issue faced by B2B buyers is the lack of adequate training and support for personnel who will operate measuring instruments. Without proper training, employees may misuse the equipment, leading to inaccurate measurements and potential safety hazards. This is especially critical in sectors such as healthcare, where precision is paramount. Buyers often find themselves with advanced instruments that their staff are ill-prepared to use effectively.

The Solution:

To ensure effective utilization of measuring instruments, buyers should prioritize training and support as part of the procurement process. Engage with suppliers who offer comprehensive training programs, both on-site and online, tailored to the specific instruments purchased. Request detailed user manuals and operational guidelines during the purchase phase. Establish a feedback loop with employees to identify ongoing training needs and consider refresher courses as part of your operational strategy. Additionally, leveraging online resources such as video tutorials and webinars can enhance understanding and operational proficiency, ultimately leading to improved measurement accuracy and safety compliance.

Strategic Material Selection Guide for measuring instruments supplier

When selecting materials for measuring instruments, international B2B buyers must consider various factors that influence performance, durability, and cost. Here, we analyze four common materials used in the manufacturing of measuring instruments, focusing on their properties, advantages, disadvantages, and implications for buyers from regions like Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Stainless Steel in Measuring Instruments?

Stainless steel is renowned for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures and pressures. It typically has a temperature rating of up to 800°C and can handle pressures exceeding 1000 psi, making it suitable for a wide range of applications, including industrial and laboratory environments.

Pros and Cons:

– Pros: Stainless steel’s durability and resistance to rust and corrosion make it ideal for harsh environments. It is also easy to clean and sterilize, which is crucial in industries like food and pharmaceuticals.

– Cons: The primary drawback is its higher cost compared to other materials like plastic. Additionally, stainless steel can be heavier, which may not be suitable for portable measuring devices.

Impact on Application:

Stainless steel is compatible with a variety of media, including water, oils, and chemicals. However, it may not be suitable for highly acidic or alkaline substances without proper coatings.

Considerations for International Buyers:

Buyers must ensure compliance with international standards such as ASTM and DIN for stainless steel grades. Understanding local regulations regarding material certifications is crucial, especially in regions with stringent quality control.

How Does Plastic Compare as a Material for Measuring Instruments?

Plastic, particularly high-performance polymers like PTFE and PVC, offers a lightweight and cost-effective alternative to metals. These materials are often used in applications where weight is a concern or where corrosion resistance is paramount.

Pros and Cons:

– Pros: Plastics are generally less expensive and lighter than metals, making them ideal for portable instruments. They also provide excellent chemical resistance, particularly against acids and bases.

– Cons: Plastics typically have lower temperature and pressure ratings compared to metals, which can limit their application range. They may also be less durable over time, especially in high-stress environments.

Impact on Application:

Plastic materials are often used in environments where exposure to corrosive substances is expected. However, they may not be suitable for high-temperature applications, which can lead to deformation.

Considerations for International Buyers:

Buyers should be aware of the specific grades of plastics that comply with local regulations. Understanding the chemical compatibility of plastics with the intended media is essential to avoid product failure.

What Advantages Do Ceramics Offer in Measuring Instruments?

Ceramics are increasingly used in specialized measuring instruments due to their exceptional hardness, wear resistance, and thermal stability. They can withstand high temperatures (up to 1600°C) and are non-conductive, making them suitable for specific applications.

Pros and Cons:

– Pros: Ceramics are highly resistant to wear and can operate in extreme temperatures, making them ideal for applications in aerospace and automotive industries. They are also chemically inert, which is beneficial in sensitive measurements.

– Cons: The brittleness of ceramics makes them prone to cracking under mechanical stress. Additionally, they can be more expensive to manufacture and process.

Impact on Application:

Ceramics are often used in applications involving abrasive materials or high-temperature environments. However, their brittleness limits their use in dynamic or high-impact scenarios.

Considerations for International Buyers:

Buyers should ensure that ceramic materials meet specific industry standards. Understanding the manufacturing processes and certifications is vital, especially in regions with strict quality requirements.

What Role Does Copper Play in Measuring Instruments?

Copper is a traditional material used in various measuring instruments, particularly those involving electrical conductivity. It offers excellent thermal and electrical conductivity, making it suitable for sensors and thermocouples.

Pros and Cons:

– Pros: Copper’s high conductivity allows for accurate measurements and quick response times. It is also relatively inexpensive and easy to work with.

– Cons: Copper is prone to corrosion and oxidation, which can affect measurement accuracy over time. It also has a lower temperature rating compared to stainless steel.

Impact on Application:

Copper is ideal for applications requiring electrical connections and thermal measurements. However, its susceptibility to corrosion necessitates protective coatings in certain environments.

Considerations for International Buyers:

Buyers should evaluate the corrosion resistance of copper in their specific applications and ensure compliance with relevant standards. Understanding local market preferences for materials can also influence purchasing decisions.

Summary Table of Material Selection for Measuring Instruments

| Material | Typical Use Case for measuring instruments supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Industrial sensors, laboratory equipment | Excellent corrosion resistance | Higher cost and weight | High |

| Plastic | Portable measuring devices, chemical applications | Lightweight and cost-effective | Lower temperature/pressure ratings | Low |

| Ceramics | Aerospace sensors, high-temperature applications | Exceptional hardness and wear resistance | Brittle and expensive to process | Med |

| Copper | Electrical sensors, thermocouples | High conductivity and low cost | Prone to corrosion and oxidation | Low |

This guide provides a comprehensive overview of material selection for measuring instruments, helping international B2B buyers make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for measuring instruments supplier

When selecting a supplier for measuring instruments, understanding the manufacturing processes and quality assurance (QA) protocols is crucial for international B2B buyers. This knowledge not only helps in evaluating potential suppliers but also ensures that the products meet the necessary standards and specifications required in various industries.

What Are the Main Stages of Manufacturing for Measuring Instruments?

The manufacturing process for measuring instruments typically involves several key stages, each critical for ensuring the final product’s accuracy and reliability.

Material Preparation

The first step in manufacturing measuring instruments involves the careful selection and preparation of raw materials. Suppliers often use high-quality metals, plastics, and electronic components. It’s essential to verify that materials comply with industry standards, as the choice of material directly impacts the instrument’s performance. B2B buyers should inquire about the sourcing of materials, ensuring that they come from reputable suppliers with proper certifications.

Forming Techniques Used in Measuring Instruments Manufacturing

Once materials are prepared, they undergo various forming techniques. Common methods include machining, molding, and 3D printing. Machining is prevalent for metal components, allowing for precise dimensions and tolerances. Injection molding is often used for plastic parts, enabling the mass production of complex shapes. Advanced techniques like 3D printing are emerging, providing flexibility and rapid prototyping capabilities.

Buyers should assess whether the supplier utilizes state-of-the-art machinery and technologies, as this can influence production efficiency and product quality.

Assembly Processes for Measuring Instruments

After forming, the assembly process integrates various components into a finished measuring instrument. This stage may involve both manual and automated assembly techniques. Manual assembly is often required for intricate components, while automated systems can enhance consistency and speed.

B2B buyers should inquire about the assembly procedures and whether they follow standard operating protocols. Understanding the assembly process can provide insights into the supplier’s capabilities and potential for customizations.

Finishing Techniques That Ensure Quality

The final stage in manufacturing is finishing, which includes surface treatment, calibration, and final inspections. Finishing techniques can involve painting, anodizing, or applying protective coatings, which enhance durability and aesthetic appeal. Calibration is critical, ensuring that the instruments provide accurate measurements.

Buyers should confirm that the supplier has a robust calibration process in place, ideally certified by recognized authorities, which is crucial for compliance with international standards.

How Is Quality Assurance Implemented in Manufacturing Measuring Instruments?

Quality assurance (QA) is a vital aspect of the manufacturing process, ensuring that measuring instruments meet specified standards throughout production.

What Are the Relevant International Standards for Measuring Instruments?

International standards such as ISO 9001 are essential for establishing a quality management system within manufacturing. ISO 9001 certification indicates that a supplier adheres to quality management best practices, focusing on continuous improvement and customer satisfaction. Additionally, industry-specific certifications such as CE marking (for compliance with European standards) and API standards (for the petroleum industry) are critical for ensuring that instruments are safe and reliable.

B2B buyers should prioritize suppliers that hold these certifications, as they reflect a commitment to quality and compliance.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically divided into several checkpoints during the manufacturing process:

-

Incoming Quality Control (IQC): This initial inspection verifies the quality of raw materials before they enter the production line. It helps catch defects early and ensures compliance with specifications.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC involves regular inspections and tests to ensure that production adheres to quality standards. This step helps identify any deviations early, minimizing rework and waste.

-

Final Quality Control (FQC): At this stage, finished products undergo thorough inspections and testing to verify they meet all specifications before shipment. This may include functional tests, performance checks, and compliance with international standards.

What Common Testing Methods Are Used in Measuring Instruments QA?

Testing methods for measuring instruments vary based on the type of instrument and its intended use. Common methods include:

- Functional Testing: Ensures that the instrument operates correctly under specified conditions.

- Calibration Testing: Verifies the accuracy of measurements against known standards.

- Environmental Testing: Assesses the instrument’s performance under various environmental conditions, such as temperature and humidity.

B2B buyers should ask suppliers about their testing protocols and results, as this information can provide confidence in the reliability of the instruments.

How Can B2B Buyers Verify a Supplier’s Quality Control Processes?

Verifying a supplier’s quality control processes is essential for building trust and ensuring product quality. Here are several actionable steps for B2B buyers:

-

Conduct Audits: Regular audits of the supplier’s facilities can reveal insights into their manufacturing practices and quality control measures. Buyers should consider both scheduled and surprise audits to gauge compliance.

-

Request Quality Reports: Suppliers should be willing to provide detailed reports on quality control measures, including IQC, IPQC, and FQC data. These reports should outline defect rates, corrective actions taken, and continuous improvement initiatives.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. This is particularly beneficial for international buyers who may face challenges in conducting on-site audits.

What Are the Quality Control and Certification Nuances for International Buyers?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, must consider various nuances when assessing suppliers.

-

Cultural and Regulatory Differences: Buyers should be aware of cultural attitudes towards quality and the varying regulatory requirements across regions. For instance, European standards may be more stringent compared to those in other regions.

-

Documentation and Traceability: Proper documentation of QC processes and traceability of components is critical. Buyers should ensure that suppliers maintain detailed records that can be audited if necessary.

-

Language Barriers: Communication is key in international transactions. Buyers should confirm that suppliers can provide documentation and support in a language they understand.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance protocols is essential for international B2B buyers looking to source measuring instruments. By focusing on the critical stages of manufacturing, relevant international standards, and effective verification methods, buyers can make informed decisions that align with their quality expectations and business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘measuring instruments supplier’

In the ever-evolving landscape of industrial measurement, sourcing the right measuring instruments supplier is critical for maintaining operational efficiency and accuracy. This guide offers a step-by-step checklist designed to help B2B buyers, particularly from Africa, South America, the Middle East, and Europe, navigate the complexities of procurement in this niche market.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of successful procurement. Understand the exact measurement requirements, such as range, precision, and environmental conditions. Consider factors like industry standards and compliance regulations relevant to your region or sector.

- Key Considerations:

- Identify the type of measuring instruments needed (e.g., digital, analog).

- Determine compatibility with existing systems and equipment.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in measuring instruments. Utilize online resources, industry directories, and trade shows to compile a list of companies that meet your criteria.

- Action Points:

- Look for suppliers with a proven track record in your industry.

- Consider geographical proximity to reduce shipping times and costs.

Step 3: Evaluate Supplier Certifications

Before moving forward, verify the certifications and quality standards of each supplier. Certifications such as ISO 9001 or specific industry-related certifications ensure that the supplier adheres to quality management standards.

- What to Check:

- Ask for copies of relevant certifications and validate their authenticity.

- Review any compliance with international standards, especially if sourcing from different regions.

Step 4: Request Product Samples

Request samples of the measuring instruments you intend to procure. This step allows you to evaluate the quality and functionality of the products firsthand.

- Why It’s Important:

- Testing samples can help identify potential issues before making a bulk purchase.

- Ensure that the instruments meet your technical specifications and operational needs.

Step 5: Analyze Pricing and Payment Terms

Once you have shortlisted suppliers, analyze their pricing structures and payment terms. It’s crucial to ensure that the costs align with your budget while also reflecting the quality of the products offered.

- Considerations:

- Look for hidden costs such as shipping, duties, or taxes that may affect the overall price.

- Discuss payment options, including credit terms and discounts for bulk purchases.

Step 6: Check Customer Reviews and References

Seek feedback from other businesses that have procured from your potential suppliers. Customer reviews and case studies provide insight into the supplier’s reliability, service quality, and post-purchase support.

- How to Proceed:

- Contact references directly to ask about their experiences.

- Utilize online platforms and industry forums to gauge overall sentiment.

Step 7: Negotiate and Finalize Contracts

Once you have completed your due diligence, negotiate terms and conditions with your chosen supplier. Ensure that contracts clearly outline product specifications, delivery timelines, warranties, and service agreements.

- Important Aspects:

- Review the contract for clarity and completeness before signing.

- Ensure that there are provisions for addressing any potential disputes or issues.

By following this comprehensive checklist, B2B buyers can make informed decisions when sourcing measuring instruments suppliers, ensuring they select a partner that meets their technical and operational needs.

Comprehensive Cost and Pricing Analysis for measuring instruments supplier Sourcing

What Are the Key Cost Components for Measuring Instruments Suppliers?

Understanding the cost structure of measuring instruments suppliers is crucial for international B2B buyers aiming to make informed purchasing decisions. The primary cost components include:

-

Materials: The type and quality of materials used in manufacturing measuring instruments significantly influence costs. High-grade materials often lead to better durability and performance but increase the overall price.

-

Labor: Labor costs vary by region and are influenced by local wage rates and the skill level required for assembly and calibration. Countries with lower labor costs may offer more competitive pricing, but this could affect product quality.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: Specialized tools and equipment necessary for production also contribute to initial setup costs. Custom tooling may be required for specific product lines, impacting the overall pricing strategy.

-

Quality Control (QC): Rigorous QC processes ensure the reliability of measuring instruments, which adds to the cost. Suppliers that maintain high-quality standards may charge a premium but can help mitigate risks for buyers.

-

Logistics: Transportation and handling costs can vary widely based on shipping methods, distances, and customs duties, especially for international buyers. Understanding these costs is vital for total cost estimation.

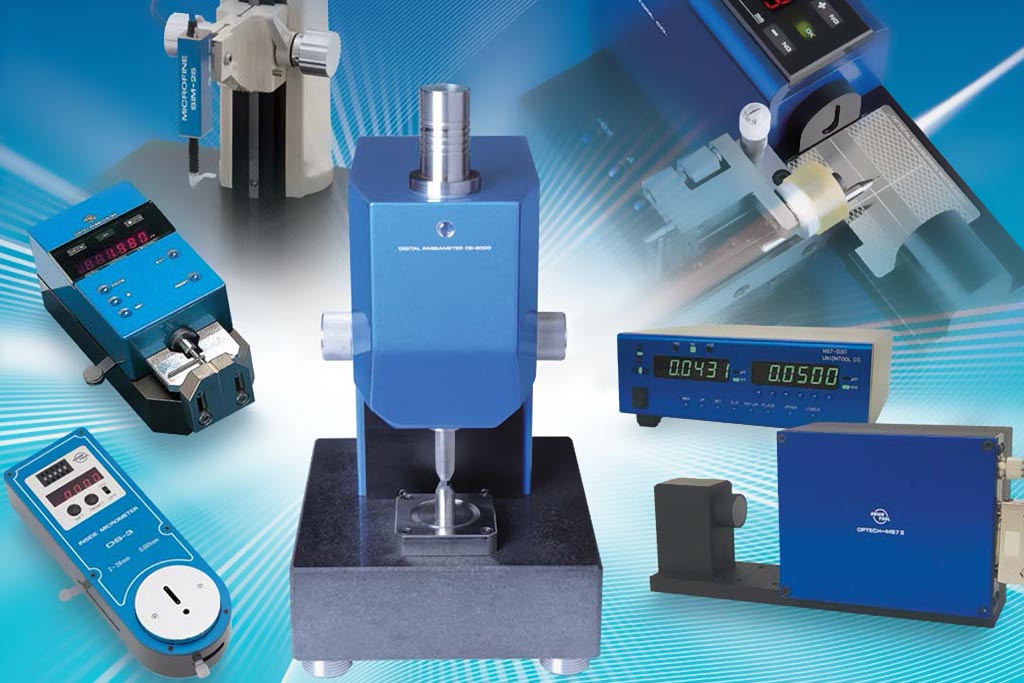

A stock image related to measuring instruments supplier.

- Margin: Suppliers typically add a profit margin to their total costs. This margin can vary based on market competition, brand reputation, and perceived product value.

How Do Pricing Influencers Affect Measuring Instruments?

Several factors can influence the pricing of measuring instruments, which international buyers must consider:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes can often lead to reduced per-unit costs. Buyers should negotiate MOQs that align with their needs while maximizing savings.

-

Specifications and Customization: Custom features or specifications can significantly increase costs. Buyers should assess whether these enhancements are essential for their applications.

-

Materials and Quality Certifications: Instruments made from premium materials or those certified to specific industry standards may come at a higher price. Buyers should weigh the benefits of such certifications against their budget.

-

Supplier Factors: The supplier’s reputation, reliability, and service level can impact pricing. Established suppliers may charge more but offer better guarantees and support.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) can help buyers estimate additional costs related to shipping and responsibilities during transit. This knowledge is crucial for cost-effective sourcing.

What Are the Best Buyer Tips for Cost-Efficiency?

To maximize cost-efficiency when sourcing measuring instruments, buyers should consider the following strategies:

-

Negotiation: Engage in open discussions with suppliers about pricing structures. Highlighting potential long-term partnerships can often lead to better deals.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the TCO, which includes maintenance, operational costs, and potential downtime. A lower upfront cost may not always be the most economical choice in the long run.

-

Understanding Pricing Nuances: Be aware of regional pricing variations. For instance, suppliers in Europe might have different pricing strategies compared to those in Africa or South America. Familiarize yourself with local market conditions to negotiate effectively.

-

Seek Quotes from Multiple Suppliers: Obtaining quotes from various suppliers can provide a clearer picture of market pricing and help identify the best deals.

-

Stay Informed About Market Trends: Keep abreast of industry trends, technological advancements, and economic conditions that may affect pricing and availability. This knowledge can enhance negotiation leverage.

Disclaimer on Indicative Prices

It is essential to note that prices for measuring instruments can fluctuate based on market conditions, supplier availability, and changes in raw material costs. Therefore, buyers should always verify current pricing and terms directly with suppliers before making purchasing decisions.

Alternatives Analysis: Comparing measuring instruments supplier With Other Solutions

What Are the Alternatives to Measuring Instruments Supplier?

In the realm of measuring instruments, businesses often seek alternatives that align with their operational requirements and budget constraints. Understanding these alternatives can help international B2B buyers make informed decisions that enhance productivity and efficiency. Below, we compare the traditional measuring instruments supplier against two viable alternatives: digital measuring solutions and manual measuring techniques.

Comparison Table

| Comparison Aspect | Measuring Instruments Supplier | Digital Measuring Solutions | Manual Measuring Techniques |

|---|---|---|---|

| Performance | High accuracy and reliability | Very high accuracy, real-time data analysis | Moderate accuracy, dependent on user skill |

| Cost | Moderate to high | Variable, often lower in long-term | Low initial cost, but time-intensive |

| Ease of Implementation | Requires training and setup | User-friendly interfaces, quick setup | Minimal setup, but requires skill |

| Maintenance | Regular calibration needed | Minimal, software updates required | Occasional recalibration needed |

| Best Use Case | Industrial applications requiring precision | Construction and engineering projects needing quick data | DIY projects or small-scale applications |

What Are the Pros and Cons of Digital Measuring Solutions?

Digital measuring solutions, such as laser distance meters and digital calipers, offer significant advantages over traditional measuring instruments. These tools provide real-time data analysis, enhancing decision-making and reducing errors. They are generally easy to use, with intuitive interfaces that facilitate quick adoption. However, the initial investment can be variable, and businesses must consider software updates and potential compatibility issues with existing systems as part of the ongoing costs.

How Do Manual Measuring Techniques Compare?

Manual measuring techniques, such as tape measures and rulers, are often seen as cost-effective solutions for smaller projects or DIY tasks. They require minimal initial investment and have a straightforward setup process. However, the accuracy of these methods can significantly depend on the user’s skill level, which can lead to inconsistencies in measurements. Additionally, while they are low-cost, the time spent measuring can offset these savings, making them less efficient for larger or more complex projects.

How to Choose the Right Solution for Your Needs?

When selecting between a measuring instruments supplier and its alternatives, B2B buyers should consider their specific operational needs, budget constraints, and the scale of their projects. For industries that prioritize precision and require a high level of accuracy, investing in a reputable measuring instruments supplier may be the best choice. Conversely, for businesses that operate on tighter budgets or need flexible solutions, digital measuring tools or manual techniques may provide adequate performance without the significant upfront costs. Ultimately, understanding the unique advantages and limitations of each option will guide buyers in making the most informed decision that aligns with their organizational goals.

Essential Technical Properties and Trade Terminology for measuring instruments supplier

What Are the Key Technical Properties of Measuring Instruments?

Understanding the technical specifications of measuring instruments is crucial for international B2B buyers, particularly those sourcing from Africa, South America, the Middle East, and Europe. Here are some essential properties to consider:

-

Material Grade

– Definition: Refers to the type and quality of materials used in the manufacturing of measuring instruments. Common materials include stainless steel, aluminum, and various plastics.

– Importance: The material grade affects durability, accuracy, and resistance to environmental factors. For instance, stainless steel is preferred for its corrosion resistance, making it ideal for outdoor or industrial applications. -

Tolerance

– Definition: The allowable deviation from a specified measurement. It is often expressed in millimeters or microns.

– Importance: Tolerance is critical in applications requiring high precision, such as in the aerospace or automotive industries. Understanding tolerance levels helps buyers ensure that the instruments meet their specific operational needs. -

Calibration Range

– Definition: The range of values within which a measuring instrument can accurately measure.

– Importance: Buyers must select instruments with appropriate calibration ranges for their applications. For example, thermometers used in food processing need to accurately measure temperatures between 0°C and 100°C. -

Resolution

– Definition: The smallest increment that can be measured by the instrument.

– Importance: Higher resolution allows for more precise measurements, which is vital in scientific research or high-stakes manufacturing processes. -

Operating Environment

– Definition: The conditions under which the measuring instrument will be used, including temperature, humidity, and exposure to chemicals.

– Importance: Instruments must be suited for their intended environments to ensure longevity and reliability. For example, instruments used in a laboratory may require different specifications than those used in a construction site.

What Are Common Trade Terms Used in the Measuring Instruments Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common trade terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help buyers identify the best sources for high-quality measuring instruments and components. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units that a supplier is willing to sell.

– Importance: Knowing the MOQ is essential for budget planning and inventory management. Buyers should negotiate MOQs to ensure they meet their operational needs without overcommitting resources. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and terms for specific products or services.

– Importance: An RFQ helps buyers compare offers from multiple suppliers, ensuring they receive competitive pricing and favorable terms. -

Incoterms (International Commercial Terms)

– Definition: A series of pre-defined commercial terms published by the International Chamber of Commerce that are widely used in international trade.

– Importance: Understanding Incoterms is crucial for determining the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. This knowledge can significantly impact the total landed cost of measuring instruments. -

Lead Time

– Definition: The amount of time between the initiation of an order and its completion.

– Importance: Buyers must consider lead times when planning their supply chains. Longer lead times can affect project timelines and inventory levels, making it essential to communicate expectations with suppliers.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, streamline their procurement processes, and foster better relationships with suppliers in the measuring instruments industry.

Navigating Market Dynamics and Sourcing Trends in the measuring instruments supplier Sector

What Are the Current Market Dynamics and Key Trends in the Measuring Instruments Supplier Sector?

The measuring instruments supplier sector is undergoing significant transformation driven by technological advancements, increasing demand for precision, and evolving regulatory standards. Key global drivers include the rise of automation and smart manufacturing, particularly in industries such as automotive, healthcare, and energy. International B2B buyers from regions like Africa, South America, the Middle East, and Europe are witnessing a shift towards digital measurement technologies, such as IoT-enabled devices that provide real-time data analytics. This trend is crucial for enhancing operational efficiency and ensuring compliance with stringent regulations.

Additionally, the integration of AI and machine learning into measurement processes is facilitating predictive maintenance and reducing downtime. Buyers are increasingly interested in suppliers that offer not just products but comprehensive solutions that include service and support. The focus on data security is also rising, with many buyers seeking suppliers who can ensure that their systems are protected against cyber threats.

A stock image related to measuring instruments supplier.

In Europe, particularly in Germany and Poland, there is a growing emphasis on local sourcing as a response to geopolitical tensions and supply chain disruptions experienced during the pandemic. This trend is prompting international buyers to evaluate suppliers based not only on cost but also on reliability and the ability to meet local regulations. For buyers in Africa and South America, emerging markets present opportunities to partner with suppliers who understand the unique challenges of these regions, such as infrastructure limitations and varying regulatory landscapes.

How Important Is Sustainability and Ethical Sourcing for International B2B Buyers in This Sector?

Sustainability and ethical sourcing have become paramount considerations for international B2B buyers, particularly in the measuring instruments supplier sector. Environmental impact is a significant concern, as industries increasingly face pressure to reduce their carbon footprints and comply with sustainability regulations. Suppliers who prioritize eco-friendly practices, such as using renewable materials and minimizing waste in their production processes, are gaining favor with conscientious buyers.

The importance of ethical supply chains cannot be overstated. Buyers are now looking for suppliers who demonstrate transparency in their sourcing practices and adhere to labor rights and fair trade principles. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential criteria for supplier selection. Additionally, buyers are increasingly demanding products made from sustainable materials, such as recycled plastics or biodegradable components, which not only meet environmental standards but also resonate with their corporate social responsibility goals.

As international buyers navigate the complexities of sourcing, they must critically assess potential suppliers’ commitments to sustainability and ethical practices. This approach not only mitigates risk but also enhances brand reputation and fosters long-term partnerships.

What Is the Brief Evolution of the Measuring Instruments Supplier Sector?

The measuring instruments supplier sector has evolved significantly over the decades, transitioning from traditional analog devices to sophisticated digital technologies. In the early 20th century, mechanical instruments dominated the market, offering limited precision and functionality. The introduction of electronic measurement tools in the mid-20th century marked a revolutionary shift, enabling greater accuracy and efficiency.

The late 20th and early 21st centuries witnessed the advent of computer-aided design (CAD) and simulation technologies, which transformed product development and measurement accuracy. Today, the sector is characterized by the integration of IoT and AI, enabling real-time data collection and analysis. This evolution reflects the broader trends in industrial automation and digital transformation, positioning the measuring instruments supplier sector at the forefront of innovation and responsiveness to market demands.

In conclusion, understanding the market dynamics, sustainability imperatives, and the historical evolution of the measuring instruments supplier sector is essential for international B2B buyers looking to make informed sourcing decisions. By aligning with suppliers who embrace technological advancements and ethical practices, buyers can ensure they remain competitive in an increasingly complex global marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of measuring instruments supplier

-

How do I choose the right measuring instruments supplier for my business needs?

Selecting the right measuring instruments supplier involves evaluating their product range, industry expertise, and customer service. Begin by assessing their certifications and compliance with international standards, as this can indicate quality assurance. Additionally, seek suppliers with a proven track record in your specific industry, as they will understand your unique requirements better. Request samples and evaluate their responsiveness and support during the vetting process, as good communication is key to a successful partnership. -

What are the key considerations for customizing measuring instruments?

When considering customization of measuring instruments, first identify your specific needs and applications. Discuss your requirements with potential suppliers to understand their customization capabilities, including modifications in size, functionality, or features. Ensure they have experience in producing tailored solutions and can provide examples of past projects. Additionally, inquire about lead times and cost implications, as customized instruments may have different pricing structures compared to standard models. -

What is the minimum order quantity (MOQ) for measuring instruments from suppliers?

Minimum order quantities (MOQs) can vary significantly among measuring instrument suppliers. Generally, MOQs depend on the type of instrument, the complexity of customization, and the supplier’s production capabilities. When sourcing from international suppliers, it’s advisable to clarify MOQs upfront to avoid unexpected costs. In some cases, suppliers may offer flexibility for first-time buyers or smaller businesses, so don’t hesitate to negotiate terms that suit your purchasing capacity. -

What payment terms should I expect when dealing with international suppliers?

Payment terms can differ widely based on the supplier’s policies and the nature of your transaction. Common terms include upfront payment, partial payment upon order confirmation, and balance upon delivery. For international transactions, consider using secure payment methods such as letters of credit or escrow services to protect your investment. Always clarify the terms in advance and ensure they are documented in your purchase agreement to avoid misunderstandings. -

How can I ensure quality assurance when sourcing measuring instruments?

To ensure quality assurance, request detailed information about the supplier’s quality control processes. Look for certifications such as ISO 9001, which indicates adherence to international quality management standards. Additionally, ask for product samples and conduct thorough inspections upon delivery. Establishing a clear communication channel for ongoing support and addressing any issues promptly is crucial for maintaining quality throughout your partnership. -

What logistics considerations should I keep in mind when importing measuring instruments?

Logistics is a critical aspect of importing measuring instruments. First, evaluate shipping options and timelines, as delays can impact your operations. Understand the customs regulations in your country, including tariffs and duties, to avoid unexpected costs. Collaborate with suppliers who have experience in exporting to your region, as they can provide valuable insights on documentation and compliance requirements, ensuring a smooth import process. -

How can I verify the reputation of a measuring instruments supplier?

Verifying a supplier’s reputation involves researching their history, customer reviews, and industry presence. Utilize online platforms and business directories to read feedback from previous clients. Networking within industry associations or forums can provide insights from peers who have worked with the supplier. Additionally, request references and case studies to better understand their capabilities and reliability in meeting customer needs. -

What are the advantages of sourcing measuring instruments from local versus international suppliers?

Sourcing from local suppliers often provides benefits such as reduced shipping times, lower logistics costs, and easier communication. Local suppliers may also offer faster support and service due to geographical proximity. Conversely, international suppliers may provide a broader range of advanced technologies and competitive pricing. When making your decision, weigh the importance of these factors against your specific needs, budget, and operational capabilities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for measuring instruments supplier

What Are the Key Takeaways for B2B Buyers in Sourcing Measuring Instruments?

In conclusion, strategic sourcing of measuring instruments is pivotal for international B2B buyers aiming to enhance operational efficiency and ensure compliance with industry standards. By leveraging a robust supplier network, businesses can access advanced technologies, competitive pricing, and reliable support. Buyers should prioritize suppliers who demonstrate a commitment to quality, innovation, and sustainability, as these factors significantly impact long-term partnerships.

How Can Buyers Prepare for Future Sourcing Challenges?

As the market evolves, buyers from Africa, South America, the Middle East, and Europe must stay ahead of trends that could affect supply chains, such as geopolitical changes and technological advancements. Establishing clear communication channels with suppliers and conducting regular market assessments will be essential to navigate these challenges effectively.

What Steps Should Buyers Take Next?

As you embark on your sourcing journey, consider engaging with suppliers who align with your strategic goals. Evaluate their capabilities, certifications, and customer reviews to ensure a match with your requirements. Take proactive steps today to build partnerships that will drive your business forward. The future of measuring instruments procurement is bright, and with careful planning and execution, you can position your organization for success in a competitive global landscape.