Unlock Quality & Savings: Your Silk Fabric Supplier Guide (2025)

Introduction: Navigating the Global Market for silk fabric supplier

In today’s competitive landscape, sourcing quality silk fabric suppliers can be a daunting task for international B2B buyers. With the growing demand for luxurious textiles in diverse markets, understanding the intricacies of silk fabric procurement is crucial. This guide aims to equip buyers from Africa, South America, the Middle East, and Europe—particularly in regions like Poland and Saudi Arabia—with the knowledge needed to navigate the complexities of the global silk market.

The silk industry is vast, encompassing various types of silk, each with unique applications ranging from fashion to home textiles. Buyers often face challenges in identifying reputable suppliers, assessing product quality, and understanding cost structures. This guide addresses these concerns by offering in-depth insights into the types of silk available, practical applications, and effective strategies for vetting suppliers.

By providing actionable information on pricing, quality control, and the latest market trends, this guide empowers B2B buyers to make informed purchasing decisions. Whether you are looking to enhance your product offerings or establish long-term supplier relationships, understanding the silk fabric market will enable you to capitalize on opportunities and mitigate risks. With the right knowledge at your fingertips, navigating the global silk market becomes not just a possibility, but a pathway to success.

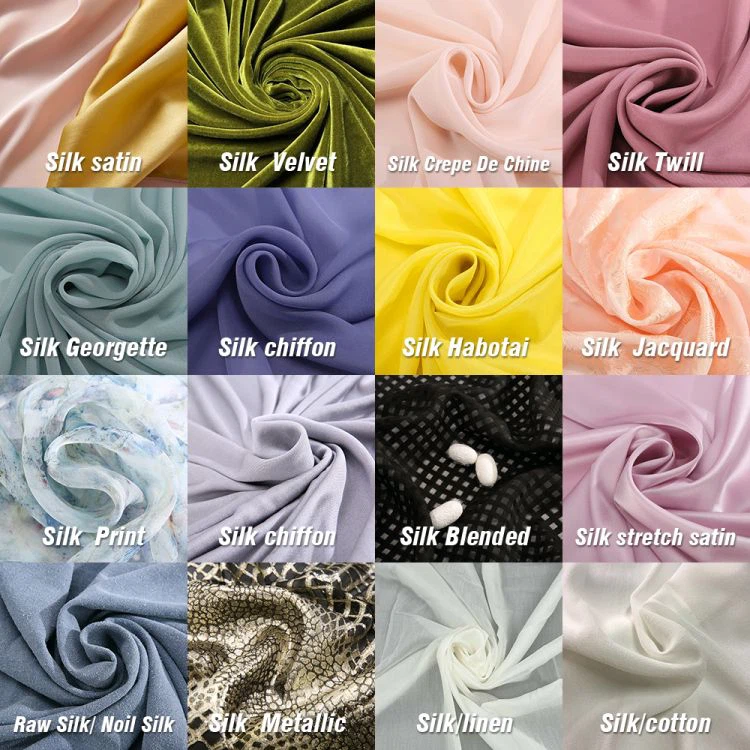

Understanding silk fabric supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mulberry Silk Supplier | Sourced from the silkworms that feed exclusively on mulberry leaves, resulting in a soft, lustrous fabric. | High-end fashion, luxury home textiles | Pros: Superior quality, smooth texture. Cons: Higher price point. |

| Tussah Silk Supplier | Produced from wild silkworms, offering a more textured finish and natural color variations. | Eco-friendly fashion, artisanal products | Pros: Unique aesthetic, sustainable sourcing. Cons: Less uniformity in quality. |

| Charmeuse Silk Supplier | Known for its glossy front and matte back, often used in evening wear and lingerie. | Fashion apparel, lingerie, and accessories | Pros: Elegant drape, luxurious appearance. Cons: Requires careful handling and care. |

| Habotai Silk Supplier | Lightweight and semi-sheer, often used for linings and summer garments. | Linings, scarves, and lightweight clothing | Pros: Cost-effective, versatile. Cons: Less durable compared to heavier silks. |

| Crepe Silk Supplier | Features a crinkled texture, providing a unique drape and flow, suitable for various garments. | Dresses, blouses, and formal wear | Pros: Excellent drape, soft feel. Cons: Can be challenging to sew due to its texture. |

What are the Characteristics of Mulberry Silk Suppliers?

Mulberry silk suppliers focus on silk derived from silkworms that exclusively consume mulberry leaves. This type of silk is renowned for its softness, sheen, and durability, making it ideal for high-end fashion and luxury home textiles. B2B buyers should consider the supplier’s sourcing practices and certifications, as these can impact the quality and sustainability of the silk. While mulberry silk is more expensive, its superior qualities often justify the investment for brands targeting upscale markets.

How Does Tussah Silk Differ from Other Types?

Tussah silk suppliers provide silk made from wild silkworms, resulting in a fabric that features a more textured finish and a variety of natural colors. This type of silk is particularly appealing for eco-conscious brands and those seeking artisanal products. When purchasing from tussah silk suppliers, buyers should evaluate the sourcing methods and the ecological impact of production. The unique aesthetic and sustainable credentials can attract a niche market, although the variability in quality may require careful inspection.

Why Choose Charmeuse Silk Suppliers for Fashion?

Charmeuse silk is characterized by its glossy front and matte back, making it a popular choice for evening wear, lingerie, and high-fashion accessories. Suppliers of charmeuse silk often emphasize the luxurious feel and elegant drape of their products. B2B buyers should consider the supplier’s ability to provide consistent quality, as charmeuse can vary significantly in weight and finish. While it offers a stunning visual appeal, buyers must also account for its delicate nature, which requires careful handling and maintenance.

What Are the Benefits of Working with Habotai Silk Suppliers?

Habotai silk suppliers offer a lightweight and semi-sheer fabric that is commonly used for linings, scarves, and summer garments. This type of silk is cost-effective, making it an attractive option for businesses looking to balance quality with budget constraints. When sourcing from habotai silk suppliers, B2B buyers should assess the fabric’s weight and transparency to ensure it meets their specific application needs. While it may not be as durable as heavier silk types, its versatility allows for a range of creative uses.

How Can Crepe Silk Suppliers Enhance Your Product Line?

Crepe silk suppliers specialize in a crinkled texture that provides a unique drape, making it suitable for dresses, blouses, and formal wear. This silk type is favored for its soft feel and excellent drape, but it can present challenges during sewing due to its texture. B2B buyers should consider the supplier’s expertise in crepe silk, as well as their ability to deliver consistent quality and color options. While crepe silk can elevate the elegance of a garment, careful handling during production is essential to avoid complications.

Related Video: How silkworms make silk

Key Industrial Applications of silk fabric supplier

| Industry/Sector | Specific Application of Silk Fabric Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | High-end Clothing and Accessories | Enhances brand value through luxury appeal | Quality certification, ethical sourcing, and lead times |

| Home Textiles | Luxury Bedding and Upholstery | Differentiates product offerings in a competitive market | Fabric durability, colorfastness, and care instructions |

| Medical and Healthcare | Surgical Drapes and Gowns | Provides hypoallergenic and breathable options | Compliance with health regulations and sterilization processes |

| Automotive and Aerospace | Interior Trim and Upholstery | Lightweight yet durable material improves performance | Fire retardancy, weight specifications, and supplier reliability |

| Hospitality and Events | Table Linens and Drapery for Events | Elevates guest experience and brand image | Customization options, delivery timelines, and bulk pricing |

How is Silk Fabric Used in the Fashion and Apparel Industry?

Silk fabric suppliers play a pivotal role in the fashion and apparel industry, providing materials for high-end clothing and accessories. The luxurious texture and sheen of silk elevate the perceived value of garments, allowing brands to command premium prices. International B2B buyers must focus on sourcing silk that meets quality certifications, ensuring ethical production practices, and understanding the lead times involved in manufacturing. This is particularly crucial for markets in Europe and the Middle East, where consumer preferences lean towards sustainable and high-quality fabrics.

What Are the Applications of Silk in Home Textiles?

In the home textiles sector, silk is utilized for luxury bedding and upholstery, offering a unique combination of comfort and aesthetic appeal. The natural properties of silk, such as its temperature-regulating abilities, enhance the quality of sleep and overall living experience. Buyers from Africa and South America should prioritize sourcing silk that boasts durability and colorfastness, ensuring that products can withstand regular use and maintain their appearance over time. Clear care instructions are also essential for end consumers to maximize product longevity.

How Does Silk Fabric Benefit the Medical and Healthcare Industry?

The medical and healthcare sector benefits from silk fabric’s hypoallergenic properties, making it an excellent choice for surgical drapes and gowns. These materials provide breathability while minimizing the risk of allergic reactions, which is crucial in clinical environments. For international B2B buyers, compliance with health regulations is non-negotiable, and understanding sterilization processes is vital when sourcing silk for medical applications. This focus on safety can help suppliers build trust and reliability within the healthcare community.

What Role Does Silk Play in Automotive and Aerospace Industries?

In the automotive and aerospace industries, silk is valued for its lightweight yet durable characteristics, particularly in interior trim and upholstery. This application not only contributes to weight reduction—improving fuel efficiency—but also enhances the overall aesthetic of the vehicle or aircraft. Buyers must consider specific requirements such as fire retardancy and weight specifications when sourcing silk for these applications. Reliability in the supply chain is crucial, especially given the stringent safety standards in these industries.

How is Silk Fabric Used in Hospitality and Events?

Silk fabric suppliers cater to the hospitality industry by providing exquisite table linens and drapery for events, significantly elevating the guest experience. The luxurious appearance of silk enhances the ambiance of any setting, making it a preferred choice for high-end hotels and event planners. Buyers should look for customization options to align with branding and theme requirements, while also considering delivery timelines and bulk pricing to manage costs effectively. This approach can help businesses create memorable experiences for their guests.

Related Video: Printed Fabric Production

3 Common User Pain Points for ‘silk fabric supplier’ & Their Solutions

Scenario 1: Inconsistent Quality of Silk Fabrics

The Problem:

B2B buyers often struggle with the inconsistency in silk fabric quality from suppliers, which can lead to significant issues in production and customer satisfaction. For instance, a clothing manufacturer in South America may receive a shipment of silk that varies in weight, sheen, and texture from what was previously ordered. This inconsistency can result in product defects, increased returns, and a damaged reputation. Buyers feel frustrated and anxious, especially when they have made commitments to their clients based on specific quality standards.

The Solution:

To mitigate quality inconsistencies, B2B buyers should establish clear quality control protocols with their silk fabric suppliers. This includes requesting comprehensive fabric samples before placing bulk orders. Buyers can also consider implementing a third-party inspection service to evaluate the quality of the silk upon arrival. Additionally, maintaining open lines of communication with suppliers about specific quality expectations and any changes in production processes can help align both parties. Regular audits and visits to the supplier’s facilities can further enhance transparency and build trust.

Scenario 2: Complex Sourcing Processes for Silk Fabrics

The Problem:

International buyers, particularly from Africa and the Middle East, may encounter complex and lengthy sourcing processes when looking for reliable silk fabric suppliers. This is often compounded by language barriers, cultural differences, and varying business practices, which can result in miscommunication and delays. For example, a buyer in Saudi Arabia might find it challenging to navigate the procurement landscape in China, leading to frustration and potential loss of business opportunities.

The Solution:

To streamline the sourcing process, buyers should utilize online platforms that specialize in connecting B2B buyers with silk fabric suppliers. These platforms often provide user-friendly interfaces, allowing buyers to filter suppliers by region, product specifications, and reviews from other customers. Engaging with local trade associations or chambers of commerce can also provide invaluable insights and recommendations for reputable suppliers. Furthermore, hiring a local sourcing agent who understands the regional market dynamics can bridge cultural gaps and facilitate smoother negotiations.

Scenario 3: High Shipping Costs and Delays for Silk Fabrics

The Problem:

Another significant pain point for B2B buyers is the high shipping costs and potential delays associated with importing silk fabrics. Buyers in Europe, for example, may find that the logistics of transporting silk from Asia can significantly inflate their overall costs and disrupt their supply chain. Delays in delivery can result in missed deadlines and unhappy customers, leading to financial losses and strained business relationships.

The Solution:

To address shipping challenges, buyers should explore multiple shipping options and negotiate terms directly with freight forwarders. Establishing long-term relationships with logistics partners can lead to better rates and more reliable service. Buyers should also consider consolidating orders to maximize shipping efficiency and minimize costs. Additionally, using a just-in-time inventory system can help mitigate the impact of delays by ensuring that production schedules remain flexible. Lastly, keeping abreast of international trade regulations and potential tariffs can assist in forecasting costs and planning accordingly.

Strategic Material Selection Guide for silk fabric supplier

When selecting materials for silk fabric, international B2B buyers must consider various factors that influence the performance, cost, and suitability of the end products. Below, we analyze four common materials used in the production of silk fabric, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Mulberry Silk?

Mulberry silk is the most common type of silk and is produced by silkworms that feed exclusively on mulberry leaves.

- Key Properties: Mulberry silk is known for its exceptional softness, luster, and strength. It has a high tensile strength, making it durable under various conditions, and it is naturally hypoallergenic.

- Pros & Cons: The primary advantage of mulberry silk is its luxurious feel and appearance, which makes it suitable for high-end garments and home textiles. However, it can be relatively expensive compared to synthetic alternatives, and its care requirements can complicate manufacturing processes.

- Impact on Application: Mulberry silk is highly compatible with dyeing processes, allowing for vibrant colors that appeal to fashion markets. However, it is sensitive to temperature and moisture, which can affect its performance in humid climates.

- Considerations for Buyers: Buyers must ensure compliance with international quality standards, such as ASTM D5034 for fabric strength, and consider local preferences for silk products in their respective markets.

How Does Tussah Silk Compare in Performance?

Tussah silk, produced by wild silkworms, offers a different set of characteristics compared to mulberry silk.

- Key Properties: Tussah silk is coarser and has a more textured finish, which provides a unique aesthetic. It is less shiny than mulberry silk but offers good durability.

- Pros & Cons: The key advantage of tussah silk is its lower cost, making it a more accessible option for a wider range of products. However, its rough texture may not be suitable for all applications, particularly those requiring a smooth finish.

- Impact on Application: Tussah silk is well-suited for rustic or artisanal products, appealing to niche markets. Its natural color variations can also enhance the uniqueness of the end product.

- Considerations for Buyers: Buyers should be aware of the varying quality standards for tussah silk and ensure that their suppliers adhere to relevant certifications, such as Oeko-Tex, to guarantee safety and environmental compliance.

What Benefits Does Charmeuse Silk Offer for Luxury Products?

Charmeuse silk is a lightweight fabric known for its luxurious drape and sheen, making it popular in high-end fashion.

- Key Properties: Charmeuse silk has a satin weave that gives it a glossy surface on one side and a dull finish on the reverse. It is lightweight yet strong, with a good drape.

- Pros & Cons: The primary advantage of charmeuse silk is its elegant appearance, making it ideal for evening wear and lingerie. However, it can be prone to snagging and may require careful handling during manufacturing and washing.

- Impact on Application: Charmeuse silk is often used in garments that require a flowing silhouette, but its delicate nature limits its use in more rugged applications.

- Considerations for Buyers: Buyers targeting the luxury market should ensure their suppliers can provide charmeuse silk that meets high standards of quality and ethical sourcing, particularly in regions with strict regulations like Europe.

How Does Silk Blend Fabric Enhance Versatility?

Silk blend fabrics combine silk with other materials, such as cotton or polyester, to enhance performance and versatility.

- Key Properties: Blending silk with other fibers can improve durability and reduce costs while maintaining some of silk’s desirable properties, such as softness and luster.

- Pros & Cons: The advantage of silk blends is their versatility in various applications, from everyday wear to high-fashion items. However, the blending process can compromise some of silk’s natural benefits, such as breathability.

- Impact on Application: Silk blends are suitable for a wide range of products, including clothing and home textiles, making them appealing to budget-conscious buyers.

- Considerations for Buyers: Buyers should evaluate the specific blend ratios and the resulting fabric properties, ensuring they align with their target market’s expectations and compliance standards.

Summary Table of Material Selection for Silk Fabric Supplier

| Material | Typical Use Case for silk fabric supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Mulberry Silk | High-end garments and home textiles | Luxurious feel and appearance | Expensive and care-intensive | High |

| Tussah Silk | Rustic and artisanal products | Lower cost | Rough texture | Medium |

| Charmeuse Silk | Evening wear and lingerie | Elegant appearance | Prone to snagging | High |

| Silk Blend | Everyday wear and versatile textiles | Improved durability and cost | Compromised natural benefits | Medium |

This strategic material selection guide aims to equip international B2B buyers with the insights needed to make informed decisions when sourcing silk fabric, considering both performance and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for silk fabric supplier

What Are the Key Stages in Silk Fabric Manufacturing Processes?

The manufacturing process of silk fabric involves several critical stages that ensure high-quality output. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

-

Material Preparation

The first stage involves sourcing high-quality silk fibers, typically derived from the cocoons of the Bombyx mori moth. Suppliers must ensure that the silk is free from defects and impurities. The raw silk is then reeled from the cocoons, which involves unwinding the silk threads carefully to maintain their integrity. Buyers should inquire about the sourcing practices of suppliers to ensure they use ethical and sustainable methods. -

Forming

In this stage, the silk threads are spun into yarn. This process can involve various techniques, including traditional hand-spinning or modern mechanized spinning. The choice of technique can affect the texture and quality of the final fabric. B2B buyers should seek suppliers that utilize techniques that align with their desired fabric characteristics, such as softness or durability. -

Assembly

After the yarn is produced, the next step is weaving or knitting the fabric. Weaving can be done using various patterns and techniques, such as plain, satin, or twill weaves. Each method affects the fabric’s appearance and usability. Buyers should ask suppliers about their weaving capabilities and whether they can meet specific design requirements. -

Finishing

The finishing stage involves treating the fabric to enhance its properties, such as softness, luster, and resistance to wrinkles or stains. Techniques may include dyeing, printing, and applying chemical treatments. It’s essential for B2B buyers to understand the finishing processes used by suppliers, as they can significantly impact the final product’s quality and longevity.

How Is Quality Assurance Implemented in Silk Fabric Production?

Quality assurance (QA) is a vital component in the manufacturing of silk fabrics, ensuring that the final product meets international standards and customer expectations.

-

Adherence to International Standards

Many silk fabric suppliers adhere to international quality standards, such as ISO 9001, which outlines requirements for a quality management system. This certification indicates that the supplier has established processes to ensure product quality and customer satisfaction. B2B buyers should prioritize suppliers with recognized certifications, as this is often a marker of reliability and quality assurance. -

Industry-Specific Certifications

In addition to ISO standards, suppliers may also hold industry-specific certifications such as CE marking for European markets or API standards for specific fabric applications. These certifications can provide additional assurance regarding product safety and performance. Buyers should verify that the suppliers possess relevant certifications for their target markets. -

Quality Control Checkpoints

Effective quality control (QC) involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Conducting checks during production to identify and rectify defects early.

– Final Quality Control (FQC): A thorough inspection of the finished product before it is shipped to the buyer.

Buyers should inquire about the specific QC measures employed by suppliers at each of these stages.

What Common Testing Methods Are Used in Silk Fabric Quality Control?

Testing methods are critical in verifying the quality of silk fabrics. Some common methods include:

- Physical Testing: Assessing the fabric’s strength, tear resistance, and durability through standardized tests.

- Chemical Testing: Checking for harmful substances, dyes, and colorfastness to ensure compliance with safety regulations.

- Visual Inspection: Conducting thorough visual checks for defects, inconsistencies, or imperfections in the fabric.

B2B buyers should request documentation of testing procedures and results to verify supplier claims about quality.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying the quality control practices of a silk fabric supplier is crucial for establishing trust and ensuring product quality. Here are some actionable steps:

-

Supplier Audits

Conducting on-site audits can provide insights into the supplier’s manufacturing processes and quality control measures. During the audit, buyers can evaluate the facilities, review quality control documentation, and meet with quality assurance personnel. -

Requesting Quality Reports

Buyers should request detailed quality reports that outline the results of various testing methods and quality control measures. These reports should include information on the frequency of inspections and any corrective actions taken for identified issues. -

Third-Party Inspections

Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality control processes. These agencies can conduct random inspections and testing of the silk fabric before shipment to ensure compliance with quality standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate specific nuances in quality control:

- Regulatory Compliance: Different countries have varying regulations regarding textile imports. Buyers should familiarize themselves with the regulations applicable in their region to ensure compliance.

- Cultural Considerations: Understanding the cultural context of suppliers can enhance communication and foster better relationships, impacting the overall quality of service and product.

- Risk Management: Assessing the risks associated with suppliers in different regions, including political stability and economic conditions, can affect quality assurance. Buyers should consider diversifying their supplier base to mitigate risks.

By understanding the manufacturing processes and quality assurance practices of silk fabric suppliers, international B2B buyers can make informed decisions that align with their needs for quality, compliance, and ethical sourcing.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘silk fabric supplier’

Introduction

Navigating the sourcing of silk fabric suppliers can be a complex process, especially for international B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe. This guide provides a step-by-step checklist that outlines essential actions to ensure you select a reliable supplier who meets your business needs. By following these steps, you can streamline your sourcing process and mitigate risks associated with international procurement.

Step 1: Define Your Technical Specifications

Before initiating contact with potential suppliers, it is crucial to clearly define your technical requirements for silk fabric. This includes specifications such as fabric weight, weave type, and desired finishes.

- Why it matters: Precise specifications help suppliers understand your needs, leading to more accurate quotes and samples.

- What to look for: Ensure that your requirements align with your end-use applications, whether for apparel, home textiles, or other industries.

Step 2: Conduct Market Research for Suppliers

Research the market landscape to identify potential silk fabric suppliers that align with your specifications and business goals. Utilize trade directories, industry forums, and trade shows to gather insights.

A stock image related to silk fabric supplier.

- Why it matters: Understanding the market helps you identify reputable suppliers with a track record of quality and reliability.

- What to look for: Focus on suppliers with positive reviews, a strong presence in your target markets, and those who specialize in silk fabrics.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

- Why it matters: Evaluating suppliers reduces the risk of partnering with unqualified vendors and ensures they can meet your quality standards.

- What to look for: Assess their production capacity, quality assurance processes, and responsiveness to inquiries.

Step 4: Verify Supplier Certifications and Compliance

Check for relevant certifications and compliance with international standards, such as ISO certifications or compliance with eco-friendly practices.

- Why it matters: Certifications provide assurance regarding the quality and sustainability of the products.

- What to look for: Ensure that the supplier adheres to labor laws and environmental regulations, particularly if sourcing from regions with varying standards.

Step 5: Request Samples and Assess Quality

After narrowing down your list of potential suppliers, request fabric samples to evaluate their quality firsthand. This step is essential to confirm that the fabric meets your specifications.

- Why it matters: Seeing and feeling the fabric allows you to assess its texture, durability, and overall quality before making a bulk order.

- What to look for: Pay attention to color consistency, weave integrity, and any defects that may affect the fabric’s usability.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations regarding pricing, payment terms, delivery schedules, and any warranties or return policies.

- Why it matters: Clear agreements help establish expectations and reduce misunderstandings down the line.

- What to look for: Ensure terms are favorable for your business while also being fair to the supplier, fostering a collaborative relationship.

Step 7: Establish a Communication Plan

Effective communication is vital for a successful partnership. Establish a clear communication plan to facilitate ongoing dialogue with your supplier.

- Why it matters: Regular communication helps in addressing issues promptly and builds a stronger relationship over time.

- What to look for: Set up regular check-ins and updates, and ensure there are clear points of contact from both sides for efficiency.

By following this checklist, international B2B buyers can confidently source silk fabric suppliers that meet their needs while fostering successful long-term partnerships.

Comprehensive Cost and Pricing Analysis for silk fabric supplier Sourcing

What are the Key Cost Components in Sourcing Silk Fabric?

When sourcing silk fabric from suppliers, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The quality of silk, whether mulberry or tussah, significantly influences the cost. Higher-grade silk will naturally come at a premium.

-

Labor: Labor costs vary depending on the region of production. For example, countries with established silk industries, like China and India, may offer competitive labor rates, while others may incur higher costs due to skill levels and labor laws.

-

Manufacturing Overhead: This includes expenses related to factory maintenance, utilities, and administrative costs. In regions with advanced manufacturing capabilities, these costs might be lower due to economies of scale.

-

Tooling: Investment in machinery and tools for silk production can be substantial. Suppliers that utilize modern technology may pass these costs onto buyers but can also offer higher quality and efficiency.

-

Quality Control (QC): Implementing stringent quality control processes ensures product consistency but adds to costs. Buyers should inquire about the QC measures in place to ensure the silk meets their specifications.

-

Logistics: Transporting silk fabric internationally can significantly impact overall costs. Factors such as shipping method, distance, and customs duties should be evaluated.

-

Margin: Each supplier will have a different markup based on their operational costs and desired profit margin, making it crucial for buyers to compare multiple suppliers.

How Do Price Influencers Affect Silk Fabric Sourcing?

Several factors can influence the pricing of silk fabric, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically benefit from economies of scale. Buyers should negotiate MOQs to achieve better pricing.

-

Specifications and Customization: Custom designs or specific fabric weights can increase costs. Clearly defining specifications early in negotiations can help manage expenses.

-

Materials and Quality Certifications: Fabrics with certifications (like OEKO-TEX or GOTS) may cost more but provide assurance regarding sustainability and safety.

-

Supplier Factors: The reputation, reliability, and negotiation flexibility of the supplier can affect pricing. Engaging with well-established suppliers may yield better service but could come at a higher cost.

-

Incoterms: Understanding the chosen Incoterms (like FOB, CIF, etc.) is vital. They define who bears the cost and risk at different stages of the shipping process, impacting the final price.

What Buyer Tips Can Help Optimize Silk Fabric Sourcing Costs?

To navigate the complexities of silk fabric sourcing, international buyers should consider the following tips:

-

Effective Negotiation Strategies: Building a strong relationship with suppliers can facilitate better pricing and terms. Highlighting long-term partnership potential may encourage suppliers to offer discounts.

-

Focus on Cost-Efficiency: Assessing the Total Cost of Ownership (TCO) rather than just the unit price can lead to better purchasing decisions. Consider aspects such as durability, shipping costs, and potential waste in production.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional economic conditions and currency fluctuations that may affect pricing. Investigating local market conditions can provide leverage during negotiations.

-

Disclaimer on Indicative Prices: Keep in mind that prices for silk fabric can vary widely based on the aforementioned factors. Always request updated quotes and consider potential price changes due to market dynamics.

By understanding these cost components, price influencers, and strategic tips, B2B buyers can make informed decisions when sourcing silk fabric, ensuring that they achieve both quality and cost-effectiveness in their procurement processes.

Alternatives Analysis: Comparing silk fabric supplier With Other Solutions

When considering silk fabric suppliers, it is essential for B2B buyers to explore various alternatives that can meet their specific needs and preferences. This section will compare silk fabric suppliers with two viable alternatives: synthetic fabric suppliers and cotton fabric suppliers. Each option has unique attributes, and understanding these can help buyers make informed decisions.

| Comparison Aspect | Silk Fabric Supplier | Synthetic Fabric Supplier | Cotton Fabric Supplier |

|---|---|---|---|

| Performance | Luxurious feel, high durability, natural sheen | Good durability, versatile, but may lack breathability | Soft, breathable, and comfortable, but less durable than silk |

| Cost | Higher initial investment | Generally lower cost, varies with quality | Moderate cost, often more affordable than silk |

| Ease of Implementation | Requires careful sourcing, potential import issues | Readily available, easier to source locally | Widely available and easy to procure |

| Maintenance | Requires special care (dry cleaning recommended) | Generally low maintenance, easy to clean | Moderate maintenance, machine washable |

| Best Use Case | High-end fashion, luxury items, upholstery | Everyday apparel, sportswear, industrial applications | Casual wear, home textiles, and affordable clothing |

What Are the Advantages and Disadvantages of Synthetic Fabric Suppliers?

Synthetic fabric suppliers offer products made from materials like polyester, nylon, or spandex. The primary advantage of synthetic fabrics is their affordability and versatility. They are widely available and can be sourced locally, which reduces lead times and shipping costs. Additionally, synthetic fabrics often have excellent moisture-wicking properties, making them suitable for activewear. However, they may not provide the same luxurious feel and breathability as silk, which can be a drawback for high-end fashion applications.

How Does Cotton Fabric Compare to Silk Fabric Suppliers?

Cotton fabric suppliers provide a natural alternative that is soft, breathable, and comfortable for everyday use. Cotton is often more affordable than silk, making it an attractive option for businesses focused on cost-effectiveness. It is also easy to maintain, as most cotton fabrics can be machine washed. However, cotton lacks the luxurious sheen and durability of silk, which may limit its use in high-end or luxury markets. Additionally, cotton may not hold dye as vibrantly as silk, which can affect the visual appeal of finished products.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting between silk fabric suppliers and alternative options, B2B buyers should consider their target market, product positioning, and budget. If the goal is to create high-end fashion items or luxury upholstery, silk fabric suppliers may be the best choice due to the superior quality and aesthetic appeal. Conversely, if the focus is on producing affordable, everyday apparel or home textiles, synthetic or cotton fabric suppliers may provide more cost-effective solutions. Ultimately, the decision should align with the buyer’s specific needs, market demands, and long-term business strategy.

Essential Technical Properties and Trade Terminology for silk fabric supplier

What Are the Essential Technical Properties of Silk Fabric?

When sourcing silk fabric, understanding its technical properties is crucial for making informed purchasing decisions. Here are several key specifications to consider:

1. Material Grade

Material grade refers to the quality classification of silk, which can significantly impact the fabric’s durability and appearance. High-grade silk, such as Mulberry silk, is known for its lustrous finish and softness, making it ideal for luxury garments. For B2B buyers, selecting the appropriate material grade is essential for meeting customer expectations and maintaining brand reputation.

2. Weight (GSM)

Weight is measured in grams per square meter (GSM) and affects the fabric’s drape and opacity. Lighter silk (around 80-120 GSM) is often used for delicate garments, while heavier silk (150 GSM and above) is suitable for structured clothing and upholstery. Understanding GSM allows buyers to select the right silk for their specific applications, ensuring product suitability and customer satisfaction.

3. Tolerance Levels

Tolerance levels indicate the allowable variations in the dimensions or weight of silk fabric. For instance, a tolerance of +/- 5% in fabric width can affect the cutting and sewing processes. Knowing the tolerance levels helps manufacturers avoid production issues and ensures that the end products meet exact specifications, which is vital for maintaining quality control.

4. Weave Type

The weave type (e.g., satin, twill, or plain) significantly influences the texture and visual characteristics of silk fabric. Satin weave, for instance, offers a smooth and shiny surface, while twill provides a more textured feel. B2B buyers should consider the weave type to match the fabric’s aesthetic and functional requirements with their intended use, whether in fashion or home textiles.

5. Color Fastness

Color fastness refers to the fabric’s ability to retain its color when exposed to various conditions, such as washing or sunlight. This property is crucial for maintaining the appearance of silk over time. Buyers must inquire about color fastness ratings to ensure that the silk they source will meet their quality standards and resist fading, particularly for products exposed to light or frequent washing.

What Are Common Trade Terms in the Silk Fabric Industry?

Understanding trade terminology is vital for effective communication and negotiation with suppliers. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces products that are marketed by another company under its own brand name. In the silk industry, this means that a supplier can manufacture silk fabrics according to the specifications provided by a buyer. This is beneficial for B2B buyers looking for custom solutions tailored to their brand’s needs.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum quantity of fabric that a supplier is willing to sell. This term is crucial for buyers to understand, as it impacts inventory costs and production planning. A higher MOQ might require a larger upfront investment, which could be a barrier for smaller businesses or startups.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products or services. For B2B buyers, issuing an RFQ is an effective way to gather competitive pricing from multiple suppliers, helping them make informed sourcing decisions and negotiate better terms.

4. Incoterms (International Commercial Terms)

Incoterms are standardized terms that define the responsibilities of buyers and sellers in international trade. They clarify who is responsible for shipping, insurance, and tariffs. Understanding Incoterms is essential for B2B buyers to manage logistics effectively and avoid unexpected costs during the importation of silk fabric.

5. Lead Time

A stock image related to silk fabric supplier.

Lead time is the period between placing an order and receiving the goods. This term is particularly important in the textile industry, where timely delivery can impact production schedules. B2B buyers should always inquire about lead times to ensure that they can meet their own customers’ demands without delays.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can enhance their purchasing strategies, leading to more successful transactions in the silk fabric market.

Navigating Market Dynamics and Sourcing Trends in the silk fabric supplier Sector

What are the Key Market Dynamics and Trends Influencing Silk Fabric Suppliers?

The silk fabric market is witnessing a resurgence driven by a blend of traditional craftsmanship and modern technology. Key global drivers include a growing demand for luxury textiles, particularly in fashion and home décor, as well as the increasing popularity of sustainable and ethically sourced materials. International B2B buyers from regions like Africa, South America, the Middle East, and Europe are particularly attentive to these trends, as they shape purchasing decisions and supplier selection.

Emerging technologies such as blockchain are becoming crucial for enhancing transparency in the supply chain. Buyers are increasingly seeking suppliers who can provide detailed information about the origin of their silk, thereby ensuring quality and ethical sourcing. Additionally, the rise of e-commerce platforms tailored to B2B transactions is facilitating easier access to a wider range of suppliers. This digital transformation allows buyers from diverse regions to compare products and prices more effectively, making informed purchasing decisions.

Furthermore, the impact of global events, such as the COVID-19 pandemic, has led to shifts in sourcing strategies. Buyers are now prioritizing local suppliers to reduce lead times and transportation costs, thus reshaping traditional supply chains. The growing emphasis on customization is also influencing silk fabric suppliers to offer tailored solutions, catering to specific market needs and consumer preferences.

How Can Sustainability and Ethical Sourcing Influence B2B Relationships in the Silk Fabric Sector?

Sustainability is no longer just a trend; it has become a core component of business strategy for silk fabric suppliers. The environmental impact of silk production, particularly concerning water usage and chemical treatments, has led to increased scrutiny from both consumers and regulatory bodies. For B2B buyers, understanding the sustainability practices of potential suppliers is essential. They should seek out suppliers who employ eco-friendly practices, such as organic farming methods and sustainable dyeing processes.

Ethical sourcing is another critical aspect that influences buyer decisions. Suppliers that adhere to fair trade practices, ensuring fair wages and safe working conditions for laborers, are increasingly favored. Certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX® can serve as reliable indicators of a supplier’s commitment to sustainability and ethical practices. By partnering with certified suppliers, B2B buyers can enhance their brand reputation and meet the growing consumer demand for responsible sourcing.

Moreover, the integration of sustainability into the supply chain can lead to cost savings in the long run. By reducing waste and optimizing resource use, suppliers can offer competitive pricing while maintaining quality. Thus, international buyers should prioritize suppliers who not only meet their product specifications but also align with their values regarding sustainability and ethical sourcing.

What is the Historical Context of Silk Fabric Supply and Its Relevance Today?

The history of silk fabric dates back thousands of years, originating in ancient China where it was highly prized for its luxurious texture and sheen. Over time, the silk trade expanded along the Silk Road, connecting East and West, which established an enduring global market. Today, silk remains synonymous with luxury and quality, but the landscape has evolved significantly.

Modern silk production has seen the introduction of advanced farming techniques and technological innovations that enhance efficiency and sustainability. However, the essence of silk craftsmanship remains, making it a unique product that appeals to high-end markets. This historical context is crucial for B2B buyers, as it highlights the importance of sourcing from suppliers who respect traditional methods while also embracing modern advancements. Understanding this duality can help buyers identify suppliers that not only deliver high-quality silk but also resonate with the heritage and value that silk represents in the global market.

Frequently Asked Questions (FAQs) for B2B Buyers of silk fabric supplier

-

How do I ensure quality when sourcing silk fabric from suppliers?

To ensure quality when sourcing silk fabric, start by requesting samples from potential suppliers. This allows you to evaluate the texture, sheen, and overall quality of the fabric. Additionally, consider suppliers with certifications or quality assurance processes in place, such as ISO certifications. Engaging in third-party inspections can further guarantee that the fabric meets your standards. Lastly, establish clear quality metrics and expectations in your contracts to mitigate risks. -

What is the best way to vet silk fabric suppliers for international trade?

Vetting silk fabric suppliers involves multiple steps. Begin by researching their market reputation through reviews and testimonials from previous clients. Verify their business licenses and any relevant certifications to ensure compliance with international trade regulations. Conducting a site visit can provide insights into their operations and capabilities. Lastly, consider using third-party verification services to assess their financial stability and manufacturing practices. -

What are common payment terms offered by silk fabric suppliers?

Common payment terms for silk fabric suppliers typically include options like a 30% deposit upfront with the balance due upon delivery, or net 30/60 terms after shipment. Some suppliers may also offer letter of credit as a secure payment method, especially for larger orders. Always negotiate terms that align with your cash flow needs and ensure that you have a clear understanding of any penalties for late payments. -

What is the minimum order quantity (MOQ) for silk fabric, and how does it vary by supplier?

Minimum order quantities (MOQs) for silk fabric can vary significantly based on the supplier and their production capabilities. Typically, MOQs range from 50 to 500 meters. Suppliers may be more flexible for established clients or larger orders, so it’s worth discussing your specific needs. Keep in mind that lower MOQs might come with higher per-unit costs, which could affect your pricing strategy. -

How can I customize silk fabric to meet my specific requirements?

Customization options for silk fabric often include choices in color, weight, and design patterns. Many suppliers offer digital printing services, allowing you to create unique designs tailored to your brand. To initiate customization, provide the supplier with detailed specifications, including swatches or design files. Be prepared for additional costs and longer lead times for custom orders, and confirm the supplier’s capability to meet your requirements before proceeding. -

What logistics considerations should I keep in mind when importing silk fabric?

When importing silk fabric, consider logistics factors such as shipping methods, customs regulations, and lead times. Determine whether air freight or sea freight is more cost-effective for your shipment size and urgency. Familiarize yourself with the customs clearance process in your country, as silk may have specific import duties or restrictions. Working with a logistics partner experienced in textile imports can streamline the process and mitigate potential delays. -

What are the key certifications I should look for in silk fabric suppliers?

Key certifications to look for in silk fabric suppliers include Oeko-Tex Standard 100, which ensures that textiles are free from harmful substances, and Global Organic Textile Standard (GOTS), indicating organic production processes. Certifications like ISO 9001 demonstrate a commitment to quality management. These credentials not only enhance the credibility of the supplier but also ensure that the silk fabric aligns with sustainability and safety standards. -

How do I handle disputes with silk fabric suppliers?

Handling disputes with silk fabric suppliers requires a structured approach. Start by documenting all communications and agreements related to the issue. Engage in direct discussions with the supplier to resolve the matter amicably, aiming for a solution that satisfies both parties. If necessary, refer to the terms outlined in your contract regarding dispute resolution, which may include mediation or arbitration. Maintaining a professional demeanor throughout the process can help preserve the business relationship while addressing the dispute effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for silk fabric supplier

What Are the Key Takeaways for B2B Buyers in Silk Fabric Sourcing?

In conclusion, strategic sourcing of silk fabric offers immense potential for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. By understanding local market dynamics and leveraging global supplier networks, buyers can secure high-quality silk products that meet their specific needs. Prioritizing supplier relationships and due diligence ensures reliability and fosters innovation, which can lead to competitive advantages.

Why Is Strategic Sourcing Essential for Silk Fabric?

Emphasizing strategic sourcing allows businesses to mitigate risks associated with supply chain disruptions and fluctuating prices. It enables buyers to tap into sustainable practices, essential for meeting the growing consumer demand for ethically sourced materials. Engaging with suppliers who share similar values can enhance brand reputation and lead to stronger market positioning.

How Can International Buyers Prepare for the Future of Silk Fabric Sourcing?

Looking ahead, international B2B buyers should remain adaptable and proactive in exploring emerging markets and technologies. By investing in digital tools for supply chain management and maintaining open communication with suppliers, businesses can navigate the complexities of the silk fabric market with confidence.

As you consider your next steps in sourcing silk fabric, take action today to evaluate your supplier partnerships and explore new opportunities that align with your strategic objectives. The silk fabric market is ripe for innovation, and your proactive approach can set the stage for future success.