Unlock Quality & Savings with a Multilayer PCB Supplier (2025)

Introduction: Navigating the Global Market for multilayer pcb supplier

In an increasingly interconnected world, sourcing a reliable multilayer PCB supplier can be a formidable challenge for international B2B buyers. With varying standards, regulations, and supplier capabilities across regions, navigating this landscape can often feel overwhelming. This guide aims to demystify the complexities involved in selecting a multilayer PCB supplier by providing actionable insights tailored specifically for businesses in Africa, South America, the Middle East, and Europe, including key markets like Poland and Nigeria.

Throughout this comprehensive guide, we will explore the diverse types of multilayer PCBs available in the market, their applications across different industries, and the critical factors to consider when vetting potential suppliers. From understanding the nuances of manufacturing processes to evaluating cost structures and lead times, this resource is designed to empower informed purchasing decisions.

By equipping B2B buyers with the knowledge to identify and engage with reputable multilayer PCB suppliers, we aim to facilitate smoother procurement processes and foster long-term partnerships. Whether you are an electronics manufacturer in Nigeria seeking to enhance your product offerings or a tech startup in Poland looking for innovative solutions, this guide will serve as your roadmap to successfully navigate the global market for multilayer PCBs.

Understanding multilayer pcb supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Multilayer PCB | 4 to 12 layers, common materials like FR-4 | Consumer electronics, automotive | Pros: Cost-effective, widely available. Cons: Limited in high-frequency applications. |

| High-Frequency Multilayer PCB | Specialized materials (e.g., PTFE), optimized for RF signals | Telecommunications, aerospace | Pros: Excellent signal integrity, suitable for RF applications. Cons: Higher cost and complexity. |

| Flexible Multilayer PCB | Combination of flexibility and multilayer design | Wearable technology, medical devices | Pros: Space-saving, lightweight. Cons: More expensive and challenging to manufacture. |

| Rigid-Flex Multilayer PCB | Integrates rigid and flexible circuits in one design | Aerospace, military, high-end electronics | Pros: Versatile design, reduces assembly time. Cons: Higher production costs and design complexity. |

| Heavy Copper Multilayer PCB | Increased copper thickness for better thermal management | Power supplies, industrial applications | Pros: Enhanced thermal and current handling. Cons: Limited design flexibility and higher weight. |

What Are the Characteristics of Standard Multilayer PCBs?

Standard multilayer PCBs typically consist of four to twelve layers and are primarily made from materials like FR-4. They are the most common type of multilayer PCB and serve various industries, including consumer electronics and automotive sectors. When considering purchasing, buyers should evaluate the supplier’s capability to meet specific layer counts and material specifications, as well as lead times and cost efficiency.

Why Choose High-Frequency Multilayer PCBs for Telecommunications?

High-frequency multilayer PCBs are designed with specialized materials such as PTFE to optimize signal integrity for radio frequency (RF) applications. These PCBs are essential in industries like telecommunications and aerospace, where performance is critical. Buyers must assess the supplier’s expertise in high-frequency designs, as well as their ability to provide testing and certification for compliance with industry standards.

How Do Flexible Multilayer PCBs Benefit Wearable Technology?

Flexible multilayer PCBs combine the advantages of multilayer designs with flexibility, making them ideal for applications in wearable technology and medical devices. Their lightweight and space-saving attributes are significant advantages. However, buyers should be aware of the higher costs associated with flexible designs and ensure that their suppliers can handle the complexities of manufacturing these PCBs.

What Are the Advantages of Rigid-Flex Multilayer PCBs?

Rigid-flex multilayer PCBs integrate both rigid and flexible circuit technologies, allowing for versatile designs that can reduce assembly time. They are particularly useful in aerospace, military, and high-end electronics applications. Buyers should consider the supplier’s experience in producing rigid-flex designs, as well as their ability to manage the associated complexities and costs effectively.

When Should You Consider Heavy Copper Multilayer PCBs?

Heavy copper multilayer PCBs are characterized by increased copper thickness, which enhances thermal management and current handling capabilities. These boards are commonly used in power supplies and industrial applications. Buyers need to evaluate the supplier’s capacity to manufacture heavy copper designs, along with the implications for weight and design flexibility in their specific applications.

Related Video: Multilayer PCB Stack-up Basics | PCB Knowledge

Key Industrial Applications of multilayer pcb supplier

| Industry/Sector | Specific Application of multilayer pcb supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | Smart Devices (Wearables, Smartphones) | Enhanced functionality in compact designs | Reliability, lead time, and certification standards |

| Automotive | Advanced Driver-Assistance Systems (ADAS) | Increased safety and efficiency in vehicle operations | Compliance with automotive standards, durability, cost |

| Telecommunications | Network Infrastructure (Routers, Switches) | Improved data transmission and network reliability | Scalability, thermal management, and component compatibility |

| Medical Devices | Diagnostic Equipment (MRI, Ultrasound) | Precision and reliability in critical health applications | Regulatory compliance, biocompatibility, and traceability |

| Industrial Automation | Control Systems (PLC, Robotics) | Streamlined operations and reduced downtime | Customization capabilities, environmental resistance, and support services |

How Are Multilayer PCBs Used in Consumer Electronics?

In the consumer electronics sector, multilayer PCBs are integral for smart devices such as wearables and smartphones. These devices require high-density interconnections to manage complex functionalities in a compact form. By utilizing multilayer technology, manufacturers can enhance performance while minimizing the overall footprint. For B2B buyers in regions like South America and Africa, sourcing multilayer PCBs that ensure reliability and adhere to international quality standards is crucial, particularly given the growing demand for advanced consumer electronics.

What Role Do Multilayer PCBs Play in Automotive Applications?

Multilayer PCBs are essential in the automotive industry, especially in advanced driver-assistance systems (ADAS). These PCBs support critical functions like collision detection and lane-keeping assistance, thereby enhancing vehicle safety and efficiency. Buyers from Europe and the Middle East need to prioritize suppliers that meet stringent automotive standards and provide durable solutions capable of withstanding harsh environmental conditions. The ability to integrate multiple functionalities within a single PCB can also lead to cost savings and streamlined production processes.

How Are Multilayer PCBs Enhancing Telecommunications?

In telecommunications, multilayer PCBs are vital for network infrastructure components such as routers and switches. They enable faster data transmission and improved network reliability, which are crucial for maintaining competitive advantages in a rapidly evolving market. International buyers should focus on sourcing PCBs that offer scalability and effective thermal management, as these factors significantly impact long-term performance. Additionally, ensuring compatibility with existing components is essential for seamless integration into current systems.

Why Are Multilayer PCBs Critical in Medical Devices?

Multilayer PCBs find significant applications in diagnostic equipment like MRI and ultrasound machines. These devices demand high precision and reliability, as they are used in critical health applications. Buyers in the medical sector must prioritize suppliers that comply with regulatory requirements and offer traceable components, as these factors directly affect patient safety. The biocompatibility of materials used in PCBs is also a key consideration for medical device manufacturers looking to ensure compliance with health regulations.

How Do Multilayer PCBs Optimize Industrial Automation?

In industrial automation, multilayer PCBs are used in control systems such as programmable logic controllers (PLCs) and robotics. These PCBs facilitate streamlined operations and reduce downtime, which is vital for maintaining productivity in manufacturing environments. B2B buyers should seek suppliers that offer customization capabilities to meet specific operational needs and ensure environmental resistance to withstand industrial conditions. Support services from suppliers can also play a crucial role in maintaining system integrity over time.

3 Common User Pain Points for ‘multilayer pcb supplier’ & Their Solutions

Scenario 1: Navigating Quality Control Challenges in Multilayer PCBs

The Problem: B2B buyers often face significant hurdles when it comes to ensuring the quality of multilayer PCBs. This is especially true when sourcing from suppliers located in different regions, such as Africa or South America, where manufacturing standards may vary. Buyers may receive products that do not meet their specifications, leading to costly delays in production and potential product recalls. Moreover, the lack of established quality assurance protocols can lead to inconsistencies in the boards, affecting the overall reliability of their end products.

The Solution: To effectively navigate quality control challenges, buyers should implement a rigorous supplier evaluation process before entering into contracts. Start by assessing potential suppliers based on their certifications, such as IPC or ISO standards, which indicate adherence to international quality benchmarks. Additionally, consider conducting on-site audits or requesting third-party inspection reports.

Furthermore, establish clear communication channels with your supplier to outline quality expectations and specifications in detail. Implementing a robust quality assurance plan that includes regular checks throughout the production process can help catch issues early. Finally, utilizing a small-scale pilot run can serve as a practical method to evaluate the supplier’s capabilities before committing to larger orders, thereby minimizing risks associated with quality discrepancies.

Scenario 2: Overcoming Lead Time and Delivery Delays in PCB Procurement

The Problem: One of the most pressing issues for international buyers of multilayer PCBs is the unpredictability of lead times and delivery schedules. Delays can arise from various factors, including customs clearance, logistical challenges, and production backlogs. This unpredictability can severely disrupt project timelines, especially for companies in fast-paced industries like electronics or automotive, where time-to-market is critical.

The Solution: To mitigate lead time and delivery delays, it’s crucial to establish strong relationships with suppliers that have proven track records of reliability. Engage with suppliers who offer transparency in their production schedules and can provide real-time updates on order status.

Consider diversifying your supplier base by sourcing from multiple regions. This strategy allows you to mitigate risks associated with a single supplier and can help you adapt to unforeseen delays. Additionally, implementing a buffer stock strategy can provide a safety net during unexpected supply chain disruptions. By maintaining a small inventory of critical components, you can ensure that your production lines continue to operate smoothly even if there are temporary delays in PCB deliveries.

Scenario 3: Addressing Cost Management Issues in Multilayer PCB Sourcing

The Problem: Managing costs effectively while sourcing multilayer PCBs is a common pain point for B2B buyers. Fluctuating material prices, hidden fees, and unexpected tariffs can significantly impact the overall budget. For companies operating in regions such as the Middle East or Europe, where currency fluctuations may also affect pricing, this adds another layer of complexity to procurement strategies.

The Solution: To address cost management issues, buyers should engage in comprehensive market research to understand prevailing material prices and supplier pricing structures. It is advisable to request detailed quotations from multiple suppliers, ensuring that all potential fees (shipping, customs duties, etc.) are clearly outlined.

Implementing a strategic sourcing approach can help in negotiating better prices. Building long-term partnerships with suppliers may lead to volume discounts and improved terms over time. Additionally, consider leveraging technology, such as procurement software, to gain insights into pricing trends and manage supplier relationships more effectively. Regularly reviewing and adjusting procurement strategies based on market conditions can lead to more predictable and manageable costs in multilayer PCB sourcing.

Strategic Material Selection Guide for multilayer pcb supplier

What are the Key Materials Used in Multilayer PCBs?

When selecting materials for multilayer printed circuit boards (PCBs), several options are commonly used, each with unique properties and applications. Understanding these materials is crucial for international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, as the right choice can significantly affect product performance and compliance with regional standards.

What are the Advantages and Disadvantages of FR-4 Material?

FR-4 is one of the most widely used materials for multilayer PCBs due to its excellent electrical insulation and mechanical properties. It is a composite of woven fiberglass cloth and epoxy resin, providing a good balance between performance and cost.

Key Properties: FR-4 has a temperature rating of approximately 130°C and offers good resistance to moisture and chemicals.

Pros & Cons: The primary advantage of FR-4 is its affordability and versatility, making it suitable for a wide range of applications. However, it has limitations in high-frequency applications due to its dielectric properties, which can lead to signal loss.

Impact on Application: FR-4 is compatible with various media, making it ideal for consumer electronics, automotive applications, and telecommunications.

Considerations for International Buyers: Buyers should ensure that FR-4 materials meet local compliance standards, such as RoHS in Europe and similar regulations in Africa and South America. Additionally, understanding the manufacturing capabilities of suppliers in these regions can help ensure timely delivery and quality assurance.

How Does Polyimide Compare as a Material for Multilayer PCBs?

Polyimide is another popular choice for multilayer PCBs, particularly in applications requiring high thermal stability and flexibility.

Key Properties: Polyimide can withstand temperatures up to 260°C and is known for its excellent mechanical and thermal properties.

Pros & Cons: The key advantage of polyimide is its ability to perform in extreme environments, making it suitable for aerospace and medical applications. However, it is generally more expensive than FR-4 and can complicate the manufacturing process due to its unique handling requirements.

Impact on Application: Polyimide is particularly effective in applications that experience high thermal cycling or require high reliability, such as military and aerospace technologies.

Considerations for International Buyers: Buyers must be aware of the specific certifications required for polyimide materials, especially in highly regulated industries. Understanding local standards, such as ASTM and DIN, is crucial for compliance.

What Role Does Rogers Material Play in High-Frequency Applications?

Rogers materials are specifically designed for high-frequency applications, making them a preferred choice for RF and microwave PCBs.

Key Properties: Rogers materials can handle frequencies up to 100 GHz and have low dielectric loss, making them ideal for high-speed data transmission.

Pros & Cons: The advantage of Rogers materials lies in their superior performance in high-frequency applications. However, they are significantly more expensive than traditional materials like FR-4 and may require specialized manufacturing processes.

Impact on Application: Rogers materials are commonly used in telecommunications, radar systems, and satellite communications, where signal integrity is paramount.

Considerations for International Buyers: Buyers should consider the availability of Rogers materials in their regions and ensure that suppliers can meet the necessary specifications and certifications. Understanding local market dynamics can also aid in negotiating better pricing.

How Does Aluminum-Based Material Enhance Thermal Management in PCBs?

Aluminum-based materials are increasingly being used in multilayer PCBs to enhance thermal management, especially in LED and power electronics applications.

Key Properties: Aluminum provides excellent thermal conductivity, with a thermal conductivity rating of around 200 W/mK, making it ideal for heat dissipation.

Pros & Cons: The primary advantage of aluminum-based PCBs is their ability to manage heat effectively, improving the longevity and reliability of electronic components. However, they are generally more expensive and can complicate the manufacturing process.

Impact on Application: These materials are particularly effective in applications where heat generation is a concern, such as in power amplifiers and LED lighting.

Considerations for International Buyers: When sourcing aluminum-based materials, buyers should verify the supplier’s capabilities in handling aluminum and ensure compliance with relevant standards, such as IPC and JIS.

Summary Table of Material Selection for Multilayer PCBs

| Material | Typical Use Case for multilayer pcb supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| FR-4 | Consumer electronics, automotive | Cost-effective and versatile | Limited in high-frequency use | Low |

| Polyimide | Aerospace, medical devices | High thermal stability | Higher cost and manufacturing complexity | High |

| Rogers | RF and microwave applications | Superior performance at high frequencies | Expensive and specialized manufacturing | High |

| Aluminum | Power electronics, LED applications | Excellent thermal management | Higher cost and manufacturing complexity | Medium |

This strategic material selection guide aims to empower international B2B buyers with the knowledge needed to make informed decisions when sourcing multilayer PCBs, ensuring compliance and suitability for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for multilayer pcb supplier

What Are the Main Stages of Manufacturing Multilayer PCBs?

Manufacturing multilayer printed circuit boards (PCBs) involves several intricate stages that require precision and adherence to quality standards. Understanding these stages is crucial for international B2B buyers looking to partner with suppliers who can deliver high-quality products.

Material Preparation: How Is the Right Base Material Chosen?

The first step in the manufacturing process is material preparation. Multilayer PCBs typically use materials like FR-4, a composite of woven fiberglass cloth with epoxy resin. Buyers should ensure that suppliers source high-grade materials that meet international specifications. This phase involves:

- Material Selection: Choosing the right substrate based on the electrical requirements, thermal performance, and mechanical strength.

- Copper Foil Preparation: Copper is essential for electrical connectivity. Suppliers should utilize high-quality copper foils that prevent issues like oxidation.

- Layer Bonding: Preparing adhesive layers to bond multiple substrates together is crucial. Suppliers should use adhesives that withstand high temperatures and provide excellent dielectric properties.

How Are Multilayer PCBs Formed and Assembled?

What Techniques Are Used in the Forming Process?

The forming process involves several techniques that can vary based on the complexity of the PCB design. Key methods include:

- Photolithography: This process uses light to transfer a pattern onto the PCB layers. It is essential for creating precise circuit designs.

- Etching: After photolithography, unwanted copper is removed through chemical or mechanical etching, creating the desired circuit paths.

- Drilling: Holes are drilled for vias and component placement. High-speed drills are typically used for accuracy.

How Is the Assembly Process Conducted?

The assembly process integrates various components onto the PCB. This includes:

- Solder Paste Application: Solder paste is applied to pads where components will be mounted, ensuring strong electrical connections.

- Component Placement: Automated machines (pick-and-place) are often used to place components accurately on the PCB.

- Soldering: Techniques like reflow soldering or wave soldering are employed to secure the components onto the PCB.

What Finishing Techniques Are Essential for Multilayer PCBs?

How Do Finishing Processes Enhance PCB Quality?

Finishing processes enhance the durability and functionality of multilayer PCBs. Key techniques include:

- Surface Finish: Various surface finishes (like HASL, ENIG, or OSP) protect exposed copper from oxidation and ensure solderability.

- Conformal Coating: A protective chemical coating is applied to the PCB to protect against moisture and contaminants.

- Final Inspection and Packaging: After finishing, PCBs undergo a final inspection to verify quality before packaging and shipping.

What Are the Key Quality Control Standards for Multilayer PCBs?

How Do International Standards Impact Quality Assurance?

Quality assurance is critical in ensuring that multilayer PCBs meet the required specifications and standards. International standards such as ISO 9001 focus on quality management systems, ensuring that suppliers maintain consistent quality levels. Other relevant standards include:

- IPC Standards: These are specific to PCB manufacturing and cover everything from design to assembly.

- CE Marking: Required for products sold in the European Economic Area, ensuring compliance with safety and environmental standards.

- API Standards: Relevant for PCBs used in the oil and gas industry, ensuring they can withstand harsh conditions.

What Are the QC Checkpoints Throughout the Manufacturing Process?

How Are Quality Control Checkpoints Structured?

Quality control (QC) checkpoints are essential at various stages of the manufacturing process to ensure product reliability. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early.

- Final Quality Control (FQC): A thorough inspection of the finished product to ensure it meets all design and performance specifications.

What Common Testing Methods Are Used to Verify PCB Quality?

How Do Testing Methods Ensure PCB Reliability?

Testing methods play a crucial role in validating the quality and functionality of multilayer PCBs. Common testing techniques include:

- Electrical Testing: This checks for short circuits, open circuits, and proper component placement.

- Thermal Cycling Tests: These simulate extreme temperature changes to ensure the PCB can withstand environmental stress.

- X-ray Inspection: This non-destructive method checks for hidden defects, particularly in solder joints.

How Can B2B Buyers Verify Supplier Quality Control Practices?

What Steps Should Buyers Take to Ensure Supplier Compliance?

International B2B buyers need to conduct thorough due diligence when selecting multilayer PCB suppliers. Here are actionable steps to verify supplier quality control practices:

- Supplier Audits: Conduct regular audits to evaluate the supplier’s manufacturing processes and quality control systems. This should include reviewing their adherence to international standards.

- Request Quality Reports: Ask suppliers for their quality assurance documentation, including inspection reports and test results.

- Third-Party Inspections: Engage independent third-party inspection services to validate the supplier’s claims and ensure compliance with industry standards.

- Certifications Verification: Check for relevant certifications (like ISO, IPC, CE) to assess the supplier’s commitment to quality.

What Are the Quality Control Nuances for International Buyers?

How Do Regional Differences Impact Quality Assurance?

International buyers, particularly from Africa, South America, the Middle East, and Europe, must be aware of regional nuances in quality control practices. For instance, suppliers in Europe may have stricter compliance requirements compared to those in other regions. Buyers should consider:

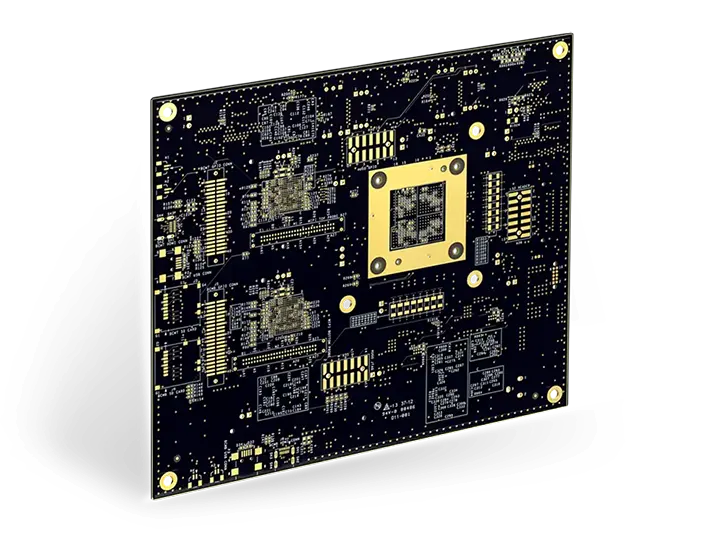

A stock image related to multilayer pcb supplier.

- Cultural Differences: Understanding local business practices can help in negotiating terms and ensuring compliance.

- Supply Chain Logistics: Consider the implications of shipping and logistics on product quality, particularly for temperature-sensitive materials.

- Regulatory Compliance: Be aware of varying regulations in different countries, which may impact the choice of materials and manufacturing processes.

By understanding the manufacturing processes and quality assurance measures for multilayer PCBs, international B2B buyers can make informed decisions and select reliable suppliers that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘multilayer pcb supplier’

Introduction

Sourcing multilayer PCBs (Printed Circuit Boards) requires careful consideration and a methodical approach, especially for international B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe. This checklist is designed to streamline your procurement process, ensuring you make informed decisions while minimizing risks and maximizing quality.

Step 1: Define Your Technical Specifications

Before you begin searching for suppliers, it’s essential to have a clear understanding of your technical requirements. This includes the number of layers, material specifications, surface finish, and any specific design constraints.

- Why it Matters: Having well-defined specifications helps suppliers provide accurate quotes and ensures compatibility with your products.

- What to Look For: Include details such as the intended application, size, and any regulatory compliance standards relevant to your industry.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential multilayer PCB suppliers. Utilize online directories, industry forums, and trade shows to gather a list of candidates.

- Why it Matters: A wide selection of suppliers increases your chances of finding the best fit for your needs.

- What to Look For: Focus on suppliers with a proven track record in your specific industry and those who cater to your geographical region.

Step 3: Evaluate Supplier Capabilities

Assess the capabilities of each potential supplier to determine whether they can meet your technical and production requirements.

- Why it Matters: Understanding a supplier’s manufacturing capabilities, technology, and equipment can prevent future production issues.

- What to Look For: Inquire about their production capacity, lead times, and the technologies they employ, such as automated assembly or advanced testing methods.

Step 4: Verify Supplier Certifications

Check for relevant certifications and quality management systems that demonstrate a supplier’s commitment to quality and reliability.

- Why it Matters: Certifications such as ISO 9001 or IPC-A-600 indicate a supplier’s adherence to industry standards, which can enhance product reliability.

- What to Look For: Request copies of certifications and any third-party audits they have undergone.

Step 5: Request Samples and Prototypes

Before placing a large order, ask for samples or prototypes to evaluate the quality of the PCBs.

- Why it Matters: This step allows you to assess the supplier’s manufacturing quality and ensure it meets your specifications.

- What to Look For: Pay attention to the finish, layer alignment, and any defects in the samples provided.

Step 6: Review Pricing and Payment Terms

Compare pricing structures among different suppliers while considering the total cost of ownership, including shipping and potential tariffs.

- Why it Matters: Understanding the full financial implications helps you make cost-effective decisions.

- What to Look For: Look for transparent pricing models and favorable payment terms that align with your cash flow needs.

Step 7: Establish Communication Channels

Effective communication is vital for a successful partnership. Establish clear channels for ongoing dialogue with your chosen supplier.

- Why it Matters: Open lines of communication facilitate problem-solving and ensure timely updates on production status.

- What to Look For: Determine the preferred methods of communication (email, phone, etc.) and establish regular check-ins throughout the production process.

By following these steps, international B2B buyers can effectively navigate the complexities of sourcing multilayer PCBs, ensuring they select a supplier that meets both their technical and business needs.

Comprehensive Cost and Pricing Analysis for multilayer pcb supplier Sourcing

When sourcing multilayer PCBs, understanding the comprehensive cost structure is vital for B2B buyers. This analysis will cover the various components that contribute to the pricing of multilayer PCBs and highlight the factors that influence these prices.

What Are the Key Cost Components for Multilayer PCB Manufacturing?

-

Materials: The choice of materials directly impacts the cost. High-performance materials, such as FR-4, polyimide, or Rogers, can be significantly more expensive than standard options. Additionally, specialized coatings and finishes, such as ENIG (Electroless Nickel Immersion Gold) or HASL (Hot Air Solder Leveling), can further affect the total material costs.

-

Labor: Labor costs vary widely based on the geographic location of the manufacturer. Regions with lower labor costs, such as parts of Africa and South America, may offer competitive pricing. However, consider the trade-off between cost and the expertise available in those regions.

-

Manufacturing Overhead: This includes the costs associated with running the manufacturing facility, such as utilities, maintenance, and administrative expenses. Overhead can be higher in regions with strict regulatory requirements, impacting the final pricing.

-

Tooling: Initial setup costs for tooling can be substantial, especially for custom designs. These costs need to be amortized over the production run, which means larger order volumes can lead to lower per-unit costs.

-

Quality Control (QC): Implementing rigorous QC processes is essential, especially for multilayer PCBs where defects can lead to significant failures. The costs associated with testing and inspection must be factored into the pricing structure.

-

Logistics: The cost of shipping and handling can vary greatly depending on the destination. For buyers in Europe and the Middle East, proximity to suppliers can reduce logistics costs, while international shipping to Africa or South America may increase expenses.

-

Margin: Suppliers will typically include a profit margin in their pricing. This margin can vary based on the supplier’s market position, brand reputation, and the complexity of the project.

How Do Price Influencers Affect Multilayer PCB Costs?

-

Volume and Minimum Order Quantity (MOQ): Pricing often depends on the volume of PCBs ordered. Higher volumes can lead to significant discounts. Understanding the supplier’s MOQ can help in negotiating better pricing.

-

Specifications and Customization: Custom specifications can increase costs due to additional engineering time and resources required. Buyers should clarify their needs upfront to avoid unexpected charges later in the process.

-

Material Selection: The choice of base materials and finishes can drastically affect the overall price. Buyers should weigh the necessity of high-grade materials against their project requirements.

-

Quality Certifications: Suppliers with industry certifications (such as ISO 9001 or IPC standards) may charge a premium. However, these certifications often ensure higher quality and reliability, which can be crucial for certain applications.

-

Supplier Factors: The supplier’s reputation, experience, and location can influence pricing. Established suppliers may have higher prices but offer reliability and quality assurance, while newer suppliers might provide lower prices with greater risk.

-

Incoterms: The agreed-upon Incoterms will determine who is responsible for shipping costs and risks, which can significantly affect the total price. Buyers should negotiate these terms to ensure clarity in pricing.

What Are the Best Practices for International B2B Buyers When Sourcing Multilayer PCBs?

-

Negotiate Effectively: Understanding the full cost structure allows buyers to negotiate better terms. Highlighting your potential for larger orders can often persuade suppliers to offer discounts.

-

Focus on Total Cost of Ownership (TCO): Consider not just the initial purchase price but the long-term costs associated with maintenance, reliability, and potential failures. A slightly higher upfront cost may lead to lower TCO.

-

Understand Pricing Nuances: Be aware of regional pricing differences, especially when sourcing from Africa, South America, the Middle East, and Europe. Economic conditions, currency fluctuations, and local regulations can all impact pricing.

-

Request Detailed Quotes: Ask suppliers for itemized quotes to understand where costs are coming from. This transparency will help in comparing offers from different suppliers.

-

Stay Informed About Market Trends: Keep an eye on global market trends that could affect material costs and availability. This knowledge can provide leverage during negotiations.

In conclusion, a thorough understanding of the cost structure and pricing influencers is essential for international B2B buyers sourcing multilayer PCBs. By leveraging these insights, buyers can make informed decisions that align with their project requirements and budgetary constraints.

Alternatives Analysis: Comparing multilayer pcb supplier With Other Solutions

Introduction: Exploring Alternatives to Multilayer PCB Suppliers

In the rapidly evolving electronics landscape, selecting the right multilayer PCB supplier is crucial for businesses. However, it’s essential to evaluate alternatives that could potentially meet your project needs while offering different benefits. This analysis will compare multilayer PCB suppliers against two viable alternatives: rigid PCBs and flexible PCBs. Understanding these options can help B2B buyers make informed decisions tailored to their specific requirements.

Comparison Table

| Comparison Aspect | Multilayer PCB Supplier | Rigid PCB Solution | Flexible PCB Solution |

|---|---|---|---|

| Performance | High signal integrity and density | Good for standard applications | Excellent for dynamic applications |

| Cost | Higher due to complexity | Generally lower cost | Can be higher due to material costs |

| Ease of Implementation | Requires specialized processes | Straightforward design | More complex design and manufacturing |

| Maintenance | Moderate; less prone to failure | Low; easy to replace | Moderate; sensitive to stress |

| Best Use Case | Advanced electronics requiring compact size | General consumer electronics | Wearable tech and compact devices |

What Are the Pros and Cons of Rigid PCB Solutions?

Rigid PCBs are often the go-to choice for many standard electronic applications. They offer a straightforward design process, making them easier to implement and manufacture. Their cost-effectiveness is a significant advantage, especially for bulk production. However, they lack the flexibility needed for applications that require bending or dynamic movement. This can limit their use in certain high-tech products where space and mobility are critical.

What Are the Advantages and Disadvantages of Flexible PCB Solutions?

Flexible PCBs are designed for applications where space and weight are at a premium. They are ideal for wearable technology and other compact devices that require bending or folding. The performance of flexible PCBs can be superior in dynamic environments, as they can withstand stress better than rigid options. However, the design and manufacturing processes can be complex and more expensive, which may deter some businesses from choosing this solution.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between multilayer PCB suppliers and alternative solutions like rigid or flexible PCBs, consider your specific project requirements. Evaluate factors such as performance needs, budget constraints, and ease of implementation. For businesses focused on advanced electronics that require high-density circuit designs, multilayer PCBs may be the best choice despite their higher costs. Conversely, if your project involves standard applications or requires flexibility, exploring rigid or flexible PCB solutions could provide significant advantages. Ultimately, aligning your choice with your product goals and operational capabilities will lead to a successful outcome.

Essential Technical Properties and Trade Terminology for multilayer pcb supplier

What Are the Key Technical Properties of Multilayer PCBs?

Understanding the critical specifications of multilayer printed circuit boards (PCBs) is essential for B2B buyers, especially those navigating the complexities of international procurement. Here are several key technical properties to consider:

1. Material Grade: Why Is It Important for Your PCB?

The material grade of a multilayer PCB determines its performance, reliability, and overall quality. Common materials include FR-4 (a flame-retardant epoxy resin) and Rogers (for high-frequency applications). Selecting the appropriate material is vital as it affects thermal management, dielectric properties, and the ability to handle environmental stressors. Buyers should assess the specific needs of their applications to choose the right material grade, ensuring longevity and functionality.

2. Tolerance: How Does It Impact PCB Functionality?

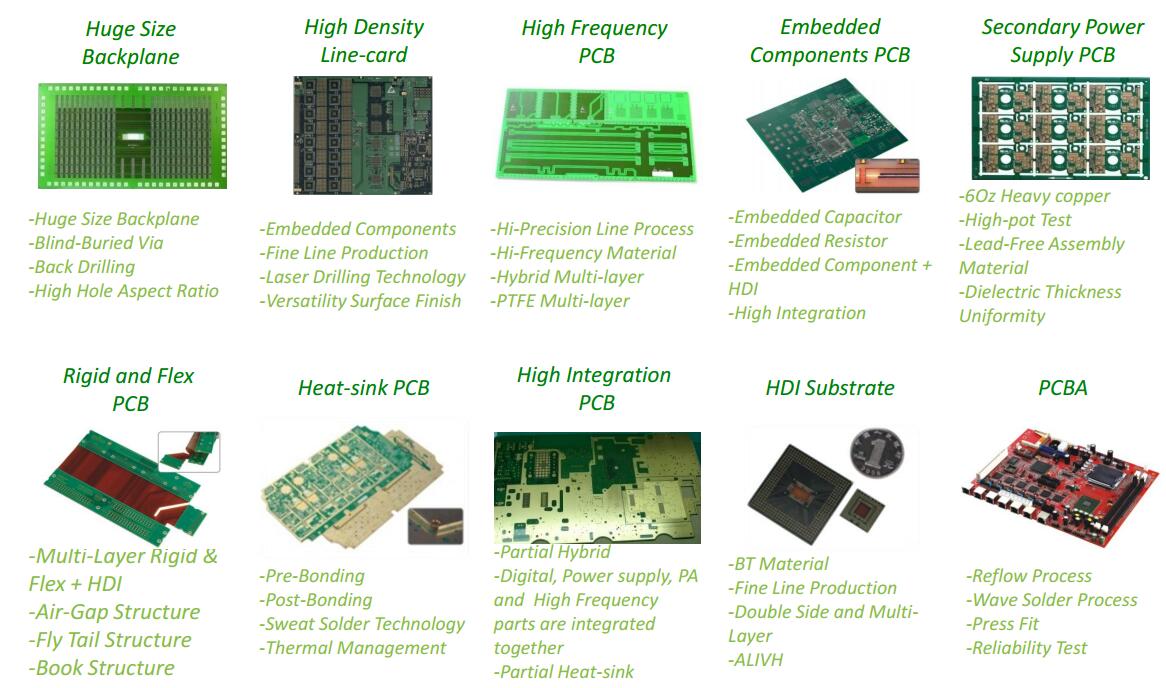

A stock image related to multilayer pcb supplier.

Tolerance refers to the permissible limits of variation in manufacturing dimensions. For multilayer PCBs, tight tolerances (e.g., ±0.05mm) are crucial for ensuring that components fit correctly and function as intended. Poor tolerance can lead to assembly issues and product failures, which ultimately affects the reliability of the end product. B2B buyers must communicate their tolerance requirements clearly to suppliers to avoid costly rework or delays.

3. Layer Count: What Should You Consider?

The layer count of a PCB indicates the number of conductive layers within the board. Multilayer PCBs can have anywhere from 4 to over 20 layers, depending on the complexity of the circuit design. A higher layer count allows for more intricate designs and compact layouts, but it also increases manufacturing complexity and cost. B2B buyers should evaluate the trade-off between design needs and budget constraints when specifying layer counts.

4. Surface Finish: How Does It Affect Performance?

The surface finish of a multilayer PCB is essential for solderability and corrosion resistance. Common finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservative). Each type has its advantages, such as cost-effectiveness or excellent solderability. Buyers should choose a surface finish that aligns with their production processes and end-use requirements to ensure optimal performance.

5. Dielectric Constant: Why Is This Relevant?

The dielectric constant (Dk) of a PCB material influences signal integrity and performance, particularly in high-frequency applications. A lower Dk is generally preferred for RF applications to minimize signal loss. Understanding the dielectric properties is crucial for B2B buyers involved in telecommunications, automotive, or aerospace industries, where signal integrity is paramount.

What Are Common Trade Terms in Multilayer PCB Procurement?

Navigating the terminology used in the multilayer PCB industry can be daunting for international B2B buyers. Here are some essential terms to familiarize yourself with:

1. OEM: What Does It Mean for Your Business?

OEM stands for Original Equipment Manufacturer. This term refers to companies that produce components or products that are used in another company’s end product. For B2B buyers, working with an OEM supplier can streamline the procurement process and ensure that the components meet specific quality standards.

2. MOQ: How Does Minimum Order Quantity Affect Your Purchase?

MOQ, or Minimum Order Quantity, represents the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management, as it can impact cash flow and storage costs. Buyers should negotiate MOQs that align with their operational needs to optimize procurement efficiency.

3. RFQ: What Role Does It Play in Sourcing?

An RFQ, or Request for Quotation, is a document sent to suppliers requesting pricing and terms for specific products or services. This process is vital for comparing different suppliers and making informed purchasing decisions. B2B buyers should ensure their RFQs are detailed to receive accurate quotes and avoid misunderstandings.

4. Incoterms: How Do They Influence Shipping and Delivery?

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international trade. They clarify who is responsible for shipping, insurance, and tariffs during transportation. Familiarity with Incoterms helps B2B buyers mitigate risks and ensure smooth logistics, particularly when sourcing multilayer PCBs from overseas suppliers.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions, streamline procurement processes, and enhance collaboration with multilayer PCB suppliers.

Navigating Market Dynamics and Sourcing Trends in the multilayer pcb supplier Sector

What Are the Key Trends Shaping the Multilayer PCB Supplier Market?

The multilayer PCB (printed circuit board) supplier market is experiencing significant shifts driven by globalization and technological advancements. Key trends include the rise of automation in manufacturing processes, which enhances efficiency and reduces production costs. Furthermore, the increasing demand for smaller, more complex electronic devices is pushing suppliers to innovate in design and fabrication techniques. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, understanding these trends is crucial for making informed sourcing decisions.

Emerging technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) are becoming integral in PCB design and production, leading to smarter, more adaptive supply chains. Buyers are increasingly seeking suppliers who can provide not only quality products but also rapid prototyping and flexible manufacturing capabilities. Another notable trend is the consolidation of suppliers; larger firms are acquiring smaller ones to expand their technological capabilities and market reach. This trend can impact pricing and availability, making it essential for buyers to diversify their supplier base.

How Can Sustainability and Ethical Sourcing Impact My PCB Procurement Strategy?

Sustainability is becoming a crucial consideration in the multilayer PCB supplier sector. The environmental impact of PCB manufacturing, including the use of hazardous materials and energy consumption, is under increasing scrutiny. International B2B buyers are now prioritizing suppliers that demonstrate a commitment to sustainable practices. This includes the use of eco-friendly materials, such as lead-free solder and recyclable substrates, which can significantly reduce the environmental footprint of the final product.

Moreover, ethical sourcing is paramount in today’s global market. Buyers should ensure that their suppliers adhere to fair labor practices and comply with international regulations. Certifications such as ISO 14001 (Environmental Management) and RoHS (Restriction of Hazardous Substances) are indicators of a supplier’s commitment to sustainability and ethical operations. By aligning with these standards, buyers can enhance their brand reputation while also minimizing risks associated with supply chain disruptions or reputational damage.

What Is the Historical Context of the Multilayer PCB Supplier Market?

The multilayer PCB industry has evolved dramatically since its inception in the 1960s. Initially, PCBs were predominantly single-layer and utilized primarily in simple electronic devices. As technology advanced and consumer demand for more sophisticated electronics grew, multilayer PCBs became essential for compact and efficient designs. This shift was marked by significant innovations in materials and manufacturing processes, allowing for greater complexity and functionality in electronic devices.

Today, multilayer PCBs are foundational in various sectors, including telecommunications, automotive, and medical devices. The evolution of this market has been driven by the need for higher performance, reliability, and miniaturization of electronic components. For B2B buyers, understanding this historical context can provide insights into current market dynamics and help in evaluating potential suppliers based on their technological capabilities and experience in the field.

In conclusion, navigating the multilayer PCB supplier sector requires a keen awareness of market trends, sustainability practices, and historical developments. By leveraging this knowledge, international B2B buyers can make strategic sourcing decisions that align with their organizational goals and values.

Frequently Asked Questions (FAQs) for B2B Buyers of multilayer pcb supplier

-

How do I choose the right multilayer PCB supplier for my business?

Choosing the right multilayer PCB supplier involves evaluating several key factors. Start by assessing the supplier’s experience and expertise in multilayer PCB production. Look for certifications such as ISO 9001 and IPC standards, which indicate quality management systems and adherence to industry standards. Additionally, consider their manufacturing capabilities, including the technology they use and their ability to handle complex designs. Request samples and references from previous clients to gauge their reliability and quality. Lastly, ensure they have robust communication channels and support for international buyers. -

What are the common minimum order quantities (MOQ) for multilayer PCBs?

Minimum order quantities (MOQ) for multilayer PCBs can vary widely depending on the supplier and the complexity of the design. Typically, MOQs may range from 5 to 100 pieces for standard designs, while more complex or custom designs might require higher quantities. It is essential to clarify the MOQ with your chosen supplier, as some may offer flexibility for smaller orders, especially for new clients or prototyping. Understanding the MOQ will help you plan your budget and inventory management effectively. -

What customization options are available when sourcing multilayer PCBs?

Most multilayer PCB suppliers offer a range of customization options to meet specific client needs. Customization can include various layer counts, material choices (like FR-4, Rogers, or aluminum), surface finishes (HASL, ENIG, etc.), and specific dimensions. Additionally, you can specify design features such as vias, pads, and traces tailored to your product requirements. It is crucial to communicate your exact needs during the design phase and confirm that the supplier has the capability to deliver on your specifications. -

How do payment terms work when dealing with multilayer PCB suppliers?

Payment terms can significantly affect your procurement process. Most suppliers require a deposit (typically 30-50%) upon order confirmation, with the balance due before shipment. Some suppliers may offer net payment terms (e.g., 30 days) for established clients. It is essential to discuss and negotiate payment terms upfront to avoid misunderstandings. Also, consider the currency exchange rates and payment methods (wire transfer, PayPal, etc.) since these can impact your overall cost and transaction security, especially in international deals. -

What quality assurance processes should I expect from a multilayer PCB supplier?

Quality assurance is critical in multilayer PCB manufacturing. Reputable suppliers should have rigorous QA processes in place, including in-process inspections, automated optical inspections (AOI), and functional testing of the final product. Additionally, they should provide documentation, such as test reports and certifications, to validate their quality standards. As a buyer, request to see these processes in action or inquire about their quality control protocols to ensure that the supplier can deliver products that meet your specifications and reliability standards. -

What logistics considerations should I keep in mind when sourcing multilayer PCBs internationally?

When sourcing multilayer PCBs from international suppliers, logistics plays a vital role in timely delivery and cost management. Consider shipping options (air freight vs. sea freight), as well as potential customs duties and tariffs that may apply upon import. It’s advisable to work with suppliers who have experience in handling international shipments and can provide reliable tracking information. Ensure that both parties agree on delivery timelines and responsibilities for any delays or damages during transit to avoid complications. -

How can I effectively communicate my multilayer PCB requirements to the supplier?

Effective communication is crucial for successful collaboration with your multilayer PCB supplier. Start by providing detailed design specifications, including schematics and Gerber files. Use clear and concise language to outline your project requirements, timelines, and any critical deadlines. Regularly engage in discussions or meetings to address any questions or concerns. Utilize project management tools for better tracking and updates. Establishing a strong line of communication will help minimize misunderstandings and align expectations throughout the production process. -

What should I do if I receive defective multilayer PCBs?

In the event of receiving defective multilayer PCBs, promptly contact your supplier to report the issue. Document the defects with photographs and detailed descriptions to support your claim. Most reputable suppliers have return policies and warranty provisions for defective products. Work with them to resolve the issue, whether through a replacement or refund. It’s also a good practice to analyze the root cause of the defects to prevent similar issues in future orders and to maintain a good relationship with the supplier.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for multilayer pcb supplier

In navigating the complex landscape of multilayer PCB suppliers, strategic sourcing emerges as a vital approach for international B2B buyers. By prioritizing quality, reliability, and cost-effectiveness, businesses can secure a competitive edge in their respective markets. Key takeaways include the importance of establishing strong relationships with suppliers, leveraging advanced technology for efficient production, and understanding regional supply chain dynamics—particularly for buyers from Africa, South America, the Middle East, and Europe.

As you explore potential suppliers, consider the long-term benefits of strategic sourcing, which not only enhances product quality but also fosters innovation. Engaging with suppliers who demonstrate commitment to sustainability and ethical practices can significantly bolster your brand reputation in increasingly conscientious markets.

Looking ahead, the multilayer PCB sector is poised for growth, driven by advancements in technology and the increasing demand for sophisticated electronic devices. As an international buyer, now is the opportune time to reevaluate your sourcing strategies. Embrace the future of multilayer PCBs by actively seeking partnerships that align with your business goals and values. Your next strategic move could redefine your competitive landscape.