Unlock Quality & Savings: Choosing a Business Card Manufacturer (2025)

Introduction: Navigating the Global Market for business card manufacturer

Navigating the global market for business card manufacturing can be a daunting task for B2B buyers, especially those located in diverse regions such as Africa, South America, the Middle East, and Europe. The challenge lies not just in finding a reliable supplier but also in understanding the various types of business cards available, their applications, and the nuances of pricing and quality assurance. This comprehensive guide is designed to empower international B2B buyers by providing critical insights into the sourcing process of business cards, covering everything from material selection to supplier vetting and cost considerations.

In this guide, you will explore the different types of business cards, including eco-friendly options and premium finishes, along with their specific uses across various industries. The importance of thorough supplier vetting cannot be overstated, as it directly impacts the quality of the final product. Additionally, we delve into cost analysis, helping you understand how to achieve the best value without compromising on quality.

By equipping you with actionable knowledge, this guide aims to facilitate informed purchasing decisions, ensuring that your organization can effectively represent itself in the global marketplace. Whether you are based in Germany, Spain, or any other region, the insights provided here will help streamline your procurement process and enhance your networking efforts.

Understanding business card manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Digital Business Card Printers | Fast turnaround, customizable designs, eco-friendly options | Startups, freelancers, small businesses | Pros: Quick production; Cons: Higher per-unit cost. |

| Offset Printing Manufacturers | High volume production, vibrant color quality, multiple finishes | Corporations, event planners, agencies | Pros: Cost-effective for large orders; Cons: Longer lead times. |

| Specialty Card Producers | Unique materials (e.g., metal, plastic), innovative designs | Luxury brands, tech companies, real estate | Pros: Stand out in competitive markets; Cons: Higher price point. |

| Online Printing Services | User-friendly platforms, bulk discounts, wide range of templates | E-commerce businesses, international buyers | Pros: Convenient; Cons: Quality can vary. |

| Local Print Shops | Personalized service, community engagement, fast local delivery | Local businesses, networking events | Pros: Supports local economy; Cons: Limited design options. |

What Are the Characteristics of Digital Business Card Printers?

Digital business card printers are renowned for their quick turnaround times and high customization capabilities. They often use eco-friendly materials, making them suitable for environmentally conscious businesses. Ideal for startups and freelancers, these printers allow for small runs without high setup costs. Buyers should consider the higher per-unit cost compared to bulk options, but the speed and flexibility can justify the investment for urgent needs.

How Do Offset Printing Manufacturers Operate?

Offset printing manufacturers are ideal for businesses needing high-volume production with vibrant color quality. They utilize a printing technique that transfers ink from a plate to a rubber blanket, ensuring consistent results across large batches. This method is particularly beneficial for corporations and event planners who require a polished look for extensive print runs. However, buyers should be aware of longer lead times and the need for larger orders to achieve cost-effectiveness.

What Makes Specialty Card Producers Unique?

Specialty card producers focus on unique materials such as metal or plastic, catering to businesses that want to make a bold statement. These cards are often used by luxury brands, tech companies, and real estate agents looking to differentiate themselves in competitive markets. While they offer innovative designs that can leave a lasting impression, the price point is typically higher, making them a significant investment for B2B buyers.

Why Choose Online Printing Services for Business Cards?

Online printing services offer a convenient solution for businesses, featuring user-friendly platforms and a wide variety of templates. They often provide bulk discounts, making them an attractive option for e-commerce businesses and international buyers. While the ease of use is a significant advantage, buyers should be cautious as the quality can vary between providers. It’s essential to read reviews and request samples before placing large orders.

What Are the Benefits of Local Print Shops?

Local print shops provide a personalized service that can cater to the specific needs of businesses, especially those engaged in community-based marketing. They offer fast local delivery and can often accommodate last-minute requests. This option is particularly beneficial for local businesses and networking events. However, buyers may find that local shops have limited design options compared to larger manufacturers, which could restrict creativity.

Key Industrial Applications of business card manufacturer

| Industry/Sector | Specific Application of Business Card Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Corporate Services | Networking Events and Conferences | Enhances professional image and facilitates connections | Quality of materials, design customization options |

| Technology | Product Launches and Trade Shows | Promotes brand visibility and product information | Speed of production, compliance with branding guidelines |

| Hospitality and Events | Business Partnerships and Client Introductions | Builds trust and establishes professional relationships | Eco-friendly materials, multilingual options |

| Financial Services | Client Meetings and Financial Consultations | Reinforces brand identity and professionalism | Security features, regulatory compliance |

| Education | Alumni Networking and Recruitment Drives | Strengthens institutional branding and alumni relations | Affordability, design options for diverse demographics |

How are Business Cards Used in Corporate Services?

In the corporate services sector, business cards are essential during networking events and conferences. They serve as a tangible representation of a professional’s identity, allowing for easy exchange of contact information. For international B2B buyers, sourcing high-quality cards is crucial as it reflects the brand’s professionalism. Buyers should consider customization options to align with their corporate branding and ensure the use of durable materials that withstand frequent handling.

What Role Do Business Cards Play in Technology?

For technology companies, business cards are pivotal during product launches and trade shows. They help convey essential product information while promoting brand visibility among potential clients and partners. Buyers in this sector should prioritize manufacturers that offer quick turnaround times to meet event deadlines and ensure compliance with specific branding guidelines. The ability to incorporate QR codes or augmented reality features can further enhance the card’s effectiveness in engaging tech-savvy audiences.

How Are Business Cards Valuable in Hospitality and Events?

In the hospitality and events industry, business cards are vital for establishing partnerships and client introductions. They foster trust and facilitate professional relationships, crucial for success in this competitive sector. International buyers should consider eco-friendly materials as sustainability is increasingly important to consumers. Additionally, offering multilingual card options can help cater to diverse clientele, enhancing communication and connection.

Why Are Business Cards Important in Financial Services?

In the financial services sector, business cards reinforce brand identity and professionalism during client meetings and consultations. They serve as a reminder of the service provider and can influence potential clients’ perceptions. Buyers in this field should seek cards with security features to protect sensitive information and ensure compliance with industry regulations. The choice of design should reflect the brand’s values and the trustworthiness expected in financial dealings.

How Do Business Cards Support Educational Institutions?

Educational institutions utilize business cards during alumni networking and recruitment drives to strengthen their branding and maintain relationships with former students. These cards help communicate the institution’s values and offerings effectively. When sourcing cards, buyers should focus on affordability without compromising quality, as they may require bulk orders. Design options should appeal to diverse demographics, catering to both current students and alumni.

Related Video: Business Finance: Sources and Uses of Funds

3 Common User Pain Points for ‘business card manufacturer’ & Their Solutions

Scenario 1: Difficulty in Achieving Desired Design Quality

The Problem: Many B2B buyers face challenges when trying to achieve the desired quality in the design and print of business cards. This often stems from miscommunication between the buyer and the manufacturer regarding design specifications, leading to a final product that does not align with the buyer’s expectations. Issues such as color fidelity, paper quality, and finishing options can result in business cards that appear unprofessional, which can negatively impact the company’s image.

The Solution: To ensure the final product meets your expectations, it is crucial to establish clear communication with the business card manufacturer from the outset. Start by providing detailed design specifications, including color codes (like Pantone), preferred paper weight, and finishing options (such as matte or glossy). Request physical samples before placing a bulk order to assess the quality firsthand. Additionally, consider using design software that allows you to create mockups, which can be shared with the manufacturer to ensure everyone is aligned on the expected outcome. Establishing a feedback loop where both parties can discuss adjustments will help in refining the design and ultimately lead to a high-quality final product.

Scenario 2: Long Lead Times Affecting Business Operations

The Problem: B2B buyers often encounter long lead times when ordering business cards, which can disrupt their operations and marketing initiatives. This is particularly problematic for businesses that require cards for upcoming events, meetings, or networking opportunities. Delays can arise from various factors, including production capacity, shipping logistics, and order volume.

The Solution: To mitigate lead time issues, it’s essential to plan ahead and establish a relationship with a reliable business card manufacturer. Discuss your timelines and deadlines upfront, and consider ordering in bulk during quieter periods to avoid rush charges and ensure availability. Additionally, inquire about expedited production options and shipping services that the manufacturer may offer. Implementing an inventory management strategy can also help by keeping a stock of business cards on hand, reducing the need for last-minute orders and ensuring you are always prepared for networking opportunities.

Scenario 3: Limited Customization Options Leading to Generic Products

The Problem: Many manufacturers offer limited customization options, which can lead to generic-looking business cards that fail to represent the unique identity of a company. This is especially concerning for businesses in competitive industries where standing out is crucial. Buyers may find that the standard templates available do not align with their branding, making it challenging to convey their message effectively.

The Solution: To address this issue, seek out manufacturers that specialize in custom solutions and are open to collaborating on unique designs. When discussing your project, emphasize the importance of brand identity and express your desire for a tailored approach. Provide examples of designs you admire and be clear about your brand’s color palette, logo usage, and typography preferences. Additionally, consider engaging a graphic designer to help create a bespoke design that reflects your brand’s ethos. This investment can yield business cards that not only look professional but also resonate with your target audience, thereby enhancing your brand’s visibility and memorability in the market.

Strategic Material Selection Guide for business card manufacturer

When selecting materials for business cards, manufacturers must consider various properties and characteristics that impact performance, durability, and cost. Below, we analyze four common materials used in the production of business cards, providing insights tailored for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe.

What are the Key Properties of Paper Business Cards?

Paper is the most traditional and widely used material for business cards. It typically comes in various weights and finishes, influencing the tactile experience and visual appeal.

- Key Properties: Paper cards can range from 200 to 400 gsm (grams per square meter), affecting their sturdiness. They are generally not waterproof but can be treated with coatings for added durability.

- Pros & Cons: Paper cards are cost-effective and easy to print on, allowing for vibrant colors and intricate designs. However, they are less durable than plastic or metal options and may bend or tear easily.

- Impact on Application: Paper is suitable for standard printing processes and can easily be customized. However, exposure to moisture can lead to damage, making them less ideal in humid climates.

- Considerations for International Buyers: Compliance with local standards (e.g., ISO 9001 for quality management) is essential. Buyers should also consider regional preferences for card weight and finish, which can vary significantly.

How Do Plastic Business Cards Compare?

Plastic cards have gained popularity due to their durability and modern appeal.

- Key Properties: Made from PVC or PET, plastic cards are waterproof, tear-resistant, and can withstand various environmental conditions. They can be produced in thicknesses similar to credit cards.

- Pros & Cons: The main advantage of plastic cards is their longevity and resistance to wear. However, they are more expensive to produce and may require specialized printing techniques.

- Impact on Application: Plastic cards are ideal for businesses that require a premium look and feel, especially in sectors like hospitality or luxury goods. They can also be used for loyalty programs or membership cards.

- Considerations for International Buyers: Buyers must be aware of recycling regulations and environmental impact, especially in regions with strict sustainability policies. Compliance with ASTM standards for plastics can also be a consideration.

What Advantages Do Metal Business Cards Offer?

Metal cards are a niche option that provides a unique aesthetic and tactile experience.

- Key Properties: Typically made from stainless steel or aluminum, metal cards are incredibly durable and resistant to bending or tearing. They can also be finished with various coatings for aesthetic appeal.

- Pros & Cons: The primary advantage is their premium feel and durability, making them suitable for high-end branding. However, they are significantly more expensive and heavier than paper or plastic cards.

- Impact on Application: Metal cards are often used in industries where a strong first impression is crucial, such as finance or luxury brands. They can be engraved or printed, but the process is more complex.

- Considerations for International Buyers: Buyers should consider the weight and shipping costs associated with metal cards. Additionally, they must ensure compliance with relevant metalworking standards in their respective regions.

What Makes Eco-Friendly Materials Important for Business Cards?

Eco-friendly materials, such as recycled paper or biodegradable plastics, are becoming increasingly important in the business card industry.

- Key Properties: These materials are designed to minimize environmental impact, often using sustainable sourcing and production methods.

- Pros & Cons: The advantage of eco-friendly cards lies in their appeal to environmentally conscious consumers. However, they may not always offer the same durability as traditional materials.

- Impact on Application: Eco-friendly cards are suitable for businesses that prioritize sustainability in their branding. They can enhance a company’s image and attract like-minded customers.

- Considerations for International Buyers: Buyers should verify certifications such as FSC (Forest Stewardship Council) for paper products or compliance with local environmental regulations.

Summary Table of Material Selection for Business Cards

| Material | Typical Use Case for Business Card Manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Paper | General business use, networking events | Cost-effective and customizable | Less durable, susceptible to damage | Low |

| Plastic | Premium branding, loyalty cards | Durable and waterproof | Higher production cost | Medium |

| Metal | High-end branding, finance sectors | Unique aesthetic and durability | Expensive and heavier | High |

| Eco-Friendly | Sustainable brands, environmentally conscious | Appeals to eco-conscious consumers | May lack durability | Medium |

This strategic material selection guide provides a comprehensive overview for B2B buyers, enabling informed decisions that align with their branding and operational needs.

In-depth Look: Manufacturing Processes and Quality Assurance for business card manufacturer

What Are the Main Stages in the Manufacturing Process of Business Cards?

Manufacturing business cards involves several critical stages, each designed to ensure high-quality final products that meet client specifications. Understanding these stages can help B2B buyers make informed decisions when sourcing from manufacturers.

1. Material Preparation: What Materials Are Used for Business Cards?

The journey of a business card begins with selecting the right materials. Common materials include:

- Paper Stock: The most prevalent choice, ranging from standard cardstock to premium options like linen or textured finishes. The weight of the paper (measured in grams per square meter, or GSM) significantly influences the card’s durability and feel.

- Plastic: For more durable cards, some manufacturers offer options like PVC or PET, which are waterproof and tear-resistant.

- Specialty Materials: Other materials, such as metal or wood, may be used for unique branding needs.

The preparation stage involves cutting the material to the required dimensions and ensuring it is free from defects. This step is crucial as it sets the foundation for the card’s overall quality.

2. Forming: How Are Business Cards Shaped and Printed?

Once the materials are prepared, the next step is forming. This includes the actual printing and shaping of the business cards:

- Printing Techniques:

- Digital Printing: Ideal for short runs and customization, this method allows for quick turnaround times and vibrant colors.

- Offset Printing: More suitable for larger quantities, offset printing provides superior quality and color accuracy but requires longer setup times.

-

Screen Printing: Often used for specialty inks or finishes, screen printing allows for unique textures or effects.

-

Die-Cutting: After printing, cards are often die-cut to achieve specific shapes or rounded corners, enhancing their visual appeal.

3. Assembly: What Does the Assembly Process Involve?

In many cases, business cards require assembly, especially when additional elements are involved, such as:

- Foil Stamping: Adding a metallic finish to enhance branding.

- Embossing/Debossing: Creating a raised or recessed effect for added texture.

- Lamination: Coating cards in a protective layer to improve durability and provide a glossy or matte finish.

Each assembly technique adds to the card’s uniqueness and can significantly impact the overall perception of the brand.

4. Finishing: How Does the Finishing Process Enhance Quality?

Finishing is the final touch that ensures business cards are ready for distribution. This stage may include:

- Cutting and Trimming: Ensuring all cards are uniform in size and free from any excess material.

- Quality Checks: Conducting final inspections to catch any printing errors, misalignments, or defects before packaging.

A robust finishing process not only ensures aesthetic quality but also prepares the cards for safe handling and shipping.

What Quality Assurance Practices Should B2B Buyers Expect?

Quality assurance (QA) is essential in the business card manufacturing process to ensure that the final product meets international standards and client expectations. Here’s a detailed look at QA practices that B2B buyers should consider.

Relevant International Standards: Which Certifications Should You Look For?

B2B buyers should be aware of international standards that guarantee product quality and reliability. Key certifications include:

- ISO 9001: This standard focuses on quality management systems, emphasizing customer satisfaction and continuous improvement.

- CE Marking: Particularly relevant for products that may come into contact with consumers, ensuring compliance with health, safety, and environmental protection standards.

Understanding these certifications can provide buyers with confidence in a manufacturer’s commitment to quality.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints throughout the manufacturing process are critical to ensuring product integrity. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to verify that they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing to catch defects early in the process.

- Final Quality Control (FQC): A thorough inspection of finished products before they are packaged and shipped, ensuring that they meet all specifications.

These checkpoints help in identifying issues at various stages, reducing waste and ensuring high-quality output.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control practices of potential suppliers:

- Audits: Conducting on-site audits to evaluate a manufacturer’s processes, quality control systems, and adherence to international standards.

- Requesting Reports: Asking for quality assurance reports that detail testing results and quality metrics.

- Third-Party Inspections: Engaging independent inspection agencies to assess product quality before shipment. This is especially vital for buyers in Africa, South America, the Middle East, and Europe, where local regulations may vary.

What Are Common Testing Methods in Quality Assurance?

Testing methods are integral to the quality assurance process, ensuring that business cards meet durability and aesthetic standards. Common methods include:

- Print Quality Tests: Evaluating color accuracy, alignment, and clarity of print.

- Durability Tests: Assessing how well cards withstand bending, tearing, or exposure to moisture.

- Adhesion Tests: For laminated cards, testing how well the laminate adheres to the card material.

These tests help manufacturers identify potential weaknesses and ensure that the final product meets customer expectations.

Conclusion: How Can Buyers Ensure Quality in Business Card Manufacturing?

When sourcing business cards from manufacturers, B2B buyers must prioritize understanding the manufacturing processes and quality assurance practices in place. By focusing on material selection, manufacturing stages, and rigorous quality control, buyers can ensure they receive high-quality products that effectively represent their brand. Engaging in due diligence through audits and requiring certifications will further guarantee that suppliers maintain the highest standards, ultimately leading to successful business partnerships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘business card manufacturer’

In the competitive landscape of business card manufacturing, international B2B buyers must approach sourcing with a structured strategy. This guide serves as a practical checklist to help you navigate the procurement process effectively, ensuring that you find the right manufacturer that meets your specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for aligning your needs with a manufacturer’s capabilities. Consider aspects such as size, material (e.g., paper quality, plastic, or metal), finish (matte or glossy), and printing technology (digital or offset). This clarity will help you communicate effectively with potential suppliers and ensure that the end product meets your standards.

Step 2: Research Potential Suppliers

A thorough research phase is essential to identify credible business card manufacturers. Utilize online platforms, industry directories, and trade shows to compile a list of potential suppliers. Pay attention to their experience in your specific market and geographic region, as this can influence their understanding of local trends and preferences.

Step 3: Evaluate Supplier Certifications

Before proceeding with a supplier, verify their certifications and compliance with industry standards. Look for certifications such as ISO 9001 for quality management and environmental certifications like ISO 14001. These credentials indicate a commitment to quality and sustainability, which can be particularly important for buyers from regions like Europe, where regulatory compliance is stringent.

Step 4: Request Samples

Once you have narrowed down your options, request samples of their previous work. This will give you a tangible sense of the quality of their products. Evaluate the samples based on print quality, durability, and adherence to your specifications. This step helps mitigate risks associated with final product quality.

Step 5: Assess Production Capacity and Lead Times

Understanding a manufacturer’s production capacity and lead times is crucial for meeting your business timelines. Inquire about their average production times for various order sizes and their ability to handle bulk orders. This information will help you plan your inventory and ensure timely delivery to your clients.

Step 6: Negotiate Pricing and Payment Terms

Pricing is always a critical factor in any B2B transaction. Engage in negotiations to secure competitive pricing while ensuring that quality is not compromised. Additionally, clarify payment terms, including deposit requirements and payment methods. This transparency can prevent misunderstandings later in the process.

Step 7: Establish Communication Channels

Effective communication is key to a successful partnership with your chosen manufacturer. Set up clear channels for ongoing communication, whether through email, phone, or a project management tool. Regular updates and feedback loops will help you address any issues quickly and keep the project on track.

By following these steps, international B2B buyers can streamline their sourcing process for business card manufacturers, ultimately leading to a more efficient procurement experience and higher-quality end products.

Comprehensive Cost and Pricing Analysis for business card manufacturer Sourcing

Understanding the cost structure and pricing dynamics of business card manufacturing is crucial for international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe. This guide provides a comprehensive analysis of the various cost components and factors influencing pricing, along with actionable insights to enhance purchasing decisions.

What are the Key Cost Components in Business Card Manufacturing?

-

Materials: The primary materials used in business card production include paper stock, inks, and finishes. The choice of paper—ranging from standard cardstock to premium textured or recycled options—significantly affects the overall cost. Buyers should evaluate the long-term benefits of higher-quality materials against immediate budget constraints.

-

Labor: Labor costs encompass the wages of skilled workers involved in design, production, and finishing processes. In regions with higher labor costs, such as Europe, buyers may experience elevated prices. Conversely, sourcing from countries with lower labor rates can provide cost savings, but may compromise quality if not managed correctly.

-

Manufacturing Overhead: This includes the indirect costs associated with production, such as utilities, rent, and equipment maintenance. Overhead can vary significantly depending on the manufacturer’s location and operational efficiency. Buyers should inquire about these costs to understand their impact on pricing.

-

Tooling: Custom tooling or dies are often necessary for unique card shapes or designs. This one-time cost can be substantial, so buyers should consider the potential for long-term savings through bulk orders or repeat business.

-

Quality Control (QC): Ensuring high-quality output is crucial in business card manufacturing. QC processes may add to costs but are essential for maintaining brand reputation. Buyers should seek manufacturers with robust QC practices to minimize errors and reprints.

-

Logistics: Transportation and shipping costs can fluctuate based on the distance and shipping method selected. Understanding the logistics involved, including Incoterms, is vital to accurately assess total costs.

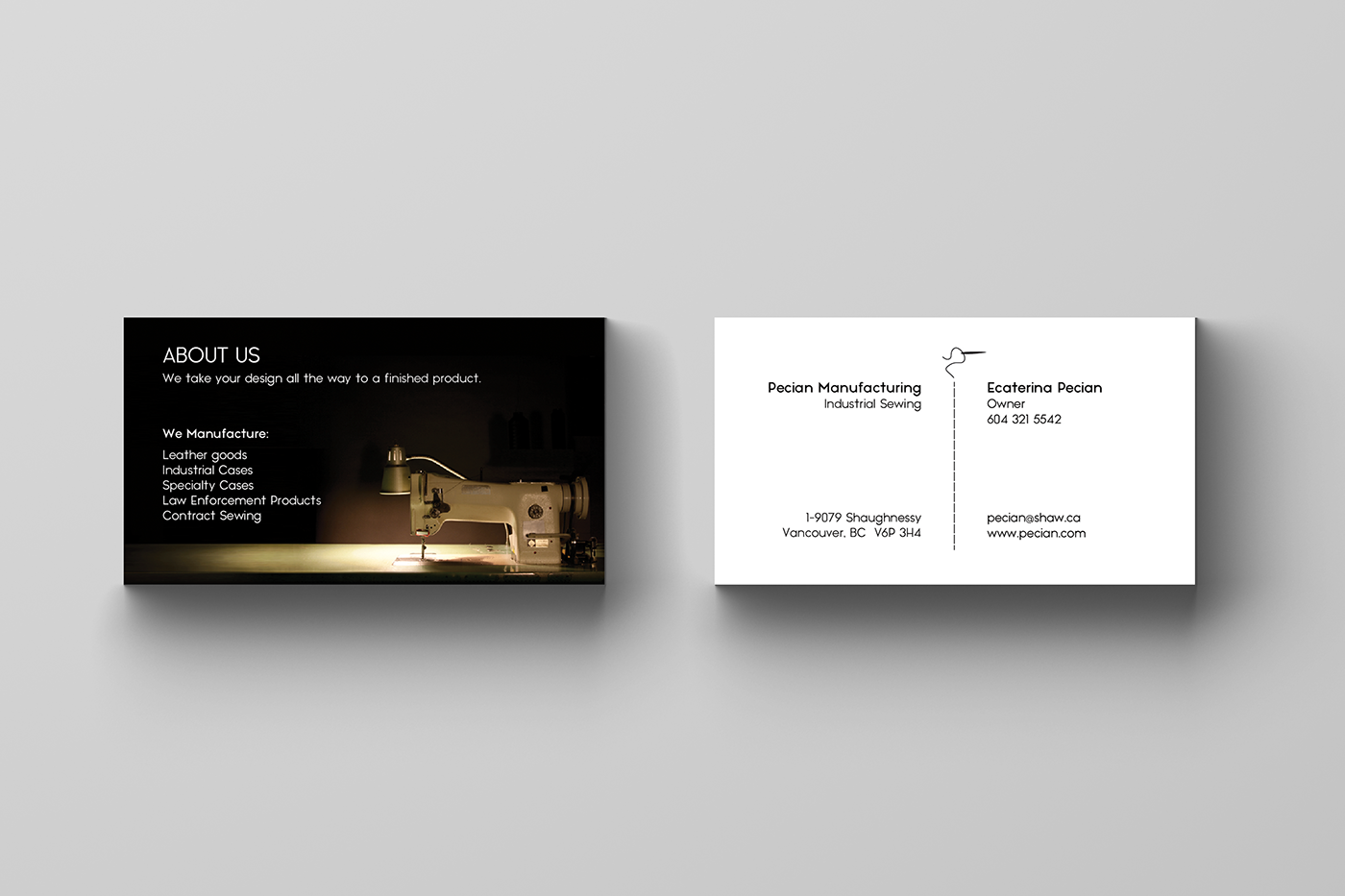

A stock image related to business card manufacturer.

- Margin: Manufacturers typically include a profit margin in their pricing structure, influenced by market competition and perceived value. Buyers should be prepared to negotiate to achieve a favorable price while ensuring quality.

How Do Price Influencers Affect Business Card Sourcing?

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often attract discounts. Buyers should evaluate their needs to find the right balance between quantity and cost savings.

-

Specifications and Customization: Customized designs, unique finishes, and special requests can elevate costs. When sourcing, consider whether such specifications are essential or if standard options suffice.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., FSC certified paper) can increase costs but may offer additional benefits in terms of sustainability and durability.

-

Supplier Factors: The manufacturer’s reputation, experience, and service level can influence pricing. Established suppliers may charge more due to their reliability and quality assurance.

-

Incoterms: Understanding the terms of shipping and delivery is crucial. Different Incoterms can affect the final cost, including who bears the risk and cost at various points in the supply chain.

What Buyer Tips Can Help Optimize Costs?

-

Negotiate Effectively: Always enter negotiations with clear benchmarks of pricing based on market research. Be open to discussing bulk orders or long-term contracts for better rates.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the costs associated with shipping, storage, and potential reprints. A slightly higher upfront cost for quality may lead to lower TCO in the long run.

-

Stay Informed on Pricing Nuances: International buyers should be aware of currency fluctuations and local economic factors that can affect pricing. Engaging with local representatives or experts can provide insights into market trends.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Regular communication and feedback can foster loyalty and mutual benefit.

Conclusion

Navigating the complexities of business card manufacturing costs requires a strategic approach. By understanding the key cost components, price influencers, and leveraging effective negotiation strategies, international B2B buyers can optimize their sourcing decisions. Always remember to account for the total cost of ownership to ensure the best value for your investment.

Alternatives Analysis: Comparing business card manufacturer With Other Solutions

When considering the best way to obtain business cards, B2B buyers have several options beyond traditional business card manufacturers. It’s crucial to evaluate these alternatives based on factors such as performance, cost, ease of implementation, maintenance, and best use cases. Below is a comparison of business card manufacturers against two viable alternatives: digital business card solutions and print-on-demand services.

| Comparison Aspect | Business Card Manufacturer | Digital Business Card Solutions | Print-on-Demand Services |

|---|---|---|---|

| Performance | High-quality, physical cards tailored to brand specifications. | Instant sharing and easy updates, but lacks physical presence. | Good quality, but dependent on the supplier’s technology and materials. |

| Cost | Typically higher initial investment due to bulk printing. | Lower cost, often subscription-based or pay-per-use. | Variable costs; often more affordable for low quantities. |

| Ease of Implementation | Requires design and printing setup, which can be time-consuming. | Simple app or platform usage with minimal setup. | User-friendly online platforms, but may require design skills. |

| Maintenance | Low maintenance once printed; cards can be stored and used as needed. | Regular updates needed to keep information current. | Limited maintenance; cards are printed as needed. |

| Best Use Case | Ideal for networking events and formal business interactions. | Best for tech-savvy individuals and those who frequently update contact details. | Suitable for small businesses or startups needing flexibility in order quantities. |

What Are the Benefits and Drawbacks of Digital Business Card Solutions?

A stock image related to business card manufacturer.

Digital business card solutions, such as apps and online platforms, allow users to create and share contact information via smartphones or email. The primary advantage of digital cards is their convenience; users can update their information in real-time and share it instantly. However, the lack of a physical presence can hinder networking opportunities, as traditional business cards often leave a more lasting impression. Digital cards may also require users to have a smartphone or access to technology, which could limit their reach in regions with lower tech adoption.

How Do Print-on-Demand Services Compare to Traditional Manufacturing?

Print-on-demand services offer flexibility, allowing businesses to print cards only as needed. This can be cost-effective for companies that do not require large quantities of cards at once. The process typically involves using an online platform where users can design their cards and order them in small batches. However, the quality can vary significantly based on the provider, and turnaround times may be longer compared to traditional manufacturing, which can be a disadvantage for urgent needs.

Conclusion: How Should B2B Buyers Choose the Right Solution for Their Needs?

When selecting the right solution for business cards, B2B buyers should carefully consider their specific needs, including the intended use of the cards, budget constraints, and the importance of physical versus digital presence. For formal networking events or client meetings, investing in high-quality printed cards from a manufacturer may be worthwhile. Conversely, tech-savvy buyers looking for flexibility and frequent updates may find digital solutions more appealing. Print-on-demand services can serve as a middle ground, offering a balance of quality and cost-effectiveness for smaller businesses or those with fluctuating needs. Ultimately, aligning the chosen solution with the company’s branding strategy and operational requirements will lead to the best outcomes.

Essential Technical Properties and Trade Terminology for business card manufacturer

What Are the Essential Technical Properties for Business Card Manufacturing?

When selecting a business card manufacturer, understanding the technical properties of business cards is crucial. Here are some key specifications that B2B buyers should consider:

-

Material Grade

The quality of the card material is paramount. Common options include cardstock, plastic, and recycled materials. Cardstock typically ranges from 300 to 400 gsm (grams per square meter), with higher gsm indicating thicker, more durable cards. Choosing the right material affects not only the card’s appearance but also its longevity, making it essential for maintaining a professional image. -

Finish Type

The finish of a business card can significantly influence its tactile and visual appeal. Options include matte, glossy, or uncoated finishes. A matte finish offers a sophisticated look and is easier to write on, while glossy finishes enhance color vibrancy but can smudge easily. Understanding the intended use of the card can guide the selection of the appropriate finish. -

Tolerance

Tolerance refers to the acceptable variation in dimensions during the manufacturing process. For business cards, typical tolerances might be ±0.5 mm. Proper tolerance ensures uniformity across batches, which is critical for branding consistency. Buyers should confirm that their manufacturer adheres to these tolerances to avoid inconsistencies in card sizes. -

Printing Technology

Different printing technologies, such as offset, digital, or letterpress, yield varying results in color fidelity and texture. Offset printing is ideal for large runs and offers high-quality color reproduction, while digital printing is more flexible for smaller quantities. Understanding the printing method can help in selecting a manufacturer who meets specific quality requirements.

-

Coating Options

Coatings such as UV coating, aqueous coating, or lamination provide additional protection and enhance the card’s visual appeal. UV coatings add gloss and durability, while aqueous coatings are more environmentally friendly. Buyers should consider the intended usage of the cards when selecting coatings, as these factors can affect durability and appearance. -

Customization Capabilities

The ability to customize cards—through die-cut shapes, embossing, or foil stamping—can differentiate a brand in a competitive market. Ensuring that a manufacturer can meet specific customization needs is essential for creating unique, impactful business cards.

What Trade Terminology Should B2B Buyers Understand in Business Card Manufacturing?

Familiarity with industry jargon can streamline communication and negotiation with manufacturers. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

An OEM produces goods that are branded and sold by another company. In the context of business cards, it refers to manufacturers that produce cards based on the specifications provided by the buyer. Understanding OEM relationships can help buyers assess quality control and production standards. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of products a manufacturer is willing to produce. This term is vital for budgeting and inventory planning, as some manufacturers may require orders of hundreds or thousands of cards to ensure profitability. -

RFQ (Request for Quotation)

An RFQ is a document sent to manufacturers to solicit pricing and terms for a specific order. It typically outlines the required specifications, quantities, and deadlines. Properly crafting an RFQ can lead to better pricing and terms, making it a critical step in the purchasing process. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can clarify shipping costs and liability, helping to avoid misunderstandings in cross-border purchases. -

Lead Time

Lead time is the duration from placing an order to receiving the finished product. It is crucial for planning marketing strategies and inventory management. Buyers should inquire about lead times during negotiations to ensure they meet deadlines. -

Proofing

Proofing is the process of reviewing a sample of the business card before full production. This step is essential for identifying any design issues or errors in printing. Buyers should insist on proofing to ensure the final product meets their expectations.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when selecting a business card manufacturer, ensuring quality, cost-effectiveness, and brand alignment.

Navigating Market Dynamics and Sourcing Trends in the business card manufacturer Sector

What Are the Current Market Dynamics and Sourcing Trends in the Business Card Manufacturing Sector?

The global business card manufacturing sector is experiencing significant shifts influenced by technological advancements and changing consumer preferences. Key drivers include the rise of digital networking platforms, which has led to a decline in traditional business card usage. However, the demand for high-quality, aesthetically appealing cards remains robust, particularly in regions like Europe and the Middle East, where networking events continue to thrive.

Emerging technologies, such as digital printing and eco-friendly materials, are transforming the manufacturing process, allowing for shorter production runs and more customization options. B2B buyers from Africa, South America, and Europe are increasingly seeking suppliers who can offer quick turnaround times and the flexibility to adapt designs for specific markets. Additionally, advancements in e-commerce platforms have made it easier for international buyers to source business cards from manufacturers across the globe, facilitating competitive pricing and a broader range of options.

How Is Sustainability and Ethical Sourcing Impacting the Business Card Manufacturer Sector?

Sustainability has become a cornerstone of modern sourcing strategies in the business card manufacturing sector. The environmental impact of traditional printing processes and materials is prompting international buyers to prioritize ethical sourcing practices. This includes selecting suppliers who utilize recycled paper, soy-based inks, and sustainable production methods.

Certifications such as FSC (Forest Stewardship Council) and SFI (Sustainable Forestry Initiative) are now critical for manufacturers looking to appeal to eco-conscious clients. B2B buyers are increasingly scrutinizing their supply chains, ensuring that their vendors adhere to ethical practices that mitigate environmental harm. This trend is particularly strong in Europe, where regulations surrounding sustainability are becoming more stringent. By aligning with manufacturers who prioritize sustainability, companies not only reduce their ecological footprint but also enhance their brand image in a market that values corporate social responsibility.

What Is the Brief Evolution of the Business Card Manufacturing Sector?

The business card manufacturing sector has evolved significantly over the past few decades. Initially dominated by traditional printing techniques, the industry saw a shift towards digital printing in the late 1990s, which revolutionized the production process. This transition allowed for greater customization, faster turnaround times, and more cost-effective solutions for small and medium-sized enterprises.

In recent years, the rise of e-commerce has further transformed the landscape, enabling businesses to order cards online with ease. Additionally, the focus on sustainability has prompted manufacturers to innovate with eco-friendly materials and processes. As digital networking becomes more prevalent, the role of business cards is also shifting, necessitating ongoing adaptation from manufacturers to meet the changing demands of international B2B buyers.

This evolution underscores the importance of staying informed about market dynamics and sourcing trends, enabling buyers to make strategic decisions that align with their business goals and values.

Frequently Asked Questions (FAQs) for B2B Buyers of business card manufacturer

-

How do I choose the right business card manufacturer for my needs?

Choosing the right business card manufacturer involves evaluating several factors. Start by assessing the manufacturer’s portfolio to ensure they have experience with designs similar to what you envision. Check for customization options, as unique branding elements are crucial for your business. Additionally, consider their production capabilities, turnaround times, and minimum order quantities (MOQs). Reading reviews and seeking recommendations from other businesses can provide insights into reliability and quality. Lastly, verify their compliance with international trade standards, especially if you are importing from regions like Asia or Europe. -

What are the typical minimum order quantities (MOQs) for business cards?

Minimum order quantities (MOQs) for business cards can vary widely among manufacturers, typically ranging from 100 to 1,000 cards. Some manufacturers may offer smaller runs for a higher price per card, which can be beneficial for startups or businesses needing low quantities. However, larger orders usually reduce the per-unit cost, making it economical for established companies. When sourcing, inquire about pricing tiers based on quantity to find the best fit for your budget and needs. -

What customization options should I look for in a business card manufacturer?

When sourcing a business card manufacturer, look for a variety of customization options that align with your brand identity. This includes choices in card stock, finishes (such as matte, glossy, or textured), sizes, and shapes. Additionally, consider whether they offer design services or templates that can aid in your creative process. The ability to incorporate unique features like embossing, foil stamping, or QR codes can enhance the card’s appeal. Ensure that the manufacturer can accommodate your specific branding requirements to create a lasting impression. -

What payment terms are commonly offered by business card manufacturers?

Payment terms for business card manufacturers often include options like full payment upfront, a deposit with the balance due upon completion, or payment upon delivery. Terms can vary based on the manufacturer’s policies and your relationship with them. For international buyers, understanding the currency exchange rates and potential transaction fees is crucial. It’s advisable to negotiate terms that provide a balance of security for both parties, ensuring you receive quality products while maintaining cash flow. -

How do I ensure quality assurance in business card manufacturing?

To ensure quality assurance in business card manufacturing, request samples before placing a large order. This allows you to evaluate the print quality, materials, and overall finish. Additionally, inquire about the manufacturer’s quality control processes, such as regular inspections and adherence to international standards. Establishing clear communication regarding your specifications and expectations can help mitigate issues. If possible, choose manufacturers with certifications, such as ISO, which indicate a commitment to quality management practices. -

What logistics considerations should I keep in mind when ordering business cards internationally?

When ordering business cards internationally, logistics play a crucial role in the timeline and cost of your order. Consider shipping methods, as air freight is faster but more expensive than sea freight. Understand the import regulations and customs duties applicable to your country to avoid unexpected charges. It’s also beneficial to discuss delivery timelines with your manufacturer to ensure that your order arrives on schedule. Lastly, consider partnering with logistics companies that specialize in international shipping to streamline the process. -

How do I vet potential business card suppliers?

Vetting potential business card suppliers involves several steps. Start by researching their reputation online, checking reviews and testimonials from previous clients. Request references to gain insights into their reliability and service quality. Evaluate their production capabilities, including machinery and technology, to ensure they can meet your specific needs. Additionally, assess their communication responsiveness and willingness to accommodate your requirements. Engaging in a trial order can also provide a practical assessment of their services. -

What factors influence the cost of business cards?

The cost of business cards is influenced by multiple factors, including the type of paper stock, printing methods (digital vs. offset), finishing options (such as lamination or embossing), and the complexity of the design. Custom shapes or sizes can also increase costs. Additionally, the quantity ordered plays a significant role; larger orders typically reduce the cost per unit. When budgeting, consider all these elements and request detailed quotes from manufacturers to compare pricing effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for business card manufacturer

In conclusion, the strategic sourcing of business cards presents a unique opportunity for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe. By focusing on quality, sustainability, and supplier relationships, businesses can enhance their brand image and communication effectiveness. Prioritizing suppliers who demonstrate a commitment to innovation and sustainability not only aligns with global best practices but also meets the growing consumer demand for responsible business practices.

What Are the Key Takeaways for International B2B Buyers?

International buyers should consider several critical factors when sourcing business cards. Evaluate suppliers based on their production capabilities, compliance with quality standards, and ability to offer customization. Engaging with manufacturers that leverage advanced printing technologies and sustainable materials can lead to superior products that resonate with your target audience.

How Can Strategic Sourcing Influence Your Business Growth?

Strategic sourcing is not merely a procurement function; it is a strategic lever that can drive growth and competitive advantage. By cultivating strong partnerships with reliable manufacturers, companies can ensure consistency in product quality while optimizing costs.

What’s Next for B2B Buyers?

As we move forward, the landscape of business card manufacturing will continue to evolve, driven by technological advancements and shifting market demands. Buyers are encouraged to stay informed about industry trends and to actively seek out innovative suppliers who can provide value-added services. Embrace the future of business networking with confidence—your next business card could be the catalyst for your next big opportunity.