Unlock Cost Savings: The Ultimate LCD China Sourcing Guide (2025)

Introduction: Navigating the Global Market for lcd china

Navigating the global market for LCDs from China can be a daunting task for international B2B buyers, especially when considering factors such as quality assurance, supplier reliability, and cost-effectiveness. The challenge of sourcing high-quality LCD products that meet specific industry standards is compounded by the sheer volume of manufacturers available in China. This guide offers a comprehensive resource for B2B buyers looking to understand the myriad types of LCD products available, their applications in various industries, and effective strategies for vetting suppliers.

In this guide, you will explore the diverse categories of LCDs, from standard displays to specialized screens tailored for unique applications. We will delve into best practices for assessing supplier credibility, including certifications, production capabilities, and customer reviews. Additionally, we will provide insights on pricing structures and cost-saving strategies that can empower your purchasing decisions.

Whether you are a buyer from Africa, South America, the Middle East, or Europe—countries like France and Poland—you will find actionable insights that equip you to make informed decisions in your procurement process. By leveraging the information in this guide, you can enhance your sourcing strategy and establish fruitful partnerships with reliable suppliers in China, ultimately driving your business success in a competitive global market.

Understanding lcd china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| TFT-LCD | Thin Film Transistor technology for improved color and response. | Consumer electronics, medical devices. | Pros: High resolution, fast response. Cons: Limited viewing angles. |

| IPS-LCD | In-Plane Switching for wider viewing angles and better color. | Professional monitors, smartphones. | Pros: Excellent color accuracy. Cons: Higher cost compared to TN panels. |

| VA-LCD | Vertical Alignment technology for high contrast ratios. | TVs, gaming monitors. | Pros: Deep blacks, good for dark environments. Cons: Slower response times. |

| OLED-LCD | Organic Light Emitting Diode technology for vibrant colors. | High-end displays, signage. | Pros: Superior contrast, flexible designs. Cons: Higher price, potential burn-in issues. |

| QLED-LCD | Quantum Dot technology for enhanced brightness and color range. | TVs, high-performance displays. | Pros: Bright and vivid colors. Cons: Still relies on backlighting, less efficient. |

What are the Characteristics and Suitability of TFT-LCD Displays for B2B Buyers?

TFT-LCD (Thin Film Transistor Liquid Crystal Display) technology is widely recognized for its high resolution and fast response times, making it suitable for applications in consumer electronics and medical devices. The key characteristic of TFT-LCDs is the use of thin film transistors to enhance image quality and color reproduction. B2B buyers should consider TFT-LCDs for environments where quick refresh rates are critical, such as in gaming or medical imaging. However, their limited viewing angles may not be ideal for all applications, especially in collaborative settings.

Why Choose IPS-LCD Displays for Professional Use?

IPS-LCD (In-Plane Switching Liquid Crystal Display) is favored in professional settings due to its exceptional color accuracy and wide viewing angles. This makes IPS-LCDs ideal for applications in graphic design, photography, and video editing, where precise color representation is paramount. B2B buyers should look for IPS panels when the visual fidelity of images is critical, despite the higher costs compared to other technologies like TN (Twisted Nematic). The investment often pays off in enhanced productivity and better-quality outputs.

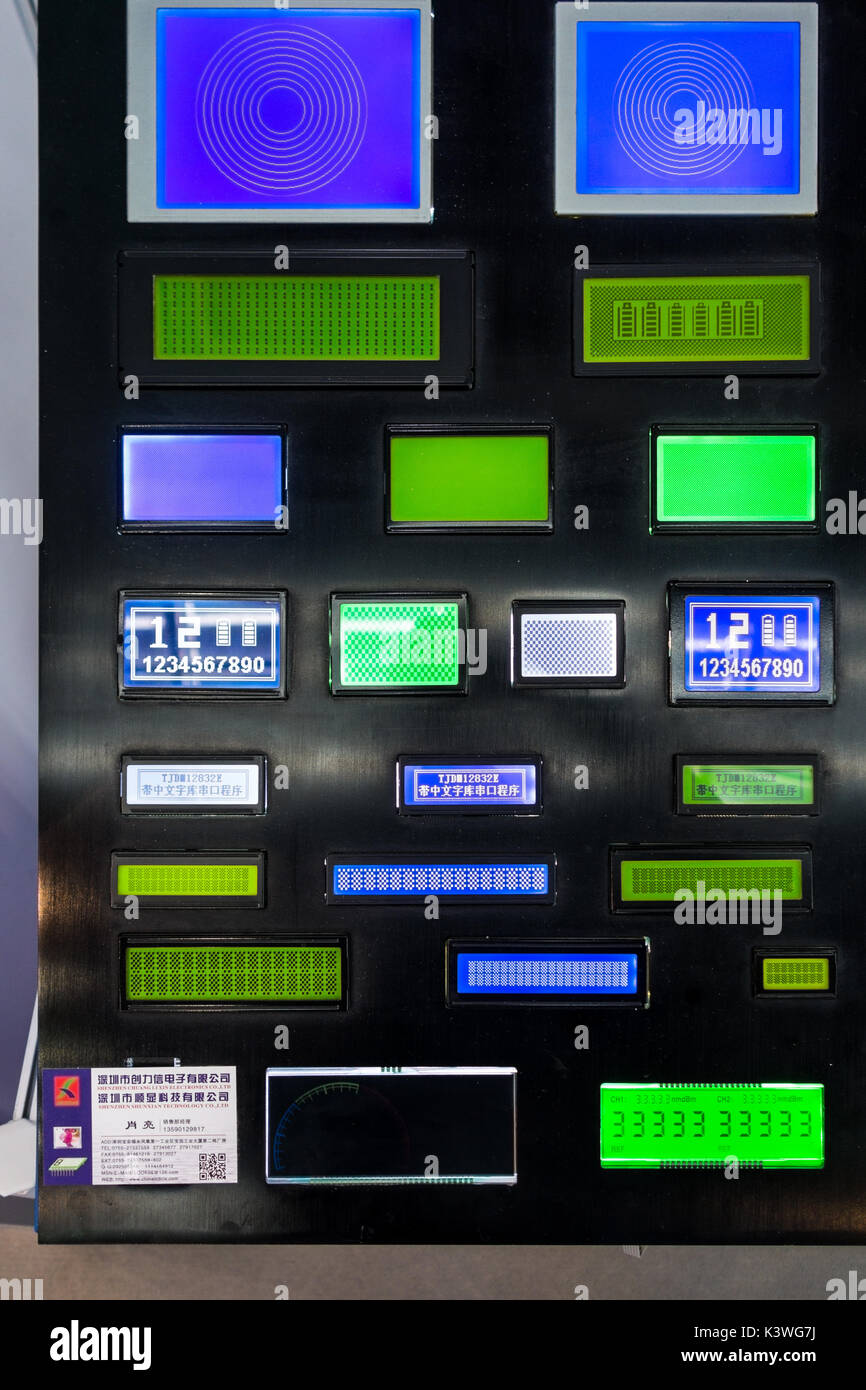

A stock image related to lcd china.

How Do VA-LCD Displays Benefit Gaming and Home Theater Setups?

VA-LCD (Vertical Alignment Liquid Crystal Display) technology is known for its high contrast ratios, making it particularly effective in environments with low light, such as gaming and home theater setups. The deep blacks and vibrant colors provided by VA-LCDs enhance the overall viewing experience. However, buyers should be aware of the slower response times, which might not be suitable for fast-paced gaming. When selecting VA-LCDs, consider the application environment to maximize their strengths.

What Advantages Does OLED-LCD Technology Offer for High-End Displays?

OLED-LCD (Organic Light Emitting Diode) technology stands out for its ability to produce vibrant colors and deep contrasts, making it a prime choice for high-end displays and digital signage. The flexibility in design also allows for innovative display formats. While OLEDs provide superior visual quality, B2B buyers must consider the higher price point and potential for burn-in, especially in applications where static images are common. This technology is best suited for premium markets where image quality is a top priority.

Why Should B2B Buyers Consider QLED-LCD Displays?

QLED-LCD (Quantum Dot Light Emitting Diode) technology enhances brightness and color range, making it a strong contender for high-performance displays in commercial settings. The key feature of QLEDs is their ability to produce bright, vivid colors while maintaining efficiency. However, since QLEDs still rely on traditional backlighting, they may not achieve the same level of contrast as OLED displays. For buyers focused on vibrant visuals without the high cost of OLED, QLEDs present a balanced option for various applications, including corporate presentations and entertainment venues.

Related Video: Monitors Explained – LCD, LED, OLED, CRT, TN, IPS, VA

Key Industrial Applications of lcd china

| Industry/Sector | Specific Application of lcd china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | Television Displays | High-resolution displays enhance user experience and engagement. | Look for suppliers with certifications for quality and safety standards. |

| Automotive | Dashboard Displays | Provides real-time data visualization for better driver awareness. | Ensure compatibility with various vehicle models and durability standards. |

| Industrial Equipment | Control Panels | LCDs improve monitoring and control of machinery operations. | Seek suppliers who can provide customization for specific industrial needs. |

| Healthcare | Medical Imaging Devices | Enhances diagnostic accuracy through clear imaging. | Verify compliance with medical device regulations and standards. |

| Retail | Digital Signage | Attracts customers and promotes products effectively. | Focus on suppliers who can offer scalable solutions for various retail environments. |

How is ‘lcd china’ Used in Consumer Electronics and What Problems Does It Solve?

In the consumer electronics sector, LCDs from China are predominantly used in television displays. These high-resolution screens provide vibrant colors and sharp images, significantly enhancing the viewing experience. International B2B buyers should ensure that suppliers adhere to quality certifications such as ISO and CE to guarantee product safety and reliability. Additionally, understanding the supply chain logistics is crucial for timely delivery, especially for buyers in Africa and South America where infrastructure may vary.

What are the Applications of ‘lcd china’ in Automotive Displays?

In the automotive industry, LCDs are utilized in dashboard displays that provide critical information such as speed, fuel levels, and navigation. These displays enhance driver awareness and safety by presenting data in a clear, accessible format. Buyers should consider sourcing from manufacturers that specialize in automotive-grade displays, as these products must meet rigorous durability and temperature resistance standards. European buyers, particularly from countries like France and Poland, should also consider local regulations regarding automotive components.

How Do Industrial Applications Benefit from ‘lcd china’?

Industrial equipment employs LCDs in control panels, allowing operators to monitor and manage machinery efficiently. The clarity of LCDs facilitates real-time data visualization, leading to improved operational decision-making. Buyers in sectors like manufacturing should look for suppliers that offer customization options to meet specific operational requirements. Additionally, understanding the technical specifications and certifications can help mitigate risks associated with equipment failures.

What Role Does ‘lcd china’ Play in Healthcare Imaging?

In healthcare, LCDs are integral to medical imaging devices, where they enhance the clarity and accuracy of diagnostic images. This is critical for effective patient care and treatment decisions. B2B buyers in the medical field must prioritize suppliers who comply with stringent medical device regulations and can provide documentation of their products’ reliability. Given the global nature of healthcare procurement, establishing strong relationships with certified manufacturers is essential for ensuring consistent quality.

How is ‘lcd china’ Transforming Retail Environments?

In the retail sector, LCDs are increasingly used for digital signage, which helps attract customers and effectively promote products. These displays can be updated in real-time, allowing for dynamic marketing strategies. Buyers should focus on sourcing from suppliers that can offer scalable solutions to accommodate various retail sizes and configurations. Understanding the local market trends and consumer behavior in regions such as the Middle East can also enhance the effectiveness of digital signage strategies.

Related Video: LABORATORY APPARATUS AND THEIR USES

3 Common User Pain Points for ‘lcd china’ & Their Solutions

Scenario 1: Sourcing Quality LCD Panels from China

The Problem:

International B2B buyers often face challenges in sourcing high-quality LCD panels from China. Given the vast number of manufacturers, differentiating between quality products and subpar offerings can be overwhelming. Buyers may encounter issues such as receiving defective products, inconsistent quality, or even counterfeit goods. This is particularly concerning for businesses in industries such as automotive or consumer electronics, where product reliability is paramount. Additionally, language barriers and cultural differences can complicate negotiations and lead to misunderstandings about product specifications and quality standards.

The Solution:

To overcome these challenges, buyers should engage in thorough due diligence when selecting suppliers. Start by researching potential manufacturers through platforms like Alibaba or Global Sources, where you can view ratings, reviews, and past transaction histories. Once a shortlist is created, request product samples to evaluate quality firsthand. It’s also advisable to establish clear specifications and quality standards upfront. Consider using third-party inspection services that can conduct quality checks before shipment. This ensures that the products meet your requirements and minimizes the risk of defects upon arrival. Furthermore, investing in a local agent who understands the market can bridge communication gaps and facilitate smoother negotiations.

Scenario 2: Navigating Import Regulations for LCD Products

The Problem:

B2B buyers often find it challenging to navigate the complex landscape of import regulations when purchasing LCD panels from China. Different countries have varying standards for product safety, environmental compliance, and tariffs, which can lead to unexpected delays and costs. For buyers in regions like Africa or South America, where regulatory frameworks may be less transparent, this can result in shipments being held at customs, leading to financial losses and disruptions in the supply chain.

The Solution:

To effectively navigate these regulations, it’s crucial for buyers to conduct comprehensive research on the import laws applicable to their specific region. Utilize resources such as government trade websites or consult with legal experts specializing in international trade law. Prior to placing an order, verify that your suppliers can provide necessary certifications, such as CE or RoHS, which may be required for compliance. Establishing a relationship with a customs broker can also streamline the import process, ensuring that all paperwork is in order and duties are calculated accurately. By proactively managing regulatory compliance, buyers can avoid costly delays and ensure a seamless import experience.

Scenario 3: Managing Supply Chain Disruptions in the LCD Market

The Problem:

Supply chain disruptions are a common pain point for B2B buyers sourcing LCD panels from China, particularly in the wake of global events like the COVID-19 pandemic. Fluctuations in demand, shipping delays, and geopolitical tensions can significantly impact the availability of components. For companies reliant on just-in-time inventory practices, these disruptions can lead to production halts and customer dissatisfaction, ultimately affecting the bottom line.

The Solution:

To mitigate the risks associated with supply chain disruptions, businesses should adopt a multi-sourcing strategy. This involves identifying and qualifying multiple suppliers across different regions, which can provide a safety net in case one source encounters issues. Additionally, consider building strategic partnerships with suppliers to enhance collaboration and transparency. Implementing a robust inventory management system can also help track stock levels and anticipate shortages, allowing for proactive ordering. Lastly, maintaining open lines of communication with suppliers can foster quicker responses to potential disruptions, enabling businesses to adapt their plans swiftly and minimize impact. By taking these steps, B2B buyers can enhance their resilience against supply chain challenges while ensuring a consistent flow of products.

Strategic Material Selection Guide for lcd china

What Are the Key Materials Used in LCD Manufacturing in China?

When sourcing materials for LCD (Liquid Crystal Display) manufacturing, international B2B buyers must consider various factors that affect performance, cost, and compatibility. Below, we analyze four common materials used in the production of LCDs, focusing on their properties, advantages, disadvantages, and implications for buyers, particularly from Africa, South America, the Middle East, and Europe.

Which Glass Types Are Commonly Used in LCD Manufacturing?

Key Properties:

The primary glass used in LCD panels is soda-lime glass, known for its excellent optical clarity and thermal stability. It can withstand temperatures up to 600°C and has a low coefficient of thermal expansion, making it suitable for various applications.

Pros & Cons:

Soda-lime glass is relatively inexpensive and easy to manufacture, making it a common choice. However, it is less durable compared to specialized glass types like aluminosilicate, which is more resistant to thermal shock and scratches.

Impact on Application:

The choice of glass affects the display’s overall quality, including brightness and color accuracy. Soda-lime glass is compatible with most media used in LCDs, but specialized applications may require more robust materials.

Considerations for Buyers:

Buyers in regions like Europe must ensure compliance with EU regulations regarding glass recycling and environmental safety. Standards such as EN 12150 for tempered glass may also apply.

How Do Liquid Crystal Materials Influence LCD Performance?

Key Properties:

Liquid crystals are the core of LCD technology, with distinct properties such as birefringence and electro-optic effects. These materials can operate effectively at various temperatures, typically between -20°C to 70°C.

Pros & Cons:

The primary advantage of liquid crystals is their ability to manipulate light efficiently, leading to high-quality images. However, they can be sensitive to temperature fluctuations, which may affect performance over time.

Impact on Application:

The choice of liquid crystal affects response times and viewing angles. Specific formulations are better suited for high-performance displays, while others may be adequate for standard applications.

Considerations for Buyers:

International buyers should consider the specific formulations used in their regions. Compliance with industry standards like ISO 13485 for medical devices may be necessary if the LCDs are intended for healthcare applications.

What Role Do Polarizers Play in LCD Technology?

Key Properties:

Polarizers are typically made from polyvinyl alcohol (PVA) and are essential for controlling light transmission. They can withstand moderate temperatures but may degrade under extreme conditions.

Pros & Cons:

Polarizers enhance contrast and color saturation, making them vital for high-quality displays. However, they can be costly and may require careful handling during manufacturing to avoid damage.

Impact on Application:

The effectiveness of polarizers directly impacts the visibility of the LCD under various lighting conditions. Poor-quality polarizers can lead to glare and reduced image quality.

Considerations for Buyers:

Buyers should ensure that polarizers meet international standards such as ASTM D1003 for haze and transmission, especially when sourcing from regions with stringent quality controls.

How Do Backlight Materials Affect LCD Functionality?

Key Properties:

Backlight systems typically use LEDs, which are energy-efficient and have a long lifespan. They operate effectively across a wide temperature range and are available in various colors.

Pros & Cons:

LED backlights provide even illumination and can significantly enhance display brightness. However, they may increase the overall cost of the LCD, particularly for high-end models.

Impact on Application:

The choice of backlight affects power consumption and overall display performance. High-quality backlights can improve color reproduction and energy efficiency.

Considerations for Buyers:

B2B buyers should consider energy efficiency ratings and compliance with local regulations, such as the EU’s Ecodesign Directive, which mandates energy-efficient products.

Summary of Key Materials for LCD Manufacturing

| Material | Typical Use Case for lcd china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Soda-Lime Glass | Standard LCD displays | Cost-effective and easy to manufacture | Less durable than specialized glass | Low |

| Liquid Crystals | Core component of LCD technology | High-quality image manipulation | Sensitive to temperature fluctuations | Medium |

| Polarizers | Enhancing contrast and color | Improves visibility and color saturation | Can be costly and fragile | Medium |

| LED Backlights | Backlighting for LCD displays | Energy-efficient and long lifespan | Higher initial cost | High |

This comprehensive analysis provides international B2B buyers with essential insights into material selection for LCD manufacturing in China, ensuring informed decision-making aligned with regional standards and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for lcd china

What Are the Main Stages of the LCD Manufacturing Process?

The manufacturing of LCDs (Liquid Crystal Displays) involves several critical stages that ensure the final product meets the required specifications for quality and performance. Understanding these stages is essential for international B2B buyers aiming to source high-quality LCDs from China.

Material Preparation: What Materials Are Used in LCD Production?

A stock image related to lcd china.

The initial phase involves sourcing high-purity materials essential for LCD production. Key materials include liquid crystal compounds, glass substrates, polarizers, and color filters. Manufacturers typically source these materials from specialized suppliers to ensure compatibility and quality. The purity and quality of these materials directly impact the performance and lifespan of the LCDs.

How Is the Forming Process Conducted?

The forming stage involves the precise cutting and shaping of glass substrates, which serve as the foundation for the LCD. This is achieved using automated glass cutting machines that ensure minimal defects. The glass is then coated with transparent conductive materials like indium tin oxide (ITO), which are vital for controlling pixel activation.

What Techniques Are Used During Assembly?

During the assembly phase, the prepared components are meticulously combined. The assembly involves placing the liquid crystal material between two glass substrates, followed by the integration of color filters and polarizers. Automated assembly lines are typically employed to enhance precision and efficiency, minimizing human error. This stage is crucial as any misalignment can lead to display issues.

How Does the Finishing Stage Enhance LCD Quality?

The finishing stage includes various processes such as sealing, testing, and packaging. Manufacturers apply adhesives to secure the components and ensure durability. Quality checks are conducted to identify any defects before packaging. This stage is vital for ensuring that the LCDs can withstand shipping and handling, particularly for international buyers.

What Are the Quality Assurance Practices in LCD Manufacturing?

Quality assurance (QA) is a pivotal aspect of the LCD manufacturing process, ensuring that the final products adhere to international standards and meet customer expectations.

Which International Standards Should B2B Buyers Be Aware Of?

International quality standards, such as ISO 9001, are essential for guiding manufacturers in maintaining quality management systems. Compliance with these standards assures buyers that the manufacturer has established processes to consistently produce quality products. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) ensure that products meet specific regional safety and performance criteria.

What Quality Control Checkpoints Are Implemented?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials and components before they enter the production line. Ensuring that all materials meet the specified standards is critical for avoiding defects later in the process.

-

In-Process Quality Control (IPQC): Continuous monitoring during production helps identify issues early. This involves regular inspections and testing to ensure that the assembly process adheres to quality standards.

-

Final Quality Control (FQC): Before shipping, finished products undergo rigorous testing to assess functionality, display quality, and durability. This ensures that only high-quality LCDs reach the market.

What Common Testing Methods Are Used in LCD Quality Assurance?

Manufacturers employ various testing methods to ensure quality, including:

- Visual Inspection: A manual check for visible defects such as scratches or discoloration.

- Functional Testing: Verifying that the LCD operates as intended under different conditions.

- Durability Testing: Assessing the LCD’s resistance to physical stress, temperature changes, and humidity.

- Color Calibration: Ensuring that the display meets color accuracy standards.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of potential suppliers is crucial. Here are actionable steps to ensure reliable sourcing:

What Should Be Included in Supplier Audits?

Conducting supplier audits can help buyers assess manufacturing capabilities and quality control measures. Key areas to focus on include:

- Manufacturing Processes: Evaluate the efficiency and technology used in production.

- Quality Management Systems: Review documentation related to compliance with international standards like ISO 9001.

- Employee Training: Ensure that staff are trained in quality assurance practices.

How Can Buyers Obtain Quality Reports?

Requesting quality reports from suppliers can provide insights into their performance history. These reports should detail:

- Defect Rates: Information on the percentage of defective products in past batches.

- Testing Results: Documentation of the tests performed on previous shipments, including any failures and corrective actions taken.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can add an extra layer of assurance. These independent entities can perform:

- Pre-shipment Inspections: Verify that products meet quality standards before they are shipped.

- Random Sampling: Conduct tests on a selection of units to ensure consistency across batches.

What Are the Quality Control and Certification Nuances for International Buyers?

Understanding the nuances of quality control and certification is vital for international B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe.

How Do Regional Standards Affect Sourcing Decisions?

Different regions may have varying standards and certifications. For instance, European buyers often prioritize CE certification, while buyers in the Middle East may require compliance with local regulations. Understanding these regional nuances can guide sourcing decisions and ensure compliance with local market requirements.

What Additional Considerations Should Buyers Keep in Mind?

- Cultural Differences: Be aware of cultural differences in business practices and communication styles, particularly when negotiating terms with suppliers from different regions.

- Language Barriers: Ensure that all quality documentation is available in a language that is understandable to all parties involved.

By focusing on these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when sourcing LCDs from China, ensuring they receive high-quality products that meet their specifications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘lcd china’

When sourcing LCDs from China, it’s essential to follow a structured approach to ensure you choose the right suppliers and products for your needs. This practical checklist will guide you through the critical steps of the sourcing process, helping you mitigate risks and maximize value.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. This includes the size, resolution, display technology (e.g., LCD vs. OLED), and any specific features such as touch functionality or energy efficiency.

– Why it matters: Having precise specifications will help you communicate effectively with potential suppliers and ensure that the products meet your expectations.

– What to look for: Create a detailed specification sheet to share with suppliers, which will serve as a basis for quotes and comparisons.

Step 2: Conduct Market Research

Engage in thorough market research to understand current trends, pricing, and leading suppliers in the LCD industry. Utilize online platforms, trade shows, and industry publications to gather relevant information.

– Why it matters: Understanding the market landscape will help you make informed decisions and negotiate better terms with suppliers.

– What to look for: Identify key players, emerging trends, and potential challenges that may affect pricing or availability.

Step 3: Identify and Evaluate Potential Suppliers

Compile a list of potential suppliers based on your research. Evaluate them by requesting company profiles, product catalogs, and references from previous clients.

– Why it matters: Thoroughly vetting suppliers reduces the risk of partnering with unreliable companies and ensures you receive quality products.

– What to look for: Pay attention to the supplier’s experience, reputation in the market, and any certifications that demonstrate compliance with international standards.

Step 4: Request Samples for Quality Assessment

Once you have shortlisted suppliers, request samples of their LCD products to assess quality and compatibility with your requirements. This step is critical before placing large orders.

– Why it matters: Samples provide a tangible way to evaluate the quality and performance of the products, helping you avoid costly mistakes.

– What to look for: Examine the samples for defects, color accuracy, and overall performance. Ensure they meet your technical specifications.

Step 5: Negotiate Terms and Conditions

After selecting a supplier based on quality and reliability, enter into negotiations regarding pricing, payment terms, lead times, and warranties.

– Why it matters: Effective negotiation can significantly affect your bottom line and ensure favorable terms for your business.

– What to look for: Ensure clarity on delivery schedules, return policies, and after-sales support to mitigate risks in the supply chain.

Step 6: Verify Compliance and Certifications

Before finalizing your purchase, verify that the supplier complies with relevant international standards and possesses necessary certifications, such as ISO or CE certifications.

– Why it matters: Compliance ensures that the products meet safety and quality standards, which is crucial for maintaining your brand’s reputation.

– What to look for: Request documentation proving their compliance and conduct independent verification if necessary.

Step 7: Establish a Communication Plan

Finally, set up a communication plan with your chosen supplier to facilitate smooth interactions throughout the ordering and delivery process.

– Why it matters: Clear communication helps prevent misunderstandings and ensures that both parties are aligned on expectations.

– What to look for: Establish regular check-ins and updates to monitor the progress of your orders and address any issues promptly.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing LCDs from China, ensuring a successful procurement process.

Comprehensive Cost and Pricing Analysis for lcd china Sourcing

What Are the Key Cost Components in LCD Sourcing from China?

When sourcing LCDs from China, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The quality of the raw materials directly affects the final product’s price. High-quality glass, backlighting components, and electronic parts can significantly increase costs. Buyers should evaluate the trade-off between material quality and pricing to ensure they meet their product requirements.

-

Labor: Labor costs in China can vary based on the region and the skill level required for manufacturing LCDs. Skilled labor may demand higher wages, impacting overall production costs. It is crucial for buyers to assess whether the labor cost aligns with the desired quality and complexity of the LCDs.

-

Manufacturing Overhead: This includes costs related to utilities, factory maintenance, and administrative expenses. Efficient manufacturers often have lower overhead costs, which can be passed on to the buyer in the form of competitive pricing.

-

Tooling: Custom tooling for specific LCD designs can be a significant upfront investment. Buyers should consider the amortization of these costs over the volume of units purchased, as higher volumes can dilute the tooling expense per unit.

-

Quality Control (QC): Implementing stringent QC measures is crucial to ensure product reliability. This may incur additional costs, but it is essential for minimizing defects and returns, ultimately enhancing customer satisfaction.

-

Logistics: Shipping costs from China to the buyer’s location can vary widely based on distance, shipping method, and current freight rates. Understanding Incoterms and choosing the right logistics partner can help optimize these costs.

-

Margin: Suppliers typically include a margin in their pricing, which can vary based on competition and demand. Negotiating effectively can help reduce this margin and lower the overall price.

How Do Price Influencers Affect LCD Pricing in B2B Transactions?

Several factors influence the pricing of LCDs, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer better pricing for larger orders. Understanding the MOQ is essential to determine if the order size aligns with pricing advantages.

-

Specifications and Customization: Customized LCDs will generally cost more than standard models due to additional design and production requirements. Buyers must weigh the necessity of customization against budget constraints.

-

Material Quality and Certifications: Premium materials and certifications (such as RoHS or CE) can increase costs but also add value in terms of compliance and performance. Buyers should assess the necessity of these certifications based on their market.

-

Supplier Factors: The reputation and reliability of the supplier can significantly affect pricing. Established suppliers may charge more for their proven quality and service, while newer suppliers might offer lower prices to gain market entry.

-

Incoterms: Understanding the shipping terms can greatly influence the total landed cost. Different Incoterms (like FOB, CIF, etc.) will dictate who is responsible for costs at various stages of the shipping process, affecting overall pricing.

What Are Effective Buyer Tips for Cost-Efficiency in LCD Sourcing?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, can enhance their cost-efficiency by implementing the following strategies:

-

Negotiate Wisely: Engage in open discussions with suppliers about pricing, especially if placing large orders. Consider building long-term relationships that could yield better pricing over time.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, evaluate the TCO, which includes shipping, tariffs, handling, and potential return costs. This holistic view will provide a clearer picture of the actual expenditure.

-

Consider Payment Terms: Negotiating favorable payment terms can improve cash flow. Options like letter of credit (LC) may provide security while allowing for better negotiation on prices.

-

Stay Informed on Market Trends: Prices can fluctuate based on global supply chain dynamics, so staying updated on market conditions can help buyers time their purchases better.

-

Assess Local Regulations: Be aware of import duties and regulations that can affect the overall cost. Engaging a local expert can help navigate these complexities.

Disclaimer on Pricing

Prices for LCDs can vary significantly based on the aforementioned factors, and the information provided should be seen as indicative. Buyers are encouraged to conduct thorough market research and supplier evaluations to obtain the most accurate and relevant pricing information tailored to their specific needs.

Alternatives Analysis: Comparing lcd china With Other Solutions

Understanding Alternatives for LCD Solutions

When considering LCD solutions, particularly those sourced from China, it is essential to explore viable alternatives that can meet specific business requirements. This analysis aims to compare ‘LCD China’ with other technologies, providing B2B buyers with insights into the most suitable options for their needs. The alternatives discussed here include OLED Displays and LED Displays, both of which have distinct characteristics that can affect performance, cost, and application.

Comparison Table of LCD China and Alternatives

| Comparison Aspect | LCD China | OLED Displays | LED Displays |

|---|---|---|---|

| Performance | Good color accuracy | Superior color contrast | Brightness varies |

| Cost | Generally low | Higher initial cost | Moderate cost |

| Ease of Implementation | Easy integration | More complex setup | Simple installation |

| Maintenance | Low maintenance | Moderate maintenance | Low maintenance |

| Best Use Case | Standard displays | High-end applications | General-purpose displays |

What Are the Pros and Cons of OLED Displays?

Pros: OLED (Organic Light Emitting Diode) displays are known for their exceptional color contrast and deeper blacks, making them ideal for high-end applications such as televisions and professional monitors. They offer a wider viewing angle and faster refresh rates compared to traditional LCDs. Their flexibility allows for thinner, lighter designs, which can be advantageous in product development.

Cons: The primary drawback of OLED technology is its higher cost, which can be a barrier for budget-conscious businesses. Additionally, OLED displays can suffer from burn-in issues if static images are displayed for prolonged periods, necessitating careful usage in certain applications.

What Are the Advantages and Disadvantages of LED Displays?

Pros: LED (Light Emitting Diode) displays provide high brightness levels and energy efficiency, making them suitable for outdoor and brightly lit environments. They are less prone to burn-in compared to OLEDs and typically have a longer lifespan. The cost of LED displays is generally moderate, making them accessible for various applications.

Cons: While LED technology offers good brightness, it may not match the color accuracy and contrast of OLED displays. The viewing angles can also be limited, leading to color distortion when viewed from the sides. Depending on the specific type of LED display (e.g., edge-lit vs. full-array), the performance can vary significantly.

How Should B2B Buyers Choose the Right Display Solution?

When selecting a display solution, international B2B buyers should evaluate their specific needs against the characteristics of each technology. If cost-effectiveness and low maintenance are priorities, LCDs sourced from China may be the best option. However, for applications that demand superior image quality and color performance, OLED displays may justify their higher price. Meanwhile, LED displays offer a balanced solution for businesses that require brightness and energy efficiency without the premium of OLED. Ultimately, understanding the unique advantages and limitations of each alternative will empower buyers to make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for lcd china

What Are the Key Technical Properties of LCDs from China?

When sourcing Liquid Crystal Displays (LCDs) from China, understanding the technical specifications is vital for B2B buyers. Here are some essential properties to consider:

-

Material Grade

– The material grade of an LCD impacts its durability and performance. Common materials include glass substrates and liquid crystals, which should meet specific industry standards (like RoHS compliance). Higher-grade materials typically ensure better image quality and longevity, which can significantly reduce replacement costs for businesses. -

Resolution

– Resolution refers to the number of pixels in each dimension that the display can show. It is crucial for applications requiring high detail, such as medical imaging or graphic design. Common resolutions include Full HD (1920×1080) and 4K (3840×2160). Opting for higher resolutions can enhance user experience and productivity, making it a key consideration for B2B buyers. -

Brightness (nits)

– Measured in nits, brightness determines how well an LCD can perform in various lighting conditions. Displays with higher brightness levels (300 nits and above) are essential for outdoor use or environments with bright ambient light. Understanding brightness specifications helps buyers select appropriate displays for their specific applications, ensuring optimal visibility. -

Viewing Angle

– The viewing angle defines how far off-axis a user can be while still seeing a clear image. For example, a display with a wide viewing angle (up to 178 degrees) is ideal for collaborative environments where multiple users view the screen simultaneously. This property is essential for enhancing user engagement and comfort. -

Response Time

– Response time indicates how quickly a pixel can change from one color to another, typically measured in milliseconds (ms). Lower response times (1ms to 5ms) are essential for applications involving fast motion, such as gaming or video playback. For B2B buyers, selecting displays with appropriate response times can prevent ghosting and motion blur, enhancing overall performance.

What Trade Terminology Should B2B Buyers Know When Purchasing LCDs?

Navigating the trade landscape requires familiarity with specific jargon. Here are common terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that manufactures products that are then marketed and sold by another company. Understanding this term is crucial for buyers seeking to source displays that meet specific requirements or branding standards. Working with reputable OEMs ensures product quality and reliability. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest number of units a supplier is willing to sell. This term is vital for budgeting and inventory management, especially for small to medium enterprises. Buyers should negotiate MOQs to align with their project needs without incurring excessive costs. -

RFQ (Request for Quotation)

– An RFQ is a document that buyers send to suppliers to request pricing and terms for specified products. This process helps B2B buyers compare offers and negotiate better deals. Crafting a detailed RFQ can lead to more favorable responses and streamline the procurement process. -

Incoterms (International Commercial Terms)

– Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects like shipping costs, risk transfer, and delivery points. Familiarity with these terms helps buyers avoid misunderstandings and ensures smoother logistics. Key Incoterms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). -

Lead Time

– Lead time refers to the time taken from placing an order to receiving the product. This term is crucial for project planning and inventory management. Understanding lead times helps B2B buyers make informed decisions regarding order quantities and timing to meet project deadlines.

In conclusion, by grasping both the technical specifications and trade terminology relevant to LCDs sourced from China, international B2B buyers can make informed decisions that enhance their purchasing strategy and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the lcd china Sector

What Are the Key Market Dynamics and Trends in the LCD China Sector?

The LCD market in China has emerged as a pivotal player in the global technology landscape, driven by several key factors. Firstly, the rapid advancement of consumer electronics, including smartphones, tablets, and televisions, has spurred demand for high-quality display technologies. Additionally, the growing adoption of LCDs in sectors such as automotive, healthcare, and industrial applications is expanding the market’s reach. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions.

Emerging trends include the shift towards larger display formats and the integration of smart technologies into LCD panels. As businesses increasingly prioritize user experience, the demand for high-resolution displays and innovative features such as touch functionality is on the rise. Furthermore, the proliferation of 5G technology is expected to enhance the capabilities of LCD displays, leading to further market expansion. Buyers should also keep an eye on the competitive landscape, as several Chinese manufacturers are investing in R&D to enhance their product offerings and maintain market leadership.

How Is Sustainability Shaping Sourcing in the LCD China Sector?

Sustainability is becoming a cornerstone of sourcing strategies in the LCD sector. The environmental impact of LCD production, including energy consumption and waste generation, has prompted manufacturers to adopt more sustainable practices. For B2B buyers, aligning with suppliers who prioritize eco-friendly production methods is not just a moral obligation but also a market differentiator.

Ethical sourcing is gaining traction as consumers increasingly demand transparency in supply chains. Buyers should look for suppliers that offer certifications such as ISO 14001 (Environmental Management) and RoHS (Restriction of Hazardous Substances), which indicate adherence to environmental regulations. Furthermore, the use of ‘green’ materials, such as recycled glass and energy-efficient manufacturing processes, can significantly reduce the carbon footprint associated with LCD production. By prioritizing sustainability, international buyers can enhance their brand reputation while contributing to a healthier planet.

What Is the Historical Context of the LCD Market in China?

The evolution of the LCD market in China dates back to the early 1990s when the country began investing heavily in display technology. Initially, the focus was on meeting domestic demand, but as manufacturing capabilities improved, China became a global hub for LCD production. This transformation was fueled by government support, foreign investments, and collaborations with international tech firms.

By the early 2000s, Chinese companies began to dominate the LCD market, leveraging cost advantages and scaling up production capabilities. Today, China is the largest producer of LCD panels, supplying to various industries worldwide. This historical context is essential for B2B buyers as it illustrates the competitive advantages and technological advancements that Chinese manufacturers bring to the table, making them formidable partners in the global LCD supply chain.

Frequently Asked Questions (FAQs) for B2B Buyers of lcd china

-

How do I find reliable suppliers for LCDs from China?

Finding reliable suppliers requires thorough research and vetting. Start by utilizing B2B platforms such as Alibaba, Made-in-China, or Global Sources, where you can filter suppliers by ratings and certifications. Request samples to evaluate quality, and check their business licenses and certifications. Additionally, consider visiting trade shows or industry exhibitions in China, as they provide opportunities to meet suppliers face-to-face and establish trust. -

What are the key factors to consider when sourcing LCDs from China?

When sourcing LCDs, consider product specifications, quality certifications, supplier reliability, and pricing. It’s also essential to evaluate the supplier’s production capacity and lead times. Other factors include the minimum order quantity (MOQ), customization options, and after-sales support. Understanding the regulatory requirements for importing electronics in your region is crucial to avoid compliance issues. -

What is the typical minimum order quantity (MOQ) for LCDs from Chinese suppliers?

MOQs for LCDs can vary significantly based on the supplier and the type of display. Generally, they range from 100 to 1,000 units. Some suppliers may offer lower MOQs for specific models or during promotional periods. Always negotiate MOQs and consider whether they align with your business needs and inventory management strategy. -

What payment terms should I expect when sourcing LCDs from China?

Payment terms can differ, but common practices include a 30% upfront deposit and 70% balance before shipment. Some suppliers may accept letters of credit or PayPal for smaller orders. It’s essential to negotiate terms that provide you with a balance of security and flexibility, ensuring you have recourse if issues arise with your order. -

How can I ensure quality assurance for LCDs sourced from China?

To ensure quality, establish clear specifications and request samples before committing to larger orders. Consider hiring a third-party inspection service to conduct quality checks at different production stages. Implementing a quality assurance agreement with your supplier can also help ensure compliance with your standards, reducing the risk of defective products. -

What logistics considerations should I keep in mind when importing LCDs from China?

Logistics considerations include shipping methods, freight costs, and customs clearance processes. Choose between air freight for faster delivery or sea freight for cost efficiency. Work with a freight forwarder experienced in electronics imports to navigate customs regulations and ensure compliance with local laws. Additionally, factor in potential delays due to port congestion or regulatory changes. -

What are the common challenges faced when sourcing LCDs from China?

Common challenges include language barriers, cultural differences, and varying quality standards. Additionally, navigating international trade regulations and customs requirements can be complex. To mitigate these issues, establish clear communication channels with suppliers, engage a local agent if needed, and conduct thorough due diligence before finalizing contracts. -

How do I handle disputes with Chinese suppliers regarding LCD orders?

Handling disputes involves clear communication and documentation. Start by addressing the issue directly with the supplier, outlining your concerns and desired resolutions. If necessary, escalate the matter through formal channels, such as mediation or arbitration, especially if you have a contract in place. Utilizing platforms like Alibaba can provide additional dispute resolution support, ensuring both parties adhere to agreed terms.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for lcd china

What Are the Key Takeaways for B2B Buyers in Strategic Sourcing of LCDs from China?

In conclusion, the strategic sourcing of LCDs from China offers international B2B buyers a unique opportunity to capitalize on competitive pricing, advanced technology, and extensive manufacturing capabilities. Establishing robust relationships with reliable suppliers is crucial to navigate the complexities of global supply chains, especially for buyers from Africa, South America, the Middle East, and Europe. Emphasizing due diligence, risk management, and quality assurance will enable companies to mitigate potential disruptions and ensure consistent supply.

How Can International Buyers Leverage These Insights for Future Success?

As the demand for LCD technology continues to grow across various industries, international buyers must remain proactive and adaptive. Engaging in long-term partnerships, investing in technology, and staying updated on market trends will enhance their competitive edge.

What Should B2B Buyers Do Next in Their Sourcing Strategy?

We encourage B2B buyers to evaluate their current sourcing strategies and consider the strategic insights shared in this guide. By doing so, they can better position themselves to leverage the vast potential of the LCD market in China and beyond. As we move forward, embracing innovation and collaboration will be key to sustaining growth in this dynamic landscape.