Unlock Custom Solutions: Your Datsun Truck Custom Guide (2025)

Introduction: Navigating the Global Market for datsun truck custom

The global market for Datsun truck customization presents significant opportunities for international B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. Sourcing customized Datsun trucks can be a complex endeavor, often fraught with challenges related to supplier reliability, quality assurance, and pricing transparency. This guide aims to demystify the process, providing a comprehensive overview of the various types of customizations available, their applications across different industries, and strategies for effectively vetting suppliers.

Buyers will benefit from insights into the latest trends in Datsun truck modifications, including performance upgrades, aesthetic enhancements, and functional adaptations tailored to specific business needs. Additionally, the guide covers essential factors such as cost considerations, potential return on investment, and logistical challenges in sourcing from international suppliers. By equipping B2B buyers with actionable knowledge and best practices, this guide empowers them to make informed purchasing decisions, ensuring that they select the right modifications that align with their operational goals.

Whether you are looking to enhance the durability of your fleet in the rugged terrains of South America or seeking versatile solutions for urban logistics in European cities, understanding the nuances of Datsun truck customization is crucial. This guide serves as a vital resource for businesses aiming to optimize their fleet capabilities while navigating the complexities of the global marketplace.

Understanding datsun truck custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Datsun 620 Custom | Compact size, classic styling, versatile bed options | Small cargo transport, delivery | Pros: Affordable, easy to customize. Cons: Limited payload capacity. |

| Datsun 720 Custom | Enhanced payload capacity, rugged design | Construction, agriculture | Pros: Durable, larger cargo space. Cons: Older models may require maintenance. |

| Datsun 521 Custom | Iconic design, good fuel efficiency | Urban delivery, light hauling | Pros: Economical, reliable. Cons: Spare parts may be harder to find. |

| Datsun Truck with Off-Road Modifications | Elevated suspension, off-road tires | Off-road logistics, adventure tours | Pros: Versatile for diverse terrains. Cons: Higher initial investment. |

| Datsun Truck with Electric Conversion | Electric drivetrain, eco-friendly | Green logistics, urban transport | Pros: Low operational costs, sustainable. Cons: Higher upfront costs, charging infrastructure needed. |

What are the key characteristics of the Datsun 620 Custom?

The Datsun 620 Custom is recognized for its compact size and classic styling, making it a popular choice for businesses needing small cargo transport solutions. Its versatile bed options allow for various configurations, suitable for urban delivery services. B2B buyers should consider its affordability and ease of customization, although its limited payload capacity may restrict heavier loads.

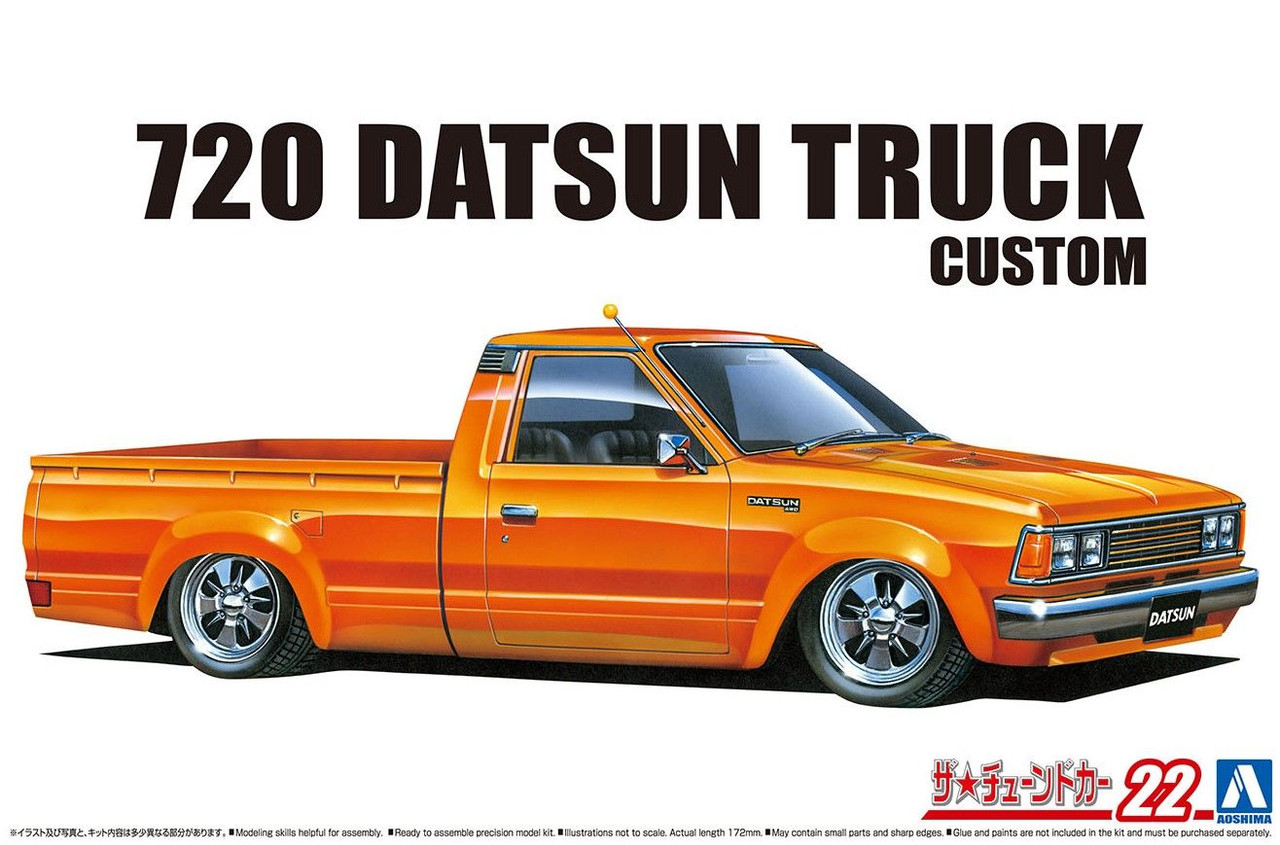

A stock image related to datsun truck custom.

How does the Datsun 720 Custom cater to larger cargo needs?

The Datsun 720 Custom stands out due to its enhanced payload capacity and rugged design, making it ideal for construction and agricultural applications. This model is built to withstand tough environments, providing businesses with a reliable workhorse. While it offers durability and larger cargo space, potential buyers should be prepared for maintenance needs associated with older models.

Why is the Datsun 521 Custom a reliable choice for urban delivery?

A stock image related to datsun truck custom.

The Datsun 521 Custom features an iconic design and good fuel efficiency, making it an excellent option for urban delivery and light hauling. Its economical nature appeals to businesses looking for reliable, cost-effective transport solutions. However, buyers should be aware that sourcing spare parts may pose challenges due to the vehicle’s age.

What advantages do off-road modifications provide for Datsun Trucks?

Datsun Trucks with off-road modifications, such as elevated suspension and off-road tires, are tailored for businesses engaged in off-road logistics and adventure tours. These modifications enhance the vehicle’s versatility across diverse terrains, making them suitable for various applications. Despite the advantages, buyers should consider the higher initial investment required for such specialized vehicles.

How does an electric conversion impact Datsun Truck operations?

Datsun Trucks with electric conversions present a sustainable alternative for businesses focused on green logistics and urban transport. The electric drivetrain significantly lowers operational costs while contributing to environmental sustainability. However, buyers must weigh the higher upfront costs and the need for adequate charging infrastructure when considering this option.

Related Video: CA18DET Swapped 1984 Datsun Sunny Custom Pickup Truck

Key Industrial Applications of datsun truck custom

| Industry/Sector | Specific Application of datsun truck custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Transportation of agricultural products and equipment | Efficient logistics and reduced transport costs | Availability of custom modifications for terrain adaptability |

| Construction | Hauling construction materials and tools | Increased productivity on-site and reduced downtime | Durability and load capacity to meet heavy-duty requirements |

| Retail and Distribution | Delivery of goods to local markets and customers | Enhanced supply chain efficiency and customer satisfaction | Customization for cargo space and ease of loading/unloading |

| Tourism and Hospitality | Shuttle services for tourists and local excursions | Improved guest experience and operational flexibility | Comfort features and customization for passenger capacity |

| Logistics and Warehousing | Last-mile delivery solutions | Streamlined operations and reduced delivery times | Compatibility with various cargo types and delivery needs |

How is the Datsun Truck Custom Used in Agriculture?

In the agricultural sector, the Datsun truck custom is frequently employed for transporting produce and equipment across farms and markets. Its robust build and customizable features allow it to navigate rough terrains, which is particularly beneficial in rural areas of Africa and South America where road conditions can be challenging. Buyers in this industry should consider sourcing options that provide modifications for increased cargo space and enhanced suspension systems to accommodate heavy loads.

What Role Does the Datsun Truck Custom Play in Construction?

In construction, the Datsun truck custom serves as a vital logistics vehicle, transporting materials, tools, and machinery to and from job sites. Its adaptability makes it suitable for various construction tasks, enhancing overall site productivity. International buyers should prioritize sourcing trucks that offer increased payload capacity and durability to withstand the demanding conditions of construction environments.

How Can Retail and Distribution Benefit from Datsun Truck Custom?

Retailers and distributors utilize the Datsun truck custom for efficient last-mile deliveries, ensuring that goods reach local markets and consumers swiftly. This capability helps businesses improve their supply chain efficiency and enhance customer satisfaction by reducing delivery times. When sourcing, businesses should look for customization options that maximize cargo space and facilitate easy loading and unloading processes.

Why is the Datsun Truck Custom Ideal for Tourism and Hospitality?

In the tourism and hospitality sector, the Datsun truck custom can be adapted for shuttle services, enhancing the guest experience by providing comfortable and reliable transportation for tourists. Its flexibility allows operators to customize the interior for passenger comfort and capacity. Buyers should consider sourcing trucks that offer amenities such as air conditioning and ample seating to meet the expectations of international travelers.

How Does the Datsun Truck Custom Enhance Logistics and Warehousing Operations?

Logistics and warehousing companies often leverage the Datsun truck custom for last-mile delivery solutions, enabling them to efficiently move goods from distribution centers to end customers. The vehicle’s reliability and adaptability can significantly streamline operations and reduce delivery times. When sourcing, businesses should evaluate the truck’s compatibility with various cargo types and its ability to meet specific delivery requirements, ensuring it aligns with their operational goals.

Related Video: Sci6 Q3 – Characteristics and Uses of Simple Machines

3 Common User Pain Points for ‘datsun truck custom’ & Their Solutions

Scenario 1: Difficulty Sourcing Quality Parts for Datsun Truck Customization

The Problem: One of the primary challenges faced by B2B buyers looking to customize Datsun trucks is the difficulty in sourcing quality parts. Many international buyers report a lack of reliable suppliers who can provide OEM or high-quality aftermarket parts. This challenge is compounded by the fact that many parts for older Datsun models may not be readily available in local markets, leading to delays and increased costs in the customization process. Additionally, buyers often struggle with the inconsistency in part quality, which can affect the overall performance and safety of the customized vehicle.

The Solution: To effectively navigate this sourcing challenge, buyers should establish relationships with reputable suppliers who specialize in Datsun truck parts. Utilizing online marketplaces and forums dedicated to Datsun enthusiasts can lead to finding suppliers with positive reviews and proven track records. Participating in global automotive trade shows can also provide opportunities to connect with manufacturers and distributors. Furthermore, buyers should prioritize suppliers who offer guarantees on their products and have a transparent return policy. Creating a detailed parts list and cross-referencing it with multiple suppliers can also ensure quality and availability before making a purchase.

Scenario 2: Navigating Customization Regulations in Different Countries

The Problem: B2B buyers often face regulatory hurdles when customizing Datsun trucks for different markets. Regulations regarding vehicle modifications vary significantly across countries and regions, especially in Africa, South America, and the Middle East. Buyers may not be aware of specific laws concerning emissions, safety standards, or vehicle modifications, which can lead to costly compliance issues or the inability to register the vehicle legally.

The Solution: To mitigate the risks associated with regulatory compliance, buyers should conduct thorough research on the laws governing vehicle customization in their target markets. Consulting with local automotive experts or legal advisors can provide valuable insights into specific requirements. Additionally, buyers should consider using local modification shops that are familiar with regional regulations, as they can ensure that the customized Datsun truck meets all necessary legal standards. Keeping abreast of changes in regulations through industry associations or government publications will also help buyers stay compliant and avoid any pitfalls.

Scenario 3: Ensuring Efficient Communication with Customization Service Providers

The Problem: Effective communication is crucial when working with customization service providers, yet many B2B buyers report challenges in this area. Language barriers, different time zones, and cultural differences can lead to misunderstandings and misaligned expectations. This often results in delays, additional costs, and unsatisfactory outcomes in the customization process.

The Solution: To enhance communication with customization service providers, B2B buyers should establish clear channels of communication from the outset. Utilizing project management tools that allow for real-time updates and feedback can help bridge communication gaps. Additionally, creating a comprehensive project brief that outlines expectations, timelines, and specific requirements can significantly reduce misunderstandings. Buyers may also consider hiring a local liaison or consultant who understands both the cultural nuances and technical jargon involved in the customization process, facilitating smoother interactions and ensuring that the final product aligns with their vision.

Strategic Material Selection Guide for datsun truck custom

When selecting materials for custom Datsun trucks, international B2B buyers must consider a variety of factors that influence performance, cost, and compliance with regional standards. Below, we analyze four common materials used in the custom fabrication of Datsun trucks, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Steel in Datsun Truck Customization?

Steel is a widely used material in automotive applications due to its strength and durability. It typically has a high tensile strength, making it suitable for structural components. Steel also offers good temperature resistance, withstanding high pressures without deforming. However, it is prone to corrosion, which can be a significant drawback in humid or coastal environments.

Pros and Cons: The primary advantage of steel is its cost-effectiveness and ease of fabrication. It is relatively inexpensive compared to other materials, making it a popular choice for bulk purchases. However, its susceptibility to rust can lead to increased maintenance costs and reduced lifespan if not properly treated.

Impact on Application: Steel is compatible with a wide range of media, including fuel and oil. However, buyers should consider the need for protective coatings or galvanization, especially in regions with high humidity.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM for the United States or DIN for Europe. Understanding the corrosion resistance requirements for specific climates is also crucial.

How Does Aluminum Compare for Custom Datsun Trucks?

Aluminum is another popular material, particularly in applications where weight reduction is critical. It is lightweight yet strong, providing excellent corrosion resistance, which makes it ideal for outdoor applications. Aluminum can also handle a wide range of temperatures.

Pros and Cons: The main advantage of aluminum is its lightweight nature, which can improve fuel efficiency and handling. However, it is generally more expensive than steel, and its manufacturing processes can be more complex, requiring specialized equipment.

Impact on Application: Aluminum is compatible with various media, including fuels and oils, and its resistance to corrosion makes it suitable for long-term outdoor use.

Considerations for International Buyers: Buyers must be aware of the higher costs associated with aluminum and consider the availability of suppliers in their region. Compliance with local regulations regarding aluminum alloys is also necessary.

What Role Does Composite Material Play in Datsun Truck Customization?

Composite materials, often made from a combination of plastics and fibers, are increasingly used in automotive applications for their lightweight and strength properties. They can withstand high temperatures and offer excellent corrosion resistance.

Pros and Cons: Composites provide significant weight savings and can be molded into complex shapes, which is advantageous for custom designs. However, they can be more expensive and may require specialized manufacturing processes.

Impact on Application: Composites are generally compatible with various automotive fluids and offer excellent durability against environmental factors.

Considerations for International Buyers: Buyers should evaluate the availability of composite materials in their region and ensure compliance with relevant standards. The higher cost may also necessitate a careful cost-benefit analysis.

How Does Rubber Material Function in Datsun Truck Customization?

Rubber is primarily used for seals, gaskets, and bushings in automotive applications. It provides excellent flexibility and resistance to environmental factors, including temperature fluctuations and moisture.

Pros and Cons: The key advantage of rubber is its ability to absorb vibrations and provide a tight seal, which enhances vehicle performance. However, rubber can degrade over time, especially when exposed to oils and extreme temperatures.

Impact on Application: Rubber is compatible with most automotive fluids, but its longevity may be compromised in harsh environments.

Considerations for International Buyers: Buyers should ensure that rubber components meet local standards for durability and performance. The choice of rubber type can significantly impact the overall cost and performance.

| Material | Typical Use Case for datsun truck custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Frame and structural components | Cost-effective and strong | Prone to corrosion | Low |

| Aluminum | Body panels and components | Lightweight and corrosion-resistant | Higher cost and complex fabrication | High |

| Composite | Custom body parts and panels | Significant weight savings | Expensive and requires specialized processes | Medium |

| Rubber | Seals and gaskets | Excellent flexibility and vibration absorption | Degrades over time | Low |

By understanding the properties, advantages, and limitations of these materials, international B2B buyers can make informed decisions that align with their specific needs and regional standards, ensuring optimal performance and compliance in their custom Datsun truck projects.

In-depth Look: Manufacturing Processes and Quality Assurance for datsun truck custom

What Are the Main Stages in the Manufacturing Process of Datsun Truck Custom?

The manufacturing process of a Datsun truck custom encompasses several key stages, each critical to ensuring the final product meets both quality and functional requirements. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

This initial stage involves sourcing high-quality raw materials such as steel, aluminum, and plastics. Suppliers should provide documentation verifying the origin and quality of these materials, as compliance with international standards is essential. Buyers should inquire about the supplier’s material certifications to ensure they meet the necessary specifications. -

Forming

Forming techniques used in the production of Datsun trucks include stamping, bending, and welding. Stamping involves using large presses to shape metal sheets into specific parts, while bending shapes metal into desired angles. Buyers should look for suppliers utilizing advanced CNC machinery for precision and efficiency. An effective forming process reduces waste and enhances overall product durability. -

Assembly

During assembly, various components such as the chassis, engine, and interior elements are brought together. This stage often employs automated systems to ensure consistent quality. It’s important for B2B buyers to understand the assembly line’s capabilities and whether it allows for customization options. Suppliers should be able to provide details about their assembly process and the technology used to ensure quality and efficiency.

- Finishing

The finishing stage includes painting, coating, and detailing the truck to achieve the desired aesthetic and protective qualities. Techniques such as powder coating and electrostatic painting are commonly employed to enhance durability and finish quality. Buyers should verify that the finishing processes used comply with environmental regulations and that the materials used are non-toxic.

How Is Quality Assurance Implemented in Datsun Truck Custom Manufacturing?

Quality assurance (QA) in the manufacturing of Datsun trucks is critical to maintaining high standards and ensuring customer satisfaction. This process is typically governed by international standards such as ISO 9001, which outlines the requirements for a quality management system (QMS).

-

Relevant International Standards

B2B buyers should ensure that their suppliers comply with ISO 9001, which focuses on meeting customer requirements and enhancing satisfaction through effective QMS. Other industry-specific certifications such as CE marking for safety and API for oil and gas applications may also be relevant. Understanding these certifications helps buyers assess the credibility and reliability of suppliers. -

Quality Control Checkpoints

Effective quality control (QC) involves multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This stage checks the quality of raw materials before they are used in production. Buyers should request IQC reports to verify that materials meet specified standards.

-

In-Process Quality Control (IPQC): During production, IPQC monitors processes to detect defects early. Suppliers should provide data on IPQC measures and any corrective actions taken when issues arise.

-

Final Quality Control (FQC): The final inspection ensures that the finished product meets all specifications before shipping. Buyers should ask for FQC reports, detailing the results of the final inspection and any quality metrics used.

- Common Testing Methods

Various testing methods are employed to ensure product quality, including:

- Mechanical Testing: Assessing the strength and durability of materials used in the trucks.

- Visual Inspection: Checking for surface defects and finish quality.

- Functional Testing: Ensuring that all systems, such as braking and electrical systems, function correctly.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers maintain robust quality control practices, B2B buyers should adopt a proactive approach, which includes the following strategies:

-

Conducting Audits

Regular supplier audits are essential for verifying compliance with quality standards. Buyers should establish a schedule for audits, focusing on both documentation and on-site inspections. This process can reveal potential issues in quality management practices and provide insight into the supplier’s overall operational effectiveness. -

Reviewing Quality Reports

Buyers should request access to quality control reports, including IQC, IPQC, and FQC data. These reports provide transparency into the supplier’s quality management system and help assess their commitment to maintaining high standards. -

Third-Party Inspections

Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality practices. These inspections can be particularly beneficial for B2B buyers operating in diverse markets, as they provide an additional layer of assurance regarding compliance with international standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, must navigate specific quality control nuances when sourcing Datsun truck customs. Here are some considerations:

-

Understanding Regional Standards

Different regions may have unique regulatory requirements affecting product quality. Buyers must familiarize themselves with local standards and ensure their suppliers are compliant. This knowledge helps mitigate risks related to regulatory violations. -

Cultural and Communication Considerations

Effective communication is essential for quality assurance. Language barriers and cultural differences can impact understanding quality requirements. Buyers should establish clear communication channels and documentation practices to avoid misunderstandings. -

Logistics and Supply Chain Management

The complexity of international logistics can affect product quality. Buyers should ensure that suppliers have robust logistics processes to maintain product integrity during transportation. This includes proper packaging and handling procedures.

Conclusion

In conclusion, understanding the manufacturing processes and quality assurance practices for Datsun truck customs is vital for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, and ensuring suppliers adhere to international standards and robust quality control measures, buyers can make informed decisions and establish reliable partnerships. Engaging in proactive verification methods, such as audits and third-party inspections, further strengthens the assurance of product quality, ultimately leading to successful international trade relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘datsun truck custom’

To successfully procure a custom Datsun truck, international B2B buyers must navigate a series of essential steps that ensure quality, reliability, and compliance. This guide serves as a practical checklist for buyers in Africa, South America, the Middle East, and Europe, providing actionable insights to streamline the sourcing process.

Step 1: Define Your Customization Requirements

Clearly outlining your customization needs is crucial before reaching out to suppliers. This includes specifications such as engine modifications, body design, and additional features. Understanding these requirements helps ensure that suppliers can meet your expectations and minimizes the risk of costly alterations later in the process.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers specializing in Datsun truck customizations. Utilize online platforms, industry directories, and community forums to gather information. Pay attention to reviews and feedback from previous clients to gauge reliability and service quality.

Step 3: Evaluate Supplier Capabilities

Before committing, assess the capabilities of potential suppliers. Request detailed profiles that outline their experience with custom Datsun projects, including examples of past work. This evaluation helps ensure that the supplier possesses the necessary expertise to handle your specific customization needs.

Step 4: Verify Supplier Certifications and Compliance

Ensure that the suppliers you are considering hold relevant certifications and comply with local and international regulations. This is particularly important for businesses operating in regions with stringent automotive standards. Certifications can include ISO standards, environmental compliance, and safety regulations, which collectively reflect the supplier’s commitment to quality.

Step 5: Request Detailed Quotations

Once you have shortlisted suppliers, request detailed quotations that outline costs, timelines, and payment terms. A clear breakdown of costs will help you compare different suppliers effectively and avoid hidden fees. Look for transparency in their pricing structure, as this often indicates a trustworthy supplier.

Step 6: Conduct Site Visits or Virtual Inspections

Whenever possible, conduct site visits to the supplier’s facility. This allows you to assess their operations, machinery, and overall environment. If a physical visit isn’t feasible, consider arranging a virtual inspection via video calls. This step is vital for verifying the supplier’s capabilities and work environment.

Step 7: Establish Clear Communication Channels

Effective communication is key to a successful sourcing process. Establish clear channels of communication with your chosen supplier, including preferred methods and frequency of updates. Regular check-ins help ensure that the project stays on track and that any issues are addressed promptly.

By following this checklist, international B2B buyers can enhance their procurement process for custom Datsun trucks, ensuring they select reliable suppliers who meet their specific needs and standards.

Comprehensive Cost and Pricing Analysis for datsun truck custom Sourcing

What Are the Key Cost Components for Datsun Truck Custom Sourcing?

When considering the sourcing of Datsun truck custom models, it’s essential to understand the various cost components that contribute to the total expense. The primary cost components include:

-

Materials: The choice of materials significantly influences the overall cost. High-quality materials such as steel, aluminum, and durable plastics can increase the initial expenditure but may reduce long-term maintenance costs.

-

Labor: Labor costs can vary widely depending on the geographic location of the manufacturing facility. Regions with lower labor costs may offer competitive pricing, but it’s crucial to assess the skill level and experience of the workforce to ensure quality.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help minimize overhead, thereby lowering the overall cost.

-

Tooling: Custom designs often require specialized tooling, which can be a significant upfront investment. Buyers should consider the amortization of these costs over the expected volume of production.

-

Quality Control (QC): Implementing stringent QC measures is vital to ensure product reliability and safety. While this may add to the cost, it can prevent costly recalls or warranty claims in the future.

-

Logistics: Transportation costs can greatly affect the total cost, especially for international shipments. Factors such as distance, shipping method, and customs duties play crucial roles in logistics pricing.

-

Margin: Supplier margins can vary based on the supplier’s market position and the perceived value of the product. Understanding the supplier’s cost structure can provide insights into potential negotiation points.

How Do Price Influencers Affect Datsun Truck Custom Sourcing?

Several factors can influence the pricing of Datsun truck custom sourcing:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often offer better pricing for larger orders. International buyers should negotiate MOQs that align with their production needs to achieve cost savings.

-

Specifications and Customization: Custom features can increase costs. Buyers should clearly define specifications upfront to avoid unexpected expenses during production.

-

Materials Quality and Certifications: High-quality materials and certifications (such as ISO or environmental certifications) can raise costs but provide assurance of product quality and compliance with international standards.

-

Supplier Factors: The supplier’s reputation, financial stability, and production capacity can affect pricing. Establishing a relationship with a reliable supplier can lead to better terms and pricing.

-

Incoterms: Understanding Incoterms is crucial for cost management in international trade. Terms such as FOB (Free On Board) or CIF (Cost Insurance and Freight) can significantly influence total landed costs.

What Buyer Tips Can Optimize Costs for Datsun Truck Custom Sourcing?

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, optimizing costs while sourcing Datsun trucks involves strategic approaches:

-

Negotiation: Leverage competitive quotes from multiple suppliers to negotiate better pricing. Building a long-term relationship can also yield favorable terms.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO) rather than just the purchase price. Consider factors such as maintenance, fuel efficiency, and resale value.

-

Pricing Nuances: Be aware of regional pricing differences influenced by local market conditions. Understanding the economic landscape of the supplier’s country can provide leverage in negotiations.

-

Consider Logistics: Factor in logistics costs when evaluating suppliers. A supplier closer to your market may offer better pricing despite potentially higher unit costs due to reduced shipping expenses.

-

Stay Informed: Regularly research industry trends and pricing benchmarks. Engaging with forums and industry networks can provide insights into best practices and emerging suppliers.

Disclaimer on Indicative Prices

It is important to note that the prices discussed in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific project requirements. Buyers should conduct thorough due diligence to obtain accurate pricing tailored to their needs.

Alternatives Analysis: Comparing datsun truck custom With Other Solutions

In the highly competitive market for commercial vehicles, international B2B buyers are often faced with a variety of options when considering solutions for their transportation and logistics needs. The Datsun Truck Custom is one such option, but understanding how it stacks up against other alternatives is crucial for making an informed decision. Below, we compare the Datsun Truck Custom with two viable alternatives: the Toyota Hilux and the Ford Ranger.

Comparison Table

| Comparison Aspect | Datsun Truck Custom | Toyota Hilux | Ford Ranger |

|---|---|---|---|

| Performance | Moderate load capacity, reliable engine | High load capacity, excellent off-road capabilities | Strong towing capacity, versatile performance |

| Cost | Competitive pricing, lower initial investment | Higher upfront cost, good resale value | Mid-range pricing, extensive features justify cost |

| Ease of Implementation | Simple to customize, easy to source parts | Requires specialized maintenance, parts may be less accessible | User-friendly setup, good availability of parts |

| Maintenance | Low maintenance costs, easy repairs | Moderate maintenance costs, robust service network | Slightly higher maintenance costs, extensive dealer support |

| Best Use Case | Urban deliveries, light-duty tasks | Off-road transport, heavy-duty applications | Versatile use, from urban to rugged terrains |

What Are the Pros and Cons of the Toyota Hilux Compared to Datsun Truck Custom?

The Toyota Hilux is renowned for its durability and off-road capabilities, making it an ideal choice for businesses that require a robust vehicle for rugged terrains. Its high load capacity allows for the transportation of heavy goods, making it suitable for construction and agricultural sectors. However, the initial investment is higher than that of the Datsun Truck Custom, which could be a barrier for budget-conscious buyers. Additionally, maintenance can be more complex, as it often requires specialized skills and parts that may not be as readily available in some regions.

How Does the Ford Ranger Stand Against Datsun Truck Custom?

The Ford Ranger offers an impressive blend of performance and versatility, making it a popular choice among businesses needing a reliable vehicle for varied tasks. Its strong towing capacity is particularly beneficial for logistics and heavy transport operations. While it is priced in the mid-range segment, the extensive features and technology integrated into the Ranger justify the cost. However, maintenance costs can be slightly higher than those associated with the Datsun Truck Custom, which may be a consideration for businesses looking to minimize long-term expenses.

How to Choose the Right Solution for Your Business Needs?

When evaluating the right solution for your transportation requirements, consider several factors including load capacity, terrain adaptability, and total cost of ownership. The Datsun Truck Custom may be ideal for urban environments with its competitive pricing and lower maintenance costs, while the Toyota Hilux is better suited for off-road applications. Conversely, the Ford Ranger serves as a versatile option that balances performance and features. Ultimately, the decision should align with your operational needs, budget constraints, and long-term business goals. By carefully analyzing these aspects, B2B buyers can make an informed choice that enhances their logistics efficiency and overall productivity.

Essential Technical Properties and Trade Terminology for datsun truck custom

What Are the Key Technical Properties of a Datsun Truck Custom?

When considering a Datsun truck custom, several technical properties are critical for ensuring performance, durability, and compatibility with other components. Understanding these specifications can significantly influence purchasing decisions, especially for international B2B buyers in regions such as Africa, South America, the Middle East, and Europe.

1. Material Grade: What Is Its Impact on Performance?

The material grade refers to the type and quality of materials used in manufacturing the truck’s parts, such as steel, aluminum, or composites. Higher-grade materials often provide better strength, corrosion resistance, and longevity. For B2B buyers, selecting the right material grade is crucial to ensure that the truck can withstand specific environmental conditions and operational stresses.

2. Tolerance: Why Is It Essential for Compatibility?

Tolerance defines the permissible limit or limits of variation in a physical dimension or measured value. In the context of a Datsun truck custom, tight tolerances are essential for parts that must fit together accurately, such as engine components and suspension systems. Inaccurate tolerances can lead to mechanical failures or increased wear, impacting the truck’s reliability and performance. B2B buyers should prioritize suppliers who can guarantee precise tolerances.

3. Payload Capacity: How Does It Affect Utility?

Payload capacity refers to the maximum weight that a truck can safely carry. Understanding this specification is vital for businesses that plan to use Datsun trucks for transporting goods. Exceeding the payload capacity can lead to increased wear and tear on the vehicle, potential safety issues, and regulatory violations. Buyers should consider their specific transportation needs when evaluating payload capacities.

4. Engine Specifications: What Should You Know?

Engine specifications encompass parameters such as horsepower, torque, and fuel efficiency. These factors significantly influence the truck’s performance and operational costs. B2B buyers should assess their logistical requirements, such as the types of loads and distances traveled, to choose an engine that optimally balances power and efficiency.

5. Wheelbase: How Does It Impact Maneuverability?

The wheelbase is the distance between the front and rear axles and significantly affects the truck’s handling and stability. A longer wheelbase generally offers better stability, especially when carrying heavy loads, while a shorter wheelbase enhances maneuverability. Buyers in urban areas or regions with challenging terrains should carefully consider wheelbase specifications based on their operational needs.

What Trade Terms Should B2B Buyers Understand When Purchasing Datsun Trucks?

Understanding industry terminology is crucial for effective communication and negotiation in the B2B market. Here are some key terms relevant to purchasing Datsun truck customs:

1. OEM (Original Equipment Manufacturer): What Does It Mean?

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of Datsun trucks, purchasing OEM parts ensures compatibility and quality, as these components are designed specifically for the vehicle model. B2B buyers should prioritize OEM parts for repairs and upgrades to maintain vehicle integrity.

2. MOQ (Minimum Order Quantity): Why Is It Important?

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory costs and ensure they are not over-committing to a supplier. Buyers should negotiate MOQs that align with their needs while also considering potential bulk purchase discounts.

3. RFQ (Request for Quotation): How Should You Use It?

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. For B2B buyers, issuing an RFQ is a strategic move to gather competitive pricing and terms from multiple suppliers, enabling informed purchasing decisions.

4. Incoterms: What Do They Cover?

Incoterms, or International Commercial Terms, define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers to clarify shipping costs, risk management, and delivery timelines, ensuring that all parties are aligned on their obligations.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions when purchasing Datsun truck customs, ultimately leading to more successful and efficient operations.

Navigating Market Dynamics and Sourcing Trends in the datsun truck custom Sector

What Are the Current Market Dynamics and Sourcing Trends in the Datsun Truck Custom Sector?

The Datsun truck custom sector is experiencing a resurgence driven by global demand for unique and personalized vehicles. Factors such as the growing popularity of vintage and classic vehicles among collectors and enthusiasts are shaping this market. Additionally, the rise of e-commerce platforms facilitates easier access to parts and restoration services, significantly impacting sourcing trends. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should pay attention to several key trends.

Emerging B2B Technologies and Sourcing Trends: The integration of digital marketplaces is transforming how buyers procure custom parts and services. Platforms that allow for peer-to-peer sales and auctions are gaining traction, enabling buyers to access rare components directly from sellers worldwide. Furthermore, advancements in 3D printing technology are making it possible to manufacture bespoke parts on-demand, reducing lead times and costs associated with traditional sourcing methods.

Market Dynamics for International Buyers: The fluctuating exchange rates and tariffs can influence pricing structures for international transactions. Buyers from Africa and South America, for example, should consider sourcing from regions with favorable trade agreements to minimize costs. Additionally, understanding regional preferences and compliance with local regulations is crucial for successful market entry and procurement.

How Can Sustainability and Ethical Sourcing Impact the Datsun Truck Custom Sector?

As global awareness of environmental issues rises, the importance of sustainability in sourcing practices cannot be overstated. The Datsun truck custom sector is increasingly influenced by demands for ethical sourcing and environmentally friendly materials.

Environmental Impact of Customization: Customization often involves modifications that can negatively impact the environment, such as increased emissions from modified engines. B2B buyers are encouraged to source parts that meet emissions standards and utilize sustainable materials. This not only aligns with global sustainability goals but also enhances brand reputation among environmentally conscious consumers.

Importance of Ethical Supply Chains: Buyers should prioritize suppliers who adhere to ethical labor practices and sustainable sourcing. Certifications such as ISO 14001 for environmental management and Fair Trade certifications can guide buyers in selecting responsible vendors. Establishing partnerships with suppliers committed to sustainability can enhance product offerings and meet the growing consumer demand for green products.

What Is the Brief Evolution of the Datsun Truck Custom Sector?

The Datsun truck custom sector has evolved significantly since its inception in the mid-20th century. Originally known for its affordability and reliability, Datsun vehicles gained popularity among working-class individuals and small businesses. Over the years, as classic car culture emerged, enthusiasts began to seek out Datsun trucks for customization.

Today, the sector is characterized by a blend of vintage aesthetics and modern technology, with buyers increasingly interested in unique modifications that reflect personal style. The rise of online communities and forums dedicated to Datsun customization has further accelerated this trend, enabling knowledge sharing and collaboration among enthusiasts worldwide. This evolution presents valuable opportunities for international B2B buyers to engage with a vibrant community while sourcing innovative custom solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of datsun truck custom

-

How do I find reliable suppliers for Datsun truck custom parts?

To locate trustworthy suppliers for Datsun truck custom parts, start by leveraging online B2B marketplaces such as Alibaba or TradeIndia. Evaluate potential suppliers by checking their company profiles, customer reviews, and ratings. Additionally, consider reaching out to industry-specific forums and groups, like those on Datsun-France, where enthusiasts and businesses exchange recommendations. It’s crucial to request samples and certifications to ensure the quality of the parts meets your specifications. -

What are the key customization options available for Datsun trucks?

Customization options for Datsun trucks can vary widely, from aesthetic modifications like paint jobs and decals to functional enhancements such as upgraded suspension systems, performance exhausts, and advanced infotainment setups. Many suppliers also offer bespoke options tailored to specific business needs, such as cargo modifications for logistics companies. When discussing customization, be clear about your requirements and desired outcomes to ensure the supplier can meet your expectations.

-

What should I consider when negotiating payment terms with suppliers?

When negotiating payment terms with suppliers, consider factors like the total order value, delivery timelines, and your cash flow. Common terms include partial upfront payments with the balance due upon delivery. Ensure that you clarify any additional costs, such as customs duties and shipping fees, to avoid unexpected expenses. Building a good rapport with your supplier can also lead to more favorable terms, including discounts for bulk orders or extended payment periods. -

What minimum order quantities (MOQ) should I expect for Datsun truck custom parts?

Minimum order quantities (MOQ) for Datsun truck custom parts can range from as low as 10 units to several hundred, depending on the supplier and the complexity of the customization. Smaller suppliers may have lower MOQs, while larger manufacturers often require higher quantities to justify production costs. It’s advisable to communicate your needs upfront and inquire if the supplier offers flexibility on MOQ for first-time buyers or trial orders. -

How can I ensure quality assurance (QA) when sourcing Datsun truck parts?

To ensure quality assurance when sourcing Datsun truck parts, request detailed product specifications and certifications from suppliers. Conduct factory audits if possible, or utilize third-party inspection services to verify the quality of materials and workmanship. Establishing a clear quality control process, including setting acceptable quality limits and testing protocols, is crucial. Always ask for a warranty or guarantee on the parts to protect against defects. -

What logistics considerations should I keep in mind when importing Datsun truck custom parts?

When importing Datsun truck custom parts, consider logistics factors such as shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder who understands international shipping regulations, especially for specific regions like Africa or South America. It’s also essential to factor in lead times for production and shipping, as delays can impact your business operations. Understanding the import duties and taxes applicable in your country will also help in budgeting effectively. -

How do I handle potential language barriers with international suppliers?

To navigate language barriers with international suppliers, consider using clear and simple language in your communications. Employ professional translation services or tools if necessary to ensure critical information is conveyed accurately. Additionally, establishing a primary point of contact who is fluent in both languages can streamline communication. Video calls can also help build rapport and clarify complex discussions, making it easier to resolve misunderstandings. -

What are the common shipping methods for Datsun truck custom parts?

Common shipping methods for Datsun truck custom parts include air freight, sea freight, and courier services. Air freight is faster but more expensive, making it suitable for urgent orders. Sea freight is more cost-effective for large shipments but involves longer transit times. Courier services are ideal for smaller, time-sensitive orders. Evaluate the urgency, cost, and volume of your shipment to choose the most suitable method, and always confirm tracking options with your supplier.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for datsun truck custom

In the competitive landscape of custom Datsun truck sourcing, strategic sourcing emerges as a pivotal approach for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. By leveraging insights from community forums and restoration projects, buyers can identify reliable suppliers and quality parts essential for enhancing vehicle performance and aesthetics. The emphasis on community-driven support and shared knowledge within the Datsun enthusiast networks underscores the importance of collaboration in sourcing strategies.

What are the key factors for successful strategic sourcing in Datsun trucks? Buyers should prioritize the establishment of strong relationships with suppliers, ensuring transparency in pricing and quality standards. Additionally, staying informed about market trends and product availability will empower buyers to make well-informed decisions that align with their business goals.

Looking ahead, the demand for customized Datsun trucks is expected to grow, driven by a resurgence in classic vehicle interest and the need for durable, reliable transportation solutions. International B2B buyers are encouraged to act now—engage with reputable suppliers, participate in automotive forums, and explore innovative sourcing strategies to secure a competitive edge in this evolving market. Your next strategic partnership could redefine your approach to custom Datsun trucks.