Transform Your Datsun Pickup Custom: The Ultimate Guide (2025)

Introduction: Navigating the Global Market for datsun pickup custom

Navigating the complexities of sourcing Datsun pickup customs presents a unique challenge for international B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. These buyers often face hurdles such as varying supplier standards, fluctuating costs, and the need for tailored specifications to meet local demands. This guide is designed to empower businesses by providing a comprehensive overview of the Datsun pickup custom market, detailing types, applications, and essential considerations for successful procurement.

Within these pages, you will find in-depth insights on the various models available, their adaptability across industries, and how to effectively vet suppliers to ensure quality and reliability. Additionally, we will explore cost structures, including factors that influence pricing, and strategies for negotiating favorable terms. This resource aims to streamline the purchasing process, equipping buyers with the knowledge needed to make informed decisions that align with their operational needs and budget constraints.

By addressing the specific challenges faced by B2B buyers in different regions, this guide not only enhances understanding but also fosters confidence in navigating the global market for Datsun pickup customs. Whether you are looking to enhance your fleet or expand your product offerings, the information provided will serve as a valuable tool in your sourcing journey.

Understanding datsun pickup custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Datsun 620 Custom | Compact size, lightweight, enhanced suspension | Urban deliveries, small business transport | Pros: Cost-effective, easy to maneuver. Cons: Limited cargo capacity. |

| Datsun 720 Custom | Increased payload capacity, larger engine options | Construction, landscaping, heavy-duty tasks | Pros: Robust build, versatile. Cons: Fuel efficiency may vary. |

| Datsun 510 Custom | Classic design, customizable interiors and exteriors | Vintage restorations, promotional vehicles | Pros: Aesthetic appeal, brand nostalgia. Cons: Parts availability can be an issue. |

| Datsun King Cab Custom | Extended cab for additional passenger space | Family-owned businesses, transport services | Pros: Comfort for passengers, spacious. Cons: May be pricier due to size. |

| Datsun Diesel Custom | Diesel engine for better fuel economy and torque | Long-haul transport, agricultural use | Pros: Economical for long distances. Cons: Higher initial investment. |

What are the key features of the Datsun 620 Custom for B2B buyers?

The Datsun 620 Custom is known for its compact size and lightweight design, making it an excellent choice for urban deliveries and small business transport. Its enhanced suspension allows for better handling on city roads, which is crucial for businesses that require frequent stops and starts. Buyers should consider its cost-effectiveness and maneuverability, though they should also keep in mind its limited cargo capacity, which may not suit all logistics needs.

How does the Datsun 720 Custom stand out for heavy-duty applications?

The Datsun 720 Custom features an increased payload capacity and larger engine options, making it ideal for construction, landscaping, and other heavy-duty tasks. Its robust build allows it to handle demanding environments while providing versatility for various applications. While it offers a strong performance, B2B buyers should weigh its fuel efficiency, which may fluctuate depending on usage and load.

Why is the Datsun 510 Custom popular among vintage restorers?

The Datsun 510 Custom is celebrated for its classic design and the ability to customize both interiors and exteriors. This makes it a favored option for vintage restorations and promotional vehicles, appealing to businesses looking to enhance brand nostalgia. While its aesthetic appeal is a significant advantage, buyers should be cautious about parts availability, as sourcing specific components can be challenging.

What advantages does the Datsun King Cab Custom offer for transport services?

The Datsun King Cab Custom features an extended cab design, providing additional passenger space, making it suitable for family-owned businesses and transport services. This model balances comfort with utility, allowing for longer trips without sacrificing passenger experience. However, B2B buyers should consider that the increased size may lead to higher costs compared to standard models.

How does the Datsun Diesel Custom benefit long-haul transportation?

The Datsun Diesel Custom is equipped with a diesel engine, which offers better fuel economy and higher torque, making it an excellent choice for long-haul transport and agricultural use. Its economical fuel consumption is particularly appealing for businesses that operate over extended distances. Nevertheless, potential buyers should be prepared for a higher initial investment, which may affect budget planning.

Related Video: CA18DET Swapped 1984 Datsun Sunny Custom Pickup Truck

Key Industrial Applications of datsun pickup custom

| Industry/Sector | Specific Application of datsun pickup custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Transporting produce and equipment | Enhanced mobility and reduced transport costs | Durability for rough terrains, fuel efficiency, capacity |

| Construction | Hauling construction materials | Increased efficiency in site operations | Load capacity, reliability, aftermarket support |

| Retail & Distribution | Last-mile delivery solutions | Improved delivery times and customer satisfaction | Payload capacity, fuel economy, vehicle customization |

| Mining | Personnel transport and equipment hauling | Safety and efficiency in remote locations | Off-road capability, maintenance support, sourcing parts |

| Tourism | Shuttle services for travel groups | Enhanced customer experience and service quality | Comfort features, seating capacity, reliability |

How is Datsun Pickup Custom Used in Agriculture?

In the agricultural sector, the Datsun pickup custom is primarily utilized for transporting produce from farms to markets, as well as moving farming equipment. Its robust build and adaptability make it suitable for navigating rough rural terrains, which is essential for farmers in regions such as Africa and South America. Buyers in this sector should consider the vehicle’s durability, fuel efficiency, and payload capacity to ensure it meets the demands of their operations.

What Role Does Datsun Pickup Custom Play in Construction?

The construction industry benefits significantly from the Datsun pickup custom, which is often used to haul materials such as bricks, sand, and tools to job sites. Its ability to carry substantial loads while maintaining reliability makes it a preferred choice for contractors. B2B buyers in this sector should prioritize load capacity and reliability, as well as the availability of aftermarket support to minimize downtime during critical projects.

How Does Datsun Pickup Custom Enhance Retail and Distribution?

For retail and distribution businesses, the Datsun pickup custom serves as an effective solution for last-mile delivery. Its compact size allows it to navigate urban environments easily, improving delivery times and enhancing customer satisfaction. Buyers should focus on payload capacity and fuel economy when sourcing these vehicles, as these factors directly impact operational costs and service quality.

In What Ways is Datsun Pickup Custom Used in Mining?

In the mining industry, the Datsun pickup custom is essential for transporting personnel and hauling equipment to remote sites. Its off-road capability ensures safe travel in challenging environments, making it a valuable asset for mining operations in the Middle East and Africa. Buyers should consider maintenance support and the availability of spare parts when sourcing vehicles for this demanding sector.

How is Datsun Pickup Custom Utilized in Tourism?

The tourism sector employs the Datsun pickup custom for shuttle services, providing transport for travel groups between hotels, attractions, and airports. Its comfort features and reliability enhance the overall customer experience, making it an attractive option for tour operators. When sourcing these vehicles, B2B buyers should evaluate seating capacity and the vehicle’s overall reliability to ensure high-quality service delivery.

Related Video: Industrial automation with collaborative robots – Pick and place

3 Common User Pain Points for ‘datsun pickup custom’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Datsun Pickup Custom Parts

The Problem: B2B buyers often face challenges when sourcing high-quality parts for Datsun pickup customs. This is particularly true in regions like Africa and South America, where local suppliers may not consistently offer reliable or authentic parts. Buyers may encounter counterfeit components, leading to vehicle inefficiency, increased maintenance costs, or even safety hazards.

The Solution: To mitigate this issue, buyers should establish relationships with trusted suppliers who specialize in Datsun vehicles. Conduct thorough research by checking online reviews and requesting samples of parts before committing to larger orders. Additionally, consider joining forums or communities dedicated to Datsun pickups, where experienced owners share insights on reputable suppliers. Utilizing platforms like Alibaba or local trade shows can also help in finding verified suppliers. Furthermore, ensure that the parts come with warranties or guarantees to safeguard your investment.

Scenario 2: Navigating Customization Regulations and Compliance

The Problem: Customizing Datsun pickups can be an enticing prospect, but B2B buyers often struggle with understanding the local regulations and compliance standards that govern vehicle modifications. This is particularly prevalent in the Middle East and Europe, where regulatory frameworks can vary significantly. Non-compliance can lead to fines, vehicle impoundment, or costly rework.

The Solution: Buyers should familiarize themselves with the specific regulations in their region regarding vehicle modifications. This includes understanding emissions standards, safety requirements, and any necessary inspections. Engaging with local automotive consultants or legal advisors who specialize in vehicle modifications can provide valuable insights. Additionally, when planning customizations, keep documentation of all modifications and ensure that any parts used are certified. This proactive approach will help ensure compliance and avoid unnecessary complications.

Scenario 3: Managing Installation and Technical Expertise

The Problem: Another common pain point for B2B buyers is the lack of technical expertise needed to install custom parts on Datsun pickups. Many buyers may not have access to skilled labor, leading to improper installations that can compromise vehicle performance and safety. This is especially critical for businesses relying on these vehicles for transportation or logistics.

The Solution: To address this challenge, buyers should consider partnering with experienced automotive workshops that specialize in Datsun pickups. Research local workshops through online reviews or industry referrals to ensure they have a solid reputation. It’s also beneficial to invest in training for in-house technicians or staff, ensuring they are equipped with the necessary skills for installation. Look for workshops that offer training sessions or technical workshops focused on Datsun customization. Additionally, suppliers of custom parts often provide installation guides or support, which can be invaluable for ensuring a successful installation. By prioritizing skill development and collaboration with experts, businesses can enhance the longevity and reliability of their customized Datsun pickups.

Strategic Material Selection Guide for datsun pickup custom

When selecting materials for Datsun pickup custom applications, it is crucial to consider properties that influence performance, durability, and cost-effectiveness. Below is an analysis of four common materials used in this context, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Steel for Datsun Pickup Custom Applications?

Steel is a widely used material in automotive applications due to its excellent strength-to-weight ratio. Key properties include high tensile strength, good ductility, and resistance to deformation under load. It can withstand high temperatures and pressures, making it suitable for various components such as frames and body panels.

Pros and Cons of Using Steel

Pros:

– Durability: Steel components can endure harsh conditions, making them ideal for rugged environments.

– Cost-Effectiveness: Steel is generally less expensive compared to other materials, which can lower overall production costs.

Cons:

– Corrosion Resistance: Steel is prone to rusting unless treated, which may increase maintenance costs.

– Weight: Steel is heavier than some alternatives, potentially affecting fuel efficiency.

How Does Aluminum Compare as a Material Choice for Datsun Pickup Custom?

Aluminum is another popular choice, especially for components requiring lightweight characteristics. It offers excellent corrosion resistance and thermal conductivity, making it suitable for parts like engine blocks and heat exchangers.

Pros and Cons of Using Aluminum

Pros:

– Lightweight: Reduces overall vehicle weight, enhancing fuel efficiency.

– Corrosion Resistance: Naturally forms a protective oxide layer that prevents rust.

Cons:

– Cost: Aluminum is typically more expensive than steel, impacting budget considerations.

– Manufacturing Complexity: Requires specialized techniques for welding and machining, potentially increasing production time.

What Are the Benefits of Using Composite Materials in Datsun Pickup Custom?

Composite materials, such as fiberglass and carbon fiber, are increasingly used in automotive applications for their unique properties. They offer high strength while being significantly lighter than metals.

Pros and Cons of Using Composites

Pros:

– High Strength-to-Weight Ratio: Ideal for performance applications where weight savings are critical.

– Corrosion Resistance: Composites do not rust and can withstand harsh chemicals.

Cons:

– Cost: Generally more expensive to produce, which can limit their use in budget-sensitive projects.

– Manufacturing Challenges: Requires specialized skills and equipment for fabrication.

What Considerations Should International B2B Buyers Keep in Mind for Material Selection?

International B2B buyers must consider local regulations and compliance standards, such as ASTM (American Society for Testing and Materials), DIN (Deutsches Institut für Normung), and JIS (Japanese Industrial Standards). Understanding these standards is crucial for ensuring product safety and performance. Additionally, regional preferences for materials may vary; for instance, buyers in Europe may prioritize lightweight materials for fuel efficiency, while those in Africa may focus on durability and repairability due to challenging road conditions.

Summary Table of Material Selection for Datsun Pickup Custom

| Material | Typical Use Case for datsun pickup custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Frame and body panels | High durability and strength | Prone to corrosion without treatment | Low |

| Aluminum | Engine blocks and heat exchangers | Lightweight and corrosion-resistant | Higher cost and complex manufacturing | Med |

| Composites | Performance parts and body kits | High strength-to-weight ratio | Expensive and challenging to manufacture | High |

| Plastic | Interior components and non-structural parts | Cost-effective and versatile | Lower strength and durability compared to metals | Low |

This analysis provides a comprehensive overview of the materials suitable for Datsun pickup custom applications, helping international B2B buyers make informed decisions based on their specific requirements and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for datsun pickup custom

What are the Main Stages in the Manufacturing Process of Datsun Pickup Custom?

The manufacturing process for the Datsun Pickup Custom involves several critical stages that ensure the vehicle meets quality and performance standards. Understanding these stages is essential for international B2B buyers seeking reliable suppliers.

Material Preparation

The first step in the manufacturing process is material preparation. High-quality raw materials, such as steel, aluminum, and plastics, are sourced from reputable suppliers. The selection of materials is crucial, as it affects the vehicle’s durability and performance. Buyers should inquire about the suppliers’ sourcing practices to ensure they are using materials that meet international standards.

Forming Techniques

Once the materials are prepared, the next stage involves various forming techniques. This includes stamping, bending, and welding to create the vehicle’s body and components. Advanced technologies, such as Computer Numerical Control (CNC) machines and robotic welding, are often employed to enhance precision and reduce human error. B2B buyers should consider suppliers that utilize these technologies, as they can lead to better quality and consistency in the final product.

Assembly Process

The assembly process is where all the components come together. This stage typically follows a production line system, where each team is responsible for specific tasks such as installing the engine, suspension, and interior fittings. Effective assembly processes are critical for ensuring that the vehicle operates efficiently. Buyers should look for suppliers that have streamlined assembly operations and can provide details about their production capacity and lead times.

Finishing Touches

Finally, the finishing stage includes painting, quality inspections, and final assembly checks. This stage not only enhances the vehicle’s aesthetic appeal but also serves to protect against rust and corrosion. Suppliers often use eco-friendly paints and coatings to meet environmental regulations. Buyers should confirm that their suppliers adhere to such practices, as this reflects a commitment to sustainability.

How is Quality Assurance Implemented in the Manufacturing of Datsun Pickup Custom?

Quality assurance (QA) is paramount in the manufacturing of Datsun Pickup Custom to ensure safety, reliability, and customer satisfaction. Understanding the quality control measures in place can help B2B buyers make informed decisions.

What International Standards Should Buyers Be Aware Of?

Many manufacturers adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. This certification ensures that suppliers consistently provide products that meet customer and regulatory requirements. Additionally, industry-specific certifications such as CE marking (for European markets) and API (for automotive parts) may also be relevant. Buyers should verify that their suppliers possess these certifications as part of their due diligence.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring is conducted during the manufacturing process to identify any deviations from quality standards.

- Final Quality Control (FQC): This final inspection checks the completed vehicles against predefined quality metrics before they are shipped to customers.

By understanding these checkpoints, buyers can assess the rigor of a supplier’s quality management system.

What Common Testing Methods Are Used in Datsun Pickup Custom Manufacturing?

Various testing methods are employed to ensure the quality and performance of the Datsun Pickup Custom. Some of the most common methods include:

- Destructive Testing: This involves subjecting materials and components to extreme conditions to determine their strength and durability.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and magnetic particle inspection are used to evaluate the integrity of components without causing damage.

- Performance Testing: This includes road tests to assess vehicle handling, braking, and engine performance under various conditions.

B2B buyers should inquire about the specific testing methods used by their suppliers and request documentation of testing results to validate quality claims.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers should consider implementing the following verification methods:

Conducting Supplier Audits

Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers can create a checklist based on their quality expectations and industry standards to guide the audit process.

Requesting Quality Reports

Suppliers should be able to provide comprehensive quality reports detailing their quality control processes, testing methods, and any corrective actions taken in case of defects. These reports are essential for transparency and accountability.

Engaging Third-Party Inspection Services

For added assurance, buyers can engage third-party inspection services to evaluate supplier facilities and processes. These independent assessments can help identify any potential quality issues before orders are placed.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing from suppliers in different regions such as Africa, South America, the Middle East, and Europe, B2B buyers should be aware of regional quality control nuances. Factors such as local regulations, cultural differences in business practices, and varying levels of technological advancement can impact quality assurance processes.

Understanding Regional Standards

Buyers should familiarize themselves with local standards and regulations that may affect product quality. For instance, European buyers may need to ensure compliance with stricter environmental and safety regulations compared to those in other regions.

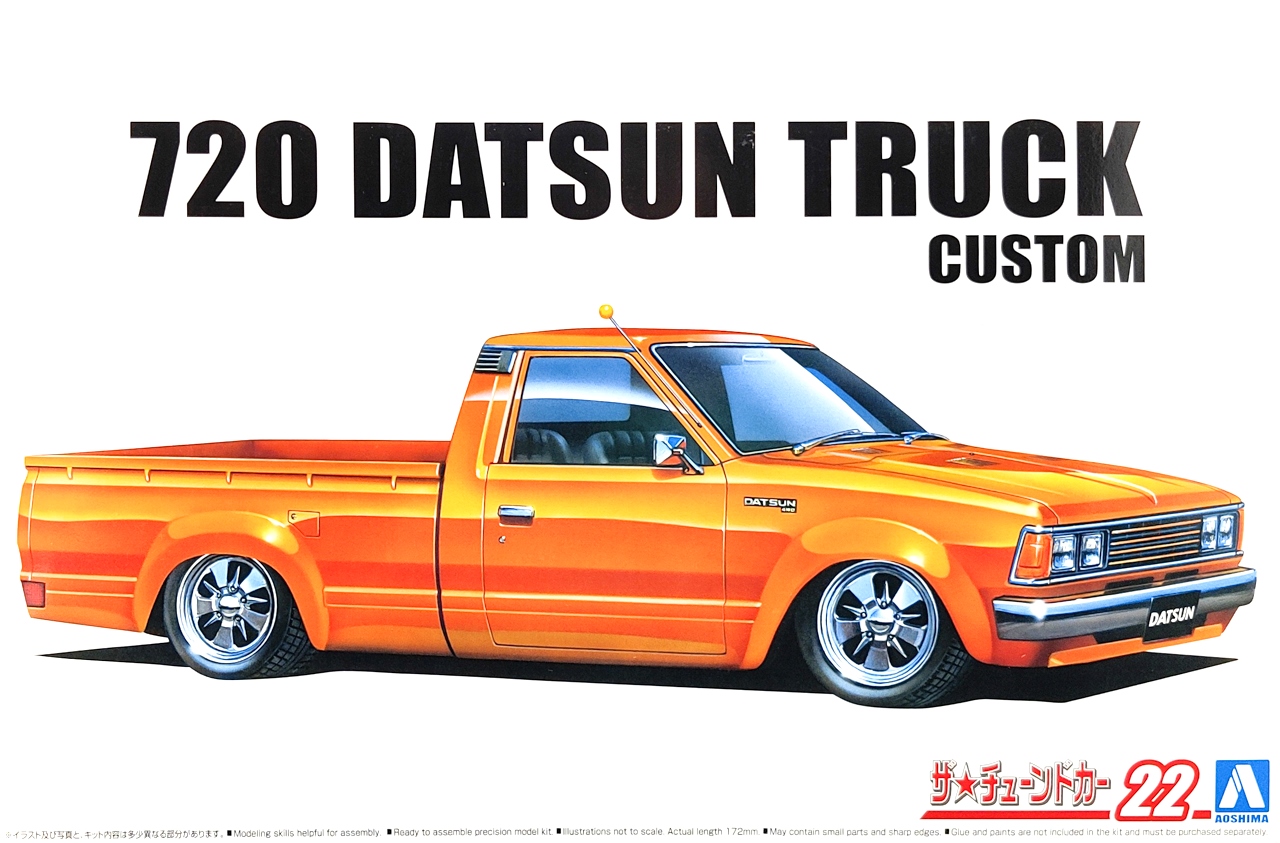

A stock image related to datsun pickup custom.

Building Strong Supplier Relationships

Establishing a good rapport with suppliers can facilitate better communication regarding quality expectations and any potential issues. Regular updates and feedback loops can help foster a culture of continuous improvement.

Conclusion

In summary, the manufacturing and quality assurance processes for the Datsun Pickup Custom are integral to ensuring product reliability and performance. By understanding the stages of manufacturing, relevant quality standards, and verification methods, international B2B buyers can make informed decisions and select suppliers that align with their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘datsun pickup custom’

Introduction

Sourcing a Datsun Pickup Custom can be a complex process, especially for international B2B buyers. This guide provides a comprehensive step-by-step checklist to streamline your procurement process, ensuring that you find a reliable supplier who meets your specific needs. By following these actionable steps, you can make informed decisions that align with your business objectives.

Step 1: Define Your Technical Specifications

Before you begin sourcing, clearly outline the technical specifications of the Datsun Pickup Custom you require. This includes dimensions, engine type, load capacity, and any custom features you may want. Having a detailed specification document helps suppliers understand your needs and reduces miscommunication.

- Consider your market: Different regions may have specific requirements regarding vehicle emissions or safety standards.

- Customization details: Specify any modifications or custom features that you need, such as paint color, interior finishes, or additional equipment.

Step 2: Conduct Market Research for Suppliers

Identifying potential suppliers is crucial in the sourcing process. Use online platforms, trade shows, and industry networks to gather a list of suppliers that specialize in Datsun vehicles or custom pickups.

- Evaluate industry reputation: Look for suppliers with a solid track record and positive reviews from previous clients.

- Consider geographical factors: Suppliers located closer to your operations may reduce shipping costs and delivery times.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is essential. Request company profiles, case studies, and references from buyers in similar industries or regions. This step ensures that you partner with a reputable supplier.

- Check certifications: Ensure suppliers comply with international quality and safety standards.

- Assess production capabilities: Confirm that the supplier can meet your volume requirements and timelines.

Step 4: Request Samples or Prototypes

If possible, request samples or prototypes of the Datsun Pickup Custom to assess the quality and craftsmanship. This step is crucial in validating that the supplier can deliver on your specifications.

- Quality inspection: Conduct a thorough inspection of the sample to ensure it meets your standards.

- Test functionality: If applicable, test any custom features to ensure they operate as intended.

Step 5: Negotiate Terms and Conditions

Once you have identified a suitable supplier, it’s time to negotiate terms and conditions. This includes pricing, payment terms, delivery schedules, and warranty information.

- Be clear on expectations: Clearly outline your expectations regarding quality and service levels to avoid future disputes.

- Consider currency fluctuations: If dealing with international suppliers, factor in potential currency risks in your negotiations.

Step 6: Finalize the Contract

After negotiations, finalize a written contract that includes all agreed-upon terms and conditions. This document should serve as a legal reference in case of any disputes.

- Review legal implications: Ensure that the contract complies with local and international laws.

- Include performance metrics: Specify performance metrics and penalties for non-compliance to protect your interests.

Step 7: Plan for Logistics and Delivery

A stock image related to datsun pickup custom.

Lastly, develop a logistics plan for the delivery of your Datsun Pickup Custom. Coordinate with your supplier to establish a clear timeline for shipment and delivery.

- Choose the right shipping method: Depending on your budget and urgency, select a shipping method that balances cost and speed.

- Prepare for customs clearance: Ensure you have all necessary documentation for customs to avoid delays upon arrival.

By following this checklist, international B2B buyers can effectively navigate the sourcing process for Datsun Pickup Customs, ensuring they find a supplier that meets their unique needs.

Comprehensive Cost and Pricing Analysis for datsun pickup custom Sourcing

What are the Key Cost Components in Datsun Pickup Custom Sourcing?

When sourcing Datsun pickups for custom orders, understanding the cost structure is crucial for effective budgeting and financial planning. The primary cost components include:

-

Materials: The quality and type of materials used significantly affect the overall cost. High-grade steel, specialized paint, and custom upholstery can increase expenses. It’s essential to assess whether sourcing locally or internationally impacts material costs.

-

Labor: Labor costs vary by region and are influenced by the skill level required for custom modifications. In regions like Africa and South America, labor might be less expensive, but the availability of skilled technicians can be a limiting factor.

-

Manufacturing Overhead: This includes utilities, rent, and administrative costs associated with production. Manufacturers with higher overhead may pass these costs onto buyers, so it’s important to inquire about their operational efficiencies.

-

Tooling: Custom tooling for specific modifications can require a significant upfront investment. Understanding whether the supplier has the necessary tools in-house or if new tooling will be required can impact pricing.

-

Quality Control (QC): Implementing stringent QC processes ensures the final product meets specifications. However, enhanced QC measures can increase costs. Buyers should weigh the value of quality assurance against potential savings.

-

Logistics: Transportation costs are a critical component, especially for international shipments. Factors like distance, shipping method, and any tariffs or customs duties need consideration.

-

Margin: Suppliers typically add a profit margin to their costs. Understanding typical margins in the industry can aid in negotiating better prices.

How Do Price Influencers Affect Datsun Pickup Custom Costs?

Several factors influence the final pricing of custom Datsun pickups:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to lower per-unit costs. It’s beneficial for buyers to negotiate MOQs to optimize pricing.

-

Specifications and Customization: The more customized a vehicle, the higher the price. Buyers should clearly define specifications to avoid unexpected costs.

-

Materials and Quality Certifications: Premium materials and certifications (like ISO or environmental compliance) can elevate costs but may also enhance resale value and durability.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their track record, but they might offer better quality and reliability.

-

Incoterms: The chosen Incoterms (like FOB, CIF) dictate who bears the shipping costs and risks. Understanding these terms can help buyers manage total costs effectively.

What Buyer Tips Can Enhance Cost-Efficiency in Datsun Pickup Custom Sourcing?

To maximize value when sourcing custom Datsun pickups, consider these actionable tips:

-

Effective Negotiation: Always negotiate prices and terms. Suppliers may have flexibility, especially for larger orders or long-term contracts.

-

Evaluate Total Cost of Ownership (TCO): Look beyond initial purchase prices. Consider maintenance, fuel efficiency, and depreciation when assessing the overall cost of the pickup.

-

Understand Pricing Nuances for International Buyers: Different regions may have unique pricing structures. For example, buyers in the Middle East may face different import tariffs compared to those in Europe. Researching these nuances can lead to substantial savings.

-

Build Relationships with Suppliers: Long-term partnerships can lead to better pricing, priority service, and improved communication, which is invaluable when modifications are required.

-

Request Detailed Quotes: Ensure all cost components are itemized in supplier quotes. This transparency allows for better comparisons and negotiation.

Disclaimer on Indicative Prices

Prices for custom Datsun pickups can vary widely based on specifications, supplier, and market conditions. It is advisable for buyers to conduct comprehensive market research and obtain multiple quotes to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing datsun pickup custom With Other Solutions

When considering the purchase of a vehicle like the Datsun Pickup Custom, it’s essential to explore various alternatives that meet similar operational needs. This analysis will help international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, make informed decisions based on performance, cost, and other critical factors.

Comparison of Datsun Pickup Custom with Alternative Solutions

| Comparison Aspect | Datsun Pickup Custom | Toyota Hilux | Ford Ranger |

|---|---|---|---|

| Performance | Good load capacity and reliability | Excellent off-road capabilities and engine options | Strong towing capacity and advanced safety features |

| Cost | Competitive pricing | Higher price point | Moderate pricing |

| Ease of Implementation | Straightforward with local dealers | Well-supported with extensive service network | Requires familiarization with advanced features |

| Maintenance | Low maintenance costs | Higher costs due to advanced technology | Moderate maintenance costs with good parts availability |

| Best Use Case | Ideal for local deliveries and agriculture | Best for rugged terrains and off-road use | Suitable for heavy-duty tasks and long-distance travel |

Detailed Breakdown of Alternatives

What are the advantages of the Toyota Hilux?

The Toyota Hilux is renowned for its durability and off-road prowess. With a robust build and a reputation for reliability, it can handle rough terrains, making it a favorite among businesses in agriculture and construction. However, its higher price point may be a barrier for some buyers, especially those looking for a cost-effective solution. Additionally, while it offers extensive service support, the complexity of some features may require more training for operators.

How does the Ford Ranger compare in terms of capabilities?

The Ford Ranger stands out for its towing capacity and advanced safety features, appealing to businesses that require a vehicle for heavy-duty tasks and long-distance journeys. Its moderate pricing makes it an attractive option, but potential buyers should note that the advanced technology may necessitate additional training for staff. The Ranger’s maintenance costs are reasonable, but parts may not be as widely available in remote areas compared to other brands.

Conclusion: How to Choose the Right Vehicle for Your Business Needs

When selecting between the Datsun Pickup Custom and its alternatives, B2B buyers should evaluate their specific operational requirements. Factors such as budget, intended use (e.g., urban deliveries versus off-road capabilities), and the availability of service and parts in their region should guide their decision. By understanding the strengths and weaknesses of each vehicle, businesses can make informed choices that align with their strategic goals and operational needs.

Essential Technical Properties and Trade Terminology for datsun pickup custom

What Are the Key Technical Properties of Datsun Pickup Custom?

When considering the procurement of Datsun pickup customs, understanding the essential technical specifications is crucial for making informed purchasing decisions. Here are some key properties to consider:

1. Material Grade

The material grade, typically referring to the type of steel or aluminum used in the vehicle’s construction, impacts durability, weight, and overall performance. High-strength steel may be preferred for enhanced resilience against impacts, while aluminum can reduce weight for better fuel efficiency. For B2B buyers, selecting the right material is vital for ensuring the vehicle meets operational demands and regulatory standards.

2. Engine Capacity

Engine capacity, measured in liters (L), determines the power output and efficiency of the vehicle. A higher engine capacity often correlates with greater towing capacity and better performance in rugged terrains, essential for buyers in regions with challenging driving conditions. Understanding engine specifications can help buyers assess whether the vehicle aligns with their logistical needs.

3. Payload Capacity

Payload capacity indicates the maximum weight the vehicle can safely carry, including cargo and passengers. This specification is critical for businesses that rely on transport for goods. A vehicle with insufficient payload capacity can lead to operational inefficiencies and potential legal issues, making it imperative for B2B buyers to evaluate this aspect thoroughly.

4. Fuel Efficiency

Fuel efficiency, usually expressed in miles per gallon (MPG) or liters per 100 kilometers (L/100 km), is a critical factor for cost management in fleet operations. Vehicles with higher fuel efficiency reduce operational costs, making them more appealing to businesses. Buyers should compare fuel consumption ratings to optimize long-term expenses.

5. Towing Capacity

Towing capacity refers to the maximum weight a vehicle can tow safely. This is particularly important for businesses that need to transport trailers or heavy equipment. Understanding the towing specifications can help buyers ensure that the Datsun pickup custom can meet their operational requirements without compromising safety.

Which Trade Terminology Should B2B Buyers Understand When Purchasing Datsun Pickup Customs?

Familiarity with industry terminology can significantly streamline the procurement process. Here are several key terms to know:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM status can help buyers ensure they are sourcing genuine parts for repairs or upgrades, thereby maintaining vehicle integrity and performance.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is particularly relevant for B2B buyers who may need to purchase multiple vehicles or parts. Being aware of MOQ can help businesses plan their budgets and inventory needs effectively.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to solicit price quotes for specific products or services. It is a crucial tool for B2B buyers, enabling them to compare prices, negotiate terms, and make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Understanding these terms is essential for B2B buyers to clarify shipping responsibilities, risk, and costs associated with the delivery of Datsun pickup customs.

5. Lead Time

Lead time refers to the amount of time from the initiation of an order to the completion of delivery. This is a critical factor for businesses that rely on timely vehicle availability for operations. Buyers should inquire about lead times to ensure they can meet their operational timelines.

By understanding these technical properties and trade terminologies, B2B buyers can make more informed decisions regarding Datsun pickup customs, ultimately leading to better procurement strategies and operational efficiencies.

Navigating Market Dynamics and Sourcing Trends in the datsun pickup custom Sector

What Are the Current Market Dynamics and Key Trends in the Datsun Pickup Custom Sector?

The Datsun pickup custom sector is experiencing significant evolution driven by global market dynamics. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly looking for vehicles that combine utility with customization options. Key trends include the rise of e-commerce platforms that facilitate direct sourcing from manufacturers, enabling buyers to customize their orders according to specific needs. Additionally, digital tools such as virtual showrooms and augmented reality applications are enhancing the purchasing experience, allowing buyers to visualize customizations before making a commitment.

Emerging markets, especially in Africa and South America, are witnessing a surge in demand for light commercial vehicles, particularly pickups that can handle diverse terrains and heavy loads. This has prompted manufacturers to offer more tailored solutions, focusing on durability and efficiency. The Middle East’s growing logistics sector is also a key driver, as businesses require reliable vehicles for transporting goods across vast distances. European buyers are increasingly prioritizing fuel efficiency and environmental impact, leading to a demand for electric and hybrid models within the Datsun lineup.

How Can Sustainability and Ethical Sourcing Impact the Datsun Pickup Custom Sector?

Sustainability and ethical sourcing are becoming critical considerations for B2B buyers in the Datsun pickup custom sector. The environmental impact of vehicle production is under scrutiny, and companies are seeking to minimize their carbon footprint by opting for suppliers that utilize sustainable practices. This includes sourcing materials that are recycled or derived from renewable resources, as well as ensuring that production processes adhere to stringent environmental regulations.

Buyers should consider suppliers that offer ‘green’ certifications, which can serve as indicators of a commitment to sustainability. Certifications such as ISO 14001 (Environmental Management) and materials with recycled content can enhance the credibility of sourcing decisions. Furthermore, ethical supply chains that prioritize fair labor practices and community engagement are increasingly important to consumers and businesses alike. By choosing partners who align with these values, B2B buyers can not only meet regulatory requirements but also build a positive brand image that resonates with environmentally conscious customers.

What Is the Evolution of the Datsun Pickup Custom Sector?

The evolution of the Datsun pickup custom sector reflects broader trends in the automotive industry. Originally launched in the mid-20th century, Datsun vehicles were known for their reliability and affordability. Over the years, the brand has adapted to changing consumer preferences, integrating technology and customization options to meet the demands of modern buyers.

In recent years, the resurgence of the Datsun brand has focused on revitalizing its image while maintaining its core values of durability and cost-effectiveness. This shift has been particularly relevant in emerging markets where the demand for versatile and customizable vehicles has grown. As the sector continues to evolve, international B2B buyers can expect more innovative solutions that cater to their specific business needs, supported by a commitment to sustainability and ethical practices.

Frequently Asked Questions (FAQs) for B2B Buyers of datsun pickup custom

-

How do I ensure the quality of Datsun pickup customs when sourcing internationally?

To ensure quality when sourcing Datsun pickup customs, begin by vetting suppliers through thorough research. Request samples to assess craftsmanship and quality. Look for suppliers with certifications or those who adhere to international quality standards. Establishing clear quality assurance protocols, including inspections during production and before shipping, can further ensure that the final product meets your expectations. Additionally, consider visiting the manufacturing facility if possible, or hire third-party inspection services to validate quality. -

What are the common customization options available for Datsun pickups?

Customization options for Datsun pickups typically include modifications to the chassis, engine enhancements, and aesthetic upgrades such as paint jobs, body kits, and interior finishes. Buyers can also request specific features like advanced infotainment systems, upgraded suspension for better performance, or enhanced cargo space. It’s crucial to communicate your specific needs to the supplier, as their capabilities may vary. Always confirm the customization options in writing to avoid misunderstandings later in the process. -

What should I consider when negotiating payment terms for Datsun pickups?

When negotiating payment terms for Datsun pickups, consider the total cost, including shipping, customs duties, and any additional fees. Discuss options such as partial upfront payments with the balance upon delivery or before shipment. Ensure that the payment terms are aligned with your cash flow needs. Using secure payment methods, such as letters of credit or escrow services, can provide additional protection for both parties. Always document all agreed terms to prevent disputes. -

How can I assess the minimum order quantity (MOQ) requirements from suppliers?

To assess the minimum order quantity (MOQ) requirements from suppliers, inquire directly with them regarding their policies. MOQs can vary significantly based on the supplier’s production capabilities and inventory levels. If the MOQ seems high, discuss your needs and see if they can accommodate smaller orders, especially if you’re a new buyer. Some suppliers may be willing to negotiate, especially if you can demonstrate the potential for larger future orders. -

What logistics considerations should I keep in mind when importing Datsun pickups?

When importing Datsun pickups, logistics considerations include understanding shipping options, transit times, and customs clearance processes. Determine the best mode of transportation—sea freight is often cost-effective for bulk shipments, while air freight can expedite delivery for smaller quantities. Additionally, ensure you have a clear understanding of the import regulations and tariffs in your destination country. Partnering with a reliable logistics provider can streamline the process and help navigate complex customs requirements. -

What are the key factors to consider when vetting suppliers of Datsun pickups?

Key factors to consider when vetting suppliers include their experience in the industry, reputation, production capacity, and compliance with international standards. Request references from previous clients and check online reviews to gauge their reliability. Additionally, assess their financial stability and ability to provide after-sales support. Conducting a factory audit can also help you understand their operational processes and quality control measures. -

How do I handle disputes with suppliers of Datsun pickups?

Handling disputes with suppliers requires a structured approach. Start by reviewing your contract to understand the agreed-upon terms. Open communication is crucial; discuss the issue directly with the supplier to seek a resolution. If direct negotiation fails, consider mediation or arbitration as outlined in your contract. Document all interactions and agreements to support your case. In severe cases, legal action may be necessary, but this should be a last resort due to time and cost implications. -

What are the benefits of sourcing Datsun pickups directly from manufacturers versus local dealers?

Sourcing Datsun pickups directly from manufacturers often provides cost savings, as it eliminates middlemen and associated markups. It also allows for greater customization options and direct communication regarding specifications and production timelines. However, local dealers may offer advantages such as established relationships, easier access to after-sales service, and reduced shipping costs. Evaluate your business needs, volume requirements, and the importance of customization when deciding between the two sourcing options.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for datsun pickup custom

In the evolving landscape of the Datsun pickup custom market, strategic sourcing stands out as a critical component for international B2B buyers. By leveraging a well-defined sourcing strategy, businesses can enhance cost efficiency, ensure quality control, and build long-term relationships with reliable suppliers. It is essential to recognize that sourcing not only impacts the bottom line but also influences customer satisfaction through improved product availability and customization options.

What Are the Key Takeaways for International Buyers?

For buyers from Africa, South America, the Middle East, and Europe, understanding regional market dynamics and supplier capabilities is paramount. Engaging with local suppliers can facilitate quicker turnaround times and reduced logistics costs. Furthermore, investing in supplier relationship management can lead to innovation and improved customization in the Datsun pickup offerings, catering to specific market needs.

How to Prepare for Future Opportunities in Sourcing?

Looking ahead, international B2B buyers should actively explore partnerships that emphasize sustainability and ethical sourcing practices. Embracing technology and data analytics can enhance decision-making processes, enabling buyers to adapt swiftly to market changes. By prioritizing strategic sourcing, businesses can not only secure a competitive edge but also contribute positively to their communities and the environment.

Seize the opportunity to refine your sourcing strategies today and position your business for future success in the Datsun pickup custom market.