Unlock Quality & Savings: The Ultimate Necklace Custom Guide (2025)

Introduction: Navigating the Global Market for necklace custom

In today’s competitive landscape, sourcing custom necklaces that align with both market trends and customer preferences poses a significant challenge for international B2B buyers. The demand for personalized jewelry is rising, with businesses looking to differentiate themselves in a crowded marketplace. This guide on navigating the global market for necklace custom aims to equip buyers with the essential knowledge needed to make informed purchasing decisions.

We will explore various types of custom necklaces, their applications across different industries, and key factors to consider when selecting suppliers. Additionally, we will delve into effective strategies for vetting suppliers, ensuring quality assurance, and understanding the cost implications of custom jewelry production. This comprehensive approach not only enhances your sourcing strategy but also mitigates risks associated with international procurement.

For B2B buyers from regions like Africa, South America, the Middle East, and Europe—including key markets such as Egypt and Saudi Arabia—this guide is tailored to address unique regional challenges and opportunities. By leveraging the insights provided, businesses can better navigate the complexities of global sourcing, fostering partnerships that lead to successful outcomes in the custom jewelry sector. Empower yourself with the knowledge to make strategic decisions that drive growth and enhance your product offerings in the competitive world of custom necklaces.

Understanding necklace custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Personalized Necklaces | Custom engravings, names, or initials | Gifts, promotional items | Pros: Unique, high perceived value. Cons: Longer production time. |

| Birthstone Necklaces | Incorporates gemstones representing birth months | Jewelry retailers, gift shops | Pros: Emotional appeal, popular for gifts. Cons: Higher material costs. |

| Charm Necklaces | Modular design with interchangeable charms | Fashion boutiques, online retailers | Pros: Customizable, trendy. Cons: Requires inventory of charms. |

| Statement Necklaces | Bold designs and large pendants | Fashion events, corporate gifting | Pros: Eye-catching, brand representation. Cons: May not suit all markets. |

| Eco-Friendly Necklaces | Made from sustainable materials | Ethical brands, eco-conscious markets | Pros: Growing demand, positive brand image. Cons: Potentially higher costs. |

What Are the Key Characteristics of Personalized Necklaces?

Personalized necklaces are defined by their custom engravings, such as names or initials, making them ideal for gifts or promotional items. This type of necklace allows businesses to cater to individual preferences, enhancing customer engagement and loyalty. For B2B buyers, it’s crucial to consider lead times, as personalization often requires additional production time, impacting inventory management.

How Do Birthstone Necklaces Appeal to B2B Buyers?

Birthstone necklaces incorporate gemstones that represent specific birth months, making them particularly appealing for jewelry retailers and gift shops. Their emotional connection to personal milestones can drive sales, especially during holiday seasons or special occasions. When purchasing, B2B buyers should evaluate the sourcing of gemstones to ensure quality and authenticity, as this can significantly affect customer satisfaction and brand reputation.

What Makes Charm Necklaces a Flexible Option for Retailers?

Charm necklaces feature a modular design that allows customers to personalize their jewelry by selecting interchangeable charms. This flexibility makes them a popular choice for fashion boutiques and online retailers aiming to attract a diverse clientele. B2B buyers should consider the logistics of stocking various charms and the potential for inventory management challenges, as a broader range can increase customer interest but complicate supply chains.

Why Are Statement Necklaces Important for Brand Representation?

Statement necklaces are characterized by their bold designs and large pendants, making them ideal for fashion events and corporate gifting. These pieces can serve as powerful tools for brand representation and visibility, attracting attention and conveying a strong message. B2B buyers should assess market trends and customer preferences when selecting statement pieces, as they need to align with the target demographic’s style.

How Do Eco-Friendly Necklaces Meet Growing Market Demands?

Eco-friendly necklaces are crafted from sustainable materials, catering to the increasing demand for ethical and environmentally conscious products. This type of necklace is particularly relevant for ethical brands and eco-conscious markets, appealing to consumers looking to make responsible purchasing decisions. B2B buyers should weigh the potential for higher costs against the growing consumer preference for sustainability, as this can influence brand loyalty and market positioning.

Related Video: Charming beaded necklace with bicone and seed beads. How to make beaded jewelry

Key Industrial Applications of necklace custom

| Industry/Sector | Specific Application of Necklace Custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | Personalized Jewelry Lines | Enhances customer loyalty and brand differentiation | Quality of materials, design capabilities, lead times |

| Corporate Gifting | Custom Necklaces for Employee Recognition | Strengthens corporate culture and employee retention | Customization options, bulk pricing, delivery timelines |

| Event Planning | Customized Necklaces for Events and Promotions | Increases brand visibility and event engagement | Design flexibility, turnaround time, minimum order quantities |

| E-commerce | Tailored Jewelry for Online Marketplaces | Attracts niche markets and boosts online sales | Packaging options, shipping logistics, return policies |

| Cultural Artifacts | Custom Necklaces Reflecting Cultural Heritage | Supports local artisans and promotes cultural identity | Ethical sourcing, authenticity verification, market demand |

How is Necklace Custom Used in Fashion Retail?

In the fashion retail sector, customized necklaces are increasingly being integrated into personalized jewelry lines. This application allows retailers to offer unique pieces that resonate with individual customers, fostering loyalty and enhancing brand differentiation. International B2B buyers, particularly from regions like Africa and South America, should consider sourcing high-quality materials and design capabilities to create unique offerings. They must also evaluate lead times to ensure timely delivery, especially during peak seasons.

What Role Does Necklace Custom Play in Corporate Gifting?

For businesses looking to strengthen corporate culture, custom necklaces serve as an excellent option for employee recognition programs. These personalized pieces can be awarded for achievements or milestones, contributing to employee retention and satisfaction. B2B buyers in the Middle East and Europe should focus on customization options that reflect the company’s values and branding. Bulk pricing and timely delivery are critical considerations for maintaining budget and schedule.

How Can Necklace Custom Enhance Event Planning?

In the event planning industry, customized necklaces are often used as promotional items or gifts, which can significantly increase brand visibility and engagement. These items can be tailored to suit the theme of an event or to reflect the brand’s identity, making them memorable for attendees. International buyers must prioritize design flexibility and turnaround time when sourcing these products, ensuring that they meet the specific needs of their events while adhering to deadlines.

Why is Necklace Custom Important for E-commerce?

E-commerce platforms benefit from tailored jewelry offerings, allowing sellers to attract niche markets and enhance online sales. Custom necklaces can be marketed as exclusive items, appealing to consumers seeking unique gifts or personal accessories. B2B buyers should consider packaging options and shipping logistics to ensure a seamless customer experience. Additionally, clear return policies are vital to build trust with consumers in the online marketplace, particularly in diverse regions like Europe and South America.

How Does Necklace Custom Support Cultural Heritage?

Custom necklaces that reflect cultural heritage are valuable in promoting local artisans and preserving cultural identity. This application is particularly relevant for businesses in regions with rich cultural traditions, such as Africa and parts of the Middle East. B2B buyers should focus on ethical sourcing and authenticity verification to ensure that the products represent the culture accurately. Understanding market demand for such items can also guide sourcing strategies and product development efforts.

Related Video: Uses and Gratifications Theory – UGT

3 Common User Pain Points for ‘necklace custom’ & Their Solutions

Scenario 1: Difficulties in Meeting Unique Market Demands

The Problem: B2B buyers, especially those operating in diverse markets across Africa, South America, and the Middle East, often struggle to meet the unique cultural and aesthetic preferences of their customers. Custom necklaces that resonate with local traditions or current trends can be hard to find. This challenge is compounded by the need for suppliers who understand these cultural nuances and can deliver products that align with customer expectations.

The Solution: To navigate this complexity, buyers should prioritize collaboration with local artisans or manufacturers who possess in-depth knowledge of regional styles and preferences. Engaging in co-design processes allows for the creation of unique pieces that not only fulfill market demands but also celebrate local craftsmanship. Additionally, establishing partnerships with suppliers who offer flexible minimum order quantities can enable businesses to test various designs without significant financial risk. This strategy ensures that the custom necklaces resonate well with target audiences, enhancing customer satisfaction and loyalty.

Scenario 2: Quality Control and Consistency Challenges

The Problem: Maintaining quality and consistency in custom necklace production can be a significant pain point, particularly when sourcing from multiple suppliers across different regions. B2B buyers often face issues with variations in materials, craftsmanship, and overall finish, leading to discrepancies that can tarnish brand reputation and customer trust.

The Solution: To mitigate quality control issues, buyers should implement a robust supplier evaluation process. This involves setting clear quality standards and conducting regular audits of potential suppliers. Establishing long-term relationships with a select few trusted manufacturers can also enhance consistency. Additionally, investing in quality assurance technologies, such as digital sampling and 3D design tools, allows buyers to visualize and approve designs before production begins. By focusing on these proactive measures, businesses can ensure that their custom necklaces meet the desired quality standards consistently.

Scenario 3: Navigating Export Regulations and Logistics

The Problem: International B2B buyers often encounter challenges related to export regulations and logistics when sourcing custom necklaces from overseas. Different countries have varying import/export laws, tariffs, and shipping requirements that can complicate the procurement process, leading to delays and unexpected costs.

The Solution: To effectively navigate these complexities, buyers should invest time in understanding the regulatory landscape of both the exporting and importing countries. This includes consulting with logistics experts or customs brokers who can provide insights into specific requirements and help streamline the shipping process. Additionally, utilizing technology platforms that offer integrated logistics solutions can simplify the tracking and management of shipments. Establishing relationships with reliable shipping partners who specialize in jewelry can also ensure smoother operations. By taking these steps, B2B buyers can minimize delays and costs, leading to a more efficient supply chain for custom necklaces.

Strategic Material Selection Guide for necklace custom

When considering materials for custom necklaces, international B2B buyers must evaluate several factors that influence the performance, durability, and aesthetic appeal of the final product. Here, we analyze four common materials used in necklace customization: gold, silver, stainless steel, and leather. Each material has unique properties and implications for manufacturing, cost, and market preferences.

What Are the Key Properties of Gold for Custom Necklaces?

Gold is renowned for its malleability and resistance to tarnish and corrosion. It can withstand a variety of environmental conditions without degrading, making it ideal for high-end jewelry. Gold is also hypoallergenic, which is a significant advantage for markets with sensitive skin concerns.

Pros & Cons: The primary advantage of gold is its luxurious appeal and high resale value. However, it is one of the more expensive materials, which can limit its accessibility for mass production. Additionally, the complexity of working with gold, particularly in intricate designs, can increase manufacturing costs.

Impact on Application: Gold is compatible with various media, including water and sweat, making it suitable for everyday wear. However, buyers should be aware of local regulations regarding precious metals, as some countries have specific standards for gold purity (e.g., 18K, 24K).

How Does Silver Compare as a Material for Custom Necklaces?

Silver is another popular choice for custom necklaces, known for its excellent conductivity and workability. It has a lower cost compared to gold while still offering a premium appearance. However, silver is more prone to tarnishing and requires regular maintenance to keep its luster.

Pros & Cons: Silver’s affordability and aesthetic appeal make it a popular choice for both high-end and budget-friendly designs. On the downside, its susceptibility to tarnishing can lead to increased maintenance costs and customer dissatisfaction if not properly addressed.

Impact on Application: Silver is generally compatible with a wide range of environments but can react with certain chemicals found in perfumes or lotions. Buyers should consider local preferences for silver jewelry, as some regions may favor sterling silver (92.5% purity) over other grades.

What Are the Benefits of Using Stainless Steel for Custom Necklaces?

Stainless steel is gaining popularity in the jewelry industry due to its strength, durability, and resistance to corrosion. It is an excellent choice for buyers looking for a cost-effective alternative that still offers a modern aesthetic.

Pros & Cons: The primary advantage of stainless steel is its low maintenance requirement and high durability, making it suitable for everyday wear. However, it lacks the luxurious appeal of precious metals, which might limit its marketability in high-end segments.

Impact on Application: Stainless steel is compatible with various environments, including exposure to water and sweat. It is also generally hypoallergenic, catering to consumers with sensitive skin. Buyers should ensure compliance with international standards like ASTM for material quality.

Why Consider Leather for Custom Necklaces?

Leather offers a unique texture and aesthetic that can differentiate a custom necklace from traditional metal options. It is lightweight and can be dyed in various colors, making it a versatile choice for creative designs.

Pros & Cons: Leather’s primary advantage is its ability to provide a rustic or bohemian look that appeals to specific consumer segments. However, it is less durable than metals and can degrade over time, especially with exposure to moisture.

Impact on Application: Leather is generally not suitable for environments with high moisture levels, as it can absorb water and become damaged. Buyers should consider local market trends, as leather jewelry may be more popular in certain regions than others.

Summary Table of Material Selection for Custom Necklaces

| Material | Typical Use Case for necklace custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Gold | High-end jewelry | Luxurious appeal and high value | High cost and complex manufacturing | High |

| Silver | Affordable luxury jewelry | Premium look at a lower price | Prone to tarnishing | Med |

| Stainless Steel | Everyday wear and fashion jewelry | Durable and low maintenance | Lacks luxury appeal | Low |

| Leather | Casual and artistic designs | Unique texture and lightweight | Less durable, moisture-sensitive | Med |

This strategic material selection guide provides international B2B buyers with critical insights into the properties, advantages, and limitations of each material, enabling informed decision-making that aligns with market demands and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for necklace custom

What Are the Main Stages of Manufacturing Custom Necklaces?

Manufacturing custom necklaces involves a series of intricate processes that ensure the final product meets both aesthetic and quality standards. Here’s a detailed breakdown of the typical manufacturing stages:

Material Preparation

The first step in the manufacturing process is the selection and preparation of materials. Common materials include precious metals (gold, silver, platinum), gemstones, and alternative materials like acrylic or wood. B2B buyers should ensure that suppliers source materials from reputable vendors to guarantee quality and ethical practices.

- Sourcing: Verify that materials comply with international regulations regarding ethical sourcing, especially for precious metals and gemstones.

- Pre-processing: This involves cutting and shaping raw materials into usable forms. For metals, this may include alloying and casting.

Forming Techniques

Once the materials are prepared, various forming techniques are employed to create the necklace’s desired shape and design.

- Casting: This method involves pouring molten metal into a mold to create a specific design. It’s ideal for intricate designs and allows for mass production.

- Welding and Soldering: These techniques join metal pieces together. For custom necklaces, artisans may use laser welding for precision.

- Beading and Stringing: For necklaces that incorporate beads or gemstones, stringing techniques are essential. Ensure the supplier uses durable threads or wires to enhance longevity.

Assembly Process

Assembly is where individual components come together to form the final product. This stage may involve:

- Linking: Connecting chains or components using jump rings or clasps.

- Setting: For necklaces with gemstones, proper setting is crucial. This can involve prong setting, bezel setting, or pave setting, depending on the design.

Finishing Touches

Finishing processes enhance the necklace’s appearance and durability.

- Polishing: This is done to achieve a smooth, shiny surface. Different grades of polishing compounds are used based on the material.

- Plating: Some necklaces may undergo plating (e.g., gold plating) to enhance appearance while maintaining cost-effectiveness.

- Quality Checks: Before packaging, each necklace should undergo a final quality check to ensure it meets design specifications and quality standards.

How Do Quality Assurance Practices Ensure Necklace Quality?

Quality assurance (QA) is critical in the manufacturing of custom necklaces to ensure that products meet both international standards and buyer expectations. Below are the key components of a robust QA process:

What International Standards Should B2B Buyers Look For?

B2B buyers should be familiar with relevant international quality standards that govern the jewelry manufacturing industry. Key standards include:

- ISO 9001: This standard focuses on quality management systems and helps ensure that suppliers consistently meet customer and regulatory requirements.

- CE Marking: This is particularly important for products sold in Europe, indicating compliance with safety and health standards.

- API Standards: For suppliers in the Middle East, adherence to API standards can be crucial, especially in regions with stringent regulations.

What Are the Key Quality Control Checkpoints?

Implementing a structured quality control (QC) process is vital for maintaining high standards. Typical QC checkpoints include:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival. Suppliers should provide certificates of authenticity for precious materials.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process ensures that any defects are identified and rectified early. This is essential for custom designs where precision is key.

- Final Quality Control (FQC): The final inspection before packaging checks for overall quality, including finish, assembly, and functionality of clasps or fasteners.

What Testing Methods Are Commonly Used in Necklace Manufacturing?

Various testing methods are employed to ensure the durability and safety of custom necklaces:

- Tensile Testing: This assesses the strength of materials used in the necklace, especially chains and clasps.

- Corrosion Testing: Important for metal jewelry, this evaluates how well materials resist tarnishing or corrosion over time.

- Gemstone Testing: This ensures that any gemstones used are genuine and meet quality standards, including clarity and cut.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers adhere to quality standards, B2B buyers can take several proactive steps:

- Conduct Audits: Regular audits of suppliers can help verify compliance with quality standards and manufacturing processes. Buyers can request to observe the manufacturing process firsthand.

- Request Quality Reports: Suppliers should provide detailed QC reports that outline testing methods and results.

- Third-Party Inspections: Engage third-party inspection services to conduct independent quality assessments. This adds an extra layer of assurance for buyers concerned about product quality.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in QC:

- Regulatory Compliance: Different regions have varying regulations regarding jewelry manufacturing. Ensure that suppliers are knowledgeable about and compliant with local laws.

- Cultural Sensitivities: Understanding cultural preferences and practices can influence the design and quality expectations for custom necklaces.

- Logistics and Shipping: Quality can be affected by transportation. Ensure that suppliers use appropriate packaging to protect products during shipping, especially for delicate items.

Conclusion

Understanding the manufacturing processes and quality assurance practices in the custom necklace industry is essential for B2B buyers. By focusing on material preparation, forming techniques, assembly, and finishing, along with stringent QC measures, buyers can ensure they partner with reliable suppliers who meet international standards. Engaging in thorough due diligence, including audits and third-party inspections, can further safeguard the quality of custom necklaces sourced from diverse global markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘necklace custom’

Introduction

Sourcing custom necklaces can be a complex process, especially for B2B buyers in regions like Africa, South America, the Middle East, and Europe. This guide provides a practical checklist that will help you navigate the procurement process effectively, ensuring you find reliable suppliers that meet your business needs.

1. Identify Your Market Requirements

Understanding your market’s specific demands is crucial. Analyze trends in your target regions, such as popular materials, designs, and cultural preferences. This knowledge will guide your sourcing strategy and help you communicate effectively with suppliers.

2. Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical specifications. This includes details such as materials (e.g., gold, silver, or gemstones), dimensions, and design elements. Having a well-defined specification sheet minimizes misunderstandings and ensures that you receive products that meet your expectations.

3. Conduct Thorough Supplier Research

Finding the right supplier is fundamental to successful sourcing. Look for suppliers with a strong reputation in the custom jewelry market. Review their online presence, customer reviews, and industry certifications. Consider reaching out to other businesses in your region to gather insights about their experiences.

4. ✅ Verify Supplier Certifications

Ensure that potential suppliers hold relevant certifications, such as ISO standards or ethical sourcing certifications. These credentials indicate adherence to quality and ethical manufacturing practices. Request documentation and verify their authenticity to avoid potential supply chain disruptions.

5. Request Samples Before Committing

Before placing a large order, always request samples of the custom necklaces. This allows you to assess the quality, craftsmanship, and overall appeal of the product. Evaluate the samples against your specifications to ensure they meet your expectations, and consider testing them with a focus group from your target market.

6. Negotiate Terms Clearly

Once you’ve identified a suitable supplier, initiate negotiations with clarity. Discuss pricing, payment terms, minimum order quantities, and lead times. Ensure all agreements are documented to prevent misunderstandings later on. Be open to negotiations but also firm on your requirements to establish a mutually beneficial relationship.

7. Establish a Quality Control Plan

After finalizing your order, implement a quality control plan to ensure that the production meets your standards. Define inspection criteria and communicate these to your supplier. Arrange for regular updates during the production process and consider third-party inspections if necessary, particularly if you are sourcing internationally.

By following this checklist, B2B buyers can streamline their sourcing process for custom necklaces, ensuring they partner with reliable suppliers and receive high-quality products tailored to their market’s needs.

Comprehensive Cost and Pricing Analysis for necklace custom Sourcing

What are the Key Cost Components in Necklace Custom Sourcing?

When sourcing custom necklaces, understanding the cost structure is essential for international B2B buyers. The main components that contribute to the total cost include:

-

Materials: The choice of materials (gold, silver, gemstones, etc.) significantly impacts the price. High-quality or rare materials will naturally lead to higher costs. Buyers should consider local sourcing options to reduce material costs.

-

Labor: Labor costs vary depending on the region and skill level required for crafting the necklaces. Regions with a lower cost of living may offer competitive labor rates, but it’s crucial to assess the quality of craftsmanship.

-

Manufacturing Overhead: This includes expenses related to the production facility, utilities, and equipment maintenance. Understanding the overhead costs can help buyers gauge the supplier’s pricing strategy.

-

Tooling: Custom designs may require specific molds or tools, which can add to the initial setup costs. Buyers should inquire about these costs upfront, especially if they are planning to produce large volumes.

-

Quality Control (QC): Implementing strict quality control measures is essential to ensure product consistency and reliability. This may incur additional costs, but it ultimately protects the buyer’s brand reputation.

-

Logistics: Shipping and handling costs can vary widely based on distance, shipping method, and volume. Buyers should factor in the logistics costs from the supplier’s location to their own and explore different shipping options to optimize expenses.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding this can help buyers negotiate better terms.

How Do Price Influencers Impact the Cost of Custom Necklaces?

Several factors can influence the final pricing of custom necklaces:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to reduced per-unit costs due to economies of scale. Buyers should negotiate for lower MOQs to achieve better pricing.

-

Specifications and Customization: Unique designs or additional features can significantly increase the price. It’s advisable to have a clear design brief to avoid unexpected costs.

-

Material Quality and Certifications: Premium materials with certifications (like conflict-free stones) may come at a higher price but can enhance the product’s marketability.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more, but they often provide better quality assurance.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital, as they define the responsibilities of buyers and sellers in international transactions. Choosing the right Incoterm can help minimize logistics costs and risks.

What Are Effective Buyer Tips for Cost-Efficiency in Necklace Custom Sourcing?

To maximize cost-efficiency when sourcing custom necklaces, B2B buyers should consider the following strategies:

-

Negotiation: Engage in transparent negotiations with suppliers. Highlight your long-term potential as a buyer to secure better pricing and terms.

-

Total Cost of Ownership (TCO): Look beyond the initial price and consider TCO, which includes shipping, tariffs, and potential future costs related to quality issues. This holistic view can lead to better decision-making.

-

Pricing Nuances for International Buyers: Be aware of regional pricing differences. For instance, suppliers in Africa or South America may have different cost structures compared to those in Europe or the Middle East. Understanding these nuances can aid in effective negotiations.

-

Research and Compare Suppliers: Don’t settle for the first quote. Compare multiple suppliers and their offerings to identify the best value for your specific needs.

Disclaimer on Indicative Prices

Prices for custom necklaces can fluctuate based on market conditions, material availability, and supplier pricing strategies. Therefore, it is advisable for buyers to conduct thorough market research and obtain updated quotes before making purchasing decisions.

Alternatives Analysis: Comparing necklace custom With Other Solutions

Exploring Alternatives to Necklace Custom: A Comparative Analysis

When considering the procurement of customized necklaces for your business, it’s crucial to evaluate not only the primary product but also alternative solutions that may meet your needs. This analysis will help international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, make informed decisions by comparing ‘necklace custom’ against other viable options.

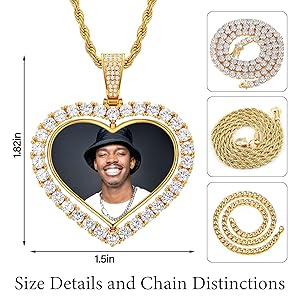

A stock image related to necklace custom.

Comparison Table of Necklace Custom and Alternatives

| Comparison Aspect | Necklace Custom | 3D Printed Jewelry | Mass-Produced Necklaces |

|---|---|---|---|

| Performance | High-quality, unique designs | High precision, varied styles | Consistent quality, limited customization |

| Cost | Moderate to high | Variable, often lower than custom | Low cost, bulk pricing available |

| Ease of Implementation | Requires skilled artisans | Requires 3D design expertise | Simple ordering process, no design needed |

| Maintenance | Moderate, dependent on materials | Low, easy to clean | Low, often durable materials |

| Best Use Case | Luxury and personalized gifts | Innovative designs, tech-savvy markets | High-volume sales, promotional items |

What Are the Pros and Cons of 3D Printed Jewelry as an Alternative?

3D printed jewelry offers a modern approach to customization. Pros include the ability to create intricate designs with high precision, allowing for innovative and complex shapes that might be difficult to achieve through traditional methods. Additionally, 3D printing can be more cost-effective for smaller production runs. However, cons involve the need for specialized skills in 3D design and printing, which may not be readily available in all markets. Furthermore, while the technology allows for customization, the materials may not match the luxurious feel of traditional handcrafted pieces.

How Do Mass-Produced Necklaces Compare?

Mass-produced necklaces are typically the most cost-effective solution for businesses looking to buy in bulk. The pros of this approach include low pricing and a straightforward purchasing process, which can be ideal for promotional events or giveaways. Additionally, they are readily available and often made from durable materials that require minimal maintenance. On the downside, the cons include a lack of uniqueness, which may not appeal to consumers seeking personalized or high-end items. Furthermore, the limited scope for customization means that businesses may struggle to differentiate their offerings in a competitive market.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the right solution for your necklace needs ultimately depends on your target market, budget, and desired product characteristics. If your focus is on luxury and personalization, ‘necklace custom’ remains a strong contender despite its higher costs and implementation complexity. For businesses targeting tech-savvy consumers or innovative markets, 3D printed jewelry may offer the unique designs and cost-effectiveness necessary for success. Conversely, if your strategy revolves around high-volume sales at competitive prices, mass-produced necklaces could be the most practical option. By carefully evaluating these alternatives against your specific business goals, you can make a more informed decision that aligns with your brand vision and customer expectations.

Essential Technical Properties and Trade Terminology for necklace custom

What Are the Key Technical Properties of Custom Necklaces?

When sourcing custom necklaces, understanding the technical properties is essential for ensuring quality and meeting specific design requirements. Here are some critical specifications that B2B buyers should consider:

-

Material Grade

The material grade refers to the quality and type of metals or materials used in the necklace’s construction, such as gold, silver, or stainless steel. Higher-grade materials not only enhance the aesthetic appeal but also influence durability and resistance to tarnishing. For B2B buyers, selecting the appropriate material grade can significantly affect the product’s marketability and longevity. -

Tolerance Levels

Tolerance levels denote the permissible limits of variation in dimensions and weight of the necklace components. This is crucial in ensuring that all parts fit together perfectly, especially for intricate designs. A tight tolerance level is often necessary for high-end pieces, while more lenient tolerances may be acceptable for bulk or lower-cost items. Understanding tolerance levels helps buyers avoid costly reworks or production delays. -

Weight Specifications

The weight of a necklace can impact both its comfort and perceived value. Buyers should specify weight requirements to ensure that the final product meets customer expectations. Lighter necklaces might appeal to a different demographic than heavier ones, making it essential to align weight specifications with target market preferences. -

Plating Thickness

For necklaces that use plated finishes, such as gold or rhodium plating, the thickness of the plating is vital. Thicker plating generally enhances durability and resistance to wear, which is particularly important for jewelry that will be worn frequently. Buyers should inquire about plating thickness to ensure the product’s longevity, especially in competitive markets. -

Finish Type

The finish type refers to the surface treatment of the necklace, which can include options like polished, matte, or brushed. Each finish type conveys a different aesthetic and can influence consumer choice. Buyers should consider which finishes align with current fashion trends and customer preferences in their target markets.

What Are Common Trade Terms in the Custom Necklace Industry?

Familiarizing yourself with industry jargon is crucial for effective communication and negotiation in the custom necklace market. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are sold under another company’s brand. In the context of custom necklaces, partnering with an OEM allows buyers to leverage existing designs and manufacturing processes, ensuring efficiency and quality. -

MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier requires for a particular order. Understanding MOQ is essential for budget planning and inventory management. Buyers must assess their sales forecasts to negotiate favorable MOQs that align with their purchasing capabilities. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. When dealing with custom necklaces, an RFQ should include detailed specifications, such as material grades, dimensions, and desired finishes. This ensures that suppliers provide accurate pricing and timelines. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers to clarify shipping responsibilities, risk management, and cost allocation. Common Incoterms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight). -

Lead Time

Lead time refers to the time taken from placing an order to delivery. This is a critical factor for B2B buyers, especially when planning inventory and sales strategies. Clear communication about lead times helps manage customer expectations and ensures timely product availability. -

CAD (Computer-Aided Design)

CAD refers to the use of software to create precise drawings and models of products, including custom necklaces. Utilizing CAD in the design phase allows for greater accuracy and facilitates modifications before production begins, which can save time and reduce errors.

By understanding these essential technical properties and trade terms, international B2B buyers can make informed decisions when sourcing custom necklaces, ultimately leading to successful partnerships and satisfied customers.

Navigating Market Dynamics and Sourcing Trends in the necklace custom Sector

What Are the Current Market Dynamics and Key Trends in the Necklace Custom Sector?

The global necklace custom sector is experiencing a transformative phase driven by technological advancements and changing consumer preferences. In recent years, there has been a significant shift toward personalization, with buyers increasingly seeking unique, bespoke designs that reflect individual identities. This trend is particularly pronounced in regions like Africa and South America, where cultural heritage plays a crucial role in jewelry design. Additionally, the rise of e-commerce platforms has made it easier for international B2B buyers to access a broader range of suppliers and manufacturers, facilitating cross-border trade.

Emerging technologies, such as 3D printing and augmented reality, are also reshaping the landscape. These innovations allow for rapid prototyping and virtual try-ons, enhancing the buying experience and reducing lead times. B2B buyers can leverage these technologies to offer customized solutions to their clients, meeting the rising demand for personalized products. Furthermore, data analytics is becoming essential in understanding market trends and consumer behavior, enabling companies to forecast demand more accurately and optimize their inventory management.

Another key trend is the increasing emphasis on local sourcing. As logistics challenges and environmental concerns grow, many buyers are exploring suppliers closer to their target markets. This shift not only reduces shipping costs and lead times but also enhances the sustainability of the supply chain. For international B2B buyers, particularly those in Europe and the Middle East, understanding these dynamics is crucial for capitalizing on emerging opportunities in the necklace custom sector.

How Is Sustainability and Ethical Sourcing Impacting the Necklace Custom Sector?

Sustainability has emerged as a pivotal consideration for international B2B buyers in the necklace custom sector. The environmental impact of jewelry production, particularly in terms of resource extraction and waste generation, has prompted a shift towards more sustainable practices. Buyers are increasingly prioritizing suppliers who demonstrate commitment to eco-friendly materials and processes. This includes the use of recycled metals, ethically sourced gemstones, and biodegradable packaging.

Ethical sourcing is not just a trend but a necessity for building trust with consumers, especially in markets where social responsibility is paramount. Certifications such as Fair Trade and Responsible Jewelry Council (RJC) provide assurance that materials are sourced in a way that respects both people and the planet. For buyers in regions like Africa and the Middle East, where community impact is significant, aligning with suppliers who uphold these ethical standards can enhance brand reputation and customer loyalty.

Moreover, integrating sustainability into supply chains can lead to cost savings in the long run. By minimizing waste and optimizing resource use, companies can improve their bottom line while contributing to a more sustainable future. International B2B buyers must prioritize partnerships with suppliers committed to sustainability and ethical sourcing to remain competitive and responsive to consumer demands.

What Is the Historical Context of the Necklace Custom Sector for B2B Buyers?

The necklace custom sector has a rich history, evolving significantly over the centuries. Initially, jewelry served as a status symbol and was often handcrafted by skilled artisans using traditional techniques passed down through generations. The rise of the industrial revolution in the 19th century introduced mass production methods, making jewelry more accessible but often sacrificing individuality and craftsmanship.

In recent decades, the resurgence of artisanal and bespoke jewelry has rekindled interest in custom pieces. This evolution is particularly relevant for B2B buyers, who are now seeking suppliers that can blend traditional craftsmanship with modern technology. Understanding this historical context helps buyers appreciate the value of unique designs and the importance of supporting sustainable practices, ensuring the sector continues to thrive in a rapidly changing market.

Frequently Asked Questions (FAQs) for B2B Buyers of necklace custom

-

How do I ensure quality when sourcing custom necklaces internationally?

To ensure quality, begin by vetting suppliers through online platforms like Alibaba or Global Sources, where you can read reviews and ratings. Request samples before placing a bulk order to evaluate craftsmanship and materials. It’s also beneficial to ask for certifications related to quality standards and compliance with local regulations. Consider hiring a third-party quality assurance service to inspect products before shipment, especially when dealing with suppliers in regions such as Africa or the Middle East. -

What are the minimum order quantities (MOQs) for custom necklaces?

MOQs for custom necklaces can vary widely depending on the supplier and the complexity of the design. Generally, you can expect MOQs to range from 50 to 500 pieces. Some manufacturers may offer lower MOQs for simpler designs or first-time buyers, while others may require higher quantities for intricate customizations. Always clarify these details upfront to avoid misunderstandings and ensure that your order aligns with your budget and sales projections. -

What are the typical payment terms for international custom necklace orders?

Payment terms vary by supplier, but common practices include 30% upfront payment and 70% before shipment. Some suppliers may offer flexible terms such as Letter of Credit (LC) or payment through escrow services for added security. It’s essential to negotiate these terms early in the conversation to ensure both parties feel secure. Consider using secure payment platforms that offer buyer protection, especially when working with new suppliers from regions like South America or Africa. -

What factors should I consider when customizing necklace designs?

When customizing necklace designs, consider your target market’s preferences, cultural significance, and current trends. Evaluate the materials you want to use, as they can impact both cost and appeal. It’s also crucial to ensure that the design aligns with your brand identity. Collaborate closely with your supplier during the design phase to ensure that they can meet your specifications while also offering insights on feasibility and production timelines. -

How can I effectively communicate my custom necklace design ideas to suppliers?

Effective communication is key to successful customization. Utilize sketches, digital mockups, and reference images to convey your vision clearly. Provide detailed descriptions of materials, dimensions, and any specific features you require. Consider using video calls for real-time discussions, which can help clarify complex ideas. Establishing a clear communication channel from the start fosters a collaborative relationship and reduces the likelihood of misunderstandings. -

What are the best practices for shipping custom necklaces internationally?

When shipping custom necklaces internationally, choose reliable logistics partners who specialize in handling delicate items. Always clarify shipping costs and timelines upfront to avoid surprises. Use proper packaging to protect the necklaces during transit, and consider insuring your shipment. Familiarize yourself with customs regulations in your destination country to ensure a smooth clearance process, particularly in regions like the Middle East and Africa, where regulations may vary significantly. -

How do I handle customs duties and taxes for imported custom necklaces?

Customs duties and taxes are determined by the country of import, and they can significantly impact your overall cost. Research the specific tariffs applicable to jewelry in your target market, as they can vary based on material and value. Ensure your supplier provides accurate documentation, including invoices and certificates of origin, to facilitate customs clearance. It’s advisable to consult with a customs broker who can provide guidance tailored to your situation and help you navigate complex regulations. -

What are the common pitfalls to avoid when sourcing custom necklaces?

Common pitfalls include failing to conduct thorough supplier vetting, which can lead to quality issues or scams. Avoid overlooking the importance of clear communication, as misunderstandings can result in unsatisfactory products. Be cautious of suppliers that offer prices that seem too good to be true, as they may compromise on quality. Additionally, neglecting to understand the logistics and customs processes can lead to unexpected delays and costs. Always conduct due diligence and establish a solid contractual agreement before proceeding.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for necklace custom

As the demand for custom necklaces continues to rise, strategic sourcing remains a pivotal factor for international B2B buyers aiming to optimize their supply chain. By leveraging a thorough understanding of market trends and supplier capabilities, businesses from Africa, South America, the Middle East, and Europe can enhance their product offerings and increase customer satisfaction. Key takeaways include the importance of establishing strong relationships with suppliers, ensuring quality control, and embracing innovative materials and designs that resonate with diverse cultural aesthetics.

A stock image related to necklace custom.

What are the future trends in custom necklace sourcing? As we look ahead, the integration of technology in the sourcing process will become increasingly important. Embracing digital platforms for supplier discovery and management can streamline procurement processes and foster collaboration. Additionally, sustainability will play a critical role in supplier selection, as consumers globally demand ethically sourced and environmentally friendly products.

International B2B buyers are encouraged to adopt a proactive approach in sourcing custom necklaces. By staying informed about industry developments and aligning sourcing strategies with market demands, businesses can position themselves for growth and success. The time to act is now—embrace strategic sourcing to unlock new opportunities in the custom jewelry market.