Transform Your Marketing: Custom Acrylic Displays Guide (2025)

Introduction: Navigating the Global Market for acrylic displays custom

In the increasingly competitive landscape of global commerce, sourcing custom acrylic displays poses a significant challenge for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. With a multitude of options available, international buyers must navigate complexities related to product quality, supplier reliability, and cost-effectiveness. This guide serves as a comprehensive resource, designed to empower businesses by providing insights into various types of acrylic displays, their applications across different industries, and essential supplier vetting processes.

Understanding the nuances of acrylic displays is crucial, as they are often utilized in retail, exhibitions, and promotional events. This guide will delve into the diverse applications of acrylic displays, helping buyers identify the best solutions for their specific needs. Furthermore, it will address critical factors influencing cost, ensuring that buyers can make informed decisions without compromising on quality. By equipping international B2B buyers with actionable insights and strategies for sourcing acrylic displays, this guide aims to enhance purchasing efficiency and foster successful business partnerships. Whether you’re operating in Kenya, Spain, or beyond, the information provided will help you optimize your sourcing process and achieve a competitive edge in your market.

Understanding acrylic displays custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Acrylic Display Cases | Enclosed structure, often lockable, highly transparent | Retail, museums, trade shows | Pros: Protects items, enhances visibility. Cons: Higher cost than open displays. |

| Acrylic Sign Holders | Lightweight, versatile, available in various sizes | Offices, restaurants, retail environments | Pros: Easy to change signage, cost-effective. Cons: Less durable than other materials. |

| Acrylic Stands | Freestanding, can be customized in shape and size | Events, exhibitions, point-of-sale | Pros: Eye-catching, customizable. Cons: Stability can be an issue with larger sizes. |

| Acrylic Shelving | Wall-mounted or freestanding, available in various thicknesses | Retail displays, showrooms | Pros: Maximizes space, enhances product visibility. Cons: Installation may require professional help. |

| Acrylic Brochure Holders | Multi-pocket designs, often wall-mounted or countertop | Offices, hotels, tourist information centers | Pros: Organizes literature, easy access. Cons: Limited capacity compared to other options. |

What Are the Characteristics of Acrylic Display Cases?

Acrylic display cases are designed to showcase products while providing protection from dust and damage. They are often lockable, making them suitable for high-value items in retail or museum settings. Their high transparency ensures that the displayed items are visible from all angles, enhancing the customer experience. When purchasing, B2B buyers should consider the size, locking mechanism, and overall design to ensure it aligns with their branding and security needs.

How Do Acrylic Sign Holders Serve Businesses?

Acrylic sign holders are lightweight and versatile, making them ideal for displaying promotional materials in various business environments. They come in different sizes and orientations, allowing businesses to showcase everything from menus to informational signage. Their ease of use makes it simple to update content, which is crucial for businesses that frequently change promotions. Buyers should look for holders that offer durability and a professional appearance to maintain brand integrity.

Why Choose Acrylic Stands for Promotions?

Acrylic stands are customizable and can be tailored to fit specific promotional needs, making them a popular choice for events and exhibitions. They can be designed in various shapes and sizes, allowing businesses to create unique displays that draw attention. While they are visually appealing, buyers should consider the stability of the stand, especially for larger displays, to ensure they can withstand various environments without tipping over.

What Are the Advantages of Acrylic Shelving?

Acrylic shelving is an excellent solution for maximizing space in retail displays and showrooms. Its clear design allows products to be showcased effectively without obstructing the view. This type of shelving can be wall-mounted or freestanding, depending on the layout of the space. When selecting acrylic shelving, B2B buyers should consider the thickness of the material and the weight capacity to ensure it meets their display needs.

How Do Acrylic Brochure Holders Enhance Information Access?

Acrylic brochure holders are designed to organize and display literature effectively in offices, hotels, and tourist information centers. With multi-pocket designs, they allow for easy access to various brochures, making them practical for customer engagement. While they provide a neat and organized appearance, buyers should be aware of the limited capacity compared to larger display solutions. Choosing the right design can significantly enhance the accessibility of information for customers.

Related Video: How To Create a Clear Acrylic Display Box Centerpiece | BalsaCircle.com

Key Industrial Applications of acrylic displays custom

| Industry/Sector | Specific Application of acrylic displays custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Point of Sale Displays | Enhances product visibility, attracting more customers | Customization options, durability, and design flexibility |

| Events and Exhibitions | Trade Show Booths | Creates an engaging brand presence, facilitates interaction | Lightweight materials, ease of transport, and assembly |

| Healthcare | Informational Signage | Improves patient navigation and enhances safety | Compliance with health regulations, clarity, and visibility |

| Hospitality | Menu and Service Displays | Elevates customer experience and promotes offerings | Weather-resistant options, aesthetic appeal, and durability |

| Education | Educational Displays | Facilitates learning by presenting information clearly | Custom sizes, educational content adaptability, and safety features |

How Are Acrylic Displays Custom Used in Retail Point of Sale?

Acrylic displays custom are pivotal in retail settings, particularly as point-of-sale (POS) displays. They are designed to enhance product visibility, drawing customers’ attention to promotions and new arrivals. For international B2B buyers from regions like Africa and South America, sourcing durable and customizable acrylic displays can significantly improve sales performance. Retailers should consider factors such as the display’s design flexibility, resistance to wear and tear, and the ability to showcase products effectively in diverse environments.

What Benefits Do Acrylic Displays Provide at Events and Exhibitions?

In the context of events and exhibitions, custom acrylic displays serve as trade show booths that create an engaging brand presence. These displays facilitate interaction with potential clients and provide essential information about products or services. For buyers in the Middle East and Europe, sourcing lightweight and easy-to-assemble acrylic displays is crucial for maximizing ROI at events. Key considerations include the display’s portability, ease of setup, and the potential for customization to fit branding needs.

How Do Acrylic Displays Enhance Healthcare Environments?

In healthcare settings, acrylic displays custom are used for informational signage that improves patient navigation and enhances safety. These displays can help guide patients through complex facilities and communicate essential information clearly. International buyers, especially from regions like Africa and Europe, must ensure that the displays comply with health regulations while being visually clear and accessible. Key sourcing considerations include visibility, durability against cleaning products, and the ability to withstand high-traffic environments.

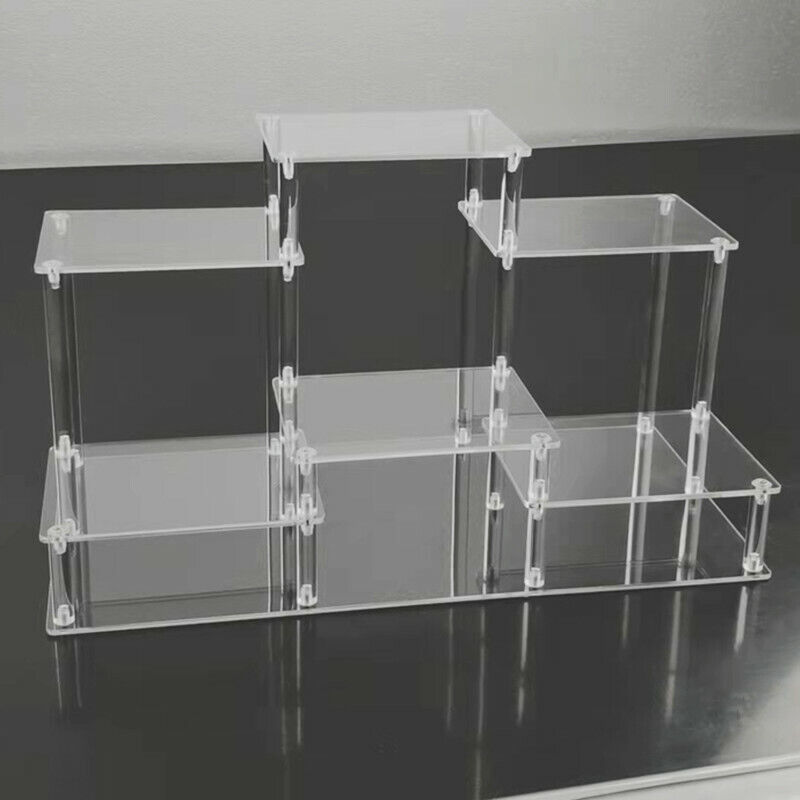

A stock image related to acrylic displays custom.

What Role Do Acrylic Displays Play in Hospitality?

In the hospitality industry, acrylic displays custom are utilized for menu and service displays, elevating the customer experience. These displays can promote daily specials or highlight signature dishes, making them an essential tool for restaurants and cafes. Buyers from South America and Europe should prioritize weather-resistant options to ensure longevity and aesthetic appeal. Considerations such as design, ease of cleaning, and the ability to adapt displays for seasonal changes are also critical for successful sourcing.

How Are Acrylic Displays Custom Used in Education?

In educational settings, acrylic displays custom are employed to create educational displays that facilitate learning by presenting information clearly and engagingly. These displays can be used for showcasing student projects, educational materials, or important announcements. For international B2B buyers, particularly from regions like Kenya and Spain, sourcing custom sizes and adaptable displays that can accommodate changing content is essential. Safety features, clarity, and the ability to withstand classroom conditions are key factors to consider when sourcing these products.

Related Video: Elegant Acrylic LED Decoration – How to Make a Edge Light Sign Emblem

3 Common User Pain Points for ‘acrylic displays custom’ & Their Solutions

Scenario 1: Difficulty in Customization for Unique Branding Needs

The Problem: Many B2B buyers struggle with sourcing acrylic displays that align with their specific branding requirements. When a company wants to showcase a new product or service, they often need displays that reflect their unique brand colors, logos, and design aesthetics. This challenge is particularly prominent in diverse markets across Africa, South America, and Europe, where local tastes and preferences can significantly differ. Buyers frequently find that off-the-shelf solutions do not meet their needs, leading to dissatisfaction and wasted investments.

The Solution: To effectively address this issue, buyers should prioritize working with manufacturers or suppliers who specialize in custom acrylic displays. Begin by gathering detailed specifications that include dimensions, colors, and any logos or graphics that need to be incorporated. Engage in a collaborative design process with the supplier, utilizing 3D modeling tools to visualize the final product before production. This proactive approach not only ensures that the display aligns with branding goals but also allows for adjustments to be made early in the process, saving time and costs associated with revisions. Additionally, consider suppliers that offer rapid prototyping services, which can further enhance the customization experience.

Scenario 2: Concerns About Durability and Environmental Factors

The Problem: B2B buyers often face concerns regarding the durability of acrylic displays, especially in environments exposed to extreme temperatures, humidity, or direct sunlight. For instance, businesses in regions like the Middle East may require displays that can withstand high heat and UV exposure without warping or discoloring. Such environmental challenges can lead to premature wear and necessitate frequent replacements, resulting in increased operational costs.

The Solution: To mitigate these durability concerns, buyers should seek acrylic displays specifically formulated for enhanced weather resistance and UV stability. When sourcing, inquire about the material properties, such as the use of anti-yellowing additives or UV inhibitors that extend the lifespan of the product. It’s also beneficial to understand the manufacturing processes; some suppliers offer thicker acrylic options or use multi-layered designs that provide additional strength. Additionally, consider implementing a routine maintenance schedule to clean and inspect displays regularly, which can help preserve their appearance and functionality over time.

Scenario 3: High Shipping Costs and Logistics Challenges

The Problem: For international B2B buyers, especially those located in Africa and South America, shipping costs and logistics can pose significant challenges when ordering acrylic displays. The delicate nature of acrylic materials makes them susceptible to damage during transit, leading to fears of receiving broken or unusable products. Moreover, high shipping fees can strain budgets, particularly for small to medium-sized enterprises.

The Solution: To overcome these logistical hurdles, buyers should explore local suppliers or manufacturers that can produce acrylic displays within their region. This not only reduces shipping costs but also minimizes the risk of damage during transit. When selecting a supplier, check for those who offer robust packaging solutions designed specifically for acrylic products. Additionally, consider negotiating bulk orders or long-term contracts that can help lower overall shipping rates. For buyers in remote areas, using freight forwarding services that specialize in fragile goods can further streamline the delivery process, ensuring that displays arrive in perfect condition and on time.

Strategic Material Selection Guide for acrylic displays custom

When selecting materials for custom acrylic displays, it’s essential to evaluate various options based on their properties, advantages, disadvantages, and how they align with the specific needs of international B2B buyers. Below, we analyze several common materials used in the production of acrylic displays, focusing on their performance characteristics, suitability for various applications, and considerations for buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Acrylic Material for Displays?

Acrylic, also known as polymethyl methacrylate (PMMA), is a widely used material for custom displays due to its excellent transparency and lightweight nature. It can withstand temperatures ranging from -40°C to 80°C, making it suitable for various environments. Acrylic is also resistant to UV light, which prevents yellowing over time, ensuring that displays maintain their clarity and aesthetic appeal.

What Are the Pros and Cons of Using Polycarbonate for Displays?

Polycarbonate is another popular material that offers superior impact resistance compared to acrylic. It can withstand temperatures from -40°C to 120°C, making it suitable for outdoor applications. However, polycarbonate is more expensive than acrylic and can scratch easily, which may necessitate additional protective coatings.

- Pros: High impact resistance, excellent thermal stability.

- Cons: Higher cost, prone to scratching.

How Does PETG Compare as a Material for Acrylic Displays?

Polyethylene Terephthalate Glycol (PETG) is a thermoplastic that combines the best attributes of acrylic and polycarbonate. It is known for its good chemical resistance and can handle temperatures up to 70°C. PETG is also easier to fabricate than acrylic, making it a preferred choice for intricate designs. However, it may not offer the same level of clarity as acrylic.

- Pros: Good chemical resistance, ease of fabrication.

- Cons: Lower clarity compared to acrylic.

What Specific Considerations Should International Buyers Keep in Mind?

For international B2B buyers, compliance with regional standards is crucial. Buyers from Africa, South America, the Middle East, and Europe should ensure that the materials they choose meet local regulations such as ASTM (American Society for Testing and Materials), DIN (Deutsches Institut für Normung), and JIS (Japanese Industrial Standards). Additionally, preferences may vary; for instance, European buyers may prioritize sustainability and recyclability, while buyers in the Middle East might focus on durability in harsh climates.

Summary Table of Material Properties

| Material | Typical Use Case for acrylic displays custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Acrylic | Retail displays, signage, and point-of-sale materials | High transparency and UV resistance | Less impact-resistant than polycarbonate | Medium |

| Polycarbonate | Outdoor signage and protective displays | Superior impact resistance | Higher cost and prone to scratching | High |

| PETG | Custom shapes and chemical-resistant displays | Good chemical resistance and easy fabrication | Lower clarity compared to acrylic | Medium |

In conclusion, understanding the properties, advantages, and limitations of each material is essential for making informed decisions in the selection of acrylic displays. By considering regional compliance and specific application needs, international B2B buyers can ensure that their custom displays are not only visually appealing but also functional and durable.

In-depth Look: Manufacturing Processes and Quality Assurance for acrylic displays custom

What Are the Key Manufacturing Processes for Custom Acrylic Displays?

The manufacturing of custom acrylic displays involves several critical stages that ensure the final product meets the specific requirements of B2B buyers. Understanding these processes can help buyers make informed decisions when sourcing from suppliers, especially in regions like Africa, South America, the Middle East, and Europe.

How Is Material Prepared for Acrylic Displays?

The first step in the manufacturing process is material preparation. Acrylic, also known as polymethyl methacrylate (PMMA), is available in sheets or granules. Suppliers typically select high-quality acrylic sheets that offer superior clarity and durability. The sheets are then cut to size using precision cutting tools, ensuring minimal waste and exact dimensions.

Additionally, suppliers may opt for special treatments or coatings on acrylic sheets to enhance properties such as UV resistance or anti-scratch capabilities. Buyers should inquire about the types of acrylic used and any treatments applied, as these factors significantly impact the product’s performance and longevity.

What Forming Techniques Are Used in Acrylic Display Manufacturing?

Once the materials are prepared, the next stage is forming. This process can involve various techniques, including:

-

Thermoforming: Acrylic sheets are heated until pliable and then shaped into the desired form using molds. This method is ideal for creating complex shapes and is commonly used for display cases and stands.

-

Laser Cutting: For intricate designs, laser cutting is employed. This technique offers precision and clean edges, which are crucial for aesthetic appeal in display products.

-

Injection Molding: In cases where high volumes of displays are needed, injection molding may be used. This process allows for consistent production of complex shapes and is efficient for large orders.

Buyers should evaluate the forming techniques used by suppliers, as these methods directly influence the quality and functionality of the displays.

How Are Acrylic Displays Assembled and Finished?

After forming, the next stage is assembly. This process may involve joining multiple acrylic parts using adhesives or mechanical fasteners. Suppliers often employ specialized techniques to ensure that joints are invisible and maintain the display’s aesthetic quality.

Finishing processes include polishing edges, applying surface treatments, and adding any necessary branding or graphics. Effective finishing not only enhances the visual appeal but also improves durability. Buyers should ask about the finishing options available, as this can be a differentiating factor in the final product.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance (QA) is paramount in the production of acrylic displays. International standards such as ISO 9001 provide a framework for quality management systems, ensuring that manufacturers maintain consistent quality in their processes.

In addition to ISO standards, industry-specific certifications like CE mark for European markets and API standards for specific applications may apply. Buyers should verify that their suppliers adhere to these standards, as this reflects a commitment to quality and safety.

What Are the Key QC Checkpoints in Acrylic Display Manufacturing?

Quality control (QC) checkpoints are established throughout the manufacturing process to ensure product integrity. Common QC checkpoints include:

-

Incoming Quality Control (IQC): Before production, raw materials are inspected for compliance with specifications. This step is crucial for ensuring that only high-quality acrylic is used.

-

In-Process Quality Control (IPQC): During manufacturing, real-time inspections are conducted to identify any deviations from standards. This includes checking dimensions, clarity, and structural integrity.

-

Final Quality Control (FQC): After assembly and finishing, the final products undergo rigorous testing. This may involve visual inspections, functional tests, and packaging checks to ensure they meet buyer specifications.

B2B buyers should request documentation of these QC processes from suppliers to ensure transparency and accountability.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s QC practices is essential for mitigating risks in international trade. Buyers can take the following steps:

-

Conduct Supplier Audits: On-site audits allow buyers to assess the supplier’s facilities, equipment, and quality management systems directly. This is particularly important for buyers from regions with varying standards.

-

Request Quality Reports: Suppliers should provide detailed reports of their QC processes, including results from IQC, IPQC, and FQC. This documentation serves as evidence of compliance with international standards.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality processes and product quality. This is especially beneficial for buyers who may not have the capacity to conduct audits themselves.

What Are the QC and Certification Nuances for International Buyers?

B2B buyers from Africa, South America, the Middle East, and Europe must be aware of specific certification and QC nuances when sourcing acrylic displays. For instance, understanding regional regulations regarding product safety, environmental impact, and materials used is crucial.

Additionally, buyers should be aware of the import/export regulations that may affect their orders. Ensuring that suppliers can provide the necessary documentation for customs clearance and compliance with local laws is vital for smooth transactions.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed choices, ensuring they receive high-quality acrylic displays that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘acrylic displays custom’

When sourcing custom acrylic displays, it’s essential to follow a structured approach to ensure you select the best suppliers and products for your business needs. This guide provides a step-by-step checklist to facilitate your sourcing process, tailored for international B2B buyers from Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Start by clearly outlining what you need from your custom acrylic displays. Consider dimensions, thickness, color, and design features. Having detailed specifications will help suppliers provide accurate quotes and ensure the final product meets your expectations.

- Consider usage scenarios: Will the displays be used indoors or outdoors? This can affect material choice.

- Design complexity: Determine if you need simple designs or more intricate customizations.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in acrylic displays. Use industry directories, trade shows, and online platforms to create a list of potential candidates.

- Evaluate their experience: Look for suppliers with a proven track record in your desired market.

- Check customer reviews: Feedback from previous clients can provide insights into reliability and quality.

Step 3: Verify Supplier Certifications

Before engaging with suppliers, verify their certifications to ensure compliance with industry standards. This step is crucial to mitigate risks associated with quality and safety.

- ISO certifications: Ensure the supplier adheres to international quality management standards.

- Material safety certifications: Check if the acrylic materials used meet safety regulations relevant to your region.

Step 4: Request Samples

Always request samples of acrylic displays before placing a bulk order. This allows you to assess the quality of materials and craftsmanship firsthand.

- Evaluate clarity and finish: Ensure the acrylic is clear and free from imperfections.

- Assess durability: Check the sturdiness and how well the sample stands up to handling.

Step 5: Discuss Pricing and Payment Terms

Engage in discussions about pricing structures and payment terms with your shortlisted suppliers. Transparency in pricing can prevent unexpected costs later on.

- Consider total cost of ownership: Look beyond the initial price; consider shipping, duties, and potential import taxes.

- Negotiate payment terms: Aim for terms that align with your cash flow needs, such as deposits or installment payments.

Step 6: Review Production and Delivery Timelines

Understand the production capabilities and delivery timelines of each supplier. Timely delivery is crucial for maintaining your project schedules.

- Ask about lead times: Ensure the supplier can meet your deadlines.

- Discuss logistics: Clarify how the products will be shipped and who will bear the costs.

Step 7: Establish Clear Communication Channels

Finally, establish effective communication channels with your chosen supplier. Clear communication is vital for addressing any issues that may arise during production.

- Set regular updates: Schedule check-ins to discuss progress and any potential challenges.

- Use collaborative tools: Consider using project management software to streamline communication.

By following these steps, you can enhance your sourcing process for custom acrylic displays, ensuring you find a reliable supplier that meets your specific needs. This checklist serves as a foundation for making informed purchasing decisions and fostering successful business relationships.

Comprehensive Cost and Pricing Analysis for acrylic displays custom Sourcing

What Are the Key Cost Components in Acrylic Displays Custom Sourcing?

When sourcing custom acrylic displays, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The cost of acrylic sheets varies significantly based on quality, thickness, and supplier. High-grade acrylic, which offers superior clarity and durability, will naturally incur higher costs. Buyers should consider the specific application of the displays to determine the appropriate material grade.

-

Labor: Labor costs depend on the complexity of the design and the location of manufacturing. For instance, countries with lower labor costs may offer competitive pricing but might compromise on skill levels and craftsmanship.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and other operational expenses. Efficient manufacturing processes can help reduce these overhead costs, which can be passed on to the buyer.

-

Tooling: Custom molds and tools for production can represent a significant upfront investment. This is especially relevant for complex designs that require specialized tooling. Buyers should negotiate tooling costs, as they can be amortized over larger production runs.

-

Quality Control (QC): Ensuring that the displays meet quality standards involves additional costs. This may include testing materials and final products, which is essential for maintaining brand integrity, especially in markets like Europe and North America.

-

Logistics: Shipping costs can be considerable, particularly for international buyers. Factors such as distance, mode of transport, and packaging will influence logistics costs. It is advisable to consider Incoterms that define the responsibilities of buyers and sellers regarding shipping.

-

Margin: Suppliers will add a profit margin on top of their costs, which can vary widely based on market conditions and competition. Understanding the market landscape can help buyers gauge reasonable margins.

How Do Price Influencers Affect Acrylic Displays Custom Sourcing?

Several factors influence pricing for custom acrylic displays:

-

Volume/MOQ: Minimum order quantities (MOQ) can affect unit pricing significantly. Higher order volumes often lead to lower per-unit costs, allowing buyers to achieve better pricing through bulk purchasing.

-

Specifications/Customization: Highly customized displays will naturally incur higher costs. Buyers should balance the need for customization with budget constraints, possibly standardizing certain features to reduce costs.

-

Materials and Quality Certifications: The choice of materials impacts not only the cost but also the quality certifications that may be required for certain markets. Higher quality materials may require additional certifications, which can increase costs.

-

Supplier Factors: The reputation and reliability of suppliers play a crucial role. Established suppliers may charge a premium due to their proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the terms of sale, such as FOB (Free On Board) or CIF (Cost, Insurance, Freight), is essential as they determine who bears the shipping costs and risks, impacting the total landed cost.

What Buyer Tips Should Be Considered for Cost-Efficiency?

International B2B buyers should consider the following strategies to optimize costs:

-

Negotiation: Engage suppliers in discussions about pricing, especially if you can commit to larger volumes. Establishing long-term partnerships may also yield better terms.

-

Total Cost of Ownership (TCO): Evaluate not just the initial purchase price, but the entire lifecycle cost of the displays, including maintenance, replacement, and shipping. This holistic view can reveal hidden costs.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and trade agreements that could affect pricing. Buyers from regions like Africa or South America should research local regulations that may impact costs.

-

Supplier Diversification: Consider sourcing from multiple suppliers to mitigate risks and leverage competitive pricing. This approach can also help in understanding different market conditions and pricing strategies.

Disclaimer on Indicative Prices

Prices for custom acrylic displays can vary widely based on the aforementioned factors. It is essential for buyers to conduct thorough market research and obtain multiple quotes to ensure they are receiving a fair price. Always account for regional variations and specific project requirements when budgeting for custom acrylic displays.

Alternatives Analysis: Comparing acrylic displays custom With Other Solutions

A stock image related to acrylic displays custom.

Acrylic displays have become a popular choice for showcasing products due to their clarity and versatility. However, buyers should also consider alternative solutions that may better meet their specific needs, particularly in international markets. This section explores viable alternatives to custom acrylic displays, providing a detailed comparison to help B2B buyers make informed decisions.

| Comparison Aspect | Acrylic Displays Custom | Polycarbonate Displays | Glass Displays |

|---|---|---|---|

| Performance | High transparency, lightweight, durable | High impact resistance, lightweight, UV resistant | Excellent clarity, scratch-resistant |

| Cost | Moderate to high | Lower than acrylic | Higher than acrylic |

| Ease of Implementation | Requires custom fabrication | Easier to cut and mold | Requires specialized handling |

| Maintenance | Low; easy to clean | Low; resistant to scratches | Moderate; requires careful handling |

| Best Use Case | Retail displays, signage | Industrial applications, outdoor displays | High-end retail, art galleries |

What are the Advantages and Disadvantages of Polycarbonate Displays?

Polycarbonate displays are an excellent alternative to acrylic due to their high impact resistance and lower cost. They are less prone to shattering, making them ideal for high-traffic areas or settings where displays might be subject to accidental impacts. Additionally, polycarbonate is UV resistant, which helps maintain color and clarity over time. However, polycarbonate can scratch more easily than acrylic, potentially affecting appearance over time. This material is particularly suited for industrial applications or outdoor displays where durability is paramount.

How Do Glass Displays Compare to Acrylic Displays?

Glass displays are renowned for their clarity and aesthetic appeal, making them an excellent choice for high-end retail environments or art galleries. They provide an upscale appearance and are highly scratch-resistant, ensuring that products are showcased without distortion. However, glass is heavier and more fragile than acrylic, requiring careful handling during installation and maintenance. Additionally, the cost of glass displays is typically higher, which may not align with all budgets. Glass is best used when the visual impact is critical, and the environment can support its weight and fragility.

Conclusion: How to Choose the Right Display Solution for Your Needs?

When selecting a display solution, B2B buyers must consider several factors, including performance, cost, ease of implementation, and maintenance requirements. Acrylic displays offer a balanced option with excellent clarity and versatility. In contrast, polycarbonate displays are more cost-effective and durable, while glass displays provide a premium look at a higher price point. By evaluating the specific needs of their business, including the display environment and target audience, buyers can choose the solution that best aligns with their goals and operational constraints. Ultimately, understanding these alternatives will empower buyers to make strategic decisions that enhance their product presentation and overall brand image.

Essential Technical Properties and Trade Terminology for acrylic displays custom

What Are the Essential Technical Properties of Acrylic Displays Custom?

When sourcing custom acrylic displays, understanding the technical properties is crucial for ensuring that the product meets specific business needs. Here are some critical specifications to consider:

1. Material Grade

Acrylic, also known as polymethyl methacrylate (PMMA), comes in various grades. The most common are extruded and cast acrylic. Extruded acrylic is less expensive and suitable for applications requiring less optical clarity, while cast acrylic offers superior clarity and durability, making it ideal for high-end displays. Understanding the appropriate grade for your needs ensures that the display will perform well in its intended environment.

2. Thickness Tolerance

The thickness of acrylic sheets can vary widely, typically ranging from 1/8 inch to 1 inch. Tolerance levels, usually ±10%, define how much the actual thickness can deviate from specified measurements. For B2B buyers, precise thickness is vital as it affects the display’s strength, weight, and overall aesthetic appeal.

3. UV Resistance

Custom acrylic displays often require UV resistance to prevent yellowing and degradation over time. UV-stabilized acrylic is treated to resist sun exposure, making it ideal for outdoor or brightly lit environments. Ensuring that your acrylic displays have adequate UV protection extends their lifespan and maintains their visual appeal.

4. Optical Clarity

The optical clarity of acrylic is a significant factor, particularly for displays designed to showcase products. High optical clarity (often rated at 92% or higher) ensures that the colors and details of the displayed items are accurately represented. This property is essential for maintaining brand integrity and customer satisfaction.

5. Impact Resistance

Acrylic is known for its impact resistance, which is significantly greater than that of glass. This property is critical for displays placed in high-traffic areas or environments where physical contact is likely. Understanding impact resistance helps buyers assess the durability and safety of their displays.

What Common Trade Terms Should B2B Buyers Know When Sourcing Acrylic Displays?

Familiarity with trade terminology is essential for effective communication with suppliers and to ensure a smooth purchasing process. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of acrylic displays, an OEM may produce custom designs based on a buyer’s specifications, allowing for personalized branding and product presentation.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for budget planning and inventory management. Buyers should assess whether the MOQ aligns with their sales projections to avoid overstocking or stockouts.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. B2B buyers use RFQs to compare options and negotiate better deals. A well-structured RFQ can streamline the sourcing process and ensure that all necessary specifications are communicated.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations and potential risks in international transactions.

5. Customization Options

This term refers to the various ways a product can be tailored to meet specific requirements, such as size, color, or design features. When sourcing acrylic displays, knowing available customization options allows buyers to create displays that align perfectly with their branding and marketing strategies.

Understanding these technical properties and trade terms empowers B2B buyers to make informed decisions when sourcing custom acrylic displays, ultimately enhancing their business operations and customer engagement.

Navigating Market Dynamics and Sourcing Trends in the acrylic displays custom Sector

What Are the Current Market Dynamics and Key Trends in the Acrylic Displays Custom Sector?

The acrylic displays custom sector is experiencing significant transformation due to evolving market dynamics and technological advancements. Global drivers include the increasing demand for visually appealing marketing solutions, particularly in retail and exhibitions. Countries in Africa, South America, the Middle East, and Europe (notably Spain and Kenya) are witnessing a surge in investments in acrylic display solutions. This shift is largely fueled by the rise of e-commerce, which necessitates innovative display solutions to attract customers both online and in physical stores.

Emerging B2B tech trends include the integration of augmented reality (AR) and 3D printing technologies in the design and production of acrylic displays. These technologies allow businesses to create customized solutions that enhance customer engagement and optimize space utilization. Furthermore, the trend towards personalization is becoming increasingly important, with buyers seeking unique designs that reflect their brand identity. This demand for customization is pushing manufacturers to adopt flexible production processes that can accommodate small batches and rapid turnaround times.

Another noteworthy trend is the rise of online sourcing platforms. International B2B buyers are increasingly leveraging these platforms to streamline their procurement processes, compare products and prices, and access a broader range of suppliers. This shift not only enhances transparency but also allows buyers to make informed decisions based on real-time market data.

How Is Sustainability Influencing Ethical Sourcing in the Acrylic Displays Custom Sector?

Sustainability is becoming a central concern for B2B buyers in the acrylic displays custom sector. The environmental impact of acrylic production, including energy consumption and waste generation, is prompting companies to seek sustainable sourcing options. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint and implementing eco-friendly practices.

The importance of ethical supply chains cannot be overstated. Buyers are looking for manufacturers that adhere to fair labor practices and responsible sourcing of raw materials. Certifications such as ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) for acrylic sourced from sustainable forests are becoming essential in supplier evaluations.

Moreover, the use of recycled acrylic materials is gaining traction as companies aim to minimize waste and promote a circular economy. This trend not only addresses environmental concerns but also appeals to consumers’ growing preference for sustainable products, thereby enhancing brand loyalty and market positioning.

What Is the Brief Evolution of Acrylic Displays in the B2B Context?

Acrylic materials have evolved significantly since their introduction in the mid-20th century. Initially used primarily in the manufacturing of simple displays, advancements in technology and material science have expanded their applications in various sectors. Over the decades, acrylic displays have transitioned from basic signage to sophisticated, custom-designed solutions that incorporate advanced features such as LED lighting and interactive elements.

The development of acrylic manufacturing techniques has also contributed to this evolution. Innovations such as laser cutting and CNC machining have allowed for greater precision and complexity in design, enabling B2B buyers to request highly customized displays that meet specific branding and marketing needs. As a result, acrylic displays have become a crucial component of modern marketing strategies, offering businesses a versatile and visually appealing way to engage customers.

In summary, understanding these market dynamics, sustainability concerns, and the historical evolution of acrylic displays can empower international B2B buyers to make informed sourcing decisions that align with their strategic objectives.

Frequently Asked Questions (FAQs) for B2B Buyers of acrylic displays custom

-

How can I ensure the quality of custom acrylic displays?

To ensure high-quality custom acrylic displays, request samples from potential suppliers before committing to larger orders. Evaluate the clarity, thickness, and durability of the acrylic used. Additionally, inquire about the manufacturing processes and quality assurance protocols they follow. Look for certifications or testimonials from previous clients to gauge their reputation and reliability. Conducting a factory visit, if feasible, can provide further assurance of their operational standards. -

What customization options are available for acrylic displays?

Customization options for acrylic displays typically include size, shape, color, thickness, and print design. Many suppliers also offer features like lighting integration, additional compartments, or branding elements. When discussing your project, clearly communicate your requirements and ask for a portfolio of past custom projects. This will help you understand the range of possibilities and inspire ideas for your unique display needs. -

What are the minimum order quantities (MOQs) for custom acrylic displays?

Minimum order quantities can vary significantly between suppliers. Some may accept orders as low as 50 units, while others might require a minimum of 100 or more, especially for custom designs. It’s important to discuss your needs upfront and see if suppliers can accommodate lower MOQs, particularly if you’re testing a new market or product line. Many suppliers are willing to negotiate based on your specific situation. -

What payment terms should I expect when sourcing acrylic displays internationally?

Payment terms can differ based on the supplier’s policies and the total order value. Common terms include a 30-50% deposit upfront with the balance due before shipment. Some suppliers may offer letters of credit or payment through secure platforms for added protection. Always clarify payment methods and conditions in advance, and consider using escrow services for large transactions to mitigate risks. -

How can I vet suppliers of custom acrylic displays?

To vet suppliers, start by checking their online presence, including their website and customer reviews. Request references and reach out to previous clients to learn about their experiences. Conduct video calls or in-person meetings to assess their professionalism and capability. Additionally, verify their certifications and compliance with international trade regulations, especially if you’re importing from regions with different standards. -

What logistics considerations should I keep in mind for importing acrylic displays?

When importing acrylic displays, consider shipping methods, customs duties, and potential tariffs. Choose a reliable freight forwarder familiar with your destination country. Ensure that your supplier provides appropriate packaging to prevent damage during transit. Familiarize yourself with local import regulations, including any restrictions on materials, to avoid delays at customs. -

What are the common uses of custom acrylic displays in various industries?

Custom acrylic displays are widely used across numerous industries, including retail, hospitality, and corporate settings. They serve as product showcases, promotional signage, or awards and recognition displays. Their versatility allows them to be used in exhibitions, trade shows, and point-of-sale environments, enhancing visibility and engagement with customers. Understanding the specific applications can help tailor your design for maximum impact. -

How can I handle disputes with suppliers of custom acrylic displays?

To effectively handle disputes, maintain clear and open communication with your supplier. Document all agreements and correspondence, including specifications, delivery timelines, and payment terms. If a dispute arises, attempt to resolve it amicably through negotiation. Should the issue persist, refer to any contracts or agreements in place. Consider involving a third-party mediator or legal counsel if necessary, especially for significant financial disputes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for acrylic displays custom

In the competitive landscape of custom acrylic displays, strategic sourcing emerges as a pivotal factor for international B2B buyers. Understanding the unique properties of acrylic, such as its durability, transparency, and versatility, allows businesses to make informed purchasing decisions that align with their branding and operational needs. Buyers from Africa, South America, the Middle East, and Europe must prioritize sourcing partners that not only provide quality products but also demonstrate a commitment to sustainability and innovation.

Moreover, leveraging local suppliers can enhance supply chain efficiency and reduce lead times. Companies should consider integrating advanced technologies in the sourcing process, such as digital platforms that facilitate real-time communication and order tracking. This approach not only streamlines operations but also fosters stronger relationships with suppliers, ultimately leading to better pricing and service.

Looking ahead, the demand for customized acrylic displays is poised to grow as businesses seek to enhance their customer engagement through innovative and visually appealing solutions. International B2B buyers are encouraged to explore emerging markets and establish partnerships that leverage local expertise and global trends. By doing so, they can position themselves at the forefront of the industry, ready to capitalize on the evolving landscape of acrylic displays.