Unlock Quality Savings: The Ultimate Kite Custom Guide (2025)

Introduction: Navigating the Global Market for kite custom

Navigating the intricate landscape of the global market for kite custom can be a daunting task for international B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. With diverse applications ranging from recreational use to promotional branding, understanding how to effectively source customized kites is crucial. This guide delves into the various types of kites available, their applications, and essential factors such as supplier vetting and cost considerations.

As businesses increasingly seek unique marketing strategies, customized kites present an innovative avenue to engage customers and enhance brand visibility. However, the challenge lies in finding reliable suppliers who can meet specific design requirements while ensuring quality and timely delivery. This comprehensive resource empowers B2B buyers by providing actionable insights into evaluating suppliers, understanding market trends, and optimizing procurement processes.

Whether you are a company in Italy looking to expand your product line or a business in South Africa seeking unique promotional items, this guide equips you with the knowledge needed to make informed purchasing decisions. By leveraging the information contained within, international buyers can navigate the complexities of kite custom sourcing with confidence, ensuring they select the best options that align with their business objectives.

Understanding kite custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single Line Kites | Simple design, typically flown with a single line. | Recreational use, events, marketing. | Pros: Easy to fly and transport. Cons: Limited maneuverability. |

| Stunt Kites | Dual or quad line control, allowing for tricks. | Entertainment events, competitions. | Pros: High engagement, versatile. Cons: Requires skill to operate. |

| Kite Banners | Customizable fabric banners for advertising. | Brand promotion, trade shows. | Pros: High visibility, customizable. Cons: Weather dependent. |

| Kite Aerial Photography (KAP) | Equipped with cameras for aerial shots. | Real estate, environmental monitoring. | Pros: Unique perspectives, cost-effective. Cons: Requires technical knowledge. |

| Box Kites | Three-dimensional structure for stability. | Education, scientific research. | Pros: Stable in high winds, innovative designs. Cons: More complex to assemble. |

What Are Single Line Kites and Their B2B Relevance?

Single line kites are the most basic type of kites, designed to be flown with a single string. They are often used in recreational settings, events, and marketing campaigns where simplicity is key. For B2B buyers, these kites are appealing due to their ease of use and transport. They are particularly suited for businesses looking to engage in community events or promotional activities, but their limited maneuverability may not meet the needs of more dynamic applications.

How Do Stunt Kites Enhance Engagement at Events?

Stunt kites are characterized by their ability to be controlled with two or four lines, allowing operators to perform tricks and maneuvers. This type of kite is ideal for entertainment events and competitions, making them a great choice for businesses aiming to attract attention or create an engaging atmosphere. B2B buyers should consider the skill level required for operation, as these kites may not be suitable for all users, but they certainly offer a high level of engagement and versatility.

Why Choose Kite Banners for Brand Promotion?

Kite banners are customizable fabric banners that can be used for advertising purposes. They provide high visibility at outdoor events, making them an excellent choice for businesses looking to promote their brand at trade shows or public gatherings. The primary consideration for buyers is the weather dependency of these banners; they may not perform well in high winds or rain, which could affect their effectiveness during outdoor events.

What Is Kite Aerial Photography (KAP) and Its Applications?

Kite Aerial Photography (KAP) integrates cameras with kites, allowing for aerial photography and videography. This innovative approach is particularly useful in industries such as real estate and environmental monitoring, where unique perspectives can provide valuable insights. B2B buyers interested in KAP should be aware of the technical knowledge required for operation, as well as the potential for cost savings compared to traditional aerial photography methods.

What Are the Advantages of Box Kites in Scientific Research?

Box kites are three-dimensional structures that offer stability in high winds, making them suitable for educational purposes and scientific research. Their unique design allows for innovative applications, such as weather monitoring or environmental studies. B2B buyers should consider the complexity involved in assembling box kites, as they may require more time and expertise compared to simpler kite designs. However, their stability and robustness can provide significant advantages in challenging conditions.

Related Video: Kite Shapes Explained (Bow, Delta, C kite, Hybrid, Flat, Aspect Ratio, Buying Choices etc)

Key Industrial Applications of kite custom

| Industry/Sector | Specific Application of kite custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Renewable Energy | Wind Energy Harvesting | Enhanced efficiency in capturing wind energy | Supplier reliability, material quality, local regulations |

| Agriculture | Crop Monitoring and Management | Improved yield through precise environmental data | Technology compatibility, data integration capabilities |

| Telecommunications | Signal Transmission and Coverage Optimization | Increased signal strength and coverage area | Compliance with local standards, installation support |

| Outdoor Recreation & Sports | Custom Kites for Events and Competitions | Unique branding opportunities and enhanced customer engagement | Customization options, durability in diverse weather conditions |

| Education and Training | Educational Tools for Physics and Aerodynamics | Engaging learning experiences and practical applications | Safety standards, educational alignment, materials used |

How is Kite Custom Used in Renewable Energy Applications?

In the renewable energy sector, kite custom is primarily utilized for wind energy harvesting. Custom-designed kites can capture high-altitude winds more efficiently than traditional wind turbines, leading to improved energy output. For B2B buyers in Africa and South America, it’s essential to consider local wind patterns and regulatory compliance when sourcing kite custom solutions. This not only maximizes energy capture but also aligns with sustainability goals in emerging markets.

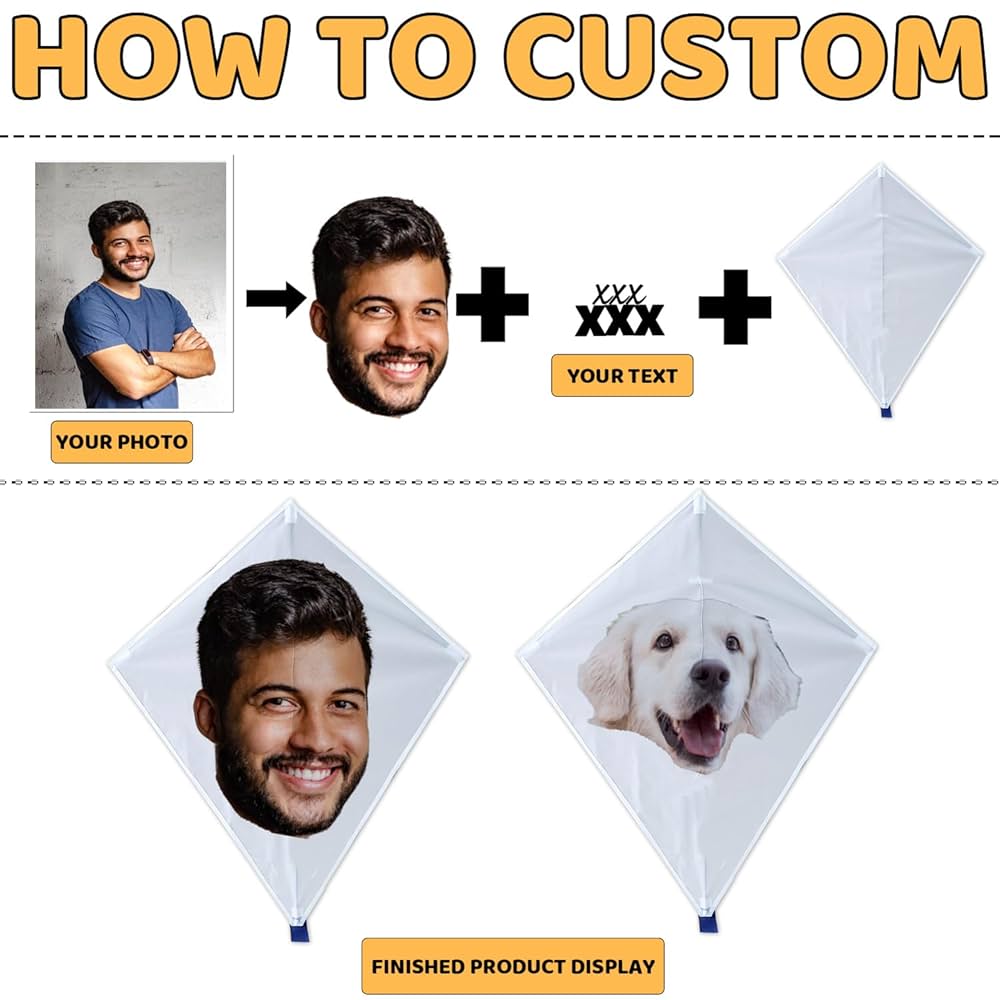

A stock image related to kite custom.

What Role Does Kite Custom Play in Agriculture?

In agriculture, kite custom serves as a tool for crop monitoring and management. These kites can be equipped with sensors to gather data on soil conditions and weather patterns, allowing farmers to make informed decisions. For international buyers from the Middle East, sourcing kites with specific sensor capabilities and durability for harsh climates is critical. This technology can significantly enhance crop yields and reduce resource wastage.

How is Kite Custom Applied in Telecommunications?

Kite custom applications in telecommunications focus on signal transmission and coverage optimization. Custom kites can be used to elevate antennas in remote areas, enhancing signal strength and coverage. Buyers from Europe, particularly in regions with challenging terrains, should ensure that the kites meet local telecommunications standards and can withstand environmental stress. This solution can lead to improved communication services and customer satisfaction.

What are the Benefits of Custom Kites in Outdoor Recreation & Sports?

In the outdoor recreation and sports industry, custom kites are crafted for events and competitions, offering unique branding opportunities and enhancing customer engagement. For businesses in Europe, particularly in Italy and Germany, sourcing kites that are visually appealing and durable against varying weather conditions is vital. This not only attracts participants but also elevates the overall experience, fostering brand loyalty.

How Can Kite Custom Enhance Education and Training?

Kite custom is also utilized in educational settings as a hands-on tool for teaching physics and aerodynamics. Custom-designed kites can provide engaging learning experiences, demonstrating principles of flight and wind dynamics. For B2B buyers in the education sector, particularly in Africa, it is important to source kites that adhere to safety standards and are suitable for diverse educational environments. This approach can foster a deeper understanding of scientific concepts among students.

Related Video: Sci6 Q3 – Characteristics and Uses of Simple Machines

3 Common User Pain Points for ‘kite custom’ & Their Solutions

Scenario 1: Inconsistent Quality in Custom Kite Manufacturing

The Problem: One of the most significant challenges faced by B2B buyers, especially in regions like Africa and South America, is the inconsistency in the quality of custom kites. Buyers often receive products that do not meet their specifications or quality standards, leading to dissatisfaction and potential financial losses. This inconsistency can stem from a variety of factors, including lack of quality control measures at the manufacturing level and miscommunication regarding design specifications. For businesses relying on these products for events or retail, such discrepancies can severely damage their reputation and customer trust.

The Solution: To mitigate these issues, buyers should establish a rigorous vetting process for potential suppliers. This includes asking for samples prior to placing large orders and verifying the supplier’s quality assurance protocols. Additionally, buyers should consider using detailed design specifications and standardized templates when communicating their requirements. Incorporating clear metrics for quality, such as material types and durability tests, can also help ensure that the final product meets expectations. Regular communication throughout the production process is vital, as is considering third-party inspections before shipment.

Scenario 2: Difficulty in Customization Options for Diverse Markets

The Problem: Another common pain point is the limited customization options offered by suppliers, particularly for B2B buyers targeting diverse markets. For instance, buyers in Europe may require specific designs that resonate with local cultures, while those in the Middle East may have different preferences. This lack of flexibility can hinder businesses from effectively marketing their products and reaching their target audiences, resulting in lost sales opportunities.

The Solution: To address this challenge, buyers should engage with suppliers who offer extensive customization options and are willing to collaborate closely during the design phase. Conducting market research to understand the preferences and cultural nuances of each target market can guide the customization process. Additionally, leveraging digital design tools that allow for rapid prototyping can facilitate quick adjustments based on feedback. Establishing long-term partnerships with suppliers who prioritize customization can lead to more tailored offerings and a competitive edge in various markets.

Scenario 3: Navigating Import Regulations and Logistics Challenges

The Problem: B2B buyers often face logistical challenges when importing custom kites, particularly in regions with stringent regulations, such as the EU. Compliance with import duties, tariffs, and customs documentation can be daunting, especially for businesses unfamiliar with the process. Delays in customs can lead to increased costs and missed deadlines, which can severely impact a buyer’s operational efficiency and customer satisfaction.

The Solution: To streamline the import process, it is crucial for buyers to familiarize themselves with the specific regulations governing kite imports in their regions. Working with experienced freight forwarders or customs brokers can provide invaluable insights into the necessary paperwork and compliance requirements. Buyers should also consider implementing an effective logistics strategy that includes clear timelines and contingency plans for potential delays. Keeping a close relationship with suppliers can facilitate better coordination regarding shipment schedules and documentation, ensuring that products arrive on time and in compliance with all regulations.

Strategic Material Selection Guide for kite custom

When selecting materials for custom kites, international B2B buyers must consider various factors that impact performance, durability, and compliance with regional standards. Here, we analyze four common materials used in kite manufacturing, examining their properties, advantages and disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Polyester in Kite Manufacturing?

Polyester is one of the most widely used materials for kite fabrics due to its excellent strength-to-weight ratio and resistance to UV light. It typically has a temperature rating of up to 120°C and is resistant to moisture, making it suitable for various weather conditions. Polyester’s inherent properties ensure that kites maintain their shape and performance over time.

Pros:

– High durability and resistance to tearing.

– Lightweight, which enhances flight performance.

– Cost-effective compared to other materials.

Cons:

– Limited resistance to extreme temperatures, which may affect performance in hot climates.

– Can degrade over time with prolonged exposure to UV light if not treated.

Impact on Application: Polyester is compatible with a wide range of environments, making it ideal for general kite applications. However, buyers should consider UV protection treatments to prolong the fabric’s lifespan.

Specific Considerations for Buyers: Compliance with ASTM D5034 for tensile strength and UV resistance is crucial. Buyers in Europe, particularly in Germany and Italy, may prefer materials that meet EU regulations for textile safety.

How Does Ripstop Nylon Compare for Kite Applications?

Ripstop Nylon is another popular choice for kite construction, known for its unique grid pattern that prevents tearing. It has a temperature rating of approximately 80°C and offers good resistance to abrasion and moisture.

Pros:

– Lightweight and strong, providing excellent performance in high winds.

– The grid structure enhances durability against tearing.

Cons:

– More expensive than polyester, which may impact overall project costs.

– Less UV resistant than polyester, requiring additional treatments for longevity.

Impact on Application: Ripstop nylon is particularly effective for high-performance kites used in competitive environments. Its lightweight nature allows for better maneuverability.

Specific Considerations for Buyers: Buyers should ensure compliance with JIS L 1096 for fabric testing. In regions like South America, where weather conditions can vary, understanding the local climate is essential for material selection.

What Are the Advantages of Mylar for Kite Customization?

Mylar, a type of polyester film, is known for its high tensile strength and excellent dimensional stability. It can withstand temperatures up to 150°C and is highly resistant to moisture and chemicals.

Pros:

– Exceptional durability and resistance to environmental factors.

– Lightweight and provides a unique aesthetic appeal due to its shiny surface.

Cons:

– Higher manufacturing complexity due to the need for specialized cutting and sewing techniques.

– Generally more expensive than traditional kite fabrics.

Impact on Application: Mylar is ideal for specialized kites that require high performance and unique designs. Its reflective properties can enhance visibility in the air.

Specific Considerations for Buyers: Compliance with ASTM D882 for tensile strength is essential. Buyers in the Middle East should consider the heat resistance of Mylar in their local climate.

Why Is Fiberglass Used in Kite Frame Construction?

Fiberglass is commonly used for kite frames due to its high strength-to-weight ratio and flexibility. It can withstand significant stress and has a temperature rating of around 100°C.

Pros:

– Provides excellent structural integrity and flexibility.

– Lightweight, which enhances overall kite performance.

Cons:

– More expensive than traditional wood or aluminum frames.

– Requires careful handling during transportation to prevent breakage.

Impact on Application: Fiberglass frames are suitable for larger kites that require additional support without adding weight.

Specific Considerations for Buyers: Buyers should ensure compliance with relevant safety standards, particularly in regions with stringent regulations like Europe. Understanding local preferences for frame materials can also influence purchasing decisions.

Summary Table of Material Selection for Kite Custom

| Material | Typical Use Case for Kite Custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | General kite applications | Cost-effective and durable | Limited UV resistance | Low |

| Ripstop Nylon | High-performance kites | Lightweight and tear-resistant | Higher cost, less UV resistant | Medium |

| Mylar | Specialized and aesthetic kites | Exceptional durability | Higher manufacturing complexity | High |

| Fiberglass | Kite frames for larger designs | Excellent strength-to-weight ratio | More expensive than alternatives | Medium |

This guide provides a comprehensive overview of material selection for custom kites, offering actionable insights for international B2B buyers. Understanding the properties and implications of each material will help ensure optimal performance and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for kite custom

What Are the Key Stages in the Manufacturing Process for Custom Kites?

The manufacturing process for custom kites involves several critical stages that ensure both quality and performance. Understanding these stages is essential for B2B buyers looking to source high-quality kites.

1. Material Preparation: Choosing the Right Components

The first stage in kite manufacturing is material preparation. Common materials include lightweight fabrics such as ripstop nylon or polyester, which are chosen for their durability and wind resistance. The selection of frames—typically made from fiberglass, carbon fiber, or aluminum—is crucial, as they provide the necessary structure and flexibility.

Tips for B2B Buyers:

- Request samples of materials to assess quality.

- Inquire about the sourcing of materials to ensure they meet international standards.

2. Forming: Crafting the Kite Shape

Once materials are prepared, the next step is forming. This involves cutting the fabric into the desired shapes and sizes, which can vary based on the kite design (e.g., delta, box, or parafoil). Advanced cutting techniques such as laser cutting are often employed to ensure precision.

Actionable Insight:

- Discuss the cutting techniques used by manufacturers to ensure accuracy and minimize waste.

3. Assembly: Bringing Components Together

After forming, the assembly process begins. This includes stitching the fabric pieces together and attaching the frame. High-quality stitching is essential for durability, and many manufacturers use reinforced seams to withstand the stresses of flying.

Key Consideration:

- Ask suppliers about their stitching techniques and the types of threads used, as this impacts the kite’s longevity.

4. Finishing: Ensuring Performance and Aesthetics

The final stage of manufacturing is finishing, where additional components such as tails, bridle lines, and graphics are added. This stage may also include quality checks to ensure that all elements are securely attached and the kite meets design specifications.

Quality Assurance Tip:

- Verify if the manufacturer has a dedicated finishing area that follows strict quality protocols.

How Is Quality Assurance Managed in Kite Manufacturing?

Quality assurance (QA) is a critical aspect of the kite manufacturing process, ensuring that the final product meets both safety and performance standards. B2B buyers should be familiar with the relevant international and industry-specific standards.

1. What International Standards Should B2B Buyers Look For?

One of the most recognized standards in manufacturing is ISO 9001, which outlines requirements for a quality management system (QMS). Compliance with ISO 9001 indicates that the manufacturer has established processes for continuous improvement.

2. What Industry-Specific Certifications Are Relevant?

In addition to ISO standards, kites may need to comply with specific certifications such as CE marking for products sold in Europe. This certification ensures that the product meets health, safety, and environmental protection standards.

Actionable Steps:

- Request documentation proving compliance with ISO 9001 and any relevant industry certifications.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves systematic processes to ensure that products meet specified requirements. The main checkpoints in kite manufacturing typically include:

1. Incoming Quality Control (IQC)

During the IQC phase, all raw materials are inspected before production begins. This includes checking the quality of fabrics, frames, and other components against pre-defined criteria.

2. In-Process Quality Control (IPQC)

The IPQC phase takes place during the manufacturing process. This includes monitoring stitching quality, assembly integrity, and adherence to design specifications at various stages.

3. Final Quality Control (FQC)

The FQC phase occurs after the kites are fully assembled. This includes thorough inspections of the finished products, ensuring they function correctly and meet all aesthetic standards.

Best Practices for B2B Buyers:

- Inquire about the frequency of QC checks and the criteria used during these inspections.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers should adopt a proactive approach to verification.

1. Conducting Audits

Regular audits of the manufacturing facility can provide insights into the QC processes in place. Consider scheduling audits before placing large orders to assess the manufacturer’s commitment to quality.

2. Requesting Reports

Ask for detailed quality reports that outline the results of IQC, IPQC, and FQC stages. These reports should highlight any issues encountered and how they were resolved.

3. Utilizing Third-Party Inspection Services

Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing process and product quality. These services can conduct random checks and provide detailed reports on compliance with international standards.

Final Advice for International Buyers

Navigating the manufacturing landscape for custom kites requires diligence, particularly for international buyers from Africa, South America, the Middle East, and Europe. Understanding the manufacturing processes, quality assurance standards, and verification methods can significantly enhance your sourcing strategy. Always prioritize suppliers that demonstrate a commitment to quality through certifications and transparent QC processes. By doing so, you can ensure that your investment in custom kites meets the highest standards of quality and performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘kite custom’

Introduction

This practical sourcing guide provides a comprehensive checklist for international B2B buyers looking to procure custom kites. With a focus on ensuring quality, compliance, and suitability for specific markets—particularly in Africa, South America, the Middle East, and Europe—this guide will help streamline the sourcing process and mitigate risks.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, it’s essential to establish clear technical specifications for your custom kites. This includes dimensions, materials, and design features that meet your market’s needs.

– Consider regional preferences: Different markets may favor specific colors, shapes, or sizes based on cultural preferences or weather conditions.

– Identify performance requirements: Ensure your specifications include factors like wind resistance and durability, which are crucial for kite performance.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers capable of meeting your specifications. Look for manufacturers with a proven track record in producing custom kites.

– Utilize online platforms: Websites like Alibaba or Global Sources can provide insights into supplier ratings and reviews.

– Check industry associations: Membership in reputable industry associations can be a good indicator of credibility and adherence to industry standards.

Step 3: Evaluate Supplier Certifications

Verifying supplier certifications is a critical step in ensuring product quality and compliance with international standards. Certifications may include ISO, CE, or specific safety standards relevant to your market.

– Request documentation: Ask for copies of certifications and any testing reports that demonstrate compliance.

– Understand market regulations: Familiarize yourself with specific regulations in your target market to ensure that your supplier meets these requirements.

Step 4: Request Samples

Always request samples before placing a bulk order. This allows you to evaluate the quality and craftsmanship of the kites firsthand.

– Assess material quality: Check the durability of materials used and how well they align with your specifications.

– Test performance: If possible, conduct a test flight to evaluate the kite’s performance under various conditions.

Step 5: Negotiate Terms and Conditions

Negotiating favorable terms is vital for a successful procurement process. This includes pricing, lead times, payment terms, and warranty conditions.

– Be clear about your needs: Clearly communicate your expectations regarding delivery timelines and after-sales support.

– Consider long-term relationships: Establish terms that foster a long-term partnership, which can lead to better pricing and reliability in future orders.

Step 6: Conduct a Factory Audit

If feasible, conduct a factory audit to assess the supplier’s production capabilities and quality control processes. This step is particularly important for high-volume orders.

– Evaluate production processes: Look for evidence of quality assurance practices and production efficiency.

– Meet the team: Engaging with the production team can provide insights into their expertise and commitment to quality.

Step 7: Finalize Your Order

Once you are satisfied with the supplier and their products, finalize your order with a clear contract that outlines all agreed-upon terms.

– Include contingencies: Ensure the contract includes clauses for quality assurance and recourse in case of non-compliance.

– Keep communication open: Maintain a dialogue with the supplier throughout the production process to address any issues proactively.

By following this step-by-step checklist, B2B buyers can effectively source custom kites that meet their specifications while ensuring quality and compliance in international markets.

Comprehensive Cost and Pricing Analysis for kite custom Sourcing

What Are the Key Cost Components in Custom Kite Sourcing?

When engaging in custom kite sourcing, understanding the cost structure is vital for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality fabrics, durable frames, and specialized materials for specific kite types (e.g., stunt kites versus traditional kites) can raise costs. Buyers should consider both the performance and durability of materials.

-

Labor: Labor costs vary based on the region of production. Skilled labor may be more expensive but can enhance the quality of the finished product. Custom designs that require specialized skills will also incur higher labor costs.

-

Manufacturing Overhead: This encompasses costs related to factory operations, utilities, and administrative expenses. Efficient production processes can help minimize overhead, but buyers should inquire about these costs during negotiations.

-

Tooling: Custom designs may require specific molds or tools, which can add to initial costs. Understanding the tooling costs is essential for evaluating the total investment.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability and customer satisfaction. However, these measures can also increase costs. Buyers should assess the QC processes in place and their impact on pricing.

-

Logistics: Shipping and handling costs, including duties and taxes, are crucial, especially for international transactions. Consideration of Incoterms is important as they define the responsibilities of buyers and sellers in shipping.

-

Margin: Suppliers will typically add a profit margin to their costs. Understanding the standard margins in the kite industry can help buyers gauge whether they are receiving a fair price.

How Do Price Influencers Affect Kite Custom Sourcing?

Several factors influence pricing in custom kite sourcing, particularly for international buyers:

-

Volume/MOQ: Minimum order quantities can drastically affect pricing. Larger orders often yield discounts. Buyers should evaluate their needs to determine the most cost-effective ordering strategy.

-

Specifications and Customization: Custom designs, colors, or features can increase costs. Buyers should clarify their specifications upfront to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., safety standards) can lead to higher prices. Buyers should weigh the benefits of quality against budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can influence costs. Established suppliers may charge more due to their experience and quality assurance practices.

-

Incoterms: Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help buyers manage logistics costs effectively.

What Are the Best Negotiation Tips for International B2B Buyers?

When negotiating prices for custom kites, particularly for buyers from Africa, South America, the Middle East, and Europe, consider the following tips:

-

Research and Benchmarking: Understand market prices and gather quotes from multiple suppliers to leverage during negotiations.

-

Focus on Total Cost of Ownership: Rather than just the purchase price, consider all costs associated with the product, including shipping, taxes, and potential tariffs. This approach helps in making informed decisions.

-

Build Long-term Relationships: Establishing a rapport with suppliers can lead to better pricing and terms. Long-term partnerships often result in more favorable conditions.

-

Be Clear on Specifications: Providing detailed specifications can prevent misunderstandings and unexpected costs later in the process.

-

Negotiate Payment Terms: Flexible payment terms can enhance cash flow. Discussing options like staggered payments or discounts for early payments can yield financial benefits.

What Should Buyers Know About Pricing Nuances in International Markets?

B2B buyers should be aware of regional pricing nuances when sourcing custom kites. Different markets may have varying expectations regarding quality, design, and price sensitivity. Additionally, currency fluctuations can impact costs significantly for international transactions.

Disclaimer: Prices can vary widely based on specifications, supplier locations, and market conditions. It is advisable to conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing kite custom With Other Solutions

In today’s dynamic B2B landscape, companies are often faced with a multitude of solutions that claim to meet their needs. When considering “kite custom,” it’s essential to evaluate alternative solutions to determine which best aligns with your specific business requirements. This analysis will provide insights into key comparative factors, enabling informed decision-making for international buyers from regions such as Africa, South America, the Middle East, and Europe.

Comparison Table of Kite Custom vs. Alternatives

| Comparison Aspect | Kite Custom | Alternative 1: Custom Software Solutions | Alternative 2: Off-the-Shelf Software |

|---|---|---|---|

| Performance | High; tailored to specific needs | Variable; depends on the vendor and customization | Generally reliable; limited by design |

| Cost | Moderate to High; investment in customization | High upfront costs; ongoing maintenance | Low to Moderate; predictable pricing |

| Ease of Implementation | Requires technical expertise; can be time-consuming | Complex; requires dedicated project management | Quick to deploy; user-friendly |

| Maintenance | Ongoing; requires technical support | High; continuous updates and support needed | Low; vendor manages updates and support |

| Best Use Case | Unique business processes needing specific solutions | Businesses with unique requirements or workflows | Standardized processes across multiple industries |

What Are the Benefits and Drawbacks of Custom Software Solutions?

Custom software solutions provide a high level of performance tailored to the unique needs of a business. They are ideal for organizations that have specific processes or functionalities that off-the-shelf solutions cannot accommodate. However, the cost can be a significant factor, as custom solutions often involve high upfront investments and ongoing maintenance fees. Additionally, the implementation process can be lengthy, requiring careful project management and technical expertise to ensure successful deployment.

How Does Off-the-Shelf Software Compare to Kite Custom?

Off-the-shelf software offers a more cost-effective and quicker deployment option for businesses. These solutions are designed to meet the general needs of a broad range of industries, making them user-friendly and easy to implement. However, they may lack the customization necessary for companies with unique requirements, potentially limiting operational effectiveness. Maintenance is typically managed by the vendor, reducing the burden on internal IT teams. For businesses with standard processes, off-the-shelf solutions may be the best choice.

Conclusion: How to Choose the Right Solution for Your Business Needs?

When selecting between kite custom and its alternatives, B2B buyers should carefully assess their specific business needs, budget constraints, and the level of customization required. Companies with unique processes that cannot be met by standard solutions may find greater value in kite custom or custom software solutions, despite the higher costs and longer implementation times. Conversely, businesses seeking a quick, cost-effective solution may benefit from off-the-shelf software, provided it meets their operational needs. Ultimately, the right choice will align with the organization’s strategic objectives and operational requirements.

Essential Technical Properties and Trade Terminology for kite custom

What Are the Key Technical Properties for Custom Kites?

When sourcing custom kites, understanding the technical specifications is crucial for ensuring product quality and performance. Here are some essential properties to consider:

-

Material Grade

The choice of materials significantly impacts the durability and performance of kites. Common materials include ripstop nylon, polyester, and fiberglass. For instance, ripstop nylon is lightweight yet strong, making it ideal for high-performance kites. Buyers should verify the material grade to ensure it meets specific use cases, such as recreational or competitive flying. -

Tension Tolerance

Tension tolerance refers to the maximum stress a kite can withstand without deforming or breaking. It is essential for maintaining shape and performance during flight. Manufacturers often specify this in Newtons (N). Buyers should seek kites with higher tension tolerances for extreme conditions or high-altitude flying. -

Size and Dimensions

Kites come in various sizes, typically measured by wingspan and height. Understanding the dimensions is crucial for ensuring the kite meets performance expectations and user requirements. For instance, larger kites can catch more wind, making them suitable for beginners, while smaller kites offer more control for experienced flyers. -

Wind Range

Each kite is designed to perform optimally within a specific wind range, usually measured in miles per hour (mph) or kilometers per hour (kph). Knowing the wind range helps buyers choose the right kite for their local conditions, enhancing user satisfaction and performance. -

Reinforcement Features

Reinforcements, such as extra stitching or reinforced seams, enhance the kite’s durability. They are particularly important for kites intended for heavy use or challenging weather conditions. Buyers should inquire about these features to ensure longevity and reliability.

A stock image related to kite custom.

- Weight

The weight of the kite affects its performance in the air. Lighter kites are easier to launch and maneuver, while heavier kites tend to withstand stronger winds. Buyers should consider the target user’s skill level and intended use when evaluating weight specifications.

What Are Common Trade Terms in the Kite Custom Industry?

Understanding industry jargon can facilitate smoother transactions and negotiations. Here are several key terms frequently used in the kite manufacturing and purchasing process:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on another company’s specifications. For buyers, partnering with an OEM can result in customized kites that meet specific design requirements without investing in production facilities. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to produce or sell. Understanding MOQ is vital for budget planning and inventory management, especially for international buyers who may face shipping and storage costs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for a specific quantity of products. This process is essential for B2B buyers to compare costs, ensure competitive pricing, and clarify specifications before making a purchase decision. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping costs, insurance, and liability. Familiarity with these terms helps buyers understand their obligations and avoid disputes during the import process. -

Lead Time

Lead time refers to the period between placing an order and receiving the goods. This term is critical for B2B buyers who need to plan their inventory and sales strategies accordingly. Understanding lead times can help businesses manage customer expectations and optimize supply chain operations. -

Customs Clearance

Customs clearance is the process of passing goods through customs so they can enter the importing country. For international buyers, being aware of customs procedures and potential tariffs is essential to avoid delays and additional costs during importation.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their business needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the kite custom Sector

What Are the Key Market Dynamics and Trends in the Kite Custom Sector?

The global kite custom sector is experiencing a robust transformation driven by various market dynamics and technological advancements. One of the primary drivers is the increasing demand for personalized and unique kite designs that resonate with local cultures and individual preferences. This trend is particularly prevalent in regions like Africa and South America, where local artisans are harnessing traditional motifs to create bespoke kites. Additionally, the rise of e-commerce platforms has enabled international B2B buyers from Europe and the Middle East to source these unique products directly from manufacturers, enhancing market accessibility and reducing lead times.

Emerging technologies such as 3D printing and digital design software are revolutionizing the way kites are produced. These technologies allow manufacturers to create intricate designs with precision and efficiency, catering to the growing consumer demand for customized products. Moreover, the integration of augmented reality (AR) in marketing strategies is enhancing customer engagement, enabling potential buyers to visualize kites in their intended environments before making a purchase.

Sourcing trends are also evolving, with a shift towards direct procurement from manufacturers rather than through intermediaries. This change allows buyers to negotiate better terms and ensures a more transparent supply chain. Notably, the kite custom market is seeing a surge in collaborations between brands and local artists, which not only supports local economies but also enriches the product offerings with cultural significance.

How Can Sustainability and Ethical Sourcing Impact the Kite Custom Sector?

Sustainability has become a pivotal consideration in the kite custom sector, as consumers and businesses alike are increasingly aware of environmental impacts. The production processes of kites can involve various materials, including plastics and synthetic fabrics, which pose environmental concerns. As a result, there is a growing emphasis on sourcing eco-friendly materials such as biodegradable fabrics and recycled plastics. B2B buyers are encouraged to inquire about the sustainability practices of their suppliers, ensuring that their procurement strategies align with global sustainability goals.

Ethical sourcing is equally important, focusing on fair labor practices and responsible production methods. Buyers are urged to seek suppliers that adhere to ethical standards, ensuring that their kites are produced in safe working conditions and that workers are compensated fairly. Certifications such as Fair Trade and Global Organic Textile Standard (GOTS) can serve as valuable indicators of a supplier’s commitment to ethical practices.

Moreover, incorporating sustainability and ethical sourcing into procurement strategies can enhance brand reputation and customer loyalty. B2B buyers who prioritize these values are more likely to attract environmentally conscious consumers, thereby creating a competitive edge in the market.

What Is the Brief Evolution of the Kite Custom Sector?

The kite custom sector has evolved significantly over the years, transitioning from traditional hand-crafted kites to a more industrialized approach that incorporates advanced technologies. Historically, kites were primarily made from natural materials such as bamboo and silk, with designs reflecting cultural narratives and local craftsmanship. As globalization took hold, the production of kites expanded, leading to mass-produced versions that often lacked the personal touch.

In recent years, however, there has been a resurgence in interest towards custom kites, driven by a desire for individuality and personalization. This shift has been facilitated by advancements in manufacturing technologies, allowing for small-scale production runs that cater to niche markets. Today, international B2B buyers are increasingly looking for unique, culturally relevant products that not only fulfill aesthetic desires but also tell a story, reflecting the rich heritage of kite making across different regions. This evolution underscores the importance of balancing tradition with innovation in the kite custom sector.

Frequently Asked Questions (FAQs) for B2B Buyers of kite custom

-

How do I ensure quality when sourcing custom kites from international suppliers?

To ensure quality when sourcing custom kites, start by thoroughly vetting potential suppliers. Look for manufacturers with a proven track record in kite production and check their certifications, such as ISO or CE. Request samples before placing large orders to evaluate the craftsmanship and materials used. Additionally, consider establishing a Quality Assurance (QA) process, which may include third-party inspections during production and before shipment to confirm that products meet your specifications. -

What are the best materials for custom kites?

The best materials for custom kites depend on the intended use and environmental conditions. For recreational kites, lightweight nylon or polyester fabric is recommended for its durability and resistance to tearing. For high-performance or professional kites, consider using ripstop fabric for added strength. Additionally, fiberglass or carbon fiber frames are preferred for their lightweight properties and rigidity, which help maintain kite shape and enhance flying performance. -

What is the minimum order quantity (MOQ) for custom kites?

Minimum order quantities (MOQ) for custom kites vary by supplier and can range from as low as 50 to over 1,000 units. When negotiating with manufacturers, inquire about their MOQ policies and whether they offer flexibility for first-time buyers or smaller businesses. If your order is below the MOQ, consider grouping orders with other buyers or exploring suppliers who specialize in smaller batch production to meet your needs. -

What are common payment terms when sourcing custom kites internationally?

Common payment terms for international B2B transactions typically include a deposit (usually 30-50%) upfront, with the balance due before shipment. Payment methods may vary, but bank transfers, letters of credit, and secure online payment platforms are popular options. Always clarify payment terms in your contract to avoid misunderstandings, and consider using escrow services for added security, especially when dealing with new suppliers. -

How can I customize my kites for branding purposes?

To customize kites for branding, collaborate with your supplier to discuss design options, including colors, logos, and patterns. Ensure your designs are suitable for the kite’s material and flying conditions. Many manufacturers offer digital mock-ups or prototypes, allowing you to visualize your branding before production. Be clear about your branding needs early in the design process to ensure the final product aligns with your marketing strategy. -

What should I consider when shipping custom kites internationally?

When shipping custom kites internationally, consider factors such as shipping costs, customs regulations, and delivery times. Choose a reliable freight forwarder familiar with international shipping laws and best practices. Ensure all documentation, including commercial invoices and packing lists, is accurate to avoid customs delays. Additionally, consider insurance options to protect your investment during transit, especially for high-value orders. -

How can I evaluate potential suppliers for custom kites?

To evaluate potential suppliers for custom kites, conduct comprehensive research including their manufacturing capabilities, experience in the industry, and customer reviews. Request references from previous clients to gain insights into their reliability and quality. Visit their facilities if possible, or conduct virtual assessments to see their production processes. Comparing multiple suppliers can also help you identify the best fit for your needs based on quality, pricing, and service. -

What are the key trends in the custom kite market?

Key trends in the custom kite market include increasing demand for eco-friendly materials and sustainable production practices, as consumers become more environmentally conscious. Innovations in design and technology, such as improved aerodynamics and lightweight materials, are also on the rise. Additionally, personalized and themed kites for events or promotional activities are gaining popularity, allowing businesses to leverage kites as unique marketing tools. Keeping an eye on these trends can help you stay competitive in the market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for kite custom

In summary, strategic sourcing for kite custom products offers international B2B buyers a pathway to optimize supply chains, reduce costs, and enhance product quality. By engaging in thorough market research and establishing robust supplier relationships, buyers from Africa, South America, the Middle East, and Europe can leverage local insights to make informed decisions. Understanding regional preferences and compliance requirements is critical in ensuring that products meet both market demand and regulatory standards.

How Can Buyers Leverage Strategic Sourcing for Competitive Advantage?

Investing in strategic sourcing not only streamlines procurement processes but also fosters innovation. By collaborating with suppliers who understand the nuances of the kite custom market, buyers can access cutting-edge designs and materials that set their offerings apart. This approach can significantly enhance brand reputation and customer satisfaction, leading to increased market share.

What Does the Future Hold for Kite Custom Sourcing?

Looking ahead, the kite custom industry is poised for growth, driven by rising consumer interest in personalized and high-quality products. International buyers should stay proactive in adapting to market trends and technological advancements. Embrace strategic sourcing as a continuous journey—one that promises to unlock new opportunities and foster sustainable partnerships. Engage with suppliers today to position your business for success in this dynamic marketplace.