Unlock Cost Savings: The Complete Guide to Mould China (2025)

Introduction: Navigating the Global Market for mould china

Navigating the global market for mould china can present a myriad of challenges for international B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. With the increasing demand for high-quality moulds in various industries—from automotive to consumer goods—sourcing the right suppliers and products becomes paramount. This guide aims to equip you with actionable insights into the types of mould china available, their applications, and the critical considerations for vetting suppliers effectively.

As you delve into this comprehensive resource, you will uncover essential information about the different types of moulds, their specific uses, and the key factors influencing cost. Furthermore, we will address the nuances of international trade, including compliance with local regulations and standards, which are especially pertinent for buyers in regions with distinct market dynamics.

By leveraging this guide, you will be empowered to make informed purchasing decisions that not only meet your operational needs but also enhance your competitiveness in the global market. Whether you are seeking to streamline your supply chain or ensure the quality of your mould china, this resource is designed to support you every step of the way, providing clarity and confidence in your sourcing endeavors.

Understanding mould china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Porcelain Mould | High durability, fine finish, translucent quality | Tableware, decorative items | Pros: Elegant appearance, high strength. Cons: Higher cost, requires careful handling. |

| Bone China Mould | Contains bone ash, lightweight, and translucent | Luxury tableware, gift items | Pros: Superior quality, excellent heat retention. Cons: More expensive, less resistant to chipping. |

| Stoneware Mould | Thick and durable, often rustic appearance | Cookware, bakeware, and dinnerware | Pros: Highly durable, versatile. Cons: Heavier, less refined appearance. |

| Earthenware Mould | Porous and less durable, often colorful glazes | Casual dining, pottery, and crafts | Pros: Affordable, wide variety of designs. Cons: Less durable, can absorb moisture. |

| Fine China Mould | Smooth finish, lightweight, often decorated | Formal dining, catering, and events | Pros: Lightweight, elegant designs. Cons: Can chip easily, may not withstand high heat. |

What Are the Characteristics of Porcelain Mould?

Porcelain mould china is recognized for its high durability and fine finish. It is made from kaolin clay, which, when fired at high temperatures, results in a translucent and resilient product. This type is particularly suitable for businesses looking to invest in high-quality tableware or decorative items. When purchasing, buyers should consider the balance between cost and the aesthetic appeal, as porcelain can be more expensive but often justifies the investment with its longevity and elegance.

How Does Bone China Mould Differ from Other Types?

Bone china mould china is unique due to its inclusion of bone ash, making it lighter and more translucent than other types. This quality makes it a preferred choice for luxury tableware and gift items. B2B buyers should focus on suppliers who offer high-quality bone china, as the product’s reputation hinges on its composition and craftsmanship. The investment can be higher, but the superior quality and heat retention make it a worthwhile choice for premium products.

Why Choose Stoneware Mould for Your Business Needs?

Stoneware mould china is characterized by its thick and durable nature, often featuring a rustic appearance. It is ideal for businesses involved in cookware, bakeware, and casual dinnerware. Buyers should consider the versatility and resilience of stoneware, which can withstand high temperatures and is less prone to chipping. However, its heavier weight and less refined aesthetic may not suit all markets, particularly those focused on high-end tableware.

What Are the Advantages and Disadvantages of Earthenware Mould?

Earthenware mould china is known for its porous nature and vibrant glazes, making it popular for casual dining and pottery. Its affordability and variety of designs appeal to businesses targeting budget-conscious consumers. However, buyers must be aware of its less durable nature, as it can absorb moisture and may not withstand heavy use. When considering earthenware, businesses should weigh the cost benefits against the potential need for more frequent replacements.

How Does Fine China Mould Enhance Formal Dining Experiences?

Fine china mould china boasts a smooth finish and lightweight construction, making it an excellent choice for formal dining settings and catering services. The elegant designs often featured in fine china can elevate any dining experience, appealing to high-end restaurants and event planners. However, buyers should be cautious of the product’s susceptibility to chipping and its limited capacity to withstand high heat. Careful supplier selection can mitigate these risks, ensuring a balance of beauty and functionality.

Related Video: Variations In Construction Projects Explained

Key Industrial Applications of mould china

| Industry/Sector | Specific Application of mould china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Production of interior and exterior components | Enhanced durability and precision in manufacturing | Supplier’s expertise in automotive standards and certifications |

| Consumer Electronics | Moulding of plastic housings and components | Cost-effective production with high-quality finishes | Quality control processes and material specifications |

| Packaging | Creation of custom packaging solutions | Improved product protection and aesthetic appeal | Customization options and lead times |

| Medical Devices | Manufacturing of medical device components | Compliance with stringent health regulations | Certifications for medical-grade materials and processes |

| Construction & Infrastructure | Moulding of concrete forms and fixtures | Increased efficiency and reduced waste in construction | Material strength and environmental compliance |

How is Mould China Used in the Automotive Industry?

In the automotive sector, mould china is crucial for producing both interior and exterior components, such as dashboards, door panels, and bumpers. The precision and durability of mould china allow manufacturers to create complex shapes that meet strict industry standards. International B2B buyers from regions like Africa and Europe should ensure their suppliers are compliant with automotive regulations and possess the necessary certifications, as these factors significantly impact product quality and safety.

What Role Does Mould China Play in Consumer Electronics?

Mould china is extensively utilized in the consumer electronics industry for moulding plastic housings and components, such as smartphone cases and appliance casings. The benefits include cost-effective mass production while maintaining high-quality finishes that appeal to consumers. Buyers should prioritize sourcing from suppliers with robust quality control measures in place to guarantee that the end products meet both aesthetic and functional requirements.

How Can Mould China Enhance Packaging Solutions?

In the packaging industry, mould china is employed to create custom packaging solutions that enhance product protection and visual appeal. This application is vital for businesses aiming to differentiate their products on the shelf. Buyers need to consider customization options and lead times when sourcing mould china, as these factors can directly influence their production schedules and market responsiveness.

Why is Mould China Important in Medical Devices?

The medical devices sector relies on mould china for manufacturing components that must adhere to strict health regulations, such as surgical tools and diagnostic devices. Mould china provides the necessary precision and reliability for these critical applications. International B2B buyers should look for suppliers that offer certifications for medical-grade materials and processes to ensure compliance and safety.

How Does Mould China Contribute to Construction & Infrastructure Projects?

In construction and infrastructure, mould china is used to create moulds for concrete forms and fixtures, which are essential for shaping and supporting structures. This application allows for increased efficiency and reduced waste during the construction process. Buyers from regions like South America and the Middle East should assess the material strength and environmental compliance of the mould china to ensure it meets the rigorous demands of construction projects.

Related Video: Uses and Gratifications Theory – UGT

3 Common User Pain Points for ‘mould china’ & Their Solutions

Scenario 1: Quality Inconsistency in Mould China Products

The Problem: One of the most pressing challenges faced by B2B buyers is the inconsistency in quality when sourcing mould china. Disparities in manufacturing processes across different suppliers can lead to variations in the final product, impacting the overall integrity of the end product. This inconsistency can result in costly production delays, increased waste, and ultimately, dissatisfied customers. For buyers in regions like Africa and South America, where local suppliers might be limited, this issue can be particularly acute.

The Solution: To mitigate quality inconsistency, it is essential to establish a robust supplier vetting process. Start by requesting samples from multiple manufacturers to evaluate their products firsthand. Utilize quality control certifications such as ISO 9001 as a benchmark for assessing supplier capabilities. Furthermore, consider implementing regular audits and inspections throughout the production process. Building a long-term relationship with a reliable supplier can also help ensure consistent quality, as they will better understand your specifications and expectations over time.

Scenario 2: Navigating Cultural and Communication Barriers

The Problem: Cultural differences and language barriers can create significant challenges when dealing with mould china suppliers, especially for international buyers from Europe and the Middle East. Misunderstandings may arise regarding specifications, timelines, and compliance with local regulations, leading to frustration and potential project delays. This can be particularly problematic in the mould manufacturing industry, where precision and attention to detail are crucial.

The Solution: To overcome these barriers, consider employing a local intermediary or agent who is well-versed in both the local culture and business practices of the mould china industry. This individual can facilitate communication and ensure that your requirements are accurately conveyed. Additionally, utilize visual aids, such as diagrams or prototype models, to bridge language gaps. Establish clear channels for communication, such as dedicated messaging apps or project management tools, to keep all parties aligned and informed throughout the process.

Scenario 3: Compliance with International Standards and Regulations

The Problem: Compliance with varying international standards can be a daunting task for B2B buyers sourcing mould china, particularly those from regions with stringent regulations such as Europe. Buyers may struggle to ensure that their mould products meet necessary safety, environmental, and quality standards, which can lead to legal complications and damage to their brand reputation.

The Solution: To ensure compliance, it is crucial to stay informed about the specific regulations that apply to your industry and region. Engage with legal experts who specialize in international trade regulations to gain insights into the requirements for your products. When sourcing mould china, ask potential suppliers for documentation that verifies their compliance with relevant standards, such as CE marking or RoHS compliance. Additionally, consider investing in third-party certification services to independently verify that your mould products meet all necessary requirements before they reach the market. This proactive approach can save you from costly setbacks and enhance your credibility in the marketplace.

Strategic Material Selection Guide for mould china

When selecting materials for mould china, international B2B buyers must consider various factors to ensure optimal performance and compliance with industry standards. Here, we analyze four common materials used in mould china, focusing on their properties, advantages, disadvantages, and implications for buyers from diverse regions.

What are the Key Properties of Porcelain in Mould China?

Porcelain is a widely used material in mould china due to its excellent thermal stability and aesthetic appeal. It can withstand high temperatures (up to 1,400°C) and exhibits low porosity, making it resistant to moisture and chemical corrosion. These properties make porcelain suitable for applications requiring durability and a smooth finish.

Pros & Cons:

– Advantages: High strength and durability, excellent thermal resistance, and a glossy finish that enhances product aesthetics.

– Disadvantages: Higher manufacturing complexity and cost compared to other materials, which may not be ideal for all budgets.

Impact on Application:

Porcelain is particularly compatible with food-grade applications, as it does not leach harmful substances. However, buyers must ensure compliance with local health and safety standards, such as FDA regulations in the United States or EU directives in Europe.

How Does Stoneware Compare for Mould China Applications?

Stoneware is another popular choice for mould china, known for its robust nature and ability to withstand thermal shock. It typically has a lower firing temperature than porcelain, making it easier to manufacture. Stoneware also offers good resistance to chipping and scratching.

Pros & Cons:

– Advantages: Cost-effective, durable, and versatile for various applications, including tableware and cookware.

– Disadvantages: Lower aesthetic appeal compared to porcelain and may not be suitable for high-end products.

Impact on Application:

Stoneware is ideal for everyday use items but may not meet the aesthetic expectations for luxury products. Buyers should consider regional preferences for tableware and cookware when selecting stoneware, especially in markets like Europe and South America.

What are the Benefits of Earthenware in Mould China?

Earthenware is characterized by its porous nature and lower firing temperature, making it a cost-effective option for mould china. While it is not as strong as porcelain or stoneware, it can be glazed to enhance its durability and aesthetic qualities.

Pros & Cons:

– Advantages: Low cost and ease of production, making it suitable for mass production.

– Disadvantages: Lower strength and durability, making it less suitable for high-stress applications.

Impact on Application:

Earthenware is often used for decorative items and casual dining ware. Buyers from regions with a strong craft tradition, such as Africa and parts of Europe, may appreciate the unique character of earthenware products.

Why Consider Bone China for High-End Mould China Products?

Bone china is a premium material known for its translucency and strength. It contains a significant percentage of bone ash, which enhances its mechanical properties and makes it highly resistant to chipping.

Pros & Cons:

– Advantages: Exceptional strength, lightweight, and an elegant appearance, making it ideal for fine dining and luxury items.

– Disadvantages: Higher cost and more stringent manufacturing processes, which may limit its accessibility for some buyers.

Impact on Application:

Bone china is favored in upscale markets, particularly in Europe and the Middle East, where consumers value high-quality tableware. Buyers should ensure that suppliers meet relevant standards for food safety and product quality.

Summary Table of Material Selection for Mould China

| Material | Typical Use Case for mould china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Porcelain | High-end tableware and cookware | High strength and durability | Higher manufacturing complexity | High |

| Stoneware | Everyday tableware and cookware | Cost-effective and versatile | Lower aesthetic appeal | Medium |

| Earthenware | Decorative items and casual dining ware | Low cost and ease of production | Lower strength and durability | Low |

| Bone China | Fine dining and luxury tableware | Exceptional strength and elegance | Higher cost and stringent processes | High |

This guide provides a strategic overview for international B2B buyers looking to select the appropriate material for mould china, considering both performance characteristics and regional market preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for mould china

What Are the Key Stages in the Manufacturing Process of Mould China?

The manufacturing process for mould china typically involves several critical stages that ensure the final product meets international standards and buyer specifications. Understanding these stages can help international B2B buyers make informed decisions when selecting suppliers.

1. Material Preparation

The first step in the manufacturing process is the preparation of raw materials. For mould china, this often includes a blend of clay, feldspar, and quartz. Quality control begins here, as the consistency and purity of these materials significantly affect the final product’s strength and appearance. Buyers should inquire about the sourcing of materials and any quality certifications that the supplier may have for their raw materials.

2. Forming Techniques

After preparing the materials, the next step is forming. This can be achieved through various techniques, including:

- Slip Casting: A common method for creating complex shapes, where a liquid clay mixture is poured into a mold and allowed to set.

- Press Molding: This technique uses pressure to shape the clay, resulting in more durable products.

- Jiggering and Jollying: Suitable for producing plates and bowls, these techniques use rotating molds to shape the clay.

B2B buyers should assess which forming techniques a supplier uses, as this can influence both the quality and cost of the final products.

3. Assembly and Drying

Once the pieces are formed, they are carefully assembled if necessary. This step can involve additional handcrafting, particularly for intricate designs. Following assembly, the products undergo a drying process to remove moisture, which is crucial to prevent cracking during firing. Buyers should ensure that suppliers have a controlled environment for drying to minimize defects.

4. Finishing Processes

The finishing stage includes glazing, painting, and other surface treatments. This is where the aesthetic appeal of mould china is enhanced. Quality assurance during this stage is critical, as it affects both the product’s appearance and durability. B2B buyers should ask for details on the types of glazes used and their compliance with safety standards, especially if the products are intended for food use.

How Is Quality Assurance Implemented in Mould China Manufacturing?

Quality assurance (QA) is an integral part of the mould china manufacturing process. It ensures that products meet specific standards before they reach the market. Here’s how quality assurance is typically implemented:

Relevant International Standards for Quality Control

International standards play a vital role in ensuring product quality. For mould china, the following standards are particularly relevant:

- ISO 9001: This standard focuses on quality management systems and is essential for any supplier looking to demonstrate their commitment to quality.

- CE Marking: Particularly important for products sold within the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: For moulds used in industrial applications, API standards ensure that the products meet specific performance and safety criteria.

B2B buyers should verify that their suppliers adhere to these standards, as compliance is a strong indicator of product reliability.

What Are the Key Quality Control Checkpoints?

Quality control involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before production begins. Suppliers should have a system in place for testing and verifying incoming materials.

-

In-Process Quality Control (IPQC): During manufacturing, periodic inspections are conducted to ensure that processes are being followed correctly and that products meet quality standards at each stage.

-

Final Quality Control (FQC): Once products are completed, a final inspection is carried out. This includes checking for defects, measuring dimensions, and ensuring that the products meet the specifications set forth by the buyer.

What Testing Methods Are Commonly Used in Mould China Manufacturing?

Various testing methods are utilized to ensure that mould china products meet quality standards:

-

Visual Inspection: The most basic form of quality control, ensuring that products are free from obvious defects.

-

Dimensional Testing: Measuring the product to ensure it meets specified dimensions and tolerances.

-

Mechanical Testing: Assessing the strength and durability of the products, particularly if they are intended for industrial use.

-

Chemical Analysis: For items intended for food use, chemical tests ensure that the glazes and materials are safe and free from harmful substances.

B2B buyers can request detailed reports of these tests to better understand the quality of the products they are considering.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control is crucial. Here are several actionable steps:

Conducting Audits

Regular audits are one of the most effective ways to ensure that a supplier adheres to quality standards. Buyers should consider conducting on-site audits or hiring third-party auditing firms that specialize in manufacturing processes.

Reviewing Quality Control Reports

Requesting and reviewing quality control reports can provide insight into a supplier’s QA processes. These reports should detail the results of IQC, IPQC, and FQC, along with any corrective actions taken for defects.

Engaging Third-Party Inspectors

Hiring third-party inspection services can offer an unbiased evaluation of a supplier’s quality control measures. These inspectors can provide detailed reports on the manufacturing processes and product quality, giving buyers peace of mind.

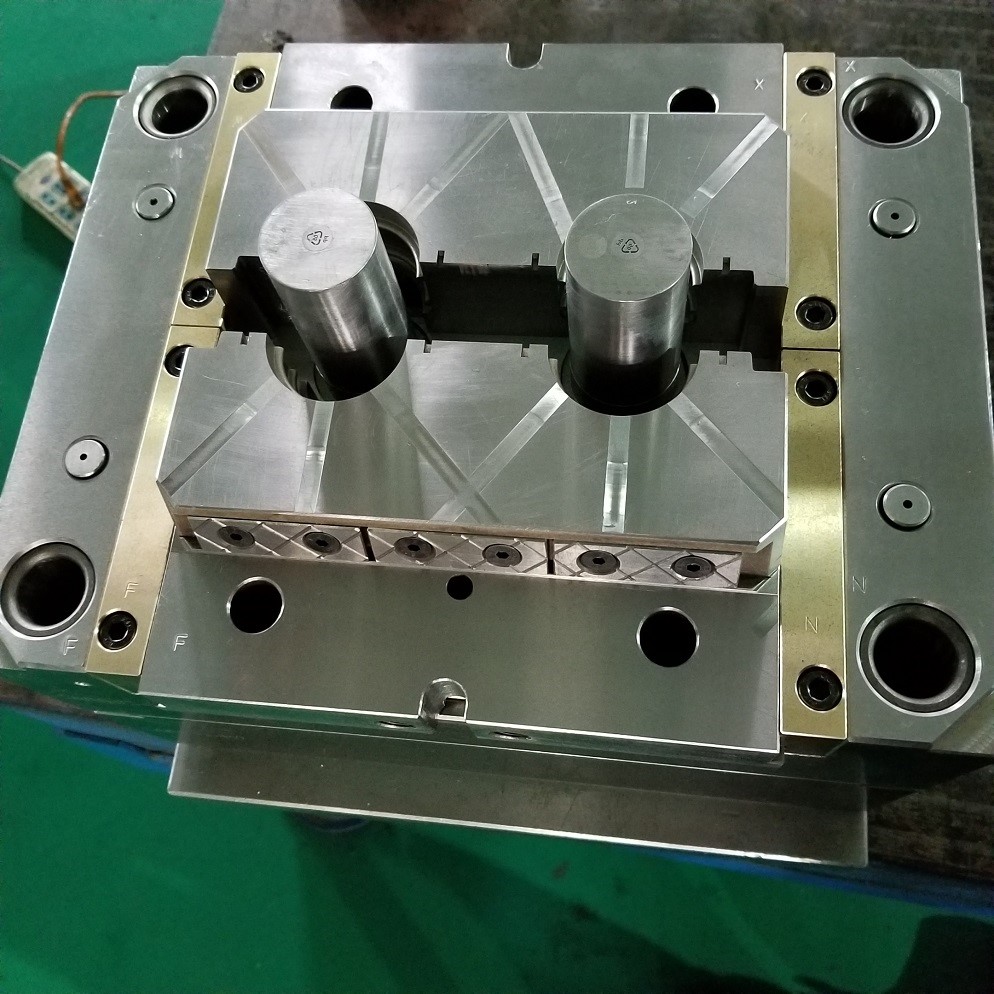

A stock image related to mould china.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing mould china, international buyers must be aware of specific nuances that may affect quality control:

-

Cultural Differences: Understanding the local manufacturing culture can impact how quality assurance is perceived and implemented. Buyers should be sensitive to these differences and establish clear communication channels.

-

Regulatory Compliance: Different regions may have varying regulations regarding product safety and quality. Buyers should familiarize themselves with local regulations and ensure that their suppliers comply.

-

Supply Chain Transparency: Establishing a transparent supply chain is vital for maintaining quality. Buyers should seek suppliers who are willing to share information about their sourcing and manufacturing processes.

By being informed about these aspects, B2B buyers can make more educated decisions, ensuring they partner with reliable suppliers in the mould china market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mould china’

In the competitive landscape of international B2B sourcing, acquiring high-quality mould china requires a strategic approach. This checklist serves as a practical guide for buyers from Africa, South America, the Middle East, and Europe, ensuring they cover all essential steps in the procurement process.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is vital for successful sourcing. This includes dimensions, materials, and design intricacies of the mould china you require. Be specific about the tolerances and finishes needed, as this will facilitate better communication with potential suppliers and minimize misunderstandings.

- Key Considerations:

- Identify the types of moulds required (e.g., injection, blow, or compression).

- Specify any industry standards that must be adhered to.

Step 2: Conduct Market Research

Understanding the market landscape helps identify reliable suppliers and current pricing trends. Research various manufacturers in regions known for mould china production, such as China and Thailand. Utilize online resources, industry reports, and trade shows to gather insights.

- Tips for Effective Research:

- Look for reviews and ratings from other B2B buyers.

- Compare pricing models and service offerings among suppliers.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough vetting is crucial. Request detailed company profiles, including their production capabilities and experience in your specific industry. Also, seek references from previous clients, particularly those located in your region.

- What to Look For:

- Certifications such as ISO or industry-specific accreditations.

- Evidence of successful projects similar to your needs.

Step 4: Verify Supplier Certifications

Confirming supplier certifications ensures that the manufacturer meets industry standards for quality and safety. This is especially important for mould china, where precision and reliability are paramount. Ask for copies of relevant certifications and check their validity.

- Important Certifications:

- ISO 9001 for quality management.

- CE marking for compliance with European regulations.

Step 5: Request Samples and Prototypes

Prior to placing a bulk order, requesting samples or prototypes is a critical step. This allows you to evaluate the quality of the mould china firsthand and make necessary adjustments before final production.

- Sample Evaluation Criteria:

- Assess the accuracy of dimensions and design.

- Check the quality of materials used and overall craftsmanship.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, negotiating favorable terms is essential. Discuss payment terms, lead times, and shipping logistics to ensure clarity and mutual agreement. This step helps to mitigate risks and align expectations.

- Key Negotiation Points:

- Payment methods (e.g., letters of credit, wire transfers).

- Delivery timelines and penalties for delays.

Step 7: Establish a Communication Plan

Effective communication with your supplier throughout the sourcing process is crucial. Establish a clear communication plan that includes regular updates on production status, quality checks, and any potential issues.

- Best Practices:

- Use project management tools for tracking.

- Schedule regular check-ins to maintain transparency.

By following this comprehensive checklist, B2B buyers can streamline their sourcing process for mould china, ensuring they partner with the right suppliers and acquire high-quality products tailored to their specific needs.

Comprehensive Cost and Pricing Analysis for mould china Sourcing

What Are the Key Cost Components in Mould China Sourcing?

When sourcing moulds from China, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The type and quality of materials used in mould production significantly impact costs. Common materials include steel, aluminum, and various polymers, each with varying price points based on market demand and quality specifications.

-

Labor: Labor costs in China are generally lower than in many Western countries, but they can vary by region and skill level. Skilled workers in cities with advanced manufacturing facilities might demand higher wages compared to those in rural areas.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and administrative expenses. A well-established factory with efficient processes may have lower overhead costs, which can reflect in the final pricing.

-

Tooling Costs: Tooling refers to the creation of the mould itself. Initial tooling costs can be substantial but are often amortized over large production runs, making it crucial to consider the expected volume when evaluating overall costs.

-

Quality Control (QC): Implementing stringent quality control measures adds to the overall cost but is essential for ensuring that the final product meets international standards. Buyers should consider the cost of QC as an investment in product reliability.

-

Logistics: Transportation and shipping costs can vary widely based on the mode of transport, distance, and current freight rates. Import duties and taxes should also be factored into the logistics costs.

-

Margin: Suppliers will typically add a profit margin to cover their costs and ensure sustainability. Understanding the average margins in the mould manufacturing sector can help in negotiating better prices.

How Do Price Influencers Affect Mould Costs?

Several factors can influence the pricing of moulds sourced from China:

-

Volume and Minimum Order Quantity (MOQ): Larger order volumes can lead to lower per-unit costs due to economies of scale. Be aware of the supplier’s MOQ, as it can significantly impact your total expenditure.

-

Specifications and Customization: Custom moulds designed to specific requirements often incur higher costs due to the additional engineering and manufacturing complexity involved. Clearly defining your needs can help avoid unexpected expenses.

-

Material Choices: Opting for premium materials can enhance durability and performance but will increase the cost. It’s crucial to balance quality with budget constraints.

-

Supplier Reputation and Certifications: Established suppliers with recognized quality certifications (e.g., ISO) may charge a premium for their services, reflecting their reliability and adherence to international standards.

-

Incoterms: The choice of Incoterms (International Commercial Terms) affects the cost structure. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) will dictate who bears the shipping costs and risks, impacting the final price.

What Negotiation Strategies Can Buyers Use to Optimize Costs?

Effective negotiation is critical for securing favorable pricing when sourcing moulds from China. Here are some actionable strategies:

-

Research Market Prices: Conduct thorough research to understand the average market rates for the specific moulds you need. This knowledge empowers you during negotiations and helps identify reasonable price expectations.

-

Leverage Volume Discounts: If you plan to order in bulk, use this as leverage in your negotiations. Suppliers are often willing to reduce prices in exchange for larger orders.

-

Discuss Payment Terms: Flexible payment terms can enhance your cash flow and reduce upfront costs. Consider negotiating for staggered payments based on production milestones.

-

Evaluate Total Cost of Ownership (TCO): Assess not just the initial purchase price but also the long-term costs associated with maintenance, logistics, and potential rework. This holistic view can guide your negotiation strategy.

-

Build Relationships: Establishing a strong relationship with suppliers can lead to better pricing and service. Regular communication and trust-building can yield long-term benefits.

Why Is It Important to Understand Pricing Nuances for International Buyers?

International buyers, particularly from Africa, South America, the Middle East, and Europe, must navigate various challenges when sourcing moulds from China. Fluctuating exchange rates, import regulations, and cultural differences can all affect pricing and procurement strategies. Staying informed about these nuances ensures that you are not only securing the best price but also fostering a sustainable supply chain.

Disclaimer on Indicative Prices

While this analysis provides a comprehensive overview of the cost and pricing dynamics in mould sourcing from China, prices can fluctuate based on market conditions and individual supplier factors. Always conduct your due diligence and obtain multiple quotes to ensure competitive pricing tailored to your specific needs.

Alternatives Analysis: Comparing mould china With Other Solutions

When exploring the manufacturing landscape, it’s essential to consider various solutions that can meet your production needs effectively. In the case of mould china, which is renowned for its versatility in creating high-quality ceramic products, there are alternative methods and technologies that may also suit specific business requirements. This section delves into a comparative analysis of mould china against two viable alternatives: injection moulding and 3D printing.

Comparison Table of Mould China and Alternatives

| Comparison Aspect | Mould China | Injection Moulding | 3D Printing |

|---|---|---|---|

| Performance | High durability and finish | Excellent for mass production | Good for prototyping and small batches |

| Cost | Moderate initial investment | High setup costs | Variable, cost-effective for low volumes |

| Ease of Implementation | Requires skilled artisans | Complex, requires machinery | User-friendly software and machines |

| Maintenance | Low maintenance | Moderate maintenance | Low maintenance, but depends on technology |

| Best Use Case | Custom and high-end products | High-volume production | Rapid prototyping and customization |

What are the Advantages and Disadvantages of Injection Moulding?

Injection moulding is a manufacturing process that involves injecting molten material into a mould to create parts. This method is particularly advantageous for high-volume production runs, as it can produce thousands of identical parts quickly and efficiently. However, the initial setup costs for moulds and machinery can be prohibitive for smaller businesses. Additionally, the process requires significant technical expertise and maintenance to ensure optimal operation. For businesses focused on large-scale production of standard parts, injection moulding can be an excellent choice, but for those needing flexibility or custom designs, it may not be the best fit.

How Does 3D Printing Compare to Mould China?

3D printing, also known as additive manufacturing, allows for the creation of complex shapes and custom designs directly from digital models. This method is particularly appealing for rapid prototyping, where time-to-market is crucial. The ability to produce small batches at a relatively low cost makes 3D printing attractive for businesses looking to test products or cater to niche markets. However, the material options can be limited compared to mould china, and the strength and finish may not always match traditional moulding methods. Companies that prioritize flexibility and quick iterations may find 3D printing to be a more suitable alternative, while those needing high durability and aesthetic quality might lean towards mould china.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right manufacturing solution depends on several factors, including the scale of production, budget constraints, and specific product requirements. For businesses in Africa, South America, the Middle East, and Europe, it’s vital to assess not only the cost and implementation aspects but also the long-term maintenance and adaptability of the chosen method. Mould china offers high-quality results for custom and high-end products, while injection moulding is ideal for mass production. Conversely, 3D printing provides agility and customization at a lower volume. By aligning production needs with the strengths and limitations of each method, B2B buyers can make informed decisions that cater to their unique market demands and operational capabilities.

Essential Technical Properties and Trade Terminology for mould china

What Are the Key Technical Properties of Mould China?

Understanding the essential technical properties of mould china is crucial for B2B buyers aiming to make informed purchasing decisions. Here are some of the critical specifications you should consider:

-

Material Grade

Mould china is typically classified into various material grades based on its composition and intended use. The most common grades include porcelain, bone china, and stoneware. Each grade has distinct characteristics regarding strength, translucency, and thermal resistance, which can significantly impact the final product’s quality and performance. For buyers, selecting the right material grade ensures the durability and aesthetic appeal of their products. -

Tolerance

Tolerance refers to the allowable deviation in dimensions and specifications during the manufacturing process. In mould china, a tight tolerance is essential to ensure that pieces fit together seamlessly, particularly for complex designs. Understanding tolerance levels helps buyers assess the precision of the mould china products they are sourcing, which is critical for applications in industries such as automotive, aerospace, and electronics. -

Firing Temperature

The firing temperature is a vital specification that affects the strength and finish of mould china. Typically, high-quality mould china is fired at temperatures ranging from 1200°C to 1400°C. This high-temperature process contributes to the material’s durability and resistance to chipping and cracking. Buyers should inquire about the firing temperatures used by manufacturers to gauge the quality of their mould china products. -

Glaze Type

The type of glaze applied to mould china not only affects its aesthetic qualities but also its functionality. Common glaze types include glossy, matte, and transparent, each offering different levels of durability, stain resistance, and ease of cleaning. Understanding the glaze type helps buyers select products that align with their branding and practical needs. -

Impact Resistance

Impact resistance measures how well mould china withstands mechanical stress and impacts. This property is especially important for products that will be used in high-traffic environments or are prone to drops and bumps. Buyers should assess the impact resistance of mould china to ensure it meets their operational needs and minimizes the risk of breakage.

What Are the Common Trade Terms Used in Mould China Transactions?

Familiarity with trade terminology is essential for international B2B buyers, as it streamlines communication and negotiations. Here are some commonly used terms in the mould china industry:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on the specifications provided by other businesses. In the mould china sector, buyers often work with OEMs to create custom designs that reflect their brand identity. Understanding OEM dynamics allows buyers to collaborate effectively with manufacturers. -

MOQ (Minimum Order Quantity)

MOQ signifies the smallest number of units that a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory management and cash flow. Knowing the MOQ helps buyers plan their orders according to budget constraints and demand forecasts. -

RFQ (Request for Quotation)

An RFQ is a formal document sent by buyers to suppliers requesting price quotes for specific products or services. In the mould china industry, submitting an RFQ helps buyers gather multiple offers and make informed comparisons. This process is essential for achieving cost efficiency and negotiating favorable terms. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that outline the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is vital for B2B buyers in mould china, as it clarifies the logistics process and helps mitigate risks associated with international transactions. -

Lead Time

Lead time refers to the time taken from placing an order to the delivery of the products. For mould china buyers, understanding lead times is crucial for planning production schedules and meeting market demands. Shorter lead times can enhance competitiveness, making it essential to discuss and agree upon timelines with suppliers upfront.

By grasping these technical properties and trade terms, international B2B buyers can enhance their sourcing strategies and foster successful partnerships in the mould china industry.

Navigating Market Dynamics and Sourcing Trends in the mould china Sector

What Are the Key Market Trends Influencing the Mould China Sector?

The global mould china market is witnessing significant transformations driven by technological advancements, changing consumer preferences, and evolving trade dynamics. One of the primary factors influencing this sector is the increasing demand for customized and high-quality products. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are seeking suppliers that can provide tailored solutions that meet specific regional needs.

Emerging technologies such as 3D printing and advanced CAD software are revolutionizing the design and manufacturing processes in the mould china sector. These innovations allow for more efficient production methods and reduced lead times, enabling businesses to respond swiftly to market demands. Furthermore, the integration of Industry 4.0 technologies, including IoT and AI, is enhancing supply chain transparency and operational efficiency, which are crucial for international buyers looking to streamline procurement processes.

Additionally, geopolitical factors, such as trade agreements and tariffs, are reshaping sourcing strategies. Buyers from Europe may find it beneficial to collaborate with suppliers in Asia to leverage cost advantages, while those in Africa and South America should consider partnerships that facilitate access to European markets. Understanding these market dynamics is essential for making informed sourcing decisions that align with global trends.

How Does Sustainability Impact Sourcing Decisions in the Mould China Sector?

Sustainability has become a paramount concern for international B2B buyers in the mould china sector. The environmental impact of traditional manufacturing processes has prompted a shift towards sustainable sourcing practices. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint and minimizing waste.

Ethical supply chains are also gaining prominence. Buyers are encouraged to assess the social responsibility of their suppliers, ensuring that they adhere to fair labor practices and contribute positively to their communities. This not only enhances brand reputation but also fosters long-term relationships built on trust and shared values.

To facilitate sustainable sourcing, buyers should look for suppliers that offer ‘green’ certifications and materials. Certifications such as ISO 14001 (Environmental Management) and products made from recycled or eco-friendly materials can serve as indicators of a supplier’s commitment to sustainability. By aligning procurement strategies with these principles, international buyers can enhance their competitive edge while contributing to a more sustainable future.

What Is the Evolution of the Mould China Sector and Its Relevance for B2B Buyers?

The mould china sector has evolved significantly over the past few decades, transitioning from traditional craftsmanship to modern, technology-driven production. Initially characterized by manual processes and limited design capabilities, the industry has embraced automation and digital technologies, enhancing both efficiency and product quality.

This evolution is particularly relevant for B2B buyers who must navigate a marketplace that offers diverse sourcing options. Understanding the historical context can provide insights into supplier capabilities and the reliability of manufacturing processes. Buyers should consider how these advancements affect product innovation, delivery timelines, and overall supply chain management.

A stock image related to mould china.

As the mould china sector continues to evolve, staying informed about historical trends and their implications can help international buyers make strategic decisions that align with current market demands. By leveraging this knowledge, businesses can optimize their sourcing strategies and foster partnerships that drive growth in an increasingly competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of mould china

-

How do I ensure the quality of mould china products before purchasing?

To ensure quality, start by requesting samples from potential suppliers. Evaluate these samples based on your specifications and quality standards. Additionally, consider conducting factory audits or hiring third-party inspection services. Check for certifications that comply with international standards, such as ISO 9001. Engaging with suppliers who provide detailed product descriptions and transparency in their manufacturing processes can also help mitigate risks associated with quality. -

What are the most important factors when selecting a mould china supplier?

Key factors include the supplier’s experience, reputation, and production capacity. Look for suppliers with a proven track record in your specific industry. Assess their ability to customize products according to your needs and their responsiveness to inquiries. It’s also crucial to verify their certifications and compliance with international regulations. Reading reviews and testimonials from other international buyers can provide valuable insights into their reliability and quality. -

What customization options are available for mould china products?

Most suppliers offer various customization options, including material selection, design modifications, and specific dimensions. Discuss your requirements in detail during the initial stages of communication. Many manufacturers can accommodate unique designs or branding requirements, but it’s essential to confirm these capabilities before placing a large order. Additionally, inquire about the associated costs and lead times for customizations to avoid surprises later. -

What is the typical Minimum Order Quantity (MOQ) for mould china?

MOQs can vary significantly based on the supplier and the complexity of the moulds. Generally, you can expect MOQs to range from 50 to several hundred units. Some suppliers may offer lower MOQs for standard designs while requiring higher quantities for custom orders. It’s advisable to negotiate these terms upfront to ensure they align with your purchasing capabilities and business needs. -

What payment terms should I expect when sourcing from mould china suppliers?

Payment terms can vary, but common practices include a 30% deposit upon order confirmation and the remaining 70% before shipment. Some suppliers may offer credit terms based on your relationship and order history. It’s important to clarify these terms early in the negotiation process and ensure they are documented in your purchase agreement. Consider using secure payment methods like letters of credit or escrow services for added protection. -

How can I navigate logistics and shipping when importing mould china?

Understanding logistics is crucial for timely delivery. Work with suppliers who have experience in international shipping and can assist with arranging freight. Familiarize yourself with import regulations in your country, including tariffs and customs procedures. Partnering with a reliable freight forwarder can streamline the process, ensuring all paperwork is handled correctly and efficiently. Always plan for potential delays by allowing extra time in your supply chain timeline. -

What should I include in my contract with a mould china supplier?

Your contract should detail product specifications, pricing, payment terms, delivery timelines, and quality assurance measures. Include clauses for penalties in case of delays or quality issues, as well as terms for dispute resolution. Clear communication about intellectual property rights, especially for custom designs, is also essential. A well-structured contract protects both parties and helps build a trustworthy business relationship. -

How do I handle potential disputes with my mould china supplier?

To manage disputes effectively, maintain open lines of communication with your supplier. Address any issues as soon as they arise, and attempt to resolve them amicably. Document all correspondence and agreements related to the dispute. If resolution fails, refer to the dispute resolution clause in your contract, which may include mediation or arbitration. Having a legal advisor familiar with international trade can also provide valuable guidance on handling disputes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for mould china

What Are the Key Takeaways for Strategic Sourcing of Moulds from China?

In conclusion, strategic sourcing of moulds from China presents significant opportunities for international B2B buyers, particularly in emerging markets such as Africa, South America, and the Middle East, as well as established regions like Europe. By prioritizing quality, supplier reliability, and cost-effectiveness, buyers can enhance their manufacturing capabilities while minimizing risks associated with sourcing. Understanding the nuances of the Chinese market, including cultural differences and regulatory frameworks, will empower buyers to make informed decisions and foster productive partnerships.

How Can Buyers Prepare for Future Trends in Mould Sourcing?

Looking ahead, the demand for innovative and customized mould solutions is expected to rise, driven by advancements in technology and changing consumer preferences. International buyers should leverage this trend by investing in long-term relationships with suppliers who can adapt to their evolving needs. Embracing digital tools and platforms for sourcing can also streamline processes, making it easier to connect with the right manufacturers.

What Steps Should You Take Next as an International Buyer?

As you navigate the landscape of mould sourcing in China, consider conducting thorough market research, attending trade shows, and utilizing local experts to enhance your sourcing strategy. By taking proactive steps now, you can position your business to capitalize on the advantages that strategic sourcing offers. Don’t hesitate to reach out to potential suppliers and start discussions that could lead to fruitful collaborations in the near future.