Unlock Cost Savings: The Ultimate Magnets Supplier Guide (2025)

Introduction: Navigating the Global Market for magnets supplier

In an increasingly interconnected global marketplace, sourcing the right magnets supplier can pose significant challenges for international B2B buyers. Companies often struggle with identifying reliable suppliers who not only meet quality standards but also understand the unique needs of diverse markets. This guide is designed to address these hurdles by providing a comprehensive overview of magnet suppliers, covering various types of magnets, their applications across different industries, and essential supplier vetting processes.

Whether you’re operating in the automotive sector in Nigeria, the electronics industry in Brazil, or manufacturing in the UAE, understanding the nuances of magnet procurement is crucial. This guide empowers B2B buyers by breaking down the complexities of magnet sourcing, including cost considerations, quality assurance, and logistical challenges. By leveraging the insights presented here, businesses can make informed purchasing decisions that align with their operational goals and market demands.

Furthermore, we delve into the specific challenges faced by buyers in Africa, South America, the Middle East, and Europe, ensuring that the strategies discussed are applicable across various regions. With actionable insights and expert analysis, this guide serves as an essential resource for any company looking to navigate the global market for magnets effectively.

Understanding magnets supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Permanent Magnets | Made from materials that maintain magnetism without power | Motors, generators, sensors, and speakers | Pros: Low maintenance, cost-effective. Cons: Limited strength compared to electromagnets. |

| Electromagnets | Magnetism generated by electric current | Lifting heavy objects, MRI machines | Pros: Adjustable strength, versatile. Cons: Requires power, can be bulky. |

| Soft Magnets | Easy to magnetize and demagnetize | Magnetic shielding, transformer cores | Pros: Quick response, good for temporary applications. Cons: Not suitable for permanent use. |

| Hard Magnets | High coercivity, retains magnetization | Permanent magnets in motors, data storage | Pros: Strong and durable. Cons: More expensive and less versatile. |

| Specialty Magnets | Custom designs for specific applications | Aerospace, medical devices | Pros: Tailored solutions, high performance. Cons: Higher costs, longer lead times. |

What Are the Characteristics of Permanent Magnets?

Permanent magnets are composed of materials that naturally retain their magnetism without the need for an external power source. Common materials include neodymium, ferrite, and samarium-cobalt. These magnets are widely used in various B2B applications, such as electric motors, generators, and speakers, due to their reliability and cost-effectiveness. Buyers should consider factors like magnetic strength, temperature stability, and size when purchasing, as these will impact performance in their specific applications.

How Do Electromagnets Differ from Other Magnet Types?

Electromagnets generate magnetism through electric current, allowing for adjustable magnetic strength. They are commonly used in industries that require lifting heavy objects, such as cranes and MRI machines. The primary consideration for B2B buyers is the power supply and the operational costs associated with using electromagnets. While they offer significant versatility and strength, the need for constant power can be a drawback in some applications.

What Are the Advantages of Soft Magnets?

Soft magnets are characterized by their ability to be easily magnetized and demagnetized, making them ideal for applications requiring temporary magnetism, such as magnetic shielding and transformer cores. Their quick response time is a significant advantage in high-frequency applications. B2B buyers should consider the magnetic permeability and core loss when sourcing soft magnets, as these factors will influence efficiency and performance in their specific setups.

Why Choose Hard Magnets for Your B2B Needs?

Hard magnets are known for their high coercivity, meaning they can retain their magnetization even in challenging environments. These magnets are typically used in permanent applications, such as motors and data storage devices. While they provide strong and durable solutions, B2B buyers should be mindful of the higher costs associated with hard magnets. Understanding the specific requirements of the application will help in selecting the right type of hard magnet.

What Makes Specialty Magnets a Unique Choice?

Specialty magnets are tailored for specific applications, often found in industries such as aerospace and medical devices. These magnets can be engineered to meet unique performance criteria, providing high levels of efficiency and reliability. However, the customization process can lead to longer lead times and higher costs. B2B buyers should evaluate the specific needs of their projects and consider the trade-offs between performance and cost when exploring specialty magnets.

Related Video: The Genius Behind Bach’s Goldberg Variations: CANONS

Key Industrial Applications of magnets supplier

| Industry/Sector | Specific Application of magnets supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Electric Motor Components | Enhanced efficiency and performance in vehicles | Quality certifications, compliance with automotive standards, reliability in high-temperature environments |

| Renewable Energy | Wind Turbine Generators | Improved energy conversion and sustainability | Sourcing magnets with high magnetic strength and corrosion resistance, adherence to environmental regulations |

| Electronics | Magnetic Sensors and Inductors | Increased accuracy and reliability in devices | Compatibility with specific electronic designs, sourcing from reputable suppliers with proven track records |

| Medical Devices | MRI Machines and Imaging Equipment | Enhanced imaging quality and patient safety | Compliance with health regulations, sourcing from suppliers with experience in medical applications |

| Industrial Automation | Robotics and Automated Systems | Increased productivity and precision in manufacturing | Long-term durability, ability to operate under varying conditions, and adherence to industry-specific standards |

How Are Magnets Used in the Automotive Industry?

In the automotive sector, magnets are critical components in electric motor assemblies, which power hybrid and electric vehicles. By improving the efficiency of these motors, magnets contribute to better fuel economy and reduced emissions. International B2B buyers, particularly in regions like Africa and the Middle East, should consider sourcing high-quality magnets that comply with automotive standards to ensure reliability and performance under various driving conditions.

What Role Do Magnets Play in Renewable Energy Solutions?

Magnets are essential in renewable energy systems, particularly in wind turbine generators where they facilitate the conversion of mechanical energy into electrical energy. The use of high-performance magnets can significantly enhance the efficiency of these systems, contributing to sustainable energy production. Buyers from South America and Europe must focus on sourcing magnets that offer high magnetic strength and corrosion resistance to withstand harsh environmental conditions.

How Are Magnets Integral to Electronics Manufacturing?

In the electronics industry, magnets are used in sensors and inductors, which are vital for the functionality of various devices, from smartphones to industrial machinery. These components help improve accuracy and reliability in electronic applications. When sourcing magnets, buyers should prioritize compatibility with specific electronic designs and ensure that suppliers have a proven track record in the electronics sector.

Why Are Magnets Crucial for Medical Devices?

Magnets play a vital role in medical imaging equipment, such as MRI machines, where they are used to generate strong magnetic fields necessary for high-quality imaging. The use of reliable and compliant magnets ensures patient safety and enhances diagnostic capabilities. B2B buyers, especially in regions like Europe and Africa, need to source magnets from suppliers who adhere to stringent health regulations and have experience in medical applications.

How Do Magnets Enhance Industrial Automation?

In industrial automation, magnets are used in robotics and automated systems to improve precision and productivity. They are essential for applications such as actuators and sensors that drive automated processes. Buyers should consider sourcing durable magnets that can operate under varying conditions while meeting industry-specific standards to ensure long-term performance and reliability in manufacturing environments.

Related Video: Everyday Uses for Magnets

3 Common User Pain Points for ‘magnets supplier’ & Their Solutions

Scenario 1: Difficulty in Finding Quality Suppliers for Custom Magnets

The Problem:

Many B2B buyers face challenges when sourcing quality magnets, especially when custom specifications are required. This can lead to frustration, as inadequate suppliers may not understand the unique requirements of different industries, resulting in poor-quality products that fail to meet operational needs. Buyers often find themselves inundated with generic options that do not align with their technical specifications, such as size, strength, or material type.

The Solution:

To overcome this challenge, buyers should prioritize establishing a clear and comprehensive specification document that outlines their exact requirements for custom magnets. This document should include details such as dimensions, magnetic strength (measured in Gauss or Tesla), material (e.g., neodymium, ferrite), and any specific coatings or finishes needed for environmental resistance. After creating this document, buyers can utilize specialized online platforms or industry-specific trade shows to identify suppliers who specialize in custom magnet production. Engaging in direct conversations with potential suppliers can also help clarify capabilities and ensure they can meet the required standards. Lastly, consider requesting samples before placing bulk orders to assess the quality firsthand.

Scenario 2: Long Lead Times and Delivery Delays

The Problem:

One of the most pressing issues for B2B buyers in the magnets sector is experiencing long lead times and unexpected delivery delays. Such delays can significantly disrupt production schedules, leading to financial losses and strained relationships with clients. Buyers often find themselves at the mercy of suppliers who do not communicate effectively about their production capabilities and timelines.

The Solution:

To mitigate lead time issues, buyers should implement a thorough vetting process when selecting suppliers. This process should include an assessment of the supplier’s production capabilities and past performance regarding delivery timelines. Establishing a clear communication protocol with suppliers can also help; setting up regular check-ins or updates can keep buyers informed about the status of their orders. Additionally, consider negotiating terms that include penalties for late deliveries or incentives for early completion to encourage timely performance. Establishing a buffer stock of essential magnets can also be a strategic move to ensure continuity in operations while waiting for new orders to arrive.

Scenario 3: Understanding the Technical Specifications and Standards

The Problem:

B2B buyers often struggle with understanding the technical specifications and standards associated with magnets, which can lead to incorrect purchases and compatibility issues. In industries such as automotive, aerospace, and electronics, specific magnetic properties and certifications are crucial, and a lack of knowledge can result in costly errors.

The Solution:

To address this knowledge gap, buyers should invest time in educating themselves about the various types of magnets and their respective applications. This can be achieved through attending webinars, industry conferences, or training sessions focused on magnet technology. Additionally, establishing a strong relationship with a knowledgeable supplier can provide invaluable insights into the specifications that are critical for their applications. Suppliers can often offer guidance on the best materials and standards to meet industry regulations. Buyers should also consider leveraging industry standards such as ISO or ASTM to ensure compliance and quality assurance in their magnet procurement process. By actively seeking information and building partnerships with experts, buyers can make informed decisions that align with their operational requirements.

Strategic Material Selection Guide for magnets supplier

When selecting materials for magnets, international B2B buyers must consider several factors that affect performance, durability, and cost. Below, we analyze four common materials used in the production of magnets, highlighting their key properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What are the Key Properties of Neodymium Magnets?

Neodymium (NdFeB) magnets are among the strongest permanent magnets available. They exhibit high magnetic strength and are capable of operating at elevated temperatures, typically up to 80°C (176°F) without significant loss of performance. However, they are prone to corrosion, necessitating protective coatings.

Pros: Neodymium magnets are compact and powerful, making them suitable for applications where space is limited. Their high magnetic energy density allows for smaller and lighter designs.

Cons: The primary drawback is their susceptibility to corrosion, which can lead to degradation over time if not properly coated. Additionally, they can be more expensive than other magnet types due to the cost of raw materials.

Impact on Application: Neodymium magnets are ideal for high-performance applications such as motors, sensors, and magnetic assemblies. However, buyers must ensure compatibility with the operating environment, especially in humid or corrosive settings.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers should also consider the availability of protective coatings to enhance durability in specific environments.

How Do Ferrite Magnets Compare in Performance?

Ferrite magnets, also known as ceramic magnets, are made from iron oxide and barium or strontium carbonate. They are less powerful than neodymium magnets but offer excellent resistance to corrosion and high temperatures, making them suitable for a variety of applications.

Pros: Ferrite magnets are cost-effective and can operate in temperatures up to 250°C (482°F). Their resistance to corrosion makes them suitable for outdoor applications.

Cons: The main limitation is their lower magnetic strength compared to neodymium magnets, which may require larger sizes for equivalent performance.

Impact on Application: Ferrite magnets are commonly used in loudspeakers, motors, and magnetic separators. Their robust nature makes them suitable for applications in harsh environments.

Considerations for International Buyers: Buyers should ensure that ferrite magnets meet local standards and regulations. Their lower cost can be attractive for bulk purchases, especially in developing markets.

What are the Advantages of Alnico Magnets?

Alnico magnets are composed of aluminum, nickel, and cobalt. They are known for their excellent temperature stability and can operate at temperatures up to 550°C (1022°F).

Pros: Alnico magnets provide stable performance over a wide temperature range and have good resistance to demagnetization.

Cons: They are generally more expensive and less powerful than neodymium magnets, which limits their use in applications requiring high magnetic strength.

Impact on Application: Alnico magnets are often used in applications such as sensors, guitar pickups, and industrial machinery where temperature stability is critical.

Considerations for International Buyers: Buyers should verify that alnico magnets comply with relevant industry standards. Their higher cost may be a factor in pricing strategies for international markets.

Why Choose Samarium Cobalt Magnets?

Samarium cobalt (SmCo) magnets are rare-earth magnets that offer a good balance between performance and temperature stability, with operational limits up to 300°C (572°F).

Pros: They are highly resistant to corrosion and demagnetization, making them suitable for harsh environments. Their magnetic strength is comparable to neodymium magnets.

Cons: The primary disadvantage is their higher cost, as they are made from rare-earth materials.

Impact on Application: SmCo magnets are ideal for applications in aerospace, military, and medical devices where reliability and performance are paramount.

Considerations for International Buyers: Buyers should assess the availability of rare-earth materials and consider sourcing strategies. Compliance with international standards is also essential for ensuring product quality.

Summary Table of Magnet Materials

| Material | Typical Use Case for magnets supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Neodymium (NdFeB) | Motors, sensors, magnetic assemblies | High magnetic strength | Prone to corrosion, higher cost | High |

| Ferrite | Loudspeakers, motors, magnetic separators | Cost-effective, corrosion-resistant | Lower magnetic strength | Low |

| Alnico | Sensors, guitar pickups, industrial machinery | Excellent temperature stability | More expensive, less powerful | Medium |

| Samarium Cobalt | Aerospace, military, medical devices | High resistance to corrosion and demagnetization | Higher cost due to rare-earth materials | High |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, enabling informed decisions based on specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for magnets supplier

What Are the Main Stages in the Manufacturing Process of Magnets?

The manufacturing process of magnets involves several critical stages, each ensuring that the final product meets the required specifications for performance and quality. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

1. Material Preparation

The first stage in magnet manufacturing involves preparing raw materials, which typically include various alloys such as neodymium, iron, and boron for permanent magnets, or ferrite for ceramic magnets. This preparation may include:

- Material Sourcing: Selecting high-quality raw materials from reputable suppliers.

- Alloying: Combining different metals to create specific magnetic properties. For example, neodymium magnets require precise ratios of neodymium, iron, and boron.

2. Forming

Once the raw materials are ready, the next step is forming them into the desired shape. This can be achieved through several techniques:

- Pressing: For sintered magnets, powdered metal is compacted in a mold under high pressure.

- Injection Molding: Used for plastic-bonded magnets, where a mixture of magnetic powder and plastic is heated and injected into molds.

- Casting: Suitable for larger or complex shapes, where molten material is poured into molds and allowed to solidify.

3. Assembly

In some cases, magnets may be assembled into larger components or products. This stage can involve:

- Magnetizing: Applying a strong magnetic field to the formed magnets to enhance their magnetic properties.

- Combining: Attaching magnets to other components, such as in motors or sensors.

4. Finishing

The final stage involves finishing processes to ensure that the magnets meet industry standards:

- Coating: Applying protective coatings (e.g., nickel, epoxy) to prevent corrosion and wear.

- Machining: Precision machining to achieve exact dimensions and tolerances.

- Quality Inspection: Conducting thorough inspections to ensure that the magnets meet specified standards.

How Is Quality Assurance Implemented in Magnet Manufacturing?

Quality assurance (QA) is crucial in the magnet manufacturing process, as it directly impacts the performance and reliability of the final product. B2B buyers should be aware of the standards and processes involved in QA.

Relevant International Standards for Magnet Quality

Several international standards govern the quality of magnets, ensuring consistency and reliability:

- ISO 9001: This standard specifies requirements for a quality management system (QMS) and is applicable to any organization, including magnet manufacturers.

- CE Marking: For products sold in Europe, CE marking indicates compliance with European health, safety, and environmental protection standards.

- API Standards: In specific industries like oil and gas, compliance with American Petroleum Institute (API) standards may be required for magnets used in critical applications.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are integral to the QA process. B2B buyers should familiarize themselves with these checkpoints to evaluate supplier capabilities:

- Incoming Quality Control (IQC): Inspects raw materials upon receipt to ensure they meet specifications.

- In-Process Quality Control (IPQC): Conducts checks during manufacturing to identify and rectify defects early in the process.

- Final Quality Control (FQC): Involves comprehensive testing of finished products to verify they meet all quality standards.

What Testing Methods Are Commonly Used in Magnet Quality Control?

To ensure that magnets meet performance and safety standards, manufacturers employ various testing methods:

- Magnetic Testing: Measures the magnetic strength and characteristics using gaussmeters or fluxmeters.

- Dimensional Testing: Utilizes calipers and micrometers to ensure that the magnets meet specified dimensions.

- Environmental Testing: Assesses how magnets perform under extreme conditions, such as high temperatures or humidity.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should implement strategies to verify the quality control processes of potential suppliers. This helps to mitigate risks associated with poor quality and ensures a reliable supply chain.

Conducting Supplier Audits

Regular audits can provide insights into a supplier’s manufacturing and quality assurance practices. During an audit, buyers should assess:

- Manufacturing Processes: Evaluate the techniques and equipment used in production.

- Quality Management Systems: Review documentation related to compliance with international standards like ISO 9001.

- Employee Training: Ensure that personnel are adequately trained in quality control practices.

Reviewing Quality Reports and Certifications

Buyers should request quality reports and certifications from suppliers. Key documents include:

- Quality Assurance Manuals: Outlines the supplier’s QA processes and standards.

- Inspection Reports: Provides data on the results of various quality checks performed during manufacturing.

- Third-Party Certifications: Independent validation of compliance with relevant standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate specific challenges when dealing with suppliers:

- Cultural Differences: Understanding regional manufacturing practices and quality expectations is crucial. Buyers should foster open communication to bridge any cultural gaps.

- Regulatory Compliance: Different regions may have varying regulations regarding product safety and quality. Buyers must ensure that suppliers comply with local and international laws.

- Logistics and Supply Chain Management: Consider the implications of shipping and customs on product quality. Ensure that suppliers have robust logistics processes to prevent damage during transport.

By focusing on these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when selecting magnets suppliers, ultimately leading to successful partnerships and superior product outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘magnets supplier’

To successfully procure magnets from international suppliers, particularly for businesses in Africa, South America, the Middle East, and Europe, follow this structured sourcing checklist. This guide aims to streamline the procurement process, ensuring that you make informed decisions that align with your technical requirements and business goals.

Step 1: Define Your Technical Specifications

Begin by outlining the specific types of magnets you need for your applications. Consider factors such as size, shape, magnetic strength (measured in Gauss or Tesla), and material type (e.g., neodymium, ferrite).

– Why It Matters: Clear specifications help in identifying the right suppliers and prevent misunderstandings later in the procurement process.

– What to Look For: Ensure you have documentation or drawings to communicate your needs effectively.

Step 2: Research and Identify Potential Suppliers

Conduct thorough market research to identify magnets suppliers who specialize in your required specifications. Utilize platforms like Alibaba, ThomasNet, or industry-specific directories to find reputable manufacturers.

– Why It Matters: A diverse supplier pool increases your chances of finding a partner who can meet your quality and pricing needs.

– What to Look For: Focus on suppliers with a proven track record in your industry, and pay attention to their geographic location for logistical considerations.

Step 3: Evaluate Supplier Capabilities

Assess potential suppliers by reviewing their manufacturing capabilities, including production capacity, technology used, and quality control processes.

– Why It Matters: Understanding a supplier’s capabilities ensures they can meet your order volume and quality standards.

– What to Look For: Request information about their production methods and any certifications (ISO, etc.) they may hold.

Step 4: Request Samples for Testing

Before making a large commitment, request samples of the magnets you intend to purchase. This step allows you to evaluate the product’s quality and suitability for your specific application.

– Why It Matters: Testing samples helps to confirm that the magnets will perform as needed in your end-use application.

– What to Look For: Check for consistency in size, strength, and material integrity.

Step 5: Verify Supplier Certifications and Compliance

Ensure that your chosen suppliers have the necessary certifications to meet international and local regulations for magnets. This includes compliance with safety standards and environmental regulations.

– Why It Matters: Compliance ensures that your procurement is not only safe but also aligns with ethical and legal standards.

– What to Look For: Look for certifications such as RoHS, REACH, or any industry-specific standards relevant to your market.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, delivery schedules, and return policies.

– Why It Matters: Clear terms protect both parties and help prevent disputes down the line.

– What to Look For: Ensure that the terms are documented in a formal contract to safeguard your interests.

Step 7: Establish Communication and Logistics Plan

Develop a clear communication plan with your supplier and outline logistics for shipping and handling. This includes discussing lead times, shipping methods, and any customs requirements for your region.

– Why It Matters: Effective communication and logistics planning are crucial for timely delivery and ongoing collaboration.

– What to Look For: Confirm the supplier’s responsiveness and willingness to accommodate your logistics needs.

By following this checklist, B2B buyers can approach the procurement of magnets with confidence, ensuring they select suppliers that meet their specific requirements and contribute to their operational success.

Comprehensive Cost and Pricing Analysis for magnets supplier Sourcing

What Are the Key Cost Components in Sourcing Magnets?

When sourcing magnets, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The type of materials used in magnet production, such as neodymium, samarium-cobalt, or ferrite, significantly affects the price. Rare earth materials tend to be more expensive due to their scarcity and processing costs.

-

Labor: Labor costs can vary greatly depending on the supplier’s location. For instance, suppliers in regions with higher wage standards may impose higher labor costs, impacting overall pricing.

-

Manufacturing Overhead: This includes utilities, factory rent, and equipment maintenance. Overhead costs can vary based on the supplier’s operational efficiency and scale of production.

-

Tooling: Custom tooling for specific magnet shapes or sizes can incur additional costs. For high-volume orders, these costs can be amortized, but for smaller runs, they can be a significant factor.

-

Quality Control (QC): Rigorous QC processes ensure product consistency and compliance with international standards, adding to the overall cost. Certifications (ISO, RoHS, etc.) may also influence pricing.

-

Logistics: Shipping costs, including freight, insurance, and customs duties, play a critical role in total expenses. Incoterms selected can greatly influence logistics costs and responsibilities.

-

Margin: Suppliers will include a profit margin that reflects their market position, competitiveness, and perceived value.

How Do Price Influencers Affect Magnet Sourcing?

Several factors can influence pricing when sourcing magnets:

-

Volume/MOQ: Minimum Order Quantities (MOQs) can impact pricing. Suppliers often offer better rates for larger volumes, allowing buyers to benefit from economies of scale.

-

Specifications and Customization: Customized magnets with specific dimensions or performance characteristics can attract higher prices. Understanding the balance between customization needs and budget is crucial.

-

Materials: The choice of materials directly correlates with costs. High-performance magnets made from rare earth materials will typically be priced higher than standard ferrite magnets.

-

Quality and Certifications: Certifications that demonstrate compliance with safety and environmental standards can increase costs. However, they may also enhance product reliability and market acceptance.

-

Supplier Factors: Supplier reputation, location, and production capabilities can influence pricing. Established suppliers with a proven track record may command higher prices due to perceived reliability.

-

Incoterms: The terms of shipment (e.g., FOB, CIF) can affect the final cost. Understanding these terms helps buyers anticipate additional costs associated with logistics.

What Are the Best Negotiation Tips for International B2B Buyers?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to better pricing and terms:

-

Research and Benchmarking: Gather data on average prices for magnets in your industry to establish a solid negotiation baseline. Understanding market trends can empower you during discussions.

-

Leverage Volume: If possible, consolidate orders to increase volume, allowing for better price negotiations. Suppliers are often more willing to offer discounts for bulk orders.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also logistics, maintenance, and disposal costs. A higher initial price may be justified by lower long-term costs.

-

Build Relationships: Establishing a rapport with suppliers can lead to favorable terms and pricing. Long-term relationships often foster better communication and flexibility.

-

Negotiate Payment Terms: Discuss payment options that may ease cash flow, such as extended payment terms or discounts for upfront payments.

-

Flexibility in Specifications: If you can be flexible with specifications or delivery times, suppliers may provide better pricing options.

What Should Buyers Keep in Mind Regarding Indicative Prices?

It is crucial for buyers to recognize that prices can vary significantly based on the factors discussed. Indicative prices should be viewed as a starting point, not a fixed cost. Fluctuations in material costs, exchange rates, and supplier capabilities can lead to price changes. Therefore, continuous market monitoring and proactive communication with suppliers are essential for securing the best deals.

Alternatives Analysis: Comparing magnets supplier With Other Solutions

Understanding Alternatives to Magnets Supplier

In the competitive landscape of B2B procurement, evaluating alternatives to a traditional magnets supplier is essential for making informed purchasing decisions. Various solutions exist that can fulfill similar needs, and understanding these options allows buyers to optimize performance, cost, and operational efficiency. Below, we compare the traditional magnets supplier model with two viable alternatives: electromagnetic systems and adhesive solutions.

Comparison Table

| Comparison Aspect | Magnets Supplier | Electromagnetic Systems | Adhesive Solutions |

|---|---|---|---|

| Performance | High magnetic strength, reliable | Adjustable magnetic strength | Varies based on type |

| Cost | Moderate to high | High initial investment, lower long-term costs | Low to moderate |

| Ease of Implementation | Simple installation | Requires technical expertise | Easy to apply, minimal training |

| Maintenance | Low maintenance needs | Moderate, periodic checks needed | Low maintenance |

| Best Use Case | Industrial applications, lifting | Adjustable operations, dynamic systems | Bonding materials, lightweight applications |

Detailed Breakdown of Alternatives

Electromagnetic Systems: Are They Worth the Investment?

Electromagnetic systems serve as a robust alternative to traditional magnets, especially in applications requiring variable magnetic strength. They can be adjusted to meet specific operational needs, making them versatile for industries like manufacturing and robotics. However, the initial investment can be significant, as these systems often require sophisticated control mechanisms and technical expertise for installation and maintenance. While the long-term operational costs may be lower due to their efficiency, the upfront costs can be a barrier for many businesses.

Adhesive Solutions: A Cost-Effective Choice?

Adhesive solutions present a more budget-friendly alternative, particularly for lightweight applications where magnetic strength is not critical. They are easy to implement, requiring minimal training or technical knowledge, which makes them ideal for small businesses or industries with less complex needs. However, the performance can vary significantly based on the type of adhesive used, and they may not provide the same level of reliability or strength as traditional magnets or electromagnetic systems. Additionally, the longevity of adhesive bonds can be a concern in high-stress environments.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right solution involves a careful analysis of your specific operational requirements, budget constraints, and the performance characteristics of each option. Buyers should consider the scale of their operations and the nature of their applications. For industries that demand high reliability and strength, a magnets supplier may still be the best choice. However, for businesses looking for flexibility and cost savings, exploring alternatives like electromagnetic systems or adhesive solutions could yield better results. Ultimately, understanding the pros and cons of each alternative will empower B2B buyers to make informed decisions that align with their strategic goals.

Essential Technical Properties and Trade Terminology for magnets supplier

What Are the Key Technical Properties of Magnets for B2B Buyers?

Understanding the essential technical properties of magnets is crucial for B2B buyers, particularly when sourcing from international suppliers. The following specifications are vital for ensuring that the magnets meet your application requirements:

-

Material Grade

The material grade defines the composition and characteristics of the magnet. Common materials include neodymium, samarium-cobalt, and ferrite. Each type has unique properties, such as magnetic strength and temperature resistance, which directly impact performance. Selecting the appropriate material grade ensures that the magnets will function effectively in your specific application, whether in automotive, electronics, or industrial machinery. -

Magnetic Strength (Gauss/Tesla)

Magnetic strength is a critical specification that indicates the intensity of the magnetic field produced by the magnet. Measured in Gauss or Tesla, this property determines how well the magnet can attract ferromagnetic materials. For B2B applications, understanding magnetic strength is essential for ensuring that the magnets can hold or lift the required weights, particularly in assembly lines and machinery. -

Tolerance Levels

Tolerance levels refer to the acceptable range of variation in the dimensions and magnetic properties of the magnets. This specification is important for precision applications where even minor deviations can lead to performance issues. Buyers must ensure that suppliers adhere to stringent tolerance standards to maintain quality and reliability in their products. -

Coating and Surface Treatment

Magnets often require coatings to prevent corrosion and enhance durability. Common coatings include nickel, zinc, and epoxy. The choice of coating affects the magnet’s lifespan, especially in harsh environments. B2B buyers should consider the operational conditions of their applications when selecting the appropriate surface treatment to ensure longevity and performance. -

Operating Temperature Range

The operating temperature range indicates the conditions under which the magnet will maintain its magnetic properties without degradation. Different materials have varying heat resistance levels. For international buyers, especially in regions with extreme temperatures, understanding this property is critical to avoid performance failure in their applications.

Which Trade Terminology Should B2B Buyers Know When Sourcing Magnets?

Familiarity with industry-specific terms can streamline the procurement process and enhance communication with suppliers. Here are some common jargon and trade terms related to magnet sourcing:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the magnet industry, buyers often source magnets from OEMs to ensure that they meet specific standards and compatibility with other components in their products. -

MOQ (Minimum Order Quantity)

MOQ is the minimum quantity of magnets that a supplier is willing to sell in a single order. Understanding MOQ is essential for budgeting and inventory management, especially for international buyers who may need to balance large orders with storage capabilities. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers requesting pricing information and terms for a specific quantity of magnets. Submitting an RFQ is a common practice for B2B transactions, allowing buyers to compare offers and negotiate better terms. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers regarding the transportation and delivery of goods. Familiarity with these terms helps B2B buyers understand shipping costs, risk management, and liability in cross-border transactions. -

Lead Time

Lead time refers to the time taken from placing an order to the delivery of the magnets. Understanding lead times is critical for supply chain planning, especially for international buyers who may face longer shipping durations and need to account for customs clearance. -

Certification Standards

Certification standards, such as ISO or RoHS, indicate compliance with industry regulations and safety requirements. B2B buyers should verify that their suppliers adhere to these standards to ensure product quality and regulatory compliance.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing magnets, ultimately leading to better product performance and successful partnerships.

Navigating Market Dynamics and Sourcing Trends in the magnets supplier Sector

What Are the Key Trends Driving the Magnets Supplier Market?

The magnets supplier market is experiencing significant evolution driven by several global factors. One of the primary drivers is the rapid advancement of technology, particularly in sectors like renewable energy, automotive, and electronics. For instance, the shift towards electric vehicles (EVs) and renewable energy sources is increasing the demand for high-performance magnets, which are essential for motors and generators. International B2B buyers from regions like Africa, South America, the Middle East, and Europe should be aware that suppliers are increasingly focusing on producing high-energy magnets, such as neodymium and samarium-cobalt, to meet this demand.

Additionally, the rise of Industry 4.0 and smart manufacturing is reshaping sourcing trends. Automation and IoT technologies are enhancing the efficiency of production processes, making it imperative for suppliers to adopt digital solutions for inventory management and customer relationship management (CRM). B2B buyers should look for suppliers who leverage these technologies to ensure timely deliveries and transparency in their operations.

Emerging markets are also seeing increased competition among suppliers, which can benefit international buyers by creating more options and potentially lower prices. However, this competition necessitates due diligence when selecting partners to ensure quality and reliability, particularly when sourcing from regions with varying standards.

How Important Is Sustainability and Ethical Sourcing in the Magnets Supplier Sector?

Sustainability has become a pivotal aspect of the magnets supplier sector, particularly for international B2B buyers who are increasingly prioritizing ethical sourcing. The environmental impact of magnet production, especially concerning rare earth metals, is significant. Suppliers must navigate the complexities of sourcing these materials responsibly to minimize ecological damage and comply with international regulations.

Ethical supply chains are essential for maintaining brand integrity and customer trust. Buyers should seek suppliers who can demonstrate commitment to sustainable practices, such as using recycled materials or adhering to ‘green’ certifications. Certifications like ISO 14001 for environmental management systems or the Responsible Minerals Initiative (RMI) can serve as indicators of a supplier’s dedication to sustainability.

Moreover, the trend towards ‘green’ magnets—those produced with environmentally friendly materials or methods—presents a growing opportunity. B2B buyers should engage with suppliers who are innovating in this space, as these products not only meet regulatory requirements but also appeal to environmentally conscious consumers.

What Is the Evolution of the Magnets Supplier Market?

The magnets supplier market has evolved significantly over the past few decades, shaped by technological advancements and changing industrial needs. Initially, the market was dominated by traditional ferrite magnets, which were widely used in various applications due to their cost-effectiveness. However, as industries began to demand higher performance, particularly in electronics and renewable energy, the focus shifted towards rare earth magnets.

The introduction of neodymium magnets in the 1980s marked a turning point, allowing manufacturers to develop smaller, more efficient devices. This innovation catalyzed growth in sectors such as telecommunications and automotive, leading to increased investments in research and development.

Today, the market is characterized by a diverse range of products tailored to specific applications, alongside a growing emphasis on sustainability and ethical sourcing practices. As international B2B buyers engage with this market, understanding its historical context can provide valuable insights into current trends and future opportunities.

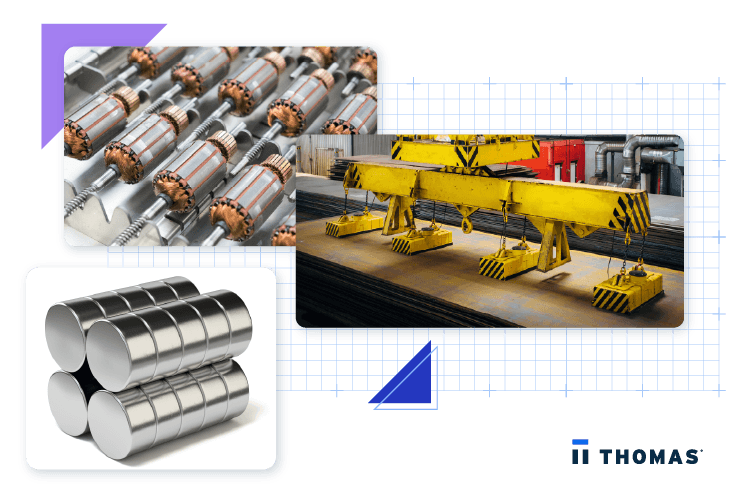

A stock image related to magnets supplier.

Frequently Asked Questions (FAQs) for B2B Buyers of magnets supplier

-

How do I choose the right magnets supplier for my business needs?

Selecting the right magnets supplier involves evaluating several factors. Start by identifying your specific requirements, such as the type of magnets (e.g., neodymium, ferrite) and their applications. Research potential suppliers based on their industry experience, product quality, and reputation. Consider requesting samples to assess the quality firsthand. Also, review their certifications and compliance with international standards to ensure they meet your business’s quality assurance needs. -

What factors should I consider when vetting international magnets suppliers?

When vetting international magnets suppliers, consider their production capacity, quality control processes, and delivery timelines. Investigate their financial stability and customer reviews to gauge reliability. It’s also crucial to assess their ability to communicate effectively in your preferred language and their responsiveness to inquiries. Lastly, verify their compliance with import/export regulations in your region to avoid future issues. -

What are the common minimum order quantities (MOQs) for magnets?

Minimum order quantities (MOQs) for magnets can vary significantly based on the supplier and the type of magnet. Generally, MOQs range from 100 to 1,000 pieces, but some suppliers may offer lower MOQs for specific products or customized orders. It’s advisable to discuss your requirements with potential suppliers to negotiate terms that suit your purchasing needs, especially if you’re a smaller business or testing a new market. -

Can I customize my magnets, and what is the process?

Yes, many magnets suppliers offer customization options, including size, shape, and magnetic strength. The customization process typically involves discussing your specific requirements with the supplier, including design specifications and quantities. After an initial consultation, the supplier may provide samples for approval before proceeding with full production. Ensure you clarify any additional costs and timelines associated with customization to avoid surprises. -

What payment terms are typically offered by magnets suppliers?

Payment terms can vary widely among magnets suppliers, especially in international trade. Common terms include full payment upfront, a deposit with the balance due upon shipment, or net 30/60 days after delivery. It’s essential to negotiate terms that align with your cash flow and budget. Additionally, consider using secure payment methods such as letters of credit or escrow services to protect your investment. -

How do I ensure quality assurance when sourcing magnets from suppliers?

To ensure quality assurance when sourcing magnets, request detailed product specifications and certifications from suppliers. Establish clear quality control measures, such as third-party inspections or factory audits, to assess manufacturing processes. Implement a testing phase where you evaluate the magnets upon receipt to verify they meet your standards. Building a good relationship with the supplier can also facilitate more transparent communication regarding quality expectations. -

What are the best logistics practices for importing magnets?

Effective logistics practices for importing magnets include selecting a reliable freight forwarder familiar with your destination’s regulations and customs procedures. Ensure you have all necessary documentation, such as commercial invoices and packing lists, to streamline customs clearance. Additionally, consider using shipping options that provide tracking and insurance to protect your investment. Plan for potential delays by allowing extra time for shipment and customs processes. -

How can I find reputable magnets suppliers in Africa, South America, the Middle East, and Europe?

To find reputable magnets suppliers in these regions, start by utilizing online platforms such as Alibaba, Global Sources, and ThomasNet. Attend industry trade shows and exhibitions where you can meet suppliers in person and assess their offerings. Networking within industry associations and forums can also provide valuable leads. Additionally, consider seeking recommendations from industry peers or conducting background checks to verify supplier credentials and reliability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for magnets supplier

In today’s competitive landscape, strategic sourcing of magnets is crucial for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. Engaging with reliable magnets suppliers can enhance supply chain resilience, reduce costs, and ensure product quality. Buyers must prioritize suppliers who demonstrate not only technical expertise but also an understanding of regional market dynamics, compliance standards, and sustainability practices.

How Can Strategic Sourcing Enhance Your Supply Chain?

Leveraging strategic sourcing enables businesses to align their procurement strategies with long-term goals, ensuring that they acquire high-quality magnets at competitive prices. This approach fosters partnerships with suppliers who can adapt to evolving market demands and technological advancements.

What Is the Future Outlook for Magnets Supply?

Looking ahead, the demand for innovative magnet solutions will continue to grow, driven by advancements in technology across various industries, including automotive, renewable energy, and electronics. International B2B buyers should actively seek out suppliers who are not only responsive to current needs but also forward-thinking in their product development.

A stock image related to magnets supplier.

In conclusion, as you navigate the global market for magnets, embrace strategic sourcing as a pathway to success. Strengthening supplier relationships and focusing on innovation will position your business favorably in an ever-evolving landscape. Take the next step today by exploring diverse suppliers and investing in partnerships that drive mutual growth and sustainability.