Unlock Quality: The Ultimate Cushion Custom Guide (2025)

Introduction: Navigating the Global Market for cushion custom

In an increasingly competitive global marketplace, sourcing high-quality custom cushions can pose significant challenges for international B2B buyers. Whether you are in Brazil seeking to enhance your hospitality offerings or in Egypt aiming to provide ergonomic solutions for office spaces, understanding the nuances of cushion customization is crucial. This guide serves as a comprehensive resource, addressing various types of cushions, their applications across industries, and essential strategies for supplier vetting.

Navigating the complexities of materials, designs, and manufacturing processes can be daunting, especially when considering regional preferences and compliance standards. Our guide delves into key aspects such as cost analysis, shipping logistics, and quality assurance, all tailored to empower buyers from Africa, South America, the Middle East, and Europe. By leveraging actionable insights, you will be equipped to make informed purchasing decisions that align with your business objectives and customer expectations.

Furthermore, this resource highlights the importance of establishing robust supplier relationships and understanding market trends, ensuring that you remain competitive in your respective markets. With a focus on practical solutions and strategic insights, this guide aims to enhance your sourcing journey, ultimately leading to superior product offerings and customer satisfaction.

Understanding cushion custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Throw Cushions | Decorative, smaller size, various shapes | Home decor, hospitality, retail | Pros: Versatile design options; Cons: Limited support for seating. |

| Support Cushions | Ergonomically designed, larger size | Office furniture, healthcare | Pros: Enhanced comfort; Cons: May require custom orders. |

| Outdoor Cushions | Weather-resistant materials, UV protection | Outdoor furniture, landscaping | Pros: Durable and long-lasting; Cons: Higher initial cost. |

| Custom Printed Cushions | Personalized designs, branding options | Corporate gifts, promotional items | Pros: Unique branding opportunities; Cons: Longer lead times. |

| Memory Foam Cushions | High-density foam, contouring support | Medical facilities, ergonomic chairs | Pros: Superior comfort and support; Cons: Heavier and bulkier. |

What Are Throw Cushions and Their B2B Applications?

Throw cushions are often smaller and serve primarily decorative purposes. Their variety of shapes and designs makes them ideal for enhancing the aesthetic appeal of spaces, particularly in the hospitality industry and retail environments. B2B buyers should consider the material and design to align with their brand identity. While they offer a wide range of design options, throw cushions may not provide adequate support for seating, which could be a drawback in environments where comfort is paramount.

How Do Support Cushions Enhance Comfort in B2B Settings?

Support cushions are larger and ergonomically designed to provide enhanced comfort and support. They are commonly used in office furniture and healthcare settings, where prolonged sitting can lead to discomfort. When purchasing support cushions, businesses should evaluate the specific ergonomic needs of their workforce or clientele. Although they improve comfort significantly, buyers should be aware that support cushions may require custom orders, potentially increasing lead times.

What Makes Outdoor Cushions a Smart Investment for B2B Buyers?

Outdoor cushions are specifically designed to withstand various weather conditions, utilizing materials that are both durable and UV-resistant. They find applications in outdoor furniture and landscaping projects, making them a popular choice for businesses in the hospitality and recreational sectors. While their longevity and durability are significant advantages, buyers should also consider the higher initial investment cost when integrating outdoor cushions into their offerings.

Why Choose Custom Printed Cushions for Branding Purposes?

Custom printed cushions provide businesses with the opportunity to showcase their brand through personalized designs. They are particularly effective as corporate gifts or promotional items, making them a valuable tool for marketing campaigns. B2B buyers should assess the lead times for custom orders and the minimum order quantities, as these factors can impact inventory management. While they offer unique branding opportunities, the longer lead times may pose challenges for businesses with tight deadlines.

What Are the Benefits of Memory Foam Cushions in Professional Environments?

Memory foam cushions are crafted from high-density foam that contours to the body, providing superior comfort and support. They are commonly used in medical facilities and ergonomic chairs, where user comfort is critical. B2B buyers should consider the weight and bulkiness of memory foam cushions, as these factors may affect shipping and storage. Although they offer exceptional comfort, the heavier nature of these cushions can be a disadvantage in terms of mobility and placement.

Related Video: How to Pick the Right Cushion!

Key Industrial Applications of cushion custom

| Industry/Sector | Specific Application of cushion custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Interior cushioning for vehicles | Enhances comfort and safety, reducing noise levels | Material durability, compliance with safety standards |

| Furniture Manufacturing | Custom cushions for seating products | Increases product appeal and customer satisfaction | Design flexibility, material sourcing options |

| Aerospace | Cushions for aircraft seats and interiors | Weight reduction and improved passenger comfort | Certification requirements, fire resistance |

| Healthcare | Cushions for medical equipment and furniture | Supports patient comfort and reduces pressure sores | Biocompatibility, ease of cleaning, and durability |

| Packaging | Protective cushioning for fragile goods | Minimizes damage during transport and storage | Sustainability of materials, cost-effectiveness |

How is ‘cushion custom’ used in the automotive industry?

In the automotive sector, custom cushions are critical for enhancing the interior comfort of vehicles. These cushions are designed to absorb vibrations and reduce noise, contributing to a more enjoyable driving experience. For international B2B buyers, especially in Africa and South America, sourcing cushions that meet specific durability and safety standards is essential. This includes compliance with regulations pertaining to fire resistance and material longevity, ensuring that the cushions can withstand various environmental conditions.

What are the applications of cushion custom in furniture manufacturing?

In furniture manufacturing, custom cushions are tailored for seating products, such as sofas and chairs. These cushions not only improve the aesthetic appeal but also significantly enhance customer satisfaction by providing greater comfort. Buyers from Europe and the Middle East should consider the design flexibility and material options available, as well as the ability to meet specific ergonomic requirements. Ensuring that the cushions are made from sustainable materials can also be a key selling point in competitive markets.

How does ‘cushion custom’ play a role in the aerospace sector?

Cushions in the aerospace industry serve multiple functions, including providing comfort to passengers and reducing the overall weight of aircraft interiors. Custom cushions are designed to meet stringent certification requirements and must often be fire-resistant to comply with safety regulations. For B2B buyers in this sector, especially those from Europe and the Middle East, sourcing cushions that are lightweight yet durable is crucial. Additionally, understanding the specific certifications required for aviation products can streamline the sourcing process.

In what ways are cushions utilized in the healthcare industry?

In the healthcare sector, custom cushions are essential for medical equipment and furniture, such as hospital beds and wheelchairs. These cushions are designed to support patient comfort and help prevent pressure sores, which can lead to serious health complications. International buyers, particularly from regions like Africa and South America, should prioritize sourcing cushions that are biocompatible and easy to clean. Additionally, the durability of materials used is critical to ensure long-term use in healthcare settings.

How is ‘cushion custom’ applied in packaging?

In packaging, custom cushions are used to protect fragile goods during transport and storage. These cushions are designed to minimize damage, ensuring that products arrive in perfect condition. For B2B buyers, particularly in South America and Africa, sourcing sustainable cushioning materials can be a significant consideration, especially as companies increasingly focus on eco-friendly practices. Additionally, cost-effectiveness plays a vital role in selecting the right cushioning solutions to maintain competitive pricing in the market.

Related Video: How to Insert Foam into a Cushion Casing

3 Common User Pain Points for ‘cushion custom’ & Their Solutions

Scenario 1: Sourcing Quality Materials for Custom Cushions

The Problem: B2B buyers often face the daunting task of sourcing high-quality materials for custom cushions. In regions like Africa and South America, where access to premium fabrics and fillings may be limited, buyers can struggle to find suppliers who meet their quality standards. This challenge can lead to delays in production, increased costs, and ultimately, dissatisfied end customers. The pressure to maintain quality while managing costs can create a significant roadblock for businesses looking to compete in the market.

The Solution: To overcome this challenge, buyers should establish relationships with reputable suppliers who specialize in custom cushion materials. Conduct thorough research to identify suppliers with a proven track record in quality and reliability. Use platforms like Alibaba or Global Sources to compare options, and don’t hesitate to request samples before committing to bulk orders. Additionally, consider partnering with local artisans who can provide unique materials and craftsmanship, helping to boost the local economy while ensuring product quality. Regularly communicate with suppliers to clarify specifications and quality expectations, ensuring that your custom cushions meet both aesthetic and functional requirements.

Scenario 2: Navigating Customization Options for Diverse Markets

The Problem: In the B2B landscape, particularly for international buyers from Europe and the Middle East, catering to diverse customer preferences can be a challenge. Different regions have varying tastes, styles, and functional needs when it comes to custom cushions. A buyer may find it difficult to navigate the myriad of customization options available while ensuring that the final product resonates with their target market. This can lead to mismatched products and wasted inventory.

The Solution: Conduct market research to understand the specific preferences of your target demographic. Utilize surveys, focus groups, or social media polls to gather insights on desired colors, patterns, and materials. Once you have this data, work closely with suppliers to develop a range of customizable options that align with these preferences. Implement a modular approach to cushion design, allowing clients to mix and match elements according to their tastes. This flexibility not only enhances customer satisfaction but also increases your product appeal across different markets, leading to higher sales potential.

Scenario 3: Managing Lead Times and Production Schedules

The Problem: Timely delivery is critical in B2B transactions, yet many buyers face issues with long lead times and unanticipated delays in the production of custom cushions. This is particularly prevalent for buyers in regions with less robust supply chains, such as parts of Africa and South America. Delays can disrupt sales cycles, lead to lost revenue, and damage relationships with clients who expect prompt service.

The Solution: To mitigate lead time issues, establish clear communication channels with your suppliers to set realistic timelines and expectations. Implement a just-in-time inventory system to minimize stock levels while ensuring you can meet demand. Consider diversifying your supplier base to include local manufacturers who can offer faster turnaround times. Additionally, employ project management tools to monitor production schedules and identify potential bottlenecks early. By maintaining transparency with your clients regarding lead times and proactively addressing potential delays, you can build trust and improve client satisfaction in the long run.

Strategic Material Selection Guide for cushion custom

What Are the Key Properties of Common Materials for Cushion Custom?

When selecting materials for custom cushions, international B2B buyers must consider various properties that directly influence product performance. Here, we analyze four common materials: polyurethane foam, polyester fiber, memory foam, and latex foam. Each material offers unique characteristics that can impact durability, cost, and suitability for different applications.

How Does Polyurethane Foam Perform in Cushion Custom Applications?

Polyurethane foam is a versatile material known for its excellent resilience and adaptability. It typically has a temperature rating between -30°C and 100°C and is resistant to moisture, making it suitable for various environments.

Pros: Polyurethane foam is lightweight, cost-effective, and easy to manufacture, allowing for mass production. Its durability makes it suitable for high-traffic areas, such as commercial seating.

Cons: While it is resistant to moisture, prolonged exposure to water can lead to degradation. Additionally, lower-quality polyurethane foams may not provide adequate support over time.

Impact on Application: This material is compatible with a wide range of upholstery fabrics, making it a popular choice for furniture and automotive applications.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards, such as ASTM D3574 for foam testing. Understanding the local climate can also guide material selection, as moisture levels may affect foam longevity.

What Are the Advantages and Disadvantages of Polyester Fiber?

Polyester fiber is another common choice for cushion custom products. It is known for its good temperature resistance, typically ranging from -20°C to 80°C, and has decent moisture resistance.

Pros: This material is highly durable, resistant to fading, and easy to clean, making it ideal for outdoor applications. It is also relatively inexpensive, which can lower overall production costs.

Cons: Polyester fiber can compress over time, leading to reduced comfort. Additionally, it may not provide the same level of support as foam-based materials.

Impact on Application: Polyester is compatible with various outdoor fabrics, making it suitable for garden furniture and recreational vehicles.

Considerations for International Buyers: Buyers in the Middle East should consider UV resistance in polyester selections due to high sun exposure. Compliance with standards like ISO 105 for colorfastness may also be necessary.

Why Choose Memory Foam for Cushion Custom Solutions?

Memory foam is renowned for its ability to conform to body shapes, providing exceptional comfort and support. It typically has a temperature range of -10°C to 60°C and is sensitive to pressure and temperature changes.

Pros: The primary advantage of memory foam is its pressure-relieving properties, making it ideal for seating and bedding applications. It is also resistant to dust mites and allergens.

Cons: Memory foam can be more expensive than other materials, and it may retain heat, which could be uncomfortable in warmer climates.

Impact on Application: This material is particularly suitable for high-end furniture and specialized medical cushions.

Considerations for International Buyers: Buyers from Europe should be aware of the EU regulations regarding chemical emissions from foam materials, such as REACH compliance. Ensuring that memory foam meets these standards is crucial for market entry.

What Are the Benefits of Using Latex Foam in Cushion Custom Products?

Latex foam is a natural material derived from rubber trees, known for its durability and elasticity. It typically has a temperature range of -20°C to 70°C and is resistant to mold and mildew.

Pros: Latex foam is highly durable and offers excellent support and comfort. It is also hypoallergenic, making it suitable for sensitive individuals.

Cons: The primary disadvantage is its higher cost compared to synthetic materials. Additionally, latex foam can be heavier, which may complicate shipping and handling.

Impact on Application: Latex is often used in premium bedding and high-quality furniture applications.

Considerations for International Buyers: Buyers from regions such as Egypt should ensure that latex products comply with local health and safety standards. Additionally, understanding the supply chain for natural latex can help in sourcing sustainably.

Summary Table of Material Selection for Cushion Custom

| Material | Typical Use Case for cushion custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane Foam | Commercial seating, automotive applications | Lightweight and cost-effective | Degrades with prolonged moisture exposure | Medium |

| Polyester Fiber | Outdoor furniture, recreational vehicles | Highly durable and easy to clean | Compresses over time | Low |

| Memory Foam | High-end furniture, medical cushions | Excellent pressure relief | Retains heat and can be expensive | High |

| Latex Foam | Premium bedding, high-quality furniture | Durable and hypoallergenic | Higher cost and heavier weight | High |

In-depth Look: Manufacturing Processes and Quality Assurance for cushion custom

What Are the Main Stages in the Manufacturing Process for Custom Cushions?

The manufacturing process for custom cushions typically involves several key stages: material preparation, forming, assembly, and finishing. Understanding these stages is crucial for B2B buyers to ensure they are sourcing high-quality products that meet their specific needs.

How Is Material Prepared for Custom Cushions?

Material preparation is the foundational step in the cushion manufacturing process. This stage involves selecting the right fabrics and foams based on factors such as durability, comfort, and aesthetic appeal. Buyers should look for suppliers that use high-quality materials like high-density polyurethane foam or memory foam, as these provide longevity and comfort.

Once the materials are selected, they undergo cutting and shaping. Precision cutting tools, such as CNC machines, are often used to ensure consistency in size and shape. This is critical as it affects the overall quality and performance of the cushion.

What Techniques Are Used in Forming Custom Cushions?

Forming is where the cushion takes its shape. Various techniques can be employed, including:

-

Compression Molding: This method involves placing foam in a mold and applying heat and pressure to shape it. This is ideal for producing cushions that require specific contours.

-

Injection Molding: Commonly used for creating more complex shapes, this technique injects liquid foam into a mold, allowing for intricate designs that might not be possible with traditional cutting methods.

-

Sewing and Stitching: After forming, fabric covers are sewn together to encase the foam. The stitching quality is essential; double stitching is preferred for durability.

How Are Custom Cushions Assembled?

The assembly stage combines all components into the final product. Quality assembly ensures that the cushion maintains its shape and provides the desired comfort level. Key considerations during this stage include:

-

Zipper Installation: Many custom cushions feature removable covers for easy cleaning. Ensure that zippers are robust and well-placed.

-

Quality Control During Assembly: Regular checks should be conducted throughout the assembly process to catch any defects early.

What Quality Assurance Standards Are Relevant for Custom Cushions?

Quality assurance (QA) is vital in the manufacturing of custom cushions to ensure safety, durability, and customer satisfaction. B2B buyers should familiarize themselves with relevant international and industry-specific standards.

How Does ISO 9001 Impact Cushion Manufacturing?

ISO 9001 is a widely recognized international standard for quality management systems (QMS). Manufacturers that comply with ISO 9001 demonstrate a commitment to consistent quality and customer satisfaction. Buyers should inquire about their suppliers’ ISO certifications as this can provide assurance of reliable processes and product quality.

Which Industry-Specific Certifications Should Buyers Look For?

In addition to ISO standards, certain industry-specific certifications can indicate adherence to safety and quality benchmarks:

-

CE Marking: Essential for products sold in the European Economic Area, CE marking signifies compliance with health, safety, and environmental protection standards.

-

API Certification: Particularly relevant for cushions used in industrial applications, API standards ensure that products meet rigorous performance criteria.

What Are the Critical QC Checkpoints in Custom Cushion Manufacturing?

Quality control checkpoints are integral to the manufacturing process. The main QC checkpoints include:

-

Incoming Quality Control (IQC): Before materials are used, they should undergo IQC to verify that they meet specified standards.

-

In-Process Quality Control (IPQC): This involves monitoring the production process to identify and rectify defects as they occur.

-

Final Quality Control (FQC): After assembly, FQC is conducted to ensure that the finished product meets all quality standards before shipment.

What Common Testing Methods Are Used to Ensure Cushion Quality?

Several testing methods are employed to verify the quality and performance of custom cushions:

-

Durability Testing: This includes compression and tensile tests to assess the material’s ability to withstand use over time.

-

Flammability Testing: Cushions must meet specific flammability standards, particularly in regions with stringent safety regulations.

-

Comfort Testing: Evaluating the comfort level of cushions through user trials can provide valuable insights into product performance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers maintain high-quality standards, B2B buyers should take proactive steps to verify their QC practices:

-

Conduct Audits: Regular audits of suppliers can help verify compliance with quality standards and identify potential areas for improvement.

-

Request Quality Reports: Suppliers should be willing to provide documentation of their quality control processes and any certifications they hold.

-

Utilize Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality practices.

What Are the Nuances of QC and Certification for International Buyers?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of specific nuances in QC and certification:

-

Regional Standards: Different regions may have varying safety and quality standards. It’s crucial for buyers to understand these requirements to avoid regulatory issues.

-

Cultural Considerations: Communication barriers can impact the quality assurance process. Establishing clear guidelines and expectations with suppliers can help mitigate misunderstandings.

-

Supply Chain Transparency: Buyers should seek suppliers that offer transparency in their supply chains, including information about sourcing materials and manufacturing practices.

By understanding the manufacturing processes and quality assurance measures involved in custom cushion production, B2B buyers can make informed purchasing decisions that align with their business needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cushion custom’

In the competitive landscape of custom cushions, international B2B buyers must navigate a variety of factors to ensure successful procurement. This checklist serves as a practical guide to streamline your sourcing process, providing actionable insights tailored to the specific needs of buyers from Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements for custom cushions. This includes dimensions, materials, styles, and any specific features such as waterproofing or fire resistance. Having a detailed specification helps suppliers understand your needs and ensures that you receive accurate quotes.

- Considerations:

- Material types (e.g., cotton, polyester, memory foam).

- Desired design elements (e.g., patterns, colors).

Step 2: Research and Shortlist Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in custom cushions. Utilize online directories, industry trade shows, and trade associations to compile a list of viable candidates. A well-researched shortlist can save time and lead to better supplier relationships.

- Actionable Tips:

- Look for suppliers with a strong online presence and positive reviews.

- Consider suppliers who exhibit at trade shows relevant to your industry.

Step 3: Evaluate Supplier Capabilities

Assess the capabilities of each supplier on your shortlist. Request detailed information about their production processes, technology, and capacity to meet your order volume. Understanding their operational strengths will help ensure they can deliver on your specifications.

- Key Factors:

- Production lead times and flexibility.

- Quality control measures in place.

Step 4: Request and Compare Quotes

Once you have shortlisted potential suppliers, request quotes based on your defined specifications. Comparing quotes not only helps in understanding the market price but also reveals the level of service and value each supplier offers.

- What to Compare:

- Pricing structures (including bulk discounts).

- Payment terms and delivery timelines.

Step 5: Verify Supplier Certifications and Compliance

Ensure that the suppliers you are considering adhere to relevant industry standards and certifications. This is particularly important if you are sourcing from regions with varying regulations. Compliance with safety and environmental standards protects your brand and ensures product quality.

- Check for:

- ISO certifications relevant to manufacturing.

- Compliance with local and international trade regulations.

Step 6: Request Samples for Quality Assessment

Before finalizing your order, request samples of the custom cushions to evaluate quality. This step is critical in assessing the craftsmanship, materials, and overall product suitability for your needs.

- What to Look For:

- Durability and comfort of materials.

- Adherence to your specified designs and dimensions.

Step 7: Establish Clear Communication Channels

Effective communication is essential for a successful sourcing experience. Set up clear channels for ongoing dialogue with your chosen supplier to address any issues promptly and ensure alignment throughout the production process.

- Consider:

- Regular check-ins via email or video calls.

- Utilizing project management tools for transparency.

By following this step-by-step sourcing checklist, B2B buyers can effectively navigate the complexities of procuring custom cushions, ultimately leading to successful partnerships and high-quality products tailored to their needs.

Comprehensive Cost and Pricing Analysis for cushion custom Sourcing

What Are the Key Cost Components in Cushion Custom Sourcing?

When analyzing the cost structure for cushion custom sourcing, several components play a crucial role in determining the final price. These include:

-

Materials: The choice of fabric, filling, and other materials significantly influences costs. High-quality, durable materials often come at a premium, but they can enhance product longevity and customer satisfaction.

-

Labor: Labor costs vary by region and can be influenced by local wage standards and skill levels. For instance, sourcing from countries with lower labor costs might reduce overall expenses but could compromise quality if not managed properly.

-

Manufacturing Overhead: This includes expenses related to utilities, rent, and indirect labor associated with production. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Custom designs often require specialized tooling, which can add to initial costs. However, investing in the right tools can lead to better efficiency and quality in the long run.

-

Quality Control (QC): Implementing stringent QC measures is vital for maintaining product standards. While this may increase costs, it is essential for ensuring that the final product meets buyer specifications.

-

Logistics: Transportation and shipping costs can fluctuate based on distance, mode of transport, and current fuel prices. Understanding these logistics is crucial for accurate cost forecasting.

-

Margin: Suppliers typically add a margin to cover their risks and profits. This can vary widely based on the supplier’s positioning in the market.

How Do Pricing Influencers Affect Cushion Custom Costs?

Several factors can influence pricing in the cushion custom market:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs. Suppliers may offer discounts for bulk purchases, making it advantageous for buyers to assess their needs accurately.

-

Specifications/Customization: The more specific and intricate the customizations, the higher the costs. Buyers should clearly outline their requirements to avoid unexpected price hikes.

-

Materials: The choice of high-end versus standard materials can significantly impact pricing. Buyers should evaluate the balance between cost and quality to meet their target market’s expectations.

-

Quality Certifications: Products that meet certain quality standards or certifications may incur higher production costs, but they can also command higher prices in the market.

-

Supplier Factors: The supplier’s reputation, experience, and location can influence pricing. Established suppliers may charge a premium for their reliability and quality assurance.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for international transactions. They determine who is responsible for shipping costs, insurance, and risk, affecting the overall pricing structure.

What Buyer Tips Can Enhance Cost-Efficiency in Cushion Custom Sourcing?

International B2B buyers can adopt several strategies to enhance cost-efficiency:

-

Negotiate Effectively: Always engage in negotiations with suppliers. Understanding market rates and being prepared to discuss terms can lead to more favorable pricing.

-

Consider Total Cost of Ownership (TCO): Rather than focusing solely on the purchase price, consider the TCO, which includes logistics, maintenance, and potential warranty costs. This holistic view can help in making more informed purchasing decisions.

-

Explore Multiple Suppliers: Obtaining quotes from various suppliers can provide a clearer picture of the market and help identify the best value options.

-

Be Aware of Pricing Nuances: Different regions have different pricing structures. For example, buyers from Africa and South America may encounter different import duties and taxes compared to European buyers. Understanding these nuances can help in budgeting more accurately.

-

Build Long-Term Relationships: Developing strong relationships with suppliers can lead to better pricing, priority service, and more favorable terms over time.

Conclusion

Understanding the comprehensive cost and pricing analysis for cushion custom sourcing is essential for international B2B buyers. By focusing on the key cost components, recognizing pricing influencers, and adopting strategic buyer tips, companies can make informed decisions that enhance both cost-efficiency and product quality. Always remember that indicative prices may vary based on market conditions, and staying informed will provide a competitive advantage.

Alternatives Analysis: Comparing cushion custom With Other Solutions

When evaluating the best solution for cushioning needs in various industries, B2B buyers must consider not only ‘cushion custom’ products but also alternative methods that could fulfill similar requirements. Each option presents unique benefits and challenges, making it essential to analyze them side by side. This analysis will help international buyers from regions like Africa, South America, the Middle East, and Europe make informed decisions tailored to their specific operational needs.

Comparison Table: Cushion Custom vs. Alternatives

| Comparison Aspect | Cushion Custom | Foam Padding | Inflatable Cushions |

|---|---|---|---|

| Performance | High durability, tailored fit | Moderate cushioning, less durable | Adjustable firmness, portable |

| Cost | Higher initial investment | Low to moderate cost | Moderate cost, variable |

| Ease of Implementation | Requires design input, longer lead time | Easy to source and install | Requires air pumps, setup time |

| Maintenance | Low maintenance, durable materials | Moderate, can degrade over time | Requires regular checks for leaks |

| Best Use Case | Custom applications, high-impact areas | General cushioning needs | Temporary or mobile solutions |

What Are the Pros and Cons of Foam Padding as an Alternative?

Foam padding is a widely used alternative due to its affordability and ease of availability. It provides moderate cushioning for various applications, making it suitable for general use in packaging or furniture. However, while foam is easy to source and install, it may not offer the same level of durability or customization as cushion custom products. Over time, foam can degrade, leading to reduced performance and necessitating more frequent replacements. Buyers seeking a cost-effective yet functional solution might consider foam padding, especially for less critical applications.

How Do Inflatable Cushions Compare in Terms of Versatility?

Inflatable cushions offer a unique advantage with their adjustable firmness, making them highly versatile for different uses. They are portable and can be quickly deployed in various settings, making them ideal for temporary cushioning needs. However, the requirement for air pumps and the potential for leaks can complicate their implementation and maintenance. While they are moderately priced, buyers must weigh the convenience of portability against the need for regular upkeep and the risk of punctures. Inflatable cushions are best suited for scenarios where mobility and temporary use are paramount, such as in event setups or emergency applications.

Conclusion: How to Choose the Right Cushioning Solution for Your Business

Selecting the appropriate cushioning solution involves assessing your specific operational requirements, budget constraints, and desired performance outcomes. For B2B buyers, understanding the nuances between cushion custom products and alternatives like foam padding and inflatable cushions is crucial. Custom cushions provide tailored solutions for high-impact applications, while foam is a practical choice for general use. Inflatable options cater to those needing portability and flexibility. By evaluating these factors, buyers can make informed decisions that align with their business goals and operational needs, ensuring optimal protection and efficiency in their processes.

Essential Technical Properties and Trade Terminology for cushion custom

What Are the Essential Technical Properties of Custom Cushions?

Understanding the technical properties of custom cushions is vital for international B2B buyers to ensure product quality and performance. Here are some critical specifications to consider:

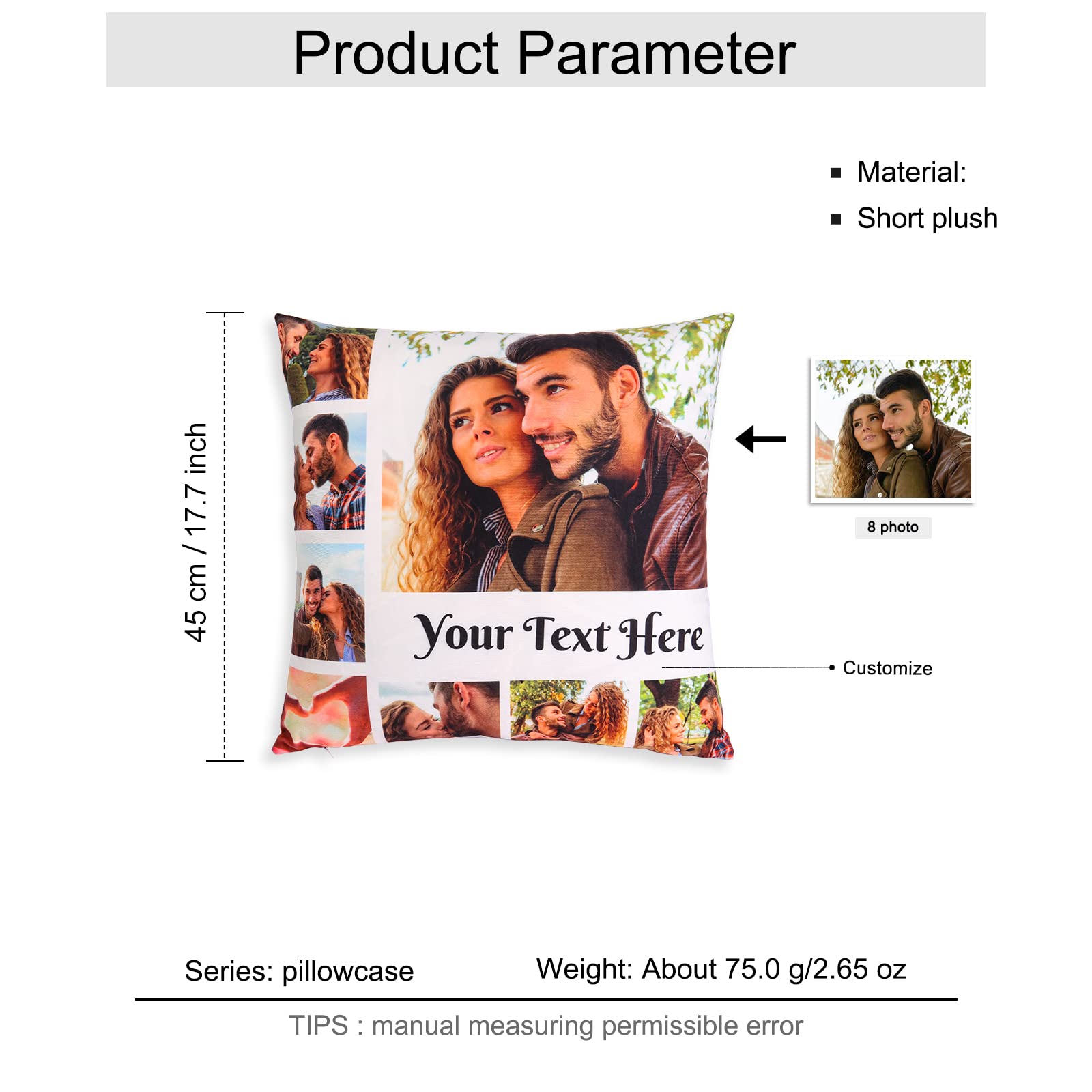

A stock image related to cushion custom.

1. Material Grade: What Should You Look for in Cushion Materials?

The material grade directly affects the durability, comfort, and performance of cushions. Common materials include high-density foam, memory foam, polyester, and natural fibers. Each grade has unique characteristics; for instance, high-density foam offers better resilience and longevity, making it ideal for commercial applications. Buyers should assess the material grade based on their specific needs, such as climate conditions or intended use, to ensure optimal performance.

2. Density: How Does Density Impact Cushion Comfort?

Density refers to the weight of the foam per cubic foot and is a crucial factor in determining comfort and support. Higher density foams typically provide more support and are more durable, while lower density options may be softer but less long-lasting. For B2B buyers, understanding the density can help in selecting cushions that meet the comfort and durability needs of their target market.

3. Tolerance: Why Is Tolerance Important in Manufacturing?

Tolerance indicates the allowable deviation from a specified measurement in the manufacturing process. For custom cushions, maintaining tight tolerances ensures that products fit precisely into their intended spaces, whether for furniture or automotive applications. Buyers should prioritize suppliers who can consistently meet tolerance specifications to avoid costly reworks and ensure customer satisfaction.

4. Fire Retardancy: What Safety Standards Should You Consider?

Fire retardancy is a critical property, especially in regions with strict safety regulations. Cushions that meet fire safety standards reduce the risk of fire hazards in residential or commercial settings. Buyers should inquire about certifications such as CAL 117 or BS 5852 to ensure compliance with local regulations and enhance product safety.

5. Water Resistance: How Does Water Resistance Affect Cushion Lifespan?

Water resistance is an essential property for cushions used in outdoor or high-humidity environments. Fabrics treated for water resistance help prevent mold and mildew growth, extending the lifespan of the cushions. B2B buyers should assess the level of water resistance required based on their intended use, particularly in regions prone to wet conditions.

What Are Common Trade Terms in the Custom Cushion Industry?

Familiarity with trade terminology can streamline negotiations and foster better supplier relationships. Here are some essential terms:

1. OEM (Original Equipment Manufacturer): What Does OEM Mean for Custom Cushions?

OEM refers to companies that manufacture products that are sold under another company’s brand. In the custom cushion industry, OEM partnerships can allow buyers to leverage existing manufacturing capabilities while focusing on branding and marketing. Understanding OEM relationships can help buyers identify reliable suppliers who can meet specific design requirements.

2. MOQ (Minimum Order Quantity): Why Is MOQ Important for Your Procurement Strategy?

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it can impact inventory management and cost efficiency. Knowing the MOQ helps buyers plan their orders effectively, ensuring they meet their demand without over-committing financially.

3. RFQ (Request for Quotation): How to Use RFQ for Better Pricing?

An RFQ is a formal request to suppliers for pricing on specific products. For custom cushions, issuing an RFQ allows buyers to compare prices, materials, and lead times from multiple suppliers. This process is essential for negotiating better deals and ensuring competitive pricing in the market.

4. Incoterms: What Are Incoterms and How Do They Affect International Shipping?

Incoterms, or International Commercial Terms, define the responsibilities of buyers and sellers in international trade. These terms specify who is responsible for shipping, insurance, and tariffs, which can significantly affect overall costs. Understanding Incoterms helps buyers avoid unexpected expenses and ensures clarity in shipping agreements.

By grasping these essential technical properties and trade terms, international B2B buyers can make informed decisions, ensuring that their custom cushion products meet market demands while optimizing procurement processes.

Navigating Market Dynamics and Sourcing Trends in the cushion custom Sector

What Are the Key Market Dynamics and Trends in the Cushion Custom Sector?

A stock image related to cushion custom.

The cushion custom sector is experiencing significant evolution driven by several global trends. One of the primary drivers is the growing demand for personalized products in the interior design and furniture markets. B2B buyers from regions like Africa, South America, the Middle East, and Europe are increasingly seeking custom solutions that cater to unique market needs and consumer preferences. This trend is further fueled by advancements in technology, such as 3D printing and AI-driven design software, which allow manufacturers to produce custom cushions with greater efficiency and lower costs.

Emerging sourcing trends reflect a shift towards online platforms and marketplaces that facilitate direct connections between buyers and manufacturers. These platforms are crucial for international buyers looking to source cushions tailored to local tastes and requirements. Additionally, the rise of omnichannel retailing is influencing how B2B buyers interact with suppliers, driving the need for seamless integration of online and offline purchasing experiences.

Market dynamics also reveal a competitive landscape, with a growing number of suppliers expanding their offerings. Buyers should be aware of regional variations in material availability and pricing, particularly in emerging markets where local sourcing can lead to cost advantages. Understanding these dynamics enables buyers to navigate the complexities of the cushion custom sector effectively.

How Important Is Sustainability and Ethical Sourcing in the Cushion Custom Sector?

Sustainability is becoming increasingly vital in the cushion custom sector, as consumers and businesses alike prioritize environmental responsibility. The cushion manufacturing process can have significant environmental impacts, including waste generation and resource depletion. As a result, B2B buyers are encouraged to consider suppliers who demonstrate a commitment to sustainable practices, such as using eco-friendly materials and reducing carbon footprints.

Ethical sourcing is equally important, particularly in regions like Africa and South America, where supply chains can be complex. Buyers should seek suppliers that uphold fair labor practices and provide transparency in their sourcing processes. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® can guide buyers in identifying materials that are both sustainable and ethically produced.

Incorporating sustainability and ethical sourcing into procurement strategies not only enhances brand reputation but also meets the growing consumer demand for responsible products. By prioritizing these factors, international B2B buyers can build stronger partnerships with suppliers and contribute to a more sustainable cushion custom market.

What Is the Historical Context of the Cushion Custom Sector?

The cushion custom sector has its roots in traditional upholstery practices, evolving significantly over the decades. Initially, cushions were predominantly mass-produced with limited customization options, primarily serving the needs of large-scale retailers. However, as consumer preferences shifted towards personalization in the late 20th century, manufacturers began exploring custom solutions to meet these demands.

The turn of the 21st century saw a technological revolution, with the introduction of CAD software and advanced textile technologies. These innovations allowed for greater design flexibility and efficiency in production, paving the way for the contemporary cushion custom market. Today, international B2B buyers benefit from a rich history of craftsmanship combined with modern technology, enabling them to source unique and tailored cushion solutions that resonate with their target markets.

In summary, understanding the market dynamics, embracing sustainability, and recognizing the historical context are essential for international B2B buyers looking to thrive in the cushion custom sector. By leveraging these insights, buyers can make informed sourcing decisions that align with their business objectives and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of cushion custom

-

How do I choose the right supplier for custom cushions?

Choosing the right supplier requires thorough research and evaluation. Start by checking their industry experience and customer reviews. Look for suppliers who specialize in custom cushions and have a proven track record in your target market (e.g., Africa, South America). Request samples to assess the quality of materials and craftsmanship. Additionally, verify their production capacity to meet your order requirements and their compliance with international quality standards. Engaging in direct communication can also help gauge their responsiveness and willingness to accommodate your specific needs. -

What are the key factors to consider when customizing cushions?

When customizing cushions, consider fabric type, filling material, size, shape, and design elements such as colors and patterns. Assess the intended use—whether for outdoor furniture or indoor décor—as this will influence material selection. Additionally, think about ergonomics and comfort, particularly if the cushions will be used for prolonged seating. Collaborating with designers or using 3D rendering can help visualize the final product. Finally, ensure that your customizations align with your target market’s preferences and trends to enhance appeal. -

What is the typical minimum order quantity (MOQ) for custom cushions?

The MOQ for custom cushions can vary significantly among suppliers, typically ranging from 50 to 500 units. Factors influencing MOQ include the complexity of the design, the materials used, and the supplier’s production capabilities. Smaller businesses might find suppliers with lower MOQs, but this may come at a higher per-unit cost. It’s advisable to negotiate with suppliers, especially if you plan for larger future orders. Understanding the supplier’s pricing structure will help you budget effectively. -

What payment terms should I expect when sourcing custom cushions?

Payment terms can differ widely between suppliers and regions. Common practices include a deposit (usually 30-50%) before production, with the balance due upon completion or before shipment. Some suppliers may offer more flexible terms based on your relationship or order size. Ensure to clarify all payment methods accepted, such as bank transfers or letters of credit, particularly for international transactions. Familiarizing yourself with the supplier’s policies can help mitigate financial risks. -

How can I ensure quality assurance for my custom cushions?

Quality assurance begins with selecting a reputable supplier who adheres to international quality standards. Request certifications and references from previous clients. Implementing a rigorous inspection process during production can help catch defects early. Consider hiring a third-party quality control inspector if ordering large quantities. Additionally, establishing clear specifications and guidelines for your cushions upfront can minimize misunderstandings and ensure that the final product meets your expectations. -

What logistics considerations should I keep in mind when importing custom cushions?

Logistics for importing custom cushions involve several key considerations: shipping costs, customs duties, and lead times. Work closely with your supplier to understand their shipping options and timelines. Choose a reliable freight forwarder experienced in handling textile imports. Be aware of customs regulations in your country, especially regarding tariffs and import restrictions. Planning for potential delays in customs clearance is essential, so factor in extra time to avoid disruptions to your supply chain. -

How do I handle potential disputes with suppliers of custom cushions?

To minimize disputes, establish clear contracts that outline terms, specifications, payment schedules, and delivery timelines. Open communication is crucial; maintain regular contact with your supplier throughout the production process. If a dispute arises, address it promptly and professionally. Use negotiation to find a mutually acceptable solution, and document all correspondence. If necessary, consider mediation or arbitration as a means of resolving conflicts without resorting to legal action, which can be costly and time-consuming. -

What are the environmental considerations when sourcing custom cushions?

Sustainability is becoming increasingly important in the cushion industry. When sourcing custom cushions, inquire about the materials used—opt for eco-friendly fabrics and fillings, such as organic cotton or recycled materials. Assess the supplier’s manufacturing processes for environmental impact, such as waste management and energy use. Certifications like GOTS (Global Organic Textile Standard) can indicate a commitment to sustainable practices. By prioritizing sustainability, you can enhance your brand’s reputation and appeal to environmentally conscious consumers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cushion custom

As international B2B buyers navigate the landscape of custom cushions, strategic sourcing emerges as a pivotal factor for success. By focusing on quality, sustainability, and supplier reliability, businesses can not only enhance their product offerings but also build lasting relationships with manufacturers. Understanding local market dynamics, particularly in regions like Africa, South America, the Middle East, and Europe, is essential for making informed purchasing decisions.

How can businesses leverage strategic sourcing for competitive advantage? By prioritizing suppliers who demonstrate innovation and adaptability, companies can access cutting-edge designs and materials that meet evolving consumer preferences. Engaging with diverse markets allows for a broader selection of products, which can lead to better pricing and improved supply chain resilience.

Looking forward, the demand for custom cushions is expected to grow, driven by trends in home decor and furniture design. International buyers are encouraged to actively seek partnerships that align with their strategic goals. Embrace the opportunity to collaborate with suppliers who share your vision for quality and sustainability. The future of custom cushions is promising—position your business to thrive in this dynamic market.