The Ultimate Guide to Surgical Instrument Manufacturer (2025)

Introduction: Navigating the Global Market for surgical instrument manufacturer

In today’s complex global market, sourcing surgical instruments can pose significant challenges for B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. With a myriad of options available, how can you ensure that the surgical instrument manufacturer you choose meets your quality, compliance, and cost-effectiveness requirements? This comprehensive guide is designed to illuminate the intricacies of selecting the right surgical instrument manufacturers for your specific needs, empowering you to make informed purchasing decisions that align with your operational goals.

Throughout this guide, we will explore various types of surgical instruments, their applications across different medical specialties, and the critical factors to consider when vetting suppliers. Additionally, we will delve into cost considerations, helping you understand the pricing landscape and how to negotiate favorable terms. By providing actionable insights and practical strategies, this guide aims to equip international buyers with the tools needed to navigate the competitive landscape of surgical instrument procurement.

As you embark on your sourcing journey, this guide will serve as a valuable resource, offering clarity and direction in an industry that can often feel overwhelming. Whether you are based in bustling Jakarta or the vibrant markets of Riyadh, understanding the dynamics of surgical instrument manufacturing will enhance your purchasing strategy and ensure that you acquire the best products for your healthcare institution.

Understanding surgical instrument manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OEM Surgical Instrument Manufacturers | Produce instruments based on client specifications and branding | Hospital supply chains, private label products | Pros: Customization, brand control. Cons: Longer lead times, potential quality variability. |

| Custom Surgical Instrument Manufacturers | Offer tailored solutions for specific surgical needs | Specialized surgical procedures, niche markets | Pros: High adaptability, precise fit for needs. Cons: Higher costs, longer development times. |

| Mass Production Surgical Instrument Manufacturers | Focus on high-volume production of standard instruments | General surgical practices, hospitals | Pros: Cost-effective, consistent quality. Cons: Limited customization, less flexibility. |

| Specialty Surgical Instrument Manufacturers | Create instruments designed for specific surgical fields (e.g., orthopedics, cardiology) | Specialized medical facilities, research institutions | Pros: Expertise in niche areas, enhanced performance. Cons: Higher prices, limited availability. |

| Contract Surgical Instrument Manufacturers | Provide manufacturing services for other brands under contract | B2B partnerships, product outsourcing | Pros: Reduced overhead, access to manufacturing expertise. Cons: Less control over production, potential IP risks. |

What Are OEM Surgical Instrument Manufacturers and How Do They Operate?

OEM (Original Equipment Manufacturer) surgical instrument manufacturers specialize in creating instruments based on the specific requirements of their clients. They often work closely with hospitals and medical organizations to develop products that align with their branding and quality standards. For B2B buyers, key considerations include the potential for customization and brand control, but they should also be mindful of longer lead times and the risk of quality variability depending on the manufacturer’s standards.

How Do Custom Surgical Instrument Manufacturers Cater to Unique Needs?

Custom surgical instrument manufacturers focus on providing tailored solutions for specific surgical applications. They excel in creating instruments that meet unique surgical requirements, making them ideal for specialized procedures. B2B buyers in niche markets should consider the adaptability of these manufacturers and their ability to deliver precise instruments. However, buyers should also be aware that these products often come at a higher cost and may require longer development times.

What Advantages Do Mass Production Surgical Instrument Manufacturers Offer?

Mass production surgical instrument manufacturers are designed for high-volume production of standardized instruments. This model is particularly beneficial for general surgical practices and hospitals that require reliable and cost-effective solutions. The primary advantages for B2B buyers include consistent quality and lower costs per unit. However, the trade-off includes limited customization options, which may not suit all surgical needs.

Why Choose Specialty Surgical Instrument Manufacturers for Niche Markets?

Specialty surgical instrument manufacturers focus on creating instruments tailored for specific surgical fields, such as orthopedics or cardiology. They bring a high level of expertise and performance enhancements to their products, making them suitable for specialized medical facilities and research institutions. For B2B buyers, investing in these instruments can lead to improved surgical outcomes. However, buyers should anticipate higher prices and potential availability challenges.

What Are the Benefits of Partnering with Contract Surgical Instrument Manufacturers?

Contract surgical instrument manufacturers provide outsourced manufacturing services for other brands, allowing companies to leverage their expertise without the overhead of direct production. This arrangement can be advantageous for B2B buyers looking to streamline operations or expand their product lines. While this model offers access to manufacturing expertise and reduced costs, buyers must consider the implications of less control over production processes and potential intellectual property risks.

Related Video: Basic Surgical Instrument Passing (part 1 of 2)

Key Industrial Applications of surgical instrument manufacturer

| Industry/Sector | Specific Application of Surgical Instrument Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Production of Surgical Instruments for Hospitals | Enhanced patient outcomes and operational efficiency | Quality certifications, compliance with local regulations |

| Dental | Custom Dental Surgical Instruments | Improved precision in dental procedures | Material quality, ergonomic design |

| Veterinary | Surgical Instruments for Animal Care | Better healthcare for animals, leading to increased trust | Animal-specific designs, sterilization processes |

| Research & Development | Surgical Instruments for Clinical Trials | Support for innovative medical solutions | Cost-effectiveness, adaptability to various studies |

| Education | Training Surgical Instruments for Medical Schools | Enhanced learning experiences for future healthcare professionals | Durability, realistic simulation features |

How is Surgical Instrument Manufacturing Applied in Healthcare?

In the healthcare sector, surgical instrument manufacturers play a crucial role by supplying high-quality tools that facilitate surgical procedures in hospitals and clinics. These instruments are designed to improve patient outcomes by ensuring precision and reliability during operations. International B2B buyers must consider certifications like ISO and CE mark compliance, as well as local regulatory requirements, to ensure the instruments meet safety standards and efficacy.

What are the Benefits of Custom Dental Surgical Instruments?

Custom surgical instruments in the dental industry are tailored to meet the specific needs of dental procedures, enhancing precision and effectiveness. Manufacturers provide tools that allow dental professionals to perform complex procedures with greater accuracy. For buyers in regions like Africa and South America, sourcing instruments that are ergonomically designed and made from high-quality materials is critical, as these factors directly impact the quality of care provided to patients.

How are Surgical Instruments Used in Veterinary Care?

Veterinary practices increasingly rely on surgical instrument manufacturers to supply specialized tools that cater to animal healthcare needs. These instruments help veterinarians perform surgeries with the same level of care and precision as in human medicine. For B2B buyers in the Middle East and Europe, it’s essential to consider animal-specific designs and sterilization processes to ensure instruments are not only effective but also safe for use on various species.

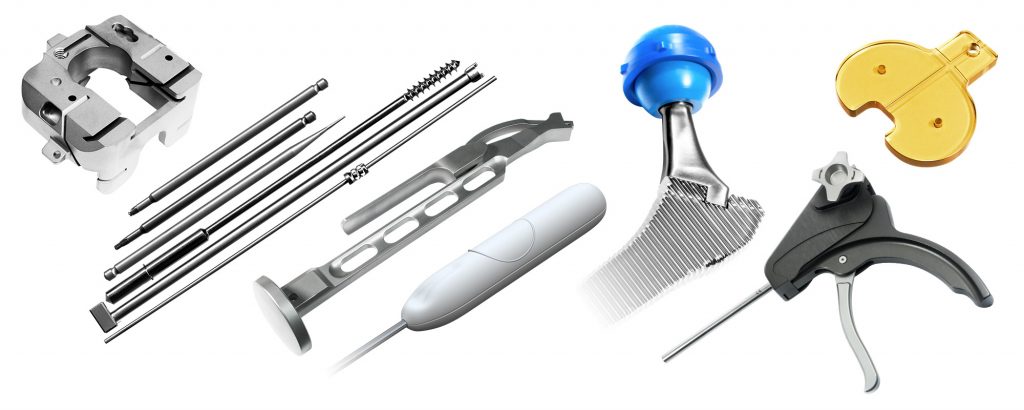

A stock image related to surgical instrument manufacturer.

Why are Surgical Instruments Important in Research & Development?

In the research and development sector, surgical instruments are pivotal for conducting clinical trials and advancing medical technologies. Manufacturers must provide instruments that are adaptable and cost-effective to support innovative solutions. International buyers should prioritize sourcing from manufacturers that offer a range of instruments that can be customized for different studies, ensuring that they meet the evolving needs of medical research.

How Do Training Surgical Instruments Benefit Medical Education?

Training surgical instruments are vital for medical schools and educational institutions, providing students with hands-on experience in a controlled environment. These instruments are designed to simulate real surgical scenarios, enhancing the learning experience for future healthcare professionals. Buyers from diverse regions, including Europe and South America, should focus on sourcing durable and realistic simulation tools that can withstand repeated use while providing a true-to-life training experience.

Related Video: 100 Commonly Used Surgical Instruments and their names and uses

3 Common User Pain Points for ‘surgical instrument manufacturer’ & Their Solutions

Scenario 1: Navigating Quality Assurance Challenges in Surgical Instruments

The Problem: B2B buyers often struggle with ensuring that surgical instruments meet rigorous quality and safety standards. This is especially critical in regions like Africa and the Middle East, where regulatory frameworks may vary significantly. Inconsistent quality can lead to product recalls, legal issues, and ultimately, harm to patients. Buyers may feel overwhelmed by the need to vet suppliers and ensure that their instruments are not only effective but also safe for use in critical surgical procedures.

The Solution: To navigate quality assurance challenges effectively, B2B buyers should establish a robust vendor qualification process. Start by requesting certifications such as ISO 13485, which ensures that manufacturers meet international quality management standards for medical devices. Additionally, engage with suppliers who provide comprehensive documentation and transparency regarding their manufacturing processes, including sourcing of raw materials and adherence to sterilization protocols. It’s beneficial to conduct on-site audits when feasible, or to utilize third-party audit services to assess the supplier’s facilities. Building long-term relationships with manufacturers who prioritize quality can also lead to more consistent product delivery and enhanced support in case of issues.

Scenario 2: Overcoming Supply Chain Disruptions for Timely Deliveries

The Problem: International B2B buyers frequently encounter supply chain disruptions that delay the delivery of surgical instruments. Factors such as geopolitical tensions, trade tariffs, and logistical challenges can hinder timely access to critical surgical tools. For hospitals and clinics in regions like South America and Europe, these delays can result in postponed surgeries and dissatisfied patients, putting pressure on healthcare providers.

The Solution: To mitigate supply chain disruptions, buyers should adopt a dual-sourcing strategy. This involves identifying multiple suppliers for the same instruments across different geographical locations. By diversifying the supplier base, buyers can reduce dependency on a single source and create a buffer against unforeseen disruptions. Additionally, establishing clear communication channels with suppliers can help buyers stay informed about potential delays and collaborate on alternative solutions. Consider leveraging technology such as supply chain management software to track orders and optimize inventory levels. Building strategic partnerships with logistics companies can also enhance delivery reliability.

Scenario 3: Addressing Customization Needs for Specific Surgical Procedures

The Problem: Many surgical procedures require specialized instruments that may not be readily available from standard suppliers. B2B buyers in regions with diverse healthcare needs, such as the Middle East and Africa, often face the challenge of sourcing customized surgical instruments tailored to specific surgical practices. This can result in inefficiencies and increased costs, as standard instruments may not meet the nuanced requirements of certain procedures.

The Solution: To address customization needs, B2B buyers should proactively communicate their specific requirements to manufacturers during the sourcing process. Engage in detailed discussions about the surgical procedures and outcomes desired, allowing manufacturers to understand the functional specifications needed. Consider forming partnerships with manufacturers that have a proven track record in developing bespoke instruments, as they can provide insights into design capabilities and material options. It may also be beneficial to participate in collaborative product development, wherein buyers can provide feedback during the design phase to ensure the final product meets the operational needs of the surgical teams. Leveraging technology, such as 3D printing, can also facilitate rapid prototyping and reduce lead times for custom instruments.

Strategic Material Selection Guide for surgical instrument manufacturer

What Are the Key Materials Used in Surgical Instruments?

When selecting materials for surgical instruments, manufacturers must consider various factors that affect performance, durability, and compliance with international standards. Here, we analyze four common materials used in the production of surgical instruments: stainless steel, titanium, carbon fiber, and plastics. Each material has unique properties that cater to different surgical needs and buyer preferences.

How Does Stainless Steel Perform in Surgical Instruments?

Stainless steel is the most widely used material in surgical instruments due to its excellent mechanical properties and corrosion resistance. It typically has a high-temperature rating, making it suitable for sterilization processes. The most common grades used are 304 and 316, with 316 offering superior corrosion resistance, particularly against saline solutions.

Pros:

– High durability and strength, making it suitable for repeated use.

– Cost-effective compared to other materials, which is advantageous for budget-conscious buyers.

– Easy to manufacture and can be polished to a high finish, enhancing its aesthetic appeal.

Cons:

– While resistant to corrosion, it can still rust if not properly cared for.

– Heavier than some alternatives, which may not be suitable for all applications.

Impact on Application:

Stainless steel is compatible with various sterilization methods, including autoclaving, making it ideal for surgical settings. However, buyers should ensure compliance with ASTM standards for medical devices.

Why Choose Titanium for Surgical Instruments?

Titanium is another popular choice, particularly for instruments that require high strength-to-weight ratios. It is known for its exceptional corrosion resistance and biocompatibility, making it suitable for implants and long-term surgical applications.

Pros:

– Lightweight, which reduces fatigue for surgeons during lengthy procedures.

– Highly resistant to corrosion, even in harsh environments.

– Biocompatible, minimizing the risk of adverse reactions in patients.

Cons:

– Generally more expensive than stainless steel, which could be a concern for budget-limited buyers.

– More challenging to manufacture and shape, leading to increased production costs.

Impact on Application:

Titanium is particularly effective in orthopedic and dental instruments, where biocompatibility is crucial. International buyers should verify compliance with ISO and ASTM standards for titanium medical devices.

What Role Does Carbon Fiber Play in Surgical Instrument Manufacturing?

Carbon fiber is increasingly being used in surgical instruments due to its lightweight and high-strength properties. It is particularly beneficial in instruments that require precision and maneuverability.

Pros:

– Extremely lightweight, allowing for better control and reduced fatigue.

– High tensile strength, making it suitable for precision instruments.

– Resistant to temperature changes and chemical corrosion.

Cons:

– More expensive than traditional materials, which may deter some buyers.

– Limited compatibility with sterilization processes, requiring careful consideration.

Impact on Application:

Carbon fiber is ideal for specialized surgical tools, especially in minimally invasive procedures. Buyers from regions with stringent regulations should ensure compliance with relevant standards.

How Do Plastics Fit into the Surgical Instrument Material Landscape?

Plastics, particularly high-performance polymers like PEEK (Polyether ether ketone), are increasingly used in surgical instruments, especially for disposable items. They offer unique advantages in terms of weight and cost.

Pros:

– Lightweight and cost-effective, making them ideal for single-use instruments.

– Can be molded into complex shapes, allowing for innovative designs.

– Generally resistant to chemicals and moisture.

Cons:

– Less durable than metals, limiting their use to single-use applications.

– Potential for lower temperature resistance compared to metals.

Impact on Application:

Plastics are often used in endoscopic instruments and other disposable tools. International buyers should be aware of compliance with medical-grade material standards.

Summary Table of Material Properties for Surgical Instruments

| Material | Typical Use Case for surgical instrument manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | General surgical instruments | High durability and cost-effective | Can rust if not maintained properly | Medium |

| Titanium | Orthopedic and dental instruments | Lightweight and biocompatible | Higher cost and manufacturing complexity | High |

| Carbon Fiber | Precision surgical tools for minimally invasive procedures | Extremely lightweight and strong | Higher cost and limited sterilization compatibility | High |

| Plastics | Disposable surgical instruments | Cost-effective and moldable | Less durable, suitable for single use | Low |

This guide provides a foundational understanding of the materials commonly used in surgical instrument manufacturing, helping international B2B buyers make informed decisions based on performance, cost, and compliance with industry standards.

In-depth Look: Manufacturing Processes and Quality Assurance for surgical instrument manufacturer

What Are the Main Stages of Manufacturing Surgical Instruments?

The manufacturing of surgical instruments involves a series of intricate processes designed to ensure precision, durability, and compliance with international quality standards. The key stages in the manufacturing process include:

-

Material Preparation: The process begins with selecting the right materials, typically stainless steel or titanium, known for their strength and resistance to corrosion. The materials undergo rigorous inspection to ensure they meet the required specifications. For international buyers, it is crucial to verify the source and quality of these materials, as they directly impact the performance of the surgical instruments.

-

Forming: This stage involves shaping the raw materials into the desired instrument forms using techniques such as forging, casting, or machining. Advanced CNC (Computer Numerical Control) machines are often employed to achieve high precision. B2B buyers should inquire about the technology used in this stage, as it can significantly affect the final product’s quality.

-

Assembly: After forming, components are assembled. This may include soldering, welding, or using mechanical fasteners. The assembly process must be meticulously monitored to prevent defects. Buyers should look for manufacturers that implement stringent assembly protocols to ensure consistency and reliability.

-

Finishing: The final stage involves polishing, coating, and sterilizing the instruments. Finishing not only enhances the instrument’s aesthetic appeal but also ensures its functionality and longevity. It’s vital for B2B buyers to confirm the types of finishes used and their compliance with industry standards, as this can impact the instrument’s performance in surgical settings.

How Is Quality Assurance Managed in Surgical Instrument Manufacturing?

Quality assurance (QA) is a critical aspect of surgical instrument manufacturing, ensuring that products meet both safety and effectiveness standards. The following elements are essential in the QA process:

-

International and Industry-Specific Standards: Compliance with ISO 9001 is fundamental, as it outlines the requirements for a quality management system (QMS). Additionally, industry-specific certifications such as CE marking (for European markets) and API (American Petroleum Institute) standards may apply. B2B buyers from Africa, South America, the Middle East, and Europe should ensure that their suppliers possess the relevant certifications for their respective markets.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before manufacturing begins. It is essential to ensure that materials meet specified requirements.

– In-Process Quality Control (IPQC): During manufacturing, IPQC monitors the processes to identify any deviations from standards. Regular checks at this stage can prevent defects from reaching the final product.

– Final Quality Control (FQC): This final assessment occurs before products are packaged and shipped. FQC ensures that all instruments meet the required specifications and standards. -

Common Testing Methods: Various testing methods are utilized to validate the quality of surgical instruments, including:

– Dimensional Inspection: Verifying that instruments meet specified measurements.

– Functional Testing: Assessing the usability of the instruments in simulated surgical environments.

– Sterility Testing: Ensuring that instruments are free from contamination.

How Can B2B Buyers Verify Supplier Quality Control Processes?

To ensure that a surgical instrument manufacturer adheres to rigorous quality standards, B2B buyers can implement several verification methods:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing and quality assurance processes. Audits can assess compliance with international standards and the effectiveness of their QMS.

-

Requesting Quality Reports: Suppliers should provide documentation of their quality control processes, including test reports and compliance certificates. Buyers should thoroughly review these documents to ensure transparency and accountability.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing processes and final products. These inspections can validate that the instruments meet the specified standards and are safe for use.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

B2B buyers must navigate various nuances when it comes to quality control and certification, especially in diverse regions like Africa, South America, the Middle East, and Europe. Here are some critical considerations:

-

Regional Regulatory Requirements: Different regions may have specific regulatory requirements that impact the certification process. For example, the FDA in the United States has stringent requirements for medical devices, while the European Union has its own set of regulations. Buyers should familiarize themselves with the regulations applicable in their target market.

-

Cultural and Communication Factors: Effective communication with suppliers is vital. Cultural differences may affect how quality assurance processes are perceived and implemented. Establishing clear expectations and fostering open lines of communication can help mitigate misunderstandings.

-

Local Partnerships: Collaborating with local agents or partners who understand the regional market can facilitate smoother transactions and ensure compliance with local regulations. These partnerships can also provide valuable insights into the quality standards expected in the region.

Conclusion

Understanding the manufacturing processes and quality assurance protocols in surgical instrument manufacturing is essential for B2B buyers looking to source high-quality products. By focusing on material preparation, forming, assembly, and finishing, alongside implementing robust quality control measures, manufacturers can deliver instruments that meet the highest standards. Buyers should prioritize verifying supplier processes through audits, quality reports, and third-party inspections, while also considering the nuances of international certification requirements. By taking these steps, B2B buyers can ensure that they are partnering with reliable suppliers who prioritize quality and safety in their products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘surgical instrument manufacturer’

In the complex world of sourcing surgical instruments, international buyers must navigate various factors to ensure they partner with reliable manufacturers. This step-by-step checklist will help you make informed decisions and streamline your procurement process.

Step 1: Define Your Technical Specifications

Establishing precise technical specifications is critical for sourcing the right surgical instruments. Consider factors such as material quality, instrument types (e.g., scissors, forceps), and intended usage. Clear specifications help in communicating your needs effectively to potential suppliers and aid in evaluating their offerings.

Step 2: Conduct Market Research on Suppliers

Understanding the market landscape is essential for identifying suitable manufacturers. Research suppliers based in your target regions—Africa, South America, the Middle East, and Europe—using industry reports, trade shows, and online directories. This knowledge allows you to gauge the competitive landscape and find manufacturers that align with your requirements.

Step 3: ✅ Verify Supplier Certifications

Before engaging with a supplier, ensure they hold relevant certifications such as ISO 13485 or CE marking, which indicate compliance with international quality standards. Certification verification not only ensures product safety and efficacy but also mitigates risks associated with regulatory non-compliance.

Step 4: Request Samples and Conduct Quality Inspections

Obtaining product samples is crucial to assess the quality and functionality of the surgical instruments. Evaluate the samples for durability, precision, and ergonomics. Additionally, consider third-party quality inspections to validate manufacturing processes and material integrity, especially when sourcing from overseas.

Step 5: Evaluate Supplier Capabilities and Capacity

Assess the supplier’s manufacturing capabilities, including technology, workforce expertise, and production capacity. Understanding their operational scale will help you determine if they can meet your volume requirements consistently. Also, inquire about their lead times and flexibility in handling urgent orders.

Step 6: Assess Communication and Support Structures

Effective communication is vital for a successful partnership. Evaluate how responsive and accessible the supplier is during initial interactions. A supplier that provides dedicated support and clear communication channels can significantly enhance the procurement process and resolve issues quickly.

Step 7: Negotiate Terms and Conditions

Once you have shortlisted potential suppliers, it’s time to negotiate terms. Discuss pricing, payment terms, delivery schedules, and after-sales support. Ensure that the agreements are documented to protect both parties and clarify expectations.

By following this structured checklist, B2B buyers can effectively navigate the complexities of sourcing surgical instruments, ensuring quality, compliance, and reliability in their procurement processes.

Comprehensive Cost and Pricing Analysis for surgical instrument manufacturer Sourcing

Understanding the cost structure and pricing strategy for sourcing surgical instruments is crucial for international B2B buyers. This analysis delves into the various components that contribute to the overall cost, as well as the factors influencing pricing decisions.

What Are the Key Cost Components in Surgical Instrument Manufacturing?

-

Materials: The choice of materials is foundational in the production of surgical instruments. High-quality stainless steel, titanium, and other specialized alloys not only impact the durability and performance of the instruments but also contribute significantly to the cost. Buyers should seek suppliers who can provide detailed specifications and certifications for materials used.

-

Labor: Labor costs vary by region and can be influenced by local wage standards, skill levels, and labor regulations. For instance, countries with lower labor costs may offer competitive pricing, but buyers must consider the quality of craftsmanship and potential trade-offs in instrument performance.

-

Manufacturing Overhead: This encompasses indirect costs related to the production process, including utilities, facility maintenance, and administrative expenses. Understanding these overhead costs can provide insights into the supplier’s pricing strategy.

-

Tooling: The initial setup for manufacturing surgical instruments involves significant investment in tooling and machinery. Custom designs may require specialized tooling, leading to higher costs. Buyers should evaluate the tooling capabilities of potential suppliers to ensure they can meet specific design requirements.

-

Quality Control (QC): Rigorous quality assurance processes are vital in the production of surgical instruments. Suppliers often pass on the costs of QC protocols, which may include testing and certifications, to buyers. It’s essential to inquire about the QC measures in place and their impact on pricing.

-

Logistics: Shipping costs can vary widely based on the distance from the manufacturer to the buyer, the shipping method, and any tariffs or duties applicable to the transaction. Buyers should assess the total logistics costs, including potential delays and risks associated with international shipping.

-

Margin: The profit margin for manufacturers can fluctuate based on the market demand, competition, and the overall value proposition of the instruments. Understanding the margin expectations can aid in negotiating fair prices.

How Do Price Influencers Affect Surgical Instrument Sourcing?

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Larger orders typically lead to reduced per-unit costs. Buyers should negotiate MOQs that align with their purchasing needs while ensuring they do not overstock.

-

Specifications and Customization: Customized instruments often command higher prices due to the additional costs in design and production. Buyers should be clear about their specifications to avoid unexpected costs.

-

Materials and Quality Certifications: Instruments made from premium materials with recognized quality certifications (like ISO or CE markings) may be priced higher. Buyers should weigh the importance of these factors against their budget constraints.

-

Supplier Factors: The reputation, reliability, and service quality of a supplier can influence pricing. Established suppliers may charge a premium but often offer better support and consistency in quality.

-

Incoterms: Understanding Incoterms is critical for international transactions. They dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, directly impacting the total cost of ownership.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

-

Negotiate Effectively: Engage in open discussions with suppliers about pricing and seek to understand their cost structures. Highlighting long-term relationships can lead to better pricing agreements.

-

Assess Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, warranty, and operational costs associated with the instruments. This holistic view can lead to more informed purchasing decisions.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing structures due to local economic conditions, regulatory environments, and market demand. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research to inform their sourcing strategies.

Disclaimer on Indicative Prices

Prices for surgical instruments can fluctuate based on market conditions, supplier negotiations, and changes in raw material costs. This analysis provides a general framework for understanding cost structures and pricing but does not represent fixed pricing. Buyers should seek formal quotes tailored to their specific requirements and circumstances.

Alternatives Analysis: Comparing surgical instrument manufacturer With Other Solutions

Understanding the Importance of Alternatives in Surgical Instrument Procurement

In the competitive landscape of healthcare procurement, understanding the alternatives to traditional surgical instrument manufacturers is crucial for international B2B buyers. This analysis not only highlights the available options but also enables buyers to make informed decisions that align with their operational needs and budget constraints. Below, we compare surgical instrument manufacturers with two viable alternatives: 3D Printing of Surgical Instruments and Robotic Surgical Systems.

Comparison Table of Surgical Instrument Solutions

| Comparison Aspect | Surgical Instrument Manufacturer | 3D Printing of Surgical Instruments | Robotic Surgical Systems |

|---|---|---|---|

| Performance | High precision and reliability | Variable; dependent on technology used | High; enhances surgeon capabilities |

| Cost | Moderate to high | Potentially lower; initial setup costs may vary | High; requires significant investment |

| Ease of Implementation | Established supply chains | Requires skilled personnel and training | Complex; requires specialized training |

| Maintenance | Regular upkeep needed | Low for printed instruments, but printers require maintenance | High; regular servicing and updates needed |

| Best Use Case | Standard surgical procedures | Custom or one-off instruments | Complex and minimally invasive surgeries |

What Are the Pros and Cons of 3D Printing Surgical Instruments?

3D printing has emerged as a revolutionary alternative to traditional manufacturing methods. One of its primary advantages is the ability to create customized instruments tailored to specific surgical needs, which is particularly beneficial in regions with diverse healthcare demands. Additionally, the cost of materials can be lower than that of traditional instruments, especially for low-volume production.

However, the performance of 3D printed instruments can vary significantly based on the technology and materials used. Moreover, the initial investment in 3D printing technology and the need for skilled personnel can pose challenges. For B2B buyers in regions like Africa or South America, where resources may be limited, these factors must be carefully considered.

How Do Robotic Surgical Systems Compare to Traditional Manufacturers?

Robotic surgical systems represent a cutting-edge solution that enhances the capabilities of surgeons through precision and minimally invasive techniques. These systems can reduce recovery times and improve patient outcomes, making them attractive for hospitals looking to invest in advanced surgical options.

On the downside, the cost of robotic systems is considerably higher than that of traditional surgical instruments. The complexity of implementation and the need for specialized training can also be barriers, particularly in regions with limited access to advanced medical technology. Buyers from the Middle East and Europe may find that while the investment is significant, the potential return in terms of improved patient care and operational efficiency can justify the expense.

How Can B2B Buyers Choose the Right Surgical Instrument Solution?

Selecting the right solution for surgical instruments requires a thorough understanding of both current needs and future aspirations. B2B buyers should assess their operational capabilities, budget constraints, and the specific requirements of their healthcare facilities. While traditional surgical instrument manufacturers offer reliability and established supply chains, alternatives like 3D printing and robotic systems can provide unique benefits tailored to specific scenarios.

By conducting a comprehensive analysis of each option’s performance, cost, implementation, and maintenance needs, buyers can make informed decisions that optimize their surgical offerings and enhance overall patient care. Ultimately, the choice will depend on balancing innovation with practicality, ensuring that the selected solution aligns with the strategic goals of the healthcare provider.

Essential Technical Properties and Trade Terminology for surgical instrument manufacturer

What Are the Key Technical Properties of Surgical Instruments?

When selecting surgical instruments, international B2B buyers must understand critical technical properties that impact performance, safety, and compliance. Here are essential specifications to consider:

1. Material Grade: Why Is It Crucial for Surgical Instruments?

Surgical instruments are primarily made from stainless steel, titanium, or specialty alloys. The material grade determines the instrument’s corrosion resistance, strength, and durability. For instance, instruments made from high-grade stainless steel (like 316L) offer superior resistance to rust and staining, which is vital for maintaining hygiene standards in medical environments. Buyers should prioritize suppliers who can provide certification of material grade, ensuring compliance with international standards.

2. Tolerance: How Does It Affect Instrument Precision?

Tolerance refers to the permissible limit of variation in a physical dimension of the surgical instrument. Precision is critical in surgical settings, where even minor deviations can lead to complications. Instruments with tighter tolerances (e.g., ±0.01 mm) are often essential for intricate procedures. Buyers should inquire about the manufacturing process to ensure that the specified tolerances are consistently met.

3. Surface Finish: What Role Does It Play in Functionality?

The surface finish of surgical instruments influences not only their aesthetic appeal but also their functionality and safety. A smooth finish reduces friction, minimizes wear, and lowers the risk of contamination. Various finishes, such as passivation or electropolishing, can enhance corrosion resistance and biocompatibility. B2B buyers should assess the finishing processes utilized by manufacturers to guarantee quality and compliance with medical standards.

4. Sterilization Compatibility: Why Is It Important?

Surgical instruments must be compatible with various sterilization methods, such as steam, ethylene oxide, or plasma. Understanding the sterilization process is crucial for ensuring that instruments are safe for use in clinical settings. Buyers should inquire about the manufacturer’s recommendations for sterilization and whether the instruments have been validated for specific methods.

5. Ergonomics: How Does It Impact Surgical Outcomes?

Ergonomics in surgical instruments refers to their design, which affects usability and comfort during procedures. Instruments designed with ergonomic principles can reduce fatigue and improve control, resulting in better surgical outcomes. B2B buyers should consider the ergonomic features of instruments, especially when sourcing products for long or complex procedures.

What Are Common Trade Terms in the Surgical Instrument Industry?

Understanding trade terminology is vital for effective communication and negotiation in the B2B landscape. Here are key terms that buyers should be familiar with:

1. OEM (Original Equipment Manufacturer): What Does It Mean?

An OEM refers to a company that produces components or products that are used in another company’s end product. In the surgical instrument industry, buyers may work directly with OEMs to create custom instruments or source specific designs. Understanding OEM relationships can lead to better pricing and quality assurance.

2. MOQ (Minimum Order Quantity): Why Is It Significant?

MOQ is the smallest quantity of a product that a supplier is willing to sell. For surgical instruments, MOQs can impact inventory management and cost-efficiency. Buyers should negotiate MOQs to align with their purchasing capacity while ensuring they receive competitive pricing.

3. RFQ (Request for Quotation): How Can It Streamline Procurement?

An RFQ is a document sent to suppliers asking for pricing and terms for specific products. In the surgical instrument sector, issuing RFQs allows buyers to compare offers from multiple manufacturers, ensuring they obtain the best value. This practice can lead to better supplier relationships and more informed purchasing decisions.

4. Incoterms: What Are They and Why Do They Matter?

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international transactions. They clarify aspects such as shipping costs, insurance, and risk transfer. Familiarity with Incoterms helps B2B buyers avoid misunderstandings and ensures smooth logistics when importing surgical instruments from various regions.

By grasping these essential technical properties and trade terms, international B2B buyers can make informed decisions, ensuring they source high-quality surgical instruments that meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the surgical instrument manufacturer Sector

What are the Key Market Dynamics and Trends in the Surgical Instrument Manufacturing Sector?

The global surgical instrument manufacturing market is driven by several key factors, including technological advancements, an increasing prevalence of chronic diseases, and a growing demand for minimally invasive surgeries. The market is projected to experience significant growth, particularly in emerging economies across Africa, South America, the Middle East, and Europe. International B2B buyers should be aware that advancements in materials science, such as the development of biocompatible and antimicrobial surfaces, are influencing product design and functionality.

Emerging B2B technology trends are reshaping the sourcing landscape. The integration of artificial intelligence (AI) and machine learning in supply chain management enhances predictive analytics, allowing manufacturers to optimize inventory levels and reduce lead times. Additionally, the rise of digital platforms for procurement is making it easier for buyers to compare suppliers and negotiate better terms. Blockchain technology is also gaining traction, offering enhanced traceability and transparency in the sourcing process, which is particularly relevant for buyers concerned with regulatory compliance and quality assurance.

Furthermore, regional dynamics play a crucial role in market trends. In Africa and the Middle East, the focus is shifting towards establishing local manufacturing capabilities to reduce dependency on imports. In contrast, South America and Europe are witnessing increased collaboration between manufacturers and healthcare providers to co-develop innovative surgical solutions. B2B buyers should leverage these trends to identify strategic sourcing partnerships that align with their operational needs and market demands.

How Can Sustainability and Ethical Sourcing Impact Surgical Instrument Manufacturing?

Sustainability has become a pivotal concern in the surgical instrument manufacturing sector, as the environmental impact of production processes comes under scrutiny. The importance of ethical sourcing cannot be overstated; international B2B buyers are increasingly prioritizing suppliers that demonstrate commitment to sustainable practices. This shift is driven by consumer demand for responsible business practices and regulatory pressures to reduce carbon footprints.

Incorporating environmentally friendly materials and processes is essential for manufacturers aiming to meet these demands. Buyers should look for surgical instruments made from recycled or sustainably sourced materials, as well as those that are designed for longevity and reusability. Certifications such as ISO 14001 (Environmental Management) and Oeko-Tex Standard 100 (Textiles) are indicators of a supplier’s commitment to sustainability. By partnering with manufacturers who adhere to these standards, B2B buyers can enhance their own sustainability credentials while contributing to a greener supply chain.

Moreover, ethical supply chains are integral to mitigating risks associated with labor practices and sourcing transparency. Buyers should conduct thorough due diligence on potential suppliers, ensuring they comply with international labor standards and engage in fair trade practices. This not only helps in avoiding reputational damage but also fosters long-term relationships with suppliers committed to ethical business practices.

How Has the Surgical Instrument Manufacturing Sector Evolved Over Time?

The surgical instrument manufacturing sector has undergone significant transformation over the past few decades, evolving from traditional craftsmanship to advanced manufacturing techniques. Initially characterized by manual production methods, the industry has embraced automation and precision engineering, leading to enhanced product quality and reduced manufacturing costs.

The introduction of computer-aided design (CAD) and computer numerical control (CNC) machining has revolutionized the way surgical instruments are designed and produced. These technologies enable manufacturers to create complex geometries with high precision, catering to the specific needs of modern surgical practices. Furthermore, the rise of global supply chains has facilitated access to a wider range of materials and components, allowing manufacturers to innovate continuously.

As the sector continues to evolve, B2B buyers must remain agile and informed about the latest technological advancements and market dynamics. Engaging with suppliers who are at the forefront of these changes can provide significant competitive advantages in a rapidly changing healthcare landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of surgical instrument manufacturer

-

How do I ensure quality when sourcing surgical instruments from manufacturers?

To ensure quality when sourcing surgical instruments, start by verifying the manufacturer’s certifications, such as ISO 13485, which indicates compliance with quality management standards. Request samples to evaluate the craftsmanship and durability of the instruments. Conduct factory audits, if possible, to assess their manufacturing processes and quality control measures. Additionally, check for customer reviews and testimonials from other international buyers to gauge reliability and product performance. -

What are the key factors to consider when selecting a surgical instrument manufacturer?

When selecting a surgical instrument manufacturer, consider their industry experience, product range, and production capacity. Evaluate their ability to customize instruments to meet specific needs, and assess their compliance with international regulations. Check their customer service and communication responsiveness, as these are crucial for ongoing partnerships. Finally, consider logistics capabilities, including shipping times and costs, to ensure timely delivery of products. -

What is the minimum order quantity (MOQ) when sourcing surgical instruments?

Minimum order quantities (MOQ) can vary significantly between manufacturers. Generally, MOQs for surgical instruments range from 50 to 500 units, depending on the complexity and type of the instrument. It’s essential to discuss your specific needs with potential suppliers to negotiate MOQs that align with your purchasing capacity. Some manufacturers may offer flexibility for first-time buyers or bulk orders, so explore these options to optimize your procurement strategy. -

What payment terms are commonly offered by surgical instrument manufacturers?

Payment terms can vary widely among surgical instrument manufacturers. Common arrangements include payment in full upfront, partial payments, or payment upon delivery. Some suppliers may offer credit terms based on your purchasing history and relationship. It’s advisable to clarify terms before finalizing agreements to avoid misunderstandings. Consider using secure payment methods, such as letters of credit or escrow services, to protect your investment in international transactions. -

How can I verify the credibility of a surgical instrument manufacturer?

To verify a manufacturer’s credibility, begin by researching their business history, including how long they have been in operation and their reputation in the industry. Look for certifications and compliance with international quality standards. Utilize platforms like LinkedIn to connect with other buyers and gather insights about their experiences. Request references and follow up with previous clients to assess satisfaction levels and product quality. -

What customization options are available when sourcing surgical instruments?

Many surgical instrument manufacturers offer customization options tailored to the specific needs of healthcare providers. Customization can include variations in size, design modifications, and material choices. Discuss your requirements in detail with potential suppliers to understand their capabilities. Some manufacturers may also provide branding options, allowing you to add your logo or specific labeling to instruments, enhancing your brand visibility. -

What quality assurance measures should I look for in a surgical instrument manufacturer?

Quality assurance measures are critical when sourcing surgical instruments. Look for manufacturers that implement rigorous quality control protocols at each production stage, including material sourcing, manufacturing, and final inspection. Verify if they conduct regular testing and compliance checks against international standards. Ask about their warranty policies and procedures for handling defects or returns, as these are indicators of their commitment to quality. -

How can I manage logistics and shipping when sourcing surgical instruments internationally?

Managing logistics when sourcing surgical instruments requires careful planning. Work with manufacturers that have experience in international shipping to ensure compliance with customs regulations. Discuss shipping options and timelines upfront to avoid delays. It may be beneficial to engage a freight forwarder who specializes in medical supplies to navigate the complexities of international transport. Always factor in potential tariffs and duties to your overall cost analysis.

Important Disclaimer & Terms of Use

A stock image related to surgical instrument manufacturer.

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for surgical instrument manufacturer

In the dynamic landscape of surgical instrument manufacturing, strategic sourcing emerges as a pivotal element for success. By prioritizing quality, cost-effectiveness, and supplier reliability, international B2B buyers can enhance their operational efficiency and ensure superior patient outcomes. For buyers in Africa, South America, the Middle East, and Europe, understanding regional supply chain nuances and leveraging local partnerships can lead to significant competitive advantages.

How can international B2B buyers leverage strategic sourcing for better procurement? The answer lies in adopting a proactive approach to supplier evaluation, focusing on certifications, compliance with international standards, and a track record of innovation. Engaging in collaborative relationships with manufacturers not only fosters trust but also opens up avenues for customized solutions tailored to specific market needs.

Looking ahead, the demand for advanced surgical instruments will continue to grow, driven by technological advancements and increased healthcare spending. Buyers should remain vigilant, exploring emerging markets and innovative suppliers to stay ahead in this evolving sector. Embrace strategic sourcing as a cornerstone of your procurement strategy, and position your organization for sustained success in the global healthcare arena. The future is bright for those who act decisively today.