Transform Your Ride: The Ultimate 1963 Chevy Truck Custom Guide (2025)

Introduction: Navigating the Global Market for 1963 chevy truck custom

Navigating the global market for a 1963 Chevy truck custom presents a unique set of challenges for international B2B buyers. As demand grows for classic vehicles that combine nostalgia with modern customization options, sourcing reliable suppliers can become complex. This guide aims to demystify the procurement process by providing insights into various types of customizations, applications in different industries, and effective supplier vetting strategies.

From understanding the nuances of parts sourcing to evaluating customization capabilities, this comprehensive resource will equip buyers with the knowledge needed to make informed purchasing decisions. We explore key factors such as cost implications, quality assurance practices, and the importance of after-sales support, all crucial for businesses looking to invest in classic trucks for either resale or operational purposes.

International B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Turkey and Australia—will find tailored information that addresses their specific market dynamics. By leveraging this guide, businesses can enhance their procurement strategies, ensuring that they not only secure high-quality 1963 Chevy truck customs but also build sustainable relationships with trusted suppliers across the globe.

Understanding 1963 chevy truck custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Fleets | Multiple trucks tailored for specific industries | Logistics, Construction, Agricultural | Pros: Cost-effective for bulk purchases. Cons: Limited customization options per unit. |

| Restored Classics | Original parts, vintage aesthetics | Collectibles, Specialty Shows | Pros: High resale value, unique appeal. Cons: Higher maintenance costs, less reliability. |

| Performance Modifications | Enhanced engines, suspension upgrades | Racing, Off-Road Applications | Pros: Improved performance, tailored for specific uses. Cons: Potentially higher insurance costs. |

| Utility Customizations | Custom beds, toolboxes, and storage solutions | Trades, Service Industries | Pros: Increased functionality, tailored to business needs. Cons: May require additional investments for modifications. |

| Electric Conversions | Electric drivetrains, modern technology | Eco-Friendly Businesses, Urban Deliveries | Pros: Lower operational costs, sustainability. Cons: Initial conversion costs can be high. |

What Are the Characteristics of Custom Fleets?

Custom fleets of 1963 Chevy trucks are designed to meet the specific needs of businesses, particularly in logistics and construction. These trucks can be outfitted with specialized equipment and branding, making them ideal for companies that require uniformity across multiple vehicles. When purchasing, B2B buyers should consider the overall cost savings associated with bulk orders and the potential for tailored fleet management solutions.

How Do Restored Classics Stand Out?

Restored classics are cherished for their vintage appeal and authenticity. These trucks often feature original parts and meticulous craftsmanship, making them attractive to collectors and businesses wanting to showcase their heritage. Key purchasing considerations include the truck’s condition, documentation of restoration, and potential for appreciation in value. Buyers should weigh the pros of unique branding against the cons of ongoing maintenance.

What Are the Benefits of Performance Modifications?

Performance modifications enhance the capabilities of 1963 Chevy trucks, making them suitable for racing or off-road applications. These trucks can be fitted with advanced engines and upgraded suspensions, providing a competitive edge. B2B buyers in industries that require high-performance vehicles should evaluate the specific modifications needed for their operations and consider the long-term costs, including insurance and maintenance.

Why Consider Utility Customizations?

Utility customizations transform 1963 Chevy trucks into practical workhorses. Features like custom beds, toolboxes, and storage solutions cater to trades and service industries, enhancing functionality and efficiency. Buyers should assess their specific operational needs and the potential return on investment for these modifications. While utility customizations can increase upfront costs, they often lead to greater productivity.

What Makes Electric Conversions a Smart Choice?

Electric conversions of 1963 Chevy trucks are becoming increasingly popular due to their sustainability and lower operational costs. These trucks are equipped with electric drivetrains, making them an excellent choice for eco-friendly businesses and urban deliveries. B2B buyers should consider the initial investment for conversion against the long-term savings on fuel and maintenance, along with the growing demand for green solutions in the marketplace.

Related Video: 1963-72 Chevy & GMC Truck Longbed to Shortbed Conversion

Key Industrial Applications of 1963 chevy truck custom

| Industry/Sector | Specific Application of 1963 Chevy Truck Custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Custom transport for farm produce and equipment | Enhanced mobility and efficiency in transport | Availability of parts for modifications and repairs |

| Construction | Workhorse for transporting materials and tools | Reliable and durable vehicle for job site logistics | Compliance with local regulations and emissions standards |

| Event Management | Unique vehicle for promotional events and parades | Distinctive branding and attraction for events | Customization options for branding and durability |

| Tourism and Hospitality | Vintage truck for tours and experiences | Unique offering that enhances customer experience | Consideration of insurance and maintenance for vintage vehicles |

| Logistics and Delivery | Custom delivery vehicle for last-mile logistics | Cost-effective solution for urban deliveries | Fuel efficiency and payload capacity for specific routes |

How is the 1963 Chevy Truck Custom Used in Agriculture?

In the agricultural sector, the 1963 Chevy Truck Custom is often utilized for transporting farm produce and equipment. Its robust build and customizable features allow farmers to adapt the truck for various hauling needs, from delivering fresh produce to transporting tools and machinery. International buyers, particularly from regions like Africa and South America, must consider sourcing parts for ongoing maintenance and modifications to ensure the truck meets their specific agricultural demands.

What Role Does the 1963 Chevy Truck Custom Play in Construction?

For the construction industry, the 1963 Chevy Truck Custom serves as a reliable workhorse, adept at transporting materials and tools to job sites. Its sturdy design can handle rough terrains, making it ideal for construction environments. Businesses in Europe and the Middle East should focus on ensuring compliance with local regulations, including emissions standards, when sourcing these trucks for construction purposes.

How Can Event Management Benefit from the 1963 Chevy Truck Custom?

In event management, the 1963 Chevy Truck Custom is a standout choice for promotional events and parades. Its vintage aesthetic can enhance branding and attract attention, making it a valuable asset for event planners looking to create memorable experiences. When sourcing this vehicle, businesses should explore customization options that align with their branding strategies while ensuring the vehicle’s durability for frequent use.

Why is the 1963 Chevy Truck Custom Ideal for Tourism and Hospitality?

The tourism and hospitality sectors benefit from the 1963 Chevy Truck Custom by using it for unique tours and experiences. This vintage truck can provide tourists with a nostalgic ride, enhancing their overall experience and adding value to local attractions. Buyers from international markets must consider insurance and maintenance aspects specific to vintage vehicles to ensure a smooth operation.

How Does the 1963 Chevy Truck Custom Aid in Logistics and Delivery?

In logistics and delivery, the 1963 Chevy Truck Custom can be adapted as a cost-effective solution for last-mile deliveries in urban areas. Its ability to navigate narrow streets and deliver goods directly to customers makes it a practical choice for businesses looking to improve their delivery services. Buyers should assess the truck’s fuel efficiency and payload capacity to optimize their logistics operations effectively.

Related Video: Chevy C10 Gets lowered – Vice Grip Garage EP21

3 Common User Pain Points for ‘1963 chevy truck custom’ & Their Solutions

Scenario 1: Navigating Sourcing Challenges for Custom Parts

The Problem:

B2B buyers, particularly those in emerging markets in Africa and South America, often face significant hurdles when sourcing custom parts for a 1963 Chevy truck. The challenge lies in identifying reliable suppliers who can provide high-quality components that meet specific customization requirements. Many buyers report difficulties in verifying the authenticity of parts, leading to concerns about compatibility and performance. This situation is exacerbated by limited access to local suppliers and the risk of dealing with unscrupulous vendors.

The Solution:

To effectively navigate sourcing challenges, B2B buyers should prioritize building a network of trusted suppliers. Start by leveraging online platforms and forums dedicated to classic car restoration to gather recommendations from other enthusiasts and professionals. It’s advisable to request samples or detailed product specifications before placing bulk orders, ensuring that the parts meet quality standards. Additionally, consider attending trade shows or automotive expos where reputable vendors showcase their products. Establishing direct communication with suppliers can also facilitate negotiations and lead to better pricing or custom solutions tailored to specific needs.

Scenario 2: Overcoming Compliance and Regulatory Issues

The Problem:

B2B buyers often encounter regulatory hurdles when importing custom parts for a 1963 Chevy truck. Different countries have varying regulations regarding automotive parts, which can lead to delays, additional costs, or even confiscation of goods. Buyers from the Middle East and Europe, for example, may struggle with compliance to EU regulations or local standards that dictate safety and environmental considerations, complicating the import process significantly.

The Solution:

To mitigate compliance risks, it is essential for buyers to thoroughly research and understand the regulatory landscape of both their home country and the exporting country. Engaging with a customs broker or legal expert familiar with automotive regulations can provide invaluable insights into necessary documentation and compliance requirements. Buyers should also consider partnering with suppliers who have experience navigating these regulations and can provide guidance. Ensuring that all parts meet international quality and safety standards not only eases the import process but also enhances the product’s marketability.

Scenario 3: Ensuring Quality Control During Customization

The Problem:

Quality control is a pressing concern for B2B buyers customizing a 1963 Chevy truck. When parts are modified or custom-built, there’s always a risk that the final product will not match the specifications or quality expected. This issue can lead to costly rework, delays in project completion, and ultimately, dissatisfied customers. Buyers from regions with less stringent manufacturing standards may particularly struggle to find reliable partners who maintain high-quality craftsmanship.

The Solution:

Implementing a robust quality assurance process is crucial. Buyers should develop detailed specifications and standards for all custom parts, ensuring that suppliers understand the requirements upfront. Regular communication with suppliers during the production phase is essential; consider requesting progress updates and photos to monitor quality. If possible, perform on-site inspections or hire third-party quality control services to verify that the production aligns with your standards. Additionally, establishing a clear return policy for defective parts can safeguard against potential losses and ensure accountability from suppliers. By prioritizing quality control, buyers can significantly enhance the reliability and satisfaction of their custom truck projects.

Strategic Material Selection Guide for 1963 chevy truck custom

What Materials Are Commonly Used for Customizing a 1963 Chevy Truck?

When customizing a 1963 Chevy truck, the selection of materials is crucial to ensure durability, performance, and aesthetic appeal. Here are three common materials that international B2B buyers should consider:

How Does Steel Benefit Customization of a 1963 Chevy Truck?

Key Properties: Steel is renowned for its high strength and durability, making it an ideal choice for structural components. It typically has a temperature rating of around 2000°F (1093°C) and excellent corrosion resistance when treated.

Pros & Cons: The primary advantage of steel is its robustness, which contributes to the longevity of the vehicle. However, it can be heavy, which may affect fuel efficiency and handling. Additionally, manufacturing complexity can increase if intricate designs are required, leading to higher costs.

Impact on Application: Steel is compatible with various media, including fuels and oils, making it suitable for components like frames and body panels. However, in humid environments, unprotected steel may corrode, necessitating protective coatings.

Considerations for International Buyers: Buyers from regions such as Africa and South America should ensure that the steel complies with local standards (e.g., ASTM, DIN). Understanding the availability of treated versus untreated steel is also crucial to mitigate corrosion risks.

What Role Does Aluminum Play in Customizing a 1963 Chevy Truck?

Key Properties: Aluminum is lightweight and resistant to corrosion, with a melting point of approximately 1220°F (660°C). Its strength-to-weight ratio is excellent, making it ideal for performance applications.

Pros & Cons: The main advantage of aluminum is its lightweight nature, which enhances fuel efficiency and handling. However, it can be more expensive than steel and may require specialized welding techniques, increasing manufacturing complexity.

Impact on Application: Aluminum is particularly suitable for parts exposed to moisture, such as the engine bay and undercarriage. Its compatibility with various automotive fluids is also a plus.

Considerations for International Buyers: Buyers in Europe and the Middle East should be aware of the specific grades of aluminum used in automotive applications, ensuring compliance with standards like JIS or EN. The availability of aluminum components can vary, impacting lead times.

How Does Fiberglass Enhance Customization Options for a 1963 Chevy Truck?

Key Properties: Fiberglass is a composite material known for its lightweight and high strength-to-weight ratio. It is resistant to corrosion and can withstand temperatures up to 300°F (149°C).

Pros & Cons: The primary advantage of fiberglass is its versatility in design, allowing for unique shapes and styles. However, it can be less durable than metals and may require special care during installation to avoid cracking.

Impact on Application: Fiberglass is often used for body panels and custom hoods, providing aesthetic flexibility without significantly increasing weight. Its chemical resistance makes it suitable for various automotive environments.

Considerations for International Buyers: Buyers should ensure that the fiberglass used meets local safety and environmental regulations. In regions like Australia and Turkey, understanding the resin types and their compliance with standards is essential.

Summary of Material Selection for 1963 Chevy Truck Customization

| Material | Typical Use Case for 1963 Chevy Truck Custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Frame, body panels, structural components | High strength and durability | Heavy, potential for corrosion | Medium |

| Aluminum | Engine components, body panels | Lightweight, corrosion-resistant | Higher cost, requires special welding | High |

| Fiberglass | Body kits, custom hoods | Design flexibility, lightweight | Less durable, care needed during installation | Medium |

This guide provides international B2B buyers with actionable insights into material selection for customizing a 1963 Chevy truck, ensuring informed decisions that align with regional standards and requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 1963 chevy truck custom

What Are the Key Manufacturing Processes for Custom 1963 Chevy Trucks?

When it comes to manufacturing a custom 1963 Chevy truck, a meticulous process is involved that ensures both quality and performance. Understanding the stages of manufacturing can help B2B buyers make informed decisions when sourcing parts or finished products.

Material Preparation: What Should You Know?

The first step in the manufacturing process involves selecting high-quality materials that meet the specifications for durability and performance. Common materials used for the 1963 Chevy truck include:

- Steel: Primarily for the frame and body panels, chosen for its strength and workability.

- Aluminum: Often used in components like the engine for weight reduction.

- Plastic and Composites: Used in interior components and some exterior parts to reduce weight and improve fuel efficiency.

Quality assurance begins at this stage, with suppliers often required to provide material certifications that confirm compliance with international standards.

How Is the Forming Process Carried Out?

The forming process involves shaping the prepared materials into the necessary components. Techniques utilized include:

- Stamping: This is commonly used for body panels. Large presses shape flat sheets of metal into the desired form.

- Welding: Essential for joining components, various welding techniques (MIG, TIG) are employed to ensure strong bonds.

- Machining: Precision machining is used for parts that require specific tolerances, such as engine components and suspension parts.

Each technique has its own quality control measures to ensure that the finished parts are free from defects and meet design specifications.

What Does the Assembly Process Entail?

The assembly process is where all the formed components come together. This stage typically includes:

- Sub-Assembly: Smaller components, such as the engine or transmission, are assembled separately before being integrated into the main vehicle structure.

- Main Assembly Line: Here, the truck’s body is mounted on the chassis, followed by the installation of the interior, electrical systems, and other components.

Quality checkpoints are critical during assembly to ensure that every part fits correctly and operates as intended. Regular audits of the assembly line can help maintain quality standards.

What Are the Finishing Techniques Used?

Finishing techniques are applied to enhance the aesthetic appeal and durability of the 1963 Chevy truck. This includes:

- Painting: A multi-step process that often includes surface preparation, primer application, and multiple coats of paint, followed by clear coating for protection.

- Polishing and Detailing: Ensuring that all surfaces are smooth and visually appealing, which can include chrome plating for decorative parts.

Quality control during the finishing process is vital to ensure that the final product meets customer expectations and industry standards.

How Is Quality Assurance Implemented in Manufacturing?

Quality assurance is a fundamental aspect of the manufacturing process for the 1963 Chevy truck. Various international standards and industry-specific regulations guide these practices.

What International Standards Should You Be Aware Of?

- ISO 9001: This quality management standard is applicable globally and ensures that manufacturers meet customer and regulatory requirements consistently.

- CE Marking: Particularly relevant for products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For parts related to the engine and performance systems, adherence to American Petroleum Institute standards ensures reliability and safety.

B2B buyers should inquire about certifications when sourcing from manufacturers to ensure compliance with these standards.

What Are the Key Quality Control Checkpoints?

Quality control involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspection of raw materials and components upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing monitoring during the manufacturing process to catch defects early.

- Final Quality Control (FQC): A thorough inspection of the finished product before it leaves the factory to ensure it meets all specifications.

These checkpoints are critical for maintaining quality and reliability, especially for international buyers who may have different expectations.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying the quality control measures of suppliers is essential for B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. Here are some actionable insights:

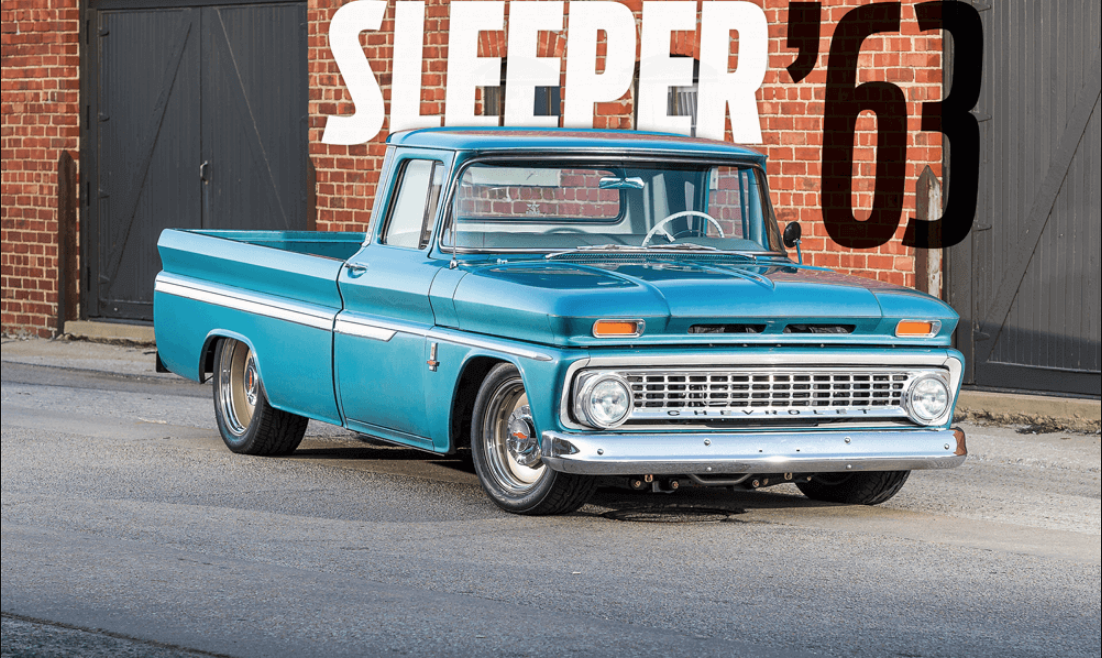

A stock image related to 1963 chevy truck custom.

What Should You Look for in Supplier Audits?

- Conduct Regular Audits: Schedule audits to assess the manufacturing processes and quality assurance measures in place. This can include reviewing documentation and observing operations firsthand.

- Request Quality Reports: Suppliers should provide regular quality reports that detail inspection results, defect rates, and corrective actions taken.

- Third-Party Inspections: Consider hiring third-party inspectors to conduct independent evaluations of the manufacturing processes and final products.

What Are the Quality Control Nuances for International Buyers?

B2B buyers must navigate various regulatory landscapes and quality expectations when sourcing internationally. Key considerations include:

- Understanding Local Standards: Different regions may have unique quality standards. Familiarize yourself with the regulations relevant to your target market.

- Cultural Sensitivity: Communication styles and business practices may differ across regions. Building strong relationships with suppliers can foster better quality assurance practices.

By understanding these processes and quality assurance measures, international B2B buyers can make more informed decisions when sourcing custom 1963 Chevy trucks or their components, ensuring they meet the necessary standards and expectations for their markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘1963 chevy truck custom’

To successfully procure a custom 1963 Chevy truck, international B2B buyers must navigate a series of critical steps. This guide offers a structured checklist to ensure a smooth sourcing process, particularly for buyers from Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Clearly outline what you need in your custom 1963 Chevy truck. This includes specifications such as engine type, body style, interior features, and any custom modifications. Having a precise list helps potential suppliers understand your requirements and enables you to compare offerings effectively.

- Considerations:

- Engine options (e.g., V8, electric conversions)

- Desired modifications (e.g., suspension upgrades, paint jobs)

Step 2: Research and Identify Reputable Suppliers

Conduct thorough research to identify suppliers who specialize in custom vehicles, particularly classic trucks. Look for companies with a strong track record and positive customer reviews. This step is crucial to ensure you are dealing with a reliable partner.

- Resources:

- Online forums and classic car communities

- Industry-specific trade shows and exhibitions

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; seek independent reviews to validate their credibility.

- What to look for:

- Years in business and experience with custom builds

- Portfolio of past projects that align with your specifications

Step 4: Request Detailed Quotes

Once you have shortlisted suppliers, request detailed quotes that outline costs associated with materials, labor, and any additional services. A comprehensive quote will help you understand the total investment required and avoid hidden fees later on.

- Key elements to include:

- Breakdown of costs for parts and labor

- Timeline for completion and delivery

Step 5: Verify Compliance with Local Regulations

Ensure that the custom truck complies with the regulations in your country or region. This is especially important if you are importing the vehicle. Understanding these regulations can prevent legal complications or additional costs.

- Important factors:

- Emission standards and safety regulations

- Import duties and taxes applicable to classic vehicles

Step 6: Establish Clear Communication Channels

Effective communication is vital throughout the sourcing process. Establish clear channels with your supplier to discuss project updates, changes, and any issues that arise. Regular communication helps maintain transparency and builds trust.

- Suggested methods:

- Scheduled updates via email or video calls

- Use project management tools for tracking progress

Step 7: Finalize Contracts and Payment Terms

Before starting the project, finalize all contracts and payment terms. Ensure that all agreements are documented, covering aspects such as payment schedules, warranties, and delivery expectations. This step protects both parties and clarifies obligations.

- Considerations:

- Payment milestones (e.g., deposit, progress payments)

- Warranty terms for workmanship and parts used

A stock image related to 1963 chevy truck custom.

By following this practical sourcing guide, B2B buyers can effectively navigate the complexities of procuring a custom 1963 Chevy truck, ensuring a successful transaction and satisfaction with their investment.

Comprehensive Cost and Pricing Analysis for 1963 chevy truck custom Sourcing

What Are the Key Cost Components for 1963 Chevy Truck Custom Sourcing?

When sourcing custom parts for a 1963 Chevy truck, understanding the comprehensive cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The selection of materials significantly impacts costs. For custom builds, high-quality steel, aluminum, or composite materials may be necessary, depending on the desired specifications.

-

Labor: Skilled labor is essential for the assembly and customization of parts. Labor costs can vary widely based on location and the complexity of the work involved.

-

Manufacturing Overhead: This includes costs related to factory operations, equipment maintenance, utilities, and other indirect costs associated with production.

-

Tooling: Custom tooling may be required for specific parts, which can add to the initial setup costs. This is a significant investment for lower volume orders.

-

Quality Control (QC): Ensuring that all parts meet the required standards necessitates a robust quality control process, which can incur additional costs.

-

Logistics: Shipping costs can be substantial, particularly for international buyers. Factors such as distance, weight, and shipping methods will influence these costs.

-

Margin: Suppliers will typically include a profit margin in their pricing, which can vary based on their business model and the competitive landscape.

How Do Price Influencers Affect the Total Cost of Custom Parts?

Several factors influence the pricing of custom parts for a 1963 Chevy truck:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs. Suppliers may offer discounts based on volume, which can significantly impact overall pricing.

-

Specifications and Customization: The more customized the parts, the higher the cost. Complex designs or unique specifications require more resources and time.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (e.g., ISO, ASTM) can influence pricing. Higher-grade materials or certified suppliers typically command higher prices.

-

Supplier Factors: Supplier reputation, experience, and reliability can also affect pricing. Established suppliers may charge a premium for their services.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) dictate responsibility for shipping costs and risk, influencing the overall price structure for international transactions.

What Are the Best Buyer Tips for Negotiating Pricing?

B2B buyers, especially those from Africa, South America, the Middle East, and Europe, should consider the following tips to enhance their negotiation and cost-efficiency:

-

Negotiate Effectively: Establish clear communication with suppliers regarding your requirements and be open to discussing pricing structures. Understanding their cost components can empower you during negotiations.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the upfront costs but also the long-term costs associated with maintenance, logistics, and potential downtime. This holistic view can guide better purchasing decisions.

-

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations, tariffs, and import duties that could affect the overall cost. Building relationships with suppliers familiar with international trade can mitigate risks.

-

Seek Multiple Quotes: Gathering quotes from various suppliers can provide insight into market pricing and help identify the most competitive options.

-

Consider Long-Term Partnerships: Establishing a long-term relationship with a supplier can lead to more favorable terms and pricing in the future, as suppliers may offer loyalty discounts or priority service.

Disclaimer on Indicative Prices

Prices for custom parts for the 1963 Chevy truck can vary widely based on the aforementioned factors. Buyers should conduct thorough research and obtain multiple quotes to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing 1963 chevy truck custom With Other Solutions

When considering the purchase of a classic vehicle like the 1963 Chevy Truck Custom, it’s important for B2B buyers to evaluate alternatives that may better suit their operational needs or financial constraints. This analysis will compare the 1963 Chevy Truck Custom against two viable alternatives: the 1972 Ford F-100 and the 1980 Toyota Hilux. Each option presents unique advantages and potential drawbacks, making it essential to consider various aspects before making a decision.

| Comparison Aspect | 1963 Chevy Truck Custom | 1972 Ford F-100 | 1980 Toyota Hilux |

|---|---|---|---|

| Performance | Strong V8 engine, good torque for heavy loads | Reliable V8 options, good power | Efficient 4-cylinder, lower power but great fuel economy |

| Cost | Higher restoration costs, potential for appreciation | Moderate cost, good availability | Generally lower initial cost, high resale value |

| Ease of Implementation | Requires specialized restoration knowledge | Easier to find parts, straightforward maintenance | Simple design, easy to repair |

| Maintenance | Higher maintenance due to age, specialized parts | Moderate maintenance, readily available parts | Low maintenance, robust reliability |

| Best Use Case | Classic shows, collector’s value, heavy-duty work | General use, vintage restoration projects | Daily driver, off-road use, small business applications |

What Are the Advantages and Disadvantages of the 1972 Ford F-100 Compared to the 1963 Chevy Truck Custom?

The 1972 Ford F-100 is a strong contender in the classic truck market. Its V8 engine options provide reliable power, making it suitable for a variety of tasks. The availability of parts is a significant advantage, allowing for easier repairs and maintenance compared to the Chevy. However, while the F-100 is generally more affordable, it may not offer the same level of collector’s appeal as the Chevy, which could impact its long-term value.

How Does the 1980 Toyota Hilux Compare with the 1963 Chevy Truck Custom?

The 1980 Toyota Hilux brings a different value proposition, particularly for businesses that prioritize reliability and fuel efficiency. The Hilux’s simple design makes it easy to maintain and repair, with a reputation for durability. This vehicle is ideal for daily driving and off-road use, making it a practical choice for small businesses in rugged environments. However, its lower power output compared to the Chevy and Ford trucks could limit its capability for heavy-duty tasks.

How Can International B2B Buyers Make the Right Choice Between These Options?

For international B2B buyers, selecting the right vehicle involves understanding the specific needs of their operations. If the primary goal is to make a statement and engage in classic vehicle shows, the 1963 Chevy Truck Custom may be the best choice due to its iconic status and potential for appreciation. Conversely, if reliability and lower costs are more critical, the 1980 Toyota Hilux could be the most suitable option. The 1972 Ford F-100 serves as a middle ground, offering a balance of performance and ease of maintenance.

In conclusion, buyers should conduct a thorough analysis of their operational requirements, budget constraints, and long-term goals when deciding among these options. Each vehicle presents unique strengths and weaknesses, and understanding these will aid in making a well-informed decision that aligns with their business strategy.

Essential Technical Properties and Trade Terminology for 1963 chevy truck custom

What are the Essential Technical Properties of a 1963 Chevy Truck Custom?

When considering a custom 1963 Chevy truck, various technical properties are critical for international B2B buyers to understand. These specifications not only ensure the vehicle’s performance but also impact its longevity and resale value.

1. Material Grade of Body Panels

The body panels of a 1963 Chevy truck are typically made from high-grade steel. Understanding the material grade is crucial as it affects durability and susceptibility to rust. For B2B buyers, sourcing trucks with galvanized or rust-resistant materials is essential, especially in regions with high humidity or salt exposure, such as coastal areas in Africa and South America.

2. Engine Specifications and Tolerances

The standard engine for the 1963 Chevy truck is a 230 cubic inch (3.8 L) inline-six or an optional 283 cubic inch (4.6 L) V8. Tolerances in engine manufacturing—like piston clearance and crankshaft alignment—are vital for performance and fuel efficiency. B2B buyers should prioritize suppliers who provide detailed engine specs and tolerances to ensure optimal operation and ease of maintenance.

3. Weight Distribution and Payload Capacity

Weight distribution is critical for handling and stability, particularly when the truck is loaded. The 1963 Chevy truck has a payload capacity of approximately 1,400 to 2,000 pounds, depending on the configuration. Buyers should assess whether the truck’s design meets their logistical needs, especially for operations requiring heavy loads in markets across Europe and the Middle East.

4. Braking System Specifications

The braking system must be robust enough to handle the vehicle’s weight and intended use. The 1963 model typically features drum brakes, but many custom builds upgrade to disc brakes for enhanced stopping power. B2B buyers should inquire about brake specifications and options, as safety is paramount when transporting goods.

5. Electrical System Ratings

The electrical system, including wiring and battery specifications, should be evaluated for reliability and compatibility with modern accessories. The 1963 Chevy truck originally used a 12-volt system, but upgrades to higher amperage batteries may be necessary for custom builds. Understanding these ratings helps buyers ensure that their vehicles can support additional equipment without electrical failures.

What are Common Trade Terms Relevant to 1963 Chevy Truck Customs?

Familiarity with industry jargon is essential for effective communication in B2B transactions. Here are some common terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer. In the context of a 1963 Chevy truck, sourcing OEM parts ensures compatibility and quality. B2B buyers should prioritize OEM components for repairs and restorations to maintain the vehicle’s integrity.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for international buyers looking to import multiple vehicles or parts, as it impacts inventory costs and shipping logistics.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing for specific products or services. For B2B buyers interested in custom modifications for their Chevy trucks, issuing an RFQ can streamline the procurement process and help compare offers from different suppliers.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. They clarify shipping, insurance, and tariffs. Buyers from Africa, South America, and Europe should familiarize themselves with Incoterms to ensure smooth cross-border transactions.

5. VIN (Vehicle Identification Number)

The VIN is a unique code assigned to each vehicle, containing information about its manufacturer, model, and year. For B2B buyers, verifying the VIN is essential for ensuring authenticity and compliance with import regulations.

Conclusion

Understanding the essential technical properties and trade terminology related to the 1963 Chevy truck custom is vital for international B2B buyers. By focusing on these specifications and terms, buyers can make informed decisions that enhance their operational efficiency and investment value.

Navigating Market Dynamics and Sourcing Trends in the 1963 chevy truck custom Sector

What Are the Current Market Dynamics in the 1963 Chevy Truck Custom Sector?

The global market for custom vehicles, particularly classic models like the 1963 Chevy truck, is experiencing a significant resurgence driven by nostalgia and the increasing popularity of vintage restorations. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are capitalizing on this trend. Emerging technologies, such as advanced 3D printing and digital fabrication, are revolutionizing the sourcing process, allowing for the creation of custom parts that are both cost-effective and high-quality.

Additionally, the rise of online marketplaces has transformed how buyers and suppliers connect, enabling easier access to a global network of manufacturers and parts suppliers. These platforms often provide detailed specifications, customer reviews, and competitive pricing, making it simpler for buyers to source the best products for their needs. Furthermore, the shift towards electric and hybrid conversions in classic vehicles is gaining momentum, prompting B2B buyers to seek out suppliers who can offer conversion kits and components compatible with the 1963 Chevy truck.

How Can B2B Buyers Incorporate Sustainability and Ethical Sourcing in Their Purchases?

Sustainability has become a cornerstone of modern supply chains, and B2B buyers in the 1963 Chevy truck custom sector must consider the environmental impact of their sourcing decisions. The importance of ethical supply chains is underscored by increasing consumer awareness and regulatory pressures regarding the sourcing of materials. Buyers should seek suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials or implementing energy-efficient manufacturing processes.

Certifications such as ISO 14001 for environmental management and the Forest Stewardship Council (FSC) for sustainably sourced wood can serve as indicators of a supplier’s commitment to sustainability. Additionally, using ‘green’ materials, such as low-VOC paints and eco-friendly upholstery, not only reduces environmental impact but also appeals to a growing market segment that prioritizes sustainable products. By prioritizing sustainability in their sourcing strategies, international buyers can enhance their brand reputation and meet the evolving demands of environmentally conscious consumers.

What Is the Historical Context of the 1963 Chevy Truck in the Custom Market?

The 1963 Chevy truck has a rich history that significantly influences its current market appeal. Originally released as part of Chevrolet’s C/K series, the 1963 model is celebrated for its robust design, versatility, and performance capabilities. Its classic lines and sturdy frame have made it a popular choice for customization, with many enthusiasts opting for modifications that enhance both aesthetics and functionality.

Over the decades, the truck has become an icon in the classic car community, often featured in car shows and restoration projects. This historical significance not only adds value to the vehicle but also fosters a passionate community of collectors and builders. As a result, the 1963 Chevy truck custom sector remains vibrant, attracting international B2B buyers looking to tap into the nostalgia and craftsmanship associated with this classic model.

Frequently Asked Questions (FAQs) for B2B Buyers of 1963 chevy truck custom

-

How do I choose the right supplier for a 1963 Chevy truck custom?

When selecting a supplier for a 1963 Chevy truck custom, it is crucial to assess their experience and reputation in the industry. Look for suppliers with positive reviews and a strong portfolio showcasing their previous work. Verify their certifications and compliance with international quality standards. Additionally, consider their ability to provide customization options that align with your specific needs. Establishing clear communication and understanding their production capabilities will also help ensure they can meet your timeline and quality expectations. -

What customization options are available for a 1963 Chevy truck?

Customization options for a 1963 Chevy truck can vary widely depending on the supplier. Common options include engine upgrades, transmission choices, and modern amenities like air conditioning and sound systems. Exterior modifications might involve paint jobs, custom bodywork, or aftermarket parts like bumpers and grilles. Interior enhancements can include new upholstery, dashboard upgrades, and modern technology integration. Be sure to discuss your desired features with potential suppliers to understand their capabilities and any additional costs involved. -

What are the minimum order quantities (MOQ) for international purchases of 1963 Chevy trucks?

Minimum order quantities for purchasing 1963 Chevy trucks can vary based on the supplier’s policies and production capabilities. Many suppliers may have an MOQ of one vehicle, especially for custom builds, while others might require larger orders for bulk pricing. It’s essential to clarify the MOQ during initial discussions to ensure it aligns with your purchasing plans. Additionally, inquire about pricing tiers based on order size, as larger orders may yield significant discounts. -

What payment terms should I expect when buying a custom 1963 Chevy truck?

Payment terms for purchasing a custom 1963 Chevy truck typically include a deposit upon order confirmation, often ranging from 20% to 50% of the total cost. The remaining balance is usually due before delivery or upon completion of the build. Some suppliers may offer financing options or payment plans for larger purchases. Always review the payment terms in detail to avoid any misunderstandings, and consider using escrow services for added security in international transactions. -

How can I ensure quality assurance when sourcing a custom 1963 Chevy truck?

To ensure quality assurance when sourcing a custom 1963 Chevy truck, request detailed documentation of the supplier’s quality control processes. This may include information about their manufacturing standards, inspection procedures, and warranties offered on the vehicles. Conducting factory visits or requesting third-party inspections can provide additional confidence in their operations. Additionally, ask for references from previous clients to gauge their satisfaction with the quality of the products received. -

What logistics considerations should I keep in mind for importing a 1963 Chevy truck?

When importing a 1963 Chevy truck, logistics considerations include shipping methods, costs, and customs regulations. Choose a reliable freight forwarder experienced in handling vehicle shipments, as they can assist with documentation and customs clearance. Understand the destination country’s import regulations, including duties and taxes applicable to classic vehicles. Additionally, consider transit times and insurance options to protect your investment during transport. -

How can I verify the authenticity of a 1963 Chevy truck before purchasing?

Verifying the authenticity of a 1963 Chevy truck involves checking the Vehicle Identification Number (VIN) against official records. Request documentation that proves the vehicle’s history, including previous ownership and any modifications made. Engaging an expert mechanic or appraiser familiar with classic cars can provide a professional assessment of the vehicle’s condition and originality. Additionally, consider obtaining a vehicle history report to uncover any potential issues, such as accidents or title discrepancies. -

What are the most common issues to look for in a custom 1963 Chevy truck?

When evaluating a custom 1963 Chevy truck, be vigilant for common issues such as rust, which can significantly affect the vehicle’s structural integrity. Inspect the engine and transmission for signs of wear or leaks, and ensure that all electrical components function correctly. Pay attention to the quality of the custom work, including paint finishes and interior installations. Lastly, take the truck for a test drive to assess handling, braking, and overall performance, ensuring it meets your expectations before finalizing the purchase.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 1963 chevy truck custom

In conclusion, the strategic sourcing of parts and services for a custom 1963 Chevy truck is not just about acquiring materials; it is a vital component of building a successful business strategy. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, must focus on establishing strong relationships with reliable suppliers who can provide high-quality components while ensuring compliance with local regulations.

How Can Strategic Sourcing Enhance Your Customization Process?

By leveraging strategic sourcing, businesses can reduce costs, improve product quality, and enhance supply chain efficiency. It is essential to consider factors such as supplier reputation, production capabilities, and logistical support when selecting partners. Additionally, engaging with local suppliers can not only foster community relationships but also reduce shipping costs and lead times.

What Should International Buyers Consider Moving Forward?

As the market for custom vehicles grows, it is crucial for international buyers to stay informed about emerging trends and technologies that can impact sourcing strategies. Embracing innovation and sustainability in sourcing practices will position businesses favorably in an increasingly competitive landscape.

We encourage you to take proactive steps in refining your sourcing strategy today. Connect with reputable suppliers and industry experts to explore new opportunities that will drive your business forward in the custom automotive market.