Unlock Cost Savings: The Ultimate EVSE China Guide (2025)

Introduction: Navigating the Global Market for evse china

The rapid expansion of electric vehicle (EV) infrastructure has positioned China as a pivotal player in the global Electric Vehicle Supply Equipment (EVSE) market. International B2B buyers often face challenges in sourcing reliable EVSE from China, particularly when navigating the complexities of quality assurance, supplier evaluation, and compliance with regional standards. This guide aims to demystify the process of procuring EVSE from China, addressing not only the types and applications of equipment available but also providing insights on supplier vetting, pricing strategies, and logistical considerations.

In this comprehensive resource, buyers from Africa, South America, the Middle East, and Europe—including key markets like Italy and Poland—will find actionable insights tailored to their unique needs. We delve into the critical aspects of sourcing EVSE, including understanding the diverse types of charging stations, evaluating technological advancements, and recognizing compliance requirements specific to different regions. By leveraging this guide, B2B buyers will be empowered to make informed purchasing decisions that align with their strategic goals.

With a focus on providing clarity and direction, this guide equips international buyers with the tools needed to successfully navigate the intricate landscape of sourcing EVSE from China. Whether you are looking to enhance your EV infrastructure or expand your product offerings, our expert insights will help you mitigate risks and capitalize on opportunities in this burgeoning market.

Understanding evse china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| AC Charging Stations | Utilizes alternating current; typically slower charging speeds; cost-effective. | Public charging networks, fleet operations. | Pros: Lower initial investment; widely available. Cons: Longer charging times; less suitable for high-demand users. |

| DC Fast Chargers | Provides direct current; rapid charging capabilities; higher power output. | Highway charging stations, commercial fleets. | Pros: Quick turnaround; ideal for time-sensitive applications. Cons: Higher installation costs; requires significant power infrastructure. |

| Wireless EV Chargers | Inductive charging technology; no physical connections; user-friendly. | Residential areas, luxury fleet services. | Pros: Convenient; reduces wear on charging ports. Cons: Higher cost; limited availability of compatible vehicles. |

| Smart Charging Solutions | Integrated software for monitoring and managing charging; often features load balancing. | Large businesses, utility companies, and car manufacturers. | Pros: Optimizes energy usage; can reduce operational costs. Cons: Requires technical expertise for setup; may involve ongoing software costs. |

| Portable EV Chargers | Compact and easy to transport; typically lower power output; versatile. | Emergency services, small businesses, and personal use. | Pros: Flexibility; useful in diverse settings. Cons: Slower charging speeds; may not meet high-demand needs. |

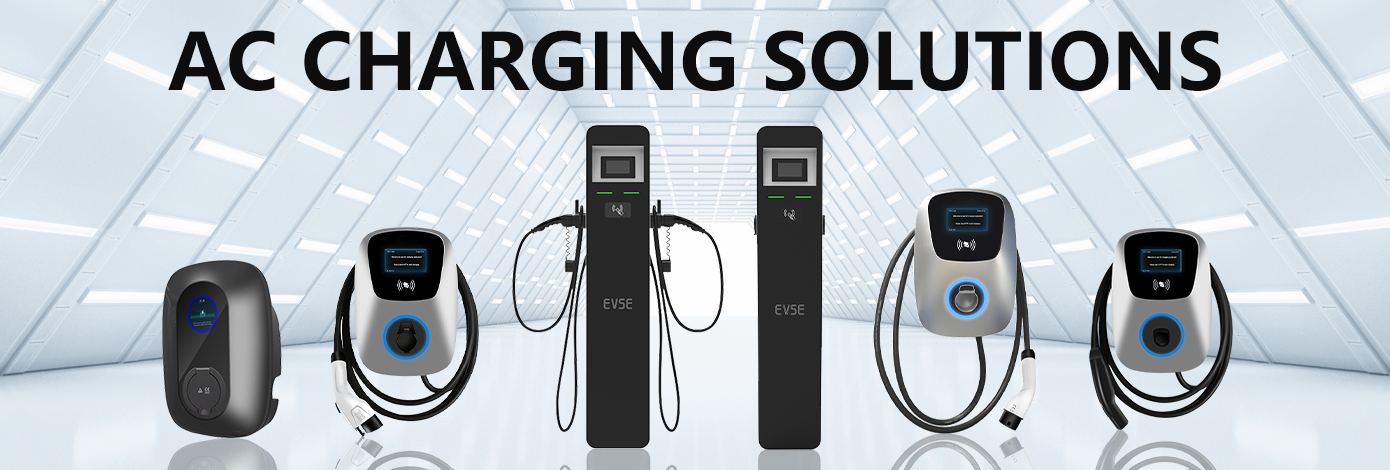

What Are the Key Characteristics of AC Charging Stations?

AC Charging Stations are the most common type of EV charging infrastructure. They use alternating current, which is generally more cost-effective to install than direct current systems. These stations are suitable for public charging networks and fleet operations where extended charging times are acceptable. B2B buyers should consider the lower initial investment and widespread availability, but be mindful of the longer charging durations, which may not meet the needs of high-demand users.

How Do DC Fast Chargers Benefit B2B Applications?

DC Fast Chargers are designed for rapid charging, providing direct current to electric vehicles, resulting in significantly reduced charging times. This makes them ideal for highway charging stations and commercial fleets that require quick turnaround times. B2B buyers should weigh the benefits of speed against the higher installation costs and the need for robust power infrastructure, which can complicate deployment in certain regions.

What Makes Wireless EV Chargers Unique for Businesses?

Wireless EV Chargers utilize inductive charging technology, allowing vehicles to charge without physical connections. This feature enhances user convenience and reduces wear on charging ports, making it ideal for residential areas and luxury fleet services. However, B2B buyers must consider the higher costs associated with these systems and the limited availability of compatible vehicles in their market, which may affect overall adoption.

Why Are Smart Charging Solutions Important for Large Enterprises?

Smart Charging Solutions integrate advanced software for monitoring and managing charging operations, often including features like load balancing to optimize energy usage. These systems are particularly beneficial for large businesses, utility companies, and car manufacturers that need to manage multiple charging points efficiently. While they offer the potential for reduced operational costs, B2B buyers should be prepared for the technical expertise required for setup and potential ongoing software costs.

How Do Portable EV Chargers Provide Flexibility for Businesses?

Portable EV Chargers are compact, making them easy to transport and suitable for various applications, including emergency services and small businesses. While they offer flexibility and can be used in diverse settings, the trade-off is typically slower charging speeds. B2B buyers should assess whether the versatility meets their operational needs, especially if they have high-demand charging requirements.

Related Video: How to Test an EVSE with the Fluke FEV100 Adapter

Key Industrial Applications of evse china

| Industry/Sector | Specific Application of evse china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electric Vehicle (EV) Manufacturing | Charging infrastructure for production facilities | Enhanced efficiency in production and reduced downtime | Quality standards, scalability, and compatibility with existing systems |

| Public Transport | EV charging stations for buses and taxis | Improved public transport sustainability and reduced operational costs | Location accessibility, power supply requirements, and maintenance support |

| Logistics and Fleet Management | Depot charging solutions for delivery vehicles | Lower fuel costs and optimized fleet operation | Charging speed, fleet size compatibility, and energy management systems |

| Renewable Energy | Integration with solar energy systems for charging | Cost savings and reduced carbon footprint | Compatibility with solar technologies and grid integration capabilities |

| Hospitality and Retail | EV charging stations at hotels and shopping centers | Increased customer satisfaction and enhanced brand image | User-friendly interfaces, payment systems, and location visibility |

How is EVSE China Used in Electric Vehicle Manufacturing?

In the electric vehicle manufacturing sector, EVSE China provides crucial charging infrastructure for production facilities. This application ensures that the electric vehicles being produced can be charged efficiently throughout the assembly process. By integrating robust charging solutions, manufacturers can enhance production efficiency and minimize downtime, which is essential for meeting growing demand. International buyers should focus on sourcing equipment that meets rigorous quality standards and is scalable to accommodate future production increases.

What Role Does EVSE China Play in Public Transport?

For public transport systems, EVSE China is pivotal in establishing charging stations for electric buses and taxis. This application not only contributes to the sustainability of public transport but also helps in reducing operational costs associated with fuel consumption. By implementing EV charging infrastructure, cities can improve their public transportation offerings, attracting more users. Buyers in this sector must consider location accessibility and ensure that the charging stations can handle the required power supply and maintenance needs.

A stock image related to evse china.

How Can Logistics and Fleet Management Benefit from EVSE China?

In logistics and fleet management, depot charging solutions provided by EVSE China are essential for optimizing the operations of delivery vehicles. This application translates to significant savings in fuel costs and improved fleet efficiency. By utilizing advanced charging technologies, businesses can ensure that their vehicles are always ready for operation. When sourcing these solutions, international buyers should evaluate charging speed capabilities, compatibility with their fleet sizes, and the integration of energy management systems to maximize operational efficiency.

Why is Renewable Energy Integration Important for EVSE China?

The integration of EVSE China with renewable energy systems, such as solar energy, is becoming increasingly important. This application allows businesses to charge electric vehicles using clean energy, resulting in cost savings and a reduced carbon footprint. For companies focused on sustainability, this integration is a strategic advantage. Buyers should prioritize sourcing solutions that are compatible with solar technologies and capable of seamless grid integration to optimize energy use.

How Do Hospitality and Retail Sectors Leverage EVSE China?

In the hospitality and retail sectors, EVSE China facilitates the installation of EV charging stations at hotels and shopping centers. This application not only enhances customer satisfaction by providing convenient charging options but also boosts the brand image as an environmentally conscious business. To effectively implement these solutions, buyers need to consider user-friendly interfaces, reliable payment systems, and visibility of the charging stations to attract customers.

Related Video: What are all the Laboratory Apparatus and their uses?

3 Common User Pain Points for ‘evse china’ & Their Solutions

Scenario 1: Navigating Compliance and Regulatory Challenges in EVSE Procurement

The Problem:

International B2B buyers often face significant challenges in ensuring that Electric Vehicle Supply Equipment (EVSE) sourced from China complies with local regulations and standards. For instance, buyers from Europe may find that certain charging stations do not meet the stringent European Union (EU) directives regarding safety and environmental impact. This lack of compliance can lead to costly delays, legal liabilities, and damage to reputation if the products are not fit for the intended market.

The Solution:

To effectively navigate compliance issues, buyers should conduct thorough research on the specific regulations that apply in their target markets. Engaging with local legal experts or consultants who specialize in EVSE can provide invaluable insights. Additionally, when sourcing products from China, prioritize suppliers who are well-versed in international standards and can provide certifications such as CE, UL, or ISO. Requesting detailed documentation and compliance reports during the procurement phase can mitigate risks and ensure that the products meet necessary requirements.

Scenario 2: Overcoming Quality Assurance Concerns with Chinese Suppliers

The Problem:

Quality assurance is a paramount concern for B2B buyers when dealing with suppliers in China. Many buyers report issues with inconsistent product quality, which can lead to operational inefficiencies and increased maintenance costs. This is particularly problematic for companies planning to deploy EVSE in multiple locations, as variations in product quality can result in a lack of uniformity and reliability in service delivery.

The Solution:

To combat quality assurance challenges, buyers should implement a multi-tiered vetting process for potential suppliers. This includes assessing suppliers’ manufacturing processes, quality control protocols, and past performance records. Establishing a partnership with a third-party quality assurance firm can also provide an additional layer of oversight. Conducting on-site inspections and audits during the production phase can further ensure that the products meet the desired quality standards. Building long-term relationships with reputable manufacturers who prioritize quality can lead to more consistent outcomes.

Scenario 3: Managing Supply Chain Disruptions in EVSE Procurement

The Problem:

Supply chain disruptions can severely impact the timely delivery of EVSE, leading to project delays and increased costs for B2B buyers. Factors such as geopolitical tensions, shipping delays, or unexpected tariffs can create uncertainty and hinder the procurement process. For companies in Africa or South America, where logistics infrastructure may be less robust, these challenges can be even more pronounced, creating a barrier to effective market entry.

The Solution:

To mitigate supply chain disruptions, B2B buyers should diversify their supplier base. Engaging with multiple suppliers across different regions can reduce dependency on a single source and enhance flexibility. Additionally, implementing robust inventory management practices can ensure that companies have a buffer stock to accommodate potential delays. Collaborating closely with logistics partners to monitor shipping routes and timelines can provide better visibility and allow for proactive adjustments. Establishing clear communication channels with suppliers about lead times and potential risks can foster transparency and help in effective planning.

By addressing these common pain points, international B2B buyers can enhance their procurement processes and successfully navigate the complexities of sourcing EVSE from China.

Strategic Material Selection Guide for evse china

When selecting materials for Electric Vehicle Supply Equipment (EVSE) in China, international B2B buyers must consider various factors that influence product performance, compliance, and cost-effectiveness. Here, we analyze four common materials used in EVSE applications, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Copper in EVSE Applications?

Copper is widely used in EVSE due to its excellent electrical conductivity and thermal properties. It typically has a high temperature rating, making it suitable for high-power applications. Additionally, copper exhibits good corrosion resistance when properly coated, which is crucial for outdoor installations.

Pros & Cons:

Copper’s primary advantage is its superior conductivity, which minimizes energy loss during transmission. However, it is relatively expensive compared to other metals and can be prone to oxidation if not adequately protected. Manufacturing complexity can also increase due to the need for specialized coatings or treatments.

Impact on Application:

Copper is compatible with various media, including electrical currents and environmental conditions. Its use in connectors and wiring is essential for reliable performance in charging stations.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM B170 for copper wire. In regions like Europe, adherence to RoHS regulations is critical, while buyers in Africa and South America should consider local sourcing options to mitigate costs.

How Does Aluminum Compare to Copper for EVSE?

Aluminum is another popular choice for EVSE components, particularly in applications where weight is a concern. It has a lower density than copper, making it easier to handle and install. Aluminum also offers good corrosion resistance, especially when anodized.

Pros & Cons:

The primary advantage of aluminum is its cost-effectiveness and lightweight nature, which can reduce shipping and installation costs. However, it has lower electrical conductivity than copper, which may necessitate larger wire sizes to achieve the same performance. This can complicate manufacturing processes.

Impact on Application:

Aluminum is suitable for high-voltage applications but may require additional considerations for thermal management due to its lower heat resistance compared to copper.

Considerations for International Buyers:

Buyers should be aware of the specific grades of aluminum that meet industry standards, such as ASTM B221. In Europe, compliance with EN 60228 for conductors is essential, while buyers in the Middle East may need to consider local environmental conditions that could affect material performance.

What Role Does Polycarbonate Play in EVSE Components?

Polycarbonate is a thermoplastic material frequently used for enclosures and protective casings in EVSE. It offers excellent impact resistance and can withstand a range of temperatures, making it suitable for outdoor use.

Pros & Cons:

The advantages of polycarbonate include its lightweight nature and high durability, which can lead to lower overall costs in terms of maintenance and replacement. However, it may not be as heat-resistant as some metals, which could limit its use in high-temperature environments.

Impact on Application:

Polycarbonate’s compatibility with various environmental conditions makes it ideal for housing electronic components, protecting them from moisture and debris.

Considerations for International Buyers:

Buyers should ensure that polycarbonate materials comply with relevant safety standards, such as UL 94 for flammability. In regions like Europe, compliance with REACH regulations is also necessary.

How Does Stainless Steel Enhance EVSE Durability?

Stainless steel is often chosen for its strength and corrosion resistance, particularly in harsh environments. It can withstand high temperatures and pressures, making it suitable for various EVSE applications.

Pros & Cons:

The key advantage of stainless steel is its durability and longevity, which can significantly reduce lifecycle costs. However, it is more expensive than other materials and can complicate manufacturing processes due to its hardness.

Impact on Application:

Stainless steel is particularly effective in outdoor installations where exposure to the elements is a concern. Its compatibility with various media, including water and chemicals, makes it a versatile choice.

Considerations for International Buyers:

Buyers should verify that the stainless steel used meets specific standards, such as ASTM A240. In Europe, compliance with EN 10088 is essential, while buyers from Africa and South America may need to consider sourcing options that align with local regulations.

Summary Table of Material Selection for EVSE in China

| Material | Typical Use Case for evse china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Wiring and connectors | Superior electrical conductivity | Higher cost and oxidation risk | High |

| Aluminum | Structural components | Lightweight and cost-effective | Lower conductivity than copper | Medium |

| Polycarbonate | Enclosures and casings | High impact resistance | Limited heat resistance | Medium |

| Stainless Steel | Outdoor installations | Excellent durability | Higher manufacturing complexity | High |

This strategic material selection guide provides international B2B buyers with critical insights into the materials used in EVSE applications in China, helping them make informed decisions that align with their operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for evse china

What Are the Key Manufacturing Processes for EVSE in China?

When considering Electric Vehicle Supply Equipment (EVSE) manufacturing in China, understanding the key stages of production is crucial for international B2B buyers. The manufacturing process typically consists of several stages: material preparation, forming, assembly, and finishing. Each stage employs specific techniques that ensure the production of high-quality EVSE products.

-

Material Preparation

The first step involves selecting high-grade materials such as metals, plastics, and electronic components. Suppliers often source materials from local and international vendors, ensuring compliance with environmental regulations. Quality assurance starts at this stage, with rigorous testing of incoming materials to verify they meet specifications. -

Forming Techniques

In this phase, raw materials are transformed into components through various techniques such as stamping, molding, and machining. CNC (Computer Numerical Control) machining is prevalent due to its precision and ability to produce complex shapes. Buyers should inquire about the types of machinery used and the qualifications of the operators to ensure high-quality outputs. -

Assembly Processes

The assembly stage is where individual components come together to form the final EVSE unit. Automated assembly lines are commonly utilized, enhancing efficiency and consistency. Workers undergo specialized training to handle components with care, especially sensitive electronic parts. It is advisable for B2B buyers to understand the assembly workflow to gauge production capabilities. -

Finishing Techniques

The finishing stage includes painting, coating, and quality checks before products are packaged. This stage is essential for aesthetics, corrosion resistance, and overall durability. Techniques such as powder coating and surface treatment are widely used. Buyers should verify that the finishing processes align with their specific needs, especially if the equipment will be exposed to harsh environmental conditions.

How Is Quality Assurance Implemented in EVSE Manufacturing?

Quality assurance (QA) is a critical aspect of the EVSE manufacturing process, ensuring that products meet international standards and customer expectations. B2B buyers should be familiar with both general and industry-specific quality standards.

-

What International Standards Apply to EVSE Manufacturing?

Manufacturers typically adhere to ISO 9001, which outlines the requirements for a quality management system (QMS). Compliance with this standard indicates a commitment to consistent quality and customer satisfaction. In addition, certifications like CE (Conformité Européenne) for the European market and API (American Petroleum Institute) standards for certain components are important indicators of quality. -

What Are the Key Quality Control Checkpoints?

Quality control is integrated throughout the manufacturing process, with specific checkpoints identified as follows:

– Incoming Quality Control (IQC): This step involves inspecting raw materials and components upon arrival. Any substandard materials are rejected to prevent downstream issues.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early. This includes regular inspections and tests at various stages of production.

– Final Quality Control (FQC): Before products are packaged and shipped, a thorough inspection is conducted to ensure they meet all specifications and standards. This includes functional tests and visual inspections. -

What Common Testing Methods Are Used in EVSE Quality Control?

Various testing methods are employed to ensure the reliability and safety of EVSE products:

– Electrical Testing: Ensures that the electrical components function correctly and safely.

– Environmental Testing: Assesses how well the equipment can withstand temperature fluctuations, humidity, and exposure to various environmental conditions.

– Safety Testing: Compliance with safety standards is verified through rigorous testing to prevent hazards such as electric shock or fire.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential before entering into a partnership.

-

Conducting Supplier Audits

Performing audits is one of the most effective ways to assess a supplier’s manufacturing processes and quality control practices. Buyers should request access to the supplier’s QMS documentation, including ISO certifications, and conduct on-site inspections if possible. An audit can reveal insights into the supplier’s operational efficiency and commitment to quality. -

Requesting Quality Reports

Suppliers should provide documentation of their quality control processes, including inspection reports, testing results, and corrective action plans for any issues encountered. These reports can give buyers a clearer picture of the supplier’s reliability. -

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can provide an unbiased evaluation of the supplier’s quality control measures. These services can conduct pre-shipment inspections and testing, ensuring that the products meet the agreed-upon specifications before they leave the factory.

What Are the Quality Certification Nuances for International Buyers?

Understanding the nuances of quality certifications is vital for B2B buyers operating in different regions. For instance, European buyers must ensure compliance with CE marking, which indicates that products meet EU safety, health, and environmental requirements. Meanwhile, buyers in Africa and South America may need to consider local regulations and standards, which could differ significantly from international norms.

Moreover, it’s essential for buyers to communicate their quality expectations clearly to suppliers. This ensures that there is mutual understanding regarding product specifications, testing requirements, and compliance with relevant certifications.

Conclusion

Navigating the complexities of manufacturing processes and quality assurance in EVSE production in China requires diligence and thorough understanding. By focusing on key manufacturing stages, quality standards, and verification processes, international B2B buyers can make informed decisions and establish successful partnerships with Chinese suppliers. Understanding the nuances of quality assurance will not only mitigate risks but also enhance the overall value of the supply chain.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘evse china’

The purpose of this guide is to provide international B2B buyers with a structured approach to sourcing Electric Vehicle Supply Equipment (EVSE) from China. This step-by-step checklist will help you navigate the complexities of the procurement process, ensuring that you make informed decisions and establish successful partnerships.

Step 1: Define Your Technical Specifications

Before you begin sourcing EVSE, it’s essential to clarify your technical requirements. Consider factors such as charging speed, compatibility with various electric vehicles, and necessary safety standards. Clearly defined specifications will help you communicate effectively with suppliers and ensure that the products meet your operational needs.

Step 2: Conduct Market Research

Understanding the EVSE market landscape in China is crucial. Research the latest trends, technologies, and pricing models. Identify potential suppliers and assess their market reputation through industry reports, forums, and trade associations. This research will provide you with insights into the competitive landscape and help you identify the most suitable partners.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is key. Request detailed company profiles, including years in business, production capacity, and expertise in EVSE manufacturing. Ask for case studies and references from clients in similar markets to validate their capabilities and reliability. This due diligence will mitigate risks associated with supplier selection.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers possess the necessary certifications and compliance documents. Look for international standards such as ISO 9001 for quality management and local certifications relevant to your market. Verifying these credentials not only guarantees product quality but also ensures compliance with regulatory requirements in your region.

Step 5: Request Samples for Testing

Before finalizing any orders, request product samples to assess quality firsthand. Testing samples allows you to evaluate the performance, safety features, and overall compatibility with your requirements. Ensure that the samples meet your specifications and provide feedback to the supplier for any necessary adjustments.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Establish clear terms that protect your interests, including warranties and after-sales support. Effective negotiation can lead to better pricing and terms that align with your business strategy.

Step 7: Establish Clear Communication Channels

Maintain open lines of communication with your supplier throughout the sourcing process. Utilize tools such as project management software or regular video calls to discuss progress, address any concerns, and ensure alignment on expectations. Clear communication fosters a stronger partnership and helps mitigate potential misunderstandings.

By following this checklist, B2B buyers from Africa, South America, the Middle East, and Europe can streamline their sourcing process for EVSE from China, ensuring they make informed decisions and build successful supplier relationships.

Comprehensive Cost and Pricing Analysis for evse china Sourcing

What Are the Key Cost Components for EVSE Sourcing from China?

When sourcing Electric Vehicle Supply Equipment (EVSE) from China, understanding the cost structure is essential for international B2B buyers. The primary components that contribute to the overall cost include:

-

Materials: The type and quality of materials used in manufacturing EVSE can significantly affect pricing. Common materials include metals, plastics, and electronic components. High-quality materials often lead to longer-lasting products but may increase initial costs.

-

Labor: Labor costs in China are generally lower than in many Western countries. However, the level of expertise required for specialized EVSE components can influence these costs. Skilled labor for assembly or installation may come at a premium.

-

Manufacturing Overhead: This includes costs related to utilities, factory maintenance, and administrative expenses. Understanding the manufacturer’s overhead can provide insights into their pricing strategy.

-

Tooling: Custom tooling for specific EVSE designs can be a significant upfront cost. Buyers should consider whether the tooling costs are amortized over a large order volume, potentially lowering the per-unit cost.

-

Quality Control (QC): Implementing rigorous quality control measures can add to manufacturing costs but is essential for ensuring product reliability. Buyers should inquire about the QC processes used by suppliers.

-

Logistics: Shipping costs can vary widely based on the chosen Incoterms and shipping methods. Land, air, or sea freight options will influence delivery times and costs.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. Understanding the typical margins in the EVSE market can help buyers negotiate better prices.

How Do Price Influencers Affect EVSE Costs from China?

Several factors can influence the pricing of EVSE when sourcing from China:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs due to economies of scale. Discussing MOQs with suppliers can lead to better pricing arrangements.

-

Specifications and Customization: Customized solutions may lead to higher costs due to additional design and tooling requirements. Buyers should clearly communicate their specifications to avoid unexpected price increases.

-

Materials and Quality Certifications: Higher quality materials and certifications (like ISO or CE) can increase costs but may provide long-term savings through reduced maintenance and greater customer satisfaction.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more for their proven quality, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is crucial for calculating total costs. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can significantly impact final pricing and logistics responsibilities.

What Buyer Tips Can Help Optimize Costs When Sourcing EVSE?

-

Negotiation Strategies: Always be prepared to negotiate. Understanding the cost structure allows buyers to identify areas where suppliers may have flexibility. Building a relationship can also yield better terms.

-

Focus on Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operational costs. A cheaper initial price may not be the most cost-effective option in the long run.

-

Research Pricing Nuances: International buyers, especially from regions like Africa, South America, the Middle East, and Europe (e.g., Italy, Poland), should be aware of local market conditions that can influence pricing, such as tariffs or import duties.

-

Request Multiple Quotes: Obtaining quotes from various suppliers can provide a clearer picture of the market and help identify competitive pricing.

-

Be Aware of Fluctuating Prices: Prices for materials and logistics can change frequently due to market conditions. Regularly reviewing contracts and supplier relationships can help mitigate risks associated with price volatility.

Disclaimer on Indicative Prices

It is essential to note that prices can vary based on numerous factors, including market conditions and specific supplier agreements. Buyers should always conduct thorough research and obtain updated quotes before making purchasing decisions.

Alternatives Analysis: Comparing evse china With Other Solutions

Exploring Alternatives to EVSE China: What Are the Options?

When considering charging infrastructure for electric vehicles (EVs), international B2B buyers must weigh various solutions. EVSE China has emerged as a prominent option, but it’s essential to explore alternative technologies and methods that may better suit specific business needs. This analysis compares EVSE China with two viable alternatives: European EV Charging Solutions and American Smart Charging Systems.

| Comparison Aspect | Evse China | European EV Charging Solutions | American Smart Charging Systems |

|---|---|---|---|

| Performance | High efficiency; rapid charging capabilities | Robust performance; compatible with multiple EV models | Advanced features; integrates with smart grids |

| Cost | Generally lower initial investment | Higher upfront cost; but includes extensive features | Moderate investment; long-term savings through efficiency |

| Ease of Implementation | Relatively easy to install; localized support | Varies; may require additional infrastructure | Requires integration with existing systems; potentially complex |

| Maintenance | Low maintenance due to durable components | Moderate maintenance; European standards ensure quality | Higher maintenance; advanced tech may require specialized knowledge |

| Best Use Case | Ideal for rapid deployment in emerging markets | Best for established markets with regulatory support | Suitable for tech-forward companies wanting smart solutions |

What Are the Advantages and Disadvantages of European EV Charging Solutions?

European EV Charging Solutions are recognized for their high standards and compatibility across various EV models. Their robust performance is enhanced by adherence to strict regulatory frameworks, ensuring safety and reliability. However, the initial investment can be significantly higher than that of EVSE China. This cost may deter some businesses, particularly in developing regions, where budget constraints are a critical factor. Additionally, implementation can vary, depending on local infrastructure, which may complicate the deployment process.

How Do American Smart Charging Systems Compare?

American Smart Charging Systems offer advanced features, such as integration with smart grids and dynamic load management. These systems can optimize energy usage, resulting in long-term operational savings. However, their complexity may pose challenges during installation and maintenance. Companies must ensure they have the technical expertise to manage these systems effectively. While the initial investment is moderate, the potential for efficiency gains can make this a worthwhile option for tech-oriented businesses, especially in markets with established EV infrastructure.

How Can B2B Buyers Choose the Right EV Charging Solution?

Selecting the right EV charging solution requires a thorough understanding of your specific operational needs and market conditions. For businesses in Africa, South America, and the Middle East, the cost-effectiveness and ease of implementation of EVSE China may make it the most suitable option, particularly for rapid deployment in emerging markets. Conversely, European EV Charging Solutions might be more appropriate for companies looking for reliability and compliance with stringent standards in established markets. Lastly, American Smart Charging Systems could appeal to businesses seeking innovative technologies that enhance energy efficiency but require a commitment to technical expertise.

In conclusion, B2B buyers must carefully assess their operational context, budget constraints, and long-term goals when comparing EVSE China with alternative solutions. By aligning the choice of EV charging infrastructure with their strategic objectives, businesses can optimize their investments and enhance their sustainability efforts.

Essential Technical Properties and Trade Terminology for evse china

What Are the Key Technical Properties of EVSE Products from China?

When considering Electric Vehicle Supply Equipment (EVSE) from China, understanding its essential technical properties is critical for making informed purchasing decisions. Here are some key specifications that international B2B buyers should be aware of:

-

Material Grade

– The quality of materials used in EVSE construction significantly affects durability and performance. Common materials include high-grade aluminum and stainless steel, which offer corrosion resistance and longevity. Buyers should assess material certifications to ensure compliance with international standards, especially when sourcing for regions with varying climates. -

Charging Power Capacity

– The charging power capacity, typically measured in kilowatts (kW), determines how quickly an electric vehicle can be charged. Standard levels include Level 2 (up to 22 kW) and DC Fast Charging (up to 350 kW). B2B buyers must match the charging capacity with the needs of their clientele to maximize efficiency and customer satisfaction. -

Ingress Protection (IP) Rating

– The IP rating indicates the degree of protection against dust and water intrusion. An IP rating of at least IP65 is recommended for outdoor EVSE installations to ensure reliability in various weather conditions. Understanding these ratings helps buyers select equipment that will perform well in their specific environments. -

Tolerance Levels

– Tolerance levels refer to the permissible limits of variation in dimensions and performance. High-precision components with tight tolerances are essential for safety and compatibility with various vehicle models. Buyers should verify that manufacturers adhere to stringent quality control processes to minimize defects. -

Communication Protocols

– EVSE must support various communication protocols such as OCPP (Open Charge Point Protocol) and ISO 15118 for seamless integration with charging networks and user interfaces. Knowledge of these protocols is crucial for buyers looking to implement smart charging solutions.

What Common Trade Terminology Should B2B Buyers Know?

Understanding trade terminology is essential for effective communication and negotiation in the EVSE market. Here are some key terms that international buyers should familiarize themselves with:

-

OEM (Original Equipment Manufacturer)

– An OEM produces parts or equipment that may be marketed by another manufacturer. In the context of EVSE, working with an OEM can assure buyers of product authenticity and quality, as these manufacturers often adhere to rigorous industry standards. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers to manage inventory costs and ensure they meet supplier requirements without overcommitting capital. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing and other details for specified products or services. It is a crucial step in the procurement process, allowing buyers to compare options and make informed decisions based on budget and specifications. -

Incoterms (International Commercial Terms)

– Incoterms define the responsibilities of buyers and sellers in international trade transactions. Familiarity with terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) helps buyers understand shipping costs and liabilities, thus facilitating smoother negotiations. -

Lead Time

– Lead time is the time taken from placing an order to receiving the goods. For B2B buyers, understanding lead times is essential for project planning and ensuring that EVSE installations align with market demands.

By grasping these technical properties and trade terms, B2B buyers from Africa, South America, the Middle East, and Europe can navigate the EVSE landscape in China more effectively, ensuring they make informed decisions that align with their operational needs and market conditions.

Navigating Market Dynamics and Sourcing Trends in the evse china Sector

What Are the Key Market Dynamics in the EVSE China Sector for International Buyers?

The Electric Vehicle Supply Equipment (EVSE) sector in China is rapidly evolving, driven by a combination of global sustainability initiatives and local government policies that prioritize electric mobility. International B2B buyers, especially those from Africa, South America, the Middle East, and Europe, should be aware of several key trends shaping the landscape.

One significant driver is the Chinese government’s commitment to reducing carbon emissions, which has resulted in substantial investments in EV infrastructure. This includes the expansion of charging networks and the integration of advanced technologies such as smart charging solutions. Additionally, there is a growing emphasis on interoperability standards, which allows for seamless integration across different EV models and charging stations, enhancing user experience.

Emerging B2B tech trends include the rise of digital platforms that facilitate the sourcing of EVSE components, enabling buyers to access a wider range of suppliers and products. Blockchain technology is also gaining traction for improving supply chain transparency and traceability, which is particularly vital for international transactions. Buyers from regions like Europe, which have stringent compliance requirements, will find these advancements beneficial.

In summary, the market dynamics in the EVSE sector are characterized by strong governmental support, technological advancements, and a growing emphasis on interoperability. International buyers must stay informed about these trends to effectively navigate the sourcing landscape and capitalize on opportunities.

How Can Sustainability and Ethical Sourcing Impact Your B2B Decisions in the EVSE Sector?

Sustainability and ethical sourcing have become critical considerations for international B2B buyers in the EVSE sector. As global awareness of environmental impact grows, buyers are increasingly seeking products that align with sustainable practices. This includes sourcing materials that are recyclable, reducing waste in the manufacturing process, and opting for suppliers who adhere to ethical labor practices.

The environmental impact of EVSE production cannot be overlooked. Components such as batteries and charging units often require materials that can lead to significant ecological degradation if not sourced responsibly. International buyers must evaluate their suppliers’ practices, looking for certifications that indicate adherence to environmental standards, such as ISO 14001, which focuses on effective environmental management systems.

Furthermore, many buyers are now prioritizing suppliers who utilize “green” certifications and sustainable materials. This not only enhances the company’s brand reputation but also aligns with the growing consumer demand for eco-friendly products. For instance, sourcing from manufacturers that use recycled metals or biodegradable plastics can significantly reduce the overall carbon footprint of the supply chain.

In essence, incorporating sustainability and ethical sourcing into B2B decisions not only meets regulatory and consumer expectations but also fosters long-term relationships with suppliers committed to responsible practices.

What is the Brief Evolution of the EVSE Sector in China?

The EVSE sector in China has undergone significant evolution over the past decade. Initially, the market was primarily focused on basic charging infrastructure, largely driven by domestic demand for electric vehicles. However, as technological advancements emerged, the sector expanded to include smart charging solutions, fast-charging networks, and advanced payment systems.

Government policies have played a pivotal role in this evolution, with initiatives aimed at promoting electric vehicle adoption and enhancing charging infrastructure. The introduction of subsidies and incentives has encouraged manufacturers to innovate and improve the efficiency of their EVSE products.

Today, the Chinese EVSE market is not only the largest in the world but also a hub for technological innovation, attracting international buyers seeking to leverage these advancements. Understanding this evolution is essential for B2B buyers looking to make informed decisions in a rapidly changing landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of evse china

-

How do I evaluate the quality of EVSE products from China?

To assess the quality of Electric Vehicle Supply Equipment (EVSE) from Chinese suppliers, consider requesting product certifications such as CE, UL, and ISO. Conduct factory audits or third-party inspections to verify manufacturing practices. Additionally, seek samples for testing and review customer testimonials or case studies. Engaging a local expert familiar with the Chinese market can provide insights into reputable manufacturers and help ensure the products meet your standards. -

What are the key factors to consider when selecting a supplier for EVSE in China?

When selecting an EVSE supplier in China, evaluate their production capacity, technological expertise, and experience in exporting to your region. Assess their ability to provide customized solutions tailored to local market needs, including voltage specifications and plug types. It’s also crucial to consider their communication responsiveness and support services, which can greatly influence the efficiency of your procurement process. -

What payment terms should I negotiate when sourcing EVSE from China?

When negotiating payment terms, consider options such as a letter of credit (LC) for secure transactions or a partial upfront payment followed by the balance upon delivery. Aim for terms that provide you with leverage and security, especially if you are ordering large quantities. Additionally, clarify the currency for transactions to avoid exchange rate fluctuations and ensure that the terms are aligned with your cash flow management strategies. -

What minimum order quantities (MOQs) are typical for EVSE suppliers in China?

MOQs for EVSE suppliers in China can vary widely, typically ranging from 50 to 500 units depending on the manufacturer and product type. Some suppliers may offer lower MOQs for customized products, especially if you are willing to cover setup costs. Always clarify MOQs upfront and explore negotiation options, particularly if you are entering a long-term partnership that could lead to larger future orders. -

How can I ensure timely delivery of EVSE products from China?

To ensure timely delivery, establish clear timelines in your purchase agreement and maintain regular communication with your supplier. Consider using freight forwarders who specialize in international shipping, as they can help navigate customs and logistics challenges. Additionally, opt for suppliers with a proven track record of on-time delivery, and inquire about their inventory management practices to minimize delays.

A stock image related to evse china.

-

What are the common customization options for EVSE sourced from China?

Many Chinese manufacturers offer extensive customization options for EVSE, including branding, specific voltage configurations, and features tailored to local regulations. Discuss your requirements in detail with the supplier to explore available options. Additionally, request prototypes to evaluate the customization before placing a large order, ensuring that the final product meets your specifications and market needs. -

How do I verify the legitimacy of an EVSE supplier in China?

To verify a supplier’s legitimacy, conduct thorough background checks by reviewing their business licenses, certifications, and company history. Utilize platforms such as Alibaba or Global Sources, which offer verification services for suppliers. Additionally, consider visiting the supplier’s factory or hiring a local consultant to perform due diligence, ensuring that they have a solid reputation and meet international quality standards. -

What logistics considerations should I keep in mind when importing EVSE from China?

When importing EVSE from China, consider logistics factors such as shipping methods (air vs. sea), customs clearance procedures, and potential tariffs or duties applicable in your country. Ensure your supplier provides all necessary documentation, including commercial invoices and packing lists. Collaborating with a reputable freight forwarder can facilitate smoother logistics, helping you navigate the complexities of international trade and ensuring compliance with local regulations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for evse china

How Can Strategic Sourcing Enhance Your EVSE Procurement from China?

As the electric vehicle charging infrastructure market continues to expand globally, the significance of strategic sourcing from China becomes increasingly evident. International B2B buyers, especially from Africa, South America, the Middle East, and Europe, can leverage China’s manufacturing strengths and technological advancements to secure competitive pricing and superior product quality in Electric Vehicle Supply Equipment (EVSE).

By prioritizing partnerships with reputable Chinese suppliers, buyers can not only enhance their supply chain resilience but also gain access to innovative solutions that align with local market demands. The importance of conducting thorough market research and due diligence cannot be overstated; it allows companies to identify the right suppliers who meet their specific needs while adhering to international quality standards.

What Should International Buyers Consider for Future Sourcing?

Looking ahead, international buyers should remain vigilant about evolving market trends, regulatory changes, and technological advancements within the EVSE sector. Engaging in strategic sourcing will not only facilitate cost savings but also foster sustainable practices that are increasingly valued by consumers and governments alike.

In conclusion, the future of EVSE procurement from China is promising. B2B buyers are encouraged to take proactive steps in building relationships with Chinese manufacturers, ensuring they are well-positioned to capitalize on the growth of the electric vehicle market. Embrace strategic sourcing as a vital component of your procurement strategy to drive success in your EVSE initiatives.