The Ultimate Guide to Optical Fiber China (2025)

Introduction: Navigating the Global Market for optical fiber china

In today’s interconnected world, sourcing high-quality optical fiber from China presents both opportunities and challenges for international B2B buyers. The rapid expansion of digital infrastructure across Africa, South America, the Middle East, and Europe underscores the importance of reliable and efficient communication networks. However, navigating the complexities of the global optical fiber market can be daunting, especially when it comes to identifying trustworthy suppliers, understanding product specifications, and managing costs effectively.

This comprehensive guide aims to empower B2B buyers with actionable insights into the optical fiber market in China. We will explore various types of optical fiber products, their applications in diverse industries, and essential criteria for vetting suppliers. Additionally, we will provide an in-depth analysis of pricing structures, helping you to make informed purchasing decisions that align with your business objectives.

With a focus on the unique needs of buyers from regions like Africa, South America, the Middle East, and Europe, this guide is designed to simplify the sourcing process. By equipping you with the knowledge and tools necessary to navigate this market, we aim to foster successful partnerships and drive growth in your organization. Whether you are looking to enhance your telecommunications infrastructure or expand your product offerings, understanding the landscape of optical fiber in China is crucial for your success.

Understanding optical fiber china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Mode Fiber (SMF) | Smaller core diameter, optimized for long-distance | Telecommunications, Data Centers | Pros: Higher bandwidth, lower attenuation. Cons: More expensive, requires precise alignment. |

| Multi-Mode Fiber (MMF) | Larger core diameter, supports multiple light modes | Local Area Networks (LAN), Short-distance | Pros: Cost-effective, easier to install. Cons: Limited distance, higher modal dispersion. |

| Armored Fiber Optic Cable | Protective layer against physical damage | Industrial, Outdoor, Military Applications | Pros: Enhanced durability, resistance to environmental factors. Cons: Heavier, potentially higher costs. |

| Loose Tube Fiber | Multiple fibers within a protective tube | Outdoor installations, Harsh environments | Pros: Flexibility, protection against temperature changes. Cons: More complex installation, potential for fiber breakage. |

| Ribbon Fiber | Flat, ribbon-like configuration for high density | High-density data centers, Telecommunication | Pros: Space-saving, efficient for mass splicing. Cons: Requires specialized splicing tools, less common. |

What are the Characteristics of Single-Mode Fiber (SMF)?

Single-Mode Fiber (SMF) features a core diameter of approximately 8-10 micrometers, allowing only one mode of light to propagate. This design enables it to transmit data over long distances with minimal signal loss, making it ideal for telecommunications and data center applications. B2B buyers should consider the higher initial investment and the necessity for precise installation techniques, which can lead to increased labor costs. However, the long-term benefits of reduced attenuation and higher bandwidth often justify the expense.

How Does Multi-Mode Fiber (MMF) Differ from Single-Mode Fiber?

Multi-Mode Fiber (MMF) has a larger core diameter, typically around 50-62.5 micrometers, which allows multiple light modes to travel simultaneously. This makes MMF suitable for short-distance applications, such as Local Area Networks (LANs). For B2B buyers, MMF is generally more cost-effective and easier to install than SMF. However, it has limitations in distance and bandwidth compared to SMF, resulting in higher modal dispersion. Buyers must assess their specific needs for distance and data rates before choosing MMF.

What Advantages Does Armored Fiber Optic Cable Offer?

Armored Fiber Optic Cable is designed with an additional protective layer, making it highly resistant to physical damage. This type of fiber is particularly beneficial for industrial, outdoor, and military applications where environmental factors pose a risk. B2B buyers should weigh the enhanced durability and longevity against the potential for higher costs and increased weight. While the initial investment may be greater, the reduced risk of damage can lead to significant savings over time.

Why Choose Loose Tube Fiber for Outdoor Installations?

Loose Tube Fiber consists of multiple fibers housed within a protective tube, providing flexibility and protection against environmental changes. This design is particularly suited for outdoor installations and harsh environments. For B2B buyers, the primary considerations include the complexity of installation and the risk of fiber breakage. However, the ability of loose tube fibers to withstand temperature fluctuations and mechanical stress makes them a reliable choice for companies operating in challenging conditions.

What Makes Ribbon Fiber Ideal for High-Density Applications?

Ribbon Fiber features a flat, ribbon-like configuration that allows for high-density installations, making it ideal for data centers and telecommunications. This type of fiber enables efficient mass splicing, which can significantly reduce installation time and costs. B2B buyers must consider the specialized splicing tools required for ribbon fiber, as well as its less common availability compared to traditional fiber types. Despite these challenges, the space-saving and efficient nature of ribbon fiber can provide substantial benefits in high-demand environments.

Related Video: Optical Fiber Mode Theory (Basics, Fields & Types) Explained in Optical Fiber Communication

Key Industrial Applications of optical fiber china

| Industry/Sector | Specific Application of Optical Fiber China | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | High-speed Internet Infrastructure | Enhances connectivity and bandwidth capabilities | Ensure compliance with local regulations and standards. |

| Healthcare | Medical Imaging and Diagnostics | Improves precision in diagnostics and treatments | Look for suppliers with ISO certifications for quality. |

| Manufacturing | Industrial Automation and Control Systems | Increases efficiency and reduces downtime | Assess the durability and environmental resistance of fibers. |

| Transportation | Intelligent Transportation Systems (ITS) | Optimizes traffic management and safety | Evaluate integration capabilities with existing systems. |

| Security and Surveillance | Fiber Optic Security Systems | Provides high-security surveillance solutions | Prioritize suppliers with proven track records in security. |

How is Optical Fiber Used in Telecommunications?

In the telecommunications sector, optical fiber from China is primarily utilized to build high-speed internet infrastructure. This application enhances connectivity by providing greater bandwidth and faster data transmission rates compared to traditional copper cables. For international B2B buyers, especially those in regions like Africa and South America, sourcing high-quality optical fibers that comply with local regulations is crucial to ensure seamless integration into existing networks and to meet growing consumer demands for reliable internet services.

What Role Does Optical Fiber Play in Healthcare?

In healthcare, optical fiber is integral to medical imaging and diagnostics technologies, such as endoscopes and laser surgery tools. These applications significantly improve the precision of diagnostics and treatment procedures, leading to better patient outcomes. Buyers in the Middle East and Europe should focus on suppliers that have ISO certifications, ensuring that the optical fibers meet stringent quality and safety standards required in medical applications.

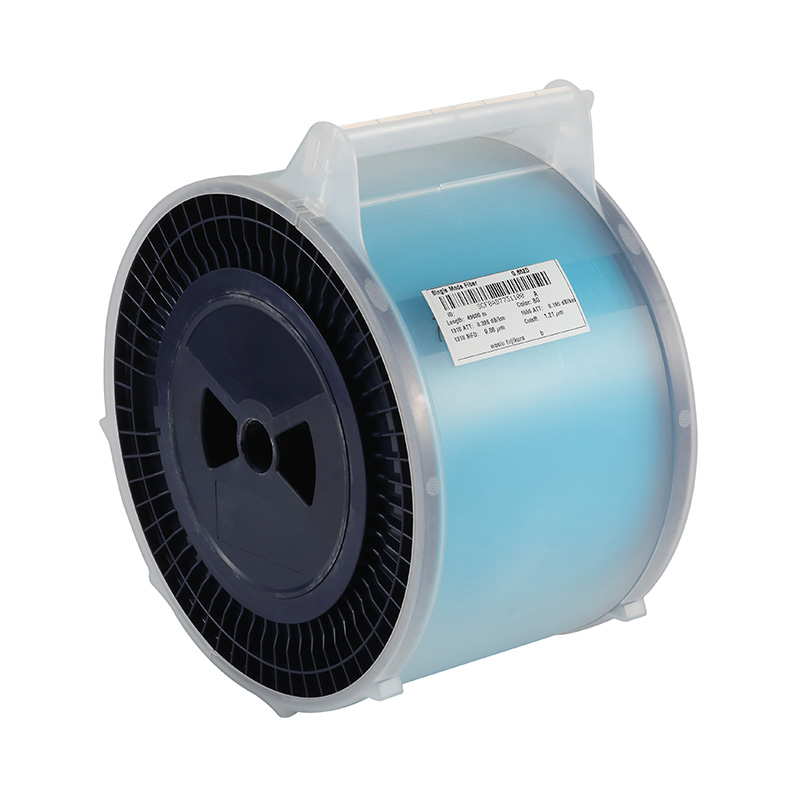

A stock image related to optical fiber china.

How Does Optical Fiber Benefit Manufacturing Industries?

The manufacturing industry leverages optical fiber for industrial automation and control systems. Optical fibers facilitate high-speed data transmission between machinery, enhancing operational efficiency and reducing downtime. For B2B buyers in Europe and South America, it is vital to assess the durability and environmental resistance of the optical fibers to ensure they can withstand the rigorous conditions often present in manufacturing environments.

What are Intelligent Transportation Systems (ITS)?

Optical fiber is critical in developing Intelligent Transportation Systems (ITS), which optimize traffic management and improve safety on roadways. By providing real-time data transmission from sensors and cameras, businesses can enhance their transportation infrastructure. Buyers from Africa and the Middle East should evaluate the integration capabilities of optical fibers with existing systems, ensuring that new installations can work seamlessly with current technologies.

How is Optical Fiber Used in Security and Surveillance?

In the realm of security and surveillance, fiber optic systems are employed to create high-security environments. These systems are less susceptible to interference and tapping, providing a robust solution for sensitive applications. International B2B buyers, particularly from Europe and South America, should prioritize suppliers with proven track records in security solutions, ensuring that the optical fibers offered can meet the high standards required for effective surveillance systems.

Related Video: Optical fiber cables, how do they work? | ICT #3

3 Common User Pain Points for ‘optical fiber china’ & Their Solutions

Scenario 1: Navigating Quality Assurance Challenges in Sourcing Optical Fiber from China

The Problem: One of the most pressing challenges faced by B2B buyers in Africa, South America, the Middle East, and Europe when sourcing optical fiber from China is ensuring product quality. Buyers often encounter inconsistencies in manufacturing standards, which can lead to unreliable fiber optic cables that fail to meet specifications. This can result in costly downtimes and damage to reputation if the products do not perform as expected. Additionally, language barriers and cultural differences may hinder effective communication with suppliers, further complicating the quality assurance process.

The Solution: To mitigate quality assurance issues, B2B buyers should adopt a multi-faceted approach to sourcing. First, it is essential to conduct thorough due diligence on potential suppliers. This includes checking certifications such as ISO 9001, which indicates a commitment to quality management. Buyers can also request samples of optical fiber products to evaluate their performance and reliability in real-world conditions before making bulk purchases.

Additionally, establishing a direct line of communication with suppliers can enhance clarity and understanding. Consider hiring a local intermediary or consultant who is well-versed in the Chinese market to facilitate discussions and ensure that specifications are accurately conveyed. Conducting factory visits or utilizing third-party inspection services can further ensure that the manufacturing processes align with the agreed-upon standards.

Scenario 2: Overcoming Supply Chain Disruptions for Timely Deliveries

The Problem: International B2B buyers often face significant delays in the supply chain when ordering optical fiber from China. Issues such as port congestion, customs delays, and unexpected shipping costs can derail project timelines, leading to frustration and financial losses. This is especially problematic for industries reliant on timely installations, such as telecommunications and data centers, where delays can compromise service delivery.

The Solution: To combat supply chain disruptions, buyers should implement strategic planning and risk management practices. Start by diversifying the supply base—consider sourcing from multiple suppliers in different regions of China. This not only mitigates risks associated with a single supplier but also creates competitive pricing opportunities.

Investing in supply chain management software can provide real-time tracking of orders and shipments, helping buyers anticipate delays and adjust their project timelines accordingly. Additionally, fostering strong relationships with logistics partners can facilitate smoother transport processes. Engaging a freight forwarder with expertise in navigating Chinese customs and logistics can help in preempting potential delays and ensuring timely delivery.

Scenario 3: Addressing Compatibility Issues with Existing Infrastructure

The Problem: Another common pain point for B2B buyers is the compatibility of optical fiber products with existing network infrastructure. Buyers often encounter situations where newly acquired optical fiber cables do not integrate seamlessly with older systems or equipment, leading to performance issues and additional costs for retrofitting or upgrading components.

The Solution: To avoid compatibility issues, buyers should conduct a comprehensive assessment of their current infrastructure before sourcing new optical fiber products. This involves cataloging existing systems, understanding the specifications of current equipment, and identifying any potential gaps in compatibility.

When selecting optical fiber from China, buyers should prioritize suppliers that provide detailed technical specifications and compatibility information for their products. Engaging in discussions with suppliers about existing infrastructure can lead to tailored recommendations that suit specific needs. Furthermore, buyers may consider consulting with a network engineer who can provide insights into the best types of fiber optics that will work with their systems. Implementing this proactive approach will not only streamline installations but also enhance overall network performance and reliability.

Strategic Material Selection Guide for optical fiber china

When selecting materials for optical fiber applications in China, it is crucial for international B2B buyers to consider the properties, advantages, and limitations of various materials. This guide analyzes four common materials used in optical fiber production, providing insights that can help buyers make informed decisions tailored to their regional requirements.

What are the Key Properties of Glass Fiber in Optical Fiber Production?

Glass fiber is the most widely used material in optical fiber manufacturing due to its superior light transmission properties. It typically exhibits high-temperature resistance (up to 1000°C) and excellent corrosion resistance, making it suitable for various environmental conditions.

Pros & Cons:

The durability of glass fiber is a significant advantage, as it can withstand harsh conditions and has a long lifespan. However, it is relatively expensive compared to other materials, which may impact overall project costs. Manufacturing complexity is also a factor, as the production process requires specialized equipment and skilled labor.

Impact on Application:

Glass fiber is compatible with a wide range of media, including telecommunications and data transmission, making it ideal for urban and rural connectivity projects.

Considerations for Buyers:

Buyers from regions like Africa and South America should ensure compliance with international standards such as ASTM and DIN, which can influence the choice of glass fiber suppliers.

How Does Plastic Fiber Compare in Optical Fiber Applications?

Plastic optical fiber (POF) is gaining traction due to its flexibility and ease of installation. It generally has a lower temperature rating (around 85°C) and is less resistant to harsh chemicals compared to glass fiber.

Pros & Cons:

The primary advantage of POF is its cost-effectiveness and lightweight nature, which simplifies installation. However, it has a shorter lifespan and lower performance in terms of data transmission speed and distance, making it less suitable for high-demand applications.

Impact on Application:

POF is often used in short-distance applications, such as home networking and automotive systems, where high bandwidth is not a critical requirement.

Considerations for Buyers:

International buyers should be aware of the specific standards applicable to POF in their regions, as compliance may vary significantly, especially in Europe and the Middle East.

What Role Does Steel Play in Optical Fiber Cable Protection?

Steel is often used as an outer protective layer for optical fiber cables, providing mechanical strength and protection against environmental hazards.

Pros & Cons:

The key advantage of steel is its durability and resistance to physical damage, which is essential for outdoor installations. However, it can increase the overall weight of the cable and may lead to higher shipping costs. Additionally, the manufacturing process for steel-reinforced cables can be complex.

Impact on Application:

Steel-reinforced optical fibers are especially suitable for installations in rugged environments, such as in mining or industrial settings, where mechanical protection is paramount.

Considerations for Buyers:

Buyers should ensure that the steel used complies with local and international standards, as varying regulations could affect material sourcing and project timelines.

How is Aluminum Used in Optical Fiber Cable Manufacturing?

Aluminum is another material commonly used for the protective layers of optical fiber cables. It is lightweight, corrosion-resistant, and offers a good balance between cost and performance.

Pros & Cons:

The primary advantage of aluminum is its lightweight nature, which reduces shipping costs and facilitates easier installation. However, it may not provide the same level of mechanical protection as steel, making it less suitable for high-risk environments.

Impact on Application:

Aluminum is often used in environments where weight is a concern, such as aerial installations or in areas with moderate environmental hazards.

Considerations for Buyers:

International buyers should verify the aluminum grades used in optical fiber cables to ensure compliance with local regulations and standards, particularly in Europe and the Middle East.

Summary Table of Material Selection for Optical Fiber in China

| Material | Typical Use Case for optical fiber china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass Fiber | Telecommunications, data transmission | Superior light transmission, durability | High cost, complex manufacturing | High |

| Plastic Fiber | Home networking, automotive systems | Cost-effective, easy installation | Short lifespan, lower performance | Low |

| Steel | Outdoor installations, industrial settings | Excellent mechanical protection | Increased weight, complex production | Medium |

| Aluminum | Aerial installations, moderate hazard areas | Lightweight, corrosion-resistant | Less mechanical protection than steel | Medium |

This strategic material selection guide provides a comprehensive overview for B2B buyers looking to navigate the complexities of optical fiber materials in China. Understanding the properties, advantages, and limitations of these materials is essential for making informed purchasing decisions that align with regional compliance and project requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for optical fiber china

What Are the Key Stages in the Manufacturing Process of Optical Fiber in China?

The manufacturing process of optical fiber in China involves several critical stages that ensure the production of high-quality fibers suitable for various applications. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: What Raw Materials Are Used?

The first stage of manufacturing optical fiber involves the preparation of raw materials. The primary material used is silica, which is processed into preforms. These preforms are created through a method called chemical vapor deposition (CVD), where gaseous reactants are introduced into a furnace to create a solid silica rod. Additional materials, such as dopants, are added to modify the refractive index and enhance the fiber’s performance.

How Is Optical Fiber Formed?

Once the preform is ready, the next step is the fiber drawing process. This involves heating the preform in a furnace until it softens and can be drawn into thin strands of fiber. The drawing process is controlled meticulously to maintain the desired diameter, typically around 125 micrometers for standard optical fibers. The temperature and drawing speed are adjusted to ensure uniformity and minimize defects.

What Are the Assembly and Finishing Processes?

After the fibers are drawn, they undergo assembly and finishing. This includes coating the fibers with protective materials to prevent damage and enhance durability. The coatings also serve to improve the fiber’s optical performance. The assembled fibers are then spooled onto reels for shipping. During this stage, special attention is given to the handling and storage conditions to avoid any stress or bending that could affect performance.

What Quality Assurance Measures Are Implemented in Optical Fiber Manufacturing?

Quality assurance (QA) is vital in the manufacturing of optical fibers, ensuring that the final product meets international standards and customer expectations. Various quality control (QC) checkpoints are established throughout the production process.

Which International Standards Are Relevant for Optical Fiber Quality Control?

A stock image related to optical fiber china.

International standards such as ISO 9001 play a significant role in the quality assurance of optical fibers. ISO 9001 outlines the requirements for a quality management system, emphasizing continuous improvement and customer satisfaction. Additionally, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) are crucial for compliance in specific markets.

What Are the Key QC Checkpoints in Optical Fiber Manufacturing?

In optical fiber manufacturing, several QC checkpoints are established:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify and rectify defects in real-time.

- Final Quality Control (FQC): After production, a comprehensive inspection is conducted to verify that the finished products meet all quality criteria before shipment.

How Are Common Testing Methods Applied in Optical Fiber QC?

Testing methods for optical fibers include:

- Attenuation Testing: Measures the signal loss over a specific distance, ensuring the fiber meets performance specifications.

- Refractive Index Profiling: Assesses the refractive index distribution within the fiber, which is critical for performance.

- Mechanical Testing: Evaluates the tensile strength and flexibility of the fiber to ensure it can withstand environmental stresses.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are actionable steps to ensure the reliability of your suppliers:

-

Conduct Supplier Audits: Regular audits help assess compliance with quality standards and operational capabilities. Buyers should consider on-site visits to evaluate the manufacturing facility directly.

-

Request Quality Reports: Suppliers should provide detailed quality reports, including test results and compliance certifications. This transparency builds trust and allows buyers to verify adherence to standards.

-

Utilize Third-Party Inspection Services: Engaging independent inspection services can provide an unbiased evaluation of the supplier’s quality control measures. This step is particularly beneficial for buyers who cannot visit suppliers in person.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

When dealing with international suppliers, buyers must be aware of specific nuances in quality control and certifications:

-

Regional Compliance: Different regions may have varying compliance requirements. For instance, European buyers must ensure that products meet CE marking requirements, while other regions may have different standards.

-

Understanding Certification Validity: Certifications such as ISO 9001 have specific validity periods and require periodic renewal. Buyers should verify the current status of a supplier’s certifications.

-

Cultural Considerations: Understanding cultural differences in business practices can affect quality perceptions. Establishing clear communication and expectations is crucial for successful partnerships.

By understanding the manufacturing processes and quality assurance measures in the optical fiber industry, B2B buyers can make informed decisions, ensuring they select reliable suppliers who meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘optical fiber china’

The following guide provides a step-by-step checklist for B2B buyers looking to source optical fiber from China. This structured approach aims to streamline your procurement process while ensuring quality and reliability in your supply chain.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial before initiating the sourcing process. Consider factors such as the type of optical fiber (single-mode vs. multi-mode), required length, and environmental considerations (e.g., temperature ranges, moisture resistance). Defining these parameters helps prevent miscommunication with suppliers and ensures that you receive products that meet your operational needs.

Step 2: Research the Market Landscape

Understanding the market landscape for optical fiber in China is essential for identifying potential suppliers. Conduct thorough market research to identify key players, pricing trends, and the latest technological advancements. Utilize industry reports and online platforms to gather information, which will empower you to make informed decisions and negotiate effectively.

Step 3: ✅ Verify Supplier Certifications

Before engaging with suppliers, verify their certifications and compliance with international quality standards. Look for certifications such as ISO 9001 for quality management systems and RoHS compliance for hazardous substances. These certifications indicate a supplier’s commitment to quality and safety, which is vital for maintaining your brand’s reputation.

Step 4: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your requirements. Request detailed company profiles, including their production capabilities, experience in the industry, and customer references. Engaging with suppliers that have a proven track record in optical fiber production will significantly reduce risks associated with quality and delivery timelines.

Step 5: Request Samples for Quality Assurance

Before placing a bulk order, always request samples of the optical fiber products. This allows you to assess the quality and suitability of the materials for your specific applications. During this stage, conduct tests based on your technical specifications to ensure that the products meet performance expectations.

Step 6: Negotiate Payment Terms and Conditions

Once you have selected a supplier, negotiate favorable payment terms and conditions. Discuss options such as letters of credit, advance payments, or payment upon delivery to mitigate financial risks. Clear payment terms protect both parties and establish a foundation for a long-term business relationship.

Step 7: Plan for Logistics and Shipping

Finally, develop a logistics and shipping plan to ensure smooth delivery of the optical fiber. Consider factors such as shipping methods, customs clearance procedures, and potential delays. Collaborating with a reliable freight forwarder can help streamline this process and ensure timely delivery, reducing downtime in your operations.

By following this structured checklist, B2B buyers can effectively navigate the complexities of sourcing optical fiber from China, ensuring they find reliable suppliers that meet their specific needs.

Comprehensive Cost and Pricing Analysis for optical fiber china Sourcing

What Are the Key Cost Components in Optical Fiber Sourcing from China?

When sourcing optical fiber from China, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The quality of raw materials, such as glass and polymer, significantly influences the price. High-grade materials often come at a premium but ensure better performance and longevity.

-

Labor: Labor costs in China are generally lower than in Western countries, but they can vary based on the region and skill level required for manufacturing. Skilled labor may command higher wages, impacting overall costs.

-

Manufacturing Overhead: This includes utilities, factory maintenance, and administrative expenses. Efficient factories with streamlined operations often have lower overheads, which can translate into better pricing for buyers.

-

Tooling: The cost of molds and machinery used in production is a one-time expense that can be amortized over large production runs. Custom tooling can increase initial costs but may be necessary for specialized products.

-

Quality Control (QC): Implementing stringent QC processes incurs additional costs but is essential to ensure product reliability. Buyers should weigh the costs of QC against the risks of defects and potential failures in the field.

-

Logistics: Shipping costs can vary widely based on destination, shipping method, and weight. It’s important for buyers to consider both the cost and time of delivery when selecting suppliers.

-

Margin: Suppliers will add a markup to their costs to ensure profitability. Understanding the supplier’s pricing model can help buyers negotiate better deals.

How Do Price Influencers Impact Optical Fiber Costs?

Several factors influence the final pricing of optical fiber sourced from China:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically attract lower per-unit costs. Buyers should assess their needs to determine the right balance between inventory and cost efficiency.

-

Specifications and Customization: Customized products or specific technical requirements can increase costs. Buyers should clarify their needs upfront to avoid unexpected charges later.

-

Materials and Quality Certifications: Higher quality materials and certifications (like ISO or RoHS compliance) can raise costs. Buyers must evaluate whether the additional investment in quality is justified by performance requirements.

-

Supplier Factors: The reputation, experience, and location of the supplier can influence pricing. Established suppliers may charge more but often provide better reliability and service.

-

Incoterms: The choice of Incoterms affects shipping responsibilities and costs. Understanding terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is essential for calculating total costs.

What Buyer Tips Can Enhance Cost-Efficiency in Optical Fiber Sourcing?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, here are actionable tips to enhance cost-efficiency:

-

Negotiate Smartly: Engage in transparent negotiations. Establish a clear understanding of your requirements and be open to discussing pricing based on long-term partnerships.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but the total cost over the product’s lifecycle. This includes installation, maintenance, and potential downtime costs.

-

Be Aware of Pricing Nuances: International buyers should be aware of fluctuations in currency exchange rates and how they can impact costs. Additionally, tariffs and trade agreements may affect pricing and should be factored into the overall budget.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to better pricing, priority service, and access to exclusive deals. Long-term partnerships often yield more favorable terms.

-

Stay Informed About Market Trends: Understanding the broader market dynamics, such as demand spikes or supply chain disruptions, can empower buyers to make informed purchasing decisions and negotiate better prices.

Disclaimer on Indicative Prices

Pricing for optical fiber sourcing from China can fluctuate based on market conditions, material costs, and supplier pricing strategies. Buyers are advised to conduct thorough research and obtain multiple quotes to ensure competitive pricing aligned with their specific needs.

Alternatives Analysis: Comparing optical fiber china With Other Solutions

Introduction to Comparing Alternatives for Optical Fiber Solutions

In the quest for efficient communication infrastructure, B2B buyers often seek alternatives to traditional optical fiber solutions. While “Optical Fiber China” represents a high-performance option for data transmission, it is essential to consider other technologies that may better align with specific business needs, budgets, and implementation strategies. This analysis will compare Optical Fiber China with two viable alternatives: copper cabling and wireless communication technologies, providing insights tailored for international buyers from Africa, South America, the Middle East, and Europe.

Comparison Table of Optical Fiber China and Alternatives

| Comparison Aspect | Optical Fiber China | Copper Cabling | Wireless Communication |

|---|---|---|---|

| Performance | High bandwidth, low attenuation | Moderate bandwidth, higher attenuation | Variable bandwidth, affected by distance and obstacles |

| Cost | Higher initial investment, lower long-term costs | Lower initial costs, higher maintenance costs | Varies widely; can be low for short distances but may require significant investment for reliability |

| Ease of Implementation | Requires specialized installation | Easier installation, widely understood | Quick setup, but may need more extensive infrastructure for large networks |

| Maintenance | Low maintenance, durable | Moderate maintenance, susceptible to damage | Varies; can require frequent upgrades and repairs |

| Best Use Case | Long-distance, high-demand data transmission | Short to medium-distance applications | Flexible solutions for mobile and temporary setups |

What Are the Pros and Cons of Copper Cabling Compared to Optical Fiber China?

Copper cabling is a well-established technology in the telecommunications sector. One of its significant advantages is its lower initial investment, making it attractive for smaller businesses or those with budget constraints. Additionally, the installation process is straightforward and does not require specialized skills. However, copper cabling has limitations in performance, particularly in terms of bandwidth and signal attenuation over long distances. This makes it less suitable for high-demand applications where data speed and reliability are critical.

How Does Wireless Communication Technology Compare to Optical Fiber China?

Wireless communication technologies offer flexibility and convenience, particularly in environments where physical cabling is impractical. They can be deployed rapidly and allow for mobile connectivity, making them ideal for temporary setups or areas with challenging terrain. However, the performance of wireless solutions can vary significantly based on distance, obstacles, and environmental factors, which may lead to inconsistent service quality. Additionally, while initial costs may be low, businesses may face ongoing expenses related to upgrades and maintenance to ensure reliable connectivity.

Conclusion: How to Choose the Right Solution for Your Business Needs

When deciding between Optical Fiber China and its alternatives, B2B buyers should carefully assess their specific requirements, including performance needs, budget constraints, and the nature of their operational environment. For businesses demanding high-speed and long-distance data transmission, Optical Fiber China may be the most suitable option despite its higher upfront costs. Conversely, for organizations looking for budget-friendly solutions with moderate performance needs, copper cabling may suffice. Wireless technology, while offering unmatched flexibility, may be best for companies requiring temporary setups or mobile connectivity. Ultimately, understanding these options will enable buyers to make informed decisions that align with their strategic goals and operational demands.

Essential Technical Properties and Trade Terminology for optical fiber china

What Are the Key Technical Properties of Optical Fiber?

Understanding the essential technical properties of optical fiber is crucial for international B2B buyers, especially when considering procurement from China. Here are several critical specifications to keep in mind:

1. Material Grade

The material grade of optical fiber refers to the quality of the glass or polymer used in manufacturing. Common materials include silica glass and plastic optical fibers. Higher-grade materials typically offer better performance in terms of attenuation (signal loss) and durability. For buyers, selecting the right material grade is vital, as it affects the longevity and reliability of the fiber in various applications.

2. Attenuation Coefficient

The attenuation coefficient measures how much signal loss occurs over a specific distance, usually expressed in decibels per kilometer (dB/km). A lower attenuation coefficient indicates better performance, allowing for longer transmission distances without the need for signal boosters. B2B buyers should prioritize fibers with low attenuation for high-performance networks.

3. Core Diameter

The core diameter of an optical fiber impacts its light-carrying capacity and bandwidth. Standard core diameters include 50 µm and 62.5 µm for multimode fibers, while single-mode fibers typically have a core diameter of 8-10 µm. Understanding core diameter is essential for buyers, as it influences the type of applications the fiber can support, such as telecommunications or data centers.

4. Numerical Aperture (NA)

Numerical aperture is a dimensionless number that characterizes the range of angles over which the fiber can accept light. A higher NA indicates that the fiber can gather more light, improving efficiency. Buyers should consider the NA when selecting fibers for applications requiring high light collection efficiency, such as in harsh environments.

5. Temperature Rating

The temperature rating of optical fiber indicates the range of temperatures in which the fiber can operate without performance degradation. Common ratings are -40°C to +85°C. Buyers need to ensure that the fiber they choose can withstand the environmental conditions of their intended application, especially in regions with extreme temperatures.

What Are Common Trade Terms in the Optical Fiber Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the optical fiber market. Here are several key trade terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand name. In the optical fiber industry, OEMs might produce fiber cables that are branded and sold by telecommunications companies. Buyers should consider OEM partnerships for customized solutions tailored to specific needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to gauge whether a supplier can meet their purchasing needs without overcommitting resources. Negotiating MOQs can sometimes lead to better pricing for larger orders.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing for specific products or services. It typically includes detailed specifications and quantities. For B2B buyers, issuing an RFQ can help streamline the procurement process and ensure that they receive competitive pricing and terms from multiple suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in international transactions. They specify who is responsible for shipping, insurance, and tariffs. Understanding Incoterms is crucial for B2B buyers to mitigate risks and clarify costs associated with shipping optical fiber products.

5. Lead Time

Lead time refers to the time it takes for a supplier to fulfill an order from the moment it is placed until it is delivered. For B2B buyers, understanding lead times is essential for project planning and inventory management, particularly when dealing with international suppliers where delays may occur.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing optical fiber from China, ensuring that they select products that meet their specific needs and operational requirements.

Navigating Market Dynamics and Sourcing Trends in the optical fiber china Sector

What Are the Current Market Dynamics Driving Optical Fiber Sourcing?

The optical fiber sector in China has experienced significant growth, driven by the increasing demand for high-speed internet and advanced telecommunications infrastructure. As countries globally push for digital transformation, the need for reliable and efficient data transmission continues to rise, making optical fiber a critical component in various industries. For international B2B buyers from Africa, South America, the Middle East, and Europe, understanding these market dynamics is essential.

Key trends include the adoption of 5G technology, which requires extensive fiber optic networks to support faster connectivity and more devices. Additionally, the growing emphasis on smart cities and IoT (Internet of Things) applications is propelling demand for optical fibers. Buyers should also be aware of the competitive landscape; while China is a dominant player, emerging markets in Southeast Asia are beginning to establish their presence, potentially impacting pricing and availability.

Another noteworthy trend is the shift towards integrated solutions, where companies offer bundled services that include installation, maintenance, and support alongside fiber products. This trend can influence sourcing decisions, as buyers may prioritize vendors that can deliver comprehensive solutions rather than just raw materials.

How Is Sustainability Influencing B2B Sourcing in the Optical Fiber Sector?

Sustainability is becoming a paramount concern in the optical fiber industry. The environmental impact of production processes and the importance of ethical supply chains are critical factors for international B2B buyers. Companies are increasingly held accountable for their sourcing practices, and buyers from regions like Europe are particularly vigilant about sustainability standards.

Optical fiber manufacturers are adopting ‘green’ certifications and eco-friendly materials, which not only reduce environmental harm but also enhance brand reputation. Buyers should seek suppliers that demonstrate a commitment to sustainability through certifications such as ISO 14001 or adherence to the EU’s REACH regulations. By prioritizing suppliers who practice ethical sourcing, buyers can mitigate risks associated with reputational damage and regulatory compliance.

Furthermore, the lifecycle of optical fibers can be optimized through recycling and reuse initiatives, which can significantly reduce waste. Engaging with suppliers who invest in sustainable practices can lead to long-term partnerships that align with corporate social responsibility goals and contribute to a more sustainable industry.

What Is the Historical Context Behind Optical Fiber Development in China?

The evolution of optical fiber technology in China began in the late 20th century when the country recognized the importance of modern telecommunications infrastructure. Initially reliant on foreign technology, China rapidly advanced its capabilities through significant investments in research and development, resulting in a robust domestic optical fiber manufacturing sector.

By the early 2000s, China emerged as a global leader in optical fiber production, driven by a combination of government support and the growing domestic demand for telecommunications services. This historical trajectory has positioned Chinese manufacturers at the forefront of technological advancements, making them key players for international B2B buyers seeking reliable optical fiber solutions.

Understanding this evolution can provide valuable insights into the capabilities and innovations that Chinese suppliers bring to the table, enabling buyers to make informed sourcing decisions that align with their technological needs and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of optical fiber china

-

How do I solve quality assurance issues when sourcing optical fiber from China?

To address quality assurance concerns, start by thoroughly vetting suppliers. Request certifications such as ISO 9001 and relevant product quality standards specific to optical fiber. Conduct factory audits if possible, or engage third-party inspection services to verify product quality before shipment. Establish clear quality expectations and performance benchmarks in your contract, including penalties for non-compliance. Finally, consider ordering samples to assess quality firsthand before committing to larger orders. -

What is the best way to find reliable suppliers of optical fiber in China?

Finding reliable suppliers involves utilizing platforms like Alibaba, Global Sources, and Made-in-China, where you can filter suppliers by ratings, years in business, and customer reviews. Attend trade shows or exhibitions focused on telecommunications to meet suppliers in person and evaluate their offerings. Additionally, leverage industry networks and trade associations to gain recommendations for reputable suppliers. Always perform due diligence by checking references and assessing financial stability before finalizing any agreements. -

What are the typical minimum order quantities (MOQ) for optical fiber products?

MOQs for optical fiber can vary widely depending on the supplier and the type of product. Generally, you can expect MOQs to range from 100 to 1,000 kilometers of fiber. However, some suppliers may be willing to accommodate smaller orders for new customers or specific projects. Always clarify MOQs during initial discussions and negotiate terms that align with your business needs while considering the impact on pricing and shipping costs. -

What payment terms are commonly accepted when buying optical fiber from China?

Common payment terms include T/T (telegraphic transfer), PayPal, and L/C (letter of credit). Many suppliers prefer a 30% deposit upfront with the remaining 70% paid before shipment. For larger orders or established relationships, suppliers may offer more flexible terms. Always ensure that payment terms are clearly defined in your contract to avoid disputes later. Additionally, consider using escrow services for added security in transactions. -

How can I ensure timely delivery of optical fiber shipments from China?

To ensure timely delivery, start by discussing lead times with your supplier during negotiations. Establish a clear timeline for production and shipping, and include penalties for delays in your contract. Utilize reliable logistics partners with experience in international shipping to avoid customs delays. Consider air freight for urgent orders, although it may be more expensive than sea freight. Lastly, maintain regular communication with your supplier throughout the shipping process to address any potential issues promptly. -

What customization options are available for optical fiber products sourced from China?

Many Chinese suppliers offer customization options, including fiber type, cable length, and connector types. To explore these options, clearly communicate your specific requirements during initial discussions. Some suppliers can also provide custom packaging and labeling solutions to align with your branding needs. Be mindful that customization may affect lead times and pricing, so discuss these factors upfront to ensure your expectations align with the supplier’s capabilities. -

What should I know about import regulations for optical fiber products in my region?

Import regulations for optical fiber vary by country and region. It’s essential to familiarize yourself with the specific customs regulations and standards applicable to telecommunications equipment in your location. This may include certifications, safety standards, and import duties. Engage a customs broker or logistics expert who understands the regulations in your country to ensure compliance and avoid delays or additional costs. Proper documentation is crucial, so keep all invoices, certificates, and shipping documents organized. -

How can I manage supplier relationships effectively when sourcing optical fiber from China?

Effective supplier relationship management involves clear communication, setting mutual expectations, and regular check-ins. Establish a point of contact within the supplier’s organization to streamline communication. Schedule periodic reviews to assess performance, discuss challenges, and explore opportunities for improvement or collaboration. Building trust through transparency and timely payments can also foster a stronger partnership. Finally, be open to feedback and show appreciation for your supplier’s efforts to create a collaborative atmosphere.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for optical fiber china

The global optical fiber market presents significant opportunities for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe. By adopting strategic sourcing practices, companies can optimize their supply chains, reduce costs, and enhance the quality of their fiber optic products. Engaging with reputable suppliers in China allows buyers to leverage competitive pricing while ensuring compliance with international standards.

How Can Strategic Sourcing Benefit Your Business in Optical Fiber Procurement?

Strategic sourcing not only fosters long-term relationships with manufacturers but also enables buyers to stay ahead of technological advancements. Buyers should prioritize suppliers that invest in research and development, ensuring they have access to the latest innovations in optical fiber technology. Additionally, understanding the regional dynamics of the Chinese market can aid in anticipating shifts in pricing and availability.

What Should International Buyers Consider Moving Forward?

As the demand for high-speed connectivity continues to rise globally, international buyers must remain agile and informed. By building a diversified supplier network and implementing best practices in sourcing, businesses can secure a competitive edge. Embrace the evolving landscape of optical fiber procurement by exploring new partnerships and continuously evaluating supplier performance.

In conclusion, the future of optical fiber sourcing in China is promising. By taking proactive steps today, international buyers can position themselves for success in a dynamic market. Start exploring your options now to harness the full potential of this vital technology for your business growth.