Unlock Cost Savings: The Ultimate CNC Machining Service China (2025)

Introduction: Navigating the Global Market for cnc machining service china

Navigating the complexities of sourcing CNC machining services from China can be a daunting task for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, including countries like Spain and Germany. With varying supplier capabilities, quality standards, and logistical challenges, making informed decisions is crucial for ensuring the success of your manufacturing projects. This comprehensive guide on CNC machining service in China addresses these challenges by providing detailed insights into the types of machining services available, their applications across various industries, and effective strategies for vetting potential suppliers.

Buyers will benefit from an exploration of cost factors, including how to negotiate favorable terms and identify hidden expenses, allowing for better budgeting and resource allocation. Additionally, the guide delves into best practices for establishing partnerships with Chinese suppliers, ensuring compliance with international quality standards, and streamlining communication despite potential language barriers.

Empowering B2B buyers with actionable insights, this guide serves as a vital resource for making informed purchasing decisions that align with your business objectives. By understanding the nuances of the CNC machining landscape in China, you can effectively mitigate risks and foster successful collaborations that enhance your competitive edge in the global market.

Understanding cnc machining service china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Milling | Utilizes rotating cutting tools to remove material. | Aerospace, automotive, medical devices | Pros: High precision, versatile; Cons: Longer setup time. |

| CNC Turning | Rotates the workpiece against a stationary cutting tool. | Manufacturing of cylindrical parts | Pros: Excellent for round shapes; Cons: Limited to rotational parts. |

| CNC Laser Cutting | Uses laser technology for cutting materials. | Signage, custom parts, electronics | Pros: High accuracy, clean cuts; Cons: Material limitations. |

| CNC Waterjet Cutting | Employs high-pressure water jets for cutting. | Stone, glass, and thick metals | Pros: No heat-affected zone; Cons: Slower than other methods. |

| CNC 3D Printing | Builds parts layer by layer using additive processes. | Prototyping, complex geometries | Pros: Rapid prototyping, design flexibility; Cons: Surface finish may require post-processing. |

What Are the Key Characteristics of CNC Milling Services?

CNC milling is characterized by its use of rotating cutting tools to remove material from a stationary workpiece, allowing for the creation of complex shapes and precise dimensions. It is suitable for a wide range of materials, including metals, plastics, and composites. Buyers should consider the machine’s capabilities, such as the number of axes (typically 3 to 5), tooling options, and the ability to handle large workpieces, especially for applications in industries like aerospace and automotive.

How Does CNC Turning Differ from Other CNC Machining Services?

CNC turning focuses on rotating the workpiece against a stationary cutting tool, making it ideal for manufacturing cylindrical parts such as shafts and bushings. This method is particularly effective for high-volume production runs, where consistent quality and efficiency are crucial. Buyers should evaluate the lathe’s capacity, tooling options, and material compatibility to ensure it meets their production needs.

What Advantages Does CNC Laser Cutting Offer to B2B Buyers?

CNC laser cutting is distinguished by its use of high-powered lasers to cut through various materials with exceptional precision. This method is particularly popular for applications in signage, electronics, and custom parts manufacturing due to its ability to produce intricate designs with clean edges. Buyers should consider the thickness and type of materials they intend to cut, as well as the laser’s cutting speed and operational costs.

Why Choose CNC Waterjet Cutting for Specific Applications?

CNC waterjet cutting utilizes high-pressure water jets to cut through materials without generating heat, making it ideal for sensitive materials like glass and certain metals. This technique is advantageous for creating intricate designs without altering the material properties. Buyers should assess the waterjet’s cutting speed, nozzle capabilities, and the types of materials it can handle to ensure it aligns with their production requirements.

In What Scenarios is CNC 3D Printing Most Beneficial?

CNC 3D printing is an additive manufacturing process that builds parts layer by layer, which is ideal for rapid prototyping and creating complex geometries that traditional methods might struggle with. This service is particularly beneficial for industries that require quick iterations and design flexibility, such as aerospace and consumer products. Buyers should consider the printer’s material capabilities, print resolution, and post-processing needs when evaluating this service for their projects.

Related Video: What is CNC Machining and How Does it Work?

Key Industrial Applications of cnc machining service china

| Industry/Sector | Specific Application of CNC Machining Service China | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Manufacturing of aircraft components | High precision and lightweight parts for fuel efficiency | Compliance with international aviation standards |

| Automotive | Production of engine and transmission parts | Enhanced performance and reliability of vehicles | Quality assurance and testing certifications |

| Medical Devices | Fabrication of surgical instruments and implants | Customization and high biocompatibility | Regulatory compliance and material traceability |

| Electronics | Production of housings and components for devices | Cost-effective mass production with tight tolerances | Lead times and scalability for rapid prototyping |

| Industrial Equipment | Creation of machine parts and tooling | Improved operational efficiency and reduced downtime | Supplier reliability and after-sales support |

How is CNC Machining Service China Used in Aerospace?

In the aerospace industry, CNC machining service from China is crucial for manufacturing components such as turbine blades and structural parts. These components require exceptional precision and lightweight materials to enhance fuel efficiency and performance. International buyers must ensure that the suppliers comply with stringent aviation standards and certifications, addressing quality assurance to mitigate risks associated with safety and reliability.

What are the Applications in the Automotive Sector?

CNC machining plays a vital role in producing engine components, transmission parts, and chassis elements for the automotive sector. By leveraging advanced machining techniques, manufacturers can achieve enhanced performance and reliability in vehicles. International B2B buyers should prioritize suppliers with robust quality management systems and certifications to ensure that the components meet the demanding standards of the automotive industry, particularly in markets like Europe where regulations are stringent.

How Does CNC Machining Benefit Medical Device Manufacturing?

In the medical device sector, CNC machining is utilized to fabricate surgical instruments and implants that require high precision and customization. The ability to produce complex geometries from biocompatible materials allows manufacturers to meet specific patient needs effectively. Buyers must focus on sourcing from suppliers who adhere to regulatory compliance and can provide documentation for material traceability, essential for maintaining safety and efficacy in medical applications.

What is the Role of CNC Machining in Electronics Manufacturing?

CNC machining services are integral to the electronics industry, particularly for producing housings and intricate components for devices such as smartphones and computers. The precision offered by CNC machining ensures that parts fit perfectly, contributing to the overall performance of electronic devices. International buyers should consider the scalability of suppliers to accommodate varying production volumes and the ability to meet tight deadlines for rapid prototyping and product launches.

How is CNC Machining Applied in Industrial Equipment Production?

In industrial equipment manufacturing, CNC machining is employed to create machine parts and tooling that enhance operational efficiency. High-quality components reduce downtime and maintenance costs, which is critical for businesses aiming to optimize productivity. Buyers from diverse regions should evaluate the reliability of suppliers and the availability of after-sales support to ensure that any operational issues can be promptly addressed, thereby safeguarding their investment in CNC machined parts.

3 Common User Pain Points for ‘cnc machining service china’ & Their Solutions

Scenario 1: Navigating Quality Assurance Challenges in CNC Machining

The Problem:

One of the most pressing challenges faced by international B2B buyers, particularly those sourcing from China, is ensuring consistent quality in CNC machined parts. Buyers often encounter discrepancies between the specified tolerances and the actual output, which can lead to costly production delays and rework. This is particularly critical for industries such as aerospace or automotive, where precision is non-negotiable. Furthermore, communication barriers can exacerbate these issues, making it difficult for buyers to convey their quality expectations clearly.

The Solution:

To mitigate quality assurance challenges, buyers should establish a robust quality control protocol right from the start. This includes requesting detailed documentation of the manufacturer’s quality management system (QMS) and certifications, such as ISO 9001. Engaging in a pre-production sample approval process, often referred to as First Article Inspection (FAI), allows buyers to verify that the initial batch meets their specifications before full-scale production begins.

Additionally, consider utilizing third-party inspection services that specialize in CNC machining. These services can conduct on-site inspections at various stages of the manufacturing process, ensuring that any deviations are identified early. Establishing clear communication channels with the supplier, including regular updates and progress reports, can also significantly enhance transparency and help maintain quality standards throughout the production run.

Scenario 2: Overcoming Lead Time and Delivery Delays

The Problem:

Lead times can be a major pain point for B2B buyers looking to procure CNC machining services from China. Many companies experience extended delivery timelines due to a variety of factors, including high demand, shipping delays, or inefficiencies in the manufacturing process. Such delays can disrupt supply chains, particularly for businesses that operate on tight schedules or have just-in-time inventory systems.

The Solution:

To address lead time concerns, buyers should prioritize suppliers with a proven track record of timely delivery. When evaluating potential CNC machining partners, inquire about their production capacity and their ability to scale operations to meet urgent demands. It’s also beneficial to establish contracts that include specific delivery timelines and penalties for delays, incentivizing the supplier to adhere to agreed-upon schedules.

Buyers can further streamline their procurement process by considering local suppliers or those with warehouses in proximity to their operational base. This strategy not only reduces shipping times but also mitigates the risks associated with international freight, such as customs delays. Additionally, leveraging technology like supply chain management software can provide real-time visibility into the production and shipping processes, allowing buyers to proactively manage potential delays.

Scenario 3: Managing Cost Fluctuations in CNC Machining Services

The Problem:

Cost management is another significant challenge for B2B buyers sourcing CNC machining services from China. Fluctuations in material costs, labor rates, and currency exchange rates can lead to unexpected expenses that strain budgets and affect project feasibility. This unpredictability can be especially daunting for businesses that require precise budgeting and financial forecasting.

The Solution:

To manage and mitigate cost fluctuations, buyers should engage in thorough market research before finalizing contracts. Understanding the current trends in material pricing and labor costs can help buyers negotiate better rates and make informed decisions about sourcing. Establishing long-term relationships with suppliers can also provide stability, as many manufacturers are willing to offer price locks for committed orders.

Additionally, implementing a transparent pricing structure in contracts can protect buyers from sudden increases. This includes specifying the basis for pricing adjustments, such as fluctuations in raw material costs or changes in labor rates. Regularly reviewing and assessing supplier performance and market conditions can empower buyers to make strategic decisions that optimize costs over time.

Strategic Material Selection Guide for cnc machining service china

When selecting materials for CNC machining services in China, international B2B buyers must consider various factors that affect the performance, cost, and suitability of the final products. Below, we analyze four common materials used in CNC machining, focusing on their properties, advantages, limitations, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Aluminum in CNC Machining?

Aluminum is a lightweight metal known for its excellent machinability and corrosion resistance. It has a relatively low density, making it suitable for applications where weight is a critical factor. Key properties include good thermal and electrical conductivity, along with a melting point of around 660°C.

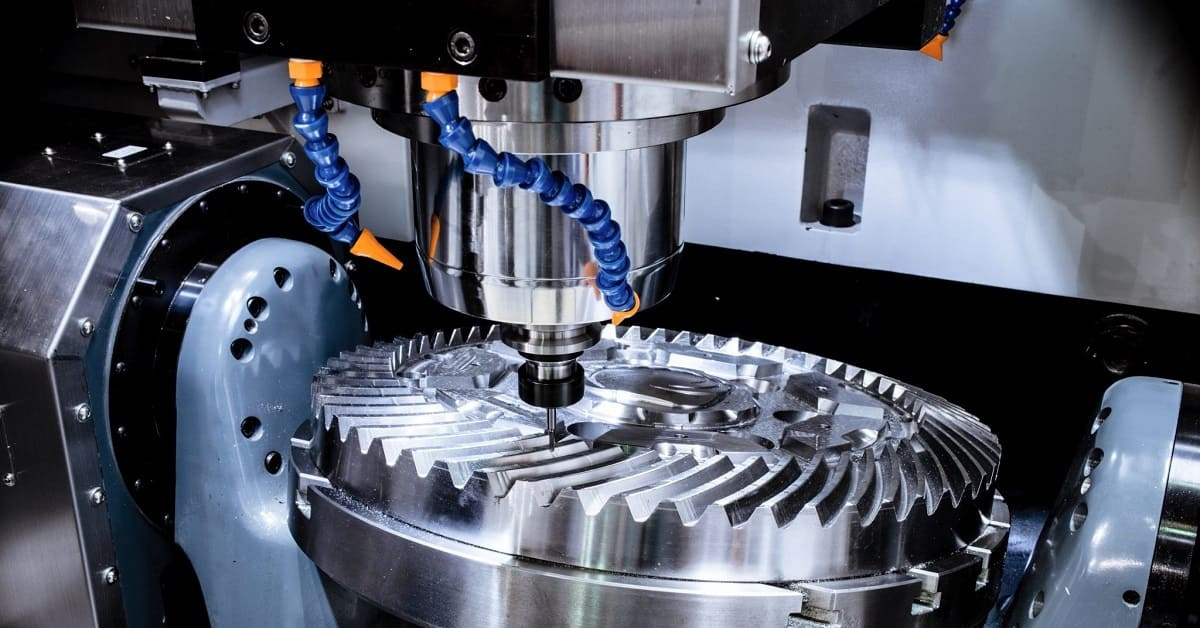

A stock image related to cnc machining service china.

Pros & Cons:

– Advantages: Aluminum is durable, easy to machine, and can be anodized for enhanced surface protection. Its lightweight nature makes it ideal for aerospace and automotive applications.

– Disadvantages: While generally cost-effective, aluminum can be more expensive than some plastics and may not be suitable for high-stress applications due to lower tensile strength.

Impact on Application:

Aluminum is compatible with various media, including water and certain chemicals, making it suitable for automotive and industrial applications.

Considerations for International Buyers:

Buyers should ensure compliance with standards such as ASTM B221 or DIN 1725 when sourcing aluminum components. Additionally, understanding local regulations regarding aluminum recycling can be beneficial.

How Does Stainless Steel Perform in CNC Machining?

A stock image related to cnc machining service china.

Stainless steel is renowned for its strength, durability, and resistance to corrosion and oxidation. It is often used in environments exposed to moisture and chemicals. Key properties include a high melting point (around 1400°C) and excellent mechanical properties.

Pros & Cons:

– Advantages: Stainless steel offers high durability and is suitable for a wide range of applications, including food processing and medical devices.

– Disadvantages: It can be more challenging to machine than aluminum due to its hardness, leading to higher tooling costs and longer production times.

Impact on Application:

Its corrosion resistance makes stainless steel ideal for applications involving harsh environments, such as marine and chemical processing.

Considerations for International Buyers:

Buyers from regions like Europe should be aware of compliance with standards such as EN 10088 for stainless steel grades. Understanding the specific grade required for their application is crucial.

Why Choose Plastics for CNC Machining?

Plastics, such as polycarbonate and nylon, are increasingly popular in CNC machining due to their versatility and lower cost. Key properties include a wide range of thermal and chemical resistances, depending on the type of plastic used.

Pros & Cons:

– Advantages: Plastics are lightweight, cost-effective, and can be easily molded into complex shapes. They also offer good insulation properties.

– Disadvantages: Plastics may not be suitable for high-temperature applications and can be less durable than metals.

Impact on Application:

Plastics are often used in consumer products, electrical components, and automotive parts where weight savings are essential.

Considerations for International Buyers:

Buyers should ensure that the selected plastic complies with relevant standards, such as ASTM D638 for tensile properties. Understanding the environmental impact and recyclability of plastics is also vital.

What Are the Benefits of Using Titanium in CNC Machining?

Titanium is known for its exceptional strength-to-weight ratio and corrosion resistance. It is often used in aerospace, medical implants, and high-performance applications. Key properties include a melting point of around 1668°C and excellent fatigue resistance.

Pros & Cons:

– Advantages: Titanium is highly durable and resistant to extreme environments, making it suitable for aerospace and medical applications.

– Disadvantages: It is more expensive than other materials and can be challenging to machine, requiring specialized tools and techniques.

Impact on Application:

Titanium is compatible with a wide range of media, including seawater, making it ideal for marine applications.

Considerations for International Buyers:

Buyers should be aware of compliance with standards such as ASTM F136 for titanium used in medical applications. Understanding the supply chain and sourcing challenges is also crucial due to titanium’s limited availability.

Summary Table of Material Selection for CNC Machining Services

| Material | Typical Use Case for cnc machining service china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components, automotive parts | Lightweight and corrosion-resistant | Lower tensile strength compared to steel | Medium |

| Stainless Steel | Food processing equipment, medical devices | High durability and corrosion resistance | Harder to machine, higher tooling costs | High |

| Plastics | Consumer products, electrical components | Cost-effective and versatile | Not suitable for high-temperature use | Low |

| Titanium | Aerospace, medical implants | Exceptional strength-to-weight ratio | High cost and challenging to machine | High |

This comprehensive analysis provides international B2B buyers with valuable insights into material selection for CNC machining services in China, helping them make informed decisions that align with their specific application needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc machining service china

What Are the Main Stages of Manufacturing for CNC Machining Services in China?

CNC machining services in China follow a structured manufacturing process that includes several key stages: material preparation, forming, assembly, and finishing. Understanding these stages can help international B2B buyers assess quality and efficiency.

How Is Material Prepared in CNC Machining?

Material preparation is the first critical step in the CNC machining process. This involves selecting high-quality raw materials such as metals, plastics, or composites based on the specifications outlined in the design. The materials are then cut to size and shape, which may include processes like sawing or shearing. For B2B buyers, ensuring that suppliers utilize certified materials can enhance product reliability and longevity.

What Forming Techniques Are Commonly Used in CNC Machining?

Once the materials are prepared, the next stage is forming. This is where the actual machining occurs. CNC machines utilize various cutting techniques such as milling, turning, and drilling. The choice of technique depends on the part’s complexity and the required precision. For instance, milling is often used for complex shapes, while turning is ideal for cylindrical parts. B2B buyers should inquire about the types of CNC machines used, as advanced technologies like 5-axis machining can significantly enhance precision and efficiency.

What Quality Control Measures Are Implemented in CNC Machining?

Quality assurance is a cornerstone of the CNC machining process, ensuring that products meet international standards. In China, manufacturers often adhere to ISO 9001 for general quality management, along with industry-specific certifications such as CE for European markets and API for the oil and gas sector.

What Are the Key QC Checkpoints in CNC Machining?

Quality control in CNC machining involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This is performed on raw materials and components upon receipt to ensure they meet specified requirements. Suppliers should provide documentation like certificates of compliance.

-

In-Process Quality Control (IPQC): This involves monitoring the manufacturing process in real-time. Operators regularly check dimensions and tolerances during machining to catch any deviations early.

-

Final Quality Control (FQC): After the machining process, products undergo a final inspection to verify that they conform to all specifications. This may include visual inspections and dimensional checks using precision measuring tools.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control measures is essential to mitigate risks. Here are some actionable insights:

What Audit Processes Should Be Considered?

-

Supplier Audits: Conducting onsite audits can provide a comprehensive understanding of a supplier’s quality management system. Look for ISO certifications and ask for evidence of regular audits performed by third parties.

-

Quality Reports: Requesting periodic quality reports can help assess a supplier’s performance over time. These reports should detail inspection results, non-conformities, and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services before shipment can provide an unbiased assessment of the product quality. This is particularly important for buyers from regions like Africa and South America, where logistical challenges may arise.

What Testing Methods Are Commonly Used in CNC Machining?

Testing methods are crucial for ensuring that the machined parts meet the required specifications. Common testing techniques include:

- Dimensional Inspection: Utilizing calipers, micrometers, and coordinate measuring machines (CMM) to verify dimensions.

- Surface Finish Testing: Ensuring that the surface finish meets the specified requirements, which can involve using roughness testers.

- Functional Testing: Depending on the component, functional testing may be necessary to ensure it operates correctly within its intended application.

What Nuances Should International Buyers Be Aware Of Regarding QC and Certification?

Understanding the nuances of quality control and certification is essential for international B2B buyers. Here are some key points:

-

Regional Standards: Different regions may have specific requirements. For instance, products exported to Europe must comply with CE marking, which indicates conformity with health, safety, and environmental protection standards.

-

Cultural Differences: Communication styles and business practices vary across regions. Buyers should be aware of these differences to foster effective collaboration with suppliers.

-

Documentation: Ensure that all relevant documentation, including quality certificates and inspection reports, is available and can be easily understood, especially when dealing with suppliers in non-English-speaking countries.

Conclusion: Enhancing Your Procurement Strategy for CNC Machining Services in China

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance measures in CNC machining is crucial for making informed purchasing decisions. By focusing on material preparation, forming techniques, quality control checkpoints, and verification methods, buyers can ensure they partner with reliable suppliers that meet their specific needs. By prioritizing quality and compliance, businesses can mitigate risks and enhance their supply chain efficiency.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc machining service china’

In this practical sourcing guide, we will outline essential steps for international B2B buyers looking to procure CNC machining services from China. This checklist is designed to help you navigate the complexities of sourcing, ensuring you find reliable suppliers that meet your specifications and quality requirements.

Step 1: Define Your Technical Specifications

Clearly outline the technical specifications for your CNC machining project. This includes dimensions, tolerances, materials, and surface finishes required for the components. Providing detailed specifications helps suppliers understand your needs and enables them to provide accurate quotes and timelines.

- Tip: Use CAD drawings or detailed sketches to convey complex designs.

- Importance: Well-defined specifications reduce the likelihood of miscommunication and errors during production.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential CNC machining service providers in China. Utilize platforms like Alibaba, Made-in-China, and Global Sources to find suppliers with a solid reputation.

- Tip: Look for suppliers with established profiles and positive reviews from previous buyers.

- Importance: A comprehensive supplier list provides you with options to compare quality, pricing, and capabilities.

Step 3: ✅ Verify Supplier Certifications

Ensure that the suppliers you are considering hold relevant industry certifications, such as ISO 9001 or ISO 13485, which indicate adherence to international quality management standards.

- Tip: Request copies of certification documents and check their validity with issuing organizations.

- Importance: Certifications are a marker of quality assurance and help mitigate risks associated with sourcing from overseas.

Step 4: Request Detailed Quotations

Ask shortlisted suppliers for detailed quotations that include pricing, lead times, and terms of service. This should encompass all aspects of the machining process, from material costs to shipping fees.

- Tip: Specify if you require samples before full production to assess quality.

- Importance: Detailed quotations allow for better price comparisons and help avoid hidden costs later in the process.

Step 5: Evaluate Supplier Capabilities

Assess the technical capabilities of potential suppliers by asking for their machinery specifications and production capacity. Understanding their equipment and technology will give insights into their ability to meet your demands.

- Tip: Inquire about their experience with similar projects or industries.

- Importance: This evaluation ensures the supplier can handle your project efficiently and with the desired precision.

Step 6: Conduct Factory Visits or Virtual Tours

If feasible, arrange factory visits to inspect the supplier’s operations. Alternatively, request virtual tours to observe their machining processes and quality control measures.

- Tip: Prepare a checklist of aspects to evaluate, such as cleanliness, equipment condition, and staff expertise.

- Importance: First-hand observations can reveal a lot about the supplier’s operational standards and commitment to quality.

Step 7: Establish Clear Communication Channels

Set up effective communication channels with your chosen supplier. Regular updates and open lines of communication will ensure that any issues can be addressed promptly during the production process.

- Tip: Use project management tools or software for tracking progress and managing documentation.

- Importance: Good communication fosters a collaborative relationship, leading to better outcomes and smoother project execution.

By following these steps, international B2B buyers can effectively navigate the sourcing process for CNC machining services in China, ensuring they partner with reliable suppliers that meet their specific needs.

Comprehensive Cost and Pricing Analysis for cnc machining service china Sourcing

What Are the Key Cost Components for CNC Machining Services in China?

When sourcing CNC machining services from China, understanding the cost structure is critical. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. Common materials like aluminum or stainless steel are generally more affordable than exotic alloys. Ensure to specify the type and grade of material to avoid unexpected costs.

-

Labor: Labor costs in China are typically lower than in Europe or the Americas. However, skilled labor, especially for complex machining tasks, can command higher wages. Understanding the expertise required for your project can help gauge labor costs accurately.

-

Manufacturing Overhead: This encompasses utilities, equipment maintenance, and facility costs. Overhead can vary based on the supplier’s operational efficiency and location within China.

-

Tooling: Tooling costs can be substantial, especially for custom parts requiring specialized tools. These costs are often one-time expenses, but they should be factored into the total pricing for projects with low production volumes.

-

Quality Control (QC): Implementing QC measures is vital to ensure product quality. Depending on the complexity and precision required, QC costs can vary. It’s advisable to discuss the QC protocols with suppliers upfront.

-

Logistics: Shipping costs can fluctuate based on the Incoterms agreed upon, distance from the manufacturing site, and the volume of the order. International shipping can add significant costs, so consider these in your overall budget.

-

Margin: Suppliers will typically add a profit margin to their costs. Understanding the average margins in the industry can help in negotiating better prices.

How Do Price Influencers Impact CNC Machining Costs?

Several factors can influence the pricing of CNC machining services:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Suppliers may offer discounts for bulk purchases, making it essential to evaluate your needs carefully.

-

Specifications and Customization: Highly customized parts require additional engineering and setup time, which can raise costs. Providing detailed specifications can help suppliers provide more accurate quotes.

-

Material Selection: The type of material impacts not only the cost but also the machining process. Some materials require more advanced machining techniques, leading to higher costs.

-

Quality and Certifications: Parts requiring certifications (e.g., ISO) or specific quality standards may incur additional costs. Ensure you communicate your quality requirements early in the process.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Established suppliers may charge more due to their reliability and quality assurance processes.

-

Incoterms: The chosen shipping terms (e.g., FOB, CIF) can affect total costs. Understanding these terms can help in budgeting and negotiations.

What Are Effective Negotiation Strategies for CNC Machining Sourcing?

-

Conduct Market Research: Familiarize yourself with average pricing for similar services. This knowledge can strengthen your negotiation position.

-

Ask for Detailed Quotes: Encourage suppliers to provide itemized quotes that break down costs. This transparency can reveal areas where costs can be reduced.

-

Leverage Volume Discounts: If you anticipate ongoing needs, negotiate for better pricing based on projected volumes rather than single orders.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial costs but also long-term costs such as maintenance, shipping, and potential rework. This holistic view can help justify higher upfront costs for better quality or service.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing and terms. A trusted partnership can also enhance communication and problem-solving.

What Should International Buyers Consider When Sourcing CNC Machining Services from China?

International buyers, especially from Africa, South America, the Middle East, and Europe, must consider the following:

-

Regulatory Compliance: Ensure that products comply with local regulations in your home country. This could affect material choices and certifications.

-

Cultural Differences: Understanding cultural nuances can facilitate smoother negotiations and partnerships.

-

Time Zones and Communication: Be mindful of time zone differences when scheduling meetings and setting deadlines.

-

Quality Expectations: Clearly outline quality expectations and ensure suppliers understand these to avoid costly errors.

Conclusion

While sourcing CNC machining services from China can present cost advantages, a thorough understanding of the cost components and price influencers is essential for making informed decisions. By leveraging negotiation strategies and considering the unique aspects of international sourcing, businesses can optimize their purchasing process and achieve better outcomes.

Alternatives Analysis: Comparing cnc machining service china With Other Solutions

Exploring Alternatives to CNC Machining Services from China

When considering CNC machining services, it’s essential to evaluate various alternatives to ensure the most suitable solution for your business needs. This section provides a comparative analysis of CNC machining services from China against other viable options, helping international B2B buyers make informed decisions.

| Comparison Aspect | Cnc Machining Service China | Additive Manufacturing (3D Printing) | Traditional Machining |

|---|---|---|---|

| Performance | High precision and repeatability | Suitable for complex geometries, but variable precision | High precision, but slower production speed |

| Cost | Competitive, often lower due to scale | Variable; can be cost-effective for low volumes | Higher labor and setup costs |

| Ease of Implementation | Requires skilled operators and programming | Relatively easy; requires minimal setup | Requires skilled labor and machine setup |

| Maintenance | Regular maintenance needed for equipment | Low maintenance; equipment can be expensive | Regular maintenance necessary, but parts can be simpler |

| Best Use Case | Large production runs with consistent quality | Prototyping, complex geometries, low-volume production | High-volume production with specific tolerances |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Additive Manufacturing (3D Printing)?

Additive manufacturing offers unique advantages, particularly in producing complex geometries that may be challenging or impossible to achieve with traditional methods. It allows for rapid prototyping, enabling businesses to test designs before full-scale production. However, while initial costs can be lower for low-volume runs, material costs can be high, and the technology may not yet match the precision of CNC machining for some applications. Additionally, the speed of production can be slower when scaling up for larger orders.

How Does Traditional Machining Compare to CNC Machining Services?

Traditional machining encompasses a range of techniques, such as turning and milling, which have been used for decades. This method can be highly effective for high-volume production runs where consistency and accuracy are critical. However, it often involves higher labor costs and more time-consuming setups, making it less cost-effective for smaller batches. Moreover, traditional machining may not provide the same level of flexibility in design changes as CNC machining or additive manufacturing, where adjustments can be made in the programming or design files.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate machining method hinges on various factors, including production volume, design complexity, cost considerations, and the required precision. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the strengths and weaknesses of each option is crucial. CNC machining services from China excel in high-volume production with consistent quality, while alternatives like additive manufacturing and traditional machining may offer unique advantages depending on specific project requirements. Careful analysis of these factors will empower buyers to make strategic decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for cnc machining service china

What Are the Essential Technical Properties in CNC Machining Services from China?

When engaging with CNC machining services, understanding key technical specifications is crucial for international B2B buyers. Here are some of the most important properties to consider:

-

Material Grade

– The material grade defines the type of raw material used in manufacturing parts, such as aluminum, steel, or plastic. Each material has specific characteristics, including strength, weight, and corrosion resistance. For B2B buyers, selecting the right material grade is essential as it directly impacts the performance and durability of the final product. -

Tolerance

– Tolerance refers to the allowable deviation from a specified dimension. In CNC machining, tighter tolerances lead to higher precision and quality. For example, a tolerance of ±0.01 mm is more precise than ±0.1 mm. B2B buyers must communicate their tolerance requirements clearly, as this affects the machining process, cost, and lead times. -

Surface Finish

– Surface finish describes the texture of a manufactured part’s surface, which can range from rough to smooth. Different applications may require specific finishes for aesthetic or functional reasons. Understanding the required surface finish helps buyers specify their needs and ensure the final product meets quality standards. -

Machining Process

– CNC machining encompasses various processes, including milling, turning, and drilling. Each process has its own advantages and is suitable for different applications. Buyers should consider which machining process aligns best with their project requirements to achieve optimal results. -

Lead Time

– Lead time refers to the time taken from the order placement to the delivery of the finished product. It is crucial for B2B buyers to understand the lead times associated with different CNC machining services, as this can impact project timelines and overall supply chain efficiency.

Which Trade Terms Should International Buyers Know in CNC Machining?

Familiarity with industry terminology can significantly enhance communication and negotiations with CNC machining providers. Here are some essential terms to understand:

-

OEM (Original Equipment Manufacturer)

– OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. B2B buyers often engage with OEMs for custom parts, emphasizing the importance of quality and reliability in the manufacturing process. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to avoid overcommitting to large orders that may not align with their needs or budget. -

RFQ (Request for Quotation)

– An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It typically includes specifications and requirements for the desired products. Providing a detailed RFQ helps ensure accurate quotes and speeds up the procurement process. -

Incoterms (International Commercial Terms)

– Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping, insurance, and risk management, ensuring smoother transactions. -

CNC (Computer Numerical Control)

– CNC refers to the automated control of machining tools through a computer. Understanding CNC is essential for buyers to appreciate the technology behind precision manufacturing and its benefits, such as increased efficiency and accuracy.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of CNC machining services in China more effectively, ensuring they make informed decisions that align with their business objectives.

Navigating Market Dynamics and Sourcing Trends in the cnc machining service china Sector

What Are the Key Market Dynamics and Trends in CNC Machining Services from China?

The CNC machining service sector in China is experiencing significant growth driven by several global factors. Firstly, the increasing demand for precision engineering across various industries such as aerospace, automotive, and electronics is a major catalyst. International buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly seeking reliable CNC service providers to maintain competitive advantages through cost-effective manufacturing solutions.

Emerging trends in B2B technology, such as the integration of advanced automation and artificial intelligence in CNC machining, are reshaping sourcing strategies. Companies are now investing in smart factories that utilize IoT (Internet of Things) to enhance production efficiency and reduce downtime. Additionally, the rise of Industry 4.0 is prompting buyers to prioritize suppliers who can offer digital capabilities, such as real-time monitoring and predictive maintenance.

Another important dynamic is the shift towards customization and rapid prototyping. As international markets demand shorter lead times and tailored solutions, CNC machining services that can efficiently adapt to these needs will stand out. Buyers are advised to assess suppliers not only on cost but also on their ability to innovate and respond to changing market demands.

How Can Sustainability and Ethical Sourcing Impact B2B Purchasing Decisions in CNC Machining?

Sustainability is becoming a crucial consideration for international B2B buyers in the CNC machining sector. The environmental impact of machining processes, including waste generation and energy consumption, is under scrutiny. As a result, buyers are increasingly seeking suppliers who demonstrate a commitment to sustainable practices.

Ethical sourcing is also gaining traction, with buyers looking for suppliers that adhere to social and environmental standards. This includes the use of eco-friendly materials, energy-efficient processes, and certifications such as ISO 14001 for environmental management. Buyers should inquire about the sustainability practices of potential CNC service providers to ensure alignment with their corporate social responsibility goals.

Furthermore, the demand for ‘green’ certifications and materials is on the rise. Suppliers who can provide documentation on the sustainability of their materials and processes will appeal to buyers focused on reducing their ecological footprint. This trend not only enhances brand reputation but also ensures compliance with increasingly stringent regulations in various regions, particularly in Europe.

What Is the Historical Context of CNC Machining Services in China?

The evolution of CNC machining services in China can be traced back to the late 20th century when the country began embracing advanced manufacturing technologies. Initially, the sector was characterized by low-cost labor and basic machining techniques. However, as China integrated into the global economy, it rapidly adopted CNC technology to meet the rising demand for precision and efficiency.

By the early 2000s, China emerged as a global leader in CNC machining, leveraging its manufacturing capabilities to cater to international markets. The focus shifted towards high-quality production, with investments in advanced machinery and skilled labor. This evolution has positioned China as a go-to destination for international B2B buyers seeking reliable and cost-effective CNC machining services. As the market continues to mature, buyers can expect ongoing advancements that will enhance the quality and efficiency of machining services.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc machining service china

-

How do I evaluate the quality of CNC machining services in China?

To assess the quality of CNC machining services, request samples of previous work, and review customer testimonials. Ensure the supplier has relevant certifications, such as ISO 9001, which indicates a commitment to quality management. Conduct a factory audit if possible to inspect equipment and processes firsthand. Additionally, inquire about their quality assurance protocols, including the use of precise measurement tools and techniques for quality control. -

What is the typical lead time for CNC machining services in China?

Lead times can vary based on the complexity of the parts and the supplier’s workload. Generally, standard CNC machining projects can take anywhere from 2 to 6 weeks from order confirmation to delivery. For urgent requests, some suppliers may offer expedited services, but this can increase costs. Always clarify lead times upfront and consider including penalties for delays in your contract to ensure timely delivery. -

What are the common payment terms for international CNC machining services?

Payment terms can vary widely among suppliers, but common practices include a 30% upfront deposit and the remaining 70% before shipment. Some suppliers may offer flexible terms like letter of credit or PayPal for smaller amounts. Always negotiate clear payment terms in your contract to avoid misunderstandings. Be cautious of suppliers asking for full payment upfront, as this can be a red flag. -

How do I ensure customization for my CNC machined parts?

To guarantee that your CNC machined parts meet specific requirements, provide detailed engineering drawings and specifications. Use CAD models to convey complex geometries effectively. Discuss customization options with the supplier early in the process, including material choices, finishes, and tolerances. A collaborative approach will help ensure the final product aligns with your expectations. -

What are the minimum order quantities (MOQs) for CNC machining in China?

Minimum order quantities can vary depending on the supplier and the complexity of the parts. Some manufacturers may accept orders as low as one unit, especially for prototypes, while others may require MOQs in the hundreds or thousands for mass production. Always confirm MOQs before engaging in negotiations, as lower MOQs can be beneficial for startups or small businesses looking to test the market. -

What should I know about logistics when sourcing CNC machining services from China?

When sourcing from China, consider logistics options for shipping, including air freight for faster delivery and sea freight for cost-effectiveness. Understand the incoterms (such as FOB or CIF) to clarify responsibilities for shipping and insurance. Partnering with a reliable freight forwarder can facilitate smoother customs clearance and help navigate any regulatory requirements for your specific country. -

How can I vet a CNC machining supplier in China effectively?

To vet a CNC machining supplier, start with online research and reviews. Use platforms like Alibaba, Global Sources, or industry-specific directories to find potential suppliers and check their ratings. Request references from past clients, and if possible, arrange for a visit to their facility. Ensure they have the necessary certifications and a transparent communication process to facilitate effective collaboration. -

What quality assurance measures should I expect from a CNC machining supplier?

A reputable CNC machining supplier should have established quality assurance protocols in place. Expect them to utilize advanced measurement tools, conduct in-process inspections, and perform final quality checks before shipping. Ask about their use of statistical process control (SPC) and whether they provide inspection reports with your order. This transparency is crucial in ensuring that the products meet your quality standards.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cnc machining service china

What Are the Key Takeaways for International B2B Buyers Considering CNC Machining Services from China?

In conclusion, strategic sourcing of CNC machining services from China presents significant advantages for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. By leveraging China’s advanced manufacturing capabilities, businesses can achieve high precision, reduced lead times, and cost efficiencies. It is essential for buyers to thoroughly evaluate suppliers based on their technological capabilities, quality assurance processes, and adherence to international standards.

Moreover, fostering strong relationships with Chinese manufacturers can lead to better negotiation terms and customized solutions that cater to specific project requirements. As the global landscape evolves, staying informed about market trends and innovations in CNC machining will empower businesses to make strategic decisions that enhance their competitive edge.

How Can International Buyers Prepare for Future CNC Machining Opportunities?

Looking ahead, the demand for CNC machining services will continue to grow as industries increasingly prioritize automation and precision engineering. International buyers should actively engage with potential suppliers, attend industry trade shows, and participate in webinars to remain ahead of the curve. By embracing a proactive approach to sourcing, businesses can not only optimize their operations but also position themselves as leaders in their respective markets. Start exploring your options today to harness the full potential of CNC machining services from China.