The Ultimate Guide to Particle Board Manufacturer (2025)

Introduction: Navigating the Global Market for particle board manufacturer

Navigating the global market for particle board manufacturing can be a daunting task for international B2B buyers, especially when sourcing high-quality materials that meet specific project needs. As businesses from Africa, South America, the Middle East, and Europe (including Australia and Brazil) increasingly turn to sustainable and versatile building materials, understanding the nuances of particle board options becomes crucial. This guide offers a comprehensive overview of the various types of particle boards, their applications across different industries, and critical factors to consider when selecting suppliers.

In addition to detailing the diverse applications of particle boards—from furniture production to construction and interior design—this resource emphasizes the importance of supplier vetting. Buyers will find actionable insights on assessing quality, reliability, and compliance with international standards, which are essential for minimizing risks associated with procurement. Furthermore, we delve into cost considerations, helping you to navigate pricing structures and negotiate effectively with manufacturers.

By equipping you with essential knowledge about particle board characteristics and supplier evaluation, this guide empowers you to make informed purchasing decisions. It aims to bridge the gap between your sourcing needs and the complexities of the global market, ensuring that you can confidently select the right materials for your projects, no matter where you are located.

Understanding particle board manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Particle Board | Made from wood chips, glue, and resin; affordable | Furniture, cabinetry, and flooring | Pros: Cost-effective; versatile. Cons: Limited moisture resistance. |

| Moisture-Resistant Particle Board | Enhanced with water-resistant additives; durable | Kitchen and bathroom cabinetry | Pros: Better durability in humid environments. Cons: Higher cost than standard. |

| High-Density Particle Board | Denser and heavier; superior strength | Heavy-duty furniture and structural applications | Pros: Excellent load-bearing capacity. Cons: More expensive and heavier to transport. |

| Laminated Particle Board | Covered with a decorative laminate; aesthetic appeal | Retail displays, countertops, and furniture | Pros: Attractive finish; easy to clean. Cons: Can be susceptible to scratching. |

| Eco-Friendly Particle Board | Made from recycled materials; sustainable | Green building projects and eco-conscious furniture | Pros: Environmentally friendly; growing market appeal. Cons: May have variable quality. |

What Are the Characteristics of Standard Particle Board?

Standard particle board is the most basic form of particle board, composed of wood chips, adhesive, and resin. It is widely used due to its cost-effectiveness and versatility, making it ideal for applications such as furniture and cabinetry. However, buyers should be mindful that standard particle board has limited moisture resistance, which may not make it suitable for high-humidity environments.

How Does Moisture-Resistant Particle Board Differ?

Moisture-resistant particle board is specifically designed for areas prone to high moisture, incorporating additives that enhance its durability. This type is commonly used in kitchens and bathrooms where traditional particle board may fail. While it offers better performance in humid conditions, it typically comes at a higher price point compared to standard options, which buyers must consider when budgeting.

What Are the Benefits of High-Density Particle Board?

High-density particle board is characterized by its increased density and weight, providing superior strength and load-bearing capabilities. This makes it an excellent choice for heavy-duty applications, such as industrial furniture and structural uses. Although it offers impressive durability, its higher cost and weight can lead to increased shipping expenses, which buyers should factor into their purchasing decisions.

Why Choose Laminated Particle Board?

Laminated particle board features a decorative laminate finish, making it visually appealing for retail displays, countertops, and various furniture applications. The laminate surface is easy to clean and maintain, which is a significant advantage for commercial settings. However, it can be prone to scratching, which may affect its longevity and appearance over time, making it essential for buyers to assess their specific use cases.

What Are the Advantages of Eco-Friendly Particle Board?

Eco-friendly particle board is crafted from recycled materials, aligning with sustainable building practices. Its growing popularity in green construction projects offers businesses an opportunity to enhance their market appeal. While the environmental benefits are significant, buyers should be aware of potential quality variations and ensure they source from reputable manufacturers to meet their standards.

Related Video: Particle Board Flooring and Waterproofing

Key Industrial Applications of particle board manufacturer

| Industry/Sector | Specific Application of particle board manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Production of cabinets, tables, and chairs | Cost-effective, lightweight, and versatile material for furniture | Quality standards, moisture resistance, and sustainability practices |

| Construction | Use in wall panels and flooring systems | Provides structural support while being eco-friendly | Compliance with local building codes and environmental regulations |

| Interior Design | Decorative wall panels and custom fixtures | Enhances aesthetic appeal while maintaining functionality | Customization options and design flexibility |

| Packaging and Shipping | Use in crates and pallets for product transport | Durable and lightweight, reducing shipping costs | Strength and load-bearing capacity for specific products |

| Retail Displays | Creation of point-of-sale displays and shelving units | Attractive and customizable displays that enhance product visibility | Material finish and weight capacity for display stability |

How is Particle Board Used in Furniture Manufacturing?

In the furniture manufacturing sector, particle board serves as a primary material for creating various items such as cabinets, tables, and chairs. Its cost-effectiveness and lightweight nature make it an attractive choice for manufacturers looking to balance quality with affordability. For international buyers, especially from Africa and South America, sourcing particle board that meets specific quality standards and environmental certifications is crucial to ensure durability and compliance with local regulations.

What Role Does Particle Board Play in Construction?

In construction, particle board is utilized in applications like wall panels and flooring systems. Its structural support capabilities, combined with eco-friendly properties, make it an appealing option for builders aiming to reduce their carbon footprint. Buyers from the Middle East and Europe should consider local building codes and environmental regulations when sourcing particle board to ensure compliance and optimal performance in construction projects.

How is Particle Board Used in Interior Design?

Interior designers often leverage particle board for decorative wall panels and custom fixtures, enhancing the aesthetic appeal of spaces while maintaining functionality. The material allows for diverse design options that can cater to various themes and styles. B2B buyers in Europe and Australia should seek suppliers that offer customization options and design flexibility to meet specific project requirements.

What are the Benefits of Using Particle Board in Packaging and Shipping?

In the packaging and shipping industry, particle board is commonly used to manufacture crates and pallets, providing a durable yet lightweight solution for transporting products. This not only reduces shipping costs but also ensures that items are securely held during transit. Buyers, particularly in South America, should prioritize the strength and load-bearing capacity of the particle board to ensure it meets the demands of their specific products.

How Does Particle Board Enhance Retail Displays?

Particle board is extensively used to create point-of-sale displays and shelving units, providing an attractive and customizable option for retailers. This material enhances product visibility and can be tailored to fit various branding needs. For B2B buyers in Africa and Europe, considering material finishes and weight capacity is essential to ensure stability and aesthetic appeal in retail environments.

Related Video: Particle board production line/ waste wood pb producing process/ 0086-139 5619 9239

3 Common User Pain Points for ‘particle board manufacturer’ & Their Solutions

Scenario 1: Difficulty in Ensuring Quality Consistency in Particle Boards

The Problem: B2B buyers often face challenges with quality inconsistency when sourcing particle boards from different manufacturers. This inconsistency can stem from variations in raw materials, production processes, or quality control measures. For businesses relying on particle boards for furniture or construction, this issue can lead to significant financial losses due to product returns, customer dissatisfaction, and project delays. Buyers from regions like Africa and South America may find it particularly challenging to verify the manufacturing standards, especially if they are sourcing from international suppliers.

The Solution: To mitigate this pain point, B2B buyers should establish a comprehensive quality assurance protocol when dealing with particle board manufacturers. This can include requesting detailed specifications and certifications, such as ISO standards or Environmental Product Declarations (EPD). Additionally, consider conducting site visits to manufacturing facilities or utilizing third-party quality inspectors who can verify that the production processes meet the required standards. Furthermore, forming long-term partnerships with manufacturers who have a proven track record of consistent quality can reduce risks. Regular audits and feedback loops can also help ensure that the quality remains consistent over time.

Scenario 2: Navigating Environmental Regulations and Sustainability Concerns

The Problem: With increasing global awareness of environmental sustainability, many B2B buyers are faced with the challenge of sourcing eco-friendly particle boards. Buyers in Europe, for instance, are often required to comply with stringent regulations regarding formaldehyde emissions and the use of sustainable materials. Failure to adhere to these regulations not only risks legal ramifications but can also harm a company’s reputation among environmentally-conscious consumers.

The Solution: Buyers should prioritize sourcing particle boards that are certified by recognized sustainability standards, such as CARB (California Air Resources Board) certification or the Forest Stewardship Council (FSC) certification. These certifications ensure that the boards are made from sustainably sourced wood and meet low-emission standards. Additionally, engage with manufacturers who are transparent about their production processes and raw material sourcing. Participating in industry forums or trade shows can also provide insights into the latest sustainable practices in particle board manufacturing. Establishing a checklist of compliance requirements based on your region’s regulations can help streamline the procurement process and ensure that all sourced materials are environmentally friendly.

Scenario 3: Managing Supply Chain Disruptions

The Problem: International B2B buyers often grapple with supply chain disruptions that can impact the timely delivery of particle boards. Factors such as political instability, transportation issues, or unexpected increases in demand can lead to delays, affecting project timelines and profitability. This is particularly relevant for buyers in the Middle East and South America, where logistical challenges may be more pronounced.

The Solution: To effectively manage supply chain risks, buyers should diversify their supplier base rather than relying on a single manufacturer. This strategy can provide alternative sourcing options if one supplier encounters issues. Additionally, implementing a just-in-time inventory system can help reduce the impact of delays by allowing businesses to respond more flexibly to supply chain fluctuations. Collaborating closely with suppliers to establish clear communication channels can facilitate timely updates regarding production timelines and potential delays. Lastly, utilizing technology, such as supply chain management software, can provide real-time insights into inventory levels and supplier performance, enabling buyers to make informed decisions swiftly.

Strategic Material Selection Guide for particle board manufacturer

What are the Key Materials for Particle Board Manufacturing?

When selecting materials for particle board manufacturing, international B2B buyers must consider several common options, each with distinct properties, advantages, and limitations. This guide analyzes four prevalent materials: wood chips, MDF (Medium Density Fiberboard), OSB (Oriented Strand Board), and recycled materials.

How Do Wood Chips Perform in Particle Board Manufacturing?

Wood chips are one of the most traditional materials used in particle board production. They are derived from various wood species and provide a natural aesthetic.

Key Properties: Wood chips offer good mechanical strength and thermal insulation. They can withstand moderate temperatures but may not perform well under high humidity conditions.

Pros & Cons: The primary advantage of wood chips is their cost-effectiveness and availability. However, they may lead to inconsistencies in product quality due to variations in wood type and size. Additionally, they can be less durable than other materials, impacting the longevity of the final product.

Impact on Application: Wood chips are well-suited for applications where aesthetic appeal is important, such as furniture and cabinetry. However, they may not be ideal for high-moisture environments.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local regulations concerning sustainable sourcing. In Europe, adherence to standards such as PEFC or FSC certifications is crucial.

What is the Role of MDF in Particle Board Production?

Medium Density Fiberboard (MDF) is made from wood fibers bonded together with adhesives under heat and pressure.

Key Properties: MDF is known for its smooth surface and uniform density. It has excellent machining properties and can be painted or veneered easily.

Pros & Cons: The main advantage of MDF is its versatility and ability to produce intricate designs. However, it is heavier and more expensive than wood chips, and it may not be as durable under high moisture conditions unless treated.

Impact on Application: MDF is ideal for applications requiring detailed finishes, such as moldings and decorative panels. However, its susceptibility to water damage limits its use in areas with high humidity.

Considerations for International Buyers: Compliance with emission standards (e.g., E1 or E0 for formaldehyde emissions) is vital, especially in Europe. Buyers should also consider the availability of MDF in their region, as transportation costs can affect pricing.

How Does OSB Compare in Particle Board Manufacturing?

Oriented Strand Board (OSB) is composed of strands of wood oriented in specific directions and bonded with adhesives.

Key Properties: OSB offers high strength and durability, with good resistance to moisture when treated.

Pros & Cons: The primary advantage of OSB is its structural integrity and cost-effectiveness. However, it may not have the same aesthetic appeal as MDF or wood chips, making it less suitable for visible applications.

Impact on Application: OSB is often used in construction, including flooring and wall sheathing, due to its strength. Its performance in humid environments makes it a preferred choice for structural applications.

Considerations for International Buyers: Buyers should ensure compliance with local building codes and standards, such as ASTM in the U.S. or EN in Europe. OSB’s acceptance varies by region, so understanding local preferences is essential.

What Are the Benefits of Using Recycled Materials in Particle Board?

Recycled materials, such as reclaimed wood or post-consumer waste, are increasingly used in particle board manufacturing.

Key Properties: Recycled materials can offer similar mechanical properties to virgin materials while reducing environmental impact.

Pros & Cons: The primary advantage is sustainability, appealing to environmentally conscious buyers. However, sourcing recycled materials can be inconsistent, affecting product quality.

Impact on Application: Recycled particle boards can be used in various applications, including furniture and construction, where sustainability is prioritized.

Considerations for International Buyers: Compliance with environmental regulations and certifications is crucial, especially in Europe, where green building standards are stringent.

Summary Table of Material Selection for Particle Board Manufacturing

| Material | Typical Use Case for Particle Board Manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood Chips | Furniture, cabinetry | Cost-effective and readily available | Inconsistent quality and durability | Low |

| MDF | Decorative panels, moldings | Smooth finish and versatility | Heavier and more expensive | Medium |

| OSB | Structural applications, flooring | High strength and moisture resistance | Less aesthetic appeal | Low |

| Recycled Materials | Sustainable furniture, eco-friendly construction | Environmentally friendly | Inconsistent quality | Medium |

This strategic material selection guide serves as a valuable resource for international B2B buyers, helping them make informed decisions based on specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for particle board manufacturer

What Are the Main Stages of the Manufacturing Process for Particle Board?

The manufacturing of particle board typically involves several critical stages, each designed to ensure the final product meets the desired specifications and quality standards. Understanding these stages can help B2B buyers from Africa, South America, the Middle East, and Europe make informed decisions when selecting suppliers.

1. Material Preparation: What Raw Materials Are Used?

The first stage involves the preparation of raw materials, predominantly wood chips, sawdust, and wood shavings. These materials are sourced from sustainable forestry practices to ensure compliance with environmental regulations. In this phase, the wood is dried to a specific moisture content, usually around 8-12%, to prevent mold growth and ensure proper bonding during the subsequent stages.

Additionally, adhesives and resins are prepared, which are crucial for the bonding process. The selection of high-quality adhesives can significantly impact the particle board’s durability and performance. B2B buyers should inquire about the types of adhesives used and their compliance with international safety standards.

2. Forming: How Is Particle Board Shaped?

Once the materials are prepared, they are blended with adhesives and then formed into mat layers. This process typically utilizes a mat forming machine, which spreads the mixture evenly to create a consistent thickness. The mat is then compressed under high pressure and temperature in a hot press, which activates the adhesive and bonds the particles together.

The forming stage is crucial as it determines the density and strength of the final product. Buyers should ensure that the manufacturer uses advanced forming techniques, such as continuous press systems, to achieve uniformity and reduce production waste.

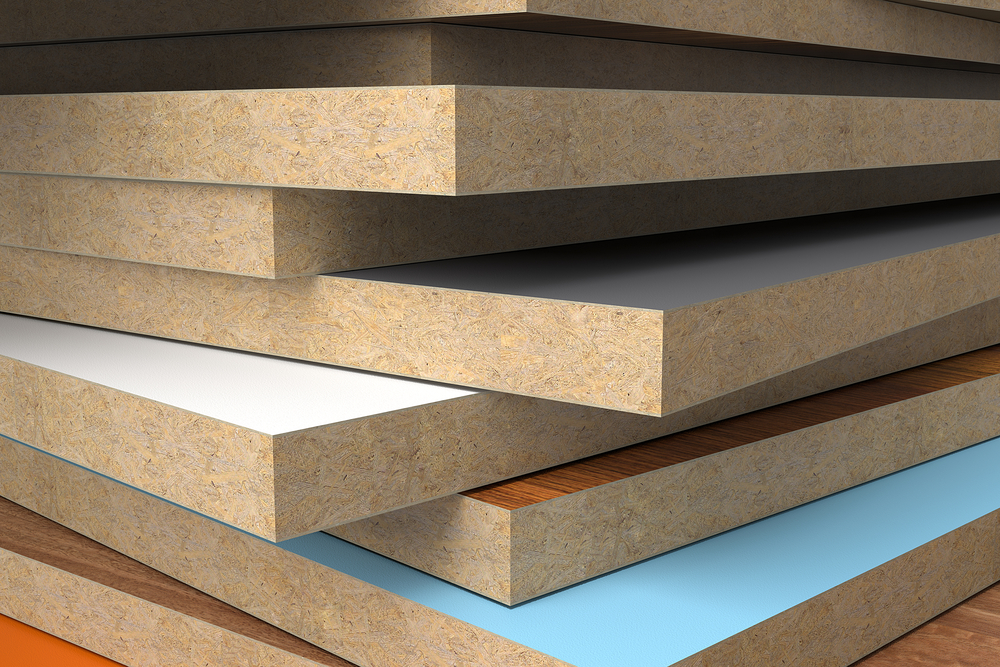

A stock image related to particle board manufacturer.

3. Assembly: What Are the Key Techniques?

After the boards are pressed and cooled, they undergo trimming and sanding to achieve precise dimensions and smooth surfaces. This assembly process may also include the application of additional finishes, such as laminates or coatings, to enhance the board’s appearance and durability.

B2B buyers should pay attention to the assembly techniques employed by manufacturers. Techniques such as edge banding and surface finishing not only improve aesthetic appeal but also contribute to the board’s moisture resistance and longevity.

4. Finishing: How Is Quality Enhanced?

The final stage in the manufacturing process involves quality checks and finishing touches. This includes sanding to ensure a smooth surface and applying finishes or treatments to enhance durability, scratch resistance, and aesthetic qualities.

Manufacturers may also apply anti-fungal or anti-bacterial treatments, which can be particularly beneficial for applications in humid or high-use environments. Buyers should inquire about the specific finishes offered and their compliance with relevant industry standards.

What Are the Key Quality Assurance Standards for Particle Board Manufacturers?

Quality assurance is critical in ensuring that particle board products meet international standards and customer expectations. B2B buyers should familiarize themselves with the following key quality assurance standards:

1. International Standards: Why Is ISO 9001 Important?

ISO 9001 is a widely recognized international standard for quality management systems (QMS). It outlines requirements for organizations to demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

For particle board manufacturers, achieving ISO 9001 certification indicates a commitment to quality and continuous improvement. Buyers should request documentation of a manufacturer’s ISO certification as part of their due diligence.

2. Industry-Specific Certifications: What Are CE and API?

In addition to ISO 9001, manufacturers may also seek industry-specific certifications. The CE marking is essential for products sold in the European Economic Area (EEA), indicating compliance with health, safety, and environmental protection standards.

The American Petroleum Institute (API) certification is relevant for manufacturers producing boards for the oil and gas industry. Buyers should verify that their suppliers hold the necessary certifications for their intended market.

What Are the Quality Control Checkpoints in Particle Board Manufacturing?

Effective quality control (QC) is essential throughout the manufacturing process to ensure product consistency and reliability. Key QC checkpoints include:

1. Incoming Quality Control (IQC): How Are Raw Materials Tested?

IQC involves inspecting raw materials upon arrival at the manufacturing facility. This includes checking wood quality, moisture content, and adhesive properties. Manufacturers should have robust procedures in place to reject substandard materials, ensuring only high-quality inputs are used in production.

2. In-Process Quality Control (IPQC): What Checks Are Conducted During Production?

During production, IPQC involves continuous monitoring of various parameters, such as temperature, pressure, and adhesive application rates. This real-time monitoring helps to identify any deviations from standard operating procedures, allowing for immediate corrective actions.

3. Final Quality Control (FQC): How Is the Finished Product Evaluated?

FQC occurs after the particle boards are manufactured. This includes dimensional checks, surface quality inspections, and testing for mechanical properties such as bending strength and durability. B2B buyers should ask for detailed reports on FQC outcomes to ensure the products meet their specifications.

How Can B2B Buyers Verify Supplier Quality Control?

Verification of a supplier’s quality control processes is vital for international buyers to mitigate risks. Here are several strategies:

1. Conducting Audits: What Should Buyers Look For?

Buyers can conduct on-site audits to assess the manufacturing processes, quality control measures, and compliance with international standards. During these audits, it’s essential to evaluate the facilities, equipment, and documentation practices.

2. Requesting Quality Reports: What Documentation Is Necessary?

B2B buyers should request quality assurance documentation, including IQC, IPQC, and FQC reports. This data provides insight into the manufacturer’s commitment to quality and highlights any areas of concern.

3. Utilizing Third-Party Inspections: How Can Independent Evaluations Help?

Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s quality control systems. These inspections can be particularly beneficial for buyers from different regions, as they ensure adherence to local and international standards.

Conclusion: What Should B2B Buyers Consider When Choosing a Particle Board Manufacturer?

When selecting a particle board manufacturer, international B2B buyers must consider the entire manufacturing process and quality assurance measures in place. Understanding the stages of production, applicable standards, and effective quality control checkpoints will empower buyers to make informed decisions. Engaging in thorough supplier verification practices, including audits and documentation requests, will further enhance the reliability of their purchasing choices. By focusing on these aspects, buyers can ensure they partner with manufacturers that deliver high-quality particle board products suitable for their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘particle board manufacturer’

The following checklist serves as a practical sourcing guide for international B2B buyers looking to procure particle boards from manufacturers. This guide provides actionable insights tailored for buyers from Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential before approaching manufacturers. Detail the dimensions, density, thickness, and intended application of the particle boards. Knowing your requirements helps in evaluating whether a supplier can meet your needs effectively.

- Consider the end-use: Different applications may require specific properties, such as moisture resistance or fire retardancy.

- Industry standards: Familiarize yourself with local and international standards relevant to particle boards to ensure compliance.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential particle board manufacturers. Utilize online platforms, trade directories, and industry forums to compile a list of candidates.

- Check online presence: Evaluate their website and product offerings to gauge professionalism and product range.

- Leverage trade shows: Participate in industry trade shows, which can provide opportunities to meet suppliers and assess product quality firsthand.

Step 3: Evaluate Supplier Certifications

Supplier certifications are crucial indicators of quality and compliance. Verify that the manufacturers possess relevant certifications, such as ISO 9001 for quality management or environmental certifications like FSC (Forest Stewardship Council).

- Request documentation: Ask for copies of certifications to validate their claims.

- Understand local regulations: Different regions may have specific regulatory requirements that suppliers must meet.

Step 4: Request Product Samples

Before making any commitments, request samples of the particle boards. This step allows you to assess the quality and suitability of the product for your needs.

- Evaluate physical characteristics: Inspect the samples for consistency in thickness, surface finish, and structural integrity.

- Conduct performance tests: If applicable, perform tests to evaluate properties like durability and moisture resistance.

Step 5: Assess Pricing and Terms

Once you have shortlisted potential suppliers, request detailed quotes that outline pricing, payment terms, and delivery schedules. Comparing offers helps in making an informed decision.

- Consider total cost: Look beyond the unit price to understand shipping costs, tariffs, and potential taxes.

- Negotiate terms: Be prepared to negotiate payment terms and discounts for bulk orders.

Step 6: Check References and Reviews

Contact references provided by the manufacturers to gather insights about their reliability and product performance. Online reviews can also provide valuable feedback.

- Ask specific questions: Inquire about the supplier’s delivery timelines, customer service, and how they handle issues.

- Cross-check reviews: Look for reviews across multiple platforms to get a balanced perspective.

Step 7: Finalize the Agreement

Once you have selected a supplier, finalize the agreement. Ensure that all terms, including specifications, pricing, delivery dates, and penalties for non-compliance, are clearly outlined.

- Legal review: Consider having a legal expert review the contract to protect your interests.

- Establish communication channels: Set up clear lines of communication for ongoing updates and support.

By following these steps, international B2B buyers can effectively navigate the sourcing process for particle boards, ensuring they select a reliable manufacturer that meets their specific needs.

Comprehensive Cost and Pricing Analysis for particle board manufacturer Sourcing

What Are the Key Cost Components in Particle Board Manufacturing?

When sourcing particle boards, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The cost of wood fibers, adhesives, and additives significantly influences the overall price. Prices can fluctuate based on the type of wood used (e.g., recycled vs. virgin materials) and market availability.

-

Labor: Labor costs vary by region and can impact the pricing structure. In countries with lower labor costs, such as certain regions in Africa and South America, manufacturers may offer more competitive pricing.

-

Manufacturing Overhead: This includes expenses related to utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can reduce overhead and ultimately lower prices.

-

Tooling: The cost of specialized equipment for production can be substantial. Buyers should consider whether the manufacturer has invested in modern tooling, as this can affect production efficiency and quality.

-

Quality Control (QC): Implementing a robust QC system incurs additional costs, but it ensures product consistency and compliance with international standards. This is particularly important for buyers requiring specific certifications.

-

Logistics: Transportation and handling costs can vary widely, influenced by the distance from the manufacturing facility to the buyer’s location and the chosen shipping method.

-

Margin: Manufacturers typically add a profit margin to cover their costs and ensure sustainability. Understanding typical margins in the industry can help buyers gauge fair pricing.

How Do Price Influencers Impact Particle Board Sourcing?

Several factors can influence the pricing of particle boards, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounted pricing. Buyers should negotiate MOQs based on their needs to optimize costs.

-

Specifications and Customization: Customized boards may incur additional costs due to specialized production processes. Clearly defining specifications upfront can prevent unexpected charges later.

-

Materials: The choice of materials directly impacts price. Higher-quality materials or certifications (e.g., eco-friendly) may increase costs but can also enhance product value.

-

Quality and Certifications: Products that meet specific international standards or certifications may command higher prices due to the added assurance of quality and compliance.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established manufacturers with a history of quality may charge a premium, but they often provide better service and support.

-

Incoterms: Understanding Incoterms is crucial for international transactions. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, directly impacting the total cost.

What Are Effective Buyer Tips for Particle Board Sourcing?

To maximize cost-efficiency and ensure a successful procurement process, international B2B buyers should consider the following strategies:

-

Negotiate Pricing and Terms: Engage in discussions with suppliers to negotiate better pricing, especially when placing large orders or if you have a long-term partnership in mind.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors such as shipping costs, potential tariffs, and the longevity of the product to understand the true cost of ownership.

-

Understand Pricing Nuances: Be aware of regional pricing differences. For instance, manufacturers in Europe may have higher labor and material costs compared to those in Africa or South America, impacting pricing strategies.

-

Research Market Trends: Staying informed about market trends and material availability can provide leverage during negotiations. Knowledge of supply chain dynamics can help in anticipating price fluctuations.

-

Ask for Transparency: Request detailed breakdowns of costs from suppliers. This can help identify areas where savings may be possible and clarify the rationale behind pricing.

Disclaimer on Indicative Prices

Pricing for particle boards can vary widely based on the factors mentioned above. Buyers are encouraged to conduct thorough market research and consult multiple suppliers to obtain the most accurate and competitive pricing.

Alternatives Analysis: Comparing particle board manufacturer With Other Solutions

A stock image related to particle board manufacturer.

When considering options for manufacturing and construction materials, it is essential to evaluate alternatives to particle board. This analysis will provide international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, with insights into comparable solutions that may better suit their specific needs.

Comparative Overview of Alternatives to Particle Board

| Comparison Aspect | Particle Board Manufacturer | MDF (Medium Density Fiberboard) | Plywood |

|---|---|---|---|

| Performance | Good for general use, less durable than plywood | Excellent surface finish, versatile in applications | High strength and durability, resistant to moisture |

| Cost | Generally affordable | Slightly higher than particle board | More expensive than both alternatives |

| Ease of Implementation | Easy to cut and shape, lightweight | Requires specialized tools for cutting | Heavier, may need advanced machinery for processing |

| Maintenance | Low maintenance | Low maintenance, but can warp if not sealed | Requires sealing for moisture resistance |

| Best Use Case | Furniture, cabinetry, and decorative applications | Cabinetry, moldings, and detailed work | Flooring, structural applications, and furniture |

What Are the Pros and Cons of MDF Compared to Particle Board?

MDF (Medium Density Fiberboard) is a popular alternative to particle board, particularly in cabinetry and furniture manufacturing. One of its key advantages is its smooth surface, which allows for a superior finish and paint adherence. However, MDF tends to be denser and heavier than particle board, making it more challenging to work with. While it offers excellent versatility in applications, its cost is typically higher, which may be a consideration for budget-conscious buyers. Additionally, MDF can be susceptible to moisture damage if not properly sealed, which is a critical factor in humid environments.

How Does Plywood Compare to Particle Board in Terms of Performance?

Plywood stands out for its strength and durability, making it suitable for more demanding applications, including flooring and structural elements. Its layered construction provides resistance to warping and splitting, especially when exposed to moisture. However, plywood is generally more expensive than both particle board and MDF, which could deter some buyers. It also requires more advanced tools for cutting and shaping, adding complexity to the manufacturing process. For projects that demand high-performance materials, plywood may be the preferred choice despite its higher cost.

Conclusion: How Can International B2B Buyers Choose the Right Solution?

Selecting the right material ultimately depends on the specific requirements of your project. For those focused on cost-effectiveness and general applications, particle board remains a viable option. However, if aesthetics and finish quality are paramount, MDF may provide the solution you need. On the other hand, for high-load-bearing applications where durability is critical, plywood is unmatched despite its higher price point. Buyers should carefully evaluate their project needs, budget constraints, and the environmental conditions of the application to make an informed decision.

Essential Technical Properties and Trade Terminology for particle board manufacturer

What Are the Essential Technical Properties of Particle Board?

Understanding the technical properties of particle board is crucial for international B2B buyers, especially those looking to make informed purchasing decisions. Here are some key specifications that manufacturers often highlight:

1. Material Grade

Material grade refers to the quality classification of the particle board, which can range from low-density to high-density variants. Higher-grade boards are typically more durable and suitable for applications requiring structural integrity, such as furniture and cabinetry. Buyers should prioritize material grade based on their specific application needs to ensure longevity and performance.

2. Density

Density, measured in kilograms per cubic meter (kg/m³), indicates the weight of the particle board. Higher density generally correlates with better mechanical properties, such as strength and resistance to wear. For B2B buyers, selecting the appropriate density can significantly impact the performance and durability of the final product, especially in high-traffic or load-bearing applications.

3. Tolerance

Tolerance refers to the permissible deviation from specified dimensions in the particle board’s thickness, width, and length. For manufacturers, maintaining tight tolerances is vital to ensure compatibility with other components in a construction or furniture assembly. Buyers should inquire about tolerance standards to avoid issues during installation or assembly.

4. Moisture Resistance

Moisture resistance is a critical property, especially in humid environments. Particle boards with moisture-resistant additives are better suited for kitchens and bathrooms. For international buyers, understanding the moisture resistance rating can help prevent future issues related to swelling, warping, or mold growth.

5. Surface Finish

The surface finish of particle board can affect both aesthetics and functionality. Options may include melamine, veneer, or laminate finishes. A well-finished surface is essential for applications where visual appeal is important, such as in consumer-facing furniture. Buyers should consider the desired finish in conjunction with cost and application requirements.

What Are Common Trade Terms Used in Particle Board Manufacturing?

Familiarizing yourself with industry terminology can streamline negotiations and purchasing processes. Here are several critical trade terms relevant to particle board manufacturing:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are sold under another company’s brand. For buyers, working with an OEM can provide access to customized particle board solutions that meet specific design requirements or standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is essential for B2B buyers to manage inventory costs effectively. This can also impact cash flow and storage considerations, especially for smaller businesses.

3. RFQ (Request for Quotation)

An RFQ is a formal document requesting pricing and terms from suppliers. It is an essential tool for B2B buyers to compare offers and negotiate better deals. A well-prepared RFQ can also clarify specifications and expectations, reducing misunderstandings during the procurement process.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, defining the responsibilities of buyers and sellers in international trade. Understanding these terms is crucial for international buyers to clarify shipping, insurance, and risk responsibilities.

5. Lead Time

Lead time refers to the time it takes from placing an order to the delivery of the product. For B2B buyers, knowing the lead time helps in planning inventory and project timelines. Longer lead times may necessitate more advanced planning and could impact production schedules.

By understanding these essential properties and terms, international B2B buyers can make more informed decisions when selecting particle board manufacturers, ensuring they choose the right products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the particle board manufacturer Sector

What Are the Current Market Dynamics and Key Trends in the Particle Board Manufacturing Sector?

The particle board manufacturing sector is experiencing significant transformations influenced by various global drivers. Key trends include an increasing demand for eco-friendly materials, driven by consumer preferences for sustainable products. This shift is particularly evident in markets across Africa, South America, the Middle East, and Europe, where buyers are seeking suppliers who prioritize sustainability and ethical practices. Technological advancements, such as automation and digitalization in manufacturing processes, are also reshaping the landscape, enhancing production efficiency and reducing costs.

International B2B buyers are increasingly leveraging data analytics and supply chain management software to optimize sourcing decisions. These technologies enable buyers to evaluate supplier performance, track material availability, and forecast market trends more accurately. Additionally, the rise of e-commerce platforms has simplified the procurement process, providing buyers with access to a wider range of suppliers and competitive pricing.

Emerging markets, particularly in Africa and South America, present new opportunities for particle board manufacturers. These regions are witnessing urbanization and infrastructure development, driving the demand for affordable housing solutions, which in turn increases the need for cost-effective building materials such as particle board. As a result, international buyers should consider diversifying their supplier base to capitalize on these growth opportunities.

How Important Is Sustainability and Ethical Sourcing in the Particle Board Manufacturing Sector?

Sustainability and ethical sourcing have become paramount in the particle board manufacturing sector. The environmental impact of traditional wood sourcing methods has prompted a shift towards sustainable practices, including the use of recycled materials and certified wood. Buyers are increasingly prioritizing suppliers who adhere to sustainability certifications, such as the Forest Stewardship Council (FSC) and Programme for the Endorsement of Forest Certification (PEFC). These certifications assure buyers that the materials used in production are sourced responsibly, minimizing deforestation and promoting biodiversity.

Moreover, consumers are becoming more environmentally conscious, which drives businesses to adopt ethical supply chains. International B2B buyers from Africa, South America, the Middle East, and Europe should ensure that their suppliers are transparent about their sourcing practices. This not only enhances brand reputation but also meets the growing regulatory requirements for sustainable business practices. By aligning with suppliers who prioritize sustainability, buyers can mitigate risks associated with environmental liabilities and contribute positively to global sustainability goals.

What Is the Brief Evolution of the Particle Board Manufacturing Sector?

The particle board manufacturing sector has evolved significantly since its inception in the mid-20th century. Initially developed as a cost-effective alternative to solid wood, particle board has gained popularity due to its versatility and ease of production. Over the years, advancements in technology have improved the quality of particle boards, making them suitable for various applications, including furniture, cabinetry, and construction.

In recent years, the industry has seen a marked shift towards sustainability, with manufacturers increasingly adopting environmentally friendly practices. The introduction of eco-friendly adhesives and the use of recycled wood and agricultural residues have transformed the production process, catering to the growing demand for sustainable materials. This evolution reflects a broader trend in the global market, where sustainability is no longer an option but a necessity for manufacturers aiming to remain competitive in the B2B landscape. As the sector continues to evolve, international buyers must stay informed about these changes to make strategic sourcing decisions that align with their business goals.

Frequently Asked Questions (FAQs) for B2B Buyers of particle board manufacturer

-

How do I solve quality concerns when sourcing from a particle board manufacturer?

To address quality concerns, start by requesting samples before placing a bulk order. Evaluate the physical properties of the samples, such as thickness, density, and surface finish. Additionally, inquire about the manufacturer’s quality assurance processes, certifications (like ISO), and past customer reviews. Establish clear quality criteria and ensure that the manufacturer agrees to these standards in your contract. Regular audits and inspections during production can further safeguard against quality issues. -

What is the best type of particle board for furniture manufacturing?

The best type of particle board for furniture manufacturing typically includes melamine-faced particle board, which offers a durable, scratch-resistant surface. For high-end furniture, consider using high-density particle board, which provides better structural integrity and longevity. Additionally, evaluate options like moisture-resistant boards for environments prone to humidity. Assess the intended use and design requirements to choose the most suitable particle board variant for your projects. -

How can I vet a particle board manufacturer effectively?

Vetting a particle board manufacturer involves several steps. Start by researching their reputation through online reviews and industry forums. Request references from previous clients to gauge their reliability and quality. Evaluate their production capacity and technology to ensure they meet your volume requirements. Finally, arrange a factory visit if possible, or conduct a virtual inspection to assess their operations and compliance with industry standards. -

What are the typical minimum order quantities (MOQs) for particle board?

Minimum order quantities (MOQs) for particle board can vary widely depending on the manufacturer and the specifications of the product. Generally, MOQs range from 500 to 1,000 square meters for standard products. Custom specifications or specialized boards may have higher MOQs. Always confirm MOQs during your negotiations to ensure they align with your purchasing strategy and budget. -

What payment terms should I negotiate with a particle board manufacturer?

When negotiating payment terms, aim for a balance that protects both parties. Common terms include a 30% upfront deposit with the remaining 70% due upon delivery or inspection. Consider options for letters of credit or escrow services for larger orders to mitigate risk. Always review the terms in the context of your cash flow and the manufacturer’s track record before finalizing the agreement. -

How do logistics and shipping impact my sourcing of particle board?

Logistics and shipping are critical factors in sourcing particle board, as they affect delivery times and overall costs. Evaluate the manufacturer’s location relative to your business to minimize shipping expenses. Discuss shipping options, including freight forwarders and insurance coverage, to ensure your products arrive safely and on time. Factor in potential customs duties and local regulations that may impact the importation process, especially when sourcing internationally. -

What customization options are available when ordering particle board?

Many particle board manufacturers offer customization options such as varying thicknesses, finishes, and colors. Some can also provide specific treatments, like moisture or fire resistance, depending on your project needs. Discuss your requirements in detail during the initial consultation to understand the manufacturer’s capabilities and any additional costs associated with custom orders. -

How can I ensure sustainable sourcing of particle board?

To ensure sustainable sourcing, look for manufacturers that comply with environmental standards such as FSC (Forest Stewardship Council) certification. This certification indicates that the wood used in the particle board comes from responsibly managed forests. Additionally, inquire about the manufacturer’s practices regarding waste management, recycling, and the use of eco-friendly adhesives. By prioritizing sustainable sourcing, you can enhance your brand’s reputation and contribute to environmental conservation.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for particle board manufacturer

How Can Strategic Sourcing Enhance Your Supply Chain for Particle Boards?

In conclusion, strategic sourcing is pivotal for international B2B buyers, especially those operating in diverse markets across Africa, South America, the Middle East, and Europe. By prioritizing quality, sustainability, and cost-effectiveness in sourcing particle boards, businesses can enhance their operational efficiency while meeting the increasing demand for environmentally friendly materials. Establishing strong relationships with reliable manufacturers not only mitigates risks associated with supply chain disruptions but also fosters innovation and adaptability within your business model.

What Are the Key Takeaways for B2B Buyers in the Particle Board Market?

Investing in strategic sourcing allows you to capitalize on competitive pricing and superior product quality. It is essential to leverage regional advantages, such as local suppliers in emerging markets, to optimize your sourcing strategy. Furthermore, maintaining transparency in supplier relationships can lead to better negotiations and long-term partnerships that are beneficial for both parties.

What Does the Future Hold for Particle Board Sourcing?

As the global market continues to evolve, the demand for particle boards is expected to rise, particularly in construction and furniture industries. By adopting a forward-thinking approach to sourcing, international buyers can ensure they remain ahead of the curve. Now is the time to reassess your sourcing strategies and explore new partnerships that align with your business goals. Invest in your supply chain today to secure a sustainable and profitable future in the particle board industry.