The Ultimate Guide to Spindle Manufacturer (2025)

Introduction: Navigating the Global Market for spindle manufacturer

In today’s competitive manufacturing landscape, sourcing high-quality spindles is a critical challenge for B2B buyers across various industries. As businesses strive for efficiency and precision in their operations, the need for reliable spindle manufacturers becomes paramount. This guide serves as a comprehensive resource, detailing the various types of spindles, their applications across industries, and essential supplier vetting processes.

International buyers, particularly from Africa, South America, the Middle East, and Europe—countries like Spain and the UK—will find actionable insights tailored to their unique market conditions. We will explore factors influencing spindle costs, such as material quality, manufacturing processes, and supplier reputation. Additionally, we will address common pitfalls in the procurement process, empowering businesses to make informed purchasing decisions that align with their operational needs and budgetary constraints.

By leveraging this guide, international B2B buyers can navigate the complexities of the global spindle market with confidence. Whether you’re looking to enhance your production capabilities or seeking innovative spindle solutions, this resource equips you with the knowledge necessary to choose the right supplier and optimize your supply chain. Explore the intricacies of spindle manufacturing and discover how to elevate your business performance through strategic sourcing.

Understanding spindle manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electric Spindles | High speed, low maintenance, integrated cooling | CNC machining, woodworking | Pros: Energy-efficient, precise; Cons: Higher upfront cost. |

| Pneumatic Spindles | Operated by compressed air, lightweight | Textile machinery, packaging | Pros: Lightweight, easy to control; Cons: Limited torque, requires air supply. |

| Hydraulic Spindles | High torque output, robust design | Metalworking, heavy-duty applications | Pros: Powerful, suitable for tough materials; Cons: Requires hydraulic system, maintenance-intensive. |

| High-Frequency Spindles | Ultra-high speed, compact design | Aerospace, electronics manufacturing | Pros: Excellent precision, reduced cycle times; Cons: Specialized applications, potential overheating. |

| Custom Spindles | Tailored designs for specific applications | Specialized machinery, unique setups | Pros: Optimized performance, meets specific needs; Cons: Longer lead times, potentially higher costs. |

What are Electric Spindles and Their Applications?

Electric spindles are known for their high-speed operation and low maintenance requirements. They often come with integrated cooling systems, which enhance their performance during extended use. These spindles are primarily utilized in CNC machining and woodworking, where precision and efficiency are paramount. When purchasing electric spindles, buyers should consider the initial investment, as they may be more costly than traditional options, but the long-term energy savings and reliability can justify the expense.

How Do Pneumatic Spindles Work and Where Are They Used?

Pneumatic spindles operate using compressed air, making them lightweight and easy to handle. They are particularly effective in applications such as textile machinery and packaging, where speed and flexibility are essential. Buyers should note that while pneumatic spindles offer ease of control and reduced weight, they may have limitations in torque output and require a constant air supply, which could affect overall operational efficiency.

What Makes Hydraulic Spindles Suitable for Heavy-Duty Applications?

Hydraulic spindles are characterized by their high torque output and robust construction, making them ideal for metalworking and other heavy-duty applications. These spindles can handle tough materials and demanding tasks effectively. However, they require a hydraulic system for operation and may involve more maintenance compared to other types. B2B buyers should weigh the benefits of power and durability against the need for a reliable hydraulic setup.

Why Choose High-Frequency Spindles for Precision Work?

High-frequency spindles are designed for ultra-high-speed applications, often found in aerospace and electronics manufacturing. Their compact design allows for excellent precision and reduced cycle times, which are critical in competitive industries. However, they may require specialized cooling solutions to prevent overheating during operation. Buyers should consider the specific requirements of their applications and the potential need for additional equipment when opting for high-frequency spindles.

What Are the Benefits of Custom Spindles for Specific Needs?

Custom spindles are tailored to meet the specific requirements of unique applications, offering optimized performance for specialized machinery setups. While they can provide significant advantages in efficiency and effectiveness, buyers should be aware of the longer lead times and potentially higher costs associated with custom manufacturing. Understanding the exact needs of the operation is crucial when investing in custom spindle solutions.

Related Video: Acme Multi-Spindle Screw Machines

Key Industrial Applications of spindle manufacturer

| Industry/Sector | Specific Application of spindle manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Precision machining of engine components | Enhanced efficiency and reduced production costs | Quality certifications, lead times, and material compatibility |

| Aerospace | Production of aircraft parts and assemblies | Improved safety standards and compliance | Regulatory compliance, precision tolerances, and delivery reliability |

| Metalworking | CNC machining for custom metal parts | Increased operational throughput and flexibility | Machine compatibility, technical support, and maintenance services |

| Textile Industry | Spindle systems for weaving and spinning machines | Higher productivity and product quality | Energy efficiency, durability, and service agreements |

| Electronics | Manufacturing of printed circuit boards (PCBs) | Enhanced accuracy and reduced defect rates | Supplier reliability, technological innovation, and cost-effectiveness |

How are spindle manufacturers applied in automotive manufacturing?

In the automotive sector, spindle manufacturers provide precision machining tools essential for producing engine components, transmission parts, and chassis elements. These spindles are integral in CNC (Computer Numerical Control) machines, allowing for high-speed and accurate machining processes. By utilizing high-quality spindles, automotive manufacturers can achieve enhanced efficiency, reduce production costs, and ensure tighter tolerances on critical components. International buyers should prioritize quality certifications and ensure compatibility with existing machinery to optimize their sourcing decisions.

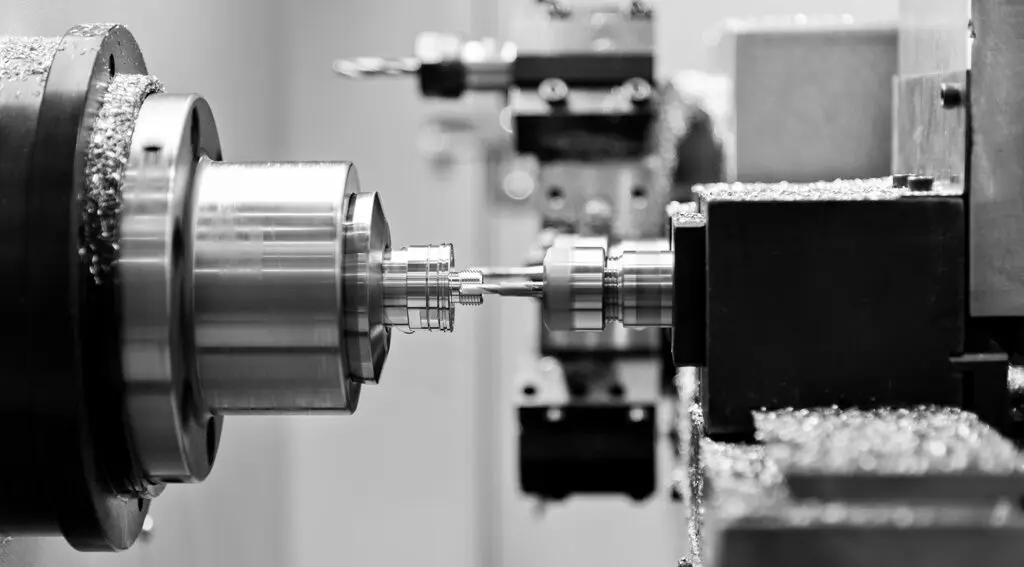

A stock image related to spindle manufacturer.

What role do spindle manufacturers play in aerospace applications?

Spindle manufacturers are vital in the aerospace industry for the production of aircraft parts and assemblies, where precision and reliability are paramount. Spindles used in machining centers help create components such as turbine blades, fuselage sections, and landing gear with stringent safety and performance standards. Aerospace buyers, particularly from Europe and the Middle East, must consider regulatory compliance and precision tolerances when sourcing spindles to ensure that their parts meet aviation safety regulations.

How do spindles enhance operations in the metalworking sector?

In metalworking, spindles are crucial for CNC machining operations that produce custom metal parts for various applications. The use of high-performance spindles allows for increased operational throughput and flexibility, enabling manufacturers to adapt quickly to changing production demands. B2B buyers in this sector should evaluate machine compatibility, technical support from suppliers, and maintenance services to ensure optimal performance and minimize downtime.

Why are spindles important for the textile industry?

Spindle systems are essential in the textile industry for weaving and spinning machines, where they drive the production of fabrics and yarns. High-quality spindles contribute to higher productivity and improved product quality by enabling consistent and reliable operation. For textile manufacturers, particularly those in Africa and South America, sourcing spindles with energy efficiency and durability can lead to significant operational cost savings and enhanced sustainability.

How do spindle manufacturers support electronics production?

In the electronics sector, spindle manufacturers provide tools for the precise machining of printed circuit boards (PCBs). High-precision spindles are essential for achieving enhanced accuracy and reducing defect rates during the manufacturing process. International buyers should focus on supplier reliability, technological innovation, and cost-effectiveness when sourcing spindles for electronics production, ensuring they meet the fast-paced demands of the industry.

Related Video: FANUC Industrial Robots | AUDI Case Study

3 Common User Pain Points for ‘spindle manufacturer’ & Their Solutions

Scenario 1: Difficulty in Identifying Quality Spindle Manufacturers

The Problem: In regions like Africa and South America, B2B buyers often struggle to identify reputable spindle manufacturers. Limited access to reliable information can lead to significant risks, including purchasing low-quality products that can jeopardize production processes. This challenge is compounded by a lack of local representation and the possibility of encountering fraudulent suppliers online, making it difficult to differentiate between trustworthy and unreliable manufacturers.

The Solution: To effectively identify quality spindle manufacturers, buyers should leverage international trade platforms and industry-specific directories that provide verified listings and customer reviews. Engaging in trade shows and industry conferences can facilitate personal connections with manufacturers, allowing buyers to assess product quality firsthand. Additionally, consider requesting samples or prototypes to evaluate performance before committing to larger orders. Collaborating with local industry associations can also provide insights and recommendations about reputable suppliers in the region.

Scenario 2: Inadequate Technical Support and Customization Options

The Problem: B2B buyers frequently face challenges in obtaining adequate technical support and customization options for spindle products. In many cases, manufacturers may offer a limited range of standard products without the flexibility to adapt to specific project requirements. This can lead to compatibility issues and increased downtime, particularly for businesses that rely on tailored solutions to meet unique operational needs.

The Solution: When sourcing spindles, prioritize manufacturers that offer comprehensive technical support and customization capabilities. Engage in discussions regarding specific operational requirements and ask for case studies or examples of previous successful customizations. It is advisable to establish a clear communication channel with the manufacturer’s engineering team to facilitate collaboration. Additionally, consider forming long-term partnerships with manufacturers who are willing to provide ongoing support and adapt their products as your business evolves. This proactive approach ensures that you receive spindles that align perfectly with your operational goals.

Scenario 3: Supply Chain Disruptions and Delivery Delays

The Problem: International B2B buyers often encounter significant supply chain disruptions that result in delivery delays for spindle orders. Factors such as geopolitical tensions, fluctuating shipping costs, and local regulations can complicate logistics, ultimately affecting production schedules. These disruptions can lead to increased operational costs and project delays, significantly impacting the bottom line.

The Solution: To mitigate the risks associated with supply chain disruptions, buyers should implement a multi-supplier strategy. By diversifying your supplier base across different regions, you can reduce reliance on a single source and improve resilience against regional disruptions. Establishing strong relationships with logistics providers is also essential; consider working with freight forwarders who have experience in navigating international shipping complexities. It’s beneficial to discuss lead times and delivery options in advance with manufacturers, ensuring that you have contingency plans in place. Regularly reviewing and adjusting your supply chain strategy in response to market conditions will help maintain a steady flow of materials, minimizing the impact of potential delays.

Strategic Material Selection Guide for spindle manufacturer

What Are the Key Materials Used in Spindle Manufacturing?

When selecting materials for spindle manufacturing, it is crucial to consider the properties that affect performance, durability, and overall application suitability. Below are analyses of four common materials used in spindle production, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Steel Perform as a Material for Spindles?

Key Properties: Steel is renowned for its high tensile strength and durability, making it suitable for high-pressure applications. It typically offers excellent wear resistance and can withstand elevated temperatures, which is essential in various industrial environments.

Pros & Cons: The primary advantage of steel is its strength and ability to handle heavy loads, which translates to longer service life. However, steel can be prone to corrosion if not treated or coated properly, which may necessitate additional costs for protective measures. The manufacturing complexity can also be higher due to the need for precise machining.

Impact on Application: Steel spindles are compatible with a wide range of media, including oils and coolants used in machining processes. However, they may not be suitable for corrosive environments without appropriate surface treatments.

Considerations for International Buyers: Buyers from regions such as Africa and South America should be aware of local standards for steel quality, such as ASTM or DIN. Compliance with these standards ensures reliability and safety in applications.

What Advantages Does Aluminum Offer for Spindle Manufacturing?

Key Properties: Aluminum is lightweight yet maintains good strength-to-weight ratios. It has excellent corrosion resistance, particularly when anodized, and is capable of dissipating heat effectively.

Pros & Cons: The key advantage of aluminum is its lightweight nature, which can reduce energy consumption in applications requiring high-speed rotation. However, it may not withstand as high loads as steel, making it less suitable for heavy-duty applications. The cost of aluminum can also be higher than that of steel, depending on market fluctuations.

Impact on Application: Aluminum spindles are particularly effective in applications involving lighter materials or where weight reduction is critical. They are compatible with various media but may be less effective in high-temperature environments.

Considerations for International Buyers: Buyers in Europe and the Middle East should consider the relevant material standards for aluminum, such as EN or JIS, to ensure compliance and quality.

Why Choose Composite Materials for Spindle Manufacturing?

Key Properties: Composite materials, often made from a combination of polymers and fibers, provide excellent strength and stiffness while being lightweight. They can also offer superior vibration damping characteristics.

Pros & Cons: The primary advantage of composites is their ability to reduce weight without sacrificing performance, making them ideal for high-speed applications. However, they can be more expensive and complex to manufacture, and their long-term durability in harsh conditions may be a concern.

Impact on Application: Composites are suitable for applications where vibration reduction is critical, such as in precision machining. They are generally resistant to a variety of chemicals, but specific compatibility should be verified.

Considerations for International Buyers: Buyers should be aware of the specific certifications for composite materials in their region, as standards can vary significantly. Understanding the local market’s acceptance of composites is crucial for successful integration.

What Role Does Brass Play in Spindle Manufacturing?

Key Properties: Brass is known for its excellent machinability and corrosion resistance, particularly in marine environments. It has good thermal and electrical conductivity, making it suitable for specific applications.

Pros & Cons: The advantages of brass include its ease of machining and resistance to corrosion, which can extend the life of the spindle in certain applications. However, brass may not be suitable for high-load applications due to its lower tensile strength compared to steel.

Impact on Application: Brass spindles are often used in applications where electrical conductivity is necessary, such as in electronic components. They are compatible with various media but should be evaluated for specific chemical interactions.

Considerations for International Buyers: Buyers from regions like Spain and the UK should ensure compliance with local standards for brass materials, as well as consider the implications of material sourcing in terms of cost and availability.

Summary Table of Material Selection for Spindle Manufacturing

| Material | Typical Use Case for spindle manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial applications | High tensile strength and durability | Prone to corrosion without treatment | Medium |

| Aluminum | Lightweight, high-speed applications | Excellent corrosion resistance | Lower load capacity than steel | High |

| Composite | Precision machining with vibration control | Lightweight with good strength | Higher manufacturing complexity | High |

| Brass | Electrical components and marine use | Excellent machinability and corrosion resistance | Lower tensile strength for heavy loads | Medium |

This guide provides a comprehensive overview of the materials commonly used in spindle manufacturing, offering valuable insights for international B2B buyers in their material selection process.

In-depth Look: Manufacturing Processes and Quality Assurance for spindle manufacturer

What Are the Key Stages in the Manufacturing Process of Spindles?

The manufacturing process for spindles involves several critical stages, each designed to ensure the final product meets the precise specifications required for various industrial applications. Understanding these stages is essential for B2B buyers looking to ensure the quality and reliability of the spindles they purchase.

-

Material Preparation

The first step in spindle manufacturing is the selection and preparation of materials. Common materials used include high-grade steel, aluminum alloys, and composite materials. Each material is chosen based on the specific requirements of the spindle application, such as strength, weight, and thermal stability. Material preparation involves processes like cutting, machining, and treating to ensure the material meets the necessary standards. -

Forming

The forming stage involves shaping the prepared materials into the desired spindle geometry. Techniques such as CNC (Computer Numerical Control) machining, forging, and casting are commonly used. CNC machining is particularly favored for its precision and ability to produce complex shapes with tight tolerances. Forging enhances the mechanical properties of the spindle, while casting can be cost-effective for high-volume production. -

Assembly

Once the individual components are formed, they undergo assembly. This stage often includes the integration of various parts such as bearings, housings, and drive mechanisms. Automated assembly lines are frequently used to enhance efficiency and ensure consistency. Each assembly step is critical, as improper assembly can lead to performance issues in the final product. -

Finishing

The finishing stage enhances the spindle’s surface quality and durability. Techniques such as grinding, polishing, and coating are employed to achieve the desired surface finish. This stage not only improves aesthetics but also helps in reducing wear and tear, thereby extending the life of the spindle.

How Is Quality Assurance Implemented in Spindle Manufacturing?

Quality assurance (QA) is a vital component of spindle manufacturing that ensures products meet international standards and customer expectations. The following are key aspects of QA processes that international B2B buyers should be aware of.

-

International Standards Compliance

Spindle manufacturers typically adhere to international quality standards such as ISO 9001. This standard focuses on quality management systems and emphasizes continuous improvement, customer satisfaction, and effective process management. Other industry-specific certifications, like CE marking for compliance with European safety standards or API (American Petroleum Institute) standards for oil and gas applications, are also critical. -

Quality Control Checkpoints

Various checkpoints are established throughout the manufacturing process to ensure quality at every stage:

– Incoming Quality Control (IQC): This involves inspecting raw materials before they enter production. Suppliers must provide certifications and test reports for the materials used.

– In-Process Quality Control (IPQC): Continuous monitoring during manufacturing ensures that any deviations from specifications are caught early. This might include dimensional checks and visual inspections.

– Final Quality Control (FQC): After the assembly and finishing processes, spindles undergo rigorous testing to confirm they meet all specifications. This can include functional testing, load testing, and vibration analysis. -

Common Testing Methods for Spindles

Testing methods vary but typically include:

– Dimensional Inspection: Utilizing tools like calipers and micrometers to verify measurements.

– Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and magnetic particle inspection help identify internal flaws without damaging the spindle.

– Performance Testing: Spindles are tested under simulated operational conditions to ensure they perform as expected.

How Can B2B Buyers Verify Supplier Quality Control?

A stock image related to spindle manufacturer.

For international buyers, especially those from regions like Africa, South America, the Middle East, and Europe, ensuring the quality of spindle suppliers is crucial. Here are actionable steps for verifying supplier quality control:

-

Supplier Audits

Conducting on-site audits allows buyers to assess the manufacturer’s facilities, equipment, and quality control processes firsthand. During audits, buyers should evaluate the adherence to international standards, the condition of manufacturing equipment, and the qualifications of the staff. -

Requesting Quality Assurance Reports

Suppliers should be able to provide detailed quality assurance reports that outline their processes, testing results, and compliance with relevant standards. Buyers should request these documents as part of their procurement process. -

Third-Party Inspections

Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality assurance processes. These agencies can conduct inspections at various stages of the manufacturing process and provide certification of compliance. -

Understanding QC and Certification Nuances

Buyers should be aware of the specific quality control nuances that vary by region. For instance, regulations and standards in Europe may differ significantly from those in Africa or South America. It’s important to ensure that the supplier is compliant with the specific standards relevant to the buyer’s region and industry.

What Additional Considerations Should B2B Buyers Keep in Mind?

When sourcing spindles internationally, B2B buyers must consider logistical aspects such as lead times, shipping costs, and potential tariffs. Understanding the manufacturing capabilities and quality assurance practices of suppliers can significantly mitigate risks associated with international procurement.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices is essential for B2B buyers seeking reliable spindle suppliers. By focusing on these critical areas, buyers can make informed decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘spindle manufacturer’

In the competitive landscape of manufacturing, selecting the right spindle manufacturer is critical for the success of your operations. This guide provides a practical checklist to streamline your sourcing process, ensuring that you make informed decisions that align with your technical requirements and business goals.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential before reaching out to potential suppliers. This includes determining the spindle type, size, material, and any specific performance characteristics required for your application.

– Consider: The operational environment (e.g., temperature, humidity) and load capacity that the spindle will need to handle.

Step 2: Conduct Market Research

Understanding the market landscape helps identify potential manufacturers that meet your specifications. Research industry trends, leading brands, and emerging players in the spindle manufacturing sector.

– Utilize: Online resources, trade shows, and industry reports to gather insights on supplier capabilities and market positioning.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request detailed company profiles, product catalogs, and case studies showcasing their experience in your industry.

– Look for: Client testimonials and references from similar businesses to gauge reliability and quality standards.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers have the necessary certifications to meet your quality and safety standards. Certifications such as ISO 9001 indicate a commitment to quality management systems.

– Check for: Compliance with international standards relevant to your industry, which can impact product reliability and performance.

Step 5: Assess Production Capabilities

Investigate the manufacturing capabilities of potential suppliers to ensure they can meet your volume requirements and delivery timelines. This includes evaluating their technology, workforce expertise, and production processes.

– Consider: The flexibility of the supplier to scale production up or down based on your changing needs.

Step 6: Request Samples and Prototypes

Before finalizing your decision, request samples or prototypes to assess the quality and performance of the spindles. This hands-on evaluation can reveal critical insights into the product’s suitability for your application.

– Focus on: Key performance metrics and overall craftsmanship that align with your operational standards.

Step 7: Establish Communication and Support Channels

Strong communication is vital for a successful supplier relationship. Ensure that the supplier provides clear channels for support, including technical assistance and customer service.

– Evaluate: Their responsiveness and willingness to address any concerns or queries during the sourcing process.

By following this checklist, international B2B buyers can effectively navigate the sourcing landscape for spindle manufacturers, making informed choices that enhance operational efficiency and product quality.

Comprehensive Cost and Pricing Analysis for spindle manufacturer Sourcing

What Are the Key Cost Components in Spindle Manufacturing?

When sourcing spindles, international B2B buyers should understand the various cost components that contribute to the overall pricing. The primary cost elements include:

-

Materials: The choice of materials significantly impacts cost. High-quality steel or specialized alloys may be more expensive but enhance durability and performance.

-

Labor: Labor costs vary by region. Countries with lower wage rates may offer competitive pricing, but it’s essential to consider the skill level and training of the workforce, as these factors influence the quality of the manufacturing process.

-

Manufacturing Overhead: This includes costs related to factory utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help reduce these overheads, allowing suppliers to offer more competitive pricing.

-

Tooling: The initial investment in tooling can be substantial, especially for custom spindles. Buyers should inquire about how these costs are amortized over production runs.

-

Quality Control (QC): Effective QC processes ensure that spindles meet specifications and certifications. Suppliers with robust QC may charge a premium, but this can reduce long-term costs associated with defects and failures.

-

Logistics: Shipping costs, including freight and customs duties, can vary widely based on location and Incoterms. Understanding these costs is crucial for accurate budgeting.

-

Margin: Suppliers typically add a profit margin to cover their risks and operational costs. This margin can fluctuate based on market demand, competition, and supplier reputation.

How Do Price Influencers Affect Spindle Sourcing?

Several factors influence the pricing of spindles that international buyers should consider:

-

Volume/MOQ: Minimum order quantities (MOQs) can impact the unit price. Higher volumes often lead to lower per-unit costs, making it beneficial for buyers to consolidate orders.

-

Specifications and Customization: Custom designs or specifications can significantly increase costs. Buyers should clearly define their requirements to avoid unexpected charges later.

-

Material Quality and Certifications: Higher quality materials and relevant certifications (e.g., ISO, ASTM) often come at a premium. Buyers need to balance their budget against the desired performance and compliance levels.

-

Supplier Factors: The reputation, experience, and location of the supplier can affect pricing. Established suppliers may charge more but offer reliability and superior customer service.

-

Incoterms: Understanding Incoterms is crucial for international transactions as they dictate who is responsible for shipping, insurance, and tariffs, directly impacting overall costs.

What Are Effective Buyer Tips for Cost-Efficient Spindle Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, here are strategic tips to enhance cost efficiency in spindle sourcing:

-

Negotiate Wisely: Engage in open discussions with suppliers about pricing. Leverage volume orders or long-term contracts to negotiate better terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with quality, maintenance, and potential downtime due to inferior products.

-

Understand Pricing Nuances: Different regions may have varying pricing models influenced by local market conditions, currency fluctuations, and trade policies. Stay informed about these factors to make better sourcing decisions.

-

Build Relationships with Suppliers: Establishing strong partnerships can lead to better pricing and priority service. Suppliers may offer discounts or more favorable terms to loyal customers.

-

Request Detailed Quotations: Ensure that all components of the cost are broken down in quotations. This transparency allows for easier comparison and identification of potential savings.

Disclaimer on Indicative Prices

Prices for spindles can vary widely based on multiple factors, including market conditions, supplier relationships, and specific buyer requirements. It is advisable for buyers to obtain multiple quotes and conduct thorough market research to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing spindle manufacturer With Other Solutions

When considering the procurement of spindle solutions, international B2B buyers must evaluate various alternatives that can meet their operational requirements. This analysis will compare traditional spindle manufacturers with alternative technologies and methodologies that serve similar functions. By understanding the key differences, buyers can make informed decisions that align with their business goals and constraints.

Comparison Table of Spindle Solutions

| Comparison Aspect | Spindle Manufacturer | CNC Machining Centers | 3D Printing Technology |

|---|---|---|---|

| Performance | High precision and reliability; ideal for continuous operations | Excellent for complex geometries and high-volume production | Versatile for rapid prototyping and low-volume production |

| Cost | Higher initial investment but lower long-term maintenance costs | Moderate initial costs with variable operational expenses | Lower initial costs, but material costs can be high |

| Ease of Implementation | Requires specialized knowledge and training for setup | Moderate complexity; requires skilled operators | User-friendly with less technical training needed |

| Maintenance | Regular maintenance needed for optimal performance | Maintenance varies by machine; can be costly | Minimal maintenance; dependent on printer quality |

| Best Use Case | High-volume production of standardized parts | Complex, custom parts requiring quick adjustments | Rapid prototyping and custom designs in small batches |

What Are the Pros and Cons of CNC Machining Centers as an Alternative to Spindle Manufacturers?

CNC (Computer Numerical Control) machining centers offer a compelling alternative for B2B buyers. They excel in producing complex geometries and can handle a variety of materials, making them suitable for custom parts that traditional spindles may struggle with. The moderate initial investment, combined with the capability for high-volume production, allows for flexibility in manufacturing. However, the need for skilled operators and ongoing maintenance can increase operational costs over time.

How Does 3D Printing Technology Compare to Traditional Spindle Manufacturing?

3D printing technology is revolutionizing the manufacturing landscape, particularly for businesses looking for rapid prototyping solutions. Its user-friendly nature and lower initial costs make it accessible for many small to medium-sized enterprises. However, while it allows for intricate designs and quick iterations, the material costs can add up, especially for high-strength applications. This technology shines in low-volume production scenarios, but it may not meet the durability and precision requirements for high-volume production like traditional spindles.

Conclusion: How Can B2B Buyers Choose the Right Solution?

Choosing the right spindle solution involves understanding specific operational needs, budget constraints, and production goals. Buyers should assess their long-term objectives—whether prioritizing precision, flexibility, or cost-effectiveness. Traditional spindle manufacturers may be ideal for companies focused on high-volume production and reliability. In contrast, CNC machining centers could be more suitable for those needing versatility and customizability. Lastly, 3D printing serves well for rapid prototyping and small batch production. By carefully weighing these alternatives, B2B buyers can ensure they select a solution that best fits their strategic objectives.

Essential Technical Properties and Trade Terminology for spindle manufacturer

What Are the Essential Technical Properties of Spindles for B2B Buyers?

When sourcing spindles, it’s crucial for international B2B buyers to understand the technical properties that influence performance and compatibility. Here are some of the key specifications:

1. Material Grade: What Should You Look For?

Material grade is a fundamental property that affects the spindle’s strength, durability, and suitability for various applications. Common materials include high-speed steel (HSS), carbide, and stainless steel. For instance, HSS is preferred for its hardness and ability to withstand high temperatures, making it ideal for machining applications. Buyers should assess the material grade based on the specific requirements of their projects to ensure optimal performance.

2. Tolerance: Why Is It Critical?

Tolerance refers to the allowable deviation from a specified dimension. In spindle manufacturing, tighter tolerances (e.g., ±0.001 mm) ensure precision in applications such as CNC machining. This precision is essential for maintaining product quality and minimizing waste. Buyers should prioritize suppliers who can meet stringent tolerance requirements to enhance their manufacturing processes.

3. Surface Finish: How Does It Impact Performance?

The surface finish of a spindle can significantly influence its efficiency and lifespan. A smoother surface finish reduces friction and wear, leading to better performance in high-speed applications. Buyers should inquire about the surface finish specifications, as they can vary widely between manufacturers. Achieving the desired surface finish can also affect the cost, so understanding this property is vital for budget planning.

4. RPM Rating: What Should You Expect?

The RPM (revolutions per minute) rating indicates the maximum speed at which a spindle can operate safely. This rating is critical for applications requiring high-speed machining. Buyers need to consider the RPM rating in conjunction with the material and application to ensure the spindle can handle operational demands without failure.

5. Load Capacity: How Much Weight Can It Handle?

Load capacity indicates the maximum weight that a spindle can support during operation. This property is particularly important in heavy machining applications. Buyers should evaluate their specific load requirements and choose spindles that can handle those loads to prevent premature wear or failure.

What Are Common Trade Terms in the Spindle Manufacturing Industry?

Understanding industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are several common terms:

1. OEM (Original Equipment Manufacturer): What Does It Mean?

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the spindle industry, OEMs are crucial as they supply the components needed for machinery. B2B buyers should engage with reputable OEMs to ensure quality and compatibility.

2. MOQ (Minimum Order Quantity): Why Is It Important?

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for budgeting and inventory management. Buyers should clarify MOQ terms with suppliers to ensure they can meet their procurement needs without incurring unnecessary costs.

3. RFQ (Request for Quotation): How Can It Benefit Your Procurement Process?

An RFQ is a document used to solicit price quotes from suppliers. It outlines specifications, quantities, and terms of purchase. Using RFQs can streamline the procurement process, ensuring buyers receive competitive pricing and clear expectations from manufacturers.

4. Incoterms: What Do They Govern?

Incoterms (International Commercial Terms) are internationally recognized rules that define the responsibilities of buyers and sellers in shipping and delivery. Understanding Incoterms is essential for buyers to clarify shipping responsibilities, costs, and risks, thus preventing misunderstandings in international transactions.

5. Lead Time: Why Is It Critical for Planning?

Lead time refers to the duration from placing an order to receiving it. This term is crucial for project planning, especially in industries with tight production schedules. Buyers should discuss lead times with suppliers to align delivery expectations with their operational timelines.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing spindles, ultimately enhancing their operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the spindle manufacturer Sector

What are the Current Market Dynamics and Key Trends in the Spindle Manufacturer Sector?

The spindle manufacturing sector is experiencing notable growth driven by several global trends. Increased industrial automation and demand for precision engineering are pivotal in shaping the market. As industries such as automotive, aerospace, and energy expand, the need for high-quality spindle solutions rises. Additionally, the proliferation of advanced manufacturing technologies, including 3D printing and CNC machining, is transforming sourcing strategies. International B2B buyers, particularly in Africa, South America, the Middle East, and Europe, should remain vigilant about these trends, as they dictate supplier capabilities and product offerings.

Emerging technologies are also influencing the spindle market. Smart manufacturing, driven by IoT and AI, is enhancing operational efficiencies and product quality. Buyers are increasingly looking for suppliers that can integrate these technologies into their manufacturing processes. Furthermore, the push for localization in supply chains, exacerbated by recent global disruptions, has led many companies to seek regional suppliers. This shift not only reduces lead times but also mitigates risks associated with global sourcing. B2B buyers should assess potential suppliers based on their technological capabilities and adaptability to changing market demands.

How Does Sustainability Impact Sourcing Decisions in the Spindle Manufacturer Sector?

Sustainability has become a critical consideration in the sourcing strategies of international B2B buyers. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes the use of renewable energy sources, efficient production methods, and minimizing carbon footprints.

Furthermore, the importance of ethical supply chains cannot be overstated. Buyers are now seeking suppliers who adhere to fair labor practices and comply with local regulations. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming essential benchmarks for evaluating potential partners. Additionally, the use of ‘green’ materials, such as recycled metals and eco-friendly lubricants, is gaining traction. By aligning with suppliers who prioritize sustainability, B2B buyers can enhance their brand reputation and meet the growing demands of environmentally conscious consumers.

What is the Brief Evolution and History of the Spindle Manufacturing Sector?

The spindle manufacturing sector has evolved significantly over the past century. Initially, spindles were primarily produced using traditional machining techniques, focusing on basic functionality and durability. However, as industries progressed, the demand for precision and efficiency led to the development of advanced manufacturing techniques. The introduction of CNC technology in the late 20th century revolutionized spindle production, allowing for higher accuracy and customization.

In recent years, the sector has seen a shift towards integrating smart technologies and automation. This evolution is essential for meeting the demands of modern industries that require not only high performance but also adaptability to changing production needs. As a result, the spindle manufacturing industry continues to innovate, ensuring it remains competitive in a rapidly evolving global market. International B2B buyers must recognize this evolution when sourcing suppliers, as it directly impacts product quality, reliability, and overall value.

Frequently Asked Questions (FAQs) for B2B Buyers of spindle manufacturer

-

How do I choose the right spindle manufacturer for my business needs?

Selecting the right spindle manufacturer involves assessing several factors including quality, production capacity, and expertise in your specific industry. Start by evaluating the manufacturer’s track record and client testimonials. It’s also critical to consider their ability to provide customization options that meet your specific requirements. Request samples to assess quality and performance, and ensure they have certifications that align with international standards, especially if you’re sourcing from regions like Africa or South America. -

What are the key qualities to look for in a spindle supplier?

The ideal spindle supplier should exhibit strong industry experience, robust quality assurance processes, and a commitment to customer service. Look for manufacturers that utilize advanced technology in their production processes and have a transparent supply chain. Additionally, ensure they offer after-sales support and are responsive to inquiries. This is particularly important for international buyers from Europe and the Middle East, where communication and reliability are critical. -

What is the minimum order quantity (MOQ) for spindles from manufacturers?

MOQs can vary widely among spindle manufacturers, often depending on the type of spindle and the customization required. Typically, MOQs can range from a few units to several hundred. It is advisable to discuss your specific needs directly with manufacturers to negotiate MOQs that align with your business objectives. For international buyers, understanding the MOQ is crucial to managing inventory and cash flow effectively. -

How can I ensure the quality of spindles I am purchasing?

To ensure quality, request detailed product specifications and certifications from the manufacturer. Conducting a factory audit or quality inspection before placing a large order can also mitigate risks. Many manufacturers provide samples or prototypes for testing, which is essential for verifying performance. Collaborating with local quality assurance agencies can further enhance your confidence in the product quality, especially for buyers in regions like Africa and South America. -

What payment terms should I expect when sourcing spindles internationally?

Payment terms can vary based on the manufacturer and the relationship established. Common terms include a deposit upon order confirmation, followed by the balance before shipment. For international transactions, consider using secure payment methods such as letters of credit or escrow services to protect both parties. Discussing payment terms upfront is crucial for avoiding misunderstandings and ensuring a smooth transaction process. -

How do I handle logistics when importing spindles from manufacturers?

Managing logistics effectively involves selecting a reliable freight forwarder familiar with international shipping regulations. Ensure the manufacturer can provide necessary documentation such as invoices, packing lists, and certificates of origin. It is also essential to consider customs duties and taxes applicable in your country. Coordinating closely with your logistics partner will help streamline the import process and minimize delays. -

Can spindle manufacturers provide customization options?

Many spindle manufacturers offer customization options to meet specific industry needs, including dimensions, materials, and performance specifications. When discussing potential orders, clearly outline your requirements and ask for examples of previous custom projects. This will help you gauge the manufacturer’s capabilities and flexibility. Customization can often enhance performance and fit within your operational framework, making it a valuable option for international buyers. -

What are the common challenges faced when sourcing spindles internationally?

International sourcing can present challenges such as language barriers, differing regulations, and varying quality standards. Time zone differences may also complicate communication. To mitigate these issues, establish clear communication protocols and consider working with local representatives or agents familiar with the market. Building strong relationships with manufacturers and understanding their operational processes can significantly ease the sourcing experience.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for spindle manufacturer

In the evolving landscape of spindle manufacturing, strategic sourcing emerges as a pivotal approach for international B2B buyers. By leveraging supplier relationships, companies can enhance their procurement processes, ensuring quality and cost-effectiveness. Buyers from Africa, South America, the Middle East, and Europe (including Spain and the UK) must prioritize partnerships with manufacturers who demonstrate reliability, innovation, and adherence to international standards.

What are the key benefits of strategic sourcing for spindle manufacturers? Enhanced supplier collaboration can lead to improved product quality and reduced lead times, ultimately boosting operational efficiency. Furthermore, understanding market dynamics and regional demands enables buyers to make informed decisions that align with their business goals.

Looking ahead, the demand for high-performance spindles will continue to rise as industries advance. International buyers should actively engage with manufacturers who are committed to sustainability and technological innovation. By doing so, you position your business for success in a competitive global market. Embrace strategic sourcing as a catalyst for growth, ensuring your operations remain agile and responsive to future opportunities.