The Ultimate Guide to Wire Harness Manufacturers (2025)

Introduction: Navigating the Global Market for Wire Harness Manufacturers

Navigating the global market for wire harness manufacturers presents a unique challenge for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. With the increasing demand for high-quality wire harnesses across various industries—such as automotive, aerospace, and telecommunications—sourcing reliable suppliers can be daunting. This guide aims to equip buyers with the necessary insights to make informed decisions when selecting wire harness manufacturers.

In this comprehensive resource, we will explore different types of wire harnesses, their applications, and the critical factors to consider when vetting suppliers. Buyers will gain a deeper understanding of the cost structures involved and learn effective negotiation strategies that can lead to better pricing and terms. Additionally, we will highlight regional considerations, ensuring that buyers are aware of the nuances in sourcing from diverse markets, including Mexico and Poland.

By leveraging this guide, B2B buyers will be empowered to navigate the complexities of the wire harness manufacturing landscape with confidence, ultimately leading to more strategic partnerships and optimized procurement processes. Whether you are looking to enhance product performance or streamline supply chain logistics, this guide serves as a vital tool for making sound purchasing decisions in a competitive global market.

Understanding Wire Harness Manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Wire Harnesses | Tailored designs to meet specific requirements | Automotive, Aerospace, Medical | Pros: Precision fit for unique needs; enhanced performance. Cons: Higher cost and longer lead times. |

| Standard Wire Harnesses | Pre-manufactured designs for common applications | Consumer Electronics, Appliances | Pros: Cost-effective; quick delivery. Cons: Limited customization options. |

| Automotive Wire Harnesses | Designed for automotive environments; high durability | Automotive manufacturing | Pros: Compliance with safety standards; robust performance. Cons: Requires specific industry knowledge. |

| Industrial Wire Harnesses | Heavy-duty, capable of withstanding harsh conditions | Industrial machinery, Robotics | Pros: High reliability in tough environments; extensive lifespan. Cons: Can be bulky and expensive. |

| Multiconductor Wire Harnesses | Multiple conductors bundled for efficiency | Telecommunications, Networking | Pros: Space-saving; simplified installation. Cons: Complexity in repairs and upgrades. |

What Are Custom Wire Harnesses and Their Key Characteristics?

Custom wire harnesses are specifically designed to meet the unique requirements of a project. They are often used in sectors like aerospace and medical, where precision and reliability are paramount. B2B buyers should consider the exact specifications needed, including wire types, lengths, and connectors. While these harnesses provide a perfect fit for specialized applications, they typically come at a higher cost and may require longer lead times for production.

How Do Standard Wire Harnesses Serve B2B Needs?

Standard wire harnesses are pre-manufactured and ideal for common applications in consumer electronics and appliances. They offer a cost-effective solution for businesses looking to save on production costs and time. However, buyers should note that while these harnesses are readily available and cheaper, they lack the customization that might be necessary for specific applications.

What Makes Automotive Wire Harnesses Unique?

Automotive wire harnesses are designed to endure the demanding conditions of vehicle operation. They are built to comply with stringent safety standards and provide robust performance. Buyers in the automotive industry must ensure that the harnesses meet regulatory requirements and are suitable for their specific vehicle models. However, they require a good understanding of automotive standards, which can complicate the purchasing process.

Why Choose Industrial Wire Harnesses for Tough Environments?

Industrial wire harnesses are crafted to withstand harsh conditions, making them ideal for use in machinery and robotics. Their high reliability and long lifespan are significant advantages for businesses in heavy industries. Nevertheless, buyers should consider the potential for bulkiness and higher costs, which may impact installation and budget.

What Are the Benefits of Multiconductor Wire Harnesses?

Multiconductor wire harnesses bundle multiple wires into a single unit, which can greatly simplify installation and save space. They are commonly used in telecommunications and networking applications. However, while they offer efficiency, the complexity of repairs and upgrades may pose challenges for B2B buyers, requiring careful planning and consideration during the purchasing process.

Related Video: Nangudi Wire Harness And Cable Assemblies Manufacturer Production Process

Key Industrial Applications of Wire Harness Manufacturers

| Industry/Sector | Specific Application of Wire Harness Manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Wiring for electrical systems in vehicles | Enhances vehicle safety and performance | Compliance with automotive standards, durability, and weight |

| Industrial Machinery | Control systems for manufacturing equipment | Increases operational efficiency and reliability | Customization options, material quality, and lead times |

| Consumer Electronics | Power and data connections in devices | Ensures product reliability and user satisfaction | Compatibility with international standards, cost-effectiveness |

| Renewable Energy | Wiring for solar panels and wind turbines | Supports sustainable energy solutions | Resistance to environmental conditions and certification needs |

| Medical Devices | Wiring for diagnostic and therapeutic equipment | Improves patient safety and device accuracy | Regulatory compliance, biocompatibility, and traceability |

How Are Wire Harness Manufacturers Used in the Automotive Industry?

In the automotive sector, wire harness manufacturers provide critical wiring solutions for various electrical systems, including lighting, infotainment, and safety features. These harnesses ensure efficient power distribution and signal transmission, enhancing vehicle safety and performance. For international buyers, especially in regions like Africa and South America, sourcing durable harnesses that comply with local automotive standards is essential. Additionally, manufacturers must consider weight reduction without compromising reliability, as this directly impacts fuel efficiency.

What Role Do Wire Harnesses Play in Industrial Machinery?

Wire harness manufacturers supply control systems for machinery used in manufacturing processes. These harnesses connect sensors, motors, and control panels, significantly increasing operational efficiency and reliability. B2B buyers in the Middle East and Europe must prioritize customization options to meet specific machinery requirements. Furthermore, sourcing high-quality materials that withstand harsh industrial environments is crucial for maintaining equipment longevity and reducing downtime.

How Are Wire Harnesses Implemented in Consumer Electronics?

In the consumer electronics industry, wire harness manufacturers create power and data connections for devices like smartphones, laptops, and home appliances. These harnesses are vital for ensuring product reliability and user satisfaction, as they facilitate seamless operation. Buyers from diverse markets, including Europe and South America, should focus on compatibility with international standards and cost-effectiveness when sourcing these components. Additionally, manufacturers must ensure that their products can handle varying power specifications across different regions.

What Are the Applications of Wire Harnesses in Renewable Energy?

Wire harness manufacturers play a pivotal role in the renewable energy sector by providing wiring solutions for solar panels and wind turbines. These harnesses support sustainable energy solutions by ensuring efficient power transmission from energy sources to storage systems. For international buyers, especially in Africa and South America, sourcing harnesses that can resist environmental conditions is vital. Moreover, understanding certification requirements for renewable energy components is crucial for compliance and market entry.

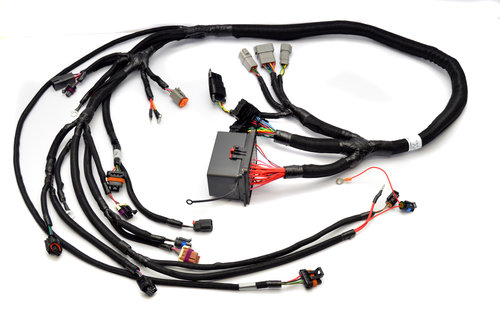

A stock image related to Wire Harness Manufacturers.

How Do Wire Harnesses Enhance Medical Devices?

In the medical device industry, wire harness manufacturers supply wiring for diagnostic and therapeutic equipment, such as imaging machines and infusion pumps. These harnesses are essential for improving patient safety and device accuracy, as they connect critical components within the devices. Buyers in this sector, particularly from Europe and the Middle East, must consider regulatory compliance and biocompatibility when sourcing wire harnesses. Traceability of materials used in manufacturing is also a key consideration to ensure adherence to stringent medical standards.

Related Video: Variosystems wire harness production

3 Common User Pain Points for ‘Wire Harness Manufacturers’ & Their Solutions

Scenario 1: Sourcing Quality Components from Reliable Wire Harness Manufacturers

The Problem:

B2B buyers often face the challenge of sourcing wire harnesses that meet strict quality and safety standards. In regions like Africa and South America, where local suppliers may lack the necessary certifications or quality control measures, it can be daunting to find a reliable manufacturer. Buyers worry about the integrity of the wire harnesses, as subpar products can lead to equipment failures, increased downtime, and safety hazards.

The Solution:

To address this issue, B2B buyers should prioritize manufacturers with established reputations and certifications, such as ISO 9001 or IPC/WHMA-A-620. Conducting thorough due diligence is essential—request samples and perform quality tests on these samples before placing bulk orders. Utilize platforms like Alibaba or ThomasNet to compare various suppliers’ offerings and read reviews from previous clients. Establishing a direct line of communication with manufacturers can also help clarify specifications and ensure that the components meet industry standards. Furthermore, consider manufacturers that offer traceability in their supply chain, providing detailed records of materials used and production processes.

Scenario 2: Navigating Complex Customization Requirements

The Problem:

Many B2B buyers encounter difficulties when needing wire harnesses tailored to specific applications. Customization demands can arise from unique product requirements or compliance with local regulations in different markets. Without clear communication and understanding of the customization process, buyers risk receiving products that do not fit their needs, leading to costly redesigns and delays in project timelines.

The Solution:

To effectively navigate customization challenges, buyers should engage manufacturers early in the design process. Share detailed specifications, including wire types, gauge sizes, and specific connector requirements. Use CAD software to create visual prototypes that can be shared with the manufacturer for feedback. Additionally, consider manufacturers that offer design support services, as they can provide insights on materials and assembly methods that could enhance performance and compliance. Establish a clear project timeline with milestones for design reviews, prototype testing, and final production to ensure both parties are aligned throughout the process.

Scenario 3: Ensuring Timely Delivery and Supply Chain Stability

The Problem:

In an increasingly globalized market, B2B buyers often face challenges related to delivery timelines and supply chain disruptions. Factors such as geopolitical issues, natural disasters, or changes in trade policies can impact the timely delivery of wire harnesses, leading to project delays and increased costs. Buyers in regions like the Middle East and Europe are particularly sensitive to these issues due to varying lead times and logistics challenges.

The Solution:

To mitigate risks associated with delivery delays, buyers should establish partnerships with manufacturers that have a proven track record of reliability and flexibility. Implementing a dual-sourcing strategy can help by identifying alternative suppliers in different regions. This approach not only provides backup options in case of disruptions but also fosters competitive pricing. Additionally, buyers should negotiate clear terms in contracts regarding lead times and penalties for delays, ensuring accountability. Regular communication with suppliers about market conditions can also help anticipate potential disruptions, allowing for proactive measures to be taken, such as adjusting order quantities or delivery schedules as needed.

Strategic Material Selection Guide for Wire Harness Manufacturers

What Are the Key Materials for Wire Harness Manufacturing?

Wire harness manufacturers often utilize a variety of materials, each with distinct properties and applications. Understanding these materials is essential for international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe. Below, we analyze four common materials used in wire harness production: copper, aluminum, polyvinyl chloride (PVC), and thermoplastic elastomers (TPE).

How Does Copper Perform in Wire Harness Applications?

Copper is the most widely used conductor in wire harnesses due to its excellent electrical conductivity, which is approximately 60% better than aluminum. It also has a high melting point (about 1,984°F or 1,085°C) and superior corrosion resistance, making it suitable for various environments, including automotive and aerospace applications.

Pros: Copper’s durability and conductivity make it ideal for high-performance applications. It is also readily available and recyclable, which can reduce costs in the long term.

Cons: The primary drawbacks of copper are its higher cost compared to aluminum and its weight, which can be a concern in applications where weight savings are critical.

Impact on Application: Copper is compatible with a wide range of media, including water and various oils, making it versatile across industries.

Considerations for International Buyers: Compliance with standards such as ASTM B170 for copper quality is crucial. Buyers should also consider local sourcing options to mitigate costs and ensure compliance with regional regulations.

What Role Does Aluminum Play in Wire Harness Manufacturing?

Aluminum is increasingly popular due to its lightweight properties, which can significantly reduce the overall weight of wire harnesses. It has a lower conductivity than copper (about 61% of copper’s conductivity), but advancements in alloying and treatment have improved its performance.

Pros: The primary advantage of aluminum is its cost-effectiveness and lightweight nature, which is beneficial for applications where weight is a critical factor, such as in the automotive and aerospace sectors.

Cons: Aluminum is more susceptible to corrosion than copper and may require additional coatings or treatments to enhance its durability.

Impact on Application: Aluminum wire harnesses are often used in applications that require reduced weight but still need reliable conductivity, such as in electric vehicles.

Considerations for International Buyers: Buyers should be aware of standards like ASTM B800 for aluminum conductors. It’s also essential to consider the local climate’s impact on aluminum’s performance, especially in humid or corrosive environments.

Why Choose PVC for Wire Insulation?

Polyvinyl chloride (PVC) is a common insulating material used in wire harnesses due to its excellent electrical insulation properties and resistance to moisture and chemicals. PVC is also flame-retardant, making it suitable for various applications.

Pros: PVC is cost-effective and offers good mechanical strength, making it a popular choice for general-purpose wire harnesses.

Cons: However, PVC can become brittle over time, especially when exposed to extreme temperatures, which may limit its application in high-temperature environments.

Impact on Application: PVC is compatible with various media, including oils and fuels, but may not perform well in high-temperature applications.

Considerations for International Buyers: Compliance with standards such as UL 758 for wire and cable is essential. Buyers should also consider the environmental regulations regarding PVC, especially in Europe, where restrictions may apply.

How Do Thermoplastic Elastomers (TPE) Compare?

Thermoplastic elastomers (TPE) combine the properties of rubber and plastic, offering flexibility and durability. TPEs are often used for insulation and jacketing in wire harnesses, especially in automotive applications.

Pros: TPEs provide excellent resistance to abrasion, chemicals, and extreme temperatures, making them suitable for harsh environments.

Cons: The main limitation is their cost, which can be higher than traditional materials like PVC.

Impact on Application: TPEs are ideal for applications that require flexibility and durability, such as in electric vehicles and industrial machinery.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards such as SAE J1128 for automotive wire harnesses. Understanding the specific TPE formulation is crucial for ensuring compatibility with the intended application.

Summary Table of Material Selection for Wire Harness Manufacturers

| Material | Typical Use Case for Wire Harness Manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Automotive, aerospace, high-performance applications | Excellent conductivity and durability | Higher cost and weight | High |

| Aluminum | Electric vehicles, lightweight applications | Cost-effective and lightweight | Susceptible to corrosion | Medium |

| Polyvinyl Chloride (PVC) | General-purpose wire harnesses | Cost-effective and good insulation | Can become brittle over time | Low |

| Thermoplastic Elastomers (TPE) | Automotive, industrial machinery | Flexibility and excellent durability | Higher cost compared to PVC | High |

This strategic material selection guide offers actionable insights for international B2B buyers, enabling informed decisions based on material properties, application suitability, and regional compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for Wire Harness Manufacturers

What Are the Key Stages in the Manufacturing Process of Wire Harnesses?

Wire harness manufacturing is a complex process involving several critical stages that ensure the final product meets the necessary specifications and standards. The primary stages include:

-

Material Preparation: This initial phase involves selecting the appropriate materials based on the required specifications for the wire harness. Common materials include copper for conductors, various types of insulation (PVC, Teflon, etc.), and connectors. B2B buyers should ensure that suppliers source materials from reputable manufacturers to guarantee quality.

-

Forming: In this stage, wires are cut to precise lengths, and connectors are attached. Techniques such as crimping and soldering are commonly used. Crimping involves compressing the connector around the wire, while soldering provides a strong electrical connection. Buyers should inquire about the machinery used and the expertise of the workforce, as these factors influence the precision of the forming process.

-

Assembly: This is where the actual assembly of the wire harness occurs. Wires are grouped, bundled, and organized according to the design specifications. Advanced manufacturers may use automated systems for assembly to enhance speed and consistency. It’s advisable for buyers to request information about the assembly techniques employed and any automation used to ensure high-quality output.

-

Finishing: The final stage includes processes such as applying protective coatings, labeling, and packaging. This stage is crucial for ensuring that the wire harnesses are ready for installation and can withstand environmental factors. B2B buyers should verify that the finishing processes comply with relevant industry standards.

How Do Quality Assurance Processes Ensure Wire Harness Reliability?

Quality assurance (QA) is vital in the wire harness manufacturing process, ensuring that products meet international and industry-specific standards. Key QA processes include:

-

International Standards Compliance: Manufacturers often adhere to standards like ISO 9001, which outlines criteria for a quality management system, ensuring consistent product quality. Additionally, industry-specific certifications such as CE marking for European markets and API standards for the oil and gas sector can be crucial. B2B buyers should prioritize suppliers with these certifications as they indicate a commitment to quality.

-

Quality Control Checkpoints: Effective QA processes incorporate multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet required specifications.

– In-Process Quality Control (IPQC): Continuous monitoring during production helps identify and rectify issues in real-time, reducing the likelihood of defects.

– Final Quality Control (FQC): A thorough inspection is conducted on the finished wire harnesses to verify their compliance with specifications before shipping. -

Common Testing Methods: Wire harnesses undergo various testing methods, including:

– Electrical Testing: Ensures that the harness can handle the required voltage and current without failure.

– Mechanical Testing: Evaluates the durability and strength of connections and materials.

– Environmental Testing: Assesses the harness’s performance under different temperature and humidity conditions.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers can implement several verification strategies:

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes, quality control measures, and adherence to international standards. This step is crucial for buyers from regions like Africa and South America, where local suppliers may not always have robust quality controls in place.

-

Requesting Quality Reports: Buyers should ask suppliers for detailed quality assurance reports that outline their QA processes, testing results, and compliance with relevant standards. These reports can serve as a basis for evaluating the supplier’s reliability.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing processes and quality controls. This is especially important for international transactions, as it helps mitigate risks associated with cross-border procurement.

What Are the Nuances of Quality Control for International B2B Buyers?

For B2B buyers operating in different geographical regions, understanding the nuances of quality control is essential. Here are some considerations:

-

Cultural Differences in Quality Standards: Different regions may have varying perceptions of quality. For instance, European manufacturers may adhere to stricter environmental and safety regulations compared to those in South America. Buyers should familiarize themselves with local standards and expectations.

-

Logistics and Supply Chain Management: International buyers should account for potential delays in shipping and customs clearance, which can affect the quality of wire harnesses. Proper planning and communication with suppliers can help mitigate these risks.

-

Regulatory Compliance: Understanding the regulatory landscape in the buyer’s country is crucial. For instance, wire harnesses used in automotive applications must comply with specific safety standards. Buyers should ensure that their suppliers are knowledgeable about these regulations and can provide necessary documentation.

Conclusion

The manufacturing processes and quality assurance measures in wire harness production are critical for ensuring reliability and performance. By understanding these processes and implementing robust verification strategies, B2B buyers from Africa, South America, the Middle East, and Europe can make informed decisions when selecting suppliers, ultimately enhancing their supply chain effectiveness.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘Wire Harness Manufacturers’

Introduction

Sourcing wire harness manufacturers requires a strategic approach, especially for international B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe. This guide provides a step-by-step checklist to streamline your procurement process, ensuring that you select a supplier that meets your technical requirements, compliance standards, and business needs.

Step 1: Define Your Technical Specifications

Before initiating contact with potential manufacturers, clearly outline your technical requirements. This includes the type of materials, wire gauge, insulation, and any specific industry standards that apply.

- Why it’s important: Defining specifications prevents miscommunication and ensures that the manufacturer can meet your product requirements from the outset.

- What to look for: Consider your product’s electrical load, environmental conditions, and any certifications required in your region.

Step 2: Research Potential Suppliers

Conduct thorough research to identify manufacturers with a solid reputation in the wire harness industry. Utilize platforms such as industry directories, trade shows, and online reviews to gather insights.

- Why it’s important: A well-established manufacturer is more likely to deliver quality products and reliable service.

- What to look for: Focus on suppliers with experience in your specific industry and check their client testimonials.

Step 3: Verify Supplier Certifications

Ensure that potential suppliers hold relevant certifications, such as ISO 9001 or UL certification. These accreditations indicate adherence to quality management standards and product safety.

- Why it’s important: Certifications ensure that the manufacturer complies with international standards, which can reduce risks associated with product liability.

- What to look for: Request copies of certifications and verify them through the issuing bodies.

Step 4: Request Samples and Prototypes

Before placing a bulk order, ask for samples or prototypes of the wire harnesses you intend to purchase. This allows you to assess the quality and suitability of the products.

- Why it’s important: Testing samples can reveal whether the manufacturer meets your technical specifications and quality expectations.

- What to look for: Evaluate the materials used, assembly quality, and any specific features relevant to your application.

Step 5: Evaluate Manufacturing Capabilities

Investigate the manufacturing capabilities of your shortlisted suppliers. This includes their production capacity, technology used, and lead times for orders.

- Why it’s important: Understanding a supplier’s capabilities helps you gauge whether they can fulfill your order in a timely manner and at the scale you require.

- What to look for: Inquire about their machinery, workforce qualifications, and any recent investments in technology.

Step 6: Assess Communication and Support

Effective communication is key to successful sourcing. Evaluate how responsive and supportive potential suppliers are during initial interactions.

- Why it’s important: Good communication can significantly ease the procurement process and facilitate problem resolution.

- What to look for: Observe their willingness to provide detailed information and support throughout the sourcing process.

Step 7: Negotiate Terms and Conditions

Once you have selected a supplier, discuss and negotiate pricing, payment terms, delivery schedules, and warranties.

- Why it’s important: Clear agreements help to avoid misunderstandings later and ensure that both parties are aligned on expectations.

- What to look for: Aim for transparency in pricing and ensure that the terms are favorable for both parties, considering currency fluctuations if applicable.

By following this checklist, international B2B buyers can effectively navigate the sourcing process for wire harness manufacturers, ensuring that they select a partner that meets their needs and expectations.

Comprehensive Cost and Pricing Analysis for Wire Harness Manufacturers Sourcing

What Are the Key Cost Components for Wire Harness Manufacturers?

When sourcing wire harnesses, understanding the cost structure is crucial for international B2B buyers. The main cost components include:

-

Materials: The choice of materials significantly impacts cost. Copper is the primary conductor, and fluctuations in copper prices can directly affect wire harness pricing. Insulation materials and connectors also contribute to the overall material costs.

-

Labor: Labor costs vary by region and can affect the total price. Countries with higher labor costs may charge more for manufacturing, whereas regions with lower labor costs might provide more competitive pricing.

-

Manufacturing Overhead: This includes expenses related to factory operation, utilities, and administrative costs. Efficient manufacturing processes can help reduce overhead costs, benefiting buyers.

-

Tooling: Initial tooling costs can be substantial, particularly for custom harnesses. Buyers should consider whether the supplier’s tooling costs are amortized over large volumes, potentially reducing per-unit costs.

-

Quality Control (QC): Investing in quality control ensures that the wire harnesses meet industry standards and specifications. High QC standards might increase costs but can reduce long-term risks associated with product failures.

-

Logistics: Transportation and shipping costs should also be considered. These can vary significantly based on the distance, shipping method, and Incoterms agreed upon.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the margin can help buyers assess whether pricing is competitive or if there’s room for negotiation.

How Do Price Influencers Affect Wire Harness Costs?

Several factors can influence the pricing of wire harnesses, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders usually result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to optimize their budget.

-

Specifications and Customization: Custom wire harnesses tailored to specific applications tend to be more expensive than standard options. Defining clear specifications upfront can help avoid unexpected costs later.

-

Materials and Quality Certifications: The choice of materials and the requirement for certifications (like ISO or RoHS) can impact pricing. Higher quality materials and certifications typically increase costs but provide greater reliability and compliance.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can affect pricing. Established suppliers with proven track records may charge a premium for their products.

-

Incoterms: The agreed terms for shipping and handling can impact total costs. Understanding Incoterms can help buyers manage logistics costs effectively.

What Are the Best Buyer Tips for Negotiating Wire Harness Prices?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, here are actionable tips:

-

Negotiate with Clear Objectives: Come prepared with market research and specific goals. Knowing the industry standard pricing can empower you during negotiations.

-

Focus on Total Cost of Ownership (TCO): Consider not just the upfront price but also the long-term costs associated with the product, including installation, maintenance, and potential downtime costs.

-

Leverage Volume Discounts: If possible, consolidate orders or collaborate with other buyers to increase order volumes, thereby unlocking lower pricing tiers.

-

Understand Pricing Nuances: Different regions may have varying pricing structures influenced by local economic conditions, tariffs, and trade agreements. Being aware of these nuances can help in making informed decisions.

-

Request Detailed Quotations: Ask suppliers for breakdowns of costs to understand where you can negotiate. This can highlight areas for potential savings, such as materials or logistics.

Disclaimer on Indicative Prices

A stock image related to Wire Harness Manufacturers.

Prices for wire harness manufacturing can vary widely based on the factors discussed. The figures provided in this analysis are indicative and should be confirmed with suppliers for accurate quotes tailored to specific projects and requirements. Always conduct thorough due diligence when selecting suppliers to ensure cost-effectiveness and quality in your sourcing decisions.

Alternatives Analysis: Comparing Wire Harness Manufacturers With Other Solutions

Understanding the Need for Alternative Solutions in Wire Harness Manufacturing

In the rapidly evolving landscape of electrical and electronic manufacturing, businesses often seek alternatives to traditional wire harness solutions. This exploration is driven by the need for enhanced performance, cost-efficiency, and adaptability to specific project requirements. For B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding these alternatives can lead to more informed procurement decisions.

Comparison Table of Wire Harness Manufacturers and Alternative Solutions

| Comparison Aspect | Wire Harness Manufacturers | Custom PCB Assemblies | Cable Management Systems |

|---|---|---|---|

| Performance | High durability and reliability; designed for specific applications | Excellent for complex circuits; allows for compact designs | Enhances organization and minimizes damage; supports various cable types |

| Cost | Generally higher due to customization and material quality | Potentially lower for high-volume runs but can increase with complexity | Lower initial costs; ongoing costs for installation and maintenance |

| Ease of Implementation | Requires skilled labor for installation; potential for design errors | Often requires specialized knowledge; integration can be complex | Simple installation; user-friendly for non-experts |

| Maintenance | Moderate; inspection needed over time to prevent wear | Low; minimal upkeep if designed well | Requires regular checks to prevent tangling or damage |

| Best Use Case | Best for automotive, aerospace, and industrial applications | Ideal for consumer electronics and compact devices | Suitable for office environments and general cable management |

Evaluating Custom PCB Assemblies as an Alternative

Custom PCB assemblies serve as a viable alternative to traditional wire harnesses, particularly in applications requiring intricate designs and compact form factors. The primary advantage of PCBs is their ability to integrate multiple functions into a single unit, significantly reducing space and weight. However, the complexity of PCB design can lead to higher costs in low-volume production runs. Additionally, while PCBs are less prone to physical damage compared to wire harnesses, they can be more difficult to repair if failures occur.

Considering Cable Management Systems

Cable management systems represent another alternative, focusing on the organization and protection of cables rather than the wiring itself. These systems can reduce clutter and enhance safety by preventing cable tangling and damage. They are particularly beneficial in environments where multiple cables are in use, such as office spaces or data centers. The main drawback is that while these systems improve organization, they do not replace the need for the electrical connections that wire harnesses provide.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between wire harness manufacturers and alternative solutions like custom PCB assemblies or cable management systems, B2B buyers should consider specific project requirements, including performance needs, budget constraints, and installation capabilities. Each solution has its strengths and weaknesses, and the right choice will depend on the unique demands of the application. By carefully evaluating these factors, businesses can make informed decisions that enhance efficiency, reduce costs, and improve overall operational effectiveness.

Essential Technical Properties and Trade Terminology for Wire Harness Manufacturers

What Are the Essential Technical Properties of Wire Harnesses?

When sourcing wire harnesses, understanding their technical properties is crucial for ensuring compatibility, safety, and efficiency in your application. Here are some key specifications that international B2B buyers should consider:

1. What Materials Are Commonly Used in Wire Harnesses?

Wire harnesses are typically made from materials such as copper, aluminum, and various plastics.

- Copper is the most common conductor due to its excellent electrical conductivity and malleability.

- Aluminum is lighter and less expensive but offers lower conductivity and is often used in applications where weight savings are critical.

- Insulation materials like PVC, XLPE (cross-linked polyethylene), and Teflon are chosen based on thermal resistance and environmental factors.

Understanding the material grades helps in evaluating performance under specific conditions such as temperature fluctuations and exposure to chemicals.

2. How Important Are Tolerances in Wire Harness Manufacturing?

Tolerances refer to the acceptable variations in dimensions and properties of components in the wire harness.

- Manufacturing tolerances can affect the fit and function of the harness in its intended application.

- For example, in automotive applications, tight tolerances are necessary to ensure connections are secure and reliable, reducing the risk of electrical failures.

Buyers should specify tolerances in their requests to ensure that the manufactured harness meets their precise requirements.

3. What Is the Significance of Temperature Ratings?

Temperature ratings indicate the maximum operating temperature that the wire harness can safely withstand.

- Common ratings include 60°C, 80°C, and 105°C.

- Selecting a harness with an appropriate temperature rating is vital for applications exposed to high heat, as exceeding these limits can lead to insulation breakdown and electrical failures.

Understanding temperature ratings aids in choosing the right harness for specific environmental conditions.

What Trade Terminology Should B2B Buyers Understand?

Familiarity with industry jargon is essential for effective communication and negotiation with wire harness manufacturers. Here are some common terms that buyers should know:

1. What Does OEM Mean in Wire Harness Manufacturing?

OEM stands for Original Equipment Manufacturer.

- This term refers to companies that produce components that are used in another company’s end products.

- For buyers, understanding whether a manufacturer is an OEM can indicate the quality and reliability of the wire harness being sourced.

2. Why Is MOQ Important for Buyers?

MOQ refers to Minimum Order Quantity.

- This is the smallest number of units that a supplier is willing to sell.

- Knowing the MOQ is crucial for budgeting and inventory management, especially for smaller businesses or projects with limited initial demand.

3. What Is an RFQ and Why Is It Necessary?

RFQ stands for Request for Quotation.

- It is a formal document sent to suppliers requesting pricing and terms for specific products.

- An RFQ helps buyers gather competitive pricing and evaluate multiple suppliers efficiently, ensuring better decision-making.

4. How Do Incoterms Affect International Shipping?

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in international trade.

- They clarify who is responsible for shipping costs, insurance, and risk during transportation.

- Understanding Incoterms is vital for buyers to avoid unexpected costs and ensure timely delivery of wire harnesses.

By familiarizing themselves with these technical properties and trade terminologies, B2B buyers can make informed decisions and streamline their procurement processes in the wire harness industry.

Navigating Market Dynamics and Sourcing Trends in the Wire Harness Manufacturers Sector

What Are the Current Market Dynamics and Key Trends in the Wire Harness Manufacturers Sector?

The wire harness manufacturing sector is witnessing significant transformations driven by global technological advancements and changing consumer demands. Key trends include the increasing adoption of automation and smart manufacturing processes, which enhance production efficiency and reduce labor costs. For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions.

One of the primary drivers in this market is the growing demand for wire harnesses in the automotive and aerospace sectors. As electric vehicles (EVs) gain traction, the need for sophisticated wiring solutions that can support advanced technologies such as battery management systems and infotainment has surged. Buyers should prioritize manufacturers who are innovating in this space, ensuring that their products meet the latest industry standards.

Moreover, the rise of Industry 4.0 has led to a heightened focus on data analytics and IoT integration within manufacturing processes. Buyers are encouraged to seek suppliers that leverage these technologies, as they can offer enhanced transparency, traceability, and predictive maintenance capabilities, ultimately leading to reduced downtime and improved supply chain efficiency.

In summary, international B2B buyers should focus on sourcing from manufacturers that demonstrate technological prowess, adaptability to industry trends, and a commitment to quality and efficiency in their wire harness solutions.

How Is Sustainability Impacting Wire Harness Manufacturers and Ethical Sourcing Practices?

Sustainability has become a pivotal concern in the wire harness manufacturing sector, influencing both production methods and sourcing practices. The environmental impact of wire harness production, particularly in terms of resource consumption and waste generation, has prompted a shift towards more sustainable practices. Buyers from Africa, South America, the Middle East, and Europe should prioritize manufacturers that adopt eco-friendly materials and processes.

Ethical sourcing is increasingly important as businesses face pressure to demonstrate corporate social responsibility. Manufacturers are now seeking certifications such as ISO 14001 (Environmental Management) and using recycled or biodegradable materials in their wire harnesses. This not only reduces the environmental footprint but also enhances brand reputation, making it an attractive proposition for B2B buyers.

Furthermore, the implementation of circular economy principles in the production of wire harnesses is gaining traction. This involves designing products for longevity, reparability, and recyclability, thus minimizing waste and promoting resource efficiency. Buyers should actively inquire about a manufacturer’s sustainability practices, including their supply chain transparency and compliance with environmental regulations.

What Is the Historical Context of Wire Harness Manufacturing Relevant to B2B Buyers?

The evolution of wire harness manufacturing can be traced back to the early 20th century when electrical systems became integral to automotive and industrial applications. Initially, wire harnesses were crafted manually, leading to inefficiencies and increased risk of errors. However, with advancements in technology, particularly during the latter half of the century, the introduction of automated production techniques revolutionized the industry.

As wire harnesses became more complex, particularly with the rise of electronic components in vehicles, manufacturers began to focus on specialized designs tailored to specific applications. This evolution underscores the importance of selecting suppliers who not only have a rich history of innovation but also a deep understanding of current technological requirements.

For international B2B buyers, recognizing this historical context can inform better sourcing strategies, ensuring that partnerships are established with manufacturers that are not only experienced but also adaptable to ongoing changes in the industry.

Frequently Asked Questions (FAQs) for B2B Buyers of Wire Harness Manufacturers

-

How do I choose the right wire harness manufacturer for my business needs?

Selecting the right wire harness manufacturer involves evaluating several key factors. Start by identifying manufacturers that specialize in your specific industry requirements, such as automotive or aerospace. Check their certifications (e.g., ISO 9001) to ensure quality standards are met. Request samples to assess their workmanship and materials. Additionally, consider their production capabilities, lead times, and flexibility in customization. Engaging with past clients can provide insight into their reliability and customer service. -

What are the typical minimum order quantities (MOQs) for wire harnesses?

Minimum order quantities (MOQs) for wire harnesses can vary significantly based on the manufacturer and the complexity of the design. Generally, MOQs can range from 100 to several thousand units. If you’re a smaller business or just starting, it’s crucial to discuss your needs with potential suppliers. Some manufacturers may offer lower MOQs for prototypes or custom orders, while others may require higher quantities to achieve cost-effective pricing. Always clarify MOQs upfront to avoid unexpected costs. -

What payment terms should I expect when sourcing wire harnesses internationally?

Payment terms when sourcing wire harnesses can vary widely between manufacturers and regions. Common terms include 30% upfront payment with the balance due upon delivery, or payment upon receipt of goods. For international transactions, consider using secure payment methods like letters of credit or PayPal for added protection. Discussing payment terms early in negotiations is essential to align expectations and ensure financial security for both parties. -

How can I ensure quality assurance in wire harness production?

To ensure quality assurance in wire harness production, look for manufacturers that implement strict quality control processes, including in-line inspections and final audits. Request documentation of their quality management system, ideally certified to standards like ISO 9001. Additionally, consider third-party quality audits or testing services to verify the integrity and reliability of your wire harnesses. Establishing clear specifications and performance criteria in your contract can also help maintain quality standards. -

What customization options are available for wire harnesses?

Customization options for wire harnesses are extensive and can include variations in wire gauge, insulation material, length, and connector types. Many manufacturers offer design services to create harnesses tailored to your specific application. Additionally, you can specify features such as color coding and labeling for easier installation and identification. Discuss your requirements with potential suppliers to understand their capabilities and the extent of customization they can provide. -

What logistics considerations should I keep in mind when sourcing wire harnesses?

When sourcing wire harnesses, logistics play a crucial role in ensuring timely delivery. Consider the shipping methods available, which may include air freight for faster delivery or sea freight for cost savings. Understand the import regulations and duties applicable in your country, as these can affect overall costs. Additionally, establishing a reliable communication channel with your supplier can help track shipments and address any issues that may arise during transit. -

How do I vet a wire harness manufacturer for reliability and performance?

Vetting a wire harness manufacturer requires thorough research and evaluation. Start by checking their industry reputation through reviews and testimonials. Verify their certifications and production capabilities. Request references from previous clients and follow up to gain insights into their experiences. Additionally, consider visiting their facility if possible, as this can provide a direct view of their operations and quality control processes. -

What are the common applications of wire harnesses across different industries?

Wire harnesses are utilized in a variety of industries, including automotive, aerospace, telecommunications, and industrial machinery. In automotive applications, they connect various electrical components and systems, while in aerospace, they ensure safe and efficient electrical operations in aircraft. Telecommunications utilize wire harnesses to manage complex wiring in devices and networks. Understanding these applications can help you select the right manufacturer that specializes in your industry needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for Wire Harness Manufacturers

What Are the Key Takeaways for Strategic Sourcing in Wire Harness Manufacturing?

In the evolving landscape of wire harness manufacturing, strategic sourcing stands out as a critical factor for success. International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, must prioritize supplier relationships that offer reliability, quality, and innovation. By leveraging comprehensive market analysis and understanding local compliance standards, companies can mitigate risks and optimize their supply chains.

Furthermore, investing in partnerships with manufacturers who demonstrate advanced technologies and sustainable practices can lead to significant cost savings and enhanced product performance. This is especially crucial for regions like Mexico and Poland, where manufacturing capabilities are expanding rapidly.

How Can International Buyers Prepare for Future Trends in Wire Harness Manufacturing?

As we look to the future, international buyers should stay informed about technological advancements such as automation and IoT integration within wire harness systems. Embracing these innovations will not only enhance production efficiency but also meet the growing demand for smarter solutions across various industries.

In conclusion, the journey towards effective strategic sourcing is ongoing. B2B buyers are encouraged to actively engage with suppliers, explore new market opportunities, and adopt a proactive approach to supply chain management. By doing so, they can position themselves for success in the dynamic global marketplace of wire harness manufacturing.