Unlock Quality & Cost Savings with Metal Custom Solutions (2025)

Introduction: Navigating the Global Market for metal custom

Navigating the global market for metal custom solutions can be a daunting task for B2B buyers, particularly those operating in diverse economic landscapes like Africa, South America, the Middle East, and Europe. The challenge often lies in sourcing tailored metal products that meet specific business needs while ensuring quality and cost-effectiveness. This guide provides a comprehensive resource for international buyers seeking to understand the intricacies of metal custom sourcing, including various types of metal products, their applications across industries, and effective supplier vetting strategies.

In this guide, you will discover essential insights into the different categories of metal custom offerings, from precision parts to structural components. We will explore how to evaluate potential suppliers based on quality certifications, production capabilities, and logistical considerations, ensuring that your procurement process is both efficient and reliable. Additionally, cost analysis techniques will be shared to help you make informed purchasing decisions that align with your budgetary constraints without compromising on quality.

Whether you are a manufacturer in need of specialized metal components or a distributor seeking reliable partnerships, this guide equips you with the knowledge to navigate the complexities of the global metal custom market. By leveraging the actionable insights provided, you can enhance your purchasing strategy, mitigate risks, and ultimately drive greater value for your organization.

Understanding metal custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Metal Fabrication | Tailored designs, various metals used, complex shapes | Aerospace, automotive, construction | Pros: High customization, precise specifications. Cons: Longer lead times, potentially higher costs. |

| Metal Stamping | High-volume production, consistent quality, precision cuts | Electronics, appliances, automotive parts | Pros: Cost-effective for large runs, quick turnaround. Cons: Limited to specific designs, initial tooling costs. |

| CNC Machining | Computer-controlled precision, versatile materials | Medical devices, aerospace, industrial tools | Pros: High precision, flexibility in design. Cons: Slower than stamping for large volumes, can be costly for small batches. |

| Metal Casting | Molding process, complex shapes, various alloys | Machinery, automotive, art sculptures | Pros: Ideal for intricate designs, good for small to medium runs. Cons: Longer production times, potential for defects. |

| Laser Cutting | High precision, clean edges, minimal material waste | Signage, custom parts, prototypes | Pros: Quick setup, excellent for prototypes. Cons: Limited material thickness, not cost-effective for large quantities. |

What is Custom Metal Fabrication and Its B2B Relevance?

Custom metal fabrication involves creating metal components tailored to specific requirements, often utilizing various metals such as steel, aluminum, and copper. This method is ideal for industries like aerospace and automotive, where precision and adherence to strict specifications are paramount. B2B buyers should consider the complexity of their designs and the lead times involved, as custom fabrication can take longer and may incur higher costs compared to off-the-shelf products.

How Does Metal Stamping Work and What Are Its Applications?

Metal stamping is a manufacturing process that involves pressing metal sheets into desired shapes using dies. This technique is particularly suited for high-volume production runs, making it a preferred choice for industries like electronics and automotive parts. Buyers should weigh the initial tooling costs against the long-term savings from mass production, as this method can be highly cost-effective for larger quantities but may limit design flexibility.

Why Choose CNC Machining for Precision Needs?

CNC (Computer Numerical Control) machining utilizes computer-controlled tools to achieve high precision in metal components. This technique is versatile, accommodating various materials and complex designs, making it suitable for sectors such as medical devices and aerospace. B2B buyers should consider the trade-off between precision and production speed, as CNC machining can be slower than stamping for large orders, but it excels in producing intricate designs in smaller batches.

What Are the Advantages of Metal Casting in Custom Projects?

Metal casting involves pouring molten metal into molds to create components of various shapes and sizes. This method is particularly effective for producing intricate designs and is commonly used in machinery and automotive applications. Buyers should be aware of the longer production times associated with casting and the potential for defects, but it remains an excellent option for small to medium production runs where detail is critical.

How Does Laser Cutting Enhance Custom Metal Production?

Laser cutting employs focused light to cut metal with high precision, resulting in clean edges and minimal material waste. This method is particularly beneficial for creating prototypes, signage, and custom parts. B2B buyers should note the advantages of quick setup and the ability to handle complex designs, though it may not be cost-effective for large quantities due to limitations in material thickness and production speed.

Related Video: CUSTOM METAL CARPORT BUILD // WORKING WITH CUSTOMERS

Key Industrial Applications of metal custom

| Industry/Sector | Specific Application of Metal Custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Custom Metal Components for Vehicles | Enhanced performance and weight reduction | Quality certifications, local suppliers, and lead times |

| Aerospace | Precision Machined Parts | Improved safety and compliance with regulations | Material specifications, traceability, and testing capabilities |

| Construction | Structural Steel Fabrication | Increased durability and design flexibility | Local regulations, load-bearing specifications, and delivery times |

| Oil & Gas | Custom Piping and Fittings | Enhanced efficiency and reduced leakage risk | Corrosion resistance, material grades, and international standards |

| Electronics | Custom Metal Enclosures | Improved thermal management and device protection | EMI shielding, precision machining capabilities, and certifications |

How is Custom Metal Applied in the Automotive Industry?

In the automotive sector, custom metal components play a crucial role in enhancing vehicle performance and reducing weight. These components include chassis parts, brackets, and engine components that are tailored to meet specific design and performance criteria. For international buyers, especially from regions like Africa and South America, sourcing these components requires a focus on quality certifications and the ability to work with local suppliers to minimize lead times. Ensuring that suppliers can meet stringent automotive standards is vital to avoid costly recalls and enhance vehicle safety.

What Role Does Custom Metal Play in Aerospace Applications?

Custom metal applications in the aerospace industry include precision machined parts, which are critical for aircraft safety and performance. These components must adhere to strict regulatory standards and undergo rigorous testing to ensure compliance. International B2B buyers from Europe and the Middle East should prioritize suppliers who provide traceability and material certification, as well as those capable of demonstrating advanced testing capabilities. The ability to source high-quality custom metal parts can significantly impact the safety and reliability of aerospace products.

How is Custom Metal Fabricated for Construction Projects?

In construction, custom metal fabrication is essential for creating structural steel elements that provide durability and design flexibility. Custom solutions can be tailored to meet specific load-bearing requirements, which is crucial for safety and compliance with local building codes. Buyers from regions such as South America and Africa should consider sourcing from local fabricators who understand regional regulations and can deliver projects on time. Additionally, evaluating the supplier’s capabilities in terms of design and fabrication technology can lead to more innovative and cost-effective construction solutions.

Why is Custom Metal Important in the Oil & Gas Sector?

The oil and gas industry requires custom piping and fittings that are specifically designed to withstand harsh environmental conditions and reduce the risk of leakage. These custom solutions are pivotal in enhancing operational efficiency and ensuring safety in extraction and transportation processes. For international buyers, especially in the Middle East, sourcing materials that meet corrosion resistance standards and international quality benchmarks is crucial. Engaging with suppliers who understand the unique challenges of the oil and gas sector can lead to better project outcomes and reduced maintenance costs.

How Does Custom Metal Enhance Electronics?

In the electronics industry, custom metal enclosures are used to improve thermal management and protect sensitive components from environmental factors. These enclosures must be designed with precision to ensure compatibility with various devices and to provide effective electromagnetic interference (EMI) shielding. For B2B buyers from Europe and South America, it is essential to source from manufacturers that can demonstrate capabilities in precision machining and have the necessary certifications for electronic components. This focus on quality can enhance product longevity and performance in the competitive electronics market.

Related Video: Forming Sheet Metal & Metal Forming Tools – Uses Explained By Gene Winfield at SEMA

3 Common User Pain Points for ‘metal custom’ & Their Solutions

Scenario 1: Inconsistent Quality Standards Across Regions

The Problem: B2B buyers in Africa and South America often face significant challenges related to inconsistent quality when sourcing custom metal components. Different manufacturers may adhere to varying standards, leading to discrepancies in product specifications, durability, and performance. This inconsistency can result in project delays, increased costs due to reworks, and ultimately, lost business opportunities. Buyers may find themselves caught in a cycle of trial and error as they attempt to identify reliable suppliers who can meet their quality expectations.

The Solution: To mitigate this issue, buyers should prioritize sourcing from manufacturers with internationally recognized certifications, such as ISO 9001, which ensures a consistent quality management system. Establishing a clear set of specifications and quality criteria before engaging with suppliers is essential. Additionally, consider conducting factory audits or requesting samples before placing large orders. Building strong relationships with suppliers can also help to create a dialogue about quality expectations and continuous improvement. By actively communicating and monitoring quality, buyers can significantly reduce the risks associated with inconsistent product standards.

Scenario 2: Complex Customization Needs and Communication Barriers

The Problem: Many B2B buyers encounter difficulties when trying to communicate their specific customization requirements for metal products. This is particularly true when dealing with suppliers in different time zones or cultural contexts, which can lead to misunderstandings and misaligned expectations. For instance, a buyer in Europe may require precise dimensions and tolerances for a custom part, but if these specifications are not clearly understood by a supplier in the Middle East, the resulting product may not fit properly, causing production delays.

The Solution: To overcome communication barriers, buyers should utilize advanced digital tools for clearer collaboration. Implementing a cloud-based project management system can facilitate real-time updates and direct communication with suppliers, allowing for immediate feedback on design specifications. Additionally, creating detailed visual aids, such as CAD drawings or 3D models, can enhance understanding and reduce ambiguity. Investing in a project manager or liaison familiar with both the technical and cultural aspects of the supplier’s region can further streamline the process and ensure that customization needs are met accurately.

Scenario 3: Navigating Import Regulations and Tariffs

The Problem: For B2B buyers, particularly those in South America and Africa, navigating the complexities of import regulations and tariffs when sourcing custom metal products can be daunting. Unexpected tariffs or customs regulations can significantly increase costs and delay delivery times, disrupting supply chains and leading to financial strain. Buyers may struggle to understand the legal requirements in their own countries as well as those in the exporting country, which can complicate the purchasing process.

The Solution: To effectively navigate these challenges, buyers should invest time in understanding the import regulations and tariffs specific to their region. Collaborating with logistics experts or customs brokers can provide valuable insights into current regulations and help streamline the import process. Additionally, maintaining open lines of communication with suppliers about their shipping practices and experiences can shed light on potential pitfalls and best practices. Buyers can also consider sourcing from manufacturers located within trade agreements or regions that offer tariff-free access to their markets, thus minimizing costs and simplifying logistics. By proactively managing these factors, buyers can enhance their overall sourcing strategy and ensure smoother operations.

Strategic Material Selection Guide for metal custom

What Are the Key Properties of Aluminum for Metal Custom Applications?

Aluminum is a lightweight metal known for its excellent corrosion resistance and high strength-to-weight ratio. It performs well under a range of temperatures, making it suitable for various applications, including aerospace and automotive components. Its ability to be easily fabricated and welded adds to its appeal in custom metal works.

Pros & Cons: The primary advantage of aluminum is its durability and resistance to corrosion, which makes it an ideal choice for outdoor applications. However, its relatively higher cost compared to other metals and lower tensile strength can be limitations in heavy-duty applications.

Impact on Application: Aluminum is compatible with many media, including water and chemicals, but it may not perform well in high-temperature environments. Buyers must consider the specific conditions under which the aluminum components will operate.

Considerations for International Buyers: For B2B buyers in Africa, South America, the Middle East, and Europe, it is crucial to ensure compliance with international standards such as ASTM and DIN when selecting aluminum. Local preferences may also dictate the choice of aluminum alloys, impacting sourcing and manufacturing decisions.

How Does Stainless Steel Compare for Metal Custom Solutions?

Stainless steel is renowned for its exceptional corrosion resistance and high strength, making it a versatile choice for various industries, including food processing, pharmaceuticals, and construction. It can withstand high temperatures and pressures, which is vital for applications involving steam or hot liquids.

Pros & Cons: The key advantage of stainless steel is its durability and ability to maintain structural integrity in harsh environments. However, the higher cost and complexity of fabrication can be significant drawbacks, especially for large-scale projects.

Impact on Application: Stainless steel is compatible with a wide range of media, including acids and alkalis, making it suitable for chemical processing applications. Its non-reactive nature is particularly beneficial in food and medical applications.

Considerations for International Buyers: Buyers must be aware of the various grades of stainless steel, such as 304 and 316, which have different properties and compliance requirements. Understanding local regulations and standards is essential for ensuring product quality and safety.

What Are the Benefits and Limitations of Carbon Steel in Custom Metal Work?

Carbon steel is a widely used material in custom metal applications due to its strength and affordability. It is suitable for structural applications and components requiring high tensile strength.

Pros & Cons: The main advantage of carbon steel is its low cost and ease of manufacturing. However, it is prone to corrosion and may require protective coatings, which can add to the overall cost and complexity of the project.

Impact on Application: Carbon steel is compatible with various media but may not be suitable for applications involving corrosive substances unless adequately treated.

Considerations for International Buyers: Buyers should be aware of the different grades of carbon steel and their respective properties, as well as the need for compliance with relevant standards. In regions like Africa and South America, local sourcing may also influence material choice.

Why Is Copper a Viable Option for Metal Custom Applications?

Copper is known for its excellent electrical conductivity and thermal properties, making it a preferred choice in electrical and plumbing applications. It also has inherent antimicrobial properties, which are beneficial in healthcare settings.

Pros & Cons: The key advantage of copper is its superior conductivity and resistance to corrosion, particularly in plumbing applications. However, its higher cost and susceptibility to oxidation can be limiting factors.

Impact on Application: Copper is compatible with water and various chemicals, making it ideal for plumbing and electrical applications. However, buyers must consider its performance in high-temperature environments.

Considerations for International Buyers: Compliance with international standards for copper products is essential, especially in applications like electrical wiring. Understanding local market preferences and availability can also impact sourcing decisions.

Summary Table of Material Selection for Metal Custom Applications

| Material | Typical Use Case for Metal Custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components, automotive parts | Lightweight and corrosion-resistant | Higher cost, lower tensile strength | Medium |

| Stainless Steel | Food processing, pharmaceuticals | Exceptional corrosion resistance | Higher cost, complex fabrication | High |

| Carbon Steel | Structural applications, heavy machinery | Low cost, high tensile strength | Prone to corrosion, requires treatment | Low |

| Copper | Electrical wiring, plumbing | Excellent conductivity and antimicrobial | Higher cost, oxidation susceptibility | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for metal custom

What Are the Main Stages of Manufacturing Processes for Metal Custom Products?

Understanding the manufacturing processes for metal custom products is crucial for international B2B buyers. The typical stages include material preparation, forming, assembly, and finishing. Each stage employs specific techniques that can significantly impact the final product’s quality and performance.

-

Material Preparation: The first stage involves selecting the right metal, which can include steel, aluminum, or specialized alloys. The chosen material is then cut, cleaned, and treated to remove impurities. Techniques like plasma cutting, laser cutting, and water jet cutting are commonly used. This stage sets the foundation for the overall quality of the final product.

-

Forming: During the forming stage, the prepared materials are shaped into the desired forms. This can be achieved through various techniques such as stamping, bending, and forging. Each technique has its advantages; for example, stamping is efficient for mass production, while forging enhances the material’s strength. Buyers should consider the forming method that aligns with their quality and budget requirements.

-

Assembly: This stage involves putting together the various components of the metal custom product. Techniques such as welding, riveting, and adhesive bonding are employed depending on the design specifications. It is crucial that the assembly is performed meticulously to ensure structural integrity and performance.

-

Finishing: The final stage includes processes like surface treatment, coating, and polishing. Finishing not only enhances the aesthetic appeal of the product but also protects it from corrosion and wear. Common finishing techniques include powder coating, anodizing, and electroplating. Buyers should inquire about the finishing processes to ensure they meet industry standards and customer expectations.

How Does Quality Assurance (QA) Fit into the Manufacturing Process?

Quality assurance is an integral part of the manufacturing process, ensuring that the final product meets both international and industry-specific standards. B2B buyers should be familiar with the various QA practices that suppliers implement.

-

International Standards: ISO 9001 is a widely recognized quality management standard that outlines requirements for establishing a quality management system. Compliance with ISO 9001 indicates that the manufacturer has a systematic approach to managing quality, which is crucial for B2B buyers looking for reliable suppliers.

-

Industry-Specific Standards: Depending on the application, other certifications may be relevant. For instance, CE marking is essential for products sold within the European Economic Area, while API (American Petroleum Institute) certification is critical for products used in the oil and gas industry. Buyers should confirm that their suppliers possess the necessary certifications relevant to their specific market.

What Are the Key Quality Control Checkpoints in Metal Custom Manufacturing?

Quality control (QC) checkpoints are vital for ensuring that products meet the required specifications throughout the manufacturing process. Common QC checkpoints include:

-

Incoming Quality Control (IQC): This initial inspection assesses the quality of raw materials before they enter the manufacturing process. Effective IQC can prevent defects from occurring later in production, saving time and resources.

-

In-Process Quality Control (IPQC): During production, IPQC involves continuous monitoring of the manufacturing processes to identify any deviations from established standards. Techniques such as statistical process control (SPC) can be employed to track performance and ensure consistency.

-

Final Quality Control (FQC): After the product is completed, FQC verifies that it meets all specifications and standards before delivery. This may include visual inspections, dimensional checks, and functional testing.

What Common Testing Methods Are Used in Quality Assurance for Metal Custom Products?

Testing is a critical component of quality assurance that helps verify the integrity and performance of metal custom products. Some common testing methods include:

- Mechanical Testing: This includes tensile testing, hardness testing, and impact testing to evaluate the material’s strength and durability.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, radiographic testing, and magnetic particle testing are used to detect internal flaws without damaging the product.

- Chemical Analysis: This ensures that the material composition meets specified requirements and standards.

B2B buyers should request detailed reports of these tests from suppliers to confirm compliance with quality standards.

How Can International B2B Buyers Verify Supplier Quality Control Practices?

Verifying a supplier’s quality control practices is essential for minimizing risks in the supply chain. Here are several strategies B2B buyers can use:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the supplier’s manufacturing processes and quality control systems. This firsthand observation can help establish trust and ensure adherence to quality standards.

-

Requesting Quality Reports: Buyers should ask for documentation such as quality assurance plans, inspection reports, and testing results. These documents provide insight into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased assessment of the supplier’s quality control practices. These inspections can be particularly useful for international transactions where buyers cannot physically visit the supplier’s facility.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

Navigating the quality control and certification landscape can be complex for international B2B buyers. Here are some nuances to consider:

- Regional Standards: Different regions may have specific quality standards that must be adhered to. For example, products exported to Europe must comply with EU regulations, while those sold in the Middle East may require adherence to local standards.

- Documentation Requirements: Buyers should be aware of the documentation needed for customs clearance and regulatory compliance. This may include certificates of conformity, test reports, and material safety data sheets (MSDS).

- Cultural Considerations: Understanding cultural differences in business practices can enhance communication and collaboration with suppliers. Buyers from Africa, South America, the Middle East, and Europe should approach negotiations with an awareness of these differences to foster productive relationships.

By understanding the manufacturing processes and quality assurance practices for metal custom products, B2B buyers can make informed decisions that lead to successful partnerships and high-quality outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metal custom’

Introduction

Sourcing custom metal products can be a complex process, especially for international B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe. This guide provides a step-by-step checklist to streamline your procurement process, ensuring you make informed decisions that align with your technical requirements and business objectives.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is the foundation of successful sourcing. Consider the materials, dimensions, tolerances, and finishes required for your custom metal products. Providing detailed specifications helps suppliers understand your needs and reduces the risk of miscommunication, ultimately leading to higher quality and satisfaction.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in custom metal fabrication. Utilize online platforms, trade shows, and industry directories to compile a list of candidates. Pay attention to their experience in your specific industry and their geographic location, as this can impact shipping times and costs.

Step 3: Evaluate Supplier Capabilities

Assess the capabilities of each supplier on your shortlist. Look for information on their machinery, technology, and workforce expertise. A supplier’s ability to meet your production volume and timelines is crucial. Additionally, check if they have experience with similar projects to ensure they can deliver on your specific requirements.

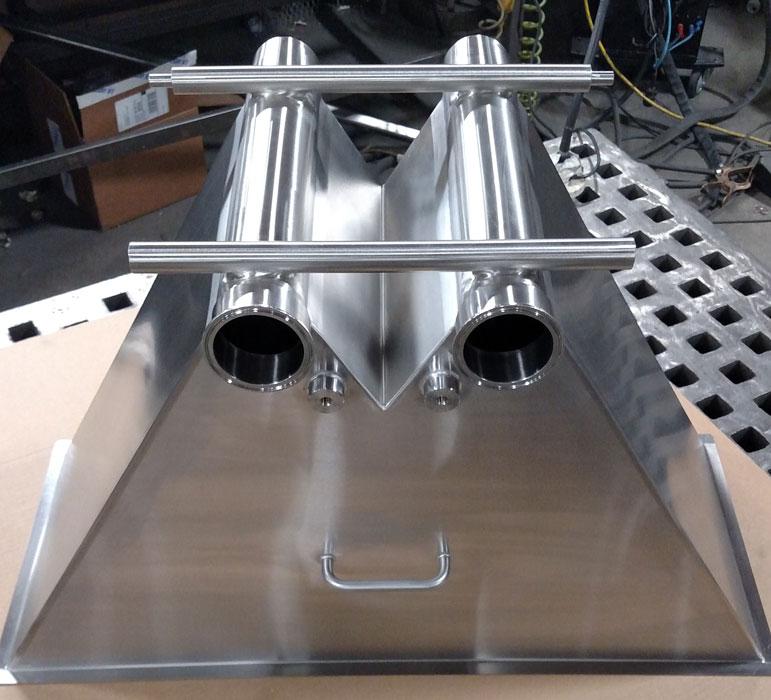

A stock image related to metal custom.

Step 4: ✅ Verify Supplier Certifications

A stock image related to metal custom.

Confirm that potential suppliers hold relevant certifications and standards that guarantee quality and compliance. Certifications such as ISO 9001 indicate a commitment to quality management systems. Understanding local regulations and industry standards can help you avoid legal issues and ensure product safety.

Step 5: Request Samples and Prototypes

Before finalizing a supplier, request samples or prototypes of their work. This step allows you to evaluate the quality of materials and craftsmanship. Inspect samples against your specifications and consider how they perform in real-world applications. This hands-on evaluation is critical for avoiding costly mistakes later on.

Step 6: Negotiate Terms and Pricing

Once you’ve identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Be transparent about your budget constraints but also focus on the value offered. A good negotiation ensures that both parties are satisfied and can lead to a long-term partnership.

Step 7: Establish a Clear Communication Plan

Effective communication is key to successful sourcing. Establish a clear communication plan that outlines points of contact, preferred communication methods, and frequency of updates. Regular check-ins and progress reports can help mitigate issues and ensure that your project stays on track.

By following this checklist, B2B buyers can navigate the complexities of sourcing custom metal products with confidence, ensuring a smoother process and better outcomes.

Comprehensive Cost and Pricing Analysis for metal custom Sourcing

What Are the Key Cost Components in Metal Custom Sourcing?

Understanding the cost structure is essential for international B2B buyers looking to source custom metal products. The primary cost components include:

-

Materials: The type of metal chosen significantly impacts pricing. For instance, stainless steel is generally more expensive than aluminum. Prices can also fluctuate based on global market trends and availability.

-

Labor: Labor costs vary by region and are influenced by the complexity of the custom metal work. Skilled labor in developed countries may command higher wages than in emerging markets, affecting the overall cost.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, rent, and equipment maintenance. Manufacturers with more advanced technology may have lower overhead per unit due to increased efficiency.

-

Tooling: Custom tooling can be a significant upfront investment, especially for unique designs. Buyers should inquire about tooling costs and whether they are included in the quoted price or charged separately.

-

Quality Control (QC): Implementing stringent QC processes can add to costs but ensures that the final product meets specifications and industry standards. This is especially important for buyers needing certifications.

-

Logistics: Transportation costs can vary widely based on distance, shipping method, and the Incoterms agreed upon. Understanding the full logistics chain is crucial for accurate pricing.

-

Margin: Suppliers will add a profit margin to cover their costs and ensure profitability. This margin can vary based on supplier reputation, relationship, and market competition.

How Do Price Influencers Affect Metal Custom Sourcing?

Several factors influence the final price of custom metal products:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) that align with their budget and needs.

-

Specifications and Customization: Unique specifications or complex designs usually incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher quality materials often come with a premium. Additionally, certifications (like ISO or ASTM) may require more rigorous testing, impacting the overall price.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, but they may also offer better quality assurance.

-

Incoterms: Different Incoterms dictate who is responsible for shipping, insurance, and duties. Selecting the right Incoterm can significantly affect total costs and risks.

What Are Effective Buyer Tips for Metal Custom Pricing Negotiation?

To maximize value in custom metal sourcing, international B2B buyers can adopt several strategies:

-

Negotiate Effectively: Understand the supplier’s cost structure and leverage this knowledge during negotiations. Be clear about your needs but also open to suggestions that could reduce costs.

-

Focus on Cost-Efficiency: Consider the Total Cost of Ownership (TCO) rather than just the purchase price. This includes maintenance, potential downtime, and logistics costs.

-

Understand Pricing Nuances: Be aware that prices can vary based on region, material availability, and market demand. Research local market conditions in Africa, South America, the Middle East, and Europe to make informed decisions.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and more favorable terms. Trust can also facilitate smoother negotiations and flexibility.

Disclaimer on Indicative Prices

Prices for custom metal sourcing can vary widely based on the aforementioned factors. Buyers are encouraged to obtain multiple quotes and perform thorough due diligence to ensure they are receiving competitive pricing that aligns with their specific requirements.

Alternatives Analysis: Comparing metal custom With Other Solutions

Understanding the Importance of Alternatives in Metal Custom Solutions

When considering metal custom solutions, it is essential for international B2B buyers to explore various alternatives that may meet their operational needs more effectively. Each solution has distinct advantages and disadvantages, which can significantly impact production efficiency, cost management, and overall project success. This section analyzes metal custom solutions against two viable alternatives: additive manufacturing and traditional machining.

Comparison Table of Metal Custom Solutions

| Comparison Aspect | Metal Custom | Additive Manufacturing | Traditional Machining |

|---|---|---|---|

| Performance | High precision and strength | Customization flexibility | Excellent surface finish |

| Cost | Moderate initial investment | Potentially higher material costs | Generally lower material costs |

| Ease of Implementation | Requires skilled labor | Requires specialized equipment | Widely available tools and skills |

| Maintenance | Low maintenance needs | Medium maintenance; technology dependent | High maintenance; wear and tear on tools |

| Best Use Case | Complex geometries and low-volume production | Prototyping and intricate designs | High-volume production and standard parts |

What Are the Advantages and Disadvantages of Additive Manufacturing?

Additive manufacturing, commonly known as 3D printing, offers significant customization capabilities, allowing businesses to produce complex parts that would be challenging with traditional methods. Its flexibility in design can lead to innovative solutions tailored specifically to client needs. However, the initial investment in advanced machinery can be high, and the cost of materials may exceed traditional methods, particularly for large-scale production. Additionally, while it excels in rapid prototyping, the speed of production for larger quantities may not be as efficient compared to traditional machining.

How Does Traditional Machining Compare to Metal Custom Solutions?

Traditional machining remains a staple in the manufacturing industry due to its cost-effectiveness and reliability for high-volume production runs. This method offers excellent surface finishes and is suitable for standard parts with well-defined geometries. However, it lacks the flexibility of metal custom solutions, especially for complex designs. Moreover, the maintenance of machining tools can be demanding, as they often require regular replacement and servicing due to wear and tear.

Conclusion: How Should B2B Buyers Choose the Right Solution?

For B2B buyers looking to select the right manufacturing solution, understanding the specific requirements of their projects is crucial. If the focus is on producing intricate designs with a need for customization, additive manufacturing may be the best route despite its higher costs. Conversely, for projects centered around high-volume production of standard components, traditional machining could provide a more economical choice. Metal custom solutions shine in scenarios where precision and unique geometries are required, making them ideal for specialized applications. Ultimately, evaluating the project’s scale, budget, and desired outcomes will guide buyers in making an informed decision.

Essential Technical Properties and Trade Terminology for metal custom

What Are the Key Technical Properties of Metal Customization?

When engaging in the metal customization industry, understanding critical technical properties is vital for B2B buyers. Here are some essential specifications to consider:

1. Material Grade

Material grade refers to the classification of metals based on their chemical composition and mechanical properties. This specification is crucial as it determines the metal’s strength, ductility, and corrosion resistance. For instance, stainless steel grades such as 304 and 316 are commonly used in various applications due to their excellent corrosion resistance. Buyers must select the appropriate grade that aligns with their project requirements to ensure durability and performance.

2. Tolerance

Tolerance is the permissible limit or limits of variation in a physical dimension. In metal customization, it signifies how much deviation is acceptable from the specified dimensions. Tight tolerances are essential for applications requiring precise fits, such as in machinery and aerospace components. Understanding tolerance levels helps buyers avoid costly mistakes and ensures compatibility among parts.

3. Surface Finish

Surface finish describes the texture and quality of the metal’s surface after processing. Common finishes include polished, anodized, or painted surfaces, each offering different aesthetic and functional benefits. A well-defined surface finish can enhance the metal’s resistance to wear and corrosion, making it a critical factor for buyers in industries like automotive or construction.

4. Yield Strength

Yield strength is the amount of stress at which a material begins to deform plastically. For B2B buyers, this property is essential when assessing a metal’s load-bearing capacity. Choosing metals with appropriate yield strength ensures that structures and components maintain integrity under operational stresses, thereby reducing the risk of failure.

5. Hardness

Hardness measures a material’s resistance to deformation or scratching. It is particularly important in applications where wear resistance is critical, such as tooling and machinery components. Buyers should consider hardness ratings to ensure that the chosen metal can withstand the intended use without excessive wear.

What Are the Common Trade Terminology Used in Metal Customization?

Familiarity with industry jargon can streamline communication and decision-making in metal customization. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the metal industry, understanding OEM relationships is vital for buyers looking for quality components that meet specific standards. Engaging with reputable OEMs can lead to reliable supply chains and quality assurance.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory management and cash flow. Understanding MOQs can help buyers negotiate better terms and avoid excess inventory costs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. It is a common practice in the B2B sector, allowing buyers to compare pricing and terms from multiple suppliers. A well-prepared RFQ can lead to better pricing and favorable terms for the buyer.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers. Understanding Incoterms is essential for B2B transactions as they dictate shipping responsibilities, insurance, and risk transfer. Familiarity with these terms can help buyers mitigate risks associated with international shipments.

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. It is a critical factor in supply chain management. Buyers should inquire about lead times to ensure that projects remain on schedule and avoid potential delays in production.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, streamline their procurement processes, and enhance their overall operational efficiency in the metal customization sector.

Navigating Market Dynamics and Sourcing Trends in the metal custom Sector

What Are the Key Market Dynamics and Trends in the Metal Custom Sector?

The metal custom sector is currently experiencing significant transformations driven by technological advancements, globalization, and evolving consumer demands. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for effective sourcing strategies. One notable trend is the increasing adoption of Industry 4.0 technologies, including automation and artificial intelligence, which enhance production efficiency and reduce lead times. These technologies facilitate real-time data analytics, allowing businesses to make informed decisions quickly.

Moreover, the rise of digital platforms and marketplaces is reshaping how buyers connect with suppliers. These platforms offer streamlined processes for procurement, enabling buyers to source materials and services from a global pool of providers. As a result, buyers can benefit from competitive pricing and enhanced product offerings. Additionally, sustainability is becoming a key consideration; companies that prioritize environmentally-friendly practices are gaining a competitive edge.

How Does Sustainability Influence Sourcing Decisions in the Metal Custom Sector?

The importance of sustainability and ethical sourcing in the metal custom sector cannot be overstated. International B2B buyers are increasingly aware of the environmental impacts associated with metal production, including carbon emissions and resource depletion. As a result, there is a growing demand for suppliers that adhere to sustainable practices and provide transparent supply chain information.

Ethical sourcing involves selecting suppliers who not only prioritize environmental considerations but also uphold labor rights and community welfare. Buyers should look for certifications such as ISO 14001 (Environmental Management) and Fair Trade, which can help verify the integrity of a supplier’s practices. Moreover, the use of “green” materials, such as recycled metals or sustainably sourced alloys, is becoming more prevalent. This not only reduces environmental impact but can also enhance a company’s brand reputation in the eyes of eco-conscious consumers.

How Has the Metal Custom Sector Evolved Over Time?

The evolution of the metal custom sector has been marked by significant technological advancements and shifts in market demands. Initially, the industry relied heavily on manual processes and traditional manufacturing techniques. However, the introduction of CNC (Computer Numerical Control) machinery and advanced fabrication technologies in the late 20th century revolutionized production capabilities, allowing for greater precision and efficiency.

In recent years, the focus has shifted towards customization and personalization in metal products, driven by consumer preferences for unique solutions. This trend has necessitated a more agile and responsive supply chain, enabling manufacturers to adapt quickly to changing market conditions. As international B2B buyers seek innovative solutions, understanding this evolution is vital for making strategic sourcing decisions in today’s competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of metal custom

-

How do I solve issues with quality control when sourcing metal custom?

To tackle quality control issues, it’s essential to implement a robust supplier vetting process. Start by requesting certifications such as ISO 9001, which indicates adherence to quality management standards. Additionally, consider conducting factory audits or requesting samples before placing large orders. Establish clear quality specifications and benchmarks in your contracts, and communicate regularly with your supplier to address any potential issues proactively. Building a strong relationship with your supplier can also facilitate better quality assurance practices. -

What is the best approach to find reliable suppliers for metal custom?

The best approach to finding reliable suppliers involves a multi-step process. Begin with online research through platforms like Alibaba, ThomasNet, or industry-specific directories. Attend trade shows and industry conferences to network with potential suppliers. Verify credentials by checking references and reviews from previous clients. Additionally, consider engaging third-party sourcing agents who have local expertise in regions such as Africa, South America, the Middle East, and Europe. This due diligence ensures you partner with a supplier that meets your quality and reliability standards. -

What are typical minimum order quantities (MOQs) for metal custom products?

Minimum order quantities (MOQs) for metal custom products can vary widely based on the supplier and the complexity of the design. Generally, MOQs can range from as low as 100 units to several thousand, especially for intricate custom pieces. When negotiating, discuss your specific needs and inquire if the supplier can accommodate smaller orders, particularly for prototypes or initial runs. Some suppliers may offer flexibility on MOQs in exchange for a higher price per unit or by bundling multiple products. -

What payment terms should I expect when sourcing metal custom?

Payment terms can significantly impact your cash flow and should be clearly defined before engaging in a contract. Common practices include a deposit upfront (typically 30-50%), with the balance due upon shipment or delivery. Some suppliers may offer credit terms based on your relationship and order history. It’s crucial to negotiate favorable terms that protect your financial interests while ensuring the supplier feels secure in the transaction. Always document payment terms in your purchase agreements to avoid misunderstandings. -

How can I ensure timely logistics and delivery when sourcing metal custom?

To ensure timely logistics and delivery, start by discussing lead times and shipping methods with your supplier upfront. Choose suppliers experienced in international shipping, particularly to your region, as they will understand local customs regulations. Utilize logistics providers that offer tracking systems to monitor your shipment. Establish contingency plans for potential delays, such as sourcing alternative suppliers or adjusting order quantities. Clear communication and planning are key to maintaining a smooth supply chain. -

What are the key factors to consider when customizing metal products?

When customizing metal products, consider factors such as material selection, design specifications, and production capabilities. Ensure the chosen materials meet your performance requirements, including durability and corrosion resistance. Collaborate closely with your supplier on design aspects to optimize manufacturability and cost-effectiveness. Also, consider the environmental impact of your choices, as sustainable practices can enhance your brand’s reputation. Lastly, ensure that the customization aligns with your end-use application to avoid costly revisions later. -

What international trade regulations should I be aware of when sourcing metal custom?

When sourcing metal custom products internationally, familiarize yourself with import/export regulations specific to both your country and the supplier’s country. Look into tariffs, duties, and compliance standards, such as REACH in Europe or similar regulations in other regions. It’s advisable to consult with customs brokers or legal experts to ensure compliance with all trade laws. Understanding these regulations will help you avoid delays and additional costs during shipping and ensure that your products meet necessary safety and quality standards. -

How can I assess the financial stability of a metal custom supplier?

To assess the financial stability of a potential supplier, request financial statements and credit reports, if available. Conduct background checks through industry databases or credit rating agencies to gain insights into their business history. Look for signs of a stable operation, such as a solid track record of fulfilling orders and positive customer feedback. Engaging in a direct conversation about their production capacity and future plans can also provide valuable insights into their stability and reliability as a partner.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for metal custom

As we draw conclusions on strategic sourcing in the metal custom sector, it is essential to emphasize the importance of a well-defined sourcing strategy. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, stand to benefit significantly from a strategic approach that prioritizes quality, cost-efficiency, and sustainability. By leveraging local suppliers alongside global partnerships, businesses can enhance their supply chain resilience and responsiveness to market fluctuations.

What are the key advantages of strategic sourcing for international buyers?

Strategic sourcing allows for better risk management, improved supplier relationships, and access to innovation. By focusing on long-term partnerships rather than transactional relationships, buyers can negotiate more favorable terms and foster collaboration that drives value creation.

How can buyers prepare for the future of metal custom sourcing?

Looking ahead, it is vital for B2B buyers to stay informed about emerging trends, including technological advancements and shifts in regulatory landscapes. Engaging in continuous market analysis and fostering open communication with suppliers will position businesses to adapt swiftly to changes.

In conclusion, the landscape of metal custom sourcing is evolving, and international buyers must embrace strategic sourcing as a crucial component of their procurement strategy. By doing so, they can unlock opportunities for growth and innovation. The time to act is now—invest in strategic sourcing to secure a competitive advantage in the global market.