Unlock Cost Savings: The Ultimate Guide to Raw Materials China (2025)

Introduction: Navigating the Global Market for raw materials china

In the complex landscape of global trade, sourcing raw materials from China presents a unique set of challenges for international B2B buyers. With fluctuating prices, diverse quality standards, and varying supplier reliability, navigating this market can feel overwhelming, particularly for businesses in Africa, South America, the Middle East, and Europe. This guide aims to demystify the process of procuring raw materials from China, focusing on key aspects such as types of materials available, their applications across industries, effective supplier vetting strategies, and cost considerations.

Understanding the intricacies of sourcing raw materials is vital for making informed purchasing decisions. This guide equips B2B buyers with actionable insights to help them identify reputable suppliers, negotiate favorable terms, and mitigate risks associated with international procurement. By exploring the diverse range of materials available—from metals and minerals to chemicals and textiles—businesses can tailor their sourcing strategies to meet specific operational needs.

Moreover, this comprehensive resource emphasizes the importance of cultural awareness and communication when engaging with Chinese suppliers, ensuring smoother transactions and fostering long-term partnerships. With a focus on practical solutions and expert recommendations, this guide empowers international buyers to confidently navigate the global market for raw materials in China, ultimately enhancing their competitive edge in a rapidly evolving marketplace.

Understanding raw materials china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Steel | High tensile strength, durability | Construction, automotive, manufacturing | Pros: Strong, versatile; Cons: Price volatility due to global demand. |

| Rare Earth Elements | Unique magnetic and conductive properties | Electronics, renewable energy, defense | Pros: Essential for advanced tech; Cons: Limited suppliers, geopolitical risks. |

| Copper | Excellent conductivity and malleability | Electrical wiring, plumbing, electronics | Pros: High demand in green technologies; Cons: Price fluctuations, environmental concerns. |

| Aluminum | Lightweight, corrosion-resistant | Aerospace, packaging, construction | Pros: Cost-effective and recyclable; Cons: Energy-intensive production process. |

| Cement | Fundamental binding material | Infrastructure, construction | Pros: Widely available, essential for construction; Cons: Carbon footprint concerns. |

What are the Characteristics of Steel as a Raw Material from China?

Steel is one of the most widely used raw materials globally, known for its high tensile strength and durability. In China, steel production is characterized by advanced manufacturing techniques and a vast supply chain network. Buyers from sectors such as construction, automotive, and manufacturing find steel indispensable due to its versatility and structural integrity. However, the market is subject to price volatility driven by global demand, which can affect budgeting and procurement strategies.

Why are Rare Earth Elements Crucial for Modern Technology?

Rare Earth Elements (REEs) are a group of 17 elements critical for various high-tech applications, including electronics, renewable energy technologies, and defense systems. China’s dominance in the production of REEs is significant, making it essential for international buyers to establish reliable sourcing channels. The unique magnetic and conductive properties of these materials make them indispensable in manufacturing advanced technology products. However, buyers should be aware of the limited number of suppliers and the geopolitical risks associated with sourcing from China.

How Does Copper Play a Role in B2B Applications?

Copper is another vital raw material, recognized for its excellent electrical conductivity and malleability. It is extensively used in electrical wiring, plumbing, and electronics, making it a crucial component in green technologies such as solar panels and electric vehicles. While copper is highly sought after, buyers must navigate price fluctuations and consider the environmental impacts of mining and production. Establishing long-term relationships with suppliers can mitigate these risks.

What are the Advantages of Using Aluminum in Various Industries?

Aluminum is prized for its lightweight and corrosion-resistant properties, making it a popular choice in industries such as aerospace, packaging, and construction. Its cost-effectiveness and recyclability enhance its appeal to B2B buyers looking for sustainable materials. However, the production of aluminum is energy-intensive, which can lead to higher costs and environmental concerns. Buyers should weigh these factors when considering aluminum for their projects.

Why is Cement a Fundamental Material in Construction?

Cement is a fundamental binding material essential for infrastructure and construction projects worldwide. China is one of the largest producers of cement, ensuring a steady supply for international buyers. Its widespread availability makes it an attractive option, but buyers must also consider the environmental impact, particularly its carbon footprint during production. Sustainable sourcing practices can help mitigate these concerns while ensuring project viability.

Related Video: Exploiting Africa – How China and Europe hunt for the raw materials of the future | DW Documentary

Key Industrial Applications of raw materials china

| Industry/Sector | Specific Application of Raw Materials from China | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Steel and Cement Production | Enhanced structural integrity and durability | Quality certifications, compliance with local standards |

| Electronics Manufacturing | Rare Earth Elements for Electronics | Improved performance and efficiency | Supplier reliability, traceability, and environmental impact |

| Automotive | Aluminum Alloys for Lightweight Components | Fuel efficiency and reduced emissions | Material specifications, cost-effectiveness, and lead times |

| Renewable Energy | Lithium for Batteries | Increased energy storage capacity | Purity levels, sourcing ethics, and geopolitical stability |

| Agriculture | Fertilizers and Soil Amendments | Enhanced crop yield and soil health | Nutrient content, compatibility with local crops, and pricing |

How are Raw Materials from China Used in the Construction Industry?

In the construction sector, raw materials from China, particularly steel and cement, are critical for building infrastructure. These materials provide the necessary strength and durability for structures, which is essential in regions prone to extreme weather conditions. International buyers, especially in Africa and South America, must ensure that the sourced materials meet local construction standards and quality certifications to avoid potential project delays and safety issues.

What Role do Rare Earth Elements Play in Electronics Manufacturing?

Rare earth elements sourced from China are vital in the electronics manufacturing industry, used in components such as magnets, batteries, and displays. These materials enhance the performance and efficiency of electronic devices, making them indispensable for tech companies. For international buyers, particularly from Europe and the Middle East, it is crucial to evaluate supplier reliability and ensure that the sourcing practices are environmentally sustainable to mitigate reputational risks.

How are Aluminum Alloys Transforming the Automotive Sector?

Aluminum alloys sourced from China are increasingly used in the automotive sector to create lightweight components. This shift contributes to fuel efficiency and reduced emissions, aligning with global sustainability goals. Buyers from regions like Australia and Kenya should focus on material specifications and cost-effectiveness, while also considering the supplier’s ability to meet lead times, which can be critical in the fast-paced automotive market.

Why is Lithium Essential for the Renewable Energy Sector?

Lithium, primarily sourced from China, is a key raw material for battery production, especially in the renewable energy sector. It plays a crucial role in increasing energy storage capacity for solar and wind energy solutions. International B2B buyers must prioritize purity levels and ethical sourcing practices, as geopolitical stability can significantly impact supply chains. Understanding local regulations and market dynamics is essential for successful procurement.

How do Fertilizers and Soil Amendments Impact Agriculture?

In agriculture, raw materials from China, such as fertilizers and soil amendments, are essential for enhancing crop yield and soil health. These products provide vital nutrients that improve agricultural productivity, particularly in regions like Africa and South America where food security is a pressing issue. Buyers should consider the nutrient content and compatibility with local crops, as well as pricing strategies to ensure cost-effectiveness in their sourcing decisions.

Related Video: Kerala News LIVE: Police Uses Water Cannons As SFI Holds March Against Kerala Governor

3 Common User Pain Points for ‘raw materials china’ & Their Solutions

Scenario 1: Navigating Quality Control Challenges in Raw Materials from China

The Problem: One of the most significant challenges for B2B buyers sourcing raw materials from China is ensuring consistent quality. Many buyers have experienced discrepancies between the materials received and the specifications provided. This often leads to production delays, increased costs, and sometimes, damage to the brand’s reputation. Buyers from regions like Africa and South America may particularly struggle with this issue due to geographical distance and varying quality standards.

The Solution: To mitigate quality control issues, it’s essential to establish a robust supplier vetting process. Start by conducting thorough research on potential suppliers, including verifying certifications and past client reviews. Engaging a local quality assurance partner can also bridge the gap in communication and standards. Before placing a large order, consider requesting samples to assess quality firsthand. Additionally, implementing regular quality audits during production can help catch issues early, ensuring that the final product meets your specifications. Utilize technology, such as supplier management software, to streamline communication and maintain records of quality checks.

Scenario 2: Overcoming Language and Cultural Barriers in Sourcing Raw Materials

The Problem: International B2B buyers often face significant language and cultural barriers when dealing with suppliers in China. Misunderstandings can arise regarding product specifications, delivery schedules, and payment terms. Buyers from the Middle East and Europe, for instance, might find it challenging to negotiate effectively due to these barriers, leading to frustration and potential losses.

The Solution: To overcome these challenges, consider employing a bilingual sourcing agent who understands both the local market and cultural nuances. This agent can facilitate communication and help negotiate favorable terms. Additionally, investing in translation software or services can assist in ensuring that all documents and communications are clear and accurate. When drafting contracts, use simple and unambiguous language to minimize misunderstandings. Educating your team about Chinese business etiquette, such as the importance of relationships (Guanxi), can also enhance interactions with suppliers, fostering better partnerships.

Scenario 3: Managing Supply Chain Disruptions When Sourcing from China

The Problem: Supply chain disruptions have become increasingly common, especially for international B2B buyers reliant on raw materials from China. Factors such as geopolitical tensions, natural disasters, or even pandemics can lead to delays in shipments and increased costs. Buyers in regions like Europe may find themselves particularly vulnerable, as they often depend heavily on timely deliveries for production schedules.

The Solution: To effectively manage potential disruptions, diversifying your supplier base is crucial. Instead of relying solely on one or two suppliers, establish relationships with multiple sources for the same raw materials. This strategy not only provides alternatives in case of disruption but also enhances competitive pricing. Additionally, consider implementing a just-in-time (JIT) inventory system, allowing for more flexibility in managing stock levels and reducing holding costs. Investing in supply chain visibility tools can also help monitor shipments in real-time, allowing you to anticipate delays and adjust plans accordingly. Establishing clear communication channels with suppliers will facilitate quick responses to any issues that may arise, ensuring that your operations remain unaffected.

By proactively addressing these common pain points, B2B buyers can enhance their sourcing strategies and build more resilient supply chains when dealing with raw materials from China.

Strategic Material Selection Guide for raw materials china

When selecting raw materials from China, international B2B buyers must consider various factors that influence product performance, compliance, and overall suitability for their specific applications. This guide analyzes four common materials sourced from China, focusing on their properties, advantages, disadvantages, and considerations for buyers, particularly from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Steel in Raw Material Sourcing?

Steel is one of the most widely used raw materials due to its strength and versatility. Key properties include high tensile strength, excellent ductility, and good corrosion resistance when treated. It can withstand high temperatures and pressures, making it suitable for a variety of applications, from construction to automotive manufacturing.

Pros & Cons: The primary advantage of steel is its durability and ability to be recycled, which aligns with sustainable practices. However, the manufacturing complexity can lead to higher costs, especially for specialized grades. Additionally, its weight may be a limitation in applications where lightweight materials are preferred.

Impact on Application: Steel is compatible with various media, including water, oil, and gases, but its corrosion resistance can vary based on the specific type of steel used. Buyers must consider the environmental conditions the material will face, particularly in humid or corrosive environments.

Considerations for International Buyers: Compliance with international standards such as ASTM or DIN is crucial. Buyers from regions like Africa and South America may face challenges related to logistics and import regulations, necessitating thorough research on local standards and certifications.

How Do Aluminum Properties Affect Material Selection?

Aluminum is renowned for its lightweight nature and resistance to corrosion. It has a lower density than steel, making it ideal for applications requiring weight reduction without sacrificing strength. Aluminum also exhibits excellent thermal and electrical conductivity.

Pros & Cons: The key advantage of aluminum is its high strength-to-weight ratio, making it perfect for aerospace and automotive applications. However, its relatively higher cost compared to steel and susceptibility to deformation under high stress can be drawbacks. Additionally, aluminum can be more complex to manufacture, especially when forming intricate shapes.

Impact on Application: Aluminum is compatible with various media, including air and water, but may not be suitable for highly acidic or alkaline environments. Buyers need to assess the specific conditions to ensure longevity and performance.

Considerations for International Buyers: Buyers should ensure compliance with standards such as JIS and consider the availability of aluminum alloys that meet their specific needs. Import tariffs and trade agreements can also impact overall costs, particularly for buyers in Europe and the Middle East.

What Are the Advantages of Using Copper as a Raw Material?

Copper is well-known for its excellent electrical conductivity and thermal properties. It is also resistant to corrosion, making it a popular choice for electrical wiring and plumbing applications. Its malleability allows for easy shaping and forming.

Pros & Cons: The main advantage of copper is its superior conductivity, which is essential for electrical applications. However, it is relatively expensive compared to other metals, and its softness can lead to wear in high-friction applications. Additionally, sourcing copper may involve ethical considerations related to mining practices.

Impact on Application: Copper is compatible with various media, including water and gases, but its use in corrosive environments must be carefully evaluated. Buyers should consider protective coatings or alloys to enhance performance.

Considerations for International Buyers: Compliance with international standards is vital, and buyers should be aware of the ethical sourcing concerns associated with copper. Buyers from Africa and South America may need to navigate complex supply chains to ensure responsible sourcing.

Why Is Plastic a Popular Choice for Raw Materials?

Plastics, particularly engineering plastics like polycarbonate and nylon, are increasingly popular due to their lightweight, corrosion-resistant properties. They can be molded into complex shapes, making them versatile for various applications.

Pros & Cons: The key advantage of plastics is their low weight and resistance to corrosion, which makes them ideal for applications in harsh environments. However, they may not withstand high temperatures or mechanical stresses as well as metals. Additionally, the environmental impact of plastic waste is a growing concern.

Impact on Application: Plastics are generally compatible with a wide range of media, but their performance can degrade under UV exposure or extreme temperatures. Buyers must consider the specific application environment when selecting plastic materials.

Considerations for International Buyers: Compliance with environmental regulations and standards is crucial, especially for buyers in Europe, where sustainability is a significant concern. Buyers should also be aware of potential import restrictions on certain types of plastics.

Summary Table of Material Properties and Considerations

| Material | Typical Use Case for raw materials china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Construction, automotive parts | High durability and recyclability | Heavy and complex manufacturing | Medium |

| Aluminum | Aerospace, automotive components | Lightweight with high strength-to-weight ratio | Higher cost and deformation risk | High |

| Copper | Electrical wiring, plumbing | Superior electrical and thermal conductivity | Expensive and ethical sourcing concerns | High |

| Plastic | Consumer goods, industrial components | Lightweight and corrosion-resistant | Limited temperature resistance and environmental concerns | Low |

This guide provides a comprehensive overview of key materials sourced from China, enabling international B2B buyers to make informed decisions that align with their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for raw materials china

What Are the Main Stages in the Manufacturing Process of Raw Materials in China?

The manufacturing process for raw materials in China typically involves several key stages: material preparation, forming, assembly, and finishing. Understanding these stages is crucial for international B2B buyers, as each step can significantly impact the quality and reliability of the final product.

-

Material Preparation: This initial stage involves sourcing high-quality raw materials, which may include metals, plastics, or composites. Suppliers often conduct rigorous inspections to ensure that the materials meet specified standards. International buyers should inquire about the origin of these materials and whether they comply with local regulations in their respective countries.

-

Forming: In this stage, the raw materials are shaped into desired forms through processes like casting, forging, or molding. The choice of technique can vary based on the material and the intended use. For example, metals may undergo forging for strength, while plastics might be molded for intricate shapes. Buyers should ask suppliers about the specific techniques employed and the rationale behind their choices.

-

Assembly: For products requiring multiple components, assembly is a critical stage. This can involve manual labor or automated processes, depending on the complexity of the product. Effective assembly ensures that all parts fit together seamlessly, which is vital for the overall performance of the product. B2B buyers should seek clarity on the assembly methods used and the skill level of the workforce involved.

-

Finishing: The final stage encompasses surface treatments, coatings, and inspections. Finishing processes can enhance durability, aesthetics, and corrosion resistance. Common techniques include painting, anodizing, and polishing. Buyers should confirm the finishing processes used and their implications for long-term product performance.

How Does Quality Assurance Fit into the Manufacturing Process for Raw Materials in China?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that products meet both international and industry-specific standards. For international B2B buyers, understanding these QA practices is essential for maintaining product integrity.

-

International Standards Compliance: Many Chinese manufacturers adhere to ISO 9001, which sets the criteria for a quality management system. This certification helps ensure that suppliers consistently provide products that meet customer and regulatory requirements. Additionally, industry-specific standards like CE (for European markets) and API (for petroleum and natural gas industries) are critical for compliance. B2B buyers should verify that their suppliers hold relevant certifications and understand the implications of these standards.

-

Quality Control Checkpoints: Effective quality control (QC) involves multiple checkpoints throughout the manufacturing process, typically categorized as Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC: This phase involves inspecting raw materials upon arrival at the manufacturing facility. It ensures that all incoming materials meet specified criteria.

- IPQC: During production, IPQC monitors the manufacturing process to identify defects early. This helps reduce waste and ensures that corrective actions can be taken promptly.

- FQC: Final inspections occur before products are shipped. This step is critical for ensuring that the end products meet all quality standards and specifications.

- Common Testing Methods in Quality Assurance: Various testing methods are employed to ensure quality, including tensile testing, fatigue testing, and dimensional checks. These tests assess the material properties and the final product’s performance. Buyers should inquire about the specific tests conducted on their products and request test reports for verification.

How Can International B2B Buyers Verify Supplier Quality Control in China?

For B2B buyers, ensuring that their suppliers uphold stringent quality control measures is paramount. Here are several strategies for verifying supplier QC:

-

Conducting Audits: One of the most effective ways to assess a supplier’s quality control practices is through on-site audits. These audits allow buyers to observe the manufacturing processes firsthand and evaluate the effectiveness of the supplier’s QC measures. Buyers should develop a comprehensive audit checklist covering all relevant aspects of the manufacturing and QC processes.

-

Requesting Quality Control Reports: Suppliers should be able to provide detailed QC reports that outline the results of inspections and tests conducted at various stages of production. These reports should include information on any defects found and the corrective actions taken. B2B buyers should demand transparency in reporting to ensure accountability.

-

Utilizing Third-Party Inspections: Engaging a third-party inspection agency can provide an unbiased assessment of the supplier’s QC practices. These agencies can conduct thorough inspections at different stages of production and provide detailed reports. This option is particularly valuable for buyers who cannot visit suppliers in person.

What Are the Quality Control and Certification Nuances for International B2B Buyers from Different Regions?

Understanding the nuances of quality control and certification is crucial for B2B buyers, especially when sourcing raw materials from China. Buyers from Africa, South America, the Middle East, and Europe may face unique challenges and considerations.

-

Regional Regulatory Compliance: Each region has its own regulatory frameworks that may influence the quality standards required. For example, European buyers must ensure compliance with CE standards, while buyers from the Middle East may need to consider local certification bodies. Buyers should familiarize themselves with these regulations and ensure that their suppliers are compliant.

-

Cultural Considerations in Quality Expectations: Different regions may have varying expectations regarding quality. African and South American buyers, for instance, may prioritize cost-effectiveness, while European buyers might focus on sustainability and environmental impact. Understanding these cultural nuances can help buyers communicate their quality expectations more effectively.

-

Navigating Language Barriers: Communication can pose challenges in international transactions. It is advisable for buyers to engage with suppliers who have English-speaking representatives or use professional translation services to avoid misunderstandings regarding quality specifications.

-

Building Long-Term Relationships: Establishing strong relationships with suppliers can enhance quality assurance. Regular communication and collaboration can lead to improved QC practices over time. B2B buyers should consider fostering partnerships that prioritize quality and reliability.

Conclusion

For international B2B buyers sourcing raw materials from China, understanding the manufacturing processes and quality assurance practices is essential. By familiarizing themselves with the stages of production, international standards, and effective verification methods, buyers can make informed decisions that ensure product quality and compliance. Taking these actionable insights into account can lead to successful partnerships and sustainable sourcing strategies in the dynamic global marketplace.

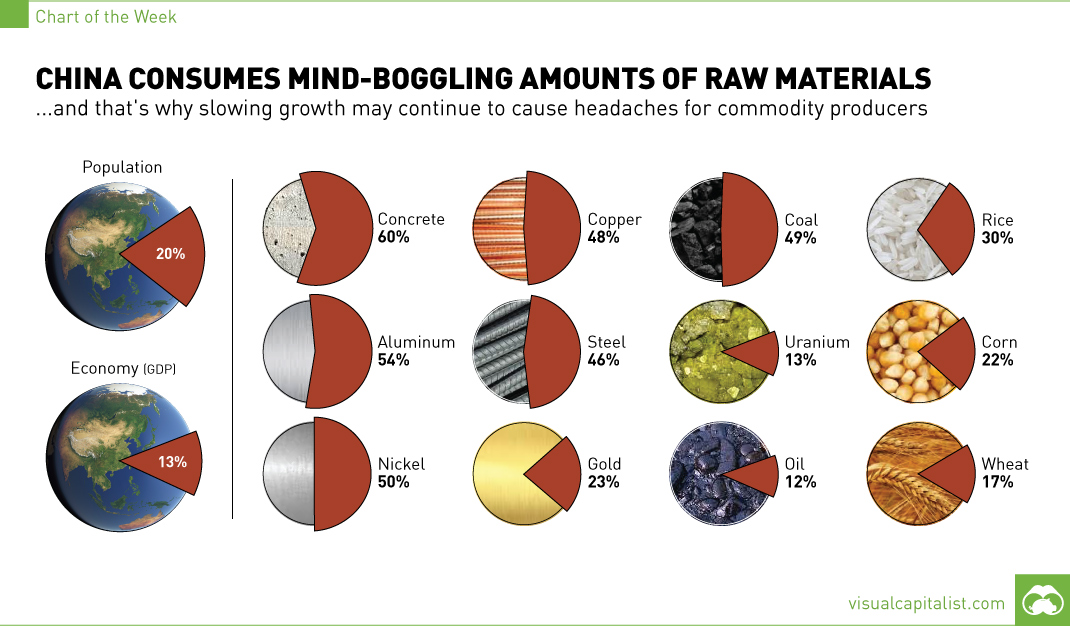

A stock image related to raw materials china.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘raw materials china’

To facilitate successful procurement of raw materials from China, it’s essential to follow a structured approach. This step-by-step checklist is designed to guide international B2B buyers from Africa, South America, the Middle East, and Europe through the sourcing process, ensuring that you make informed decisions while minimizing risks.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements of the raw materials you need. This includes dimensions, grades, quality standards, and any regulatory compliance required in your region. A well-defined specification helps avoid misunderstandings with suppliers and ensures you receive materials that meet your production needs.

Step 2: Conduct Market Research

Understanding the market landscape is crucial for sourcing efficiently. Research the types of raw materials available in China, their pricing trends, and the key suppliers. Utilize online platforms and trade publications to gather insights, which will empower you to negotiate better and identify reliable suppliers.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request documentation such as company profiles, product certifications, and references from previous clients in your industry. Look for:

– Experience in your sector: Suppliers familiar with your industry will understand your needs better.

– Product samples: Always ask for samples to verify quality before placing bulk orders.

Step 4: Verify Supplier Certifications

Ensure that your chosen supplier possesses the necessary certifications relevant to your industry, such as ISO, CE, or FDA approvals. Certifications are indicators of quality and compliance with international standards. It’s advisable to check the validity of these certifications through official channels.

Step 5: Negotiate Terms and Conditions

Once you’ve selected potential suppliers, engage in negotiations. Discuss pricing, payment terms, delivery schedules, and warranty conditions. Clear agreements help mitigate risks associated with international transactions and ensure both parties have aligned expectations.

Step 6: Establish a Communication Plan

Effective communication is vital throughout the sourcing process. Set up regular check-ins and establish preferred communication channels with your supplier. This ensures that any issues are promptly addressed and fosters a strong working relationship.

Step 7: Plan for Logistics and Shipping

Consider logistics as a critical component of your sourcing strategy. Decide on shipping methods, insurance, and customs clearance procedures. Collaborate with freight forwarders who have experience in handling imports from China to streamline the process and avoid delays.

By following these steps, B2B buyers can navigate the complexities of sourcing raw materials from China more effectively. Each step is designed to ensure that you not only find the right supplier but also establish a solid foundation for a long-term partnership.

Comprehensive Cost and Pricing Analysis for raw materials china Sourcing

What Are the Key Cost Components in Sourcing Raw Materials from China?

When sourcing raw materials from China, understanding the cost structure is critical for international B2B buyers. The primary components that contribute to the overall cost include:

-

Materials: The base cost of raw materials can vary significantly based on market demand, quality, and availability. Buyers should stay informed about fluctuations in commodity prices to anticipate changes in their sourcing costs.

-

Labor: Labor costs in China have been increasing due to rising wage standards. However, the overall labor cost remains lower than in many Western countries. Buyers should consider the skill level of the workforce and its impact on product quality.

-

Manufacturing Overhead: This encompasses costs associated with factory operations, including utilities, equipment maintenance, and indirect labor. Understanding these costs can help buyers assess the efficiency of potential suppliers.

-

Tooling: For customized products, tooling costs can be significant. This includes the creation of molds and specialized equipment necessary for production, which can be a one-time cost that impacts overall pricing.

-

Quality Control (QC): Investing in quality control measures can prevent costly defects and returns. Buyers should consider incorporating QC costs into their budget to ensure that the final products meet their specifications.

-

Logistics: Shipping costs can vary based on the mode of transport (air vs. sea), distance, and volume. Buyers should evaluate logistics options to find the most cost-effective solutions while ensuring timely delivery.

-

Margin: Suppliers will include a profit margin in their pricing. Understanding the typical margins in the industry can help buyers negotiate better terms.

How Do Price Influencers Impact the Cost of Raw Materials?

Several factors can influence the pricing of raw materials sourced from China:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit costs. Buyers should assess their needs to negotiate favorable terms that take advantage of economies of scale.

-

Specifications and Customization: Custom products or specific material grades can lead to higher costs. Buyers should be clear about their requirements to avoid unexpected expenses.

-

Materials Quality and Certifications: Higher-quality materials or those with specific certifications (such as ISO or CE) typically command a premium price. Buyers should balance quality with cost to meet their project needs.

-

Supplier Factors: The reliability, reputation, and negotiation skills of suppliers can significantly impact pricing. Researching potential suppliers and establishing strong relationships can lead to better pricing and terms.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital, as they define the responsibilities of buyers and sellers in shipping. Choosing the right terms can affect total costs, including shipping and insurance.

What Tips Can Help International Buyers Optimize Costs?

International B2B buyers should consider the following tips to enhance cost-efficiency when sourcing raw materials from China:

-

Negotiation Strategies: Effective negotiation can lead to significant cost savings. Buyers should prepare by understanding market trends and having a clear idea of their budget and requirements.

-

Evaluating Total Cost of Ownership (TCO): Beyond the purchase price, consider all associated costs, including shipping, duties, and potential wastage. A comprehensive TCO analysis can reveal the true cost of sourcing decisions.

-

Understanding Pricing Nuances: Be aware of the seasonal fluctuations in raw material prices and the impact of global supply chains. This knowledge can help in timing purchases to maximize savings.

-

Building Long-Term Relationships: Establishing strong partnerships with suppliers can lead to better pricing, priority service, and improved product quality over time.

Disclaimer on Indicative Prices

It is essential for buyers to note that prices can fluctuate based on market conditions, supplier negotiations, and changes in global trade policies. Always seek updated quotes and conduct thorough due diligence before making purchasing decisions.

Alternatives Analysis: Comparing raw materials china With Other Solutions

Exploring Alternatives to Raw Materials from China: What Are Your Options?

When considering the procurement of raw materials, international B2B buyers face a critical decision: whether to source from China or explore alternative solutions. This decision can significantly impact production quality, cost efficiency, and supply chain resilience. Below, we compare raw materials from China against two viable alternatives: local sourcing and recycled materials.

Comparison Table: Raw Materials China vs. Alternatives

| Comparison Aspect | Raw Materials China | Local Sourcing | Recycled Materials |

|---|---|---|---|

| Performance | High consistency and quality | Varies by supplier, often good quality | Quality varies, dependent on processing |

| Cost | Competitive pricing, but fluctuates | Potentially higher due to logistics | Generally lower, but may require processing costs |

| Ease of Implementation | Established supply chains | May require new partnerships | Requires specific processing infrastructure |

| Maintenance | Low maintenance; established quality controls | Varies with supplier reliability | May require additional quality checks |

| Best Use Case | High-volume production with consistent demand | Small to medium-scale production | Eco-friendly products, circular economy initiatives |

What Are the Benefits and Drawbacks of Local Sourcing?

Local sourcing can be an attractive alternative for B2B buyers in regions like Africa and South America. One of the primary advantages is the potential for shorter lead times and reduced shipping costs, which can significantly impact overall operational efficiency. Additionally, local suppliers may offer more personalized service and flexibility in orders. However, the quality of materials can vary significantly depending on the supplier, and buyers may face challenges in establishing reliable partnerships. In regions with less developed supply chains, it may also be harder to find the specific raw materials needed.

How Do Recycled Materials Compare to Raw Materials from China?

Recycled materials present a compelling alternative for businesses focused on sustainability. They often come at a lower cost compared to virgin materials, which can enhance profit margins. Additionally, using recycled materials aligns with corporate social responsibility goals and can improve brand image among environmentally-conscious consumers. However, the quality of recycled materials can be inconsistent, and additional processing may be necessary to meet specific performance standards. Companies must also invest in appropriate infrastructure to handle recycled materials, which may not be feasible for all businesses.

Making the Right Choice for Your Business Needs

Choosing the right raw material solution involves evaluating various factors tailored to your business’s specific needs. For companies prioritizing cost-effectiveness and sustainability, recycled materials may be the ideal choice. Alternatively, businesses that require consistent quality and reliable supply chains might find that sourcing from China is more advantageous despite potential cost fluctuations. Local sourcing can be an excellent option for those seeking to strengthen regional partnerships and reduce logistics costs but requires careful vetting of suppliers. Ultimately, the decision should align with your operational goals, budget constraints, and long-term sustainability initiatives.

Essential Technical Properties and Trade Terminology for raw materials china

What Are the Key Technical Properties of Raw Materials from China?

Understanding the technical properties of raw materials is crucial for international B2B buyers. Here are some essential specifications to consider:

1. Material Grade

Material grade refers to the classification of a raw material based on its composition and properties. Common grades include A, B, and C, where Grade A typically represents the highest quality. For buyers, selecting the right grade is essential to ensure that the material meets production requirements and industry standards, impacting the final product’s performance and longevity.

2. Tolerance

Tolerance defines the permissible limits of variation in a physical dimension. It is critical in manufacturing processes where precision is paramount. For instance, a tolerance of ±0.1 mm means the actual measurement can deviate by 0.1 mm from the specified dimension. Understanding tolerance levels helps buyers assess whether a supplier can meet their quality requirements, reducing the risk of defects and costly reworks.

3. Moisture Content

Moisture content indicates the amount of water present in a raw material. This is particularly significant for materials like wood, grains, and metals. High moisture levels can affect the material’s stability and performance, leading to issues such as corrosion or spoilage. Buyers should request moisture content specifications to ensure the raw material’s suitability for their intended application.

4. Chemical Composition

Chemical composition reveals the specific elements and compounds within a raw material. For example, the percentage of carbon in steel determines its strength and ductility. Buyers must be aware of the chemical composition to ensure compatibility with their production processes and to meet regulatory standards.

5. Density

Density is a measure of mass per unit volume and influences how a material will perform in various applications. Higher density materials may provide better structural support, while lower density materials can reduce shipping costs. Buyers should consider density when evaluating the cost-effectiveness of materials for their projects.

What Are Common Trade Terms Used in Raw Materials Procurement?

Familiarity with trade terminology is vital for effective communication and negotiation in international B2B transactions. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of raw materials, an OEM might provide specific materials tailored for a client’s product. Understanding OEM relationships can help buyers navigate supply chains and ensure they receive high-quality, compatible materials.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for B2B buyers as it affects inventory management and cash flow. Buyers should negotiate MOQs to align with their production needs and avoid overstocking.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request pricing and terms from suppliers for specific raw materials. It is an essential step in the procurement process, allowing buyers to compare offers and negotiate better terms. Crafting a comprehensive RFQ can lead to more favorable pricing and terms.

4. Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers in shipping goods. They clarify who is responsible for costs and risks at various stages of the shipping process. Familiarity with Incoterms helps buyers avoid misunderstandings and ensure that logistics are handled efficiently.

5. Lead Time

Lead time refers to the amount of time from placing an order to receiving the goods. It is a critical factor for production planning and inventory management. Buyers must understand lead times when sourcing raw materials to ensure they can meet their production schedules without delays.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, streamline procurement processes, and foster successful supplier relationships in the raw materials market from China.

Navigating Market Dynamics and Sourcing Trends in the raw materials china Sector

What are the Current Market Dynamics and Key Trends in the Raw Materials Sector in China?

The raw materials sector in China is undergoing significant transformation, driven by global demand fluctuations and technological advancements. One of the primary drivers is the increasing need for sustainable and environmentally-friendly materials. Countries from Africa, South America, the Middle East, and Europe are focusing on diversifying their supply chains, reducing dependency on single sources, and seeking more resilient partnerships. This shift is partly influenced by geopolitical tensions, trade tariffs, and the COVID-19 pandemic, which have highlighted the risks of over-reliance on specific markets.

A stock image related to raw materials china.

Emerging technologies are reshaping sourcing trends, with digital platforms and e-commerce solutions facilitating easier access to suppliers. International B2B buyers can leverage these technologies to streamline procurement processes and improve supply chain transparency. Additionally, blockchain technology is gaining traction for its ability to enhance traceability and security in transactions, which is especially important for buyers concerned about ethical sourcing.

In terms of market dynamics, fluctuating commodity prices and evolving regulations are affecting sourcing strategies. Buyers are advised to stay informed about market conditions, engage in long-term contracts to hedge against volatility, and consider local sourcing options to mitigate risks. The growing preference for recycled and secondary materials also presents an opportunity for buyers to align with global sustainability goals while securing cost-effective raw materials.

How Can Sustainability and Ethical Sourcing Impact B2B Procurement in Raw Materials?

The importance of sustainability and ethical sourcing in the raw materials sector cannot be overstated. As environmental concerns escalate, buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices. The environmental impact of raw materials extraction and processing is significant, making it essential for companies to assess their supply chains critically.

For B2B buyers, engaging with suppliers who have ‘green’ certifications or use sustainable materials can enhance their brand image and meet regulatory requirements. Certifications such as ISO 14001 (Environmental Management) or FSC (Forest Stewardship Council) can serve as benchmarks for evaluating supplier practices. Moreover, companies that adopt ethical sourcing strategies not only contribute to environmental conservation but also mitigate risks associated with supply chain disruptions and reputational damage.

To effectively incorporate sustainability into procurement strategies, buyers should consider implementing a supplier evaluation framework that prioritizes environmental and social governance (ESG) criteria. This approach ensures that the sourcing process aligns with the buyer’s corporate responsibility goals and enhances long-term partnerships with suppliers who share similar values.

What is the Historical Context of Raw Materials Sourcing in China?

Historically, China’s raw materials sector has been characterized by rapid industrialization and an expansive manufacturing base. Since the late 20th century, China has emerged as a global leader in raw materials production, driven by its vast natural resources and labor force. However, the landscape has evolved dramatically over the past two decades, particularly with increasing global awareness of sustainability and ethical sourcing.

The shift towards sustainable practices has been accelerated by both domestic policy changes and international pressure, prompting many Chinese suppliers to adopt greener technologies and practices. As a result, international B2B buyers now have access to a more diverse range of ethically sourced materials, allowing them to make informed decisions that align with their sustainability goals while maintaining competitiveness in the global market.

Frequently Asked Questions (FAQs) for B2B Buyers of raw materials china

-

How do I ensure the quality of raw materials sourced from China?

To guarantee the quality of raw materials, start by conducting thorough supplier vetting. Request samples to evaluate the materials and check for certifications that meet international standards. It’s also beneficial to visit manufacturing facilities if possible or hire a third-party inspection service to conduct quality assurance checks before shipment. Establish clear quality specifications in your contracts to ensure that suppliers adhere to your requirements. -

What are the common payment terms when sourcing raw materials from China?

Payment terms can vary, but common practices include a 30% deposit with the order and 70% upon delivery. Some suppliers may offer letters of credit or payment through platforms like Alibaba. Be sure to clarify payment terms upfront to avoid misunderstandings. It’s also advisable to negotiate terms that provide you with sufficient protection against potential risks, such as delays or quality issues. -

What should I consider when determining minimum order quantities (MOQ)?

When assessing MOQs, consider your business’s demand and storage capacity. Suppliers often set MOQs to optimize production efficiency and minimize costs. If the MOQ is higher than your needs, negotiate with the supplier for a smaller order or consider alternative suppliers. Additionally, factor in the potential for bulk purchasing discounts, which may make higher MOQs more financially viable. -

How can I customize raw materials to fit my specific requirements?

Customization is often possible but requires clear communication with your supplier. Discuss your specific needs regarding material specifications, sizes, and any other alterations. It’s important to provide detailed drawings or samples to ensure the supplier fully understands your requirements. Always confirm the feasibility of customization during the negotiation phase and inquire about any additional costs or lead times involved. -

What logistics considerations should I keep in mind when importing raw materials from China?

Logistics is crucial in the importing process. Evaluate shipping methods (air vs. sea) based on cost and urgency. Ensure that you understand customs regulations in your country to avoid unexpected delays or fines. Collaborating with a freight forwarder can simplify the logistics process, as they can handle documentation, customs clearance, and delivery to your location. -

How do I identify reliable suppliers in China?

To find reliable suppliers, utilize platforms like Alibaba or Global Sources and look for suppliers with verified status and positive feedback. Attend trade shows or industry exhibitions to meet suppliers in person. Conduct thorough research, including checking references and visiting their manufacturing facilities if possible. Engaging a local sourcing agent can also help navigate the market and ensure you partner with reputable suppliers. -

What are the risks of sourcing raw materials from China, and how can I mitigate them?

Risks include quality inconsistencies, shipping delays, and potential fraud. To mitigate these risks, conduct comprehensive due diligence on suppliers, including background checks and site visits. Use third-party inspection services to verify product quality before shipment. Establish clear contracts that define expectations and include clauses for dispute resolution. Additionally, consider diversifying your supplier base to reduce reliance on a single source. -

How can I stay updated on market trends for raw materials in China?

Staying updated on market trends requires continuous research. Subscribe to industry newsletters and follow trade publications focused on raw materials. Engaging with trade associations and participating in forums can provide valuable insights. Additionally, leveraging social media platforms like LinkedIn to connect with industry experts can help you gain access to the latest market developments and forecasts.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for raw materials china

In navigating the complexities of sourcing raw materials from China, international B2B buyers must prioritize strategic sourcing to optimize their supply chain. Understanding local market dynamics, including shifts in demand and pricing fluctuations, is crucial for making informed purchasing decisions. Establishing robust relationships with reliable suppliers not only enhances procurement efficiency but also mitigates risks associated with supply chain disruptions.

What Are the Key Considerations for Strategic Sourcing in China?

Buyers should focus on transparency in communication, leveraging technology for real-time data exchange, and conducting thorough supplier assessments. Emphasizing sustainability and ethical sourcing practices will also resonate with global consumers, creating a competitive edge in the marketplace.

How Can Buyers Prepare for Future Trends in Raw Material Sourcing?

Looking ahead, the landscape of raw material sourcing in China is expected to evolve with increasing regulatory changes and sustainability initiatives. By staying informed about these trends and adapting strategies accordingly, businesses can position themselves advantageously in the global market.

In conclusion, international B2B buyers from Africa, South America, the Middle East, and Europe must embrace strategic sourcing as a vital component of their procurement strategy. By fostering strong partnerships and being proactive about emerging trends, companies can navigate the challenges of sourcing raw materials from China effectively. Take action today to refine your sourcing strategies and secure a competitive advantage in your industry.