Unlock Benefits of Human Custom: The Ultimate Sourcing Guide (2025)

Introduction: Navigating the Global Market for human custom

Navigating the complexities of the global market for human custom solutions can be a daunting task for international B2B buyers, especially when sourcing tailored products that meet diverse cultural and business needs. From personalized promotional items to bespoke corporate gifts, understanding the nuances of human custom is essential for companies looking to enhance their brand presence and foster meaningful relationships in regions such as Africa, South America, the Middle East, and Europe. This guide provides a comprehensive overview of the various types of human custom products available, their applications across different industries, and strategies for effectively vetting suppliers to ensure quality and reliability.

In this resource, you will find actionable insights into the cost considerations associated with human custom solutions, enabling you to budget effectively while maximizing ROI. We will delve into the latest trends shaping the industry, helping you stay ahead of the competition and make informed decisions that resonate with your target audience. Whether you are a procurement manager in Saudi Arabia or a marketing director in Australia, this guide is designed to empower you with the knowledge and tools necessary to navigate the global landscape of human custom products. By addressing key challenges and providing practical solutions, we aim to support your efforts in creating impactful custom offerings that align with your business goals.

Understanding human custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cultural Customs | Traditions and practices specific to a culture | Marketing, product adaptation | Pros: Enhanced local engagement; Cons: Risk of misinterpretation. |

| Business Etiquette | Norms governing professional interactions | Networking, partnership development | Pros: Builds trust; Cons: Can be complex across cultures. |

| Legal Customs | Laws and regulations impacting business practices | Compliance, risk management | Pros: Avoids legal issues; Cons: Requires thorough research. |

| Social Customs | Social behaviors and informal practices | Customer service, community relations | Pros: Improves customer relations; Cons: May vary widely. |

| Religious Customs | Practices and beliefs influencing business conduct | Marketing, corporate responsibility | Pros: Aligns with values; Cons: Potential for alienation. |

What Are the Key Characteristics of Cultural Customs in B2B?

Cultural customs are the traditions and practices that define how a particular society operates. They encompass everything from communication styles to negotiation tactics. For B2B buyers, understanding these customs is crucial when entering new markets or collaborating with international partners. Key considerations include adapting marketing strategies to resonate with local values and ensuring product offerings align with cultural expectations. Misunderstanding cultural customs can lead to ineffective marketing campaigns or failed business negotiations.

How Does Business Etiquette Impact B2B Relationships?

Business etiquette refers to the accepted norms governing professional interactions, such as greetings, meetings, and negotiations. In B2B contexts, adhering to proper etiquette can significantly enhance relationship-building efforts. For buyers, it is essential to familiarize themselves with the etiquette of the regions they are engaging with, as this can influence perceptions of professionalism and respect. Navigating these norms effectively can lead to stronger partnerships and increased trust among stakeholders.

Why Are Legal Customs Important for B2B Buyers?

Legal customs encompass the laws and regulations that govern business operations in different jurisdictions. For B2B buyers, understanding these legal frameworks is critical to ensure compliance and mitigate risks. This involves thorough research into local laws, including labor regulations, import/export restrictions, and industry-specific guidelines. Failure to comply with legal customs can result in severe penalties, making it vital for international buyers to prioritize this aspect in their decision-making processes.

How Do Social Customs Affect Customer Relations in B2B?

Social customs refer to the informal practices and behaviors that characterize social interactions within a culture. These customs can play a significant role in shaping customer service approaches and community engagement strategies. B2B buyers should be aware of the social customs in their target markets to foster positive relationships with customers and stakeholders. While understanding these customs can enhance customer satisfaction, they can also vary widely, necessitating adaptability and continuous learning.

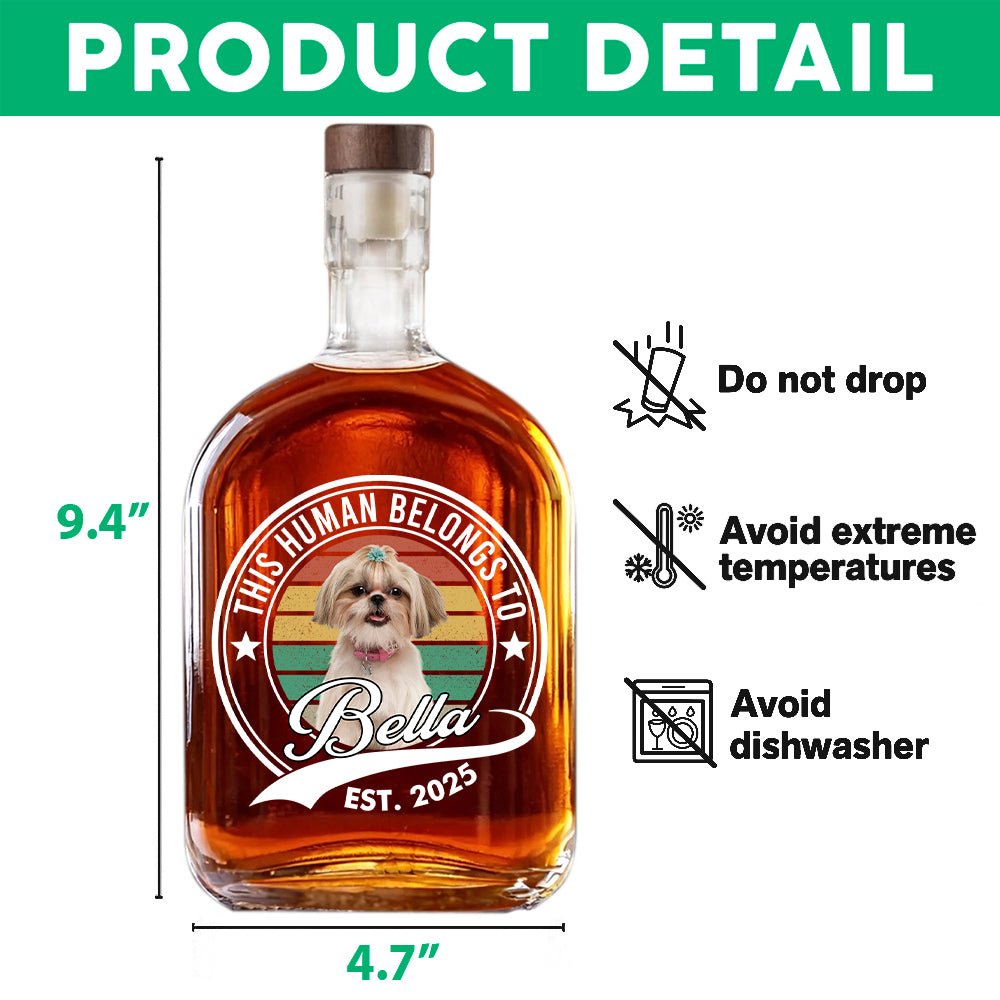

A stock image related to human custom.

What Role Do Religious Customs Play in B2B Marketing?

Religious customs involve the beliefs and practices that influence how business is conducted in various cultures. For B2B buyers, aligning marketing strategies and corporate responsibility initiatives with local religious customs can enhance brand perception and foster loyalty. Understanding the religious context is essential, as it can affect everything from product offerings to promotional timing. However, buyers must tread carefully to avoid alienating potential customers who may feel their beliefs are being exploited.

Related Video: Variation in Mathematics: Meaning, Types of Variations and Examples

Key Industrial Applications of human custom

| Industry/Sector | Specific Application of Human Custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Personalized Medical Devices | Improved patient outcomes and satisfaction | Regulatory compliance, customization capabilities |

| Fashion and Apparel | Customized Clothing and Accessories | Enhanced customer loyalty and brand differentiation | Material sourcing, production lead times |

| Automotive | Tailored Vehicle Interiors | Increased customer satisfaction and premium pricing | Supplier reliability, quality control standards |

| Aerospace | Bespoke Aircraft Interiors and Components | Enhanced comfort and safety for passengers | Compliance with aviation regulations, material quality |

| Consumer Electronics | Customizable Gadgets and Smart Devices | Increased market appeal and user engagement | Technology integration, user experience design |

How is Human Custom Used in Healthcare and What Problems Does It Solve?

In the healthcare sector, human custom is pivotal for the development of personalized medical devices, such as prosthetics and orthotics tailored to individual patient needs. These custom solutions address the unique anatomical and functional requirements of patients, leading to improved comfort and usability. For international buyers, particularly from Africa and the Middle East, it is crucial to understand local regulatory compliance and the capabilities of suppliers in providing customized solutions that meet specific medical standards.

What Are the Benefits of Customized Clothing in Fashion and Apparel?

The fashion and apparel industry leverages human custom by offering personalized clothing and accessories that cater to individual preferences and body types. This customization enhances customer loyalty and differentiates brands in a competitive market. For B2B buyers in Europe and South America, considerations include the sourcing of high-quality materials and understanding production lead times, which can significantly impact inventory management and customer satisfaction.

How Does Customization Enhance Automotive Interiors?

In the automotive sector, tailored vehicle interiors provide a unique selling proposition by enhancing customer satisfaction and allowing manufacturers to command premium pricing. Custom features, such as seating and dashboard designs, can be aligned with consumer preferences for luxury or functionality. Buyers in regions like Saudi Arabia and Australia should focus on supplier reliability and quality control standards to ensure that customized products meet both aesthetic and safety requirements.

Why is Bespoke Aerospace Customization Important?

The aerospace industry benefits from bespoke aircraft interiors and components that enhance passenger comfort and safety. Customization can include everything from seating arrangements to cabin layouts, which are increasingly important in a competitive travel market. International buyers must consider compliance with stringent aviation regulations and the quality of materials used, as these factors directly impact operational safety and passenger experience.

How Do Custom Gadgets Drive Consumer Electronics Sales?

A stock image related to human custom.

In the consumer electronics sector, human custom plays a vital role in the creation of customizable gadgets and smart devices that cater to specific user needs and preferences. This customization not only increases market appeal but also enhances user engagement, leading to higher sales. B2B buyers should prioritize sourcing partners with expertise in technology integration and user experience design to ensure that products are not only functional but also resonate with target audiences.

Related Video: USES OF ROBOTS | Robotics in Daily Life

3 Common User Pain Points for ‘human custom’ & Their Solutions

Scenario 1: Navigating Complex Regulatory Compliance in Customization Projects

The Problem:

B2B buyers often encounter significant challenges when attempting to navigate the complex regulatory landscape associated with human customization. This is particularly evident in industries like healthcare and biotechnology, where regulations can vary dramatically between countries and regions. For instance, a company in South America looking to customize a healthcare product for the European market may find itself grappling with stringent EU regulations on data protection and medical device compliance. This lack of clarity can lead to delays, increased costs, and potential legal repercussions, which are especially daunting for international buyers unfamiliar with local regulations.

The Solution:

To mitigate this pain point, buyers should engage with local compliance experts and legal advisors who specialize in the specific regulations of their target markets. Establishing partnerships with consultants who have a thorough understanding of the regulatory environment can provide invaluable insights. Additionally, leveraging technology platforms that offer compliance management tools can streamline the process of tracking regulatory changes and ensuring that customization projects adhere to all necessary guidelines. B2B buyers should also invest in training their teams on compliance issues to foster a culture of awareness and diligence, thereby reducing the risk of non-compliance.

Scenario 2: Ensuring Quality Control in Customized Human Products

The Problem:

Another prevalent issue faced by B2B buyers in the realm of human customization is maintaining consistent quality control throughout the customization process. This is particularly critical in industries such as fashion, where material sourcing and craftsmanship directly impact the final product’s quality. Buyers often struggle with ensuring that suppliers maintain their quality standards, especially when working with multiple vendors across different regions. Instances of subpar products can lead to brand reputation damage and costly returns, making quality assurance a pressing concern.

The Solution:

Implementing a robust quality management system (QMS) is essential for B2B buyers looking to uphold high standards in customized products. This includes establishing clear quality benchmarks and performance metrics for suppliers, along with regular audits and inspections. Buyers should also consider adopting a centralized platform for communication and documentation that allows for real-time monitoring of product quality at various stages of production. By fostering strong relationships with suppliers and encouraging open dialogue regarding quality expectations, buyers can ensure that customized products meet their specifications and maintain the desired level of excellence.

Scenario 3: Balancing Cost Efficiency with Customization Needs

The Problem:

Cost management is a critical concern for B2B buyers dealing with human customization, particularly in regions where budget constraints are tight. Buyers often face the dilemma of needing tailored solutions while also keeping costs manageable. This is especially true for startups and SMEs in Africa and South America, where financial resources may be limited. The tension between seeking high-quality customized products and the necessity of staying within budget can lead to compromised product features or quality, ultimately affecting business performance.

The Solution:

To effectively balance cost efficiency with customization needs, buyers should adopt a strategic sourcing approach. This involves conducting thorough market research to identify the best suppliers who can deliver quality custom solutions at competitive prices. Buyers should also explore options such as batch ordering or collaborating with suppliers on shared customization projects, which can help reduce costs. Furthermore, engaging in transparent negotiations with suppliers about budget constraints can lead to creative solutions that maintain quality while accommodating financial limitations. Regularly reviewing and refining the customization strategy based on market trends and customer feedback can also help optimize costs without sacrificing product integrity.

Strategic Material Selection Guide for human custom

What Are the Key Materials for Human Custom Applications?

In the realm of human custom applications, the selection of materials plays a pivotal role in ensuring product performance, durability, and compliance with international standards. Below, we analyze four common materials used in this field, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Stainless Steel Perform in Human Custom Applications?

Key Properties: Stainless steel is renowned for its excellent corrosion resistance, high strength, and ability to withstand high temperatures. It typically has a temperature rating of up to 800°C and can handle pressures exceeding 2000 psi, making it suitable for various demanding applications.

Pros & Cons: The durability of stainless steel is one of its most significant advantages, as it can last for decades with minimal maintenance. However, the manufacturing complexity can lead to higher costs compared to other materials. Additionally, while it is highly suitable for applications involving food and medical devices, the weight may be a concern in some designs.

Impact on Application: Stainless steel is compatible with a wide range of media, including water, chemicals, and gases, making it a versatile choice for many human custom applications.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM A240 and EN 10088. Additionally, understanding local regulations regarding stainless steel grades is crucial for ensuring product acceptance.

What Role Does Polypropylene Play in Human Custom Applications?

Key Properties: Polypropylene is a thermoplastic polymer characterized by its lightweight nature, chemical resistance, and good thermal stability, with a temperature rating of up to 100°C. It is also resistant to many acids and bases, making it suitable for various applications.

Pros & Cons: One of the main advantages of polypropylene is its low cost and ease of manufacturing, which allows for rapid production. However, it has lower mechanical strength compared to metals, which may limit its use in high-stress applications.

Impact on Application: Polypropylene is particularly effective in applications that require chemical resistance, such as in packaging or containers for hazardous materials.

Considerations for International Buyers: Buyers should be aware of compliance with standards like ISO 1133 for melt flow rate and ISO 527 for tensile properties. In regions like Africa and South America, understanding local plastic recycling regulations can also influence material selection.

Why Choose Aluminum for Human Custom Applications?

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal and electrical conductivity. It can withstand temperatures up to 600°C and is often used in applications requiring a balance of strength and weight.

Pros & Cons: The primary advantage of aluminum is its excellent strength-to-weight ratio, making it ideal for applications where weight savings are critical. However, it can be more expensive than other materials like polypropylene, and its lower hardness may lead to wear in high-friction applications.

Impact on Application: Aluminum is suitable for applications involving moderate mechanical stress and is often used in aerospace and automotive sectors, as well as in custom human interfaces.

Considerations for International Buyers: Buyers should ensure compliance with international standards like ASTM B221 and EN 573. In regions like Europe, understanding the implications of REACH regulations on aluminum sourcing can be vital.

What Are the Benefits of Using Glass in Human Custom Applications?

Key Properties: Glass is non-reactive, highly durable, and can withstand a wide range of temperatures (up to 500°C). It is also transparent, which can be beneficial for certain applications.

Pros & Cons: The key advantage of glass is its inert nature, making it suitable for applications in the pharmaceutical and food industries. However, its brittleness can be a significant drawback, as it may break under stress or impact.

Impact on Application: Glass is ideal for applications requiring visibility or where chemical interaction must be minimized, such as in laboratory settings.

Considerations for International Buyers: Compliance with standards such as ISO 3585 for borosilicate glass is crucial. Buyers from the Middle East should also consider local regulations regarding glass recycling and waste management.

Summary Table of Material Selection for Human Custom Applications

| Material | Typical Use Case for human custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Medical devices, food processing equipment | Excellent durability and corrosion resistance | Higher manufacturing complexity | High |

| Polypropylene | Packaging, chemical containers | Low cost and easy to manufacture | Lower mechanical strength | Low |

| Aluminum | Aerospace components, custom interfaces | Great strength-to-weight ratio | More expensive than plastics | Medium |

| Glass | Laboratory equipment, pharmaceutical containers | Non-reactive and durable | Brittle and can break easily | Medium |

This strategic material selection guide provides international B2B buyers with actionable insights to make informed decisions, ensuring that their human custom applications meet performance and compliance standards across various regions.

In-depth Look: Manufacturing Processes and Quality Assurance for human custom

What Are the Key Stages in the Manufacturing Process for Human Custom?

The manufacturing process for human custom involves several critical stages that ensure the final product meets the desired specifications and quality standards. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

1. Material Preparation: What Should Buyers Know?

Material preparation is the first stage in the manufacturing process. This phase includes sourcing high-quality materials, such as textiles, metals, or synthetic components, which are essential for creating durable and functional products. B2B buyers should inquire about the suppliers’ material sourcing practices, including:

- Sustainability: Are the materials sourced from environmentally responsible suppliers?

- Traceability: Can the supplier provide documentation regarding the origin of the materials?

- Compliance: Do the materials meet international standards specific to the industry, such as REACH or RoHS?

By understanding the material preparation process, buyers can ensure that the foundational components of their products are reliable and compliant with regional regulations.

2. Forming: How Is the Product Shaped?

The forming stage involves transforming raw materials into specific shapes and dimensions. This can be achieved through various techniques, including:

- Cutting: Using precision tools to cut materials to size.

- Molding: Employing molds to shape materials, particularly in the creation of custom parts.

- 3D Printing: A growing method that allows for complex shapes and rapid prototyping.

Buyers should assess the forming techniques employed by their suppliers to ensure they can achieve the desired product specifications. It’s also important to consider the scalability of these processes for larger orders.

3. Assembly: What Are the Best Practices?

Once the components are formed, they move to the assembly stage. This is where individual parts are put together to create the final product. Key aspects to consider include:

- Automation vs. Manual Labor: Suppliers may use automated assembly lines for efficiency or rely on skilled labor for intricate tasks. Understanding the balance can impact lead times and costs.

- Quality Control Integration: Are there QC measures in place during assembly to catch defects early?

B2B buyers should request detailed information on the assembly process to assess efficiency and quality.

4. Finishing: How Is Quality Achieved?

The finishing stage adds the final touches to the product, which may include painting, coating, or polishing. This step is crucial for both aesthetics and functionality. Buyers should inquire about:

- Finishing Techniques: What methods are used, and how do they affect the product’s durability?

- Environmental Compliance: Are the finishing materials compliant with international regulations?

Understanding the finishing processes helps buyers gauge the overall quality and market readiness of their products.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is a vital component of the manufacturing process, ensuring that the final product meets specified standards. B2B buyers should familiarize themselves with both international and industry-specific quality assurance standards.

1. Which International Standards Are Relevant?

One of the most recognized international standards is ISO 9001, which outlines criteria for a quality management system. It emphasizes a process approach to enhance customer satisfaction and ensure consistent quality. Other notable standards include:

- ISO 13485: Specific to medical devices.

- ISO 14001: Focuses on environmental management.

These standards provide a framework for suppliers to ensure their manufacturing processes are efficient and compliant.

2. What Industry-Specific Certifications Should Be Verified?

Depending on the nature of the human custom products, specific certifications may be required. For instance:

- CE Marking: Indicates conformity with health, safety, and environmental protection standards in the European Economic Area.

- API Certification: Relevant for suppliers of custom products in the pharmaceutical sector.

B2B buyers should confirm that their suppliers possess the necessary certifications to operate within their target markets.

How Can Buyers Ensure Effective Quality Control?

Quality control (QC) checkpoints are essential for identifying defects and ensuring product reliability. Key QC checkpoints include:

- Incoming Quality Control (IQC): Inspects raw materials upon receipt.

- In-Process Quality Control (IPQC): Monitors the manufacturing process at various stages.

- Final Quality Control (FQC): Evaluates the finished product before shipment.

By understanding these checkpoints, buyers can better assess a supplier’s commitment to quality.

1. What Common Testing Methods Are Used?

Various testing methods are employed to validate product quality, including:

- Destructive Testing: Evaluates product performance under stress until failure.

- Non-Destructive Testing: Assesses materials without causing damage, such as ultrasonic or X-ray testing.

Buyers should inquire about the testing methods used by suppliers to ensure that they align with industry standards and product requirements.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verification of a supplier’s quality control practices is crucial for establishing trust and ensuring product reliability. Here are effective methods for B2B buyers:

1. Supplier Audits

Conducting regular audits allows buyers to assess a supplier’s manufacturing processes and quality control measures firsthand. These audits can uncover potential issues and help ensure compliance with agreed standards.

2. Quality Reports

Requesting quality reports can provide insight into a supplier’s QC performance. These reports should include data on defect rates, testing outcomes, and corrective actions taken.

3. Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These services often include comprehensive evaluations and certifications, adding an extra layer of assurance.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific quality control nuances:

- Regulatory Differences: Different regions may have varying compliance requirements. Buyers should ensure their suppliers are familiar with the regulations specific to their region.

- Cultural Considerations: Understanding cultural attitudes towards quality and compliance can influence supplier relationships. Building strong partnerships often requires clear communication and mutual respect.

By taking these factors into account, international B2B buyers can enhance their procurement strategies and ensure they partner with reliable suppliers in the human custom manufacturing sector.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘human custom’

Introduction

Navigating the sourcing process for human custom solutions can be complex, especially for international B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe. This step-by-step checklist is designed to provide actionable insights that streamline your procurement process, ensuring you make informed decisions while minimizing risks associated with sourcing.

Step 1: Define Your Technical Specifications

Before initiating any sourcing activities, it is essential to clearly outline your technical specifications. This includes detailing the specific requirements, functionality, and quality standards necessary for your human custom project.

- Why It Matters: A well-defined specification serves as the foundation for evaluating suppliers and ensures that the final product aligns with your business objectives.

- What to Look For: Include dimensions, materials, compliance standards, and any unique features that are critical to your project.

Step 2: Conduct Market Research for Suppliers

Research potential suppliers in the human custom sector to identify those that align with your specifications. Utilize online platforms, industry publications, and trade shows to compile a list of reputable suppliers.

- Why It Matters: Understanding the market landscape helps you identify suppliers with the right expertise and capabilities.

- What to Look For: Focus on suppliers with experience in your region and industry, as well as those who have a proven track record of delivering quality products.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

- Why It Matters: Evaluating suppliers mitigates the risk of poor quality or delivery delays, which can significantly impact your operations.

- What to Look For: Assess their production capacity, lead times, and customer satisfaction ratings to gauge reliability.

Step 4: Verify Supplier Certifications

Ensure that your selected suppliers hold relevant certifications that demonstrate compliance with industry standards. This may include ISO certifications, safety standards, or specific local regulations.

- Why It Matters: Certifications provide assurance of quality and compliance, reducing the risk of legal issues or product recalls.

- What to Look For: Check for certifications that are recognized in your industry and region to ensure credibility.

Step 5: Request Samples or Prototypes

Before finalizing any orders, request samples or prototypes of the human custom product. This allows you to assess the quality and craftsmanship firsthand.

- Why It Matters: Evaluating a sample reduces the risk of dissatisfaction with the final product and ensures it meets your specifications.

- What to Look For: Pay attention to the details such as material quality, finish, and functionality, and compare them against your initial specifications.

Step 6: Negotiate Terms and Conditions

Once you’ve identified a suitable supplier, engage in negotiations regarding pricing, delivery schedules, payment terms, and warranty conditions.

- Why It Matters: Clear and mutually agreed-upon terms help prevent misunderstandings and set expectations for both parties.

- What to Look For: Be attentive to hidden costs, payment flexibility, and after-sales support offered by the supplier.

Step 7: Establish a Communication Plan

Finally, establish a clear communication plan with your chosen supplier. Define points of contact, communication channels, and frequency of updates throughout the sourcing and production process.

- Why It Matters: Effective communication is critical for addressing potential issues quickly and ensuring alignment throughout the project.

- What to Look For: Ensure that the supplier is responsive and provides regular updates, which can enhance collaboration and build a strong working relationship.

By following this checklist, international B2B buyers can enhance their sourcing strategy for human custom solutions, ensuring a streamlined process that leads to successful procurement outcomes.

Comprehensive Cost and Pricing Analysis for human custom Sourcing

What Are the Key Cost Components in Human Custom Sourcing?

Understanding the cost structure of human custom sourcing is crucial for international B2B buyers. The primary cost components include:

-

Materials: This encompasses the raw materials required for production. The choice of materials significantly impacts both quality and cost. For buyers in regions like Africa and South America, sourcing locally can reduce costs, whereas European buyers might prioritize higher-quality materials, even if they are more expensive.

-

Labor: Labor costs vary widely depending on the region. In countries within the Middle East, skilled labor may come at a premium, while labor in South America may be more cost-effective. Understanding local labor market dynamics can help buyers make informed decisions.

-

Manufacturing Overhead: This includes expenses related to utilities, rent, and operational costs that are not directly tied to production. Buyers should inquire about these costs when evaluating suppliers to ensure they are not inflated.

-

Tooling: Custom tooling can be a significant upfront cost. It is essential to factor this into the overall pricing, especially for orders requiring specialized designs.

-

Quality Control (QC): Ensuring that products meet required standards can incur additional costs. Buyers should consider the implications of QC processes on the total cost and seek suppliers who offer robust quality assurance.

-

Logistics: Shipping and handling costs can vary based on destination, volume, and mode of transport. For buyers in Africa and the Middle East, understanding regional logistics can help avoid unexpected expenses.

-

Margin: Finally, suppliers will include a profit margin in their pricing. Buyers should evaluate this margin against the value provided to ensure competitiveness.

How Do Price Influencers Affect Human Custom Sourcing?

Several factors can influence the pricing of human custom products:

-

Volume and Minimum Order Quantity (MOQ): Generally, higher volumes can lead to lower per-unit costs. Buyers should negotiate MOQs that align with their needs to optimize pricing.

-

Specifications and Customization: Unique specifications or customization requirements can increase costs. Buyers should clearly communicate their needs to avoid unexpected expenses.

-

Materials Used: The choice of materials directly affects pricing. Buyers should weigh the benefits of premium materials against their budget constraints.

-

Quality Certifications: Products that meet specific quality standards may command higher prices. Understanding the importance of these certifications in your market can guide purchasing decisions.

-

Supplier Factors: The reputation, location, and experience of suppliers can influence pricing. Engaging with well-established suppliers may yield better quality and reliability but often at a higher cost.

-

Incoterms: The choice of Incoterms (International Commercial Terms) can significantly impact shipping costs and responsibilities. Familiarizing oneself with these terms can help buyers make more informed decisions regarding total costs.

What Are Effective Buyer Tips for Cost Efficiency in Human Custom Sourcing?

To maximize cost efficiency in human custom sourcing, consider the following strategies:

-

Negotiation: Engage in open discussions with suppliers regarding pricing, especially if you have a long-term partnership in mind. Suppliers may be willing to provide discounts for repeat business or larger orders.

-

Total Cost of Ownership (TCO): Evaluate the total cost of ownership, including all associated costs from procurement to delivery. This holistic view can reveal hidden costs and help in making better purchasing decisions.

-

Understand Pricing Nuances for International Markets: Different regions may have varying pricing structures influenced by local economic conditions, tariffs, and trade agreements. Buyers from Africa and South America should be particularly aware of local market dynamics.

-

Conduct Supplier Audits: Regularly auditing suppliers can help ensure they maintain quality and cost standards. This practice can also uncover opportunities for cost savings.

-

Leverage Technology: Utilize procurement software and platforms that allow for better tracking of costs and supplier performance. This can lead to more informed decision-making.

Disclaimer Regarding Indicative Prices

Pricing in human custom sourcing can fluctuate based on market conditions, demand, and specific buyer requirements. The insights provided are indicative and should be validated through direct engagement with suppliers. Always conduct thorough market research to ensure accurate budgeting.

Alternatives Analysis: Comparing human custom With Other Solutions

When considering the implementation of ‘human custom’ solutions, it’s essential for international B2B buyers to explore viable alternatives that may meet their specific needs more effectively. This section will compare ‘human custom’ with other methods and technologies, helping decision-makers understand the strengths and weaknesses of each approach.

Comparison Table of Human Custom and Alternative Solutions

| Comparison Aspect | Human Custom | Artificial Intelligence (AI) Solutions | Outsourcing to Specialized Firms |

|---|---|---|---|

| Performance | High quality and personalized results | Variable; can automate but lacks personalization | High quality, depends on firm expertise |

| Cost | Generally higher due to labor costs | Lower long-term costs after initial investment | Variable; depends on the firm’s pricing |

| Ease of Implementation | Requires skilled labor and training | Requires integration and training | Relatively easy; relies on firm expertise |

| Maintenance | Ongoing training and management required | Minimal maintenance; software updates needed | Dependent on the service provider’s reliability |

| Best Use Case | Tailored solutions for niche markets | Large-scale data processing and automation | Tasks requiring specialized knowledge and skills |

What Are the Pros and Cons of Artificial Intelligence Solutions?

Artificial Intelligence (AI) solutions are rapidly gaining traction in various industries, offering automation and efficiency. One of the main advantages of AI is its ability to process large volumes of data quickly, making it ideal for businesses that require fast and accurate insights. Additionally, once implemented, AI systems typically have lower operational costs compared to human-centric solutions. However, the downside includes a lack of personalization; AI may not fully understand nuanced customer needs or cultural contexts, which can be critical in B2B interactions across diverse markets like Africa and South America.

How Does Outsourcing to Specialized Firms Compare?

Outsourcing to specialized firms presents another alternative to ‘human custom.’ This approach allows businesses to leverage external expertise without the overhead costs associated with hiring full-time staff. Companies can benefit from the specialized knowledge that these firms bring, particularly in technical or niche areas. However, the effectiveness of this method can vary significantly based on the chosen firm’s reputation and capabilities. Moreover, there may be challenges related to communication and alignment with internal business objectives, especially if the firm is located in a different region.

Conclusion: How Can B2B Buyers Choose the Right Solution?

Choosing the right solution depends heavily on the specific needs and goals of your business. For companies that prioritize personalization and high-quality results, ‘human custom’ may be the best fit, despite higher costs. Conversely, businesses looking for efficiency and lower long-term expenses might lean towards AI solutions, provided they can manage the initial implementation challenges. Finally, outsourcing can be a pragmatic choice for those needing specialized skills without the commitment of full-time hires. Ultimately, B2B buyers should assess their priorities—such as quality, cost, and ease of implementation—against the alternatives to make an informed decision that aligns with their strategic objectives.

Essential Technical Properties and Trade Terminology for human custom

What Are the Key Technical Properties for Human Custom?

In the realm of human custom, understanding the technical properties is essential for international B2B buyers. These properties can significantly impact the quality, compliance, and overall success of projects involving human custom products.

1. Material Grade

Material grade refers to the classification of materials used in manufacturing human custom products. It determines the mechanical properties, corrosion resistance, and durability of the final product. For B2B buyers, selecting the right material grade is crucial to ensure that products meet industry standards and client expectations, particularly in diverse markets like Africa and the Middle East, where environmental conditions can vary significantly.

2. Tolerance

Tolerance indicates the allowable variation in dimensions and specifications during manufacturing. It is vital for ensuring that parts fit together correctly and function as intended. For B2B buyers, understanding tolerance levels can help mitigate risks related to product failures and ensure compatibility with existing systems, especially when sourcing from multiple suppliers across different continents.

3. Surface Finish

Surface finish refers to the texture and smoothness of a product’s surface. This property affects not only the aesthetic appeal but also the functionality, such as friction and wear resistance. Buyers must consider surface finish requirements to ensure that the products not only meet performance criteria but also align with the branding and design expectations of their target markets.

4. Compliance Standards

Compliance standards are regulations that products must meet to be accepted in various markets. These may include safety, environmental, and quality standards specific to regions such as Europe or South America. For B2B buyers, ensuring compliance is essential to avoid legal complications and ensure market acceptance, particularly in highly regulated industries.

5. Lead Time

Lead time is the time taken from placing an order to the delivery of the product. In the context of human custom, understanding lead times is critical for project planning and supply chain management. Buyers from regions like Africa and South America need to account for potential delays in logistics and production when sourcing internationally.

What Are Common Trade Terms Related to Human Custom?

Familiarity with industry jargon can facilitate smoother negotiations and transactions. Here are some key trade terms that B2B buyers should know.

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is essential for B2B buyers to ensure quality and compatibility with existing systems, particularly when looking for custom solutions.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For international buyers, knowing the MOQ can help in budgeting and inventory management, especially when entering new markets where demand may be uncertain.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. For B2B buyers, submitting an RFQ can streamline the procurement process and ensure that they receive competitive pricing and terms from multiple suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers to understand shipping responsibilities, costs, and risks involved in cross-border trade.

5. Freight Forwarding

Freight forwarding is the process of arranging the transportation of goods from one place to another. Understanding this term is vital for B2B buyers to effectively manage logistics and ensure timely delivery, especially when dealing with international shipments.

By grasping these essential technical properties and trade terminologies, international B2B buyers can enhance their decision-making processes, ensuring successful transactions in the dynamic field of human custom.

Navigating Market Dynamics and Sourcing Trends in the human custom Sector

What Are the Key Market Dynamics and Trends in the Human Custom Sector?

The human custom sector is undergoing significant transformation, driven by globalization, technological advancements, and changing consumer preferences. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of these dynamics to stay competitive. A major driver is the increasing demand for personalized products, which has pushed suppliers to adopt flexible manufacturing processes. The emergence of Industry 4.0 technologies, such as IoT and AI, is revolutionizing sourcing strategies by enabling real-time data analytics and automation, enhancing efficiency and accuracy in production.

Moreover, regional trade agreements and partnerships, particularly in Africa and South America, are facilitating easier market access for international buyers. In the Middle East, the focus on diversifying economies away from oil dependency is leading to increased investment in custom solutions across various industries. Additionally, Europe is seeing a surge in demand for high-quality, bespoke products due to a growing middle class and a shift towards premium offerings. These trends are creating a dynamic marketplace where adaptability and responsiveness to consumer needs are paramount.

How Is Sustainability Influencing Sourcing Trends in the Human Custom Sector?

Sustainability is becoming a central tenet of sourcing strategies in the human custom sector. The environmental impact of production processes is under scrutiny, prompting buyers to prioritize suppliers who demonstrate a commitment to sustainable practices. This includes the use of renewable materials and efficient waste management systems. B2B buyers from regions like Europe and the Middle East are particularly keen on sourcing from companies that adhere to stringent environmental regulations and sustainability certifications.

Ethical sourcing is equally important, as consumers increasingly demand transparency in supply chains. Buyers should seek suppliers who are certified by recognized organizations, such as Fair Trade or Global Organic Textile Standard (GOTS), ensuring that their products are not only environmentally friendly but also socially responsible. By investing in ‘green’ certifications and materials, businesses can enhance their brand reputation and appeal to a conscientious consumer base, ultimately driving sales and fostering loyalty.

What Is the Historical Context of the Human Custom Sector?

Understanding the evolution of the human custom sector provides valuable insights for B2B buyers. Historically, this sector has transitioned from mass production to a focus on customization, spurred by technological innovations and changing consumer behavior. The introduction of digital printing and advanced manufacturing techniques in the late 20th century marked a significant turning point, allowing for greater personalization in product offerings.

In the early 2000s, the rise of e-commerce platforms further democratized access to custom products, enabling small and medium enterprises to compete alongside larger firms. This evolution has created a diverse landscape where B2B buyers can source unique, tailored solutions that meet specific market demands. As the sector continues to evolve, staying informed about historical trends can help buyers anticipate future shifts and adapt their sourcing strategies accordingly.

Frequently Asked Questions (FAQs) for B2B Buyers of human custom

-

How do I solve quality assurance issues when sourcing human custom?

Quality assurance is critical when sourcing human custom, especially for international buyers. Start by establishing clear quality standards and specifications for your custom requirements. Conduct thorough supplier vetting by reviewing their certifications, previous client feedback, and production processes. Consider implementing third-party quality inspections during production and before shipment to ensure adherence to your standards. Regular communication with the supplier can also help address any issues early on, allowing for adjustments to be made before final delivery. -

What is the best way to vet suppliers for human custom products?

When vetting suppliers for human custom products, it’s important to assess their reputation, experience, and capabilities. Begin by researching their business history, looking for reviews and testimonials from previous clients. Request samples to evaluate the quality of their work. Additionally, consider visiting the supplier’s facility if possible, or utilizing virtual tours. Finally, check for industry certifications and compliance with international regulations to ensure that they meet your specific needs. -

What are the minimum order quantities (MOQs) for human custom products?

Minimum order quantities (MOQs) for human custom products can vary significantly depending on the supplier and the complexity of the customization required. Generally, suppliers may set MOQs to cover production costs, which can range from a few units to thousands. It’s advisable to discuss your specific needs with potential suppliers and negotiate terms that work for both parties. Some suppliers may offer flexibility with lower MOQs for first-time buyers or trial orders. -

What payment terms should I expect when purchasing human custom?

Payment terms for human custom products typically include options such as upfront deposits, milestone payments, or full payment upon delivery. Common practices involve a 30% deposit to initiate production, with the remaining balance paid before shipment. However, terms can vary based on the supplier’s policies and your negotiation leverage. Always clarify payment terms in writing before finalizing any agreements to avoid misunderstandings and ensure compliance with international trade regulations. -

How can I ensure timely logistics and delivery for my human custom orders?

To ensure timely logistics and delivery, start by discussing shipping timelines with your supplier during the negotiation phase. Establish clear deadlines for production and shipping. Utilize freight forwarders experienced in international shipping to navigate customs regulations and documentation. Tracking shipments through reliable logistics partners can help you stay informed about delivery status. Building a buffer in your timeline can also help mitigate any unexpected delays. -

What customization options are typically available for human custom products?

Customization options for human custom products can vary widely, from material selection and color choices to unique design specifications and branding elements. When engaging with suppliers, clearly communicate your desired custom features and ask for examples of past projects. Many suppliers are willing to collaborate on designs, so consider providing sketches or samples to guide the customization process. Understanding the supplier’s capabilities will help you determine the best options for your needs. -

How do international trade regulations impact sourcing human custom?

International trade regulations can significantly impact the sourcing of human custom products. Each country has specific import/export laws that govern product standards, tariffs, and documentation. Research the regulations relevant to your target market and ensure that your supplier complies with all necessary legal requirements. Engaging with trade consultants or legal advisors can provide insights into navigating these complexities, ensuring that your transactions remain compliant and efficient. -

What are the best practices for maintaining communication with suppliers during the sourcing process?

Maintaining effective communication with suppliers is essential for successful sourcing. Establish regular check-ins, using various communication channels such as email, phone calls, or video conferences to discuss project updates and address concerns. Clearly outline expectations regarding response times and information sharing. Utilizing project management tools can help streamline communication and document all interactions. Building a strong relationship with your suppliers fosters trust and enhances collaboration throughout the sourcing process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for human custom

In today’s global marketplace, the significance of strategic sourcing in the realm of human custom cannot be overstated. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, must recognize the profound impact that thoughtful sourcing strategies have on operational efficiency and cost management. By aligning sourcing decisions with comprehensive market insights and supplier capabilities, businesses can unlock substantial value, ensuring that they are not only meeting current demands but also anticipating future trends.

What are the key takeaways for B2B buyers in the human custom sector? First, prioritize establishing strong relationships with suppliers who understand local market nuances. This approach not only enhances collaboration but also fosters innovation tailored to specific regional needs. Second, leverage technology and data analytics to inform sourcing strategies, allowing for more precise forecasting and inventory management. Finally, remain agile and adaptable, as the landscape of human custom continues to evolve in response to global economic shifts and cultural changes.

Looking ahead, the potential for growth in this sector is immense. As international markets become increasingly interconnected, B2B buyers are encouraged to engage proactively with diverse suppliers and explore new opportunities. Embrace strategic sourcing not merely as a procurement function, but as a critical driver of your business’s long-term success.