Unlock Quality & Savings with CNC Wood Router Machine China (2025)

Introduction: Navigating the Global Market for cnc wood router machine china

Navigating the global market for CNC wood router machines from China can be daunting for international B2B buyers, especially given the diverse applications these machines serve in woodworking, furniture manufacturing, and custom design projects. Sourcing reliable CNC wood router machines requires not only an understanding of the various machine types available but also a keen insight into supplier reliability and cost-efficiency. This guide aims to demystify the complexities involved in purchasing CNC wood router machines by providing comprehensive information on machine specifications, their applications across different industries, and practical tips for supplier vetting.

In this guide, we will explore the various types of CNC wood router machines, including their functionalities, the materials they can process, and their suitability for different production scales. Additionally, we will delve into the essential criteria for evaluating suppliers, such as certifications, customer reviews, and after-sales support, ensuring that buyers can make informed decisions. Understanding the cost implications, including initial investment and operational expenses, will also be a key focus.

By equipping B2B buyers from Africa, South America, the Middle East, and Europe—such as those in Thailand and Colombia—with actionable insights, this guide empowers them to navigate the complexities of sourcing CNC wood router machines effectively. With the right knowledge, buyers can enhance their production capabilities and achieve greater competitive advantage in their respective markets.

Understanding cnc wood router machine china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard CNC Wood Router | Versatile, capable of handling various woods. | Furniture making, cabinetry, signage. | Pros: Cost-effective, widely available. Cons: May lack advanced features for complex designs. |

| High-Speed CNC Router | Faster spindle speeds, optimized for production. | Mass production of wood components. | Pros: Increased efficiency, reduced cycle times. Cons: Higher initial investment, maintenance costs. |

| Multi-Function CNC Router | Combines routing with laser cutting/engraving. | Custom designs, intricate detailing. | Pros: Versatile, reduces need for multiple machines. Cons: Complexity can lead to higher operational costs. |

| 4-Axis CNC Router | Additional rotational axis for complex shapes. | Artistic applications, sculptures. | Pros: Greater design flexibility, intricate cuts. Cons: Requires skilled operators, more expensive. |

| CNC Router with Automatic Tool Change | Automated tool changing for efficiency. | High-volume manufacturing, repetitive tasks. | Pros: Saves time, reduces manual intervention. Cons: Higher upfront cost, potential for more mechanical issues. |

What are the Characteristics of Standard CNC Wood Routers?

Standard CNC wood routers are the backbone of many woodworking operations. They are designed to cut, shape, and carve wood materials with precision. These machines are typically equipped with a variety of cutting tools, allowing them to perform numerous tasks such as engraving, drilling, and milling. B2B buyers should consider their production volume and types of wood materials when selecting this type, as they are ideal for businesses focused on furniture making, cabinetry, and signage.

How Do High-Speed CNC Routers Enhance Production?

High-speed CNC routers are engineered for rapid cutting and processing, making them a preferred choice for businesses engaged in mass production. These machines can achieve higher spindle speeds, which translates to shorter cycle times and increased output. However, buyers should weigh the benefits of speed against the higher initial investment and ongoing maintenance costs. This type is particularly suitable for industries that require a steady flow of wood components, such as cabinetry and furniture manufacturing.

What Advantages Do Multi-Function CNC Routers Offer?

Multi-function CNC routers integrate various capabilities, such as routing, laser cutting, and engraving, into one machine. This versatility allows businesses to handle diverse projects without the need for multiple machines, saving both space and costs. Buyers should consider the complexity of their designs and the types of materials they will be working with, as these routers are well-suited for custom designs and intricate detailing. The investment can be justified by the broad range of applications it can serve.

Why Choose a 4-Axis CNC Router for Artistic Applications?

4-axis CNC routers offer an additional rotational axis, enabling the creation of complex shapes and artistic designs that standard routers cannot achieve. This feature is particularly beneficial for industries focused on artistry, such as sculpture and decorative woodworking. However, potential buyers must recognize that operating a 4-axis router requires skilled personnel and comes with a higher price tag. Businesses should assess their design needs and the skill level of their workforce before making a purchase.

How Does an Automatic Tool Change Feature Benefit B2B Buyers?

CNC routers equipped with an automatic tool change feature streamline the production process by reducing the need for manual tool swaps. This capability is especially advantageous in high-volume manufacturing settings, where efficiency is paramount. While the upfront costs for these machines can be significant, the time saved and reduced labor costs can lead to a favorable return on investment. Buyers should consider their production scale and the types of tasks they perform most frequently when evaluating this option.

Related Video: China Linear ATC CNC Wood Router with Saw Cutting Operational video

Key Industrial Applications of cnc wood router machine china

| Industry/Sector | Specific Application of cnc wood router machine china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Custom furniture design and production | High precision cuts and intricate designs, reducing waste | Reliability of machine performance and after-sales support |

| Sign Making | Production of custom signs and displays | Fast production times and ability to handle various materials | Material compatibility and versatility in cutting capabilities |

| Architectural Modeling | Creation of architectural models and prototypes | Enhanced detail and accuracy in model creation | Precision of CNC technology and software integration |

| Musical Instruments | Crafting of musical instrument components | Consistent quality and repeatability in production | Availability of specialized tooling and material options |

| Interior Design | Custom cabinetry and wall paneling | Unique designs tailored to client specifications | Design software compatibility and customization options |

How is CNC Wood Router Machine Used in Furniture Manufacturing?

In the furniture manufacturing sector, CNC wood router machines from China are employed for custom furniture design and production. These machines allow for high-precision cuts and intricate designs, which are essential for creating unique pieces that stand out in a competitive market. By automating the cutting process, manufacturers can significantly reduce material waste and increase production efficiency. International buyers, particularly from Africa and South America, should consider the reliability of machine performance and the availability of after-sales support when sourcing these machines.

What Role Does CNC Wood Router Play in Sign Making?

In the sign-making industry, CNC wood routers are crucial for producing custom signs and displays. They provide fast production times and the ability to work with various materials, including wood, acrylic, and metal. This flexibility allows businesses to cater to diverse client needs, from simple directional signs to elaborate promotional displays. Buyers in the Middle East and Europe should focus on sourcing machines that offer material compatibility and versatility in cutting capabilities to maximize their production potential.

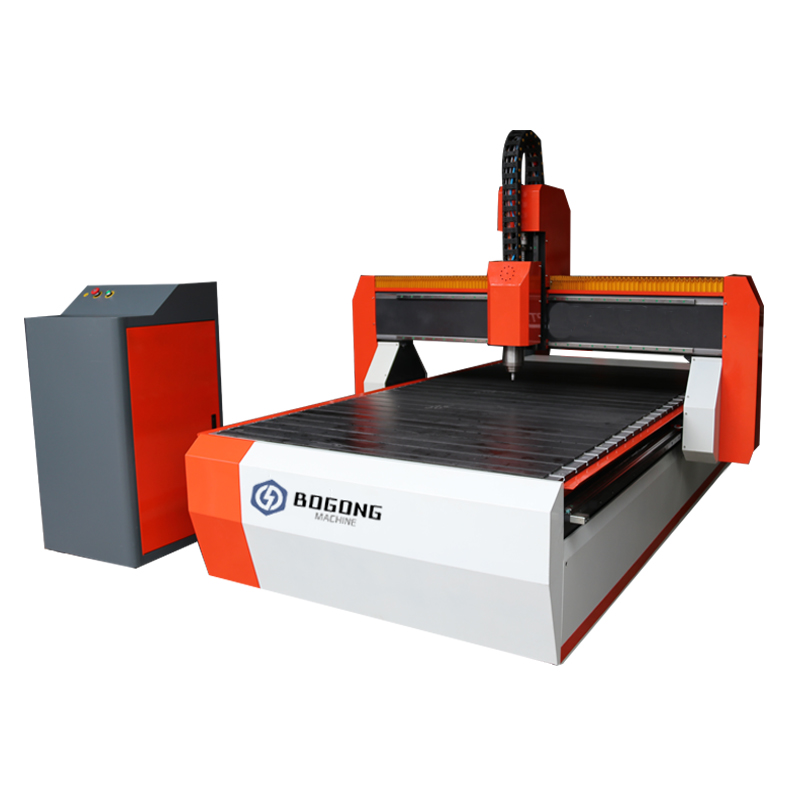

A stock image related to cnc wood router machine china.

How is CNC Technology Applied in Architectural Modeling?

CNC wood routers are extensively used in architectural modeling to create detailed models and prototypes. The precision offered by these machines ensures that every aspect of the model is accurately represented, which is critical for presentations and client approvals. International buyers, especially from Europe, should prioritize the precision of the CNC technology and its compatibility with design software to streamline their workflow and enhance model accuracy.

How Does CNC Wood Router Benefit Musical Instrument Crafting?

In the realm of musical instruments, CNC wood routers are utilized for crafting components like bodies and necks of guitars and pianos. The consistent quality and repeatability provided by CNC technology ensure that every instrument meets high standards of craftsmanship. Buyers should pay attention to the availability of specialized tooling and material options to suit the specific requirements of musical instrument production.

What is the Importance of CNC Wood Router in Interior Design?

CNC wood routers are pivotal in the interior design sector for creating custom cabinetry and wall paneling. These machines enable designers to produce unique designs tailored to client specifications, enhancing the overall aesthetic appeal of spaces. For international buyers, particularly in South America and Africa, it is essential to consider design software compatibility and the range of customization options available when sourcing CNC wood routers to meet diverse client needs.

Related Video: How I built myself a CNC router – from WOOD.

3 Common User Pain Points for ‘cnc wood router machine china’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality CNC Wood Router Machines from China

The Problem: International B2B buyers often struggle with finding reliable suppliers of CNC wood router machines in China. Many face challenges such as inconsistent product quality, lack of transparency in supplier operations, and difficulty in assessing the legitimacy of manufacturers. These issues can lead to significant financial losses, project delays, and compromised production quality. Buyers from Africa, South America, the Middle East, and Europe may find themselves overwhelmed by the sheer volume of options and the risk of engaging with subpar suppliers.

The Solution: To overcome these sourcing challenges, buyers should employ a multi-faceted approach. First, utilize platforms like Alibaba, Made-in-China, or Global Sources to search for reputable suppliers, ensuring to filter results based on verified ratings and customer feedback. It’s crucial to request sample products before placing bulk orders. Conduct thorough background checks by asking for company certifications, production capabilities, and customer references. Additionally, consider engaging a third-party inspection service to assess the manufacturing quality and compliance with international standards before shipment. This due diligence can significantly mitigate risks and ensure a smoother purchasing process.

Scenario 2: Navigating Technical Specifications and Compatibility Issues

The Problem: Another common pain point is the complexity surrounding the technical specifications of CNC wood router machines. Buyers often lack detailed knowledge about the specific features that are essential for their operations, which can result in purchasing equipment that does not meet their production needs or is incompatible with their existing systems. For instance, a buyer may need a machine that supports specific materials or software integrations, but without clear guidance, they might choose the wrong model.

The Solution: To address this issue, buyers should conduct a comprehensive needs assessment before engaging with suppliers. Identify the materials you plan to work with, the dimensions of projects, and the desired precision levels. Create a checklist of essential features such as spindle power, tool change capabilities, and software compatibility. Armed with this information, buyers can have detailed discussions with potential suppliers, asking targeted questions to ensure the machines meet their requirements. Additionally, requesting technical documentation and user manuals can provide clarity on the machine’s functionalities and compatibility, helping to avoid costly mistakes.

Scenario 3: Understanding After-Sales Support and Maintenance Requirements

The Problem: After-sales support is a critical but often overlooked aspect of purchasing CNC wood router machines. Buyers may find themselves in a difficult position if they experience equipment malfunctions or require maintenance but have no clear support pathway. This can lead to extended downtimes and increased operational costs, especially for businesses in regions with limited access to technical support or spare parts.

The Solution: Before finalizing any purchase, it is essential to inquire about the after-sales service policies of the supplier. Ask specific questions regarding warranty periods, the availability of spare parts, and the responsiveness of their technical support team. A good practice is to request case studies or testimonials from other clients regarding their experiences with after-sales service. Furthermore, consider establishing a service agreement that outlines the expected response times for technical support and maintenance services. This proactive approach ensures that buyers are not only investing in the machinery itself but also in the ongoing support that is crucial for long-term operational success.

Strategic Material Selection Guide for cnc wood router machine china

When selecting materials for CNC wood router machines, international B2B buyers must consider the properties, advantages, disadvantages, and specific applications of each material. Here, we analyze four common materials used in CNC wood router machines: Aluminum, Steel, MDF (Medium Density Fiberboard), and Plywood. Each material has unique characteristics that can significantly influence the performance and suitability of the machines for various applications.

What Are the Key Properties of Aluminum for CNC Wood Router Machines?

Aluminum is a lightweight metal known for its excellent corrosion resistance and thermal conductivity. Its properties make it ideal for parts that require precision and durability. Aluminum can withstand moderate temperatures and is relatively easy to machine, allowing for complex designs.

Pros: Aluminum is lightweight, which reduces the overall weight of the CNC machine, enhancing portability. It has a good strength-to-weight ratio, making it suitable for a wide range of applications, from furniture to intricate carvings.

Cons: While aluminum is durable, it is softer than steel and may not be suitable for heavy-duty applications. The cost can be higher compared to other materials, which may deter budget-conscious buyers.

Impact on Application: Aluminum is compatible with a variety of media, including wood, plastics, and composites, making it versatile for different projects.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers from regions like Africa and South America should consider local availability and the cost of importing aluminum.

How Does Steel Compare as a Material for CNC Wood Router Machines?

Steel is renowned for its strength and durability, making it a popular choice for CNC router frames and components. It can handle high pressures and is resistant to deformation under stress.

Pros: Steel offers excellent durability and longevity, making it ideal for heavy-duty applications. Its ability to withstand high temperatures and pressures makes it suitable for industrial environments.

Cons: Steel is heavier than aluminum, which can affect the machine’s portability. Additionally, it is prone to corrosion if not properly treated, requiring regular maintenance.

Impact on Application: Steel is ideal for applications that require high precision and strength, such as cabinetry and architectural components.

Considerations for International Buyers: Buyers should ensure that the steel used meets local standards and regulations. In regions like the Middle East, where humidity can be high, corrosion-resistant coatings may be necessary.

What Are the Benefits of Using MDF in CNC Wood Router Machines?

MDF is a composite material made from wood fibers and resin, known for its smooth surface and ease of machining. It is widely used for furniture and decorative items.

Pros: MDF is cost-effective and provides a smooth finish, making it ideal for detailed carvings and intricate designs. It is also easy to paint and laminate.

Cons: MDF is not as strong as solid wood or metal, making it less suitable for load-bearing applications. It can absorb moisture, leading to warping or swelling if not properly sealed.

Impact on Application: MDF is compatible with various woodworking applications, particularly in furniture making and decorative crafts.

Considerations for International Buyers: Buyers should be aware of the environmental regulations regarding formaldehyde emissions from MDF. Compliance with local standards is essential, especially in Europe, where regulations are stringent.

Why Choose Plywood for CNC Wood Router Machines?

Plywood is made from layers of wood veneer glued together, providing strength and stability. It is commonly used in construction and furniture making.

Pros: Plywood is strong and resistant to warping, making it suitable for a variety of applications. It is also relatively lightweight compared to solid wood.

Cons: The quality of plywood can vary significantly, and lower-grade plywood may not provide the desired finish. Additionally, it can be more expensive than MDF.

Impact on Application: Plywood is ideal for applications requiring strength and durability, such as cabinetry and structural components.

Considerations for International Buyers: Buyers should look for plywood that meets international quality standards, such as JIS or EN standards, to ensure consistency and performance.

Summary Table of Material Selection for CNC Wood Router Machines

| Material | Typical Use Case for CNC Wood Router Machine China | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Precision parts and lightweight components | Lightweight and corrosion-resistant | Softer than steel, higher cost | Medium |

| Steel | Heavy-duty applications and structural components | Excellent durability and strength | Heavier, prone to corrosion | High |

| MDF | Furniture and decorative items | Cost-effective with a smooth finish | Less strong, moisture absorption | Low |

| Plywood | Cabinetry and structural components | Strong and resistant to warping | Quality can vary, higher cost than MDF | Medium |

This guide provides a comprehensive overview of material selection for CNC wood router machines, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc wood router machine china

What Are the Key Stages in the Manufacturing Process of CNC Wood Router Machines in China?

The manufacturing process of CNC wood router machines involves several critical stages that ensure the final product meets quality and performance standards. Here’s a breakdown of these stages:

1. Material Preparation

Material selection is paramount in CNC wood router manufacturing. Typically, high-grade steel and aluminum are used for structural components due to their strength and durability. The preparation phase includes cutting raw materials to size, ensuring they meet specific dimensions and tolerances. Advanced laser cutting and CNC machining techniques are often employed to achieve precise cuts, minimizing waste and optimizing material use.

2. Forming Techniques

Once materials are prepared, the forming process begins. This may involve bending, stamping, or machining parts to achieve desired shapes. CNC machining centers are utilized extensively during this phase, allowing for high precision and repeatability. Techniques such as water jet cutting and plasma cutting are also employed to create intricate designs that are essential for the machine’s functionality.

3. Assembly of Components

Assembly is a critical stage where all the machined parts are brought together. Skilled technicians carefully fit components such as motors, gears, and control systems, ensuring that everything aligns correctly. This stage often involves the use of jigs and fixtures to maintain precision. Proper torque specifications must be adhered to, as improper assembly can lead to operational failures.

4. Finishing Processes

Finishing processes enhance the aesthetic and functional properties of the CNC wood router. This may involve surface treatments such as powder coating or anodizing to prevent corrosion and wear. Additionally, final inspections are conducted to check for any surface defects or imperfections. This stage is crucial for ensuring the machine’s longevity and reliability in various working environments.

How Is Quality Assurance Implemented in CNC Wood Router Manufacturing?

Quality assurance (QA) is integral to the production of CNC wood router machines, ensuring that products meet both international standards and customer expectations. Here are the key aspects of QA in this context:

What International Standards Are Relevant for CNC Wood Router Machines?

For B2B buyers, understanding the certifications and standards applicable to CNC wood routers is vital. The most relevant international standards include:

- ISO 9001: This standard ensures that manufacturers maintain a quality management system focused on consistent quality and customer satisfaction. Companies with ISO 9001 certification demonstrate a commitment to quality processes.

- CE Marking: Required for products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: While more common in the oil and gas sector, some CNC machines may need to meet specific API standards depending on their application.

What Are the Key Quality Control Checkpoints?

The quality control process typically involves several checkpoints:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, various checks are performed to monitor the quality of machining, assembly, and other processes.

- Final Quality Control (FQC): Before shipping, finished products undergo a final inspection to verify that they meet all specifications and quality standards.

Common testing methods during these checkpoints include dimensional checks, functional testing, and stress tests. Documenting these tests is crucial for maintaining a comprehensive quality assurance record.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, especially those from Africa, South America, the Middle East, and Europe, ensuring that suppliers adhere to rigorous quality standards is critical. Here are some actionable strategies:

What Audits and Reports Should Buyers Request?

Buyers should consider conducting audits of potential suppliers to evaluate their manufacturing processes and quality control systems. This can include:

- Factory Audits: Visiting the manufacturing facility to assess equipment, processes, and working conditions.

- Quality Reports: Requesting detailed reports on quality control measures, including statistics on defect rates and compliance with standards.

Should Buyers Engage Third-Party Inspection Services?

Utilizing third-party inspection services can provide an unbiased assessment of product quality. These services can conduct inspections at various stages of production, ensuring that the machines meet the required specifications before shipment. Engaging with reputable inspection firms adds another layer of assurance for buyers.

What Are the Unique Quality Control Nuances for International Buyers?

Understanding the nuances of quality control specific to international transactions is essential. Factors to consider include:

- Cultural Differences: Recognizing that quality expectations may vary across regions. For example, European buyers might prioritize stringent compliance with environmental regulations more than buyers from other regions.

- Language Barriers: Clear communication is vital. Buyers should ensure that all specifications and quality requirements are documented in a language understood by both parties.

- Logistics and Shipping: Quality assurance doesn’t end at the factory. Buyers should establish quality checks during shipping and receiving to address any potential damage or discrepancies that could occur in transit.

By being proactive about these quality assurance practices, international B2B buyers can make informed decisions and foster long-term partnerships with CNC wood router manufacturers in China, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc wood router machine china’

To successfully procure a CNC wood router machine from China, international B2B buyers must navigate a complex landscape of specifications, suppliers, and logistics. This guide provides a step-by-step checklist to streamline the sourcing process, ensuring you make informed and efficient purchasing decisions.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical needs. Consider the following:

– Material Types: Determine what types of wood or composite materials you will be processing.

– Machine Size and Capacity: Identify the dimensions and weight of materials your CNC router must handle.

– Functionality: Specify the desired features, such as 3D carving capabilities, spindle power, and software compatibility.

Having a well-defined specification will not only assist in finding the right machine but also facilitate better communication with suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to create a shortlist of reputable manufacturers. Utilize platforms such as Alibaba, Made-in-China, or Global Sources to:

– Check Company Background: Look for suppliers with a solid history and customer reviews.

– Assess Product Range: Ensure they offer a variety of CNC wood router machines that meet your specifications.

A comprehensive supplier assessment minimizes risks and helps you find reliable partners.

Step 3: Verify Supplier Certifications

When evaluating suppliers, confirm they possess relevant certifications. Common certifications include:

– ISO 9001: Indicates a commitment to quality management systems.

– CE Marking: Ensures compliance with European safety and health standards.

Certifications are crucial as they demonstrate a supplier’s adherence to international quality standards, which can significantly affect your machine’s performance and safety.

Step 4: Request Product Samples

Before finalizing your order, ask for samples or demos of the CNC wood router machines. This step allows you to:

– Evaluate Performance: Test the machine’s capabilities and ensure it meets your technical requirements.

– Inspect Quality: Assess the build quality and durability of the machine firsthand.

Testing samples helps mitigate the risk of purchasing equipment that does not meet your expectations.

Step 5: Negotiate Terms and Pricing

Once you’ve selected a supplier, engage in negotiations to secure favorable terms. Key areas to focus on include:

– Pricing: Discuss bulk order discounts or payment terms that suit your budget.

– Shipping and Delivery: Clarify shipping methods, lead times, and responsibilities for customs clearance.

Effective negotiation can lead to significant cost savings and improved delivery timelines.

Step 6: Review After-Sales Support and Warranty

Inquire about after-sales support and warranty options. This is vital for:

– Maintenance and Repairs: Ensure the supplier offers technical support and spare parts availability.

– Warranty Terms: Understand the warranty coverage duration and conditions.

Robust after-sales support is essential for minimizing downtime and ensuring long-term satisfaction with your machine.

Step 7: Finalize the Purchase Agreement

After all terms are agreed upon, draft a comprehensive purchase agreement that includes:

– Specifications and Pricing: Clearly outline the agreed-upon specifications and total cost.

– Payment Terms: Specify payment milestones and methods.

– Delivery Schedule: Document expected delivery dates and conditions.

A well-structured purchase agreement protects both parties and ensures clarity in the transaction process.

By following this checklist, B2B buyers can streamline their procurement process for CNC wood router machines from China, ensuring they make well-informed, strategic purchasing decisions.

Comprehensive Cost and Pricing Analysis for cnc wood router machine china Sourcing

What Are the Key Cost Components for Sourcing CNC Wood Router Machines from China?

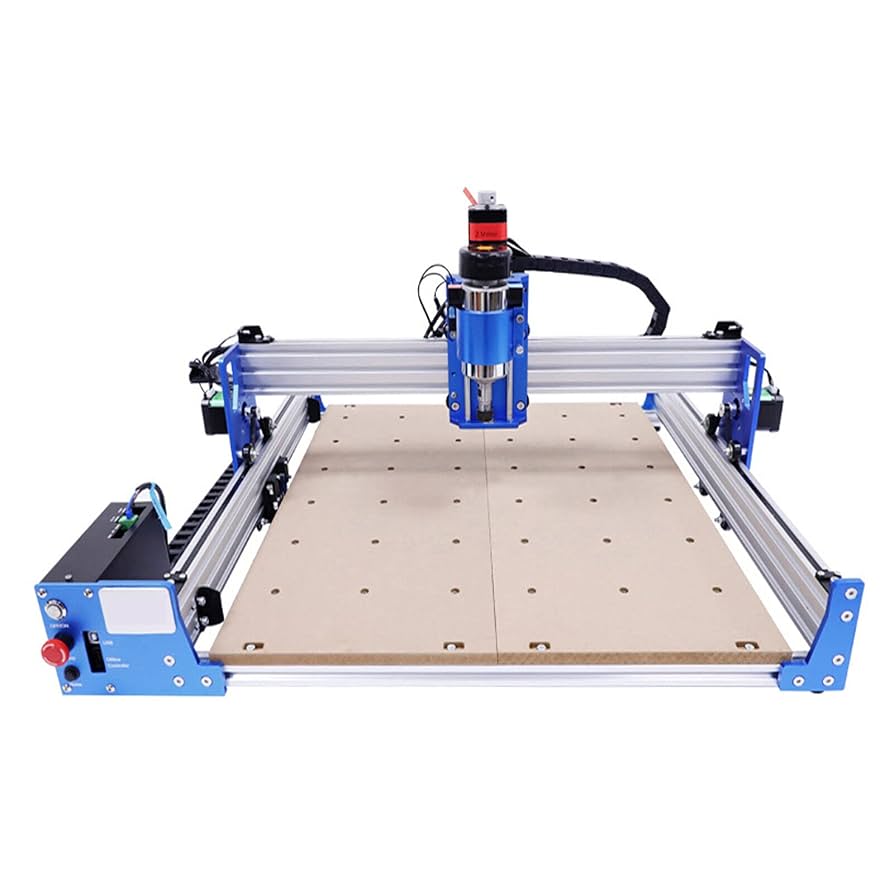

A stock image related to cnc wood router machine china.

When sourcing CNC wood router machines from China, understanding the cost structure is essential for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. Here are the primary cost components involved:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality steel and precision components increase durability and performance but also raise the price. Buyers should consider the trade-off between material quality and machine longevity.

-

Labor: Labor costs in China can vary depending on the region and the skill level of the workforce. Skilled labor will naturally command higher wages, but it also ensures better craftsmanship, which is crucial for high-precision machinery.

-

Manufacturing Overhead: This includes expenses related to factory maintenance, utilities, and administrative costs. Understanding the manufacturer’s overhead can help buyers gauge how much of the price goes toward operational costs.

-

Tooling: Tooling costs involve the equipment and tools necessary to manufacture CNC machines. Custom tooling may be required for specific designs, which can significantly affect the price.

-

Quality Control (QC): Implementing rigorous QC processes is vital for ensuring machine reliability. While this adds to the cost, it can prevent future expenses related to machine failures or defects.

-

Logistics: Shipping and handling costs can be substantial, especially for bulky machinery. Buyers should factor in freight costs, insurance, and customs duties when calculating the total expense.

-

Margin: Manufacturers will typically include a profit margin in their pricing. Understanding the industry standards for margins can aid buyers in evaluating whether a quote is reasonable.

How Do Price Influencers Impact CNC Wood Router Machine Costs?

Several factors can influence the pricing of CNC wood router machines, including:

-

Volume/MOQ (Minimum Order Quantity): Ordering in bulk can lead to significant discounts. Suppliers often provide better pricing for larger orders, making it advantageous for buyers with high demand.

-

Specifications and Customization: Custom features or specifications can add to the base price. Buyers should clearly outline their needs to avoid unexpected costs.

-

Materials and Quality Certifications: Machines built with certified materials or those that meet international standards may come at a premium. Buyers should assess the importance of certifications based on their market requirements.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their quality assurance and customer support.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can impact the total cost. For instance, opting for FOB (Free on Board) may shift some shipping responsibilities to the buyer, which could influence overall pricing.

What Are Essential Tips for Negotiating CNC Machine Prices?

For international B2B buyers looking to secure the best deals on CNC wood router machines, consider the following strategies:

-

Negotiate Wisely: Leverage your purchasing power by negotiating terms, especially if you are considering a bulk order. Suppliers may be more flexible on price with larger commitments.

-

Evaluate Total Cost of Ownership (TCO): Rather than focusing solely on the initial purchase price, assess the TCO, which includes maintenance, energy consumption, and potential downtime costs.

-

Understand Pricing Nuances: Be aware of the regional economic conditions affecting suppliers in China. Currency fluctuations, trade tariffs, and local regulations can impact pricing.

-

Request Detailed Quotes: Always ask for itemized quotes that break down costs. This transparency can help identify areas for negotiation and ensure you’re not overlooking hidden fees.

-

Consider Long-Term Relationships: Building a relationship with suppliers can lead to better pricing and terms over time. Regular business may encourage suppliers to offer discounts or prioritize your orders.

Disclaimer on Indicative Prices

Prices for CNC wood router machines can vary widely based on specifications, market conditions, and negotiation outcomes. The figures provided in this analysis are indicative and should be verified with suppliers for accuracy. International buyers should remain vigilant and conduct thorough research to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing cnc wood router machine china With Other Solutions

Exploring Alternatives to CNC Wood Router Machines from China

When considering the purchase of a CNC wood router machine, international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, may find themselves evaluating various options available in the market. Understanding the alternatives can help in making an informed decision tailored to specific operational needs. Below is a comparative analysis of CNC wood router machines from China against two notable alternatives: traditional woodworking machines and CNC laser cutting machines.

Comparison Table of CNC Wood Router Machines and Alternatives

| Comparison Aspect | CNC Wood Router Machine China | Traditional Woodworking Machines | CNC Laser Cutting Machines |

|---|---|---|---|

| Performance | High precision and speed | Moderate precision, slower speed | High precision, variable speed |

| Cost | Generally lower cost | Often cheaper upfront | Higher initial investment |

| Ease of Implementation | Requires skilled operators | Less technical expertise needed | Requires technical training |

| Maintenance | Moderate maintenance needs | Low maintenance | High maintenance due to optics |

| Best Use Case | Complex designs and mass production | Simple cuts and joinery | Intricate designs and engraving |

Detailed Breakdown of Each Alternative

What are the advantages and disadvantages of traditional woodworking machines?

Traditional woodworking machines, such as table saws, band saws, and routers, have been staples in the industry for many years. They are often more affordable than CNC machines and require less technical knowledge to operate. However, they may lack the precision and efficiency of modern CNC technology, making them less suitable for complex designs or mass production. While they are excellent for straightforward tasks, they can slow down production rates and increase labor costs due to manual operation.

How do CNC laser cutting machines compare to CNC wood routers?

CNC laser cutting machines utilize a focused laser beam to cut materials with high precision. They excel in creating intricate designs and detailed engravings, making them ideal for applications that require fine details. However, the cost of these machines is typically higher than CNC wood routers, and they require a certain level of technical expertise for both operation and maintenance. Additionally, while they can cut various materials, they may not be as effective on thicker wood compared to wood routers, which can handle larger volumes with ease.

Conclusion: How can B2B buyers choose the right solution?

When selecting the right solution for woodworking needs, B2B buyers should carefully assess their specific requirements, including the complexity of designs, production volume, budget constraints, and the skill level of available operators. While CNC wood router machines from China offer a balance of affordability and performance, traditional woodworking machines may suffice for simpler tasks. In contrast, CNC laser cutting machines provide unparalleled precision for intricate designs but at a higher cost and complexity. Ultimately, understanding the pros and cons of each option will empower buyers to make the best decision that aligns with their operational goals and capabilities.

Essential Technical Properties and Trade Terminology for cnc wood router machine china

What Are the Key Technical Properties of CNC Wood Router Machines from China?

When considering the purchase of CNC wood router machines from China, it’s vital to understand specific technical properties that can significantly impact your production efficiency and product quality. Here are some critical specifications to consider:

1. Material Grade

The material grade of the machine’s components, especially the frame and spindle, influences durability and performance. Common materials include high-grade steel and aluminum, which provide strength and stability. Choosing machines with robust material grades minimizes maintenance costs and extends the machine’s lifespan, crucial for B2B buyers looking to maximize ROI.

2. Tolerance Levels

Tolerance refers to the permissible limit of variation in a physical dimension. For CNC wood routers, tight tolerances (often within ±0.01 mm) are essential for achieving high precision in woodworking applications. Understanding tolerance levels helps ensure that the finished products meet quality standards and specifications, which is particularly important for businesses in competitive markets.

3. Spindle Power and Speed

The spindle’s power (measured in kilowatts) and speed (measured in RPM) are critical for determining the machine’s cutting capabilities. A higher spindle power allows for the cutting of denser materials, while variable speed settings enable adaptability for different wood types and thicknesses. This flexibility is vital for B2B buyers who require versatility in their manufacturing processes.

4. Work Area Dimensions

The work area dimensions (length, width, and height) of the CNC router dictate the size of the materials that can be processed. Buyers should select machines with an appropriate work area to accommodate their specific production needs. Larger work areas can enhance productivity by allowing for bigger projects without requiring multiple setups.

5. Control System

The type of control system (e.g., DSP, Mach3, or Syntec) affects user-friendliness and the machine’s operational capabilities. Advanced control systems often offer features such as offline programming and enhanced automation, which can significantly reduce labor costs and improve efficiency. It’s essential for buyers to consider the learning curve and technical support available for the chosen control system.

6. Dust Collection System

Effective dust collection is crucial for maintaining a clean work environment and ensuring the longevity of the machine. A built-in dust collection system can enhance operational efficiency and reduce health risks associated with wood dust exposure. Buyers should prioritize machines with robust dust collection capabilities to comply with safety regulations and improve workplace conditions.

What Are Common Trade Terms Related to CNC Wood Router Machines?

Understanding trade terminology is crucial for international B2B transactions, especially when sourcing CNC wood routers from China. Here are some common terms you should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. For CNC wood routers, OEM partnerships can help businesses customize machines to their specifications, ensuring they meet unique production requirements.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory management, particularly for businesses looking to optimize their supply chain without overcommitting to inventory they may not need.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products or services. Submitting an RFQ for CNC wood routers can help you compare prices and terms across different manufacturers, allowing for informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, particularly concerning shipping, insurance, and tariffs. Familiarity with Incoterms helps businesses understand their obligations and risks when purchasing CNC wood routers from abroad.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For CNC wood routers, lead times can vary based on production schedules and shipping. Understanding lead times helps businesses plan their production schedules effectively.

6. Warranty

A warranty is a promise by the manufacturer to repair or replace a product within a specified period if it fails to meet quality standards. Knowing the warranty terms for CNC wood routers is critical for risk management and budgeting for potential repairs or replacements.

By familiarizing yourself with these technical specifications and trade terms, you can make more informed purchasing decisions and optimize your operations when sourcing CNC wood router machines from China.

Navigating Market Dynamics and Sourcing Trends in the cnc wood router machine china Sector

What Are the Current Market Dynamics and Key Trends in the CNC Wood Router Machine Sector?

The CNC wood router machine sector is experiencing a significant transformation influenced by multiple global drivers. One of the primary factors is the increasing demand for customized and precision-engineered wood products across various industries, including furniture, cabinetry, and automotive. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, seek suppliers that can meet these diverse needs, manufacturers in China are adapting their offerings to provide versatile and high-quality CNC machines.

Emerging B2B technology trends are also reshaping the market. The integration of Artificial Intelligence (AI) and the Internet of Things (IoT) into CNC machines is enhancing operational efficiency and enabling predictive maintenance. This technological evolution allows buyers to optimize production processes and reduce downtime, ultimately driving profitability. Additionally, the rise of Industry 4.0 is pushing manufacturers to adopt smart manufacturing practices, making it essential for international buyers to consider suppliers who are equipped with the latest technology.

The market dynamics are further influenced by shifting trade policies and economic conditions. For instance, fluctuations in tariffs and trade agreements can impact sourcing strategies. Buyers from regions such as Europe and the Middle East should remain informed about these changes to navigate potential disruptions effectively. Understanding regional market demands and aligning with suppliers who can cater to specific needs will be crucial for successful sourcing.

How Is Sustainability and Ethical Sourcing Influencing B2B Decisions in the CNC Wood Router Machine Sector?

Sustainability has become a pivotal consideration for B2B buyers in the CNC wood router machine sector. The environmental impact of manufacturing processes, particularly in terms of resource consumption and waste generation, is under scrutiny. As a result, international buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes the use of eco-friendly materials, energy-efficient manufacturing processes, and responsible sourcing of raw materials.

Moreover, ethical supply chains are gaining importance in the purchasing decisions of B2B buyers. Buyers are looking for suppliers who adhere to fair labor practices and maintain transparency throughout their operations. Certifications such as Forest Stewardship Council (FSC) for wood products and ISO 14001 for environmental management systems can provide assurance of a supplier’s commitment to sustainability and ethical sourcing.

Incorporating sustainability into sourcing strategies not only aligns with global trends but also enhances brand reputation and customer loyalty. By collaborating with manufacturers who prioritize sustainability, international buyers can mitigate risks associated with environmental regulations and improve their competitive edge in the marketplace.

What Is the Brief Evolution of CNC Wood Router Machines and Their Relevance to B2B Buyers?

The evolution of CNC wood router machines can be traced back to the early days of numerical control technology in the 1950s, which revolutionized manufacturing processes. Initially, these machines were limited to basic tasks, but advancements in computing technology have led to significant improvements in functionality and precision. Today, CNC wood routers are equipped with sophisticated software that allows for intricate designs and automated workflows, catering to the growing demand for customization.

For B2B buyers, understanding the historical context of CNC machines is crucial. The development of these machines has significantly enhanced productivity, reduced labor costs, and improved the quality of finished products. As buyers evaluate potential suppliers, recognizing the technological advancements and capabilities of CNC wood routers can inform their purchasing decisions and ensure they select machines that meet their operational needs effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc wood router machine china

-

How do I solve issues related to CNC wood router machine maintenance?

Regular maintenance is crucial for the longevity and performance of CNC wood router machines. Start by developing a maintenance schedule that includes daily checks for wear and tear, lubrication of moving parts, and cleaning of dust and debris. Additionally, keep a log of any performance issues and address them promptly. Engaging with the supplier for technical support or training on specific maintenance procedures can further enhance machine efficiency and reduce downtime. -

What is the best CNC wood router machine for small-scale woodworking businesses?

For small-scale woodworking businesses, a CNC wood router with a compact design and user-friendly software is ideal. Look for machines that offer versatility in handling various materials, such as wood, plastic, and composites. Features such as a reliable spindle, precise motion control, and good customer support from the manufacturer can significantly enhance productivity. Research user reviews and consider demo opportunities to assess the machine’s capabilities before purchasing. -

What should I consider when vetting suppliers for CNC wood router machines in China?

When vetting suppliers, ensure they have a solid reputation and proven experience in manufacturing CNC wood routers. Check for certifications such as ISO 9001, which indicates quality management standards. Request references from previous clients and verify their after-sales support. Additionally, consider visiting the factory, if possible, to assess production capabilities and quality control processes firsthand. -

How can I customize a CNC wood router machine to suit my specific needs?

Many manufacturers offer customization options for CNC wood routers. Start by discussing your specific requirements with the supplier, such as size, power, and spindle type. Custom software solutions, tool changers, and enhanced safety features are also common options. Ensure that any modifications do not compromise the machine’s operational efficiency and that the supplier provides comprehensive support for customized features. -

What are the typical minimum order quantities (MOQ) for CNC wood router machines from China?

The MOQ for CNC wood router machines can vary significantly depending on the manufacturer and the model. Typically, MOQs range from one unit for standard models to several units for specialized machines. It’s advisable to clarify these details upfront with potential suppliers and negotiate terms that suit your purchasing strategy, especially if you are a smaller business. -

What payment terms should I expect when purchasing CNC wood router machines from China?

Payment terms can vary, but common arrangements include a deposit (usually 30%) upfront, with the balance due before shipment. Some suppliers may offer more flexible terms, such as letters of credit or installment payments. Always ensure that the payment terms are clearly outlined in the contract to avoid any disputes later on. It’s also prudent to utilize secure payment methods to protect your investment. -

How do I ensure quality assurance when importing CNC wood router machines?

To ensure quality assurance, request detailed specifications and certifications from the supplier. Conduct pre-shipment inspections to verify that the machines meet your quality standards. Engaging third-party inspection services can provide an additional layer of confidence. Moreover, consider negotiating warranty terms that cover defects and performance issues for a specified period post-purchase. -

What logistics options are available for shipping CNC wood router machines from China?

Shipping CNC wood router machines typically involves freight forwarding services. You can choose between sea freight, which is more economical for larger shipments, or air freight for faster delivery. Ensure that your supplier has experience with international shipping and can assist with customs clearance. Discuss packaging options to prevent damage during transit, and confirm insurance coverage to safeguard your investment during shipping.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cnc wood router machine china

In conclusion, the strategic sourcing of CNC wood router machines from China presents a myriad of opportunities for international B2B buyers, especially from Africa, South America, the Middle East, and Europe. By leveraging China’s manufacturing capabilities, businesses can access high-quality, cost-effective machinery tailored to their specific needs. It is crucial to focus on building strong relationships with reliable suppliers, ensuring quality control, and understanding the logistics involved in international shipping.

What are the key benefits of strategic sourcing for CNC wood router machines? The ability to negotiate better prices, access innovative technologies, and streamline operations can significantly enhance your competitive edge. Moreover, staying informed about market trends and supplier capabilities will empower you to make informed purchasing decisions.

As we look ahead, the demand for advanced CNC technology will continue to rise. International B2B buyers are encouraged to engage in proactive sourcing strategies and explore collaborative partnerships with Chinese manufacturers. This approach not only maximizes value but also positions your business to thrive in an increasingly competitive landscape. Embrace the future of woodworking technology and take action now to elevate your operations.