Unlock Cost Savings with Filter Custom Solutions (2025)

Introduction: Navigating the Global Market for filter custom

In today’s competitive landscape, sourcing high-quality custom filters can be a daunting challenge for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. The need for tailored filtration solutions is growing, yet many companies struggle to identify reliable suppliers and navigate the complexities of global trade. This guide aims to demystify the process of sourcing custom filters by providing actionable insights on various types, applications, and the crucial steps for effective supplier vetting.

This comprehensive resource covers everything from the fundamental types of custom filters—such as liquid, air, and gas filters—to their specific applications across industries, including manufacturing, pharmaceuticals, and environmental sectors. Furthermore, it delves into the essential criteria for evaluating suppliers, including quality assurance processes, certifications, and logistical considerations. By understanding the costs associated with custom filters and the factors that influence pricing, buyers can make informed decisions that align with their operational needs and budget constraints.

Ultimately, this guide is designed to empower international B2B buyers to navigate the global market for custom filters confidently. With a focus on actionable strategies and best practices, readers will gain the knowledge necessary to optimize their purchasing decisions, ensuring they source the right solutions for their unique business requirements. Whether you are in Brazil, Colombia, or any other region, this guide serves as a vital tool in your quest for excellence in filtration solutions.

Understanding filter custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mechanical Filters | Physical barriers that separate particles from fluids | Water treatment, HVAC systems | Pros: Effective at removing large particles; Cons: Regular maintenance required. |

| Electronic Filters | Use of electronic components to filter signals | Telecommunications, audio processing | Pros: High precision; Cons: More complex and costly. |

| Chemical Filters | Utilize chemical processes to remove contaminants | Oil refining, wastewater treatment | Pros: Effective for specific contaminants; Cons: Can be expensive and require careful handling. |

| Biological Filters | Leverage biological processes to filter pollutants | Aquaculture, environmental management | Pros: Sustainable and eco-friendly; Cons: Slower response time. |

| Customizable Filters | Tailored solutions based on specific business needs | Manufacturing, food and beverage production | Pros: Highly adaptable; Cons: Longer lead times for design and implementation. |

What Are Mechanical Filters and Their B2B Applications?

Mechanical filters are physical barriers that separate unwanted particles from fluids, making them essential in industries such as water treatment and HVAC systems. They are effective at removing larger particles, which can improve the overall quality of the fluid being processed. However, they require regular maintenance and cleaning to ensure optimal performance, making it crucial for B2B buyers to consider the long-term maintenance costs associated with these filters.

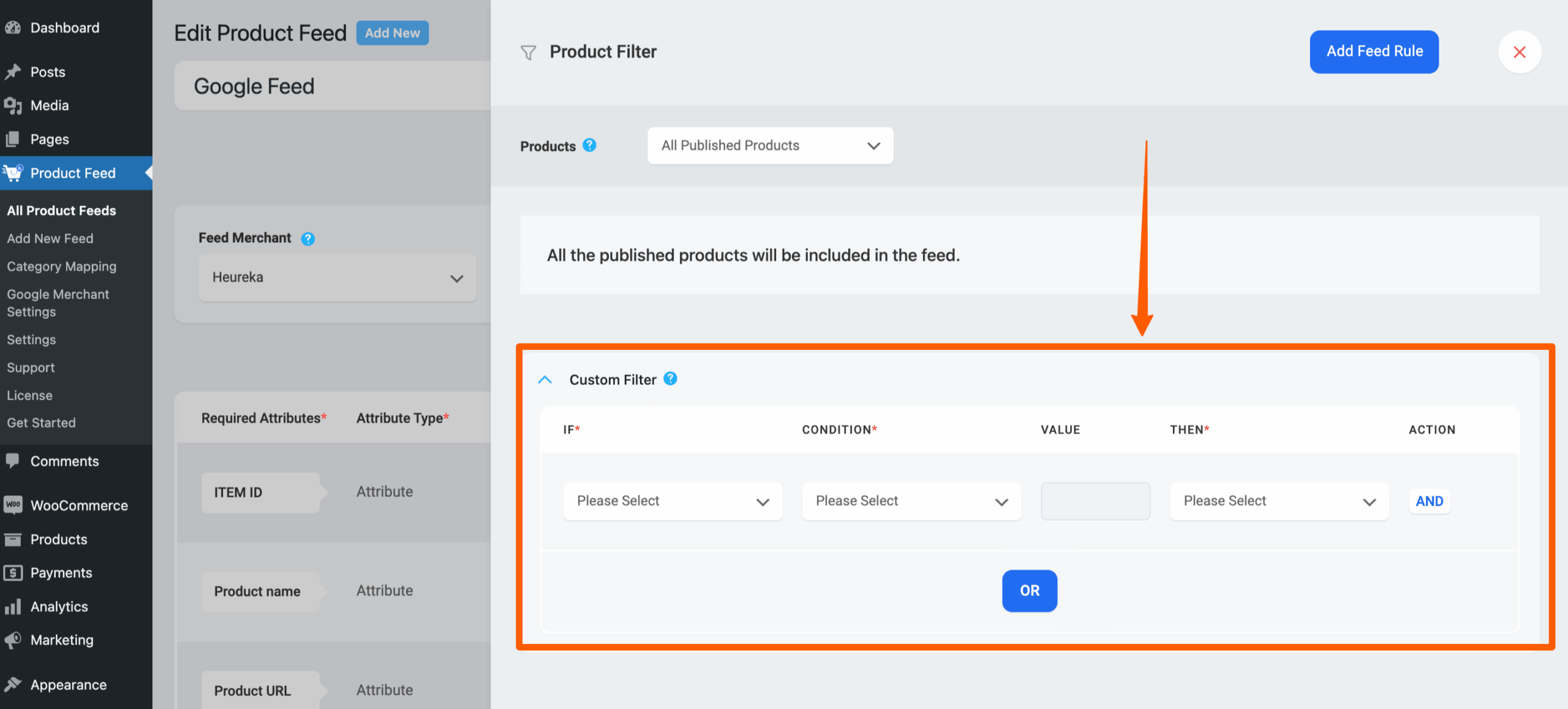

A stock image related to filter custom.

How Do Electronic Filters Function in B2B Contexts?

Electronic filters utilize electronic components to filter signals and are commonly used in telecommunications and audio processing. Their ability to provide high precision in filtering makes them invaluable in applications where signal clarity is critical. However, the complexity of these filters often leads to higher costs, which may be a consideration for B2B buyers looking to balance performance with budget constraints.

What Are the Benefits of Chemical Filters in Various Industries?

Chemical filters employ chemical processes to remove specific contaminants from fluids, making them widely used in oil refining and wastewater treatment. They are particularly effective for targeted contaminant removal, but their implementation can be expensive and may require careful handling of hazardous materials. B2B buyers should evaluate the specific needs of their operations to determine if the benefits outweigh the costs.

Why Are Biological Filters Important for Sustainable Practices?

Biological filters leverage natural processes to filter pollutants, making them popular in aquaculture and environmental management. Their sustainable and eco-friendly nature aligns with the increasing demand for environmentally responsible practices in business. However, biological filters may have a slower response time, which could be a disadvantage in industries requiring rapid filtration. Buyers should assess their operational timelines and sustainability goals when considering these solutions.

What Are the Advantages of Customizable Filters for Diverse Business Needs?

Customizable filters are designed to meet specific business requirements, making them ideal for manufacturing and food and beverage production. Their adaptability allows businesses to tailor filtration solutions to their unique challenges, enhancing efficiency and effectiveness. However, the design and implementation process can lead to longer lead times, which buyers should factor into their project timelines to avoid disruptions in operations.

Related Video: Elementor Custom Post Type With Taxonomy Filter | Filter Custom Post Type | CrocoBlock JetEngine

Key Industrial Applications of filter custom

| Industry/Sector | Specific Application of filter custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water Treatment | Customized filtration systems for wastewater | Enhances water quality, compliance with regulations | Material compatibility, filtration efficiency, cost |

| Food and Beverage | Specialized filters for beverage production | Ensures product purity, extends shelf life | Certifications, hygiene standards, customization options |

| Oil and Gas | Filtration solutions for drilling fluids | Increases operational efficiency, reduces downtime | Durability, resistance to harsh chemicals, scalability |

| Pharmaceutical | Custom filters for sterile processing | Guarantees product safety, meets stringent regulations | Quality assurance, validation processes, lead times |

| Automotive Manufacturing | Filters for air and fluid systems | Improves product reliability, enhances performance | Specifications adherence, testing standards, supply chain reliability |

How is ‘filter custom’ Used in Water Treatment?

In the water treatment sector, customized filtration systems are essential for effectively treating wastewater. These systems can be tailored to meet specific regulatory requirements and local water quality challenges. For international buyers, especially in regions like Africa and South America, sourcing filters that can handle varying contaminant levels and comply with local regulations is critical. The right filtration solution not only enhances water quality but also ensures compliance with environmental standards, protecting the company from potential fines.

What Role Do Customized Filters Play in Food and Beverage Production?

In the food and beverage industry, specialized filters are used to ensure the purity and safety of products during production. These filters prevent contaminants from entering the final product, thus extending shelf life and maintaining quality. B2B buyers from Europe and the Middle East must consider certifications and hygiene standards when sourcing these filters, as compliance with food safety regulations is paramount. Customization options can also be crucial for adapting to different beverage types and production processes.

Why Are Filtration Solutions Important in the Oil and Gas Industry?

The oil and gas industry relies heavily on filtration solutions to maintain the integrity of drilling fluids. Customized filters help remove impurities, which can lead to increased operational efficiency and reduced downtime. Buyers from regions like the Middle East, where oil extraction is prevalent, should prioritize sourcing durable filters that can withstand harsh chemicals and extreme conditions. Scalability of filtration solutions is also a key consideration, ensuring that they can adapt to varying production scales.

How Are Custom Filters Used in Pharmaceutical Manufacturing?

In pharmaceutical manufacturing, custom filters are critical for sterile processing, ensuring that products are free from contaminants. This is vital for meeting stringent industry regulations and guaranteeing product safety. International B2B buyers need to focus on quality assurance and validation processes when sourcing these filters. Additionally, understanding lead times for customized orders is essential to maintain production schedules without delays.

What Benefits Do Filters Provide in Automotive Manufacturing?

Filters play a significant role in automotive manufacturing, particularly in air and fluid systems. Customized filtration solutions improve product reliability and enhance overall performance by ensuring that contaminants do not affect engine efficiency. Buyers in this sector must pay attention to adherence to specifications and testing standards to guarantee that the filters meet the rigorous demands of automotive applications. A reliable supply chain is also crucial for ensuring timely delivery and consistent quality.

Related Video: Uses and Gratifications Theory – UGT

3 Common User Pain Points for ‘filter custom’ & Their Solutions

Scenario 1: Inconsistent Product Specifications Across Suppliers

The Problem: B2B buyers frequently encounter discrepancies in product specifications when sourcing ‘filter custom’ from multiple suppliers. For instance, a buyer in Brazil may request filters with specific dimensions and material compositions, only to find that different suppliers provide varying standards or fail to clarify the specifications adequately. This inconsistency can lead to delays, increased costs, and even reputational damage if the filters do not meet the required performance standards.

The Solution: To mitigate this issue, buyers should adopt a standardized specification sheet that clearly outlines the desired attributes of ‘filter custom’ products. This sheet should include dimensions, material types, filtration efficiency ratings, and any regulatory compliance requirements. When reaching out to suppliers, request that they provide their product specifications in accordance with this standardized format. Additionally, implementing a Quality Assurance (QA) process that includes sample testing before full-scale orders can ensure that the products meet the specified standards. This proactive approach not only streamlines the procurement process but also helps build reliable relationships with suppliers.

Scenario 2: Difficulty in Finding Reliable Suppliers for ‘Filter Custom’

The Problem: Many international B2B buyers face challenges in identifying trustworthy suppliers for ‘filter custom’, especially in regions like Africa and the Middle East where local options may be limited. Buyers often struggle with concerns regarding the supplier’s credibility, quality of products, and after-sales support. This uncertainty can lead to hesitance in making purchasing decisions and missed opportunities for competitive advantage.

The Solution: To effectively navigate the supplier landscape, buyers should leverage industry-specific platforms and networks that specialize in ‘filter custom’ products. Participating in trade shows, industry conferences, and online B2B marketplaces can help buyers connect with verified suppliers. Additionally, conducting thorough due diligence, including requesting references and reviewing case studies from existing clients, can provide insights into a supplier’s reliability. Forming strategic partnerships with local industry associations can also facilitate connections with reputable suppliers, enhancing trust and minimizing risks.

Scenario 3: Challenges in Customizing Filters to Meet Specific Needs

The Problem: B2B buyers often find it challenging to customize filters to meet their unique operational requirements. For example, a company in Colombia may need filters that can withstand specific chemical exposures or temperature variations, but many suppliers offer only standard options that do not address these specific needs. This lack of customization can lead to inefficiencies in operations and increased costs due to frequent replacements or maintenance.

The Solution: To overcome customization challenges, buyers should engage in open dialogue with suppliers about their specific needs and the performance criteria required for their filters. Providing detailed use-case scenarios can help suppliers better understand the application and recommend suitable custom solutions. Furthermore, buyers should inquire about the supplier’s capabilities in terms of design and manufacturing flexibility. Establishing a collaborative relationship can lead to innovative solutions tailored to the buyer’s needs. Additionally, consider investing in a prototype phase where small quantities of customized filters can be tested in real-world conditions before committing to larger orders. This strategy not only ensures that the filters meet operational requirements but also strengthens the buyer-supplier relationship through collaborative problem-solving.

Strategic Material Selection Guide for filter custom

What Are the Key Properties of Common Materials Used in Custom Filters?

When selecting materials for custom filters, it is essential to consider their properties that directly impact product performance. Below, we analyze four commonly used materials: stainless steel, polypropylene, fiberglass, and activated carbon.

How Does Stainless Steel Perform in Custom Filters?

Key Properties: Stainless steel is renowned for its high-temperature and pressure resistance, making it suitable for demanding applications. It also exhibits excellent corrosion resistance, particularly in harsh environments.

Pros & Cons: The durability of stainless steel is a significant advantage, as it can withstand mechanical stress and chemical exposure. However, its manufacturing complexity can lead to higher costs compared to other materials. Additionally, while stainless steel is suitable for a wide range of applications, its weight may be a drawback in portable filter systems.

Impact on Application: Stainless steel is compatible with various media, including oils, gases, and water. Its robustness makes it ideal for industries such as oil and gas, food processing, and pharmaceuticals.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local standards such as ASTM and DIN. The availability of stainless steel in different grades can also affect procurement decisions.

What Are the Benefits of Using Polypropylene in Custom Filters?

Key Properties: Polypropylene is lightweight and has a good chemical resistance profile, making it suitable for many filtration applications. It can operate effectively at moderate temperatures and pressures.

Pros & Cons: The primary advantage of polypropylene is its cost-effectiveness and ease of manufacturing. It is less durable than stainless steel, which may limit its use in high-stress environments. However, its lightweight nature can be beneficial for portable applications.

Impact on Application: Polypropylene is widely used in water filtration and chemical processing due to its compatibility with a variety of fluids. It is particularly effective in applications that require resistance to acids and bases.

Considerations for International Buyers: Buyers in South America, such as Brazil and Colombia, should consider local regulations regarding plastic materials and their impact on environmental sustainability.

Why Choose Fiberglass for Custom Filters?

Key Properties: Fiberglass offers excellent tensile strength and is resistant to corrosion and chemical degradation. It can operate effectively under high temperatures and pressures, making it suitable for demanding applications.

Pros & Cons: The durability and lightweight nature of fiberglass are significant advantages. However, it can be more expensive to produce compared to polypropylene. Fiberglass filters also require careful handling to avoid damage during installation.

Impact on Application: Fiberglass is often used in industrial filtration systems, particularly in the chemical and petrochemical industries, due to its compatibility with aggressive media.

Considerations for International Buyers: In Europe, compliance with environmental regulations regarding the disposal of fiberglass materials is crucial. Buyers should also consider the availability of local suppliers to reduce lead times.

What Role Does Activated Carbon Play in Custom Filters?

Key Properties: Activated carbon is highly porous, providing a large surface area for adsorption. It is effective in removing impurities and contaminants from gases and liquids.

Pros & Cons: The primary advantage of activated carbon is its effectiveness in improving air and water quality. However, it has a limited lifespan and may require frequent replacement, which can increase operational costs over time.

Impact on Application: Activated carbon is commonly used in air and water purification systems, particularly in municipal and industrial applications where odor and taste removal is essential.

Considerations for International Buyers: Buyers from the Middle East should be aware of the specific standards for activated carbon filtration systems. Understanding the local market demand for water purification can also guide purchasing decisions.

Summary of Material Selection for Custom Filters

| Material | Typical Use Case for filter custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Oil and gas filtration | High durability and corrosion resistance | Higher manufacturing complexity | High |

| Polypropylene | Water filtration | Cost-effective and lightweight | Less durable than metals | Low |

| Fiberglass | Industrial filtration | Excellent tensile strength | More expensive to produce | Medium |

| Activated Carbon | Air and water purification | Highly effective in contaminant removal | Limited lifespan | Medium |

By understanding the properties, advantages, and limitations of these materials, international B2B buyers can make informed decisions that align with their operational needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for filter custom

What Are the Main Stages of Manufacturing Custom Filters?

The manufacturing process for custom filters involves several key stages, each critical for ensuring the final product meets the specific needs of B2B buyers. Understanding these stages can help international buyers from regions like Africa, South America, the Middle East, and Europe make informed decisions.

1. Material Preparation: Which Materials Are Commonly Used?

The first stage in the manufacturing process is material preparation. The choice of materials significantly influences filter performance. Common materials include:

- Synthetic Fibers: Used for their durability and filtration efficiency.

- Metal Mesh: Provides strength and is often used in industrial applications.

- Activated Carbon: Effective for adsorption applications, particularly in air and water filters.

- Ceramic: Offers high resistance to heat and chemical degradation.

Buyers should inquire about the sourcing and quality of these materials, as they affect both performance and compliance with international standards.

2. Forming: How Are Filters Shaped?

The forming stage involves shaping the prepared materials into filter components. Techniques vary depending on the type of filter being produced:

- Cutting: Materials are cut to specific dimensions using precision cutting tools.

- Molding: For certain filters, materials are molded into specific shapes, often using heat and pressure.

- Layering: Multiple materials may be layered to enhance filtration capabilities.

Understanding the forming techniques can help buyers assess the suitability of the filters for their applications.

3. Assembly: What Is the Assembly Process Like?

Once the components are prepared and formed, they undergo assembly. This stage can involve:

- Adhesive Bonding: Using adhesives to join filter layers, ensuring a tight seal.

- Mechanical Fastening: Screws or clips may be used for components that require disassembly or maintenance.

- Welding: In metal filters, welding techniques may be employed for durability.

Buyers should verify the assembly methods used by their suppliers to ensure they align with their performance expectations and maintenance needs.

4. Finishing: What Finishing Techniques Are Used?

The finishing stage is crucial for enhancing filter performance and durability. Common finishing techniques include:

- Coating: Applying protective coatings can improve resistance to chemicals and environmental factors.

- Testing: Initial performance testing is often conducted to ensure the filters meet specifications.

- Labeling: Proper labeling is essential for compliance and user instructions.

Inquiring about finishing techniques can provide insights into the expected lifespan and reliability of the filters.

How Is Quality Assurance Managed in Filter Manufacturing?

Quality assurance (QA) is a pivotal aspect of the manufacturing process, ensuring that filters meet both industry standards and customer specifications. For international B2B buyers, understanding these QA processes is crucial.

What International Standards Should B2B Buyers Be Aware Of?

Many manufacturers adhere to international quality standards to ensure product reliability. Key standards include:

- ISO 9001: This standard focuses on quality management systems and is applicable across various industries, ensuring consistent quality in products and services.

- CE Marking: Required for products sold within the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

- API Standards: Particularly relevant in the oil and gas industry, these standards ensure that filters meet specific performance criteria.

Buyers should confirm that their suppliers comply with these standards to mitigate risks associated with product quality.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically structured around several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet predefined specifications.

- In-Process Quality Control (IPQC): During manufacturing, regular checks are performed to monitor adherence to quality standards.

- Final Quality Control (FQC): The final inspection occurs before products are packaged and shipped, ensuring they meet customer and regulatory requirements.

Understanding these checkpoints can help buyers assess the thoroughness of their suppliers’ QC processes.

What Common Testing Methods Are Employed?

Various testing methods are used to validate filter performance, including:

- Flow Rate Testing: Measures the volume of fluid that can pass through the filter in a given time.

- Pressure Drop Testing: Assesses the resistance of the filter to flow, which can indicate blockage or inefficiency.

- Particle Retention Testing: Determines the filter’s ability to capture particles of different sizes.

B2B buyers should request documentation of testing procedures and results to ensure the filters meet their operational requirements.

How Can B2B Buyers Verify Supplier Quality Control?

Due diligence is essential when selecting a supplier for custom filters. Here are actionable steps B2B buyers can take:

What Should Buyers Look For in Supplier Audits?

Conducting audits is a vital process for verifying a supplier’s quality control measures. Buyers should:

- Request Audit Reports: Review the findings of any third-party audits conducted on the supplier.

- Assess Compliance: Ensure the supplier adheres to relevant international standards and practices.

- Engage in On-Site Visits: If feasible, visiting the manufacturing facility can provide firsthand insight into their processes and quality measures.

How Can Buyers Utilize Third-Party Inspections?

Third-party inspections can offer an unbiased assessment of a supplier’s quality control systems. Buyers should:

- Hire Accredited Inspectors: Engage with recognized inspection agencies to ensure credibility.

- Specify Inspection Criteria: Clearly outline what aspects of the manufacturing and QC process should be evaluated.

Utilizing third-party inspections can significantly enhance the assurance of product quality.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate various nuances when it comes to quality control:

- Cultural and Regulatory Differences: Be aware that standards and practices may differ across regions. Understanding local regulations can help mitigate compliance risks.

- Language Barriers: Communication issues can arise during the QC process. Ensure that technical specifications and quality standards are clearly communicated in a common language.

- Logistical Challenges: Consider the implications of shipping and customs on product integrity. Ensure that quality checks are in place throughout the supply chain.

By being aware of these factors, B2B buyers can better navigate the complexities of international procurement and quality assurance for custom filters.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘filter custom’

The following step-by-step checklist is designed to assist international B2B buyers in sourcing custom filters effectively. This guide will help you navigate the complexities of the procurement process, ensuring you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for sourcing custom filters that meet your operational requirements. Consider the filter’s size, material, filtration efficiency, and any specific industry standards. Documenting these specifications will streamline communication with potential suppliers and help avoid misunderstandings later in the process.

Step 2: Research the Market Landscape

Understanding the market landscape is crucial for identifying potential suppliers. Conduct comprehensive research to find manufacturers and distributors of custom filters in your target regions such as Africa, South America, and Europe. Utilize industry reports, trade publications, and online platforms to gather insights into the capabilities and reputations of various suppliers.

Step 3: Evaluate Potential Suppliers

Before making any commitments, it’s essential to thoroughly vet potential suppliers. Request detailed company profiles, product catalogs, and case studies that showcase their experience in producing custom filters. Additionally, seek references from other businesses in similar industries or regions to validate their reliability and quality.

Step 4: Verify Supplier Certifications

Supplier certifications ensure that the products meet specific quality and safety standards. Check for relevant certifications such as ISO 9001 for quality management and any industry-specific certifications applicable to your needs. This verification helps mitigate risks and assures compliance with international standards.

Step 5: Request Samples for Testing

Before finalizing any orders, request samples of the custom filters for testing. This step allows you to assess the product’s performance, durability, and compatibility with your existing systems. Testing samples can prevent costly mistakes and ensure that the filters will function effectively in your operations.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations to agree on terms and conditions that are favorable for both parties. Discuss pricing, payment terms, delivery schedules, and warranty provisions. Clear agreements help establish a strong foundation for a successful long-term partnership.

Step 7: Establish a Communication Plan

Effective communication is key to a successful sourcing relationship. Create a communication plan that outlines how often you will check in with the supplier, preferred communication channels, and points of contact. Regular updates and feedback can help address any issues promptly and maintain a smooth workflow.

By following this checklist, B2B buyers can enhance their sourcing strategy for custom filters, ensuring they secure high-quality products that meet their specific needs while fostering beneficial supplier relationships.

Comprehensive Cost and Pricing Analysis for filter custom Sourcing

Understanding the cost structure and pricing dynamics of custom filter sourcing is essential for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis delves into the various cost components, pricing influencers, and buyer tips to help you make informed decisions.

What Are the Key Cost Components in Custom Filter Sourcing?

-

Materials: The choice of raw materials significantly impacts the overall cost. High-quality materials may increase initial expenses but can reduce long-term maintenance and replacement costs. For example, filters made from advanced polymers may be pricier upfront but offer better durability and efficiency.

-

Labor: Labor costs vary widely across regions. In countries like Brazil and Colombia, labor may be less expensive compared to Europe, but this can also affect quality. Understanding local wage structures and labor laws is crucial for accurate cost forecasting.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and administrative expenses that are indirectly tied to production. Efficient manufacturing processes can minimize overhead and improve pricing competitiveness.

-

Tooling: Custom tooling for filter production can represent a substantial initial investment. Buyers should consider whether suppliers have existing tooling or if new molds need to be created, as this will affect lead times and costs.

-

Quality Control (QC): Rigorous quality control processes are vital in ensuring that the filters meet necessary specifications and standards. Investing in QC can prevent costly recalls and enhance customer satisfaction.

-

Logistics: Shipping costs can vary based on distance, mode of transport, and any customs duties that apply. Incoterms chosen in the negotiation phase play a significant role in determining who bears these costs and risks.

-

Margin: Suppliers will add a profit margin on top of their costs. Understanding the typical margins in the filter industry can help buyers gauge fair pricing.

What Influences the Pricing of Custom Filters?

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes typically lead to lower per-unit costs. Buyers should negotiate MOQs to optimize pricing, especially if they can commit to larger orders.

-

Specifications and Customization: The complexity of the filter’s design and any specific customization requests will influence the price. Standardized products are usually more cost-effective than bespoke solutions.

-

Material Quality and Certifications: Filters that require specific certifications (e.g., ISO, CE) may incur additional costs. Buyers should weigh the importance of these certifications against their budget.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is crucial as they dictate the responsibilities of buyers and sellers regarding shipping costs, risks, and insurance. Choosing the right Incoterm can lead to significant savings.

What Tips Can Buyers Use for Cost-Efficiency in Custom Filter Sourcing?

-

Negotiate Effectively: Leverage your purchasing power by negotiating prices, especially for larger orders. Building a strong relationship with suppliers can lead to better terms.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, operational efficiency, and potential downtime costs when assessing overall value.

-

Research and Compare Suppliers: Conduct thorough market research to identify potential suppliers in various regions. This enables you to compare pricing, quality, and service levels effectively.

-

Stay Informed on Market Trends: Being aware of global market trends, such as shifts in raw material prices or changes in trade policies, can help you anticipate cost fluctuations and make timely purchasing decisions.

-

Leverage Technology: Utilize advanced search tools and platforms to streamline the sourcing process. This can help you find reliable suppliers quickly and efficiently.

Disclaimer on Pricing

A stock image related to filter custom.

Prices for custom filters can vary significantly based on the factors outlined above. This analysis provides indicative insights, and buyers are encouraged to conduct their own research and obtain quotations tailored to their specific needs.

Alternatives Analysis: Comparing filter custom With Other Solutions

When evaluating solutions for filtering custom data, it’s crucial for international B2B buyers to explore various alternatives. Each option presents unique advantages and disadvantages, which can significantly influence operational efficiency, cost-effectiveness, and user satisfaction. Below, we compare ‘filter custom’ against two viable alternatives: ‘Search Engine Optimization (SEO) Filters’ and ‘Data Tagging Systems’.

Comparison Table

| Comparison Aspect | Filter Custom | SEO Filters | Data Tagging Systems |

|---|---|---|---|

| Performance | High precision in filtering specific data types | Moderate; relies on keyword relevance and can miss niche queries | High; allows for granular filtering based on predefined tags |

| Cost | Moderate; dependent on customization needs | Low to moderate; primarily involves time investment | Moderate to high; requires upfront setup and ongoing maintenance |

| Ease of Implementation | Moderate; requires technical knowledge for setup | Easy; can be implemented with basic digital marketing skills | Moderate; necessitates training for effective use |

| Maintenance | Low; once set, minimal intervention needed | Moderate; requires regular updates to maintain effectiveness | High; needs continual updates and adjustments to tagging |

| Best Use Case | Specific industries needing tailored filtering solutions | Businesses focusing on digital visibility and organic reach | Organizations managing large datasets requiring detailed categorization |

What are the Pros and Cons of SEO Filters?

Pros:

SEO filters are primarily used to enhance the visibility of web content. They are cost-effective and can be implemented with minimal technical expertise. This makes them an attractive option for small to medium-sized enterprises looking to improve their online presence without significant investment.

Cons:

However, SEO filters can be less precise in filtering niche data. Their performance heavily relies on keyword relevance, which can lead to missed opportunities if the keywords are not well-defined. This method may not be suitable for businesses requiring highly specialized filtering solutions.

How Do Data Tagging Systems Compare?

Pros:

Data tagging systems excel in providing granular control over data organization. By tagging items with specific attributes, organizations can filter and retrieve data efficiently, making them particularly beneficial for businesses that manage extensive datasets.

Cons:

The downside is that data tagging systems often come with higher costs and require significant upfront investment. Additionally, they need ongoing maintenance and regular updates to ensure that the tagging remains relevant and effective, which can strain resources if not managed properly.

Conclusion: How Can B2B Buyers Choose the Right Solution?

Choosing the right filtering solution depends on the specific needs of your business. For companies requiring tailored filtering with high precision, ‘filter custom’ may be the best choice. Conversely, if cost is a primary concern and the goal is to enhance online visibility, SEO filters could suffice. For organizations with large datasets that require detailed organization, data tagging systems offer a robust solution, albeit with higher complexity and cost. B2B buyers should carefully evaluate their operational requirements, budget constraints, and the level of technical expertise available within their teams before making a decision.

Essential Technical Properties and Trade Terminology for filter custom

What Are the Key Technical Properties of Custom Filters?

When considering custom filters, several technical specifications are critical for ensuring optimal performance and compatibility with your specific requirements. Understanding these properties will enable B2B buyers, especially from Africa, South America, the Middle East, and Europe, to make informed purchasing decisions.

1. Material Grade

The material used in filter construction is paramount. Common materials include stainless steel, polypropylene, and fiberglass. Each material offers different benefits in terms of chemical resistance, temperature tolerance, and durability. For instance, stainless steel is ideal for high-temperature applications, while polypropylene is more suited for corrosive environments. Selecting the appropriate material grade ensures longevity and efficiency of the filter in its intended application.

2. Filtration Efficiency

This property refers to the filter’s ability to remove particulates from a fluid or air stream. Measured in percentages, higher filtration efficiency indicates that the filter can capture smaller particles. For B2B buyers, understanding filtration efficiency is crucial, especially in industries such as pharmaceuticals or food and beverage, where purity standards are stringent.

3. Tolerance Levels

Tolerance refers to the allowable deviation in dimensions of the filter components. It is critical for ensuring a proper fit within the assembly or system. Tight tolerances are essential in applications where precision is crucial, such as in aerospace or medical devices. Buyers should assess tolerance levels to avoid costly rework or system failures.

4. Flow Rate

Flow rate indicates the volume of fluid that can pass through the filter within a specified timeframe, typically measured in liters per minute (LPM) or gallons per minute (GPM). A filter with an inadequate flow rate can lead to bottlenecks in production processes. Buyers must evaluate flow rate to ensure that the filter meets operational demands without compromising efficiency.

5. Operating Pressure

This specification refers to the maximum pressure the filter can handle during operation. Exceeding this limit can lead to filter failure and potential damage to the entire system. Understanding the operating pressure is essential for buyers to prevent system malfunctions and ensure safety.

What Are Common Trade Terms Used in Custom Filter Transactions?

Navigating the B2B landscape for custom filters requires familiarity with industry-specific terminology. Here are some common terms that buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the filter industry, this term is crucial as it defines the source of the product and often indicates a standard of quality. Buyers should ensure they are sourcing from reputable OEMs to guarantee reliability.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers, particularly in regions where inventory management is critical. It can affect cash flow and storage capabilities, so negotiating favorable MOQs can lead to better purchasing terms.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and other information about a product. It is a key step in the procurement process and helps buyers compare offers effectively. Crafting a clear and detailed RFQ can facilitate better responses from suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in global transactions. They clarify issues such as shipping costs, insurance, and liability. Familiarity with Incoterms is essential for international buyers to avoid misunderstandings and ensure smooth transactions.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead time is crucial for planning and inventory management, especially for businesses in fast-paced industries. Buyers should always inquire about lead times to align their operational schedules.

By grasping these essential technical properties and trade terminologies, international B2B buyers can enhance their purchasing strategies for custom filters, ensuring they meet their operational needs effectively.

Navigating Market Dynamics and Sourcing Trends in the filter custom Sector

What Are the Key Market Dynamics and Trends Impacting the Filter Custom Sector?

The filter custom sector is experiencing significant transformations driven by several global factors. Increasing industrialization and urbanization, particularly in regions such as Africa and South America, are boosting demand for advanced filtration solutions across various sectors, including water treatment, pharmaceuticals, and food processing. The rise of smart technologies is also influencing sourcing trends, with automation and IoT integration becoming pivotal in filter design and functionality. International B2B buyers are increasingly looking for suppliers who can offer innovative, efficient, and customizable filtering solutions that meet specific regulatory and operational requirements.

Emerging trends such as digital transformation are reshaping procurement processes. B2B buyers are leveraging online platforms and AI-powered tools for sourcing, which streamlines supplier discovery and selection. The growing emphasis on data analytics allows businesses to make informed decisions based on market intelligence and supplier performance metrics. Buyers from Europe, the Middle East, and Latin America are particularly keen on establishing partnerships with suppliers who can provide robust data on product efficacy and compliance, ensuring that their operations are both efficient and sustainable.

How Can Sustainability and Ethical Sourcing Influence B2B Decisions in the Filter Custom Sector?

Sustainability is no longer just a trend; it’s a necessity for B2B buyers in the filter custom sector. The environmental impact of filtration products, including waste generation and resource consumption, is under scrutiny. Companies are increasingly prioritizing suppliers that adhere to sustainable practices, such as using recycled materials or biodegradable components. This shift is especially relevant for buyers in Africa and South America, where environmental regulations are becoming stricter, and consumers are demanding greener products.

Ethical sourcing is another critical aspect that influences purchasing decisions. B2B buyers are seeking suppliers who demonstrate transparency in their supply chains, ensuring that materials are sourced responsibly and that labor practices are ethical. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability. By prioritizing suppliers with these credentials, buyers can enhance their brand reputation and align with the growing consumer preference for responsible business practices.

How Has the Filter Custom Sector Evolved Over Time to Meet B2B Needs?

The filter custom sector has undergone significant evolution over the past few decades, primarily driven by advancements in technology and increasing regulatory demands. Initially focused on basic filtration methods, the industry has transitioned to offering sophisticated solutions tailored to specific applications. This evolution is particularly evident in the development of high-efficiency particulate air (HEPA) filters and advanced membrane technologies that cater to the stringent requirements of sectors like healthcare and aerospace.

As global awareness of environmental issues has risen, the sector has adapted by incorporating sustainable materials and processes into production. The introduction of smart filters, which utilize IoT for real-time monitoring and data collection, reflects the industry’s commitment to innovation and efficiency. These advancements not only enhance product performance but also provide B2B buyers with valuable insights for optimizing their operations. The ongoing evolution of the filter custom sector is a testament to its responsiveness to market demands and the need for sustainable, efficient solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of filter custom

-

How do I solve the challenge of finding reliable suppliers for custom filters?

To find reliable suppliers for custom filters, start by conducting thorough research online and utilizing B2B marketplaces such as Alibaba or Global Sources. Look for suppliers with verified credentials, positive reviews, and a robust portfolio of past projects. Reach out to industry associations or trade shows in your region to network and gather recommendations. Additionally, consider using supplier vetting services that can provide background checks and financial health assessments to ensure you partner with a trustworthy manufacturer. -

What is the best material for custom filters used in industrial applications?

The best material for custom filters depends on the specific application and environmental conditions. Common materials include stainless steel for durability and corrosion resistance, fiberglass for high-temperature applications, and polyester for general-purpose filtration. It is essential to evaluate the filter’s required efficiency, flow rate, and the type of contaminants it will encounter. Collaborating with a knowledgeable supplier can help you select the most suitable material tailored to your operational needs. -

What are the minimum order quantities (MOQ) for custom filters?

Minimum order quantities (MOQ) for custom filters can vary significantly based on the supplier and the complexity of the design. Typically, MOQs range from 50 to 500 units. For highly specialized filters, MOQs may be higher due to the costs associated with custom tooling and manufacturing. When negotiating with suppliers, clearly communicate your needs and explore options for lower MOQs or trial orders to assess the quality before committing to larger quantities. -

What payment terms should I expect when sourcing custom filters internationally?

Payment terms for international sourcing of custom filters can vary widely but typically include options like 30% upfront and 70% upon delivery, or full payment in advance for smaller orders. It’s important to negotiate terms that align with your cash flow and risk tolerance. Using secure payment methods like letters of credit or escrow services can provide additional protection. Always clarify payment terms in the contract to avoid any misunderstandings later in the transaction. -

How can I ensure quality assurance for custom filter products?

To ensure quality assurance for custom filter products, implement a comprehensive quality management system that includes pre-production samples, in-process inspections, and final product testing. Request certifications such as ISO 9001 from suppliers, which indicates adherence to quality management principles. Additionally, consider third-party inspection services to verify that products meet your specifications before shipment, particularly for international orders where you cannot physically inspect the goods. -

What are the logistics considerations for importing custom filters?

When importing custom filters, consider factors such as shipping methods, customs clearance, and lead times. Choose between air freight for faster delivery or sea freight for cost savings, depending on your urgency and budget. Ensure that all documentation, including commercial invoices and packing lists, is accurate to avoid delays at customs. Additionally, factor in potential tariffs or duties applicable to your region, and collaborate with a logistics provider experienced in international trade to navigate these complexities. -

What customization options should I discuss with my filter supplier?

When discussing customization options with your filter supplier, consider aspects like size, shape, filtration media, and specific performance characteristics (e.g., particle retention size). Inquire about branding opportunities, such as custom colors or logos. Discuss any special requirements related to your industry, such as compliance with environmental regulations or certifications. Clear communication of your needs will help the supplier provide tailored solutions that meet your operational requirements. -

How can I manage communication with suppliers from different time zones?

Managing communication with suppliers across different time zones requires strategic planning. Utilize tools like shared calendars to schedule meetings at mutually convenient times. Leverage technology by using instant messaging apps for quick queries and email for detailed communications, ensuring all parties are updated. Establish clear expectations regarding response times and preferred communication channels. Regular check-ins can also help maintain a strong relationship, fostering collaboration despite geographical barriers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for filter custom

In the dynamic landscape of custom filters, strategic sourcing emerges as a critical component for international B2B buyers. By implementing a well-defined sourcing strategy, companies can effectively reduce costs, enhance product quality, and ensure timely delivery. It is essential for buyers from regions such as Africa, South America, the Middle East, and Europe to cultivate strong relationships with reliable suppliers who understand local market nuances and regulatory requirements.

What Are the Key Benefits of Strategic Sourcing for International Buyers?

The benefits of strategic sourcing extend beyond mere cost savings. It allows buyers to leverage supplier innovations, improve supply chain resilience, and access tailored solutions that meet specific operational needs. Engaging in thorough market research and utilizing advanced sourcing technologies can further streamline the procurement process, enabling buyers to make informed decisions.

How Can Buyers Prepare for Future Trends in Custom Filters?

Looking ahead, the demand for customized filtering solutions will likely grow, driven by advancements in technology and increasing regulatory standards. International B2B buyers must stay abreast of these trends and consider integrating sustainability into their sourcing strategies. By prioritizing suppliers committed to eco-friendly practices, businesses can enhance their brand reputation while meeting customer expectations.

In conclusion, the path to successful strategic sourcing in the custom filter industry is one of continuous improvement and adaptation. International buyers are encouraged to take proactive steps now—fostering relationships with key suppliers, investing in technology, and aligning with market trends—to secure a competitive advantage in the evolving global marketplace.