The Ultimate Guide to Power Transformer Supplier (2025)

Introduction: Navigating the Global Market for power transformer supplier

In today’s interconnected world, sourcing reliable power transformer suppliers can be a daunting task for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. The challenge lies not only in identifying high-quality products but also in understanding the various applications and specifications that power transformers must meet for different industries. This comprehensive guide aims to demystify the global market for power transformers, equipping international buyers with essential insights into types, applications, supplier vetting processes, and cost considerations.

Throughout this guide, we will explore the different types of power transformers, from distribution to power and autotransformers, detailing their respective applications in sectors such as energy, manufacturing, and telecommunications. Additionally, we will provide actionable strategies for effectively vetting suppliers, ensuring compliance with international standards, and negotiating favorable pricing structures. By addressing these critical aspects, this guide empowers B2B buyers to make informed purchasing decisions that align with their operational needs and budget constraints.

Whether you are a procurement manager in Germany looking for advanced transformer solutions or a project coordinator in the UAE seeking cost-effective options, this guide offers the knowledge and tools necessary to navigate the complexities of the power transformer market with confidence. Get ready to transform your sourcing strategy and enhance your operational efficiency.

Understanding power transformer supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Step-Up Transformers | Increases voltage for transmission over long distances | Power generation, substations | Pros: Efficient for long-distance transmission. Cons: Higher initial costs. |

| Step-Down Transformers | Decreases voltage for distribution to end users | Industrial plants, commercial use | Pros: Suitable for local distribution. Cons: Limited to lower voltage applications. |

| Isolation Transformers | Provides electrical isolation between circuits | Sensitive equipment, hospitals | Pros: Enhances safety, reduces noise. Cons: Bulkier and more expensive than standard types. |

| Auto Transformers | Uses a single winding for both primary and secondary | Railways, large industrial units | Pros: Compact design, cost-effective. Cons: Less isolation, not suitable for all applications. |

| Three-Phase Transformers | Handles three-phase power efficiently | Manufacturing, large facilities | Pros: High efficiency, balanced load. Cons: More complex installation and maintenance. |

What are Step-Up Transformers and Their B2B Relevance?

Step-up transformers are crucial for increasing voltage levels for efficient power transmission over long distances. They are primarily used in power generation stations and substations where high voltage is necessary to minimize energy loss. When purchasing step-up transformers, B2B buyers should consider the transformer’s voltage rating, efficiency, and compatibility with existing systems. The higher initial costs can be offset by long-term savings through improved transmission efficiency.

How Do Step-Down Transformers Benefit Businesses?

Step-down transformers serve the purpose of reducing voltage levels to safe and usable levels for end users. Commonly found in industrial plants and commercial buildings, they ensure that equipment receives the appropriate voltage. B2B buyers should focus on the transformer’s capacity and voltage specifications to ensure they meet operational needs. While they are more affordable than step-up transformers, the limited application scope should be considered when making a purchase.

What are the Advantages of Isolation Transformers?

Isolation transformers are designed to provide electrical isolation between circuits, enhancing safety and reducing electromagnetic interference. They are particularly beneficial in settings such as hospitals and laboratories where sensitive equipment is used. Buyers should evaluate the isolation level and potential noise reduction benefits when considering this type. Although they can be bulkier and more costly, the safety enhancements make them a worthy investment for critical applications.

Why Choose Auto Transformers for Certain Applications?

Auto transformers utilize a single winding for both primary and secondary functions, making them a compact and cost-effective choice for applications like railways and large industrial setups. B2B buyers should assess the required voltage levels and load capacity when selecting auto transformers. While they offer significant savings and space efficiency, their lack of electrical isolation limits their use in sensitive applications.

What Makes Three-Phase Transformers Essential for Large Facilities?

Three-phase transformers are designed to handle three-phase power systems efficiently, making them ideal for large manufacturing and industrial facilities. They provide balanced load distribution and high efficiency, which is critical for operations requiring substantial power. Buyers should consider the transformer’s configuration and capacity to ensure it aligns with their energy demands. Although installation and maintenance can be more complex, the operational benefits often outweigh these challenges.

Related Video: Construction of Transformer and Its Types – Single Phase Transformer – Basic Electrical Engineering

Key Industrial Applications of power transformer supplier

| Industry/Sector | Specific Application of power transformer supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Energy & Utilities | Voltage regulation in power distribution networks | Ensures stable and efficient power delivery, reducing outages and maintenance costs | Compliance with local regulations, capacity requirements, and environmental standards |

| Manufacturing | Power supply for heavy machinery and production lines | Increases operational efficiency and minimizes downtime | Transformer sizing, durability, and compatibility with existing systems |

| Renewable Energy | Integration of renewable sources (solar, wind) into the grid | Supports sustainability goals and reduces reliance on fossil fuels | Grid compatibility, inverter integration, and scalability for future expansions |

| Construction & Mining | Power supply for construction sites and mining operations | Enhances productivity and safety on-site | Mobility, ruggedness, and ability to operate in harsh conditions |

| Transportation & Rail | Power supply for electric trains and metro systems | Improves efficiency and reduces carbon footprint | Compliance with safety standards, load capacity, and maintenance support |

How is Power Transformer Supplier Used in Energy & Utilities?

In the energy and utilities sector, power transformers are essential for voltage regulation in power distribution networks. They facilitate the transmission of electricity from generation sites to consumers while maintaining the appropriate voltage levels. This is crucial for minimizing energy losses and ensuring reliable service. International buyers, especially from regions like Africa and the Middle East, must consider compliance with local regulations and the capacity requirements of their grids when sourcing these transformers.

What are the Applications in Manufacturing?

Power transformers are vital in manufacturing, where they provide the necessary power supply for heavy machinery and production lines. By ensuring a consistent power supply, these transformers enhance operational efficiency and significantly reduce downtime due to power interruptions. Buyers should focus on transformer sizing, durability, and compatibility with existing systems to ensure seamless integration into their manufacturing processes, particularly in regions like South America and Europe.

How Do Power Transformers Support Renewable Energy?

The renewable energy sector increasingly relies on power transformers to integrate sources such as solar and wind into the electrical grid. These transformers help manage the variability of renewable energy, ensuring stable power delivery while supporting sustainability initiatives. For international buyers, key considerations include grid compatibility, inverter integration, and the scalability of transformer systems to accommodate future energy demands.

What is the Role in Construction & Mining?

In construction and mining, power transformers are used to supply electricity to construction sites and heavy equipment. This application enhances productivity and safety by providing a reliable power source for tools and machinery. Buyers in these industries need to prioritize the mobility and ruggedness of transformers, ensuring they can withstand harsh conditions often found in remote locations.

How Do Power Transformers Benefit Transportation & Rail?

In the transportation sector, especially in electric trains and metro systems, power transformers play a critical role in supplying the necessary electricity for efficient operation. They help reduce the carbon footprint of public transport systems, aligning with global sustainability goals. When sourcing transformers for this application, international buyers must ensure compliance with safety standards, adequate load capacity, and reliable maintenance support to guarantee long-term functionality.

Related Video: How does a Transformer work ?

3 Common User Pain Points for ‘power transformer supplier’ & Their Solutions

Scenario 1: Inconsistent Power Supply in Remote Areas

The Problem: International B2B buyers from regions such as Africa and South America often face the challenge of inconsistent power supply, especially in remote areas. This instability not only disrupts operations but can also lead to significant financial losses. Many suppliers may not fully understand the specific power quality requirements for these regions, resulting in the provision of inappropriate transformer solutions. The complexities of local regulations, environmental conditions, and infrastructure limitations further complicate the sourcing process.

The Solution: To address this issue, buyers should engage with power transformer suppliers who have a proven track record of customizing solutions for challenging environments. It is vital to communicate your specific power quality requirements, such as voltage levels, load characteristics, and frequency stability, to your supplier. Conduct thorough due diligence by reviewing case studies of similar projects in your region. Additionally, request suppliers to provide on-site assessments to evaluate local conditions and tailor transformers to meet those challenges. By fostering a collaborative relationship with your supplier, you can ensure that the transformers are not only suitable for current needs but also scalable for future growth.

Scenario 2: Delays in Delivery and Installation

The Problem: Time is of the essence in the B2B sector, particularly when it comes to the installation of power transformers. Buyers in the Middle East and Europe frequently encounter delays in the delivery and installation of transformers, which can stall projects and lead to increased costs. These delays can stem from various factors, including complex logistics, customs clearance issues, and insufficient supplier capacity to meet demand.

The Solution: To mitigate these delays, buyers should establish clear timelines and expectations with their suppliers from the outset. It is essential to understand the supplier’s production capabilities and lead times before placing an order. Buyers should also consider sourcing transformers from local or regional suppliers who can offer shorter delivery times. Implementing a robust supply chain management strategy that includes contingency planning and regular communication with suppliers can further reduce risks. Additionally, utilizing technology such as supply chain tracking software can provide real-time updates on the status of your order, allowing for proactive adjustments to project timelines.

Scenario 3: Difficulty in Understanding Technical Specifications

The Problem: Many B2B buyers, particularly those new to the power transformer market, struggle to understand the technical specifications and requirements of transformers. This lack of knowledge can lead to the purchase of inadequate or incompatible equipment, resulting in operational inefficiencies and safety risks. Buyers from diverse backgrounds may also find it challenging to communicate their needs effectively to suppliers, which can exacerbate the problem.

The Solution: To overcome this barrier, buyers should invest time in educating themselves about the fundamental aspects of power transformers, including key specifications such as power rating, efficiency, and cooling methods. Many suppliers offer technical resources, webinars, and workshops that can enhance buyers’ understanding. Furthermore, engaging with suppliers who provide comprehensive technical support and guidance can significantly improve the purchasing process. Establishing a dialogue with the supplier’s engineering team can help clarify specifications and ensure that the selected transformer meets the operational requirements. Additionally, buyers should consider requesting detailed product documentation and performance data before finalizing their orders, ensuring they make informed decisions.

Strategic Material Selection Guide for power transformer supplier

When selecting materials for power transformers, it is essential to consider their properties, advantages, and limitations, especially from a B2B perspective. Here, we will analyze four common materials used in power transformers: silicon steel, copper, aluminum, and epoxy resin. Each material has unique characteristics that can significantly impact the performance and suitability of the transformer in various applications.

What are the Key Properties of Silicon Steel in Power Transformers?

Silicon steel is widely used in the cores of power transformers due to its excellent magnetic properties. It typically has a high electrical resistivity, which reduces eddy current losses, and can operate efficiently at high temperatures, with a temperature rating often exceeding 200°C. Additionally, its corrosion resistance is moderate, making it suitable for various environments.

Pros and Cons of Silicon Steel

The main advantage of silicon steel is its high magnetic permeability, which enhances the efficiency of the transformer. However, it can be relatively expensive compared to other materials, and its manufacturing process is complex, requiring precise control to achieve optimal properties. Silicon steel is particularly suitable for applications requiring high efficiency and low noise levels.

How Does Copper Perform as a Material for Power Transformers?

Copper is another common material used in the windings of power transformers. It has excellent electrical conductivity, with a conductivity rating of about 59% IACS (International Annealed Copper Standard), and can withstand high temperatures (up to 300°C). Copper also has good corrosion resistance, especially when properly coated.

Pros and Cons of Copper

The primary advantage of copper is its superior conductivity, which allows for more compact designs and better performance. However, copper is more expensive than aluminum and can be heavier, which may affect installation and transportation costs. Additionally, in regions with high humidity, copper may require additional protective measures to prevent corrosion.

What Role Does Aluminum Play in Power Transformers?

Aluminum is often used as an alternative to copper in transformer windings. It has a lower conductivity than copper (approximately 61% of copper), but it is significantly lighter and less expensive. Aluminum can also operate at high temperatures, typically around 150°C, and has good resistance to corrosion.

Pros and Cons of Aluminum

The key advantage of aluminum is its cost-effectiveness and lightweight nature, making it easier to handle and install. However, its lower conductivity means that larger cross-sectional areas are required, which can lead to bulkier designs. Additionally, aluminum’s susceptibility to oxidation can pose challenges in certain environments, necessitating protective coatings.

Why is Epoxy Resin Important in Power Transformers?

Epoxy resin is commonly used as an insulating material in power transformers. It has excellent dielectric properties, allowing it to withstand high voltages and providing good thermal stability. Epoxy resin is also resistant to moisture and chemicals, making it suitable for various environmental conditions.

Pros and Cons of Epoxy Resin

The main advantage of epoxy resin is its outstanding insulating properties, which enhance the transformer’s reliability and safety. However, it can be more expensive than traditional insulating materials, and its curing process can be time-consuming, affecting manufacturing timelines. Additionally, while epoxy is durable, it can be brittle under certain conditions, which may lead to mechanical failures.

Summary Table of Material Selection for Power Transformers

| Material | Typical Use Case for power transformer supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Steel | Transformer cores | High magnetic permeability | Expensive and complex manufacturing | High |

| Copper | Transformer windings | Superior electrical conductivity | Heavier and costlier than aluminum | High |

| Aluminum | Transformer windings | Lightweight and cost-effective | Lower conductivity and oxidation risk | Medium |

| Epoxy Resin | Insulation material | Excellent dielectric properties | Expensive and time-consuming curing | Medium |

In conclusion, the selection of materials for power transformers is critical for optimizing performance and ensuring reliability. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should consider the specific properties, advantages, and limitations of each material, along with compliance with local standards and regulations, to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for power transformer supplier

What Are the Main Stages of Manufacturing Power Transformers?

The manufacturing process of power transformers is complex and requires meticulous attention to detail at every stage. The primary stages include material preparation, forming, assembly, and finishing. Each stage plays a crucial role in ensuring the final product meets the performance and reliability standards expected in the industry.

1. Material Preparation

The first step involves sourcing high-quality raw materials, including silicon steel for cores, copper or aluminum for windings, and insulation materials. Suppliers must ensure that these materials comply with international standards, such as IEC 60076 for power transformers. Rigorous inspections are conducted to verify that the materials meet the specified requirements, which is essential for achieving the desired electrical and thermal properties.

2. Forming

Once the materials are prepared, they undergo forming processes. This includes cutting the steel sheets to size and shaping them into the core laminations. The core is assembled using techniques that minimize air gaps and improve magnetic efficiency. Advanced methods like laser cutting and automated welding are increasingly used to enhance precision and reduce manufacturing time.

3. Assembly

The assembly stage involves winding the copper or aluminum conductors around the core. This process can be done using automated winding machines to ensure uniformity and precision. After winding, insulation is applied to prevent short circuits and ensure safety. The transformer’s tank is then assembled, which includes fitting various components like bushings, tap changers, and temperature sensors.

4. Finishing

The final stage involves testing and quality checks, as well as painting and sealing the transformer to protect it from environmental factors. Proper finishing is crucial for the longevity and reliability of the transformer in diverse operating conditions. This stage may also include the application of protective coatings that comply with international corrosion resistance standards.

How Do Quality Assurance Practices Ensure Reliability in Power Transformers?

Quality assurance (QA) is vital in the manufacturing of power transformers, as it ensures that products meet predefined quality standards and specifications. Several international and industry-specific standards guide QA practices.

Relevant International Standards for Power Transformers

B2B buyers should look for suppliers that comply with standards such as ISO 9001, which outlines quality management systems, and IEC standards specific to transformers. Compliance with CE marking, which signifies conformity with health, safety, and environmental protection standards, is also essential for products sold in the European market.

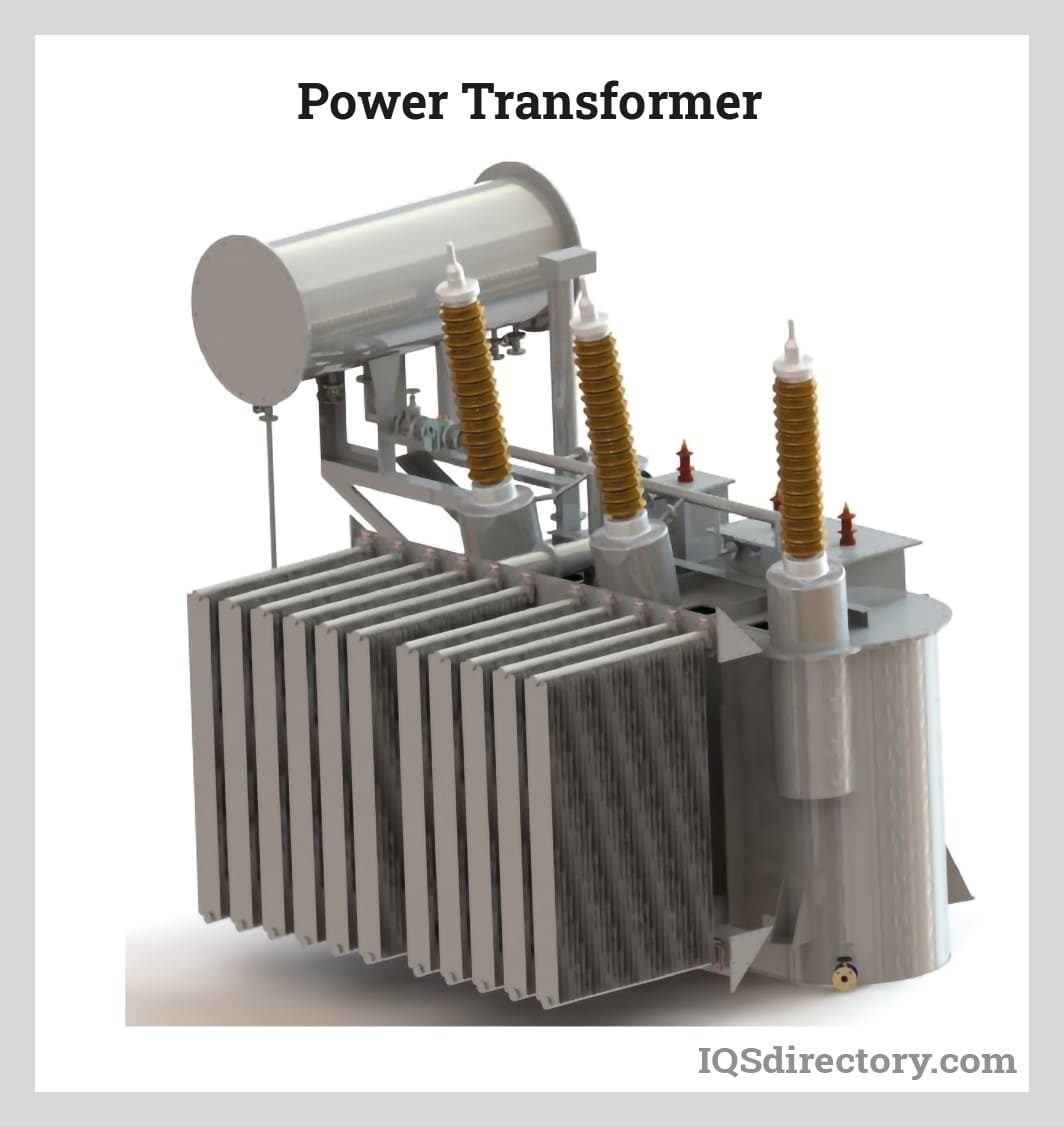

A stock image related to power transformer supplier.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is an integral part of the manufacturing process, typically divided into several checkpoints:

1. Incoming Quality Control (IQC)

This checkpoint involves inspecting raw materials upon receipt to ensure they meet the required specifications. The IQC process can include visual inspections, material tests, and documentation reviews.

2. In-Process Quality Control (IPQC)

During manufacturing, IPQC is conducted to monitor various stages of production. This includes checking the assembly process, ensuring that winding is uniform, and that insulation is correctly applied. Regular sampling and testing during this phase help identify defects early.

3. Final Quality Control (FQC)

Once manufacturing is complete, FQC involves thorough testing of the finished transformers. Common tests include insulation resistance testing, power factor testing, and temperature rise tests. These tests ensure the transformer operates efficiently under load conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying a supplier’s QC practices is critical for international B2B buyers to mitigate risks. Here are actionable strategies to assess QC:

Conducting Audits

A stock image related to power transformer supplier.

Buyers should conduct audits of potential suppliers, focusing on their manufacturing processes and quality assurance practices. Audits can be performed by the buyers’ internal teams or through third-party auditors who specialize in manufacturing standards.

Reviewing Quality Control Reports

Requesting detailed QC reports from suppliers can provide insights into their testing methods and results. Look for consistency in the QC processes and the frequency of tests conducted during manufacturing.

Engaging Third-Party Inspectors

Third-party inspections are a reliable way to verify that products meet international standards. Independent inspectors can evaluate the manufacturing process, conduct testing, and provide unbiased reports on the quality of the transformers.

What Are the Nuances of Quality Control for International B2B Buyers?

When sourcing power transformers, international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in QC:

Understanding Local Regulations

Different regions may have specific regulations regarding power transformer standards. For example, European buyers must ensure compliance with EU regulations, while Middle Eastern buyers may need to adhere to local standards set by organizations like the Gulf Cooperation Council (GCC).

Cultural Considerations in Quality Assurance

Cultural attitudes towards quality may vary between regions. Buyers should engage in open communication with suppliers to understand their commitment to quality and any challenges they may face in meeting international standards.

Building Long-Term Relationships

Fostering long-term relationships with suppliers can lead to better quality assurance practices. Regular communication and collaboration on quality issues can help ensure that suppliers remain committed to delivering high-quality transformers.

Conclusion

Understanding the manufacturing processes and quality assurance practices for power transformers is essential for B2B buyers. By being aware of the stages involved, relevant standards, and quality control checkpoints, buyers can make informed decisions when selecting suppliers. Engaging in thorough verification practices and understanding regional nuances further enhances the likelihood of securing reliable, high-quality transformers that meet international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘power transformer supplier’

In the complex landscape of procuring power transformers, international B2B buyers must navigate a series of critical steps to ensure they select a reliable supplier. This checklist serves as a practical guide, offering actionable insights tailored for buyers in Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to clearly outline your technical requirements. This includes understanding the power capacity, voltage levels, and specific design features needed for your project. Having detailed specifications will not only streamline the sourcing process but also help suppliers provide accurate quotations.

- Key Considerations:

- Voltage ratings (e.g., 11kV, 33kV)

- Power ratings (e.g., 10MVA, 50MVA)

- Cooling methods (oil-immersed vs. dry-type)

Step 2: Research and Shortlist Potential Suppliers

Conduct thorough research to identify potential suppliers with a proven track record in manufacturing power transformers. Utilize industry directories, trade shows, and online platforms to compile a list of companies.

- What to Look For:

- Industry certifications (ISO, IEC)

- Years of experience in the market

- Product range and customization options

Step 3: Evaluate Supplier Capabilities

Once you have a shortlist, assess each supplier’s production capabilities and technological expertise. This evaluation should include site visits or virtual tours to their manufacturing facilities, if possible.

- Evaluation Criteria:

- Manufacturing processes and technology used

- Quality control measures and testing facilities

- Capacity for fulfilling large orders

Step 4: Verify Supplier Certifications and Compliance

Ensuring that your supplier adheres to international standards is crucial for quality assurance. Request documentation for certifications related to safety, quality, and environmental management.

- Important Certifications:

- ISO 9001 (Quality Management)

- IEC 60076 (Power Transformer Standards)

- CE marking (European Compliance)

Step 5: Request and Analyze Quotations

After narrowing down your options, request detailed quotations from the shortlisted suppliers. Analyze these quotes not only for pricing but also for payment terms, delivery schedules, and warranty conditions.

- What to Compare:

- Pricing structures (fixed vs. variable)

- Terms of delivery (Incoterms)

- Warranty and after-sales service

Step 6: Check References and Previous Projects

Before finalizing your supplier, reach out to their existing clients for feedback. Understanding their experiences can provide invaluable insights into the supplier’s reliability and service quality.

- Questions to Ask:

- Did the supplier meet deadlines?

- How responsive is their customer service?

- Were there any issues during installation or commissioning?

Step 7: Finalize Contract and Terms

Once you have selected a supplier, draft a comprehensive contract that outlines all agreed terms. This should include specifications, pricing, delivery schedules, and penalties for non-compliance.

- Contract Essentials:

- Clear definitions of roles and responsibilities

- Dispute resolution mechanisms

- Terms for modifications or cancellations

By following this structured checklist, B2B buyers can effectively navigate the sourcing process for power transformers, ensuring a successful procurement experience that aligns with their technical and business needs.

Comprehensive Cost and Pricing Analysis for power transformer supplier Sourcing

What Are the Key Cost Components in Power Transformer Supplier Sourcing?

Understanding the cost structure of power transformers is essential for international B2B buyers. The primary cost components include:

-

Materials: The quality and type of materials used—like copper, steel, and insulation—significantly impact the overall cost. High-quality materials can enhance the performance and longevity of transformers, but they also come with a premium price.

-

Labor: Skilled labor is crucial for manufacturing power transformers, particularly for complex designs. Labor costs can vary significantly based on the region, with some countries offering lower wages but possibly less expertise.

-

Manufacturing Overhead: This includes costs associated with utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce overhead costs, ultimately lowering the price of the transformers.

-

Tooling: Custom tooling for specific transformer designs can be a significant initial investment. However, this cost can be amortized over larger production runs, making it more manageable for high-volume orders.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability and compliance with international standards. While this adds to the initial cost, it can prevent costly failures and warranty claims down the line.

-

Logistics: Transportation and warehousing costs are critical, especially for international shipments. Factors such as distance, mode of transport, and customs duties can significantly influence the final price.

-

Margin: Suppliers typically apply a profit margin that can vary based on market conditions, competition, and their financial health.

How Do Price Influencers Affect Power Transformer Costs?

Several factors can influence the pricing of power transformers:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk purchases. Buyers looking to source large quantities should negotiate to lower the per-unit cost.

-

Specifications and Customization: Custom transformers tailored to specific applications can drive costs up. Buyers should clearly define their requirements to avoid unnecessary expenses.

-

Material Quality and Certifications: Transformers that meet international standards (such as ISO or IEC certifications) may cost more, but they offer better assurance of quality and reliability.

-

Supplier Factors: The reputation, experience, and location of the supplier can affect pricing. Established suppliers may charge more due to their reliability and quality assurance.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can impact the total landed cost.

What Negotiation Strategies Should Buyers Use to Optimize Costs?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant cost savings:

-

Conduct Market Research: Understanding market prices and competitor offerings can provide leverage during negotiations.

-

Emphasize Long-term Relationships: Suppliers are often willing to offer better pricing to buyers who commit to long-term contracts or larger orders.

-

Discuss Total Cost of Ownership (TCO): Highlighting the importance of TCO, which includes installation, maintenance, and operational costs, can shift the focus from initial purchase price to overall value.

-

Be Aware of Pricing Nuances: Prices can fluctuate based on currency exchange rates, geopolitical stability, and local market conditions. Buyers should stay informed about these dynamics.

Why Is It Important to Include a Disclaimer for Indicative Prices?

Given the variability in costs associated with power transformers, including a disclaimer for indicative prices is essential. Prices can change due to fluctuations in raw material costs, labor rates, or changes in demand. By clearly stating that prices are subject to change, suppliers can manage buyer expectations and foster transparency in the procurement process.

In summary, understanding the comprehensive cost structure, price influencers, and effective negotiation strategies can empower international B2B buyers to make informed decisions in sourcing power transformers.

Alternatives Analysis: Comparing power transformer supplier With Other Solutions

In the ever-evolving landscape of electrical infrastructure, international B2B buyers often seek solutions that not only fulfill their immediate requirements but also offer long-term value. While power transformers play a critical role in energy distribution, it is essential to consider alternative solutions that may meet specific needs more effectively or economically. This section presents a comparative analysis of power transformer suppliers against alternative technologies, aiding buyers in making informed decisions.

Comparison Table of Power Transformer Supplier and Alternatives

| Comparison Aspect | Power Transformer Supplier | Alternative 1: Voltage Regulators | Alternative 2: Static Frequency Converters |

|---|---|---|---|

| Performance | High efficiency for large-scale power distribution | Moderate efficiency, ideal for voltage stabilization in localized areas | High efficiency for frequency conversion and stabilization |

| Cost | Higher initial investment, but long-term savings on energy loss | Lower initial costs but may require frequent replacements | Moderate investment with potential savings on energy costs |

| Ease of Implementation | Requires specialized installation and integration | Easier installation, can be retrofitted into existing systems | Complex installation requiring expert input |

| Maintenance | Regular maintenance needed, but generally robust | Minimal maintenance required | Moderate maintenance; sensitive to environmental conditions |

| Best Use Case | Large industrial applications, power generation facilities | Residential and small commercial applications | Renewable energy integration and industrial applications requiring frequency stability |

What Are the Advantages and Disadvantages of Voltage Regulators?

Voltage regulators serve as an excellent alternative for businesses needing localized voltage stabilization. They are particularly beneficial in areas where voltage fluctuations can lead to operational inefficiencies. The primary advantage is their lower initial cost and ease of installation, making them suitable for residential and small commercial applications. However, they may not provide the robust performance required for large-scale operations, and frequent replacements can add to long-term costs.

How Do Static Frequency Converters Compare?

Static frequency converters (SFCs) are another viable alternative that excels in converting and stabilizing frequency, making them ideal for renewable energy integration and industrial applications where frequency consistency is critical. The main advantage of SFCs is their high efficiency in maintaining stable output, which can enhance the performance of interconnected systems. However, they require a moderate initial investment and a more complex installation process, which could deter some buyers. Additionally, SFCs are sensitive to environmental conditions, necessitating careful consideration of installation locations.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting the appropriate electrical solution, B2B buyers must assess their specific operational requirements, budget constraints, and long-term goals. Power transformers remain a cornerstone for large-scale applications due to their efficiency and reliability. However, for localized needs or specialized applications, alternatives like voltage regulators and static frequency converters may provide effective solutions at a lower cost or with easier implementation. By carefully evaluating the performance, costs, and maintenance requirements of each option, buyers can make strategic decisions that align with their business objectives and operational demands.

Essential Technical Properties and Trade Terminology for power transformer supplier

What Are the Essential Technical Properties of Power Transformers?

When sourcing power transformers, understanding the critical technical properties is vital for making informed purchasing decisions. Here are some key specifications to consider:

1. Material Grade: Why Is It Important?

The material grade of a power transformer impacts its durability and efficiency. High-grade materials, such as silicon steel for the core, reduce energy losses and enhance performance. Buyers should seek suppliers that use recognized standards, ensuring the longevity and reliability of the transformers under varying operational conditions.

2. Tolerance Levels: What Do They Mean for Performance?

Tolerance levels refer to the allowable deviation from specified dimensions in transformer components. Higher tolerance indicates better precision in manufacturing, which translates to improved efficiency and reduced risk of malfunction. Buyers should inquire about tolerance standards to ensure that the transformers meet their operational requirements.

3. Insulation Class: How Does It Affect Safety?

Insulation class indicates the thermal endurance of a transformer’s insulation system. Common classes include A, B, F, and H, with each class having a different maximum temperature rating. Understanding insulation class is crucial for buyers to ensure that the transformer can operate safely within their environmental conditions without the risk of insulation failure.

4. Rated Power: Why Is It a Key Specification?

Rated power, expressed in megavolt-amperes (MVA), indicates the maximum load a transformer can handle without overheating. It is essential for buyers to select transformers that align with their system’s power demands, ensuring efficient operation and minimizing the risk of transformer damage or failure.

5. Efficiency Rating: What Should You Look For?

The efficiency rating of a transformer reflects how effectively it converts input power to output power. High-efficiency transformers reduce energy loss, leading to lower operational costs and less environmental impact. Buyers should prioritize transformers with efficiency ratings that comply with international standards, particularly in regions focused on sustainability.

6. Cooling Method: What Are Your Options?

Transformers can be cooled using various methods, including air, oil, or water. The choice of cooling method affects the transformer’s size, weight, and operational efficiency. Buyers must assess their installation environment and select a cooling method that optimally balances performance with space constraints.

What Are Common Trade Terms in the Power Transformer Industry?

Familiarizing yourself with industry terminology can greatly enhance communication with suppliers and streamline the procurement process. Here are some key terms:

1. What Is OEM (Original Equipment Manufacturer)?

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the power transformer industry, buyers often work with OEMs to ensure they receive high-quality, reliable transformers tailored to their specifications.

2. What Does MOQ (Minimum Order Quantity) Mean?

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers as it impacts inventory management and procurement costs. Negotiating MOQs can lead to cost savings, especially for larger projects.

3. What Is an RFQ (Request for Quotation)?

An RFQ is a document used by buyers to solicit price bids from suppliers for specific products or services. Including detailed specifications and requirements in an RFQ helps ensure that suppliers provide accurate quotations, facilitating better decision-making.

4. How Do Incoterms Influence Trade?

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps buyers avoid misunderstandings and ensures that all parties are clear on their obligations, particularly in international transactions.

5. What Does Lead Time Refer To?

Lead time indicates the time taken from placing an order to delivery. Understanding lead times is crucial for project planning and ensuring that transformers arrive when needed to avoid delays in operations.

Conclusion

By grasping these essential technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing power transformers. This knowledge not only aids in selecting the right products but also fosters better communication with suppliers, ultimately leading to successful procurement outcomes.

Navigating Market Dynamics and Sourcing Trends in the power transformer supplier Sector

What Are the Key Market Dynamics and Trends in the Power Transformer Supplier Sector?

The global power transformer market is undergoing significant transformation driven by increasing energy demands, advancements in technology, and a push towards renewable energy sources. Notably, regions such as Africa, South America, the Middle East, and Europe are witnessing a surge in infrastructure development, necessitating the adoption of efficient power transformers. Emerging trends include the integration of smart technologies, such as IoT-enabled transformers that allow for real-time monitoring and maintenance, thereby enhancing operational efficiency and reducing downtime.

Additionally, the shift towards renewable energy sources, such as wind and solar power, is reshaping sourcing strategies for power transformers. International B2B buyers are increasingly prioritizing suppliers who can provide transformers that are compatible with renewable energy systems. For instance, Europe is leading the way with stringent regulations and incentives for green technologies, pushing suppliers to innovate and meet these demands. In contrast, emerging markets in Africa and South America present unique challenges and opportunities, where buyers must navigate local regulations and infrastructure limitations while sourcing reliable transformers.

Furthermore, the rise of digital platforms for sourcing has made it easier for international buyers to connect with suppliers. These platforms enable buyers to compare products, assess supplier credentials, and negotiate better terms, thereby enhancing transparency and competitiveness in the market. Understanding these dynamics is crucial for B2B buyers aiming to make informed purchasing decisions in the evolving power transformer landscape.

How Important Is Sustainability and Ethical Sourcing for Power Transformer Suppliers?

Sustainability has become a critical factor in the decision-making process for B2B buyers in the power transformer sector. The environmental impact of manufacturing and operating power transformers cannot be overlooked, with traditional methods often leading to significant carbon emissions and waste. As such, buyers are increasingly seeking suppliers that prioritize sustainable practices throughout their supply chains.

Ethical sourcing is another important consideration. Buyers are encouraged to assess the environmental credentials of potential suppliers, including certifications such as ISO 14001 for environmental management and ISO 50001 for energy management. These certifications indicate a commitment to sustainable practices and can provide buyers with confidence in their sourcing decisions. Moreover, suppliers that utilize ‘green’ materials or implement energy-efficient manufacturing processes often gain a competitive edge in the market.

Investing in sustainable transformers not only aligns with corporate social responsibility goals but can also lead to long-term cost savings through improved efficiency and reduced operational costs. B2B buyers should therefore prioritize suppliers who demonstrate a strong commitment to sustainability and ethical sourcing, as this not only mitigates environmental impact but also enhances brand reputation and customer loyalty.

What Is the Brief Evolution of the Power Transformer Supplier Sector?

The power transformer industry has evolved significantly over the past century, adapting to technological advancements and changing energy landscapes. Initially, power transformers were primarily used in electrical grids to step up or step down voltage levels for transmission. However, the growing complexity of energy systems, including the integration of decentralized energy sources, has necessitated the development of more sophisticated transformer designs.

The introduction of digital technologies in the late 20th century marked a pivotal shift in the sector, leading to the advent of smart transformers capable of real-time data monitoring and enhanced operational management. Today, the focus is increasingly on sustainability, with suppliers innovating to create environmentally friendly transformers that meet the demands of a rapidly changing energy market.

As the global energy landscape continues to evolve, the power transformer supplier sector is likely to witness further advancements, emphasizing the importance of innovation and adaptability for suppliers aiming to meet the needs of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of power transformer supplier

-

How do I choose the right power transformer supplier for my business needs?

Selecting the right power transformer supplier involves evaluating their industry experience, product quality, and customer service. Look for suppliers with a proven track record in your sector and positive reviews from previous clients. Additionally, assess their production capabilities, certifications, and compliance with international standards. It’s advisable to request samples or product specifications to ensure they meet your technical requirements. Engaging in direct communication can also help gauge their responsiveness and willingness to support your specific needs. -

What are the most important certifications to look for in a power transformer supplier?

Key certifications to consider include ISO 9001 for quality management, ISO 14001 for environmental management, and IEC standards that relate to transformer safety and performance. For suppliers in regions like Africa and the Middle East, local certifications may also be relevant. Ensure that the supplier’s products meet the regulatory requirements of your target market, which may vary by country, particularly in Europe and South America. -

What are typical minimum order quantities (MOQ) for power transformers?

Minimum order quantities can vary significantly among suppliers, typically ranging from one unit for custom transformers to several dozen for standard models. When negotiating with suppliers, consider your project timelines and budget constraints. Some suppliers may be willing to accommodate lower MOQs for first-time orders or ongoing partnerships, so it’s worth discussing your specific needs to find a mutually beneficial arrangement. -

How do I negotiate payment terms with a power transformer supplier?

Negotiating payment terms typically involves discussing upfront deposits, payment schedules, and final payment conditions. Common practices include a 30% deposit upon order confirmation and the remaining 70% before shipment. Ensure you understand the supplier’s policies regarding late payments or cancellations. It may also be beneficial to explore payment methods that offer buyer protection, such as letters of credit or escrow services, especially for large transactions. -

What should I include in my supplier vetting process for power transformers?

A comprehensive supplier vetting process should include assessing their financial stability, production capacity, lead times, and quality control measures. Request references from previous clients and conduct site visits if possible. Additionally, evaluate their logistics capabilities and after-sales support. This thorough assessment will help mitigate risks and ensure you partner with a reliable supplier who can meet your operational demands. -

How can I ensure the quality of power transformers supplied to my business?

Ensuring quality starts with selecting suppliers with robust quality management systems and relevant certifications. Request detailed documentation, including test reports and compliance certificates. Establish clear quality assurance protocols, such as regular inspections and performance testing of the transformers upon arrival. Collaborating with suppliers who offer warranties or guarantees can also provide added assurance regarding product quality. -

What logistics considerations should I be aware of when sourcing power transformers internationally?

When sourcing power transformers, consider shipping methods, customs clearance processes, and potential tariffs or import duties. Evaluate the supplier’s logistics capabilities to ensure timely delivery and assess whether they can handle shipping arrangements or if you need a third-party logistics provider. Additionally, factor in lead times for production and shipping, especially when sourcing from regions like Europe or Asia, to ensure alignment with your project schedules. -

How do customization options affect the procurement of power transformers?

Customization options can significantly impact procurement timelines, costs, and supplier selection. When seeking tailored solutions, communicate your specific requirements early in the negotiation process. Understand that customized transformers may involve longer lead times and higher costs compared to off-the-shelf products. Ensure the supplier has the technical expertise and capacity to deliver on your customization needs without compromising quality or compliance with industry standards.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for power transformer supplier

How Can Strategic Sourcing Enhance Your Procurement of Power Transformers?

In conclusion, the strategic sourcing of power transformers is essential for international B2B buyers aiming to optimize their procurement processes. By focusing on key factors such as supplier reliability, technological advancements, and market trends, businesses can significantly reduce costs while ensuring high-quality equipment. Engaging with suppliers who understand the specific needs of regions like Africa, South America, the Middle East, and Europe will enhance supply chain resilience and operational efficiency.

Investing in strategic sourcing not only fosters long-term partnerships but also positions your organization to adapt to evolving market demands and regulatory landscapes. This proactive approach allows for leveraging competitive advantages in a rapidly changing energy sector.

As you consider your next steps, evaluate your current sourcing strategies and explore opportunities to collaborate with reputable suppliers. By doing so, you can ensure that your organization remains at the forefront of the energy transition, equipped with the latest technology and solutions. The future of power transformer procurement is promising, and with strategic sourcing, your business can thrive in this dynamic landscape.