Unlock Cost Savings with Aluminum Extrusion China (2025)

Introduction: Navigating the Global Market for aluminum extrusion china

Navigating the global market for aluminum extrusion from China presents a unique challenge for international B2B buyers. With the increasing demand for lightweight, durable materials across various industries, sourcing high-quality aluminum extrusion products has never been more critical. However, the complexities of international trade, supplier reliability, and fluctuating prices can make this process daunting, especially for buyers in Africa, South America, the Middle East, and Europe, including Australia and Mexico.

This comprehensive guide aims to equip B2B buyers with actionable insights into the aluminum extrusion landscape in China. We delve into the different types of aluminum extrusion profiles, their diverse applications—from construction to automotive—and provide a detailed overview of the supplier vetting process. Furthermore, we will explore cost factors, shipping logistics, and quality assurance practices that are essential for making informed purchasing decisions.

By understanding the intricacies of the aluminum extrusion market in China, buyers can mitigate risks and optimize their sourcing strategies. This guide empowers you to confidently navigate supplier relationships and make choices that align with your business needs, ensuring that you receive the best value for your investment in aluminum products. Whether you are a seasoned procurement professional or entering this market for the first time, the insights within will help you achieve your sourcing objectives effectively.

Understanding aluminum extrusion china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Aluminum Extrusion | Uniform shapes and profiles, typically used in construction | Building frames, window frames | Pros: Cost-effective, widely available. Cons: Limited customization. |

| Custom Aluminum Extrusion | Tailored designs to meet specific requirements | Specialized machinery, automotive | Pros: Highly customizable, meets specific needs. Cons: Higher costs and longer lead times. |

| Structural Aluminum Extrusion | High strength-to-weight ratio, designed for load-bearing | Bridges, high-rise buildings | Pros: Excellent durability and strength. Cons: May require additional fabrication. |

| Architectural Aluminum Extrusion | Aesthetic designs, various finishes and colors | Facades, interior designs | Pros: Enhances visual appeal, diverse applications. Cons: Can be more expensive than standard options. |

| Thermal Break Aluminum Extrusion | Insulated profiles to reduce heat transfer | Energy-efficient buildings | Pros: Improved energy efficiency, reduces HVAC costs. Cons: Higher initial investment. |

What are the Characteristics of Standard Aluminum Extrusions?

Standard aluminum extrusions are characterized by their uniform shapes and profiles that are produced in large quantities. These extrusions are primarily used in construction applications, such as building frames and window frames. For B2B buyers, the advantages include cost-effectiveness and widespread availability. However, the trade-off is limited customization options, which may not suit all specific project needs.

How Do Custom Aluminum Extrusions Differ from Standard Options?

Custom aluminum extrusions are designed to meet specific requirements of various projects, allowing for tailored shapes and dimensions. They are widely used in specialized machinery and automotive applications where unique designs are critical. While they offer high levels of customization, they come with higher costs and longer lead times, making them a significant consideration for buyers who require specific functionalities.

What Makes Structural Aluminum Extrusions Ideal for Heavy-Duty Applications?

Structural aluminum extrusions are designed with a high strength-to-weight ratio, making them ideal for load-bearing applications such as bridges and high-rise buildings. Their durability and strength are significant advantages for B2B buyers in construction and engineering sectors. However, they may require additional fabrication processes, which could increase overall project costs and timelines.

Why Choose Architectural Aluminum Extrusions for Aesthetic Projects?

Architectural aluminum extrusions are known for their aesthetic designs and the variety of finishes and colors available. They are commonly used in facades and interior design applications, enhancing the visual appeal of buildings. While they provide diverse applications and can elevate a project’s design, they often come with a higher price point compared to standard options, which should be factored into budget considerations.

What are the Benefits of Thermal Break Aluminum Extrusions?

Thermal break aluminum extrusions feature insulated profiles that significantly reduce heat transfer, making them an excellent choice for energy-efficient building designs. They are particularly beneficial in reducing heating, ventilation, and air conditioning (HVAC) costs over time. However, the initial investment is typically higher, which might deter some buyers despite the long-term savings they offer.

Related Video: Extrusion 101: Aluminum Extrusion Process Explained by ILSCO Extrusions Inc.

Key Industrial Applications of aluminum extrusion china

| Industry/Sector | Specific Application of aluminum extrusion china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural components for buildings and facades | Lightweight, durable materials reduce overall construction costs | Compliance with local building codes and standards |

| Automotive | Chassis and frame components | Improved fuel efficiency through weight reduction | Precision in dimensions and tolerances |

| Electronics | Heat sinks and enclosures | Enhanced thermal management for electronic devices | Electrical conductivity and corrosion resistance |

| Renewable Energy | Solar panel frames and mounts | Increased efficiency and durability of solar installations | UV resistance and environmental certifications |

| Packaging and Transportation | Lightweight containers and pallets | Cost savings on shipping and handling | Customization options and load-bearing capacity |

What Are the Key Industrial Applications of Aluminum Extrusion in Construction?

In the construction sector, aluminum extrusion is pivotal for creating structural components such as window frames, curtain walls, and roofing systems. The lightweight nature of aluminum allows for easier handling and installation, significantly reducing labor costs. Moreover, its durability ensures longevity, minimizing maintenance expenses. International buyers must consider compliance with local building codes, as well as the required finishes for weather resistance, especially in regions prone to harsh climates.

How Is Aluminum Extrusion Used in the Automotive Industry?

Aluminum extrusion plays a crucial role in the automotive industry, particularly in the production of chassis and frame components. By utilizing aluminum, manufacturers can achieve substantial weight savings, which directly correlates with improved fuel efficiency and reduced emissions. For B2B buyers, sourcing aluminum extrusions requires attention to precision in dimensions and tolerances to ensure compatibility with existing assembly lines and safety regulations.

What Are the Applications of Aluminum Extrusion in Electronics?

In the electronics sector, aluminum extrusion is commonly used for heat sinks and enclosures. These components are essential for managing heat generated by electronic devices, thus enhancing their performance and lifespan. Buyers should prioritize sourcing aluminum with high thermal conductivity and corrosion resistance to ensure optimal functionality in various environmental conditions. Additionally, certifications for electrical safety may be necessary, depending on the application.

How Does Aluminum Extrusion Benefit Renewable Energy Solutions?

Aluminum extrusion is increasingly being utilized in renewable energy applications, particularly in the construction of solar panel frames and mounts. The material’s lightweight properties facilitate easier installation, while its resistance to corrosion and UV degradation ensures long-lasting performance. For international buyers, it’s essential to consider environmental certifications and the ability to customize designs to meet specific project requirements, which can vary significantly across different regions.

What Are the Advantages of Using Aluminum Extrusion in Packaging and Transportation?

In the packaging and transportation sectors, aluminum extrusion is leveraged to create lightweight containers and pallets. This application leads to significant cost savings in shipping and handling due to reduced weight. When sourcing aluminum extrusions for these purposes, buyers should focus on customization options that enhance load-bearing capacity and ensure compliance with industry standards for packaging materials.

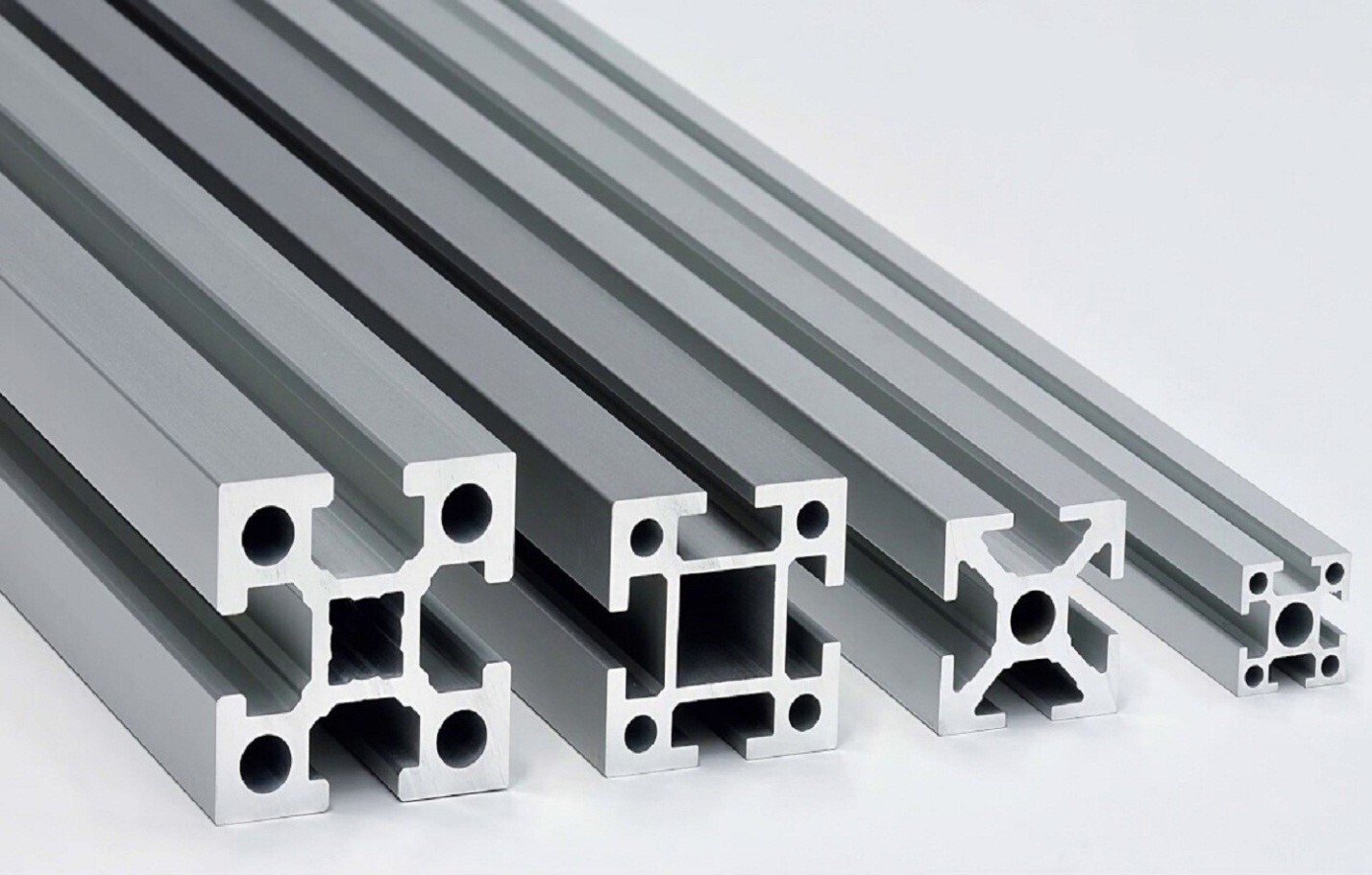

A stock image related to aluminum extrusion china.

3 Common User Pain Points for ‘aluminum extrusion china’ & Their Solutions

Scenario 1: Navigating Quality Assurance Challenges in Aluminum Extrusion from China

The Problem: B2B buyers often encounter issues related to the quality of aluminum extrusions sourced from China. Quality discrepancies can arise due to variations in manufacturing standards, material selection, and compliance with international certifications. This can lead to significant operational delays, increased costs, and potential safety hazards, particularly for industries such as construction and automotive where precision is critical.

The Solution: To overcome quality assurance challenges, international buyers should implement a multi-step quality management strategy. Begin by conducting thorough research on potential suppliers to assess their certifications (ISO 9001, for example) and quality control processes. It’s advisable to request samples before placing bulk orders, allowing you to evaluate the material properties and finish. Additionally, consider hiring third-party inspection services to conduct quality checks at various production stages. This proactive approach not only mitigates risks but also builds a more reliable supplier relationship.

Scenario 2: Overcoming Communication Barriers with Suppliers in China

The Problem: Communication barriers can significantly hinder the procurement process when dealing with suppliers in China. Language differences, cultural misunderstandings, and time zone disparities can lead to misinterpretations of specifications and delivery schedules, resulting in costly errors and project delays.

The Solution: To bridge communication gaps, buyers should establish clear and consistent communication channels. Utilize professional translation services for technical documents to ensure accuracy in specifications and requirements. Regular video conferences can also enhance understanding and foster relationships, providing a platform to clarify details in real-time. Additionally, consider engaging a local intermediary or sourcing agent who understands both the local market and your business needs. This can help navigate cultural nuances and ensure that both parties are aligned throughout the procurement process.

Scenario 3: Managing Lead Times and Delivery Reliability for Aluminum Extrusions

The Problem: Long lead times and unreliable delivery schedules are common pain points for B2B buyers sourcing aluminum extrusions from China. Factors such as production capacity, shipping delays, and customs clearance can lead to unexpected disruptions, affecting project timelines and overall business operations.

The Solution: To manage lead times effectively, buyers should implement a robust supply chain strategy that includes contingency planning. Start by identifying multiple suppliers to diversify your sourcing options, which can provide flexibility in case of delays. Establish clear timelines with your suppliers and set expectations for delivery performance. Using inventory management tools can also help in forecasting needs and optimizing order quantities, ensuring that you have sufficient stock without overcommitting resources. Additionally, consider working with freight forwarders who specialize in international shipping to streamline logistics and customs processes, reducing the risk of delays.

Strategic Material Selection Guide for aluminum extrusion china

What Are the Key Properties of Common Materials for Aluminum Extrusion in China?

When selecting materials for aluminum extrusion in China, international B2B buyers must consider various options, each with unique properties and applications. Below, we analyze four common materials: 6061 aluminum alloy, 6063 aluminum alloy, anodized aluminum, and marine-grade aluminum.

How Does 6061 Aluminum Alloy Perform in Extrusion Applications?

6061 aluminum alloy is widely recognized for its excellent mechanical properties and versatility. It has a moderate strength-to-weight ratio and is suitable for applications requiring good corrosion resistance and weldability. This alloy can withstand temperatures up to 200°C (392°F) and is often used in structural components and automotive parts.

Pros & Cons:

The main advantage of 6061 is its high strength and durability, making it ideal for demanding applications. However, its cost is relatively high compared to other aluminum alloys, which may be a consideration for budget-sensitive projects.

Impact on Application:

6061 aluminum is compatible with various media, including water and some chemicals, making it suitable for a range of industrial applications.

Considerations for International Buyers:

Buyers from regions like Africa and South America should ensure compliance with local standards, such as ASTM B221. Understanding the specific mechanical properties required for their applications is crucial.

What Are the Advantages of Using 6063 Aluminum Alloy?

6063 aluminum alloy is known for its excellent extrudability and surface finish, making it a popular choice for architectural applications, such as window frames and doors. It offers good corrosion resistance and can be anodized for enhanced durability.

Pros & Cons:

The key advantage of 6063 is its aesthetic appeal and ease of machining. However, it has lower strength compared to 6061, which may limit its use in structural applications.

Impact on Application:

This alloy is particularly suitable for applications exposed to the elements, as it performs well in outdoor environments.

Considerations for International Buyers:

Buyers in Europe and the Middle East should verify that the alloy meets local standards like EN 573-3, which governs aluminum alloys’ specifications.

Why Choose Anodized Aluminum for Extrusion?

Anodized aluminum undergoes an electrochemical process that enhances its natural oxide layer, resulting in improved corrosion resistance and surface hardness. This material is often used in consumer products, electronics, and architectural applications where aesthetics are important.

Pros & Cons:

The primary advantage of anodized aluminum is its enhanced durability and resistance to wear. However, the anodizing process can increase manufacturing complexity and costs.

Impact on Application:

Anodized aluminum is compatible with various environments, making it suitable for both indoor and outdoor applications.

Considerations for International Buyers:

Buyers should be aware of the anodizing standards relevant to their region, such as ASTM B580, to ensure compliance and quality assurance.

What Are the Benefits of Marine-Grade Aluminum?

Marine-grade aluminum, typically 5083 or 5086 alloys, is designed for high corrosion resistance in marine environments. These alloys are ideal for boat hulls, docks, and other applications exposed to saltwater.

Pros & Cons:

The significant advantage of marine-grade aluminum is its exceptional resistance to corrosion, making it suitable for harsh environments. However, it is often more expensive than standard aluminum alloys.

Impact on Application:

Marine-grade aluminum is specifically designed to withstand exposure to seawater, making it ideal for maritime applications.

Considerations for International Buyers:

B2B buyers from coastal regions should ensure compliance with marine industry standards, such as DNV GL rules, to guarantee performance and safety.

Summary Table of Material Selection for Aluminum Extrusion in China

| Material | Typical Use Case for Aluminum Extrusion China | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 6061 Aluminum Alloy | Structural components, automotive parts | High strength and durability | Higher cost compared to other alloys | High |

| 6063 Aluminum Alloy | Architectural applications | Excellent extrudability and finish | Lower strength than 6061 | Medium |

| Anodized Aluminum | Consumer products, electronics | Enhanced corrosion resistance | Increased manufacturing complexity | Medium to High |

| Marine-Grade Aluminum | Boat hulls, docks | Exceptional corrosion resistance | Higher cost than standard alloys | High |

This guide provides actionable insights for international B2B buyers, ensuring informed decisions in selecting the right materials for aluminum extrusion in China.

In-depth Look: Manufacturing Processes and Quality Assurance for aluminum extrusion china

What Are the Key Stages in the Aluminum Extrusion Manufacturing Process?

Aluminum extrusion is a process that involves transforming raw aluminum into specific shapes and profiles by forcing it through a die. This method is favored for its efficiency and versatility, allowing for the production of complex cross-sectional shapes that are essential in various industries, including construction, automotive, and electronics. The main stages of the aluminum extrusion manufacturing process include material preparation, forming, assembly, and finishing.

Material Preparation: How Is Aluminum Processed for Extrusion?

The initial stage involves preparing aluminum billets, which are solid bars of aluminum. These billets are heated to a specific temperature (typically between 400°C to 500°C) to enhance their malleability. Proper heating ensures that the aluminum can be easily extruded without cracking or deforming.

Next, the heated billets are placed in an extrusion press, where they are subjected to extreme pressure. The force compresses the aluminum and pushes it through a specially designed die, shaping it into the desired profile. This stage is critical, as the quality of the aluminum and the heating process directly impact the final product’s strength and durability.

Forming: What Techniques Are Used in Aluminum Extrusion?

A stock image related to aluminum extrusion china.

Once the aluminum is prepared, the forming stage begins. The extrusion process can employ several techniques, including direct extrusion and indirect extrusion. In direct extrusion, the aluminum is pushed through the die, while in indirect extrusion, the die is moved towards the billet. Each method has its advantages; direct extrusion is generally more common due to its efficiency, while indirect extrusion can produce more complex shapes with better surface finishes.

After the extrusion, the profile is cooled, typically using air or water quenching methods. This cooling process is essential for achieving the desired mechanical properties. Following cooling, the extruded aluminum may undergo additional shaping processes, such as bending or cutting, to meet specific design requirements.

What Are the Finishing Processes for Aluminum Extrusions?

Finishing processes play a vital role in enhancing the aesthetic appeal and performance of aluminum extrusions. Common finishing techniques include anodizing, powder coating, and polishing.

- Anodizing: This electrochemical process thickens the natural oxide layer on the aluminum surface, improving corrosion resistance and wear properties.

- Powder Coating: In this method, a dry powder is applied to the aluminum surface and then cured under heat to form a hard, protective layer. This technique allows for a wide range of colors and finishes.

- Polishing: Mechanical polishing can provide a shiny, reflective surface, which is often desired in architectural applications.

These finishing processes not only enhance the product’s appearance but also increase its lifespan, making it more suitable for demanding applications.

What International Standards and Quality Assurance Practices Should Buyers Consider?

Quality assurance is crucial in ensuring that aluminum extrusions meet specific industry standards and customer expectations. For international B2B buyers, understanding relevant quality standards is essential. Key certifications include:

- ISO 9001: This standard outlines the requirements for a quality management system and is applicable to any organization, regardless of its size or industry. Compliance indicates a commitment to consistent quality and customer satisfaction.

- CE Marking: Particularly relevant in Europe, CE marking demonstrates that a product meets EU safety, health, and environmental protection standards.

- API (American Petroleum Institute): For aluminum extrusions used in the oil and gas sector, compliance with API standards ensures that products meet rigorous safety and quality requirements.

How Are Quality Control Checkpoints Established in Aluminum Extrusion?

Quality control (QC) is integral to the manufacturing process, ensuring that products meet specified standards throughout production. Key QC checkpoints include:

- Incoming Quality Control (IQC): This step involves inspecting raw materials (aluminum billets) upon arrival to ensure they meet required specifications.

- In-Process Quality Control (IPQC): During the extrusion process, regular checks are made to monitor dimensions, surface quality, and mechanical properties. This ensures any deviations are caught early.

- Final Quality Control (FQC): Once production is complete, finished products undergo comprehensive testing. This includes dimensional checks, strength tests, and surface inspections to confirm compliance with quality standards.

What Testing Methods Are Commonly Used in Quality Assurance?

Various testing methods are employed to ensure the quality of aluminum extrusions. Common techniques include:

- Mechanical Testing: This involves tensile tests to measure the strength and ductility of the aluminum.

- Dimensional Inspection: Using tools like calipers and gauges, dimensions of the extruded profiles are checked against specifications.

- Surface Testing: Techniques such as visual inspections and non-destructive testing (NDT) methods, like ultrasonic or eddy current testing, assess surface integrity.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is critical to ensuring product reliability. Here are actionable steps:

-

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and QC systems. This includes reviewing documentation, inspecting facilities, and evaluating production practices.

-

Request Quality Reports: Suppliers should provide quality assurance documentation, including certificates of conformity, inspection reports, and test results. These documents should be transparent and readily available.

-

Engage Third-Party Inspection Services: Utilizing third-party inspection services can offer an unbiased assessment of the supplier’s quality control measures. These services can conduct audits, product inspections, and certification checks.

What Nuances in Quality Control Should International Buyers Be Aware Of?

When sourcing aluminum extrusions from China, international buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of several nuances:

- Cultural Differences: Communication styles and business practices can differ significantly. Clear and concise specifications should be provided to avoid misunderstandings.

- Regulatory Compliance: Familiarity with local regulations and standards in the supplier’s country is essential. Ensure that the supplier is compliant with both local and international standards.

- Supply Chain Transparency: Understanding the entire supply chain, from raw material sourcing to final product delivery, can help buyers assess potential risks and quality assurance practices.

By following these guidelines and understanding the intricacies of the manufacturing processes and quality assurance practices in aluminum extrusion, international B2B buyers can make informed decisions and build reliable partnerships with suppliers in China.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aluminum extrusion china’

To successfully source aluminum extrusion from China, international B2B buyers must follow a systematic approach. This checklist will guide you through the critical steps necessary to ensure a smooth procurement process, enabling you to make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Before initiating contact with suppliers, it is essential to clearly outline your technical requirements. Specifications such as dimensions, alloy types, surface finishes, and tolerances are critical for the end product’s performance. Providing detailed specifications helps suppliers understand your needs, reducing the likelihood of misunderstandings and ensuring that the final product meets quality expectations.

- Considerations: Include any industry standards or certifications required for your application.

Step 2: Conduct Market Research on Suppliers

Understanding the market landscape is vital in identifying potential suppliers for aluminum extrusion. Research various manufacturers, focusing on their reputation, production capacity, and specialization in aluminum products. Utilize platforms like Alibaba, Global Sources, and trade fairs to gather information.

- What to look for: Reviews, ratings, and recommendations from other buyers, particularly those in your region.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This process ensures that you are partnering with a reliable supplier who can deliver quality products consistently.

- Key questions: What is their production lead time? Do they have experience with your specific requirements?

Step 4: Verify Supplier Certifications

Quality assurance is paramount in sourcing aluminum extrusion. Verify that the supplier holds relevant certifications such as ISO 9001, which indicates a commitment to quality management systems. Additionally, check for compliance with any industry-specific standards applicable to your products.

- Documentation to request: Certificates of compliance, quality control processes, and inspection reports.

Step 5: Request Samples for Evaluation

Before placing a large order, request samples of the aluminum extrusion products. This step allows you to assess the quality, finish, and overall suitability of the product for your application. Testing the samples against your specifications ensures that the supplier can meet your expectations.

- Sample considerations: Ensure that the samples reflect the specifications you require and are representative of the production quality.

Step 6: Negotiate Terms and Pricing

Once you have identified a suitable supplier, negotiate terms that are favorable for both parties. Discuss pricing, payment terms, lead times, and shipping arrangements. A well-negotiated contract can prevent misunderstandings and protect your interests.

- Points to cover: Incoterms (e.g., FOB, CIF), payment methods (e.g., letter of credit, advance payment), and penalties for non-compliance.

Step 7: Establish a Communication Plan

Effective communication is crucial throughout the sourcing process. Establish a clear communication plan that outlines how and when you will interact with your supplier. Regular updates can help address any potential issues early and ensure that both parties remain aligned.

- Communication tools: Utilize email, video calls, and project management tools to facilitate ongoing dialogue and project tracking.

By following this structured checklist, B2B buyers can streamline their sourcing process for aluminum extrusion from China, reducing risks and ensuring high-quality outcomes.

Comprehensive Cost and Pricing Analysis for aluminum extrusion china Sourcing

What Are the Key Cost Components in Aluminum Extrusion Sourcing from China?

When evaluating the costs associated with sourcing aluminum extrusions from China, several critical components come into play. Understanding these can help international B2B buyers manage their budgets effectively.

-

Materials: The cost of aluminum itself is a significant factor. Prices can fluctuate based on global market conditions, alloy type, and purity. Additionally, sourcing recycled aluminum can lower costs but may affect quality.

-

Labor: Labor costs in China are generally lower than in many Western countries. However, the skill level of the workforce can impact the overall quality of the extrusions. Buyers should consider the implications of labor costs on production timelines and quality assurance.

-

Manufacturing Overhead: This includes operational expenses such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can lead to lower overhead costs, which can be passed on to buyers.

-

Tooling: Custom tooling is necessary for specific extrusion profiles. This one-time investment can significantly influence initial costs. Buyers should factor in tooling costs when estimating the total expenditure for new products.

-

Quality Control (QC): Implementing a robust QC process is vital to ensure product quality. Costs associated with testing and inspection can add to the overall price but are essential for maintaining standards, especially for international shipments.

-

Logistics: Shipping costs can vary widely based on the chosen Incoterms, shipping methods, and destination. Buyers should account for both freight charges and potential tariffs or customs fees when calculating total costs.

-

Margin: Suppliers typically apply a profit margin on top of their costs. Understanding the industry norms for margins can help buyers negotiate better pricing.

How Do Price Influencers Affect Aluminum Extrusion Costs?

Several factors can influence the pricing of aluminum extrusions, making it critical for buyers to be aware of these elements when negotiating.

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower unit prices due to economies of scale. Buyers should negotiate MOQs that align with their purchasing strategy to optimize costs.

-

Specifications and Customization: Custom designs or specific tolerances can increase costs. Buyers must balance their need for customization with budget constraints.

-

Materials and Quality Certifications: Higher-grade materials or those with specific certifications (e.g., ISO, ASTM) will cost more. Buyers should evaluate whether the additional expense aligns with their product requirements.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Well-established suppliers may charge a premium for their services, but this can also mean better quality assurance and reliability.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) will affect the overall cost structure. Buyers should understand how these terms impact shipping responsibilities and costs.

What Are Effective Tips for Negotiating Aluminum Extrusion Prices?

To maximize cost efficiency in sourcing aluminum extrusions from China, international B2B buyers should consider the following strategies:

-

Negotiate Terms: Establish clear communication with suppliers regarding pricing, payment terms, and delivery schedules. Being transparent about your needs can foster better relationships and potentially lead to cost savings.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial price. Consider long-term costs, including maintenance, durability, and potential waste. This holistic view can lead to more informed purchasing decisions.

-

Research Market Trends: Stay informed about the global aluminum market and trends that may affect pricing. Understanding these dynamics can provide leverage during negotiations.

-

Quality Assurance: Invest in quality control upfront to avoid costly defects later. Ensuring product quality can minimize returns and enhance overall satisfaction.

- Build Strong Relationships: Establishing long-term relationships with suppliers can lead to better pricing and priority service. Trust and reliability are often rewarded in B2B transactions.

Disclaimer

Prices for aluminum extrusions can vary widely based on market conditions, specifications, and supplier agreements. The information provided is indicative and should be validated through direct supplier negotiations and quotes.

Alternatives Analysis: Comparing aluminum extrusion china With Other Solutions

Understanding Alternatives to Aluminum Extrusion from China

When considering aluminum extrusion from China, international B2B buyers should explore various alternatives that may better fit their specific needs. These alternatives can vary in terms of performance, cost-effectiveness, implementation, and maintenance. Below, we will compare aluminum extrusion from China with two prominent alternatives: Aluminum Extrusion from Europe and Die Casting.

Comparison Table of Aluminum Extrusion Solutions

| Comparison Aspect | Aluminum Extrusion China | Aluminum Extrusion Europe | Die Casting |

|---|---|---|---|

| Performance | High strength and versatility for various applications | Superior quality with tighter tolerances | Good for complex shapes but generally lower strength |

| Cost | Lower production costs, competitive pricing | Higher costs due to labor and standards | Moderate costs, varies with complexity |

| Ease of Implementation | Quick lead times but can face logistical challenges | More straightforward logistics within Europe | Requires specialized tooling, longer setup times |

| Maintenance | Generally low maintenance; however, quality can vary | Low maintenance due to high-quality standards | Moderate maintenance; depends on alloy used |

| Best Use Case | Cost-sensitive projects needing large volumes | High-quality applications requiring precision | High-volume production of complex parts |

In-Depth Look at Alternatives

How Does Aluminum Extrusion from Europe Compare?

Aluminum extrusion from Europe is known for its superior quality and tighter tolerances, making it a suitable option for industries where precision is critical, such as aerospace and automotive. While the costs are generally higher due to labor standards and stringent regulations, the investment often pays off in terms of product quality and reliability. For B2B buyers focused on long-term partnerships and product integrity, this option can be more advantageous despite the initial higher cost.

What Are the Benefits of Die Casting?

Die casting presents a viable alternative for specific applications, particularly where complex shapes and high-volume production are required. This method allows for rapid manufacturing and can produce intricate designs with a high level of detail. However, the material strength may not match that of extruded aluminum, and the initial tooling costs can be significant. Die casting is ideal for projects that require a fast turnaround and can accommodate some compromises in strength and material properties.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Choosing the right aluminum solution depends on various factors, including project requirements, budget constraints, and product specifications. B2B buyers from Africa, South America, the Middle East, and Europe should consider not only the cost but also the quality, logistics, and maintenance aspects of each alternative. Conducting a thorough analysis of these factors will enable businesses to select the most appropriate solution that meets their operational needs while ensuring a solid return on investment.

Essential Technical Properties and Trade Terminology for aluminum extrusion china

What Are the Key Technical Properties of Aluminum Extrusion?

Understanding the essential technical properties of aluminum extrusion is critical for B2B buyers aiming to make informed purchasing decisions. Here are some key specifications:

1. Material Grade

Material grade defines the alloy composition and determines the mechanical properties of the aluminum. Common grades for extrusion include 6061, 6063, and 7075. For instance, 6061 is known for its excellent corrosion resistance and weldability, making it suitable for structural applications. Selecting the right material grade ensures the final product meets specific strength and durability requirements.

2. Tolerance

Tolerance refers to the allowable deviation from a specified dimension in the extrusion process. Precision in tolerance is crucial, especially for components that must fit together with other parts. Tight tolerances reduce the need for secondary machining, enhancing cost efficiency and product reliability. Understanding tolerance specifications helps buyers ensure that the extruded profiles will meet their design requirements.

3. Surface Finish

The surface finish of an aluminum extrusion affects its aesthetic appeal and performance. Common finishes include anodizing, powder coating, and mill finish. Each finish has different properties, such as corrosion resistance or color options. A well-chosen surface finish can enhance the longevity of the product while also meeting branding or aesthetic requirements.

4. Yield Strength

Yield strength is the maximum stress that an aluminum alloy can withstand without permanent deformation. This property is especially important in structural applications where load-bearing capabilities are critical. By understanding yield strength, buyers can select materials that will perform adequately under expected loads, reducing the risk of failure.

5. Extrusion Ratio

The extrusion ratio is the ratio of the cross-sectional area of the die to the area of the extruded product. A higher extrusion ratio often leads to better mechanical properties and surface quality. This metric can guide buyers in understanding the manufacturing capabilities and limitations of their suppliers.

What Are the Common Trade Terms in Aluminum Extrusion?

Familiarity with industry terminology is essential for effective communication and negotiation in the aluminum extrusion market. Here are several key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the aluminum extrusion industry, buyers may work with OEMs for customized profiles tailored to specific applications. Understanding OEM relationships can lead to better procurement strategies and product development.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers, as it impacts inventory costs and production planning. Knowing the MOQ helps businesses assess whether a supplier can meet their needs without excessive upfront investment.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. Crafting a detailed RFQ can result in more accurate quotes and better pricing. It is a vital step in the sourcing process, ensuring that suppliers understand the requirements.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in international transactions. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). Understanding Incoterms is essential for managing shipping costs and responsibilities, especially for international buyers.

5. Lead Time

Lead time refers to the time taken from placing an order to delivery. This term is critical for project planning and inventory management. Buyers should always inquire about lead times to ensure they can meet their project deadlines without delays.

By grasping these essential technical properties and trade terms, B2B buyers from Africa, South America, the Middle East, and Europe can navigate the aluminum extrusion landscape more effectively, making informed decisions that align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the aluminum extrusion china Sector

What Are the Current Market Dynamics in the Aluminum Extrusion Sector in China?

The aluminum extrusion market in China is experiencing robust growth driven by several global factors. A surge in demand from industries such as automotive, aerospace, and construction is propelling the market forward. Buyers from regions like Africa, South America, the Middle East, and Europe are increasingly attracted to China’s competitive pricing and advanced manufacturing capabilities. Notably, the shift towards lightweight materials in automotive and aerospace applications is a key trend influencing purchasing decisions.

Moreover, emerging technologies such as Industry 4.0 and IoT are enhancing production efficiency and quality control in the aluminum extrusion sector. The adoption of smart manufacturing practices allows suppliers to provide real-time data, facilitating better decision-making for international buyers. As the market evolves, buyers should remain vigilant of geopolitical factors and trade policies that may affect sourcing strategies.

How Can International B2B Buyers Adapt to Emerging Sourcing Trends?

International B2B buyers must stay informed about the shifting dynamics in sourcing trends within the aluminum extrusion market. A growing emphasis on just-in-time delivery and supply chain transparency is reshaping how companies engage with suppliers. The rise of digital platforms and e-commerce in B2B sourcing is also noteworthy, allowing buyers to easily access a broader range of suppliers and negotiate better terms.

Additionally, leveraging data analytics can provide insights into market trends and supplier performance, enabling buyers to make informed choices. By embracing digital tools and platforms, companies can streamline their sourcing processes, reducing lead times and costs.

What Is the Importance of Sustainability and Ethical Sourcing in Aluminum Extrusion?

Sustainability is becoming increasingly paramount in the aluminum extrusion sector, with a significant focus on reducing environmental impacts. For international B2B buyers, understanding the environmental footprint of their supply chains is essential. The aluminum industry is known for its high energy consumption; thus, sourcing from suppliers who utilize renewable energy sources and efficient manufacturing processes is crucial.

Moreover, the importance of ethical sourcing cannot be overstated. Buyers should prioritize suppliers that adhere to responsible labor practices and environmental regulations. Certifications such as ISO 14001 for environmental management and the Aluminium Stewardship Initiative (ASI) standard can guide buyers in selecting suppliers committed to sustainability. By integrating these principles into their sourcing strategies, companies can enhance their brand reputation and meet the growing demand for environmentally responsible products.

How Has the Aluminum Extrusion Sector Evolved Over Time?

The aluminum extrusion industry in China has undergone significant transformation over the past few decades. Initially focused on domestic consumption, China has rapidly become a global leader in aluminum production and extrusion, supported by government policies promoting industrial growth. The integration of advanced technologies and processes has enhanced the quality and variety of extruded aluminum products available on the market.

As international demand has risen, particularly from developing regions, Chinese manufacturers have adapted by increasing production capacity and investing in sustainable practices. This evolution has positioned China as a critical player for B2B buyers seeking reliable and innovative aluminum extrusion solutions.

In summary, understanding market dynamics, embracing sustainability, and recognizing the historical context can empower international B2B buyers to navigate the complexities of sourcing aluminum extrusion products from China effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of aluminum extrusion china

1. How do I select a reliable supplier for aluminum extrusion from China?

Selecting a reliable supplier for aluminum extrusion requires thorough research and due diligence. Start by verifying the supplier’s credentials, including business licenses and certifications such as ISO 9001 for quality management. Request references from previous clients and check their ratings on platforms like Alibaba or Global Sources. Additionally, consider conducting a factory audit to assess production capabilities, quality control processes, and working conditions. Engaging a third-party inspection service can also provide assurance of product quality before shipment.

2. What are the common minimum order quantities (MOQ) for aluminum extrusion in China?

Minimum order quantities (MOQ) for aluminum extrusion can vary significantly among suppliers. Generally, MOQs range from 500 kg to several tons, depending on the supplier and the complexity of the extrusion profiles. It’s essential to discuss your specific needs with potential suppliers, as many may offer flexibility in MOQs for ongoing partnerships or larger orders. Always clarify the MOQ before placing an order to avoid unexpected costs.

3. What payment terms should I expect when sourcing aluminum extrusion from China?

When sourcing aluminum extrusion from China, common payment terms include a 30% deposit upfront and the remaining 70% before shipment. Some suppliers may offer other arrangements, such as letters of credit or payment through platforms like PayPal or Alibaba Trade Assurance for added security. It’s crucial to negotiate payment terms that align with your cash flow needs while ensuring protection against potential risks.

4. How can I ensure quality assurance for aluminum extrusion products?

To ensure quality assurance for aluminum extrusion products, establish a clear quality control plan with your supplier. This should include pre-production samples, in-process inspections, and final product evaluations. Specify quality standards based on international benchmarks such as ASTM or EN standards. Additionally, consider hiring an independent quality control agency to conduct inspections at different stages of production to confirm compliance with your specifications.

5. What are the shipping options for importing aluminum extrusion from China?

Shipping options for importing aluminum extrusion from China typically include sea freight, air freight, and express courier services. Sea freight is the most economical for large volumes but takes longer, while air freight is faster but more expensive. For smaller orders, express services like DHL or FedEx may be viable. Ensure you discuss logistics with your supplier, including delivery times and incoterms (e.g., FOB, CIF) to clarify responsibilities and costs.

6. Can I customize aluminum extrusion designs when sourcing from China?

Yes, many Chinese suppliers offer customization for aluminum extrusion designs. You can collaborate with them to develop specific profiles, dimensions, and surface finishes tailored to your project requirements. Provide detailed drawings or CAD files to communicate your specifications clearly. Be prepared for possible additional costs and longer lead times associated with custom orders, and ensure that you receive prototypes or samples for approval before full production.

7. What regulatory considerations should I be aware of when importing aluminum extrusion?

When importing aluminum extrusion, it’s crucial to understand the regulatory requirements of your destination country. This may include import duties, tariffs, and compliance with safety and environmental standards. Some regions, such as the EU, have strict regulations regarding material quality and recycling standards. Consult with a customs broker or trade expert to ensure compliance and avoid delays or penalties during the import process.

8. How do I handle disputes with suppliers in China?

Handling disputes with suppliers in China requires clear communication and documentation. Start by addressing the issue directly with your supplier and attempting to resolve it amicably. Document all communications and agreements, as this can be vital if the situation escalates. If necessary, involve a third-party mediator or consult legal advice, especially if your contract includes arbitration clauses. Utilizing platforms like Alibaba Trade Assurance can also provide some level of protection against disputes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for aluminum extrusion china

In conclusion, strategic sourcing of aluminum extrusion from China offers significant advantages for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. By understanding the complexities of the supply chain and engaging with reputable suppliers, companies can leverage cost efficiencies, superior quality, and innovative designs that meet global standards.

What Are the Key Benefits of Strategic Sourcing from China?

International buyers can capitalize on China’s vast manufacturing capabilities and competitive pricing, which are critical for maintaining a strong market position. Moreover, establishing long-term relationships with suppliers can lead to better communication, enhanced service levels, and more favorable terms over time.

How Can B2B Buyers Prepare for Future Trends in Aluminum Extrusion?

Looking ahead, it is essential for businesses to stay informed about emerging trends in sustainability and technology within the aluminum industry. As global demand for lightweight and eco-friendly materials increases, adapting sourcing strategies to include sustainable practices will not only enhance brand reputation but also align with customer expectations.

As you consider your sourcing strategy, take proactive steps to evaluate potential partners and explore innovative solutions in aluminum extrusion. Engage with suppliers who prioritize transparency and collaboration, ensuring a resilient supply chain that can adapt to future challenges.