Unlock Cost Savings with Plastic China: The Ultimate Guide (2025)

Introduction: Navigating the Global Market for plastic china

As international B2B buyers face the challenge of sourcing quality plastic china for their diverse needs, navigating the global market can be daunting. Whether you are looking for elegant tableware for upscale dining experiences or durable containers for food storage, understanding the landscape of plastic china—its types, applications, and environmental implications—is essential. With an annual production of plastics set to double by 2050, the urgency for sustainable sourcing options is increasingly pressing, particularly for businesses operating in regions such as Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Indonesia.

This comprehensive guide delves into the intricacies of the plastic china market, covering various types of products, their applications in different industries, and practical tips for vetting suppliers. Additionally, we will discuss cost considerations and how to identify high-quality products that align with sustainability goals and compliance with emerging regulations. By equipping you with actionable insights and strategies, this guide empowers you to make informed purchasing decisions that not only meet your business requirements but also contribute positively to global sustainability efforts.

Join us as we explore the multifaceted world of plastic china and uncover the opportunities it presents for your business growth and environmental responsibility.

Understanding plastic china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Melamine Plastic China | Durable, heat-resistant, and often designed to mimic ceramic | Restaurants, catering, and events | Pros: Lightweight, break-resistant; Cons: Not microwave-safe. |

| Polypropylene China | Flexible, often translucent, and resistant to moisture | Food packaging, takeout containers | Pros: Cost-effective, recyclable; Cons: Lower aesthetic appeal. |

| Polycarbonate China | High impact resistance and clarity | Hospitality, retail displays | Pros: Durable, versatile; Cons: Can be more expensive. |

| ABS Plastic China | Strong, lightweight, and available in various colors | Consumer products, toys | Pros: Easy to mold, good for custom designs; Cons: Less heat resistant. |

| PET Plastic China | Clear, lightweight, and recyclable | Beverage containers, food packaging | Pros: High clarity, good barrier properties; Cons: Environmental concerns over disposal. |

What Are the Characteristics of Melamine Plastic China?

Melamine plastic china is highly favored in the food service industry due to its durability and resistance to breakage. It is often designed to resemble traditional ceramic dishes, making it a popular choice for restaurants and catering services looking to combine aesthetics with functionality. When purchasing melamine products, buyers should consider their intended use, as these items are not suitable for microwave use and can be sensitive to high temperatures.

How Does Polypropylene China Stand Out?

Polypropylene china is known for its flexibility and moisture resistance, making it ideal for food packaging and takeout containers. Its translucent nature allows for easy visibility of contents, which is beneficial for both suppliers and customers. B2B buyers should weigh the cost-effectiveness of polypropylene against its lower aesthetic appeal, especially if the packaging’s visual impact is a crucial consideration.

What Makes Polycarbonate China a Preferred Choice?

Polycarbonate china offers high impact resistance and clarity, making it suitable for hospitality environments and retail displays where durability is essential. Its versatility allows it to be used in various applications, from serving dishes to display cases. Buyers should assess the higher cost associated with polycarbonate products against their long-lasting performance and aesthetic advantages.

Why Choose ABS Plastic China for Custom Designs?

ABS plastic china is strong and lightweight, available in a wide range of colors, which makes it an excellent option for consumer products and toys. Its ease of molding allows for custom designs, catering to specific market demands. However, B2B buyers should note that while ABS is easy to work with, it may not withstand high temperatures as effectively as other materials.

What Are the Environmental Considerations for PET Plastic China?

PET plastic china is recognized for its clarity and lightweight nature, making it a common choice for beverage containers and food packaging. It is also recyclable, which can be a selling point for environmentally conscious businesses. However, B2B buyers should be aware of the environmental concerns related to PET disposal and consider how this may affect their brand image and sustainability goals.

Related Video: Plastic Wars (full documentary) | FRONTLINE

Key Industrial Applications of plastic china

| Industry/Sector | Specific Application of plastic china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage Packaging | Containers and lids for food products | Enhanced shelf life and reduced spoilage | Compliance with food safety regulations and certifications |

| Healthcare | Disposable medical devices and containers | Improved hygiene and reduced risk of contamination | Quality assurance and adherence to regulatory standards |

| Consumer Goods | Durable and lightweight packaging solutions | Cost-effective transportation and reduced breakage | Material strength and recyclability considerations |

| Automotive | Interior components and trims | Lightweight design that improves fuel efficiency | Compatibility with existing manufacturing processes |

| Construction | Insulation materials and piping systems | Energy efficiency and cost savings in installation | Compliance with building codes and sustainability standards |

How is Plastic China Used in Food and Beverage Packaging?

In the food and beverage industry, plastic china is extensively used for creating containers and lids that enhance product safety and longevity. These materials help in preserving the freshness of food items, reducing spoilage, and extending shelf life. For international B2B buyers, especially in regions like Africa and the Middle East, sourcing compliant materials that meet local food safety regulations is critical. Furthermore, understanding the nuances of temperature resistance and chemical compatibility can prevent product failure and enhance consumer satisfaction.

What Role Does Plastic China Play in Healthcare Applications?

In the healthcare sector, plastic china is vital for manufacturing disposable medical devices and containers. These products contribute to improved hygiene by minimizing the risk of contamination and infection in medical environments. For B2B buyers from South America and Europe, ensuring that suppliers adhere to strict regulatory standards, such as ISO certifications, is essential. Additionally, buyers should prioritize sourcing materials that are not only durable but also environmentally friendly, considering the growing demand for sustainable healthcare solutions.

How is Plastic China Beneficial for Consumer Goods Packaging?

Consumer goods companies utilize plastic china for creating durable and lightweight packaging solutions that reduce transportation costs and minimize product damage during transit. This application is particularly advantageous for businesses targeting international markets, as it helps streamline logistics while maintaining product integrity. Buyers in regions like Europe and Africa should focus on sourcing options that balance cost-effectiveness with high-quality materials. Understanding the implications of recyclability can also enhance brand reputation among environmentally conscious consumers.

In What Ways Does Plastic China Support the Automotive Industry?

In the automotive sector, plastic china is used to manufacture lightweight interior components and trims that contribute to overall vehicle efficiency. By reducing vehicle weight, these components can improve fuel economy and reduce emissions, aligning with global sustainability goals. B2B buyers in the Middle East and South America should seek suppliers who can provide materials that meet automotive industry standards for safety and performance. Additionally, compatibility with existing manufacturing processes is a key consideration to ensure seamless integration into production lines.

How is Plastic China Applied in Construction for Energy Efficiency?

In construction, plastic china is utilized for insulation materials and piping systems that enhance energy efficiency in buildings. These applications not only reduce energy costs but also support compliance with increasingly stringent building codes focused on sustainability. International B2B buyers, particularly in Europe and Africa, must prioritize sourcing materials that meet regional regulations and standards for safety and performance. Understanding the lifecycle of materials, including their recyclability, is also essential to align with global sustainability initiatives.

Related Video: Plastic Injection Molding

3 Common User Pain Points for ‘plastic china’ & Their Solutions

Scenario 1: Navigating Environmental Regulations for Plastic China

The Problem:

B2B buyers in regions like Europe and the Middle East are often overwhelmed by the complex and evolving regulations surrounding single-use plastics, including ‘plastic china’. With the EU’s Single-Use Plastics Directive and various regional regulations, businesses face challenges in ensuring compliance while sourcing products. The fear of potential fines or reputational damage due to non-compliance can hinder decision-making, leading to delays in procurement processes.

The Solution:

To effectively navigate these regulations, buyers should develop a compliance checklist that includes understanding local laws and upcoming regulatory changes. Engage with suppliers who offer transparent information about their products’ compliance with sustainability standards and regulations. Conduct regular audits of your supply chain to ensure that all materials, including plastic china, meet these legal requirements. Additionally, consider investing in products that utilize recycled materials or are certified as biodegradable, as these often align better with regulatory frameworks and can enhance your company’s reputation as a sustainable business.

Scenario 2: Ensuring Quality and Durability of Plastic China Products

The Problem:

International buyers often encounter issues with the quality and durability of plastic china products, especially when sourcing from different regions. Products may arrive damaged or fail to meet expected performance standards, leading to customer dissatisfaction and increased returns. This is particularly concerning for businesses in the hospitality sector, where the presentation and reliability of tableware are crucial.

The Solution:

To mitigate quality concerns, buyers should establish strict quality assurance protocols that include specifying material grades and performance standards in their orders. Request samples before placing bulk orders to evaluate the product firsthand. Collaborating with suppliers who have a proven track record of quality manufacturing can significantly reduce risks. It’s also advisable to incorporate a robust feedback mechanism where users can report issues, allowing for continuous improvement of the product offerings. Building strong relationships with suppliers can lead to better oversight and enhanced product quality.

Scenario 3: Managing Cost Pressures While Sourcing Plastic China

The Problem:

Cost pressures can significantly impact the purchasing decisions of B2B buyers, especially in competitive markets across Africa and South America. Buyers often face a dilemma between sourcing affordable plastic china and ensuring that they do not compromise on quality. This balancing act can lead to either overspending or accepting lower-quality products, which can ultimately affect customer satisfaction and brand reputation.

The Solution:

To manage cost pressures effectively, buyers should conduct a thorough market analysis to identify competitive pricing while ensuring quality standards are met. Engaging in bulk purchasing agreements can often lead to discounts without sacrificing quality. Additionally, explore alternatives like eco-friendly or locally sourced materials, which may offer cost benefits and align with sustainability goals. Establishing partnerships with reliable suppliers can also facilitate better pricing negotiations and more favorable payment terms, allowing for budget flexibility. Regularly reviewing and optimizing the supply chain can uncover inefficiencies, further reducing costs without impacting product quality.

Strategic Material Selection Guide for plastic china

What Are the Key Materials Used in Plastic China?

When selecting materials for plastic china, international B2B buyers must consider various factors, including performance properties, cost, and compliance with regional standards. Below, we analyze four common materials used in plastic china, focusing on their unique characteristics and implications for buyers, particularly from Africa, South America, the Middle East, and Europe.

What Are the Properties and Applications of Polypropylene (PP)?

Polypropylene (PP) is a thermoplastic polymer widely used in plastic china due to its excellent chemical resistance and lightweight nature. It can withstand temperatures up to 100°C (212°F) and has a good impact resistance, making it suitable for various applications.

Pros:

– Durability: Resistant to many chemicals and does not absorb moisture, which enhances longevity.

– Cost-Effectiveness: Generally lower in cost compared to other plastics, making it a budget-friendly option for manufacturers.

Cons:

– Heat Sensitivity: While it can handle moderate temperatures, it may deform under high heat.

– Limited Color Retention: Over time, colors may fade, affecting aesthetic appeal.

Impact on Application:

PP is compatible with food and beverage applications, as it does not leach harmful substances. However, it is essential for buyers to ensure compliance with food safety standards such as FDA or EU regulations.

How Does Melamine Compare as a Material for Plastic China?

Melamine is known for its hardness and resistance to scratches and stains, making it a popular choice for durable plastic china. It can withstand temperatures up to 120°C (248°F) and is often used in tableware.

Pros:

– Aesthetic Appeal: Melamine can be produced in a variety of colors and designs, enhancing the visual appeal of products.

– High Durability: Resistant to breakage and chipping, making it suitable for high-traffic environments like restaurants.

Cons:

– Limited Heat Resistance: Not suitable for microwave use as it can warp or release harmful chemicals.

– Higher Cost: Generally more expensive than PP and other plastics.

Impact on Application:

Melamine is ideal for decorative tableware but requires careful handling to avoid exposure to high temperatures. Buyers should ensure compliance with relevant safety standards.

What Are the Benefits and Limitations of Polycarbonate (PC)?

Polycarbonate (PC) is a versatile material known for its exceptional strength and clarity. It can handle temperatures up to 130°C (266°F) and is often used in applications requiring transparency, such as drinkware.

Pros:

– Impact Resistance: Extremely durable and resistant to shattering, making it safe for various uses.

– Transparency: Offers a glass-like appearance, which is appealing for beverage containers.

Cons:

– Cost: Higher relative cost compared to PP and melamine.

– Chemical Sensitivity: Can be affected by certain chemicals, leading to discoloration or degradation.

Impact on Application:

PC is suitable for applications where visibility is essential, but buyers must be cautious about chemical compatibility and ensure adherence to safety standards.

What Role Does Polystyrene (PS) Play in Plastic China?

Polystyrene (PS) is a low-cost plastic commonly used for disposable plastic china. It is lightweight and can be molded into various shapes, making it versatile for single-use applications.

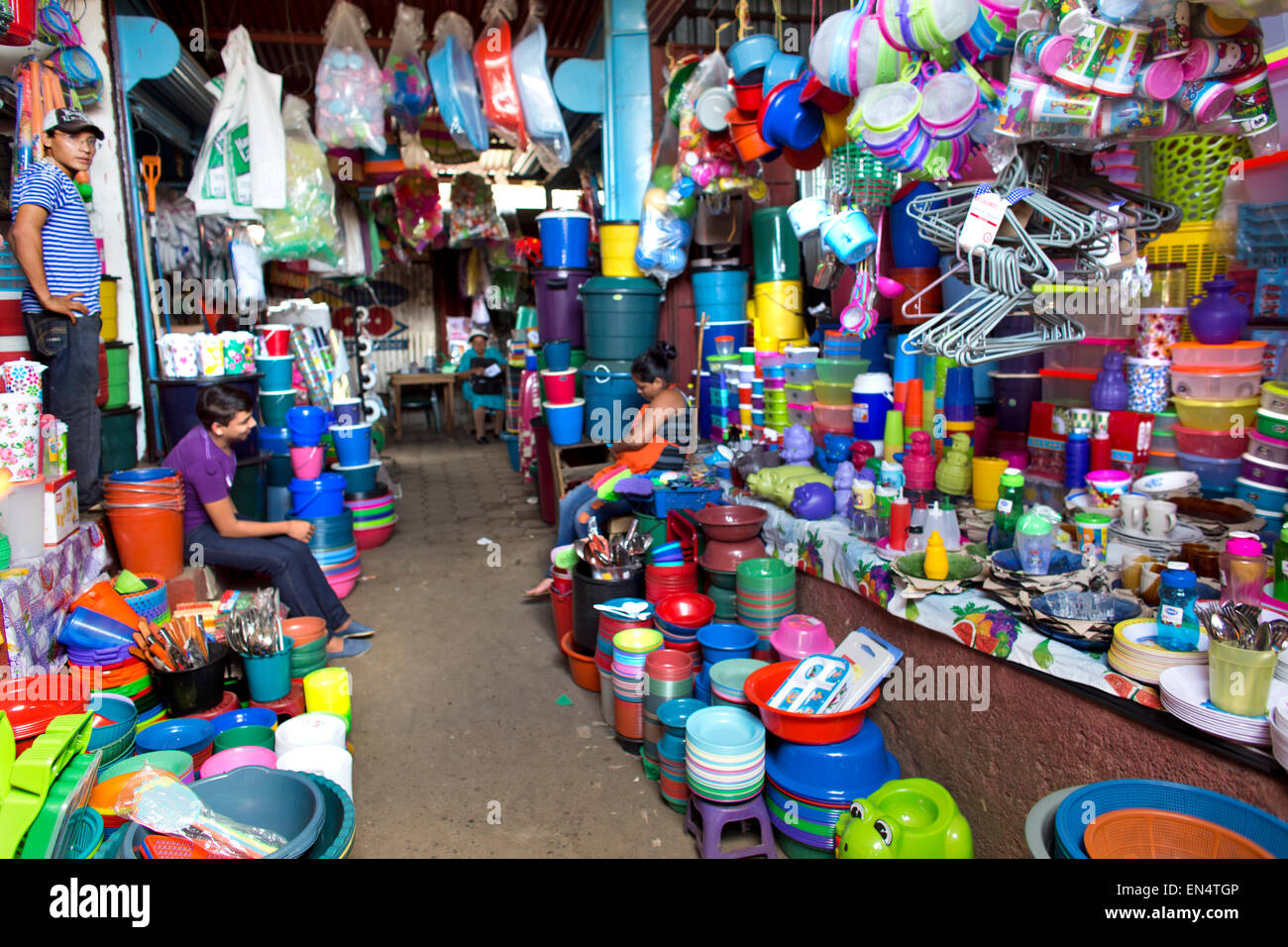

A stock image related to plastic china.

Pros:

– Affordability: One of the most cost-effective materials available for plastic china.

– Ease of Manufacturing: Simple to mold and shape, allowing for rapid production.

Cons:

– Brittleness: Prone to cracking and breaking under stress.

– Environmental Concerns: Not widely recyclable, leading to sustainability issues.

Impact on Application:

PS is suitable for events and catering where disposable items are required. However, international buyers must consider local regulations regarding single-use plastics and their environmental impact.

Summary Table of Material Selection for Plastic China

| Material | Typical Use Case for plastic china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene (PP) | Food containers, cups | Durable and moisture-resistant | Heat sensitivity | Low |

| Melamine | Decorative tableware | High durability and aesthetic appeal | Limited heat resistance | High |

| Polycarbonate (PC) | Drinkware, clear containers | Impact-resistant and transparent | Higher cost and chemical sensitivity | Med |

| Polystyrene (PS) | Disposable plates, cups | Very affordable | Brittle and environmental concerns | Low |

In conclusion, selecting the right material for plastic china involves evaluating the specific needs of the application, cost considerations, and compliance with local regulations. Buyers from diverse regions should prioritize materials that align with their operational requirements and sustainability goals.

In-depth Look: Manufacturing Processes and Quality Assurance for plastic china

What Are the Key Stages in the Manufacturing Process of Plastic China?

Manufacturing plastic china involves several critical stages that ensure the final product meets quality and aesthetic standards. Understanding these stages can help international B2B buyers make informed decisions when sourcing from suppliers.

-

Material Preparation

– Selection of Raw Materials: The process begins with selecting high-quality plastic resins, such as melamine or polypropylene, which are commonly used for plastic china. These materials are chosen based on their durability, heat resistance, and ability to mimic traditional china aesthetics.

– Compounding: Resins are mixed with additives to enhance properties like color, strength, and UV resistance. This mixture is then pelletized for easier handling. -

Forming Techniques

– Injection Molding: This is the most prevalent technique for producing plastic china. The prepared plastic pellets are heated and injected into molds that shape the items, such as plates, cups, and bowls. This method allows for high precision and consistency in product dimensions.

– Thermoforming: For some types of plastic china, thermoforming is utilized, where sheets of plastic are heated and then formed over molds. This method is often used for producing thinner, lightweight items. -

Assembly

– Joining Components: If the product consists of multiple parts (like a cup with a handle), assembly may involve techniques such as ultrasonic welding or adhesive bonding to ensure a strong and permanent connection.

– Quality Checks: During assembly, preliminary quality checks are conducted to ensure that components fit together correctly and meet design specifications. -

Finishing Touches

– Surface Treatment: The finished products may undergo surface treatments to improve aesthetics and functionality. This can include polishing, coating, or applying decals for branding purposes.

– Packaging: Finally, products are packaged using eco-friendly materials to ensure they reach the buyer in pristine condition while adhering to sustainability goals.

How Is Quality Assurance Implemented in Plastic China Manufacturing?

Quality assurance (QA) is crucial in the manufacturing of plastic china to ensure products meet international standards and buyer expectations. Here are the essential elements of QA in this context:

-

International and Industry-Specific Standards

– ISO 9001: This quality management system standard is critical for manufacturers aiming to demonstrate their ability to consistently provide products that meet customer and regulatory requirements. Suppliers should have documented processes and a commitment to continuous improvement.

– CE Marking: In Europe, plastic products must meet health, safety, and environmental protection standards to carry the CE mark. This is especially important for buyers in Europe to verify compliance.

– API Standards: For specific applications, such as food-grade materials, manufacturers may need to adhere to American Petroleum Institute (API) standards, ensuring safety in food contact materials. -

Quality Control Checkpoints

– Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials upon arrival. Suppliers should verify that materials meet predefined specifications before production begins.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are conducted to monitor production parameters and ensure compliance with quality standards.

– Final Quality Control (FQC): After production, the final inspection assesses the finished products against design specifications, ensuring no defects are present before shipping. -

Common Testing Methods for Quality Assurance

– Mechanical Testing: This includes tensile strength tests, impact resistance tests, and thermal stability tests to ensure the products can withstand everyday use.

– Chemical Testing: Testing for harmful substances (e.g., BPA, phthalates) is critical, especially for food-safe plastic china.

– Visual Inspection: A thorough visual examination is conducted to check for aesthetic defects, such as scratches, color inconsistencies, and shape anomalies.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential to mitigate risks and ensure product reliability.

-

Supplier Audits

– Conducting regular audits of potential suppliers can provide insight into their manufacturing practices, quality control processes, and adherence to international standards. Buyers should develop an audit checklist that includes compliance with ISO standards, equipment maintenance, and employee training records. -

Requesting Quality Reports

– Buyers should request detailed quality assurance reports from suppliers. These reports should outline the results of various testing methods, production batch records, and any corrective actions taken for previous defects. -

Third-Party Inspections

– Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing processes and quality assurance. These services can perform inspections at various stages of production and provide detailed reports on compliance with international standards.

What Are the Unique Challenges for International B2B Buyers in Quality Assurance?

International B2B buyers face unique challenges in ensuring quality assurance when sourcing plastic china. Here are some considerations:

-

Regulatory Compliance Across Regions

– Buyers must navigate varying regulatory requirements across regions. For instance, products must comply with the EU’s stringent regulations, while buyers in the Middle East may have different standards. Understanding these differences is crucial for compliance and market entry. -

Cultural and Communication Barriers

– Language differences and cultural nuances can lead to misunderstandings regarding quality expectations. Establishing clear communication channels and ensuring all specifications are documented can mitigate these issues. -

Supply Chain Transparency

– Ensuring transparency throughout the supply chain can be challenging, especially when dealing with multiple suppliers. Buyers should seek suppliers who are willing to share information regarding their sourcing, production processes, and quality control practices.

Conclusion

A stock image related to plastic china.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance practices in plastic china production is essential. By focusing on the key stages of manufacturing, relevant quality standards, and effective verification methods, buyers can make informed decisions that align with their quality expectations and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plastic china’

This practical sourcing guide is designed to assist international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, in procuring ‘plastic china’ effectively. By following this step-by-step checklist, buyers can ensure they make informed decisions while considering sustainability and compliance with regional regulations.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful sourcing process. Determine the exact types of plastic china you require, including dimensions, colors, and intended use. This clarity helps in communicating your needs effectively to suppliers and ensures that the products meet your quality standards.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify potential suppliers specializing in plastic china. Utilize industry directories, trade shows, and online platforms to compile a list of manufacturers. Look for suppliers with a strong presence in the regions of interest and those who have experience with international shipping, especially if you are sourcing from Asia or Europe.

Step 3: Evaluate Supplier Certifications and Compliance

Before engaging with suppliers, verify their certifications and compliance with relevant regulations. This includes checking for ISO certifications, adherence to the EU’s Single-Use Plastics Directive, and local waste management laws. Ensuring compliance not only reduces risk but also aligns with sustainability goals, which is increasingly important for consumers and businesses alike.

Step 4: Request Samples for Quality Assurance

Request samples from shortlisted suppliers to evaluate the quality of their plastic china products. Pay attention to the finish, durability, and any potential odor issues. Testing samples allows you to assess whether they meet your specifications before placing a bulk order, thereby minimizing the risk of poor-quality products.

Step 5: Compare Pricing and Terms of Sale

Once you have gathered samples and assessed quality, compare pricing structures and terms of sale from different suppliers. Consider factors such as minimum order quantities, payment terms, and shipping costs. Understanding the total cost of ownership will help you make an informed decision and avoid any hidden costs down the line.

Step 6: Negotiate Contract Terms

Engage in negotiations to establish favorable contract terms that protect your interests. Discuss delivery timelines, warranties, and return policies. A well-defined contract will help mitigate risks associated with delays or defects, ensuring a smoother procurement process.

Step 7: Establish a Communication Plan

Create a clear communication plan with your selected supplier. Define the frequency and methods of communication for updates on production and shipping. Regular check-ins can help address any issues promptly and maintain a strong working relationship, which is crucial for long-term sourcing success.

By following this comprehensive checklist, B2B buyers can streamline their procurement processes for plastic china, ensuring they meet both quality and regulatory standards while fostering sustainable practices.

Comprehensive Cost and Pricing Analysis for plastic china Sourcing

What Are the Key Cost Components in Plastic China Sourcing?

When sourcing plastic china, understanding the cost structure is vital for effective budgeting and pricing strategies. The primary cost components include:

-

Materials: The choice of plastic resin significantly impacts the cost. High-grade polymers, like polypropylene (PP) or polycarbonate (PC), are more expensive but offer enhanced durability and safety. Buyers should assess the long-term value of investing in higher-quality materials versus lower-cost alternatives.

-

Labor: Labor costs can vary widely depending on the manufacturing location. Countries with lower wage rates, such as those in Southeast Asia, may offer more competitive pricing. However, it’s essential to evaluate the skill level and efficiency of the workforce, as these factors influence the overall production quality.

-

Manufacturing Overhead: This encompasses the costs related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help minimize overhead costs, so it’s advisable to partner with suppliers who utilize advanced technologies.

-

Tooling: Initial tooling costs for molds and dies can be substantial, especially for custom designs. Buyers should inquire about tooling amortization, as this can affect pricing for smaller order quantities (MOQs).

-

Quality Control (QC): Implementing stringent QC processes ensures that products meet specified standards. While additional QC measures can raise costs, they ultimately prevent costly recalls and reputational damage.

-

Logistics: Shipping costs are influenced by the distance from the supplier, the chosen Incoterms, and the mode of transport. It’s crucial to factor in both domestic and international logistics when calculating total sourcing costs.

-

Margin: Supplier profit margins can vary widely based on their operational efficiency and market positioning. Negotiating better terms can help buyers achieve more favorable pricing.

How Do Price Influencers Affect Plastic China Sourcing?

Several key factors can influence pricing in the plastic china sourcing market:

-

Volume/MOQ: Larger order quantities generally lead to lower per-unit costs due to economies of scale. However, buyers must balance this against storage capabilities and cash flow considerations.

-

Specifications and Customization: Custom designs or specific performance requirements can increase costs. Buyers should provide clear specifications to avoid unexpected charges and delays.

-

Material Selection: The type of plastic used not only affects the cost but also the product’s performance. Suppliers may offer different grades of materials at varying price points, so evaluating the trade-off between cost and quality is crucial.

-

Quality Certifications: Products meeting international quality standards, such as ISO or FDA regulations, may command higher prices. Buyers in regulated markets should prioritize suppliers who can provide the necessary certifications.

-

Supplier Factors: The supplier’s reputation, production capacity, and flexibility can impact pricing. Established suppliers may charge a premium, but their reliability can justify the cost.

-

Incoterms: The choice of Incoterms determines the responsibilities of buyers and sellers regarding shipping and insurance. Understanding these terms is essential for accurate cost estimation.

What Are the Best Buyer Tips for Negotiating Plastic China Pricing?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies:

-

Negotiate Effectively: Leverage your purchasing power by negotiating terms that benefit both parties. Building long-term relationships with suppliers can lead to better pricing and service.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not just the purchase price but also logistics, storage, and potential quality issues. This holistic view helps in making informed sourcing decisions.

-

Understand Pricing Nuances: Be aware of market trends and fluctuations in raw material costs. Engaging with industry analysts or utilizing market intelligence can provide insights into optimal timing for orders.

-

Conduct Supplier Audits: Assess suppliers’ capabilities and practices through site visits or third-party audits. This due diligence can uncover potential risks and inform pricing negotiations.

Disclaimer on Indicative Prices

Prices for plastic china products can vary significantly based on the factors discussed above. It is essential for buyers to seek detailed quotes from multiple suppliers and consider the full spectrum of costs involved in the sourcing process.

Alternatives Analysis: Comparing plastic china With Other Solutions

Understanding Alternative Solutions to Plastic China

As the global market shifts towards sustainability, B2B buyers are increasingly evaluating alternatives to traditional products like plastic china. This section explores viable alternatives that not only meet performance needs but also align with environmental goals. By understanding the strengths and weaknesses of each option, international buyers can make informed decisions that benefit both their businesses and the planet.

Comparison Table of Plastic China and Its Alternatives

| Comparison Aspect | Plastic China | Biodegradable Tableware | Melamine Dinnerware |

|---|---|---|---|

| Performance | Durable and lightweight | Similar durability, compostable | Durable, resistant to breakage |

| Cost | Moderate initial cost | Higher initial cost | Generally lower cost |

| Ease of Implementation | Widely available | Growing market availability | Readily available |

| Maintenance | Easy to clean | Requires proper disposal | Dishwasher safe |

| Best Use Case | Casual dining events | Eco-conscious events | Everyday use in restaurants |

Analyzing Biodegradable Tableware as an Alternative

Biodegradable tableware is gaining traction as an eco-friendly alternative to plastic china. Made from materials like cornstarch or bamboo, these products break down naturally, reducing landfill waste. However, they often come with a higher initial cost compared to plastic china, which can be a concern for budget-conscious buyers. Their performance in terms of durability is comparable, but proper disposal methods must be adhered to in order to maximize their environmental benefits.

Evaluating Melamine Dinnerware for B2B Buyers

Melamine dinnerware is another popular alternative, offering durability and resistance to breakage. It is generally less expensive than biodegradable options and is widely available. Melamine is dishwasher safe, making it convenient for high-volume foodservice operations. However, it is essential to note that melamine is not biodegradable and has raised health concerns when exposed to high temperatures. This makes it less suitable for eco-conscious businesses looking to minimize their environmental impact.

Conclusion: Choosing the Right Solution for Your Business Needs

When deciding between plastic china and its alternatives, B2B buyers should consider their specific use cases, budget constraints, and sustainability goals. For businesses focused on cost-effectiveness and durability, melamine may be the best choice. Conversely, for those prioritizing environmental responsibility, biodegradable tableware offers a compelling solution despite its higher initial investment. By weighing these factors, buyers from Africa, South America, the Middle East, and Europe can select the most appropriate option for their operations, aligning their purchasing decisions with broader sustainability initiatives.

Essential Technical Properties and Trade Terminology for plastic china

What Are the Key Technical Properties of Plastic China?

When sourcing plastic china products, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications to consider:

1. Material Grade

Material grade refers to the quality and type of plastic used in production, such as Polypropylene (PP) or Polyethylene Terephthalate (PET). Different grades have unique characteristics affecting durability, flexibility, and resistance to chemicals. For B2B buyers, selecting the right material grade can impact product performance and customer satisfaction.

2. Tolerance

Tolerance indicates the allowable variation in dimensions during manufacturing. It is expressed in millimeters or percentages and is critical for ensuring that components fit together correctly. For buyers, understanding tolerance is essential to avoid costly reworks or product failures, particularly in high-precision applications.

3. Impact Resistance

Impact resistance measures a plastic’s ability to withstand sudden force or shock without breaking. This property is especially important for plastic china used in environments prone to drops or accidents, such as in catering or hospitality. B2B buyers should prioritize impact-resistant materials to enhance product longevity and reduce replacement costs.

4. Thermal Stability

Thermal stability refers to a plastic’s ability to maintain its properties under varying temperature conditions. This is crucial for products that may be exposed to heat, such as serving dishes or food containers. For international buyers, understanding thermal stability ensures compliance with food safety regulations and helps avoid product deformation during use.

5. Recyclability

Recyclability indicates whether the plastic can be repurposed after its lifecycle. With increasing global focus on sustainability, knowing the recyclability of your products can enhance brand reputation and align with environmental regulations. Buyers should consider this property to meet both consumer expectations and regulatory standards.

What Are Common Trade Terms in the Plastic China Industry?

Understanding industry jargon is vital for navigating B2B transactions effectively. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are sold under another company’s brand. In the context of plastic china, working with an OEM can allow buyers to leverage established manufacturing capabilities for customized products, enhancing their market offerings.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity a supplier is willing to sell. This term is critical for B2B buyers to understand, as it impacts inventory management and cash flow. Knowing the MOQ helps buyers plan their purchases strategically and avoid excess inventory costs.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. This process allows businesses to compare offers and negotiate better deals. For international buyers, issuing an RFQ can streamline procurement and ensure competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC). They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and duties. Familiarity with Incoterms is essential for international B2B transactions to mitigate risks and ensure smooth logistics.

5. Lead Time

Lead time refers to the duration between placing an order and receiving the product. Understanding lead times is crucial for supply chain management, especially for businesses that rely on timely deliveries to meet customer demands. Buyers should always inquire about lead times to align their inventory strategies with supplier capabilities.

By familiarizing yourself with these essential technical properties and trade terminologies, you can navigate the plastic china market more effectively, ensuring that your procurement decisions align with your business goals and customer needs.

Navigating Market Dynamics and Sourcing Trends in the plastic china Sector

What Are the Key Market Dynamics and Trends in the Plastic China Sector?

The global plastic china market is currently influenced by several key drivers, including increasing consumer demand for affordable, durable tableware and the rise of e-commerce platforms facilitating international trade. The market has seen a shift towards high-quality, aesthetically appealing products that cater to both casual dining and formal events. In regions like Africa and South America, the growing middle class is driving a surge in demand for plastic china as disposable income rises. In contrast, European markets are increasingly focusing on sustainable alternatives, influenced by stringent regulations such as the EU Single-Use Plastics Directive (SUPD).

Emerging sourcing trends include the adoption of digital platforms for procurement, which allows buyers to connect directly with manufacturers and streamline the sourcing process. Additionally, the integration of Industry 4.0 technologies is enhancing production efficiency and supply chain transparency, enabling B2B buyers to make informed decisions based on real-time data. For international buyers from the Middle East and Europe, understanding the local regulations surrounding plastic products is critical, as compliance can significantly impact market entry and competitiveness.

How Important Is Sustainability and Ethical Sourcing in the Plastic China Market?

Sustainability has become a central theme in the plastic china sector, driven by increasing awareness of environmental impacts and consumer preferences for eco-friendly products. International B2B buyers must recognize the importance of ethical sourcing, which involves selecting suppliers who adhere to sustainable practices, such as using recycled materials or eco-friendly production methods. Certifications like ISO 14001 (Environmental Management) and the Global Recycled Standard (GRS) can serve as indicators of a supplier’s commitment to sustainability.

Moreover, the plastic china market is witnessing a rise in demand for biodegradable and compostable materials as alternatives to traditional plastics. This trend is particularly relevant for buyers in Europe, where regulations are increasingly favoring sustainable practices. By prioritizing suppliers who offer green certifications or sustainable materials, international buyers can not only meet compliance requirements but also enhance their brand reputation and appeal to environmentally conscious consumers.

What Is the Evolution of the Plastic China Sector Relevant to B2B Buyers?

The plastic china sector has evolved significantly over the past few decades, transitioning from a niche market to a mainstream choice for both consumers and businesses. Initially, plastic china was seen as a low-cost alternative to traditional materials like porcelain and ceramic. However, advancements in manufacturing technology have led to improved product quality, durability, and design, making plastic china a preferred option for various settings, from casual home dining to high-end restaurants.

As global awareness of plastic waste issues has increased, the industry is now faced with the challenge of adapting to a more sustainable future. This evolution is significant for B2B buyers, as it highlights the need to align with suppliers who are proactive in addressing environmental concerns while still providing high-quality products. Understanding this historical context can help international buyers navigate the current market landscape and make strategic sourcing decisions that resonate with their business values and customer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of plastic china

-

How do I choose the right supplier for sourcing plastic china?

When selecting a supplier for plastic china, consider their production capacity, quality certifications, and previous client reviews. Verify their compliance with international standards, especially if you’re importing to regions with stringent regulations like the EU or the US. Request samples to assess quality firsthand, and ensure they have a robust supply chain that can handle your order volume. Additionally, engage in direct communication to gauge their responsiveness and willingness to accommodate your specific needs. -

What are the most important quality assurance (QA) measures for plastic china?

Key QA measures include regular inspections during production, adherence to safety and quality standards (like ISO certifications), and testing for durability and non-toxicity. It’s crucial to establish a clear QA protocol with your supplier, which should involve testing samples from each batch before shipment. Additionally, consider third-party inspections to ensure unbiased quality assessment, particularly if you’re sourcing from regions where regulations may differ. -

What are the minimum order quantities (MOQs) I should expect when sourcing plastic china?

MOQs for plastic china can vary significantly based on the supplier and the complexity of the design. Typically, manufacturers may set MOQs ranging from 500 to 5,000 units. It’s essential to discuss your specific needs with potential suppliers to negotiate MOQs that align with your business model. Some suppliers may offer flexibility for first-time orders or if you’re willing to pay a premium. -

What payment terms are common when sourcing from international suppliers?

Common payment terms include a 30% deposit upfront with the remaining 70% due before shipment. Some suppliers may also accept payment via letters of credit or escrow services for larger orders, which can provide additional security. It’s advisable to clarify payment methods, currency preferences, and any potential fees associated with international transactions to avoid misunderstandings. -

How can I customize my plastic china products?

Customization options for plastic china typically include variations in color, design, size, and branding. Discuss your specific requirements with your supplier, who should provide a clear outline of the customization process, associated costs, and lead times. Keep in mind that higher levels of customization may require larger MOQs or longer production times, so plan accordingly to meet your deadlines. -

What logistics considerations should I keep in mind when importing plastic china?

When importing plastic china, consider shipping methods, customs regulations, and potential tariffs that may apply in your destination country. Work with logistics partners who have experience in handling plastic products to ensure compliance with packaging and labeling requirements. Additionally, factor in lead times for shipping and customs clearance to avoid delays in your supply chain. -

How do I ensure sustainable sourcing of plastic china?

To ensure sustainable sourcing, choose suppliers who utilize recycled materials and comply with environmental regulations. Verify their certifications related to sustainability and inquire about their waste management practices. Engage with suppliers who are transparent about their production processes and commit to reducing plastic waste, as this aligns with the growing demand for environmentally responsible products. -

What are the key market trends influencing the plastic china industry?

Current market trends include a shift towards biodegradable and compostable materials, driven by increasing consumer awareness about plastic pollution. Additionally, there is a growing demand for customizable and eco-friendly packaging solutions. Staying informed about these trends can help you align your sourcing strategy with market demands, ensuring your products remain competitive and appealing to environmentally conscious consumers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for plastic china

What Are the Key Takeaways for International B2B Buyers in Strategic Sourcing of Plastic Products?

In the evolving landscape of plastic sourcing, international B2B buyers must prioritize sustainability and compliance with regulations, especially in regions like Europe where stringent policies are being implemented. Understanding the implications of the EU’s Single-Use Plastics Directive and the Packaging Waste Regulation is crucial for buyers looking to mitigate risks associated with sourcing from China. The shift towards sustainable alternatives presents opportunities for businesses to innovate and differentiate themselves in the market.

How Can Strategic Sourcing Enhance Your Supply Chain Efficiency?

Strategic sourcing not only improves cost efficiency but also strengthens supplier relationships. By fostering partnerships with suppliers committed to sustainability, buyers can ensure a more resilient supply chain that aligns with global environmental goals. This approach is particularly beneficial for buyers from Africa, South America, the Middle East, and Europe, where local regulations and consumer preferences are rapidly changing.

What’s Next for Plastic Sourcing in a Global Context?

Looking ahead, the demand for responsibly sourced plastic products will only increase. Buyers are encouraged to explore collaborations with suppliers who prioritize recycled materials and sustainable practices. As the industry adapts to regulatory pressures and consumer expectations, proactive engagement in sustainable sourcing strategies will position businesses for long-term success. Take action today by evaluating your current sourcing strategies and embracing sustainability as a core business principle.