Transform Your Business: The Ultimate Panel Custom Guide (2025)

Introduction: Navigating the Global Market for panel custom

Navigating the complexities of sourcing custom panels can be a daunting challenge for international B2B buyers, especially those located in Africa, South America, the Middle East, and Europe. The need for tailored solutions that meet specific industry requirements, while ensuring compliance with regional regulations, can complicate the purchasing process. This guide offers a comprehensive examination of the global market for panel custom, providing insights into types of panels, their diverse applications, and essential considerations for supplier vetting.

From understanding the nuances of material selection to evaluating cost implications, this resource aims to empower buyers with the knowledge needed to make informed purchasing decisions. It delves into key factors such as quality standards, production capabilities, and shipping logistics, ensuring that you are equipped to choose suppliers that align with your business objectives.

Moreover, the guide highlights regional considerations that may affect sourcing strategies, particularly for buyers in the UK, Poland, and beyond. By addressing common challenges and providing actionable insights, this guide serves as a valuable tool in navigating the global market for panel custom, ultimately facilitating smoother procurement processes and fostering successful international partnerships.

Understanding panel custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rigid Panel | Solid construction, high durability | Industrial equipment, signage | Pros: Long-lasting, weather-resistant; Cons: Heavier, costlier |

| Flexible Panel | Lightweight, adaptable to various shapes | Automotive interiors, portable displays | Pros: Versatile, easy to transport; Cons: Less durable, may require more maintenance |

| Acoustic Panel | Sound-absorbing materials, aesthetic designs | Offices, auditoriums, studios | Pros: Enhances acoustics, improves aesthetics; Cons: Can be more expensive, installation complexity |

| Solar Panel | Integrated photovoltaic cells for energy capture | Renewable energy systems, buildings | Pros: Energy savings, eco-friendly; Cons: High initial investment, space requirements |

| Decorative Panel | Custom designs, various finishes | Retail environments, exhibitions | Pros: Enhances branding, unique aesthetics; Cons: Potentially higher costs, may require longer lead times |

What Are the Characteristics of Rigid Panels and Their Suitability for B2B Buyers?

Rigid panels are characterized by their solid construction, which ensures high durability and resistance to environmental factors. They are particularly suitable for applications in industrial settings, such as equipment housing and signage. B2B buyers should consider the initial investment versus the long-term benefits, including lower replacement rates and maintenance costs. Additionally, the weight of rigid panels may affect shipping and installation logistics, which should be factored into purchasing decisions.

How Do Flexible Panels Offer Versatility for B2B Applications?

Flexible panels are designed to be lightweight and adaptable, making them ideal for a variety of shapes and configurations. They find extensive use in automotive interiors and portable displays, where adaptability is crucial. For international B2B buyers, the ease of transport and installation can be significant advantages. However, it is essential to weigh these benefits against their relatively lower durability, as flexible panels may require more frequent replacements or maintenance, especially in high-traffic environments.

Why Are Acoustic Panels Important for Enhancing Business Environments?

Acoustic panels are crafted from sound-absorbing materials, making them essential for improving sound quality in offices, auditoriums, and studios. Their aesthetic appeal further enhances the visual environment, making them a dual-purpose solution for B2B buyers. When considering acoustic panels, businesses should evaluate the balance between cost and the potential for increased productivity through improved acoustics. Installation complexity can be a consideration; thus, buyers should seek suppliers who offer support in this area.

What Are the Benefits of Solar Panels for B2B Buyers in Energy-Intensive Industries?

Solar panels integrate photovoltaic cells to capture energy, making them a sustainable choice for businesses looking to reduce energy costs. They are increasingly applied in renewable energy systems and building infrastructure. B2B buyers must consider the high initial investment and potential space requirements when evaluating solar panels. However, the long-term energy savings and positive environmental impact can justify the upfront costs, especially for companies committed to sustainability.

How Can Decorative Panels Enhance Branding for Businesses?

Decorative panels allow for custom designs and various finishes, providing a unique opportunity for branding in retail environments and exhibitions. B2B buyers can leverage these panels to create visually striking displays that attract customers and enhance their brand image. However, potential drawbacks include higher costs and longer lead times for custom designs. It is advisable for buyers to plan their projects well in advance to accommodate these factors while maximizing the impact of their investment.

Related Video: SOAP Web Services 13 – Service Interface and Custom Types

Key Industrial Applications of panel custom

| Industry/Sector | Specific Application of panel custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Custom control panels for machinery | Improved operational efficiency and reduced downtime | Supplier experience in specific machinery applications |

| Telecommunications | Custom enclosures for networking equipment | Enhanced protection and reliability of equipment | Compliance with international safety and performance standards |

| Renewable Energy | Custom solar panel mounts | Increased energy capture and optimized installation | Material durability and resistance to environmental factors |

| Automotive | Customized dashboard panels | Enhanced user experience and brand differentiation | Compatibility with existing vehicle designs and materials |

| Food & Beverage | Custom panels for processing equipment | Improved hygiene and compliance with industry standards | Availability of materials that meet food safety regulations |

How is ‘panel custom’ utilized in the manufacturing sector?

In the manufacturing sector, custom control panels are integral to machinery operation. These panels are tailored to specific equipment, ensuring seamless integration and functionality. By using panel custom solutions, manufacturers can significantly improve operational efficiency and reduce downtime due to equipment failures. For international buyers, it is crucial to source from suppliers who understand local regulations and have experience with the specific machinery applications relevant to their operations.

What role does ‘panel custom’ play in telecommunications?

Custom enclosures for networking equipment are vital in telecommunications, providing protection against environmental hazards and ensuring reliable performance. These panels can be designed to accommodate various components, enhancing the overall functionality of the network infrastructure. For buyers in regions like Africa or South America, sourcing from manufacturers who comply with international safety and performance standards is essential to ensure the longevity and reliability of their telecommunications equipment.

How does ‘panel custom’ enhance renewable energy solutions?

In the renewable energy sector, custom solar panel mounts are designed to maximize energy capture while ensuring stability and durability. These mounts can be tailored to specific site conditions, optimizing the installation process and improving overall energy output. Buyers from Europe and the Middle East should consider sourcing materials that are resistant to environmental factors, ensuring longevity and efficiency in diverse climates.

Why are customized dashboard panels important in the automotive industry?

Customized dashboard panels in the automotive industry not only enhance user experience but also allow for brand differentiation. These panels can be specifically designed to fit various vehicle models, integrating seamlessly with existing designs. International B2B buyers must focus on suppliers who can provide panels that are compatible with their specific vehicle designs, ensuring that quality and aesthetics meet consumer expectations.

How does ‘panel custom’ ensure compliance in the food and beverage industry?

In the food and beverage sector, custom panels for processing equipment are crucial for maintaining hygiene and compliance with industry standards. These panels can be designed to facilitate easy cleaning and prevent contamination, ensuring that businesses meet regulatory requirements. Buyers should prioritize sourcing materials that comply with food safety regulations, particularly when dealing with suppliers from different regions to ensure quality and safety in their operations.

Related Video: Industrial Control Panel Basics

3 Common User Pain Points for ‘panel custom’ & Their Solutions

Scenario 1: Overwhelming Choices in Custom Panel Specifications

The Problem: In the realm of panel custom, B2B buyers often encounter an overwhelming array of options when it comes to specifications, materials, and functionalities. For instance, a buyer in the automotive sector may struggle to determine which panel configurations will best meet their needs for durability, weight, and cost-efficiency. This indecision can lead to delays in project timelines and increased costs as they navigate through numerous suppliers and technical specifications.

The Solution: To mitigate this confusion, B2B buyers should begin by clearly defining their project requirements and operational constraints before engaging with suppliers. Creating a detailed specification document that outlines essential criteria such as environmental conditions, load requirements, and aesthetic preferences will streamline the selection process. Additionally, working with suppliers who provide comprehensive product catalogs with clear comparative metrics can help buyers make informed decisions. Engaging in early consultations with manufacturers can also yield tailored recommendations based on their expertise, ensuring that the chosen panel aligns perfectly with the buyer’s specific needs.

Scenario 2: Quality Assurance and Compliance Challenges

The Problem: Buyers often face difficulties ensuring that the custom panels they order meet industry standards and regulations, particularly when sourcing from international suppliers. For example, a company in Europe may find that panels sourced from South America do not comply with the stringent EU safety and environmental regulations. This non-compliance can lead to costly recalls, project delays, and damage to the company’s reputation.

The Solution: To navigate these challenges, B2B buyers should prioritize due diligence in supplier selection. This involves assessing the supplier’s certifications and compliance records with relevant industry standards. Buyers should also request product samples and undergo rigorous testing to verify quality and compliance before placing large orders. Establishing clear communication channels with suppliers about compliance expectations is vital, and buyers can benefit from third-party audits or inspections to ensure that the panels meet both local and international standards. Engaging legal counsel familiar with the regulations in both the buyer’s and supplier’s countries can also provide additional assurance.

Scenario 3: Integration Issues with Existing Systems

The Problem: Another common pain point arises when B2B buyers attempt to integrate custom panels into their existing systems. For instance, a manufacturer may order panels designed for a new production line, only to discover that the panels are incompatible with their current machinery or software systems. This oversight can lead to substantial downtime and additional costs as the company scrambles to make necessary adjustments.

The Solution: To avoid integration issues, buyers should conduct a thorough compatibility assessment before finalizing panel specifications. This involves collaborating with engineering teams to understand existing system requirements and potential limitations. Utilizing software tools for 3D modeling and simulation can help visualize how the custom panels will fit into the current setup. Furthermore, B2B buyers should engage with suppliers early in the design phase, as many manufacturers offer customization services that can accommodate specific integration needs. Establishing a robust feedback loop between design, engineering, and procurement teams can ensure that all parties are aligned and that the final product seamlessly integrates into existing operations.

Strategic Material Selection Guide for panel custom

When selecting materials for custom panels, international B2B buyers must consider various factors that influence product performance, cost, and compliance with regional standards. Below is a detailed analysis of four common materials used in panel custom applications: aluminum, stainless steel, polycarbonate, and fiberglass.

What Are the Key Properties of Aluminum in Panel Custom Applications?

Aluminum is a lightweight, corrosion-resistant metal that is often utilized in panel custom applications. It has excellent thermal and electrical conductivity, making it suitable for various environments. Its temperature rating typically ranges from -200°C to 600°C, depending on the alloy used.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which reduces shipping costs and simplifies installation. However, it can be more expensive than other materials like steel and may require additional coatings for enhanced corrosion resistance in harsh environments.

Impact on Application: Aluminum panels are ideal for applications requiring good thermal management or electrical conductivity, such as in electronic housings or heat exchangers.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as EN 573 for aluminum alloys. Additionally, understanding local sourcing options can help mitigate import costs.

How Does Stainless Steel Perform in Custom Panel Applications?

Stainless steel is renowned for its durability and resistance to corrosion, making it a popular choice for panel custom applications in demanding environments. It typically withstands temperatures up to 800°C and is highly resistant to various chemicals.

Pros & Cons: The key advantage of stainless steel is its strength and longevity, making it suitable for high-stress applications. However, it is heavier and more expensive than aluminum, which can impact overall project costs and logistics.

Impact on Application: Stainless steel panels are commonly used in food processing, pharmaceuticals, and marine applications due to their hygienic properties and resistance to corrosion.

Considerations for International Buyers: Buyers should be aware of compliance with ASTM A240 standards for stainless steel. In regions like South America, local suppliers may offer competitive pricing, but quality assurance is crucial.

What Are the Benefits of Using Polycarbonate in Custom Panels?

Polycarbonate is a thermoplastic material known for its high impact resistance and transparency. It can withstand temperatures ranging from -40°C to 120°C, making it versatile for various applications.

Pros & Cons: The main advantage of polycarbonate is its lightweight nature and ease of fabrication, allowing for complex shapes and designs. However, it may not be suitable for applications involving high temperatures or aggressive chemicals, which can lead to degradation.

Impact on Application: Polycarbonate panels are often used in applications requiring visibility and safety, such as protective barriers and signage.

Considerations for International Buyers: Compliance with EN 71 for safety standards is essential for buyers in Europe. In Africa, sourcing from local manufacturers can provide cost benefits, but quality verification is necessary.

Why Choose Fiberglass for Custom Panel Solutions?

Fiberglass is a composite material made from glass fibers and resin, known for its strength-to-weight ratio and corrosion resistance. It typically performs well in temperatures up to 150°C.

Pros & Cons: Fiberglass panels are lightweight and resistant to a wide range of chemicals, making them suitable for various industrial applications. However, they can be more expensive to manufacture and may require specialized handling during installation.

Impact on Application: Fiberglass is ideal for applications in chemical processing and marine environments due to its resistance to corrosion and moisture.

Considerations for International Buyers: Buyers should check compliance with ASTM D578 standards for fiberglass. In the Middle East, understanding local regulations regarding hazardous materials can influence material selection.

Summary Table of Material Selection for Panel Custom

| Material | Typical Use Case for panel custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Electronic housings, heat exchangers | Lightweight and corrosion-resistant | Higher cost than steel | Medium |

| Stainless Steel | Food processing, pharmaceuticals | Durable and hygienic | Heavier and more expensive | High |

| Polycarbonate | Protective barriers, signage | Impact-resistant and versatile | Limited high-temperature use | Medium |

| Fiberglass | Chemical processing, marine applications | Corrosion-resistant and lightweight | Higher manufacturing complexity | High |

This guide provides a strategic overview of material selection for panel custom applications, helping international B2B buyers make informed decisions that align with their specific needs and regional considerations.

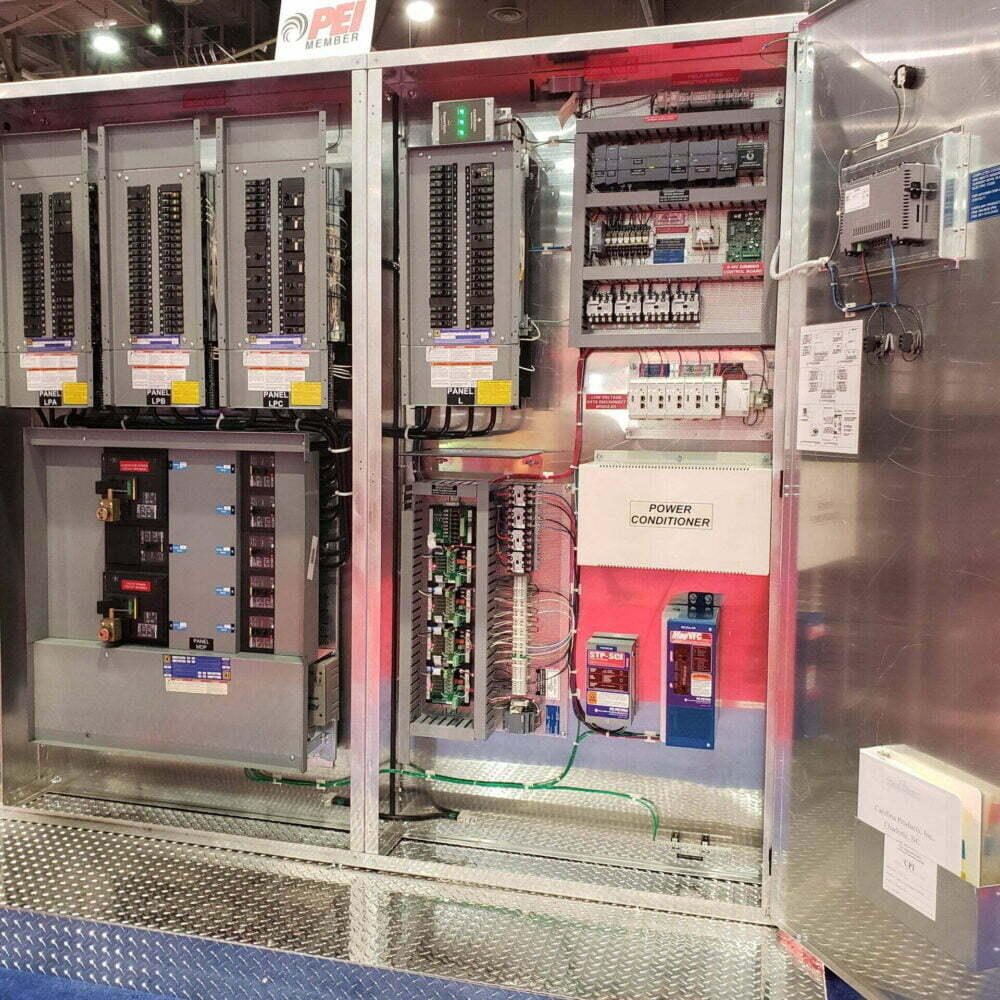

A stock image related to panel custom.

In-depth Look: Manufacturing Processes and Quality Assurance for panel custom

What Are the Main Stages of Manufacturing Processes for Custom Panels?

The manufacturing of custom panels involves several critical stages that ensure the final product meets specific requirements and quality standards. These stages typically include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in the manufacturing process is material preparation. This involves selecting the right materials based on the intended application of the custom panels. Common materials include metals, plastics, and composites. B2B buyers should consider the properties of these materials, such as strength, weight, and resistance to environmental factors, to ensure they meet their project’s needs.

A stock image related to panel custom.

Additionally, suppliers often conduct material inspections to verify that the materials conform to specified standards. Buyers should request certificates of compliance or test reports from suppliers to ensure that the materials used are of high quality and sourced responsibly.

How Is Forming Done in Panel Manufacturing?

Forming is the next step, where the prepared materials are shaped into the desired configuration. This can be achieved through various techniques, including:

- Stamping: Commonly used for metal panels, stamping involves pressing a die against the material to create specific shapes.

- Injection Molding: This is typically used for plastic panels, where molten plastic is injected into a mold to form the panel.

- CNC Machining: This method utilizes computer-controlled machines to precisely cut and shape materials, providing high accuracy for complex designs.

Each of these techniques has its advantages, and the choice often depends on the specific requirements of the custom panel, including volume, complexity, and cost considerations. Buyers should engage with suppliers to understand which techniques will best meet their needs.

What Is the Assembly Process for Custom Panels?

After forming, the assembly stage involves joining various components to create the final product. This can include welding, riveting, or using adhesives, depending on the materials and design specifications.

Quality during assembly is critical, as it directly affects the panel’s durability and functionality. Buyers should inquire about the assembly methods used and whether they comply with industry standards. Additionally, it is beneficial to understand the supplier’s experience with specific assembly techniques, especially if the panels are intended for specialized applications.

What Are the Finishing Techniques Used in Custom Panel Manufacturing?

Finishing processes enhance the appearance and performance of custom panels. Common finishing techniques include:

- Painting and Coating: This protects the panels from corrosion and improves aesthetics. Different types of coatings can be used based on environmental exposure, such as powder coating for durability or UV-resistant paints.

- Surface Treatment: Processes such as anodizing or galvanizing can increase a panel’s resistance to wear and tear.

- Quality Inspection: Final inspections ensure that the panels meet the required specifications and aesthetic standards.

B2B buyers should seek clarity on the finishing processes employed by suppliers to ensure they align with their quality expectations and industry standards.

How Is Quality Assurance Managed in Panel Manufacturing?

Quality assurance (QA) in custom panel manufacturing is crucial for ensuring product reliability and safety. International standards, such as ISO 9001, provide a framework for quality management systems. Compliance with these standards signifies that a supplier has implemented effective quality control measures throughout the manufacturing process.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically integrated into the manufacturing process through various checkpoints:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are conducted to identify any deviations from quality standards.

- Final Quality Control (FQC): This is the final inspection before the product is shipped, ensuring that all specifications have been met.

Each of these checkpoints plays a vital role in maintaining product quality and should be part of any supplier’s quality assurance program.

What Testing Methods Are Commonly Used for Quality Assurance?

Various testing methods are employed to verify the quality and performance of custom panels. These may include:

- Dimensional Inspection: Ensures that panels meet specified dimensions and tolerances.

- Mechanical Testing: Assesses the strength and durability of materials through tensile, compression, and fatigue tests.

- Environmental Testing: Evaluates how panels perform under extreme conditions, such as temperature fluctuations and humidity.

B2B buyers should request information about the testing methods used by suppliers and the frequency of these tests to gauge the reliability of the custom panels.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure the quality of custom panels, B2B buyers should implement a thorough verification process for potential suppliers. Here are some actionable steps:

- Request Documentation: Ask suppliers for quality assurance documentation, including ISO certifications, test reports, and quality control plans.

- Conduct Audits: Periodic audits of suppliers can provide insight into their manufacturing processes and quality control measures. This can be done in-person or through third-party auditing firms.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality assurance processes and the final products.

What Are the QC and Certification Nuances for International B2B Buyers?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certifications is essential. Different regions may have specific certification requirements that affect import/export processes.

For instance, European buyers may require CE marking for compliance with health, safety, and environmental protection standards. In contrast, buyers in the Middle East may need to consider local regulations that govern product specifications.

It’s advisable for buyers to familiarize themselves with these regional standards and work closely with suppliers to ensure all necessary certifications are obtained. This not only mitigates risks but also enhances the overall reliability of the supply chain.

Conclusion

Understanding the manufacturing processes and quality assurance measures for custom panels is vital for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing, alongside robust quality control practices, buyers can ensure they source high-quality products that meet their specific needs. Additionally, verifying supplier quality through audits and understanding regional certification nuances will further enhance the purchasing process, leading to successful partnerships in the global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘panel custom’

To successfully navigate the procurement of custom panels, it is essential for international B2B buyers to follow a structured approach. This practical sourcing guide outlines a step-by-step checklist designed to help you make informed decisions while ensuring quality and reliability in your sourcing process.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of any successful procurement process. Identify the specific requirements for the custom panels, including dimensions, materials, and functional attributes. This clarity will not only streamline your communication with suppliers but also minimize the risk of misunderstandings that could lead to costly errors.

- Consider performance criteria: Determine factors such as load-bearing capacity, environmental resistance, and compliance with industry standards.

- Document your specifications: Create a detailed technical document to share with potential suppliers for accurate quotations.

Step 2: Research Potential Suppliers

A comprehensive supplier search is crucial to identify manufacturers who can meet your needs. Look for companies with a proven track record in producing custom panels, particularly those that serve your industry and region.

- Utilize trade directories and platforms: Websites like Alibaba, Global Sources, and regional trade associations can provide valuable insights.

- Examine reviews and ratings: Seek feedback from previous clients to gauge supplier reliability and product quality.

Step 3: Evaluate Supplier Capabilities

Before committing to a supplier, assess their production capabilities and technology. This evaluation ensures that the supplier can not only meet your specifications but also deliver on time and within budget.

- Request information on production processes: Understanding their capabilities in terms of technology and workforce can provide insights into their efficiency.

- Check for certifications: Look for ISO certifications or industry-specific quality certifications that indicate adherence to global standards.

Step 4: Verify Supplier Certifications

It is essential to verify that your potential suppliers hold the necessary certifications that demonstrate compliance with international quality and safety standards. This step can significantly reduce the risk of future issues related to product quality.

- Request copies of certifications: Ensure that these are current and relevant to your industry.

- Cross-reference with industry standards: Familiarize yourself with specific certifications required in your region, especially if you are sourcing from overseas.

Step 5: Request Samples

Before making a large order, always request samples of the custom panels. Samples will allow you to evaluate the quality of the materials and craftsmanship firsthand.

- Assess the samples critically: Check for any defects and ensure they meet your specifications.

- Consider additional testing: If applicable, conduct performance testing to verify that the panels meet your operational requirements.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, it’s time to negotiate terms and conditions. This step is crucial to protect your interests and ensure clarity in the transaction.

- Discuss payment terms: Understand the payment structure and any associated costs.

- Clarify delivery timelines: Ensure that both parties agree on production and delivery schedules to avoid potential delays.

Step 7: Establish a Communication Plan

Finally, create a communication plan to maintain consistent and open dialogue with your supplier throughout the production process. This will help you monitor progress and address any issues promptly.

- Set up regular check-ins: Schedule updates to discuss production status and any changes to specifications.

- Utilize project management tools: Consider using digital platforms for tracking progress and enhancing collaboration.

By following this checklist, international B2B buyers can effectively source custom panels while minimizing risks and ensuring quality. Each step is designed to build a solid foundation for successful procurement, tailored to the unique needs of your business.

Comprehensive Cost and Pricing Analysis for panel custom Sourcing

What Are the Key Cost Components in Panel Custom Sourcing?

When sourcing custom panels, understanding the cost structure is critical for international B2B buyers. The primary cost components include:

-

Materials: The choice of raw materials significantly impacts pricing. High-quality materials may lead to higher costs but can enhance durability and performance, justifying the expense over time.

-

Labor: Labor costs vary by region. For example, manufacturing in countries with lower labor costs can reduce overall expenses. However, ensure that the quality of workmanship meets your standards.

-

Manufacturing Overhead: This includes costs related to utilities, factory maintenance, and administrative expenses. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Initial investments in molds and dies for custom designs can be substantial. However, this cost can be amortized over larger production runs, making it more economical in the long term.

-

Quality Control (QC): Investing in rigorous QC processes is essential for ensuring product quality. While it adds to initial costs, it can prevent costly returns and reputational damage.

-

Logistics: Shipping and handling costs can vary widely based on distance, weight, and shipping method. Consider local regulations and tariffs that may affect your total logistics expenses.

-

Margin: Suppliers will include a profit margin in their pricing. Understanding the market rate can help you negotiate better deals.

How Do Price Influencers Affect Panel Custom Costs?

Several factors can influence the pricing of custom panels, making it essential for buyers to consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically reduce per-unit costs. If feasible, consolidate orders to take advantage of economies of scale.

-

Specifications and Customization: Highly customized products often incur higher costs due to additional design and manufacturing complexities. Clearly define your specifications to get accurate quotes.

-

Materials and Quality Certifications: Premium materials and certified products command higher prices. Buyers should weigh the benefits of certifications against their budget constraints.

-

Supplier Factors: The supplier’s reputation, reliability, and geographic location can all influence pricing. Conduct due diligence to ensure you partner with a trustworthy supplier.

-

Incoterms: The terms of shipping can significantly affect costs. Familiarize yourself with terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) to understand who bears various costs during transit.

What Are Essential Buyer Tips for Cost-Efficiency in Panel Custom Sourcing?

To navigate the complexities of panel custom sourcing effectively, consider the following tips:

-

Negotiate Wisely: Establish a transparent relationship with suppliers. Use your understanding of cost components and price influencers to negotiate better terms.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider long-term factors like maintenance, durability, and potential replacement costs to get a true sense of value.

-

Understand Pricing Nuances: Different regions may have unique pricing structures and standards. Buyers from Africa, South America, the Middle East, and Europe should be aware of local market conditions and expectations.

-

Stay Informed About Market Trends: Keep abreast of market fluctuations, material costs, and supply chain disruptions. This knowledge can empower you during negotiations and sourcing decisions.

Disclaimer on Indicative Prices

Pricing in the panel custom sourcing industry can vary widely based on the factors discussed above. The figures mentioned are indicative and should be used as a guideline. Always request detailed quotes from suppliers to ensure accurate budgeting for your specific needs.

Alternatives Analysis: Comparing panel custom With Other Solutions

Understanding the Importance of Alternatives in B2B Solutions

In the fast-paced world of B2B transactions, especially for international buyers from regions like Africa, South America, the Middle East, and Europe, evaluating alternatives is crucial. While ‘panel custom’ may be an effective solution, understanding how it stacks up against other available technologies or methods can empower buyers to make informed decisions that align with their operational needs and budget constraints.

Comparison Table: Evaluating ‘Panel Custom’ Against Other Solutions

| Comparison Aspect | ‘Panel Custom’ | Alternative 1: Modular Panels | Alternative 2: Fixed Panels |

|---|---|---|---|

| Performance | High customization for specific needs | Moderate customization; quicker installation | High durability but limited customization |

| Cost | Higher initial investment; long-term ROI | Moderate cost; more affordable upfront | Lower upfront cost but potential long-term maintenance costs |

| Ease of Implementation | Requires skilled labor; longer setup time | Easier to install; less skilled labor required | Quick installation but less flexibility |

| Maintenance | Low maintenance; tailored support | Moderate maintenance; some parts may need replacement | High maintenance; wear and tear can be significant |

| Best Use Case | Specialized environments needing flexibility | Temporary setups or exhibitions | Permanent installations with minimal changes |

What Are the Pros and Cons of Modular Panels Compared to ‘Panel Custom’?

Modular panels provide a flexible alternative to ‘panel custom’, particularly in environments where adaptability is key. The primary advantage is their ease of installation, which allows for faster project completion and minimal downtime. However, while they offer moderate customization options, they may not meet the specific needs of businesses requiring highly specialized solutions. Additionally, the upfront cost is generally lower, making it an appealing choice for budget-conscious buyers. The downside is that modular panels may not perform as well in extreme conditions or specialized applications compared to a fully customized solution.

How Do Fixed Panels Stack Up Against ‘Panel Custom’?

Fixed panels are another alternative worth considering, especially for businesses looking for a low-cost solution. These panels are durable and ideal for permanent installations where changes are infrequent. The main benefit is their lower initial cost and straightforward installation process. However, they come with significant limitations in terms of customization, which can hinder operational flexibility. Over time, fixed panels may incur higher maintenance costs due to wear and tear, making them less economical in the long run compared to ‘panel custom’, which is designed for longevity and tailored support.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting between ‘panel custom’ and its alternatives, B2B buyers should carefully evaluate their specific operational requirements, budget constraints, and long-term goals. Consider factors like the expected lifespan of the solution, the environment in which it will be used, and the level of customization needed. For instance, businesses in rapidly evolving sectors may benefit more from ‘panel custom’ due to its adaptability, while those with stable environments might find fixed panels more cost-effective. Ultimately, the right choice will depend on a thorough assessment of how each solution aligns with the organization’s strategic objectives and operational realities.

Essential Technical Properties and Trade Terminology for panel custom

What Are the Key Technical Properties of Custom Panels?

When considering custom panels for your business needs, understanding the essential technical properties is crucial for ensuring quality and performance. Here are some critical specifications that international B2B buyers should be aware of:

1. Material Grade

Material grade refers to the specific classification of the raw materials used in panel production. For instance, aluminum panels may have grades such as 5052 or 6061, which denote their strength and corrosion resistance. The right material grade is vital for durability and can significantly impact the overall lifespan of the product. Buyers should ensure that the material meets industry standards to prevent future failures.

2. Tolerance

Tolerance specifies the allowable deviation from a standard measurement. For custom panels, maintaining tight tolerances is essential, especially in applications requiring precision fit, such as in aerospace or automotive industries. Understanding tolerance levels helps buyers ensure that the panels will fit seamlessly into existing structures or systems, reducing the risk of costly adjustments.

3. Thickness

Panel thickness can affect not only the strength but also the weight and insulation properties of the panel. Buyers must consider the application of the panel when selecting thickness. For instance, thicker panels may be necessary for structural applications, while thinner panels could suffice for decorative purposes. Assessing the right thickness can lead to better performance and cost efficiency.

4. Surface Finish

The surface finish of a panel impacts both aesthetics and functionality. Common finishes include powder coating, anodizing, and laminating. Each finish serves different purposes, such as enhancing corrosion resistance or providing a specific aesthetic appeal. Selecting the appropriate surface finish is essential for meeting environmental conditions and achieving the desired look.

5. Fire Rating

Fire rating indicates the panel’s ability to withstand fire exposure. In many regions, especially in commercial construction, compliance with fire safety regulations is mandatory. Understanding the fire rating of panels ensures that they meet legal standards and provide safety for occupants. Buyers should inquire about certifications and test results to confirm compliance.

What Are Common Trade Terms Relevant to Custom Panels?

Familiarity with trade terminology is just as important as understanding technical properties. Here are some common terms that international B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, partnering with an OEM can ensure high-quality products tailored to specific requirements. Understanding the role of OEMs is crucial for establishing reliable supply chains.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of products that a supplier is willing to sell. This term is particularly important for buyers looking to manage costs effectively. Understanding MOQ can help in budgeting and inventory management, ensuring that businesses do not overstock or understock essential materials.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products. Crafting a detailed RFQ can facilitate competitive pricing and ensure that all suppliers provide comparable offers. This process is vital for making informed purchasing decisions and negotiating better terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in international transactions. These terms dictate who is responsible for shipping, insurance, and tariffs, which can greatly affect overall costs. Familiarity with Incoterms helps buyers understand their obligations and rights in a transaction.

5. Lead Time

Lead time refers to the total time required to fulfill an order, from the moment it is placed to delivery. Understanding lead times is critical for planning and inventory management, especially in regions where supply chain disruptions may occur. Buyers should communicate clearly with suppliers about lead times to align production schedules effectively.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions that lead to successful procurement strategies in the custom panel market.

Navigating Market Dynamics and Sourcing Trends in the panel custom Sector

What Are the Current Market Dynamics and Key Trends in the Panel Custom Sector?

The panel custom sector is witnessing significant growth driven by several global factors. An increase in demand for tailored solutions across various industries, including construction, automotive, and consumer electronics, has propelled this market. Additionally, the rise of Industry 4.0 and advancements in digital manufacturing technologies, such as 3D printing and automation, are transforming sourcing processes. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, must stay attuned to these technological advancements to remain competitive.

Emerging trends include the shift towards just-in-time production and the adoption of agile supply chain strategies. This allows companies to respond swiftly to market fluctuations and customer demands, reducing lead times and inventory costs. Moreover, there is a growing emphasis on customization, with buyers seeking unique solutions that align with their specific operational needs. For B2B buyers in Africa and South America, understanding local market dynamics and establishing partnerships with reliable suppliers can enhance their sourcing strategies. Conversely, European buyers may benefit from leveraging established supply chains and technological innovations to optimize their operations.

How Is Sustainability Shaping Sourcing Strategies in the Panel Custom Sector?

Sustainability and ethical sourcing have become paramount in the panel custom sector, reflecting broader global environmental concerns. The environmental impact of manufacturing processes, particularly in terms of waste and resource depletion, has prompted buyers to seek suppliers committed to sustainable practices. This includes using eco-friendly materials, minimizing carbon footprints, and ensuring responsible waste management.

Ethical supply chains are equally important, as consumers increasingly demand transparency regarding sourcing practices. Certifications such as FSC (Forest Stewardship Council) and ISO 14001 (Environmental Management) are gaining traction among buyers looking for assurance that their suppliers adhere to environmental and ethical standards. For B2B buyers, particularly in regions like the Middle East and Europe, prioritizing suppliers with these certifications can enhance brand reputation and customer trust. Furthermore, incorporating sustainable practices into sourcing strategies can lead to cost savings in the long run, making it a win-win situation.

How Has the Panel Custom Sector Evolved Over Time?

The evolution of the panel custom sector can be traced back to the early days of industrial manufacturing, where standardization was the norm. Over the decades, the industry has transitioned towards customization, driven by technological advancements and changing consumer preferences. The introduction of computer-aided design (CAD) and other digital tools has allowed for greater flexibility in production processes, enabling manufacturers to create bespoke solutions that cater to specific client needs.

As globalization progressed, international trade agreements and technological diffusion facilitated the rise of a more interconnected market. This has allowed B2B buyers from Africa, South America, the Middle East, and Europe to access a wider array of suppliers and innovative technologies, ultimately enriching the customization landscape. Understanding this historical context can help buyers navigate current market dynamics more effectively, ensuring they are well-equipped to make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of panel custom

-

How do I solve the challenge of sourcing high-quality panel custom suppliers?

To effectively source high-quality panel custom suppliers, begin by conducting thorough research online and leveraging platforms like LinkedIn or industry-specific directories. Evaluate potential suppliers based on their reputation, client reviews, and case studies that showcase their previous work. Request samples to assess the quality of materials and craftsmanship. Additionally, consider setting up a visit to their facilities if feasible, which can provide insights into their production capabilities and quality assurance processes. -

What is the best way to evaluate panel custom suppliers for my business needs?

Evaluating panel custom suppliers involves assessing several key criteria. Start with their experience and expertise in your specific industry, as this can affect their understanding of your requirements. Review their production capacity, lead times, and adherence to quality standards. Additionally, inquire about their customization capabilities, technology used, and certifications. A strong communication track record is also vital, as it ensures that your needs are understood and addressed promptly throughout the partnership. -

What are common minimum order quantities (MOQs) for panel custom products?

Minimum order quantities (MOQs) for panel custom products can vary significantly based on the supplier and the complexity of the customization. Generally, MOQs can range from a few dozen to several hundred units. It’s essential to discuss your specific needs with potential suppliers, as many are willing to negotiate MOQs for first-time buyers or for ongoing partnerships. Keep in mind that larger orders may lead to better pricing and more favorable terms. -

How can I ensure quality assurance in my panel custom orders?

To ensure quality assurance in your panel custom orders, implement a multi-faceted approach. Start with clear specifications and detailed drawings to communicate your requirements. Request regular updates during the production process and, if possible, schedule on-site inspections. Additionally, consider third-party quality assurance services that can conduct inspections before shipment. Establishing a reliable feedback loop with your supplier can help address any quality concerns promptly. -

What payment terms should I expect when sourcing panel custom products?

Payment terms can vary widely among suppliers, but typical arrangements may include a deposit upon order confirmation, with the balance due before or upon delivery. Some suppliers may offer net payment terms, allowing a period (such as 30 or 60 days) for payment after receipt of goods. Always clarify payment terms upfront and consider using secure payment methods to protect your investment. Negotiating favorable terms can help manage cash flow effectively. -

What logistics considerations should I be aware of when importing panel custom products?

When importing panel custom products, logistics considerations include shipping methods, customs clearance, and delivery timelines. Evaluate the most suitable shipping options based on cost and urgency, whether by air or sea. Work with a reliable freight forwarder who understands the customs regulations in your destination country to avoid delays. Additionally, factor in potential duties and taxes that may apply, as these can impact your overall costs. -

How do I handle communication barriers with international panel custom suppliers?

To handle communication barriers with international panel custom suppliers, prioritize clarity and simplicity in your discussions. Utilize visual aids like drawings or prototypes to convey your ideas effectively. Establish a single point of contact to streamline communication and avoid confusion. Consider employing translation services if language differences pose significant challenges. Regular check-ins via video calls can also enhance understanding and foster a collaborative relationship. -

What are the key trends in the panel custom industry that international buyers should be aware of?

International buyers should be aware of several key trends in the panel custom industry, including a growing demand for sustainable materials and eco-friendly production practices. Technological advancements, such as automation and digital fabrication, are also transforming the manufacturing landscape, allowing for more precise customizations and faster turnaround times. Additionally, the rise of e-commerce is influencing supply chain dynamics, prompting suppliers to enhance their online presence and streamline order processes. Understanding these trends can help buyers make informed sourcing decisions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for panel custom

In navigating the complexities of the panel custom market, international B2B buyers must prioritize strategic sourcing to ensure they not only meet their operational needs but also enhance their competitive edge. Key takeaways from this guide emphasize the importance of understanding supplier capabilities, leveraging global sourcing networks, and fostering strong relationships with manufacturers. By adopting a strategic sourcing approach, buyers can mitigate risks associated with supply chain disruptions, manage costs effectively, and ensure compliance with regional regulations.

What does the future hold for panel custom sourcing in diverse markets? As industries evolve, particularly in Africa, South America, the Middle East, and Europe, the demand for innovative, high-quality panel solutions will continue to grow. Buyers should remain vigilant about emerging trends, such as sustainability and technological advancements, which can impact sourcing decisions.

As you strategize your sourcing initiatives, consider engaging with local suppliers and exploring partnerships that align with your business goals. Embrace the opportunities that arise from a well-structured sourcing strategy, and be proactive in adapting to the dynamic market landscape. Your success in the panel custom sector hinges on your ability to innovate and adapt—start transforming your sourcing strategy today!