The Ultimate Guide to Steering Wheel Manufacturer (2025)

Introduction: Navigating the Global Market for steering wheel manufacturer

Navigating the global market for steering wheel manufacturers presents unique challenges, particularly for international B2B buyers in regions like Africa, South America, the Middle East, and Europe. Sourcing high-quality steering wheels that meet specific industry standards and consumer preferences can be daunting. Buyers often grapple with issues such as varying quality levels, compliance with international regulations, and fluctuating costs influenced by currency exchange rates. This guide aims to demystify the complexities of sourcing steering wheels by providing a thorough exploration of types, applications, supplier vetting processes, and cost considerations.

Understanding the diverse applications of steering wheels—from automotive to industrial machinery—is crucial for making informed purchasing decisions. This guide empowers buyers by offering actionable insights into identifying reliable suppliers, negotiating contracts, and evaluating product quality. Additionally, it addresses the importance of understanding regional compliance standards and market trends, which can significantly impact procurement strategies.

By leveraging the information in this guide, B2B buyers can navigate the intricacies of the steering wheel market with confidence, ensuring they make decisions that align with their operational needs and budget constraints. Whether you are a buyer from the UK, Vietnam, or elsewhere, the knowledge provided here will help streamline your sourcing process and enhance your competitive edge in the global marketplace.

Understanding steering wheel manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OEM (Original Equipment Manufacturer) | Produces steering wheels for specific vehicle brands, ensuring compatibility and quality. | Automotive manufacturers, fleet services | Pros: High quality, brand assurance. Cons: Higher costs, limited customization. |

| Aftermarket Manufacturers | Offers a wide range of steering wheels for various vehicle makes, often with customization options. | Automotive retail, customization shops | Pros: Variety and customization, competitive pricing. Cons: Quality can vary significantly. |

| Racing Steering Wheel Producers | Specializes in lightweight, high-performance steering wheels designed for motorsport. | Racing teams, performance vehicle builders | Pros: Enhanced performance, tailored for racing. Cons: Not suitable for everyday use, higher price point. |

| Luxury Steering Wheel Makers | Focuses on premium materials and innovative designs, often featuring advanced technology. | Luxury car manufacturers, bespoke vehicle builders | Pros: High-end aesthetics, advanced features. Cons: High cost, longer lead times. |

| Electric Steering Wheel Suppliers | Develops steering wheels integrated with electronic controls for advanced driver assistance systems (ADAS). | Automotive tech companies, electric vehicle manufacturers | Pros: Future-proof technology, enhanced safety features. Cons: Requires specialized knowledge for installation. |

What Are OEM Steering Wheel Manufacturers and Their Benefits?

OEM steering wheel manufacturers are critical in the automotive supply chain, producing steering wheels specifically designed for vehicle brands. These manufacturers ensure that their products meet stringent quality and safety standards, which is essential for automotive companies and fleet services seeking reliability. When purchasing from OEMs, buyers benefit from brand assurance and compatibility, although they may face higher costs and limited customization options.

How Do Aftermarket Manufacturers Differ in the Steering Wheel Market?

Aftermarket manufacturers provide a diverse range of steering wheels suitable for various vehicle makes. They cater to automotive retailers and customization shops, offering options that allow buyers to personalize their vehicles. The main advantages of aftermarket steering wheels are their variety and competitive pricing, making them appealing to budget-conscious buyers. However, the quality can vary significantly, requiring buyers to conduct thorough research to ensure they are selecting a reputable supplier.

What Are the Unique Features of Racing Steering Wheel Producers?

Racing steering wheel producers focus on creating lightweight and high-performance wheels tailored for motorsport applications. These products are designed to enhance driver control and vehicle response, making them ideal for racing teams and performance vehicle builders. While they offer significant performance advantages, these steering wheels are not suitable for everyday use and often come with a higher price point, which may limit accessibility for some buyers.

Why Choose Luxury Steering Wheel Makers?

Luxury steering wheel makers emphasize premium materials and innovative designs, integrating advanced technology into their products. These steering wheels are often used by luxury car manufacturers and bespoke vehicle builders who prioritize aesthetics and functionality. Buyers enjoy high-end features and unique styles, but the costs are considerably higher, and lead times may be longer, which can affect project timelines.

How Do Electric Steering Wheel Suppliers Fit into the Market?

Electric steering wheel suppliers specialize in steering wheels that integrate electronic controls, crucial for advanced driver assistance systems (ADAS). These products are increasingly relevant for automotive tech companies and electric vehicle manufacturers looking to enhance safety and functionality. While they offer future-proof technology, buyers must consider the specialized knowledge required for installation, which may necessitate additional training or partnerships with tech-savvy suppliers.

Key Industrial Applications of steering wheel manufacturer

| Industry/Sector | Specific Application of Steering Wheel Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Production of OEM steering wheels | Enhances vehicle safety and performance | Quality certifications, material specifications, lead times |

| Aviation | Custom steering controls for aircraft | Increases operational efficiency | Compliance with aviation standards, weight considerations |

| Industrial Machinery | Steering systems for heavy machinery | Improves maneuverability and precision | Durability, resistance to environmental factors |

| Marine | Steering wheels for boats and vessels | Enhances navigational control | Corrosion resistance, customization options |

| Electric Vehicles (EV) | Smart steering solutions for EVs | Supports advanced driver-assistance systems | Integration with electronic systems, sustainability practices |

How Are Steering Wheels Used in the Automotive Industry?

In the automotive sector, steering wheel manufacturers provide original equipment manufacturer (OEM) steering wheels that are integral to vehicle design. These wheels enhance both safety and performance, as they are engineered to meet strict safety standards and ergonomic requirements. International B2B buyers, especially from Africa and South America, must consider quality certifications and the sourcing of materials, ensuring that they meet local regulations and consumer preferences.

What is the Role of Steering Wheels in Aviation?

In aviation, steering wheels are often customized for aircraft controls, playing a crucial role in flight operations. These steering solutions contribute to operational efficiency by allowing precise maneuvering during flight. Buyers in the Middle East and Europe should prioritize compliance with aviation standards and focus on weight considerations, as these factors directly impact aircraft performance and safety.

How Do Steering Systems Benefit Industrial Machinery?

For industrial machinery, steering wheel manufacturers produce steering systems that enhance maneuverability and precision in heavy equipment. These systems are essential for operators to navigate complex environments effectively. B2B buyers should consider durability and resistance to environmental factors when sourcing steering solutions, particularly in regions with harsh working conditions, such as Africa and South America.

Why Are Steering Wheels Important for Marine Applications?

In the marine industry, steering wheels are critical for ensuring navigational control in boats and vessels. High-quality steering systems improve safety and user experience on the water. International buyers from Europe and the Middle East should focus on sourcing steering wheels that offer corrosion resistance and customization options to meet specific vessel requirements.

How Are Smart Steering Solutions Transforming Electric Vehicles?

Steering wheel manufacturers are increasingly developing smart steering solutions for electric vehicles (EVs), integrating advanced driver-assistance systems (ADAS) that enhance safety and driving comfort. This innovation is essential for meeting the growing demand for sustainable and high-tech vehicles. Buyers should emphasize the integration of electronic systems and sustainability practices when sourcing steering solutions for EVs, particularly in markets across Europe and South America.

Related Video: The World’s Largest Bevel Gear CNC Machine- Modern Gear Production Line. Steel Wheel Manufacturing

3 Common User Pain Points for ‘steering wheel manufacturer’ & Their Solutions

Scenario 1: Inconsistent Quality Across Different Orders

The Problem: One of the major challenges faced by international B2B buyers in the steering wheel manufacturing sector is inconsistent quality across different orders. A buyer may receive steering wheels that vary in quality, material, or finish, which can lead to significant issues in their assembly lines or final products. This inconsistency not only affects product reliability but can also damage the buyer’s reputation, especially in highly competitive markets like Europe and North America where consumer expectations are high.

The Solution: To mitigate this issue, buyers should establish clear quality assurance protocols with their steering wheel manufacturers. This includes defining detailed specifications, including material grades, finish requirements, and performance standards. Implementing a third-party quality inspection can also be beneficial; buyers can schedule inspections at various production stages to ensure compliance with specifications. Regular audits of the manufacturing facilities can foster a collaborative relationship focused on quality improvement. Additionally, buyers should maintain open lines of communication to address any concerns promptly, ensuring that both parties are aligned on quality expectations.

Scenario 2: Difficulty in Customization for Local Markets

The Problem: Many B2B buyers, particularly those operating in diverse regions such as Africa and South America, struggle with the lack of customization options when sourcing steering wheels. Local markets often have specific preferences and regulatory requirements that necessitate tailored designs. This can lead to challenges in product acceptance and compliance, resulting in potential losses for buyers who invest in non-compliant or unpopular products.

The Solution: Buyers should seek manufacturers that offer flexible customization capabilities and are familiar with the local market requirements. It is crucial to engage in early discussions about customization options, such as varying sizes, materials, and design elements that cater to local preferences. Additionally, conducting market research to understand local consumer preferences can guide the customization process. Collaborating closely with manufacturers during the design phase can help ensure that the final products meet both regulatory standards and consumer expectations. Buyers should also consider forming partnerships with local design firms to enhance product acceptance in their target markets.

Scenario 3: Challenges in Supply Chain Coordination

The Problem: Coordinating the supply chain for steering wheels can be particularly challenging, especially for international buyers. Issues such as shipping delays, unexpected tariffs, and communication barriers can disrupt the flow of goods and affect production schedules. This unpredictability can lead to increased costs and project delays, which are detrimental to a business’s operational efficiency.

The Solution: To enhance supply chain coordination, buyers should implement a robust supply chain management system that includes real-time tracking of shipments and inventory levels. Establishing strong relationships with logistics partners can provide more reliable shipping options and better manage unexpected issues. Buyers should also consider diversifying their supplier base to minimize reliance on a single source, which can alleviate risks associated with supply chain disruptions. Regularly reviewing and analyzing supply chain performance can help identify bottlenecks, allowing for proactive adjustments. Additionally, leveraging technology, such as cloud-based platforms for collaborative planning, can improve communication and transparency across all parties involved in the supply chain.

Strategic Material Selection Guide for steering wheel manufacturer

What Are the Key Properties of Common Materials Used in Steering Wheel Manufacturing?

When selecting materials for steering wheels, manufacturers must consider various properties that directly impact performance and durability. The most commonly used materials include plastics, metals, leather, and composites. Each material presents unique characteristics that influence their suitability for different applications.

How Does Plastic Perform in Steering Wheel Manufacturing?

Key Properties: Plastics, particularly thermoplastics like polypropylene and polycarbonate, offer excellent temperature resistance and can withstand pressures typical in automotive environments. They are also resistant to corrosion and chemicals, making them ideal for various climates.

Pros & Cons: The primary advantage of plastics is their lightweight nature, which contributes to overall vehicle efficiency. They are also cost-effective and can be molded into complex shapes, allowing for innovative designs. However, plastics may have lower durability compared to metals and can be susceptible to UV degradation over time.

Impact on Application: Plastics are suitable for steering wheels that require frequent handling and exposure to various media, such as sweat or cleaning agents. However, they may not be ideal for high-performance vehicles where enhanced tactile feedback is crucial.

Considerations for International Buyers: Buyers from regions such as Africa and South America should ensure that the plastics used comply with local automotive standards and regulations, such as ASTM or DIN. Additionally, the availability of specific plastic grades may vary by region.

What Are the Advantages of Using Metals in Steering Wheel Manufacturing?

Key Properties: Metals like aluminum and steel provide exceptional strength and durability. They can withstand high temperatures and pressures, making them suitable for heavy-duty applications. Corrosion-resistant coatings can enhance their longevity.

Pros & Cons: The key advantage of metals is their robustness, which translates to enhanced safety and longevity of the steering wheel. However, they are heavier than plastics, which may affect vehicle weight and fuel efficiency. Manufacturing complexity is also higher due to the need for machining and welding.

Impact on Application: Metal steering wheels are often used in performance vehicles where strength and feedback are paramount. They can also support additional features like integrated controls or heating elements.

Considerations for International Buyers: Buyers in Europe and the Middle East should be aware of specific metal grades and treatment processes that comply with regional standards. Understanding the supply chain for metals, including tariffs and import regulations, is crucial.

How Does Leather Contribute to Steering Wheel Comfort and Aesthetics?

Key Properties: Leather offers a high level of comfort and tactile feedback, making it a popular choice for premium vehicles. It is naturally breathable and can withstand moderate temperatures. However, its resistance to wear and tear can vary based on the type of leather used.

Pros & Cons: The main advantage of leather is its luxurious feel and aesthetic appeal, which can enhance the vehicle’s interior. However, leather can be more expensive than synthetic alternatives and requires regular maintenance to prevent cracking or fading.

Impact on Application: Leather is ideal for steering wheels in luxury vehicles where comfort and style are prioritized. It provides excellent grip and can be treated to enhance durability against environmental factors.

Considerations for International Buyers: Buyers should consider local preferences for leather types and treatments. Compliance with ethical sourcing standards is increasingly important, particularly in Europe, where regulations around animal welfare are strict.

What Role Do Composites Play in Steering Wheel Manufacturing?

Key Properties: Composites, such as carbon fiber reinforced plastics, offer high strength-to-weight ratios and excellent resistance to fatigue and corrosion. They can be engineered to meet specific performance requirements.

Pros & Cons: The primary advantage of composites is their lightweight nature combined with high strength, making them suitable for performance-oriented applications. However, they can be more expensive and complex to manufacture, requiring specialized processes.

Impact on Application: Composites are often used in high-performance or racing vehicles where weight savings are critical. They can also be designed for specific media compatibility, enhancing overall vehicle performance.

Considerations for International Buyers: Buyers should be aware of the certification processes for composite materials, as they may differ significantly between regions. Understanding the supply chain for composite materials is essential, especially in emerging markets.

Summary Table of Material Selection for Steering Wheel Manufacturing

| Material | Typical Use Case for steering wheel manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastics | Standard vehicles, budget models | Lightweight and cost-effective | Lower durability, UV degradation potential | Low |

| Metals | Performance and heavy-duty vehicles | Exceptional strength and durability | Heavier, higher manufacturing complexity | Med |

| Leather | Luxury and premium vehicles | Comfort and aesthetic appeal | Higher cost, requires maintenance | High |

| Composites | High-performance and racing vehicles | High strength-to-weight ratio | Expensive, complex manufacturing processes | High |

This guide provides a comprehensive overview of the materials commonly used in steering wheel manufacturing, offering actionable insights for international B2B buyers navigating the complexities of material selection.

In-depth Look: Manufacturing Processes and Quality Assurance for steering wheel manufacturer

What Are the Main Stages of Manufacturing for Steering Wheels?

The manufacturing of steering wheels involves several critical stages, each designed to ensure high-quality output and reliability. The primary stages include material preparation, forming, assembly, and finishing.

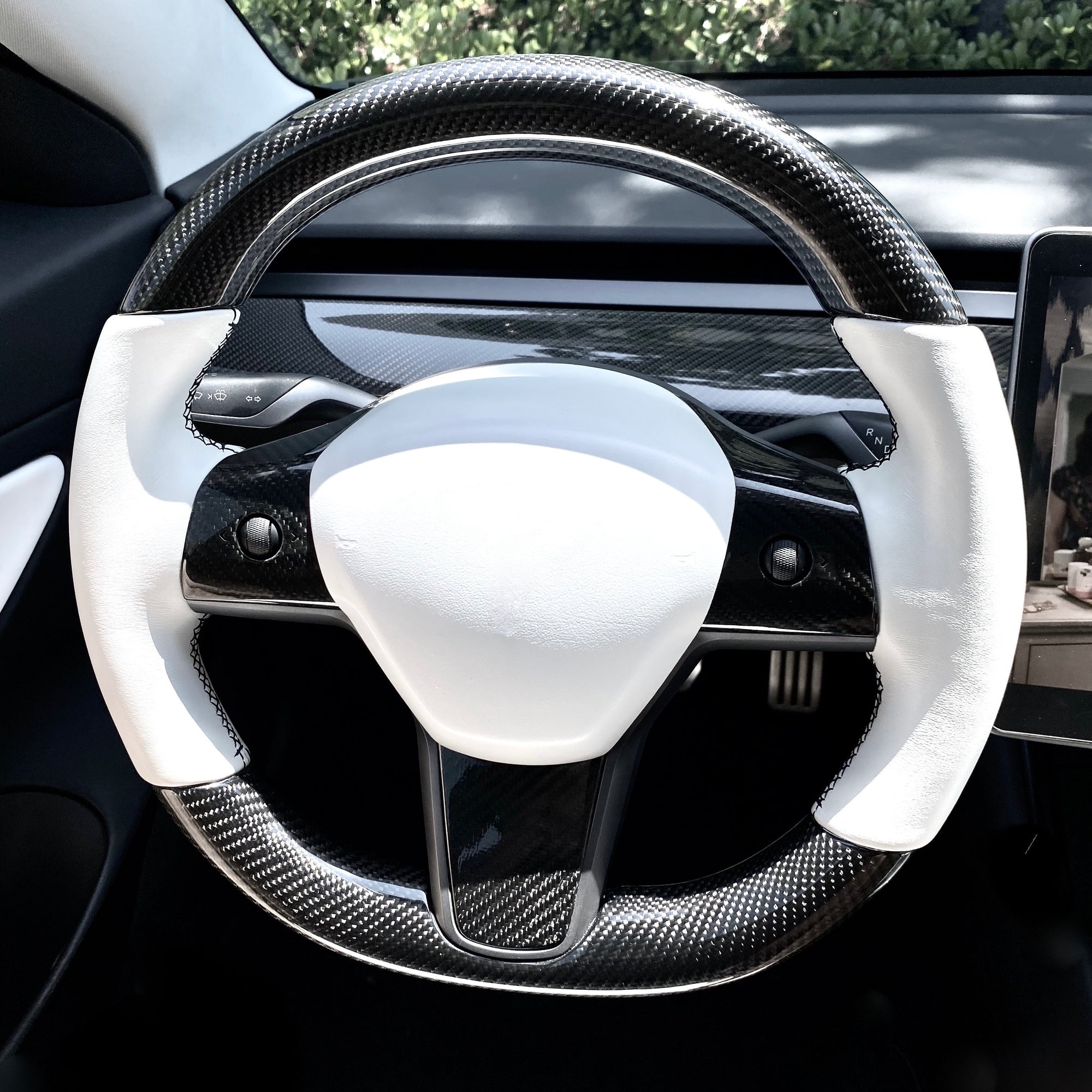

A stock image related to steering wheel manufacturer.

Material Preparation: How Are Steering Wheel Materials Selected and Processed?

Material selection is crucial in steering wheel manufacturing. Common materials include plastics, metals, and composites, chosen for their strength, durability, and aesthetic appeal.

- Material Sourcing: B2B buyers should focus on suppliers that source high-quality raw materials. For instance, high-strength thermoplastics or aluminum alloys are often preferred.

- Pre-processing: This stage involves cutting, molding, or shaping the materials to fit specific design requirements. Advanced techniques such as injection molding for plastics or die-casting for metals are employed to ensure precision.

Forming: What Techniques Are Used to Shape Steering Wheels?

The forming stage is where the raw materials are shaped into the desired steering wheel form. Techniques include:

- Injection Molding: This is widely used for plastic steering wheels, where molten plastic is injected into a mold to create the wheel’s shape.

- Die-Casting: For metal components, die-casting allows for complex shapes with tight tolerances, essential for ensuring the integrity and performance of the steering wheel.

- CNC Machining: This technology is often used for creating precise features on metal steering wheels, ensuring consistency and accuracy.

Assembly: How Are Steering Wheels Assembled?

Once the individual components are formed, they undergo assembly. This stage typically includes:

- Component Joining: Parts like the wheel rim, spokes, and center hub are assembled using various techniques, including welding, adhesive bonding, or mechanical fastening.

- Integration of Electronics: For modern steering wheels, integrating electronic components such as airbag systems or controls for audio and cruise functions is vital. This requires precise assembly to ensure functionality and safety.

Finishing: What Processes Enhance the Quality of Steering Wheels?

The finishing stage enhances the aesthetic and functional qualities of the steering wheels. Key processes include:

- Surface Treatment: Techniques such as painting, plating, or coating are applied to enhance durability and appearance. For example, a rubberized coating may be used for better grip.

- Quality Control Checks: Before the final product is packaged, thorough inspections are conducted to ensure that the steering wheels meet all design specifications and quality standards.

What Quality Assurance Practices Are Essential for Steering Wheel Manufacturers?

Quality assurance (QA) is integral to steering wheel manufacturing, ensuring that products are safe and meet international standards.

Which International Standards Should B2B Buyers Consider?

B2B buyers should ensure that their suppliers comply with relevant international quality standards, including:

- ISO 9001: This standard specifies requirements for a quality management system, ensuring consistent quality in manufacturing processes.

- CE Marking: Particularly important in Europe, CE marking indicates that the product meets EU safety, health, and environmental protection requirements.

- API Standards: For steering wheels that may be used in specialized applications, such as automotive or aerospace, compliance with API (American Petroleum Institute) standards may be necessary.

What Are the Key Quality Control Checkpoints in Steering Wheel Manufacturing?

Quality control checkpoints are vital to maintaining product integrity throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified requirements before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process is crucial for identifying defects early. This could include dimensional checks and functional testing.

- Final Quality Control (FQC): Before shipment, a thorough inspection is conducted to verify that the finished steering wheels meet all quality standards and specifications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers need to take proactive steps to verify the quality control practices of their suppliers. Effective strategies include:

- Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality assurance measures. This helps in identifying potential issues before they affect product quality.

- Requesting Quality Reports: Suppliers should provide documentation of their quality control processes and results. This includes records of inspections, testing results, and compliance with international standards.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality assurance practices. This is particularly useful for international buyers who may not be able to conduct on-site inspections.

What Nuances Should International Buyers Be Aware of Regarding Quality Control?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, need to navigate several nuances when dealing with quality control:

- Cultural Differences in Quality Perception: Different regions may have varying expectations regarding quality and standards. Understanding these cultural nuances is crucial for successful partnerships.

- Regulatory Compliance: Buyers must ensure that their suppliers comply with local regulations in their respective countries. This includes understanding the specific certifications required for importation.

- Logistical Challenges: Shipping and logistics can impact product quality. Buyers should discuss how suppliers manage storage, transport, and handling to minimize risks of damage.

By focusing on these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when selecting steering wheel manufacturers, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘steering wheel manufacturer’

The procurement of steering wheels is a critical aspect for automotive manufacturers, ensuring safety, comfort, and aesthetic appeal in vehicles. This practical sourcing guide provides a structured approach for B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, to effectively source steering wheel manufacturers.

Step 1: Define Your Technical Specifications

Why is this important? Clearly defining your technical specifications lays the foundation for your sourcing process. It ensures that all potential suppliers understand your specific needs, from design to functionality.

- Considerations: Specify materials (e.g., leather, plastic), dimensions, and any required features such as heating or integrated controls.

- Documentation: Create a detailed specification sheet that can be shared with suppliers to avoid misunderstandings.

Step 2: Research Potential Suppliers

What should you look for? Conducting thorough research on potential suppliers helps you identify those who align with your quality and technical standards.

- Sources: Utilize industry directories, trade shows, and online platforms like Alibaba or ThomasNet to compile a list of manufacturers.

- Reputation: Check online reviews and ratings to gauge the reliability and quality of products offered by these suppliers.

Step 3: Evaluate Supplier Certifications and Compliance

Why is compliance crucial? Ensuring that suppliers meet relevant industry standards and certifications is vital for quality assurance and legal compliance.

- Certifications: Look for ISO certifications, quality management systems, and compliance with safety regulations pertinent to your region (e.g., CE marking in Europe).

- Documentation: Request copies of certifications and compliance documents to verify their legitimacy.

Step 4: Request Samples and Prototypes

What is the purpose of requesting samples? Obtaining samples allows you to assess the quality, craftsmanship, and functionality of the steering wheels before placing a bulk order.

- Evaluation: Test the samples for durability, comfort, and compliance with your specifications.

- Feedback: Involve your engineering or design team in the evaluation process to gather diverse insights.

Step 5: Assess Pricing and Payment Terms

How should you approach pricing? Understanding pricing structures and payment terms is crucial for budget management and financial planning.

- Comparative Analysis: Request detailed quotes from multiple suppliers and compare them, considering the total cost of ownership, including shipping and potential tariffs.

- Negotiation: Discuss payment terms that work for both parties, such as upfront payments, milestones, or net payment terms.

Step 6: Verify Supply Chain and Delivery Capabilities

Why is supply chain reliability essential? A reliable supply chain ensures timely delivery and reduces the risk of production delays.

- Logistics: Inquire about their logistics partners and delivery timelines, especially if you are importing from different continents.

- Capacity: Assess whether the supplier can meet your volume requirements consistently.

Step 7: Establish Clear Communication Channels

What is the role of communication? Effective communication fosters transparency and helps address any issues promptly throughout the sourcing process.

- Preferred Methods: Determine preferred communication methods (e.g., email, phone, video calls) and establish points of contact within both organizations.

- Updates: Set expectations for regular updates on order status, production timelines, and any potential challenges.

By following this structured checklist, B2B buyers can streamline their procurement process, reduce risks, and ensure they select a steering wheel manufacturer that meets their technical and business needs.

Comprehensive Cost and Pricing Analysis for steering wheel manufacturer Sourcing

What Are the Key Cost Components in Steering Wheel Manufacturing?

Understanding the cost structure of steering wheel manufacturing is essential for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts cost. Common materials include plastics, leather, and metals. Higher-quality materials may increase upfront costs but can enhance durability and user satisfaction.

-

Labor: Labor costs vary by region, influenced by local wage standards and skill levels. Countries with lower labor costs may offer savings, but it’s vital to assess the quality of workmanship.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, equipment depreciation, and facility maintenance. Efficient manufacturing processes can help minimize these expenses.

-

Tooling: Tooling costs are essential for creating molds and fixtures required for production. These costs can be substantial, especially for custom designs.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability. While this may incur additional costs, it can prevent more significant expenses related to returns and warranty claims.

-

Logistics: Transportation and handling costs also play a crucial role. The shipping method, distance, and volume of goods affect logistics expenses. Proper planning can lead to significant savings.

-

Margin: Manufacturers typically add a margin to cover costs and generate profit. Understanding the average industry margins can help buyers negotiate better prices.

How Do Price Influencers Affect Steering Wheel Costs?

Several factors influence the pricing of steering wheels:

-

Volume/MOQ: Purchasing in bulk often leads to lower per-unit costs. Manufacturers typically offer discounts for larger orders, making it beneficial for buyers with consistent demand.

-

Specifications and Customization: Custom designs or specific features can increase costs. Clearly defining specifications upfront can help avoid unexpected charges later in the process.

-

Materials and Quality Certifications: The choice of materials and certifications (like ISO) can affect pricing. High-quality materials and certifications may raise costs but can be worth the investment for increased performance and safety.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established manufacturers may charge more due to their experience and quality assurance processes.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can influence the overall cost.

What Tips Can Help International Buyers Optimize Costs?

For B2B buyers, especially in Africa, South America, the Middle East, and Europe, here are practical tips to ensure cost efficiency:

-

Negotiate Terms: Don’t hesitate to negotiate pricing, especially for larger orders. Suppliers may be willing to offer better rates to secure your business.

-

Consider Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the steering wheels, including maintenance, durability, and potential warranty claims. A higher upfront cost may lead to lower TCO.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing structures. Be informed about local market conditions and currency fluctuations to make better purchasing decisions.

-

Utilize Technology: Leverage digital tools and platforms for price comparisons and supplier evaluations. This can help identify the best deals and suppliers.

Disclaimer on Indicative Prices

Prices in this analysis are indicative and may vary based on market conditions, exchange rates, and specific supplier agreements. Always conduct thorough research and consult with suppliers for the most accurate pricing information tailored to your needs.

Alternatives Analysis: Comparing steering wheel manufacturer With Other Solutions

Understanding Alternative Solutions for Steering Wheel Manufacturing

When evaluating options for steering wheel manufacturing, it’s essential for international B2B buyers to consider various alternatives. This comparison not only highlights the strengths and weaknesses of the traditional steering wheel manufacturing process but also provides insights into innovative technologies and methods that may be more suitable for specific applications. By understanding these alternatives, buyers can make informed decisions that align with their operational needs and budget constraints.

Comparison of Steering Wheel Manufacturer with Alternative Solutions

| Comparison Aspect | Steering Wheel Manufacturer | 3D Printing Technology | Modular Component Systems |

|---|---|---|---|

| Performance | High durability and reliability | Variable, depends on material used | High adaptability and customization |

| Cost | Moderate to high initial investment | Lower initial costs; material costs vary | Moderate to high based on complexity |

| Ease of Implementation | Requires specialized machinery and skilled labor | Requires design software and printer | Easier integration into existing systems |

| Maintenance | Regular maintenance needed for machinery | Minimal; depends on printer upkeep | Moderate; depends on components used |

| Best Use Case | Mass production of standardized wheels | Custom or small-batch production | Rapid prototyping and flexible designs |

In-Depth Analysis of Alternatives

What Are the Benefits of 3D Printing Technology for Steering Wheels?

3D printing technology offers significant advantages, particularly for companies focusing on custom or small-batch production. The initial investment is lower than traditional manufacturing methods, and the ability to create complex geometries allows for innovative designs that can enhance user experience. However, the performance of 3D printed wheels can vary depending on the materials used, and achieving the same level of durability as conventional manufacturing may be challenging. This technology is best suited for businesses looking to innovate or test new concepts without committing to large-scale production.

How Do Modular Component Systems Enhance Steering Wheel Solutions?

Modular component systems provide a flexible approach to steering wheel design and manufacturing. This method allows for the easy swapping of components, facilitating quick adaptations to changing market demands or regulatory requirements. The implementation of these systems can be simpler than traditional manufacturing processes, as they often integrate seamlessly into existing production lines. Nevertheless, the overall cost can rise depending on the complexity of the components and the customization required. This alternative is ideal for manufacturers aiming for rapid prototyping and those needing to adjust designs frequently.

How Should B2B Buyers Choose the Right Solution?

Choosing the right solution for steering wheel manufacturing depends on several factors, including production volume, customization needs, and budget constraints. Buyers from regions such as Africa, South America, the Middle East, and Europe should assess their specific market demands and technological capabilities. For high-volume, standardized production, traditional steering wheel manufacturing may be the most reliable option. Conversely, companies focused on innovation or bespoke solutions might find 3D printing or modular systems more beneficial. Ultimately, understanding the nuances of each alternative will empower B2B buyers to select the most suitable approach for their operational goals.

Essential Technical Properties and Trade Terminology for steering wheel manufacturer

What Are the Key Technical Properties for Steering Wheel Manufacturing?

Understanding the essential technical properties of steering wheels is vital for international B2B buyers, especially when sourcing from diverse markets such as Africa, South America, the Middle East, and Europe. Here are several critical specifications to consider:

1. Material Grade

The material used in steering wheel manufacturing significantly impacts durability, weight, and overall performance. Common materials include thermoplastic elastomers (TPE), polyurethane, and leather for the outer covering. TPE offers flexibility and resilience, while polyurethane provides a robust yet lightweight alternative. Buyers should evaluate material grades based on performance requirements and environmental factors, such as temperature variations and humidity levels.

2. Tolerance Levels

Tolerance refers to the permissible limit or limits of variation in a physical dimension. For steering wheels, maintaining precise tolerances is crucial for ensuring proper fit and function. Typical tolerances range from ±0.5 mm to ±1.0 mm, depending on the complexity of the design. Adhering to specified tolerances minimizes the risk of defects, which can lead to safety issues or increased costs in production.

3. Weight Specifications

The weight of a steering wheel can influence vehicle handling and performance. A lighter wheel can enhance responsiveness, while a heavier wheel may provide more stability. Manufacturers often design wheels to meet specific weight targets, balancing performance with material strength. Buyers should consider how weight specifications align with their vehicle design goals and user expectations.

4. Surface Finish

The surface finish of a steering wheel affects both aesthetics and functionality. Common finishes include matte, gloss, and textured surfaces, each offering different tactile and visual experiences. The finish can also influence grip, wear resistance, and ease of cleaning. Buyers should assess surface finish requirements based on their target market’s preferences and usability standards.

5. Testing Standards

Compliance with testing standards, such as ISO or SAE, is critical for ensuring quality and safety. Steering wheels undergo various tests, including fatigue, impact, and environmental testing. Buyers should inquire about the testing protocols used by manufacturers to guarantee that products meet regulatory requirements and performance expectations.

What Are Common Trade Terms in Steering Wheel Manufacturing?

Familiarity with trade terminology is essential for effective communication and negotiation in the steering wheel manufacturing sector. Here are several key terms that international B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of steering wheels, an OEM might supply parts directly to automotive manufacturers. Understanding OEM relationships can help buyers identify reliable suppliers and assess product compatibility with existing vehicles.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers, as it affects inventory management and cost efficiency. Understanding the MOQ can help buyers negotiate better terms and avoid excess stock, particularly when sourcing from international suppliers.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to invite suppliers to submit price quotations for specific products or services. For steering wheel manufacturers, an RFQ might include detailed specifications, quantities, and delivery timelines. Utilizing RFQs can streamline the procurement process and facilitate competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international trade. These terms clarify who is responsible for shipping, insurance, and tariffs, which is essential when importing steering wheels from different regions. Familiarity with Incoterms can help buyers mitigate risks and manage logistics effectively.

5. Lead Time

Lead time refers to the period between the initiation of an order and its completion. In steering wheel manufacturing, lead time can vary based on factors such as production capacity and material availability. Understanding lead times is crucial for effective project planning and inventory management, particularly in a global supply chain context.

In conclusion, grasping both the technical properties and trade terminology related to steering wheel manufacturing is essential for international B2B buyers. This knowledge not only aids in making informed purchasing decisions but also enhances negotiations and supplier relationships.

Navigating Market Dynamics and Sourcing Trends in the steering wheel manufacturer Sector

What Are the Current Market Dynamics and Key Trends in the Steering Wheel Manufacturing Sector?

The steering wheel manufacturing sector is experiencing significant evolution driven by several global factors. The rise of electric vehicles (EVs) is a major catalyst, prompting manufacturers to innovate not only in design but also in materials and technology. Countries in Africa, South America, the Middle East, and Europe are increasingly focusing on local production capabilities to meet growing demand and reduce reliance on imports. This shift is further encouraged by government incentives aimed at promoting local industries and reducing carbon footprints.

Emerging technologies such as 3D printing and advanced materials like carbon fiber and bio-based plastics are revolutionizing the production process. These innovations allow manufacturers to produce lighter, more durable steering wheels that enhance vehicle performance and safety. Additionally, the integration of smart technology, including sensors and connectivity features, is becoming more prevalent, enabling features like touch-sensitive controls and adaptive feedback systems.

For international B2B buyers, understanding these trends is crucial for making informed sourcing decisions. Engaging with suppliers who are investing in R&D and sustainable practices will not only ensure access to cutting-edge products but also align with consumer demand for environmentally friendly options. As competition intensifies, buyers must prioritize suppliers that demonstrate agility and responsiveness to market shifts.

How Can Sustainability and Ethical Sourcing Impact B2B Decisions in the Steering Wheel Sector?

Sustainability is no longer a trend but a necessity in the steering wheel manufacturing sector. The environmental impact of production processes, including the carbon footprint of materials and waste management, is under increasing scrutiny. Buyers from Africa, South America, the Middle East, and Europe are increasingly prioritizing suppliers who adhere to sustainable practices and demonstrate transparency in their supply chains.

Ethical sourcing is vital for building a reputable brand and ensuring compliance with international regulations. Buyers should look for manufacturers that utilize ‘green’ certifications such as ISO 14001 or materials that are recycled or sustainably sourced. This not only mitigates environmental impact but also enhances brand loyalty among eco-conscious consumers.

Moreover, sustainable practices can lead to long-term cost savings. By investing in efficient production technologies and waste reduction strategies, manufacturers can lower their operational costs, providing competitive pricing for B2B buyers. Ultimately, aligning sourcing decisions with sustainability goals can enhance a company’s market position and appeal to a broader audience.

What is the Historical Context of Steering Wheel Manufacturing Relevant to B2B Buyers?

A stock image related to steering wheel manufacturer.

The steering wheel manufacturing sector has evolved significantly since its inception. Initially crafted from wood and metal, steering wheels have transitioned to using synthetic materials and advanced composites to meet safety and performance standards. This evolution reflects broader automotive trends, including the shift towards lightweight and high-strength materials in vehicle design.

The introduction of safety regulations in the late 20th century also shaped the industry, leading to innovations such as collapsible steering columns and airbags integrated into steering wheels. For B2B buyers, understanding this history is crucial as it informs current manufacturing capabilities and regulatory compliance. Suppliers with a robust historical foundation are often better positioned to adapt to future market demands, making them reliable partners for international buyers navigating the complexities of the global automotive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of steering wheel manufacturer

-

How do I choose the right steering wheel manufacturer for my business needs?

Selecting the right steering wheel manufacturer involves assessing several key factors. Start by evaluating their production capabilities, quality assurance processes, and compliance with international standards. Request samples to gauge the quality of their products. Additionally, consider their experience in your specific industry and their capacity for customization. Research their reputation through customer reviews and industry references, and ensure they can meet your delivery timelines and minimum order quantities (MOQs). -

What are the common customization options available for steering wheels?

Most steering wheel manufacturers offer a variety of customization options tailored to client needs. These can include materials (such as leather, vinyl, or plastic), sizes, shapes, colors, and features like heated grips or integrated controls. Some manufacturers may also provide branding options, allowing you to incorporate logos or specific design elements. Discuss your requirements early in the sourcing process to ensure the manufacturer can accommodate your specifications. -

What are the typical minimum order quantities (MOQs) for steering wheels?

Minimum order quantities for steering wheels can vary widely based on the manufacturer and the complexity of the design. Generally, MOQs can range from a few hundred to several thousand units. It’s advisable to inquire directly with potential suppliers about their MOQs, as this will help you align your production needs with their capabilities. Some manufacturers may offer lower MOQs for initial orders or prototypes, which can be beneficial for testing before scaling up. -

What payment terms should I expect when sourcing from steering wheel manufacturers?

Payment terms can vary significantly among manufacturers. Common practices include upfront payments, partial payments upon order confirmation, and the balance upon delivery. Some suppliers may also accept letters of credit or escrow services for larger transactions, providing additional security. It’s essential to negotiate terms that suit your cash flow while ensuring the manufacturer is comfortable with the arrangement. Always confirm payment methods accepted, especially for international transactions. -

How can I ensure quality assurance when sourcing steering wheels internationally?

To ensure quality assurance, start by verifying that the manufacturer follows established quality control protocols, such as ISO certifications. Request documentation of their testing procedures and inspection reports. Consider implementing third-party inspections during production or before shipment to verify compliance with your specifications. Establish clear communication channels to address any quality concerns promptly. Building a strong relationship with your supplier can also facilitate better quality management. -

What logistics considerations should I keep in mind when importing steering wheels?

When importing steering wheels, consider logistics aspects such as shipping methods, customs regulations, and delivery times. Choose between air freight for faster delivery or sea freight for cost savings, depending on your urgency and budget. Familiarize yourself with import duties and taxes applicable in your country to avoid unexpected costs. Work closely with your supplier to coordinate shipping schedules and ensure all necessary documentation is prepared for a smooth customs clearance process. -

How do I vet potential steering wheel suppliers effectively?

Vetting potential suppliers is crucial for mitigating risks. Start by researching their business history, client testimonials, and industry reputation. Request references from previous clients to gain insight into their reliability and service quality. Conduct site visits if possible, or utilize virtual tours to assess their production facilities. Additionally, verify their compliance with international standards and certifications. Establishing a clear communication line can also help gauge their responsiveness and willingness to collaborate. -

What are the common challenges faced when sourcing steering wheels from international suppliers?

Common challenges include language barriers, cultural differences, and varying quality standards. Delays in shipping and customs clearance can also pose significant risks. It’s essential to have a robust communication strategy in place to address misunderstandings quickly. Establishing clear expectations regarding product specifications and delivery timelines can help mitigate these challenges. Building a long-term relationship with your supplier can lead to smoother transactions and better problem resolution in the future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for steering wheel manufacturer

How Can Strategic Sourcing Enhance Your Steering Wheel Procurement?

In conclusion, strategic sourcing is not just a procurement tool; it is a vital component for optimizing supply chain efficiency, particularly for steering wheel manufacturers. By leveraging global suppliers, buyers can achieve cost savings while ensuring high-quality standards. Engaging with manufacturers from diverse regions such as Africa, South America, the Middle East, and Europe allows for a more competitive edge, as these markets often offer unique materials and innovative technologies.

What Are the Key Takeaways for International Buyers?

International B2B buyers should focus on building strong relationships with suppliers, conducting thorough market research, and utilizing data-driven insights to inform their sourcing decisions. Understanding currency fluctuations and geopolitical factors can also significantly impact pricing and availability, making it crucial to stay informed and adaptable.

What’s Next for Your Steering Wheel Sourcing Strategy?

As the automotive industry continues to evolve, so too should your sourcing strategies. Embrace the opportunities that come from a more interconnected global marketplace. Take the next step by exploring potential partnerships with international manufacturers who can meet your specifications and help you stay ahead in a competitive market. Now is the time to invest in strategic sourcing to drive your business forward.