Unlock Quality: Your Guide to Custom Spring Supplier (2025)

Introduction: Navigating the Global Market for custom spring supplier

Navigating the complexities of sourcing a reliable custom spring supplier can be a daunting task for international B2B buyers, especially when considering the diverse needs of industries ranging from automotive to electronics. The challenge lies not only in finding a supplier who can meet specific technical requirements but also in ensuring quality, cost-effectiveness, and timely delivery. This comprehensive guide is designed to empower you with the insights needed to make informed purchasing decisions, focusing on the intricacies of sourcing custom springs.

Throughout this guide, we will delve into various types of custom springs, their applications across different sectors, and the critical factors to consider when vetting suppliers. Understanding the nuances of cost structures and lead times will also be explored, enabling buyers from Africa, South America, the Middle East, and Europe—such as South Africa and the UK—to navigate the global market effectively.

By providing actionable insights and a structured approach, this guide aims to streamline your sourcing process, minimize risks, and enhance your procurement strategy. Whether you are looking for compression springs, extension springs, or torsion springs, this resource will equip you with the knowledge to select the best supplier for your unique requirements.

Understanding custom spring supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Compression Springs | Designed to resist compressive forces; coiled tightly | Automotive, aerospace, and consumer products | Pros: High load capacity; versatile. Cons: Limited by coil diameter and length. |

| Extension Springs | Designed to resist stretching forces; elongated coils | Industrial machinery, fitness equipment | Pros: Ideal for applications requiring tension. Cons: Can be sensitive to overextension. |

| Torsion Springs | Designed to work by twisting; provides rotational force | Garage doors, automotive parts, and toys | Pros: Effective for rotational applications. Cons: Requires precise design to avoid failure. |

| Leaf Springs | Flat and curved design; distributes weight over a large area | Heavy-duty vehicles, trailers, and suspension systems | Pros: Great for load-bearing; robust. Cons: Heavier and bulkier than other types. |

| Custom Wire Forms | Made from wire, can be shaped into various forms | Electronics, medical devices, and custom applications | Pros: Highly customizable; suitable for unique applications. Cons: Production time can be longer. |

What Are the Characteristics and Suitability of Compression Springs?

Compression springs are typically coiled tightly and designed to resist compressive forces. They are commonly used in automotive and aerospace applications, as well as in consumer products like pens and mattresses. When considering a compression spring supplier, B2B buyers should focus on material quality and load capacity, as these factors directly affect performance and durability. Additionally, understanding the limitations regarding coil diameter and length is crucial for ensuring compatibility with specific applications.

How Do Extension Springs Function and Where Are They Used?

Extension springs are designed to absorb and store energy by resisting stretching forces. They are elongated coils that return to their original shape when the load is removed. These springs find applications in industrial machinery, fitness equipment, and various consumer products. Buyers should consider the spring’s load rating and the maximum extension to avoid failure. Since extension springs can be sensitive to overextension, selecting a reliable supplier that offers precise specifications is essential.

What Makes Torsion Springs Unique for B2B Applications?

Torsion springs operate by twisting, providing a rotational force that is ideal for applications like garage doors and automotive parts. Their unique design allows them to store energy when twisted, making them effective for applications requiring rotational movement. When purchasing torsion springs, B2B buyers should pay close attention to the required torque and the spring’s design specifications to ensure optimal performance. Precision in design is paramount, as torsion springs are prone to failure if not correctly engineered.

Why Are Leaf Springs Important in Heavy-Duty Applications?

Leaf springs are characterized by their flat and curved design, which allows them to distribute weight over a larger area. They are predominantly used in heavy-duty vehicles, trailers, and suspension systems. Buyers should consider the load-bearing capacity and the overall weight of the spring, as these factors impact vehicle performance. While leaf springs are robust and effective, they are also heavier and bulkier than other spring types, which can influence design choices.

What Are the Benefits of Custom Wire Forms for Unique Applications?

Custom wire forms are versatile components made from wire that can be shaped into various forms for specific applications. They are widely used in electronics, medical devices, and other custom applications. The primary advantage of custom wire forms is their high degree of customization, allowing businesses to tailor solutions to meet unique needs. However, buyers should be aware that production time may be longer compared to standard springs, and careful consideration should be given to the wire material and design to ensure functionality.

Related Video: 9 kinds Power spring & Constant force spring Applications | Meta Spring Industry

Key Industrial Applications of custom spring supplier

| Industry/Sector | Specific Application of custom spring supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Suspension systems | Enhanced vehicle stability and comfort | Compliance with automotive standards, durability, and customization options. |

| Industrial Machinery | Press and die springs | Improved efficiency in manufacturing processes | Load capacity, fatigue resistance, and material specifications. |

| Electronics | Precision coil springs | Reliable performance in compact devices | Tolerance levels, size precision, and electrical properties. |

| Aerospace | Landing gear and control systems | Safety and reliability in critical applications | Certification standards, weight considerations, and performance testing. |

| Medical Devices | Surgical instruments and devices | Enhanced safety and precision in medical applications | Biocompatibility, regulatory compliance, and customization needs. |

How Are Custom Springs Used in the Automotive Sector?

In the automotive industry, custom springs play a crucial role in suspension systems, where they absorb shocks and ensure a smooth ride. By utilizing tailored springs, manufacturers can enhance vehicle stability and comfort, addressing common issues like excessive bouncing or swaying. For international buyers, particularly from regions such as Africa and South America, it’s vital to ensure that springs meet specific automotive standards and regulations, while also considering factors like durability and customization to fit various vehicle models.

What Are the Applications of Custom Springs in Industrial Machinery?

Custom springs are integral to industrial machinery, particularly in press and die applications where they facilitate the efficient operation of heavy equipment. By using specially designed springs, businesses can significantly improve their manufacturing processes, ensuring consistent pressure and reducing downtime. Buyers from the Middle East and Europe should prioritize sourcing springs that offer high load capacity and fatigue resistance, as these qualities directly affect the longevity and performance of machinery in demanding environments.

How Do Custom Springs Benefit the Electronics Industry?

In the electronics sector, precision coil springs are essential components in devices such as smartphones, laptops, and other compact gadgets. These springs ensure reliable performance by providing necessary tension and support in tight spaces. For B2B buyers, particularly in Europe, sourcing springs with exact tolerances and size precision is critical, as even minor deviations can lead to device malfunction. Additionally, understanding the electrical properties of the materials used is essential for ensuring compatibility with electronic components.

Why Are Custom Springs Important in Aerospace Applications?

In aerospace, custom springs are vital for landing gear and control systems, where they contribute to the overall safety and reliability of aircraft. These springs must withstand extreme conditions and stresses, making it essential for suppliers to provide products that meet rigorous certification standards. International buyers, particularly from regions like Africa and South America, should focus on sourcing springs that not only comply with safety regulations but also consider weight reduction and performance testing to enhance aircraft efficiency.

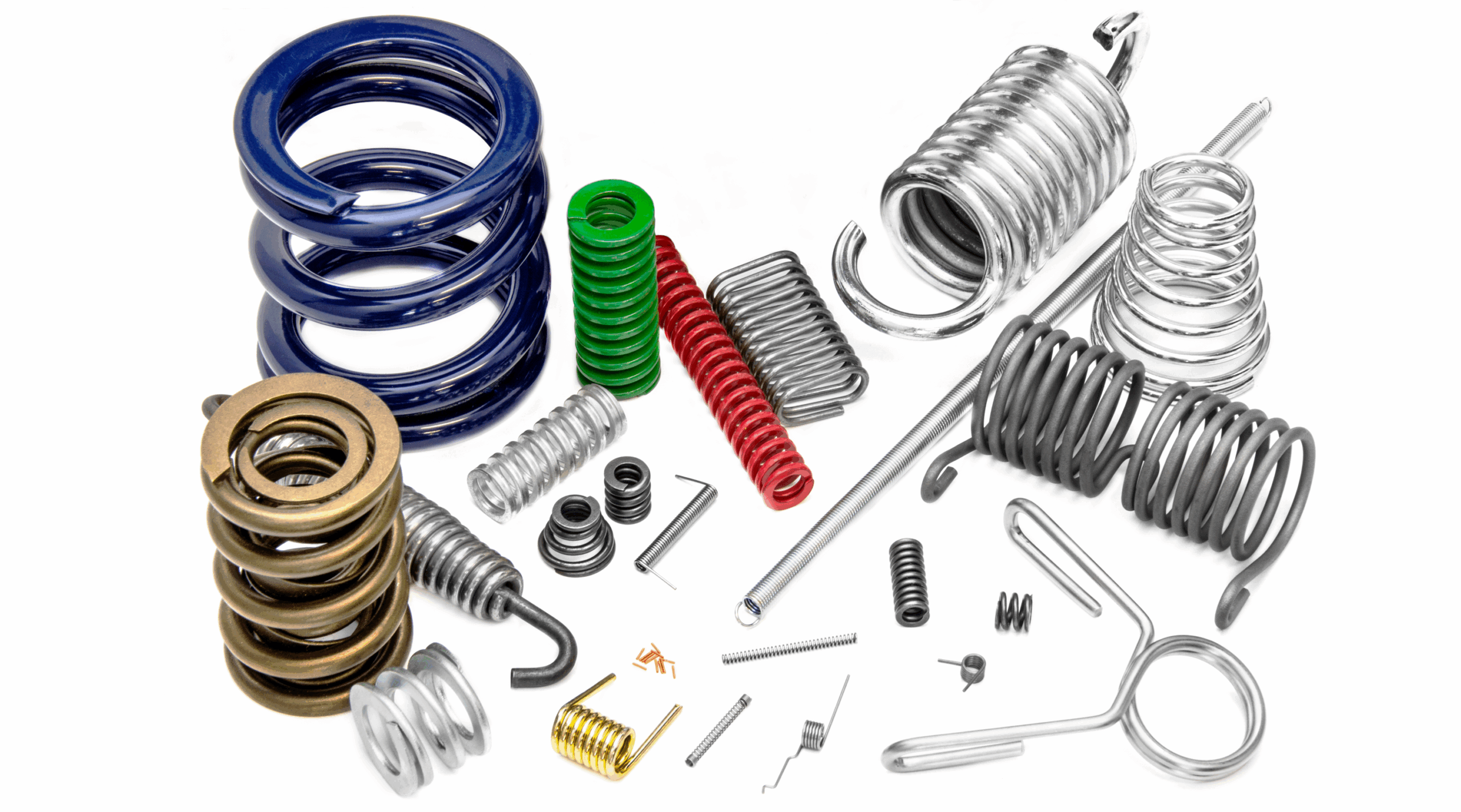

A stock image related to custom spring supplier.

How Are Custom Springs Utilized in Medical Devices?

Custom springs are increasingly found in medical devices, including surgical instruments and diagnostic equipment, where they enhance safety and precision. The biocompatibility of materials used in these springs is a critical consideration for manufacturers. Buyers from the Middle East and Europe must ensure that their suppliers comply with stringent regulatory standards, as well as provide options for customization to meet specific application requirements, ensuring that the springs contribute effectively to the overall functionality of medical devices.

3 Common User Pain Points for ‘custom spring supplier’ & Their Solutions

Scenario 1: Navigating Quality Assurance Challenges with Custom Springs

The Problem: B2B buyers often struggle with ensuring the quality and reliability of custom springs from suppliers. In industries such as automotive or aerospace, even minor defects can lead to significant safety hazards and costly recalls. Buyers may receive springs that do not meet specified tolerances or material standards, creating a ripple effect that impacts production schedules and operational efficiency. This situation is especially concerning for buyers in regions with less stringent quality controls, as the risk of subpar materials increases.

The Solution: To address quality assurance challenges, buyers should implement a robust supplier evaluation process before finalizing any contracts. This includes requesting detailed documentation of quality control procedures, certifications (such as ISO 9001), and test reports for materials used. Additionally, establishing clear communication channels with suppliers can facilitate immediate feedback on any quality concerns. It’s also advisable to incorporate a trial order phase where small batches are tested for performance and reliability before committing to larger production runs. Engaging third-party inspection services can further enhance quality assurance and ensure compliance with industry standards.

Scenario 2: Overcoming Lead Time Delays in Custom Spring Orders

The Problem: International B2B buyers frequently encounter lead time issues when sourcing custom springs. Delays can arise from various factors, including inadequate supplier capacity, logistical challenges, or unexpected demand fluctuations. These delays can disrupt production timelines, leading to missed deadlines and dissatisfied customers, particularly in fast-paced markets across Africa and South America.

The Solution: To mitigate lead time delays, buyers should prioritize suppliers who demonstrate a consistent ability to meet delivery schedules. This can be achieved by assessing supplier capacity and production capabilities during the sourcing process. Establishing a partnership with suppliers that utilize advanced manufacturing technologies, such as automation or just-in-time inventory systems, can lead to more reliable delivery timelines. Additionally, incorporating buffer stock strategies can help manage unexpected demand surges or delays. Buyers should also maintain an open dialogue with suppliers, regularly discussing production schedules and potential bottlenecks to enable proactive adjustments.

Scenario 3: Addressing Communication Barriers with Custom Spring Suppliers

The Problem: Communication barriers can pose significant challenges for B2B buyers dealing with custom spring suppliers, especially when sourcing from different countries. Misunderstandings regarding specifications, timelines, or payment terms can lead to costly mistakes and operational inefficiencies. This issue is exacerbated in regions where language differences or cultural nuances may hinder effective communication.

The Solution: To overcome communication barriers, buyers should invest in establishing clear, detailed specifications for their custom spring requirements. Utilizing visual aids, such as diagrams and prototypes, can help bridge gaps in understanding. Additionally, employing a dedicated project manager or liaison who is fluent in both languages can facilitate smoother interactions. Buyers may also consider leveraging technology solutions, such as collaborative project management tools, to maintain transparency and track progress in real-time. Regular check-ins and updates can further enhance communication, ensuring that all parties are aligned throughout the production process.

Strategic Material Selection Guide for custom spring supplier

When selecting materials for custom springs, international B2B buyers must consider a variety of factors that influence performance, durability, and cost-effectiveness. Here, we will analyze four common materials used in spring manufacturing: stainless steel, carbon steel, music wire, and titanium. Each material has unique properties, advantages, and limitations that can significantly impact the end product’s suitability for specific applications.

What Are the Key Properties of Stainless Steel for Custom Springs?

Stainless steel is renowned for its excellent corrosion resistance and high strength, making it suitable for applications in harsh environments. It typically has a temperature rating up to 800°F (427°C) and can withstand moderate pressure. The most common grades used in spring manufacturing include 302, 304, and 316, each offering varying degrees of corrosion resistance.

Pros and Cons of Stainless Steel:

– Pros: High durability, excellent corrosion resistance, and aesthetic appeal.

– Cons: Higher cost compared to carbon steel, and it can be more challenging to manufacture due to its toughness.

Impact on Application:

Stainless steel springs are ideal for applications exposed to moisture, chemicals, or saline environments, such as marine or medical devices.

Considerations for International Buyers:

Buyers in regions like Europe and South America should ensure compliance with standards such as ASTM A313 or DIN 17224. The preference for stainless steel is growing due to its longevity and reliability.

How Does Carbon Steel Compare for Custom Spring Applications?

Carbon steel is a common choice for custom springs, particularly in applications where strength is paramount. It typically offers a temperature rating of around 400°F (204°C) and is known for its high tensile strength and fatigue resistance.

Pros and Cons of Carbon Steel:

– Pros: Cost-effective, easy to manufacture, and provides excellent mechanical properties.

– Cons: Prone to rust and corrosion if not properly treated, and has lower temperature resistance compared to stainless steel.

Impact on Application:

Carbon steel springs are best suited for indoor applications or environments where exposure to moisture is minimal.

Considerations for International Buyers:

Buyers should look for compliance with standards like ASTM A228 or JIS G3502, especially in Africa and the Middle East, where environmental conditions may vary.

What Are the Advantages of Music Wire in Spring Manufacturing?

Music wire, a type of high-carbon steel, is specifically designed for spring applications. It offers exceptional tensile strength and a high fatigue limit, making it suitable for dynamic applications. Music wire typically has a temperature rating similar to carbon steel but can perform better under cyclic loads.

Pros and Cons of Music Wire:

– Pros: High strength-to-weight ratio, excellent fatigue resistance, and relatively low cost.

– Cons: Limited corrosion resistance unless coated, and it can be brittle if not properly processed.

Impact on Application:

Music wire springs are commonly used in automotive, aerospace, and industrial machinery applications where high performance is critical.

Considerations for International Buyers:

International buyers should verify compliance with ASTM A228 and ensure that suppliers can provide proper certifications, particularly in Europe where quality standards are stringent.

Why Choose Titanium for Custom Springs?

A stock image related to custom spring supplier.

Titanium springs are increasingly popular due to their high strength-to-weight ratio and excellent corrosion resistance. They can withstand temperatures up to 1,200°F (649°C) and are ideal for applications requiring lightweight materials.

Pros and Cons of Titanium:

– Pros: Exceptional strength, lightweight, and excellent corrosion resistance.

– Cons: High cost and complexity in manufacturing, which can lead to longer lead times.

Impact on Application:

Titanium springs are particularly useful in aerospace, medical, and high-performance automotive applications where weight savings are crucial.

Considerations for International Buyers:

Buyers should ensure compliance with standards such as ASTM B348 and be aware of the higher costs associated with titanium, especially in markets like Africa and South America where budgets may be tighter.

Summary Table of Material Selection for Custom Springs

| Material | Typical Use Case for custom spring supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Marine, medical devices | Excellent corrosion resistance | Higher cost | High |

| Carbon Steel | Indoor machinery, automotive | Cost-effective | Prone to rust | Low |

| Music Wire | Automotive, aerospace | High tensile strength | Limited corrosion resistance | Med |

| Titanium | Aerospace, high-performance automotive | Lightweight and strong | High cost and manufacturing complexity | High |

This strategic material selection guide provides international B2B buyers with critical insights into the properties, advantages, and limitations of various materials used in custom spring manufacturing. By considering these factors, buyers can make informed decisions that align with their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for custom spring supplier

What Are the Key Manufacturing Processes for Custom Springs?

The manufacturing of custom springs involves several critical stages that ensure the final product meets specific application requirements. Understanding these processes is vital for B2B buyers to make informed decisions when selecting a supplier.

How Is Material Prepared for Custom Spring Manufacturing?

The first stage in the manufacturing process is material preparation, which significantly influences the performance and durability of the springs. Common materials used include stainless steel, carbon steel, and alloys, each selected based on the spring’s intended application and environmental conditions.

- Material Selection: Suppliers should provide detailed specifications on the materials used, including tensile strength, corrosion resistance, and fatigue limits.

- Material Inspection: Before processing, raw materials undergo inspections to verify compliance with industry standards. These inspections may include chemical composition analysis and mechanical testing.

What Forming Techniques Are Commonly Used in Spring Manufacturing?

After material preparation, the next step involves forming the spring into its desired shape. This is where several techniques come into play:

- Coiling: This process involves winding a wire around a mandrel to create the spring shape. Coiling can be done cold or hot, depending on the material and spring design.

- Stamping: For certain types of springs, such as flat springs, stamping is employed. This technique uses dies to cut and shape the spring from flat stock material.

- Machining: In some cases, machining is used to achieve precise dimensions and tolerances, particularly for complex spring designs.

Each of these techniques contributes to the overall quality and performance of the final product, and suppliers should be able to demonstrate their capabilities and technologies used.

How Does Assembly and Finishing Affect Custom Springs?

Once the springs are formed, they may require additional assembly and finishing processes, which enhance their performance and longevity.

- Assembly: For springs that are part of larger systems, assembly may involve integrating them with other components. Suppliers should provide clear processes and capabilities for assembly.

- Finishing: This includes processes like heat treatment, surface coating, and polishing. Heat treatment can improve strength and flexibility, while coatings can enhance corrosion resistance. B2B buyers should inquire about the finishing processes used and their impact on the spring’s performance.

What Quality Assurance Standards Should B2B Buyers Expect?

Quality assurance (QA) is crucial in the custom spring manufacturing process. B2B buyers should be familiar with relevant international standards and industry-specific certifications that suppliers adhere to.

Which International Standards Are Relevant for Custom Spring Suppliers?

- ISO 9001: This is a widely recognized quality management standard that ensures suppliers have established processes for quality control and continuous improvement. Suppliers should provide documentation of their ISO 9001 certification.

- CE Marking: For springs used in European markets, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Certification: For springs used in oil and gas applications, API certifications ensure compliance with industry standards for safety and performance.

What Are the Key Quality Control Checkpoints in Spring Manufacturing?

Quality control (QC) is integrated throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials before they enter the production process. Buyers should ensure that suppliers have robust IQC procedures in place.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor production processes and identify any deviations from specifications.

- Final Quality Control (FQC): Before shipment, finished springs undergo rigorous testing to ensure they meet all specified requirements.

What Testing Methods Are Commonly Used for Custom Springs?

Various testing methods ensure that the springs meet performance and durability standards:

- Tensile Testing: This method evaluates the spring’s ability to withstand tension, providing insights into material strength and elasticity.

- Fatigue Testing: Used to determine the spring’s performance under repetitive stress, this test is crucial for applications involving dynamic loads.

- Dimensional Inspection: This ensures that the springs meet specified dimensions and tolerances, which is vital for proper fit and function in their intended applications.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers can take several steps to verify the quality control processes of potential suppliers:

- Supplier Audits: Conducting on-site audits can provide firsthand insights into a supplier’s manufacturing processes and quality control measures.

- Reviewing Quality Reports: Requesting access to quality control reports and certificates can help assess a supplier’s adherence to quality standards.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s manufacturing and QC processes.

What Are the Specific QC and Certification Nuances for International Buyers?

International B2B buyers, especially those from Africa, South America, the Middle East, and Europe, should be aware of certain nuances:

- Regulatory Compliance: Different regions may have specific regulations affecting material choices and manufacturing processes. Understanding these regulations is crucial for compliance.

- Cultural Considerations: Differences in business practices and communication styles can affect supplier relationships. Building strong partnerships based on trust and transparency is essential.

- Logistics and Shipping: The global supply chain can introduce complexities in lead times and shipping costs. Buyers should clarify these aspects upfront to avoid surprises.

By familiarizing themselves with these manufacturing processes and quality assurance measures, B2B buyers can make more informed decisions when selecting custom spring suppliers, ensuring that their needs are met with high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom spring supplier’

This guide serves as a practical sourcing checklist for international B2B buyers looking to procure custom springs. Sourcing custom springs requires careful consideration of technical specifications, supplier capabilities, and compliance with international standards. By following this step-by-step checklist, buyers can streamline their procurement process and ensure they select a reliable supplier that meets their needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to clearly define your technical requirements. This includes the type of spring (compression, extension, torsion), material specifications (steel, stainless steel, etc.), dimensions, load capacity, and any specific treatments or coatings required.

- Why It Matters: Having precise specifications helps avoid misunderstandings and ensures that the supplier can deliver exactly what you need.

- What to Look For: Be prepared to provide detailed drawings or CAD files, if necessary, to communicate your needs effectively.

Step 2: Research Potential Suppliers

Conduct thorough research to compile a list of potential custom spring suppliers. Utilize online directories, trade associations, and industry-specific forums to identify reputable companies.

- Why It Matters: A well-researched list increases the likelihood of finding a supplier that aligns with your technical and logistical requirements.

- What to Look For: Focus on suppliers that have experience in your industry and check their customer reviews and testimonials.

Step 3: Evaluate Supplier Capabilities

Assess the capabilities of your shortlisted suppliers. This includes their manufacturing processes, technology, and quality control measures.

- Why It Matters: Understanding a supplier’s capabilities ensures they can meet your specifications and delivery timelines.

- What to Look For: Request information about their production capacity, lead times, and any certifications (e.g., ISO 9001) that demonstrate their commitment to quality.

Step 4: Request Samples and Prototypes

Before making a bulk order, request samples or prototypes of the custom springs. This allows you to evaluate the quality and performance of the products firsthand.

- Why It Matters: Testing samples helps identify any potential issues before committing to a larger order.

- What to Look For: Pay attention to the material quality, finish, and adherence to your specified dimensions and load capacities.

Step 5: Verify Supplier Certifications

Ensure that your chosen suppliers have the necessary certifications and compliance with international standards. This may include ISO certifications, industry-specific compliance, and environmental standards.

- Why It Matters: Certifications provide assurance that the supplier adheres to quality and safety standards, reducing the risk of defects and non-compliance.

- What to Look For: Request copies of certifications and verify their validity with the issuing organizations.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, negotiate the terms of the contract, including pricing, payment terms, delivery schedules, and warranty policies.

- Why It Matters: Clear and mutually agreed-upon terms help prevent disputes and ensure a smooth transaction.

- What to Look For: Be specific about penalty clauses for delays and quality issues to protect your interests.

Step 7: Establish a Communication Plan

Finally, establish a communication plan with your supplier to ensure ongoing collaboration throughout the procurement process.

- Why It Matters: Effective communication helps address issues promptly and fosters a strong working relationship.

- What to Look For: Set up regular check-ins and clarify points of contact for both technical and logistical matters.

By following this checklist, B2B buyers can navigate the complex process of sourcing custom springs more efficiently, ultimately leading to successful procurement and long-term partnerships with suppliers.

Comprehensive Cost and Pricing Analysis for custom spring supplier Sourcing

What are the Key Cost Components in Custom Spring Supplier Sourcing?

When sourcing custom springs, understanding the comprehensive cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials for springs include stainless steel, carbon steel, and specialty alloys. Prices can vary based on market conditions and material grade.

-

Labor: Labor costs encompass the wages paid to skilled workers involved in the production process. This can vary widely depending on the geographical location of the supplier, with regions like Europe often commanding higher labor rates compared to Africa or South America.

-

Manufacturing Overhead: This includes indirect costs related to production, such as utilities, facility maintenance, and equipment depreciation. Buyers should inquire about how these costs are calculated and whether they are included in the quoted price.

-

Tooling: Custom springs often require specialized tooling. The initial investment in tooling can be significant, especially for complex designs. It’s essential to consider whether these costs are amortized over a production run or charged upfront.

-

Quality Control (QC): Ensuring that springs meet specific standards can incur additional costs. QC processes may involve testing, certification, and compliance with industry standards, which can be especially relevant for buyers in regulated markets.

-

Logistics: Shipping costs can vary based on the supplier’s location and the chosen shipping method. Buyers should consider the Incoterms that define the responsibilities of buyers and sellers regarding shipping and logistics costs.

-

Margin: Suppliers typically add a profit margin to their costs. Understanding the standard margins within the industry can help buyers gauge whether a quote is competitive.

How Do Price Influencers Affect Custom Spring Sourcing?

Several factors influence the pricing of custom springs, making it essential for buyers to understand these nuances:

-

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly affect pricing. Higher volumes often lead to lower per-unit costs, so buyers should assess their demand and negotiate accordingly.

-

Specifications and Customization: Customized springs with specific dimensions or properties can lead to increased costs. Buyers should clearly define their specifications to avoid unexpected charges.

-

Materials and Quality Certifications: The choice of material and the need for quality certifications (like ISO or ASTM standards) can elevate costs. Suppliers may charge more for high-grade materials or certifications that ensure compliance with safety standards.

-

Supplier Factors: The supplier’s reputation, experience, and manufacturing capabilities can influence pricing. Established suppliers may charge more due to their reliability and quality assurance practices.

-

Incoterms: Understanding Incoterms is vital for international transactions. They dictate who is responsible for shipping costs and risks, which can affect the total cost of ownership.

What Buyer Tips Can Enhance Cost-Efficiency in Custom Spring Sourcing?

International B2B buyers can adopt several strategies to optimize their sourcing process:

-

Negotiate Effectively: Leverage your purchasing volume to negotiate better pricing and terms. Building a long-term relationship with suppliers can also yield better deals.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Evaluate the total cost over the product’s lifecycle, including maintenance, replacement, and shipping costs.

-

Evaluate Pricing Nuances for International Sourcing: Be aware of currency fluctuations, trade tariffs, and local market conditions that can impact costs. Engaging with local suppliers or those with a strong understanding of your market can mitigate risks associated with international sourcing.

-

Request Detailed Quotes: Ensure that quotes break down all cost components. This transparency can help identify areas for potential cost savings and ensure that all parties are aligned on expectations.

-

Stay Informed About Market Trends: Keeping abreast of material prices and supplier capabilities can help in making informed purchasing decisions. Regularly review market reports or engage with industry analysts to understand pricing dynamics.

Disclaimer for Indicative Prices

Please note that the prices mentioned in this analysis are indicative and subject to change based on market conditions and specific supplier negotiations. Always request updated quotes and detailed breakdowns to ensure accurate budgeting for your sourcing needs.

Alternatives Analysis: Comparing custom spring supplier With Other Solutions

When evaluating the procurement of custom springs, it is crucial for international B2B buyers to consider various alternatives that can meet their specific operational needs. Each solution has its own strengths and weaknesses, and understanding these can help buyers make informed decisions that align with their business objectives.

| Comparison Aspect | Custom Spring Supplier | 3D Printing Solutions | Off-the-Shelf Springs |

|---|---|---|---|

| Performance | High precision and customization | Variable precision, depending on technology | Standardized, reliable for general applications |

| Cost | Higher initial investment due to customization | Moderate cost; cheaper for low-volume runs | Generally lower cost; bulk pricing available |

| Ease of Implementation | Requires detailed specifications and lead time | Quick prototypes possible, but full production may vary | Immediate availability; simple integration |

| Maintenance | Variable; depends on application and material | Minimal; depends on material used | Low maintenance; designed for longevity |

| Best Use Case | Specialized applications needing tailored solutions | Prototyping and low-volume specialized components | General use across various industries |

What Are the Advantages and Disadvantages of 3D Printing Solutions for Springs?

3D printing represents a significant innovation in manufacturing technology, allowing for rapid prototyping and production of components. The primary advantage is the flexibility it offers in design; intricate geometries can be achieved that may not be possible with traditional methods. Additionally, 3D printing can reduce lead times significantly for small batches. However, the performance may not match that of custom springs in high-stress applications, and the costs can escalate with larger production runs due to material limitations.

Why Should You Consider Off-the-Shelf Springs?

Off-the-shelf springs are a practical solution for many applications, offering standardized dimensions and performance characteristics. The primary advantage is cost-effectiveness, especially when purchased in bulk, which can lead to significant savings for businesses with high-volume needs. These springs are readily available, allowing for immediate implementation. However, they may lack the specific performance characteristics required for unique applications, which can lead to compromises in functionality.

How Can a B2B Buyer Decide on the Right Solution?

Selecting the right solution for spring needs involves assessing the specific requirements of your application. Consider factors such as performance, cost, and time constraints. If your project demands high precision and customization, a custom spring supplier may be the best choice despite higher costs. Conversely, for standard applications or prototyping, off-the-shelf springs or 3D printing may provide the best balance of cost and efficiency. Evaluating these aspects against your operational needs will guide you to the most suitable solution.

In conclusion, understanding the alternatives available for custom springs not only empowers B2B buyers to make informed decisions but also ensures that the chosen solution aligns with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for custom spring supplier

When dealing with custom spring suppliers, understanding the essential technical properties and terminology is crucial for making informed purchasing decisions. Here, we outline key specifications that define the quality and performance of custom springs, as well as common trade terms that facilitate communication and negotiation in the B2B marketplace.

What Are the Key Technical Properties of Custom Springs?

1. Material Grade: How Does It Impact Spring Performance?

Custom springs are manufactured from various materials, including stainless steel, carbon steel, and alloy steel. The material grade affects the spring’s strength, elasticity, and corrosion resistance. For instance, stainless steel springs are ideal for applications in humid environments, while carbon steel springs provide good fatigue resistance. Selecting the appropriate material grade is vital to ensure that the spring performs effectively under specific loads and environmental conditions.

2. Tolerance: Why Is It Critical in Spring Manufacturing?

Tolerance refers to the allowable deviation from a specified measurement. In spring manufacturing, tight tolerances are essential for ensuring that the spring fits perfectly within its designated assembly. For example, a tolerance of ±0.001 inches may be necessary for precision applications like aerospace components. Understanding tolerance levels helps B2B buyers avoid costly rework or failure in critical applications.

3. Spring Rate: How Does It Affect Load Capacity?

The spring rate is defined as the amount of force required to compress or extend the spring by a certain distance, typically measured in pounds per inch (lb/in). A higher spring rate indicates a stiffer spring, which can support heavier loads without excessive deflection. Buyers should carefully consider the spring rate to match their application’s load requirements, ensuring optimal performance.

4. Fatigue Life: What Does It Mean for Long-Term Use?

Fatigue life is the number of cycles a spring can undergo before failure due to repeated stress. It is a critical property for applications involving continuous motion or load cycling. Understanding fatigue life helps buyers select springs that will last throughout the intended lifecycle of their products, reducing maintenance costs and downtime.

5. Finish and Coating: How Do They Enhance Durability?

The finish and coating applied to a spring can significantly impact its performance and longevity. Common finishes include zinc plating, powder coating, and heat treatment, each serving to enhance corrosion resistance or improve wear properties. B2B buyers must evaluate these options based on their specific application needs and environmental conditions.

What Are Common Trade Terms Used with Custom Spring Suppliers?

1. OEM (Original Equipment Manufacturer): What Does It Signify?

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of custom springs, working with an OEM can ensure that the springs meet specific standards and are designed for compatibility with other components in a system.

2. MOQ (Minimum Order Quantity): Why Is It Important?

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory effectively and ensure that they meet their production needs without over-committing financially.

3. RFQ (Request for Quotation): How Should It Be Used?

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. Including detailed specifications in an RFQ allows suppliers to provide accurate quotations, helping buyers make cost-effective decisions.

4. Incoterms: What Do They Mean for International Trade?

Incoterms (International Commercial Terms) are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is vital for international B2B transactions, as they clarify who bears the risk at various stages of transport.

5. Lead Time: Why Is It a Critical Factor?

Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times helps buyers plan their production schedules and manage inventory levels effectively, particularly in industries where timing is critical.

By grasping these essential technical properties and trade terms, international B2B buyers can navigate the custom spring market with confidence, ensuring they select the right products to meet their specific needs.

Navigating Market Dynamics and Sourcing Trends in the custom spring supplier Sector

What Are the Current Market Dynamics in the Custom Spring Supplier Sector?

The global custom spring supplier market is witnessing significant transformations driven by technological advancements and evolving buyer preferences. International buyers, especially from Africa, South America, the Middle East, and Europe, are increasingly prioritizing suppliers that integrate smart manufacturing technologies, such as automation and IoT. These technologies enhance precision, reduce lead times, and allow for real-time inventory management, which is crucial for B2B transactions in fast-paced environments.

Emerging trends also indicate a shift towards customization and flexibility in production processes. Buyers are looking for suppliers who can offer tailored solutions to meet specific application needs, whether in automotive, aerospace, or industrial machinery. Additionally, the rise of e-commerce platforms is simplifying the sourcing process, allowing B2B buyers to compare products and prices globally with ease.

Market dynamics are further influenced by geopolitical factors and trade regulations, particularly in regions like Africa and the Middle East, where local manufacturing initiatives are gaining traction. This trend encourages international buyers to explore partnerships with regional suppliers who can offer both quality and compliance with local standards. As a result, understanding the local market landscape and regulatory frameworks is becoming increasingly important for international buyers seeking reliable custom spring suppliers.

How Are Sustainability and Ethical Sourcing Transforming the Custom Spring Supplier Industry?

Sustainability is no longer just a buzzword; it has become a critical factor in the procurement process for custom spring suppliers. Buyers are increasingly aware of the environmental impacts associated with manufacturing processes. This awareness drives the demand for suppliers who implement sustainable practices, such as using recycled materials and minimizing waste during production.

Moreover, ethical sourcing is paramount for international B2B buyers. They are seeking suppliers who can demonstrate transparency in their supply chains, ensuring that materials are sourced responsibly and labor practices meet international standards. Certifications such as ISO 14001 for environmental management and Fair Trade can provide assurances that suppliers are committed to sustainable practices.

Green certifications not only enhance a supplier’s credibility but also appeal to a growing segment of environmentally-conscious buyers. By prioritizing suppliers that adhere to sustainability standards, international buyers can contribute to global efforts in reducing carbon footprints and promoting ethical labor practices. This shift not only aligns with corporate social responsibility goals but can also result in long-term cost savings through improved efficiency and waste reduction.

How Has the Custom Spring Supplier Sector Evolved Over Time?

The custom spring supplier sector has evolved significantly over the decades, shaped by technological innovations and changing market demands. Initially, the industry focused on basic spring manufacturing, catering primarily to local markets. However, as industries expanded and globalization took hold, the need for specialized and high-quality springs became apparent.

The introduction of advanced manufacturing techniques, such as computer numerical control (CNC) machining and additive manufacturing, revolutionized production capabilities, allowing suppliers to offer more complex designs and higher precision. This evolution has enabled suppliers to meet the increasing demands for customization and rapid prototyping, which are crucial in today’s competitive B2B landscape.

Furthermore, the growing emphasis on sustainability and ethical sourcing has prompted suppliers to rethink their practices. This shift is not only a response to buyer demands but also a proactive approach to future-proofing their businesses in an increasingly environmentally-conscious market. As the industry continues to evolve, the focus will remain on innovation, quality, and sustainability, ensuring that suppliers can meet the diverse needs of international B2B buyers effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of custom spring supplier

-

How do I choose the right custom spring supplier for my business needs?

Selecting the appropriate custom spring supplier involves assessing their industry experience, technological capabilities, and certifications. Look for suppliers who specialize in your specific application, whether it’s automotive, aerospace, or electronics. Request samples to evaluate quality and performance. Additionally, consider their ability to provide customization options and meet your production timelines. Supplier reviews and case studies can also offer insights into their reliability and service quality. -

What customization options are available for custom springs?

Custom spring suppliers typically offer a range of customization options, including material type, dimensions, coil configuration, and spring force specifications. You can also specify the spring’s finish, such as coating or plating, to enhance durability and resistance to corrosion. Discuss your unique requirements with potential suppliers to ensure they can accommodate your needs and provide prototypes for testing before mass production.

-

What are the minimum order quantities (MOQ) for custom springs?

Minimum order quantities (MOQ) for custom springs can vary significantly among suppliers, often depending on the complexity of the design and manufacturing process. Generally, MOQs can range from a few hundred to several thousand pieces. It’s crucial to clarify MOQs during your initial discussions to avoid unexpected costs or delays in production. Some suppliers may offer lower MOQs for prototype runs or smaller businesses, so it’s worth negotiating. -

How do I ensure quality assurance when sourcing custom springs internationally?

To ensure quality assurance when sourcing custom springs, request detailed documentation of the supplier’s quality control processes and certifications, such as ISO 9001. Conduct factory audits if feasible, or utilize third-party inspection services to evaluate the manufacturing process. Additionally, establish clear specifications and testing requirements in your contract to maintain quality standards throughout production and delivery. -

What payment terms should I expect when working with international custom spring suppliers?

Payment terms can vary widely depending on the supplier’s policies and the nature of your agreement. Common practices include advance payments, letters of credit, or payment upon delivery. It’s advisable to negotiate terms that align with your cash flow needs while ensuring the supplier’s security. Be mindful of currency fluctuations and transaction fees, especially when dealing with suppliers in different regions. -

How can I navigate logistics when sourcing custom springs from abroad?

Navigating logistics involves understanding shipping options, customs regulations, and potential tariffs. Work closely with your supplier to determine the best shipping method, whether by air or sea, based on urgency and cost. Additionally, engage with a reliable freight forwarder who can handle customs clearance and ensure compliance with local regulations. Always factor in lead times for production and shipping to avoid disruptions in your supply chain. -

What are the common challenges faced by international B2B buyers sourcing custom springs?

Common challenges include language barriers, cultural differences, and varying standards of quality assurance. Additionally, navigating customs regulations and understanding local market dynamics can complicate the sourcing process. To mitigate these issues, establish clear communication channels with your supplier, utilize translation services if necessary, and consider working with local representatives or consultants familiar with the region’s trade practices. -

How do I handle disputes with my custom spring supplier?

Handling disputes effectively requires clear communication and documentation. Start by addressing the issue directly with the supplier to seek a resolution. If that fails, refer to your contract for any clauses related to dispute resolution, such as mediation or arbitration. Keeping detailed records of all transactions and communications will support your position. In some cases, involving a third-party mediator may help facilitate a mutually acceptable solution.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for custom spring supplier

In the evolving landscape of international trade, strategic sourcing for custom spring suppliers offers a pathway to not only optimize procurement but also enhance product quality and cost efficiency. By engaging with suppliers that align with your operational goals and understanding regional market dynamics, businesses can secure a competitive advantage. Key takeaways include the importance of conducting thorough supplier assessments, leveraging technology for better communication, and fostering long-term partnerships that yield mutual benefits.

For B2B buyers from Africa, South America, the Middle East, and Europe, the focus should be on identifying suppliers who can meet specific regional requirements while also adhering to global quality standards. As markets continue to globalize, the ability to adapt to changing demands and supply chain disruptions will be paramount.

Looking ahead, the strategic sourcing landscape is set to become even more interconnected. Buyers are encouraged to stay informed about emerging trends and technologies that can streamline sourcing processes. By taking proactive steps now, international B2B buyers can position themselves for success in an increasingly competitive marketplace. Engage with potential suppliers today to explore innovative solutions that drive growth and sustainability for your business.