Unlock Savings: The Complete Guide to 3D Printing China (2025)

Introduction: Navigating the Global Market for 3d printing china

Navigating the global market for 3D printing in China presents a unique set of challenges for international B2B buyers. With the rapid evolution of technology, sourcing high-quality 3D printing solutions that meet specific business needs can be overwhelming. Whether you’re looking for cost-effective prototyping, custom parts manufacturing, or scalable production solutions, understanding the landscape of Chinese suppliers is crucial. This guide aims to demystify the complexities of the 3D printing market in China, covering essential aspects such as different types of 3D printing technologies, various applications across industries, effective supplier vetting processes, and cost considerations.

By equipping buyers from Africa, South America, the Middle East, and Europe—specifically countries like Brazil and Argentina—with actionable insights, this guide empowers you to make informed purchasing decisions. We delve into the nuances of working with Chinese manufacturers, including strategies for overcoming language barriers, ensuring quality control, and navigating logistics. As you explore this resource, you’ll gain the knowledge needed to leverage the benefits of 3D printing while minimizing risks associated with international procurement. Ultimately, this guide serves as your roadmap to successfully tapping into the dynamic 3D printing market in China, enabling your business to innovate and thrive in a competitive global landscape.

Understanding 3d printing china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fused Deposition Modeling (FDM) | Utilizes thermoplastic filaments, layer-by-layer extrusion. | Prototyping, tool production, custom parts. | Pros: Cost-effective, wide material choice. Cons: Limited detail and surface finish. |

| Stereolithography (SLA) | Employs UV light to cure liquid resin into hardened plastic. | High-detail prototypes, dental applications. | Pros: Excellent precision and surface finish. Cons: More expensive materials and post-processing required. |

| Selective Laser Sintering (SLS) | Uses a laser to fuse powdered material, creating strong parts. | Aerospace, automotive, medical devices. | Pros: Strong, functional parts; no support structures. Cons: Higher cost and longer print times. |

| Digital Light Processing (DLP) | Similar to SLA but uses a digital light projector for curing. | Jewelry, dental models, complex prototypes. | Pros: Faster printing than SLA, high detail. Cons: Limited material options compared to FDM. |

| Multi-Jet Fusion (MJF) | Uses inkjet technology to apply a binding agent to powder. | End-use parts, functional prototypes. | Pros: Fast production speed, good mechanical properties. Cons: Initial setup costs can be high. |

What are the Characteristics of Fused Deposition Modeling (FDM)?

Fused Deposition Modeling (FDM) is one of the most popular 3D printing technologies, particularly favored for its cost-effectiveness and ease of use. It works by extruding thermoplastic filaments through a heated nozzle, allowing for the layer-by-layer construction of parts. FDM is ideal for creating prototypes, tools, and custom parts, especially in industries like consumer goods and automotive. B2B buyers should consider the variety of materials available, the relatively low cost of printers, and the trade-off with surface finish and detail quality when choosing FDM.

How Does Stereolithography (SLA) Stand Out?

Stereolithography (SLA) is known for its exceptional precision and ability to produce high-quality surface finishes. It uses UV light to cure liquid resin into solid parts, making it suitable for applications where detail is critical, such as dental models and intricate prototypes. B2B buyers must weigh the benefits of high detail against the higher costs of both equipment and materials, as well as the need for post-processing to achieve the desired finish.

Why Choose Selective Laser Sintering (SLS)?

Selective Laser Sintering (SLS) is a robust 3D printing technique that uses a laser to fuse powdered materials, resulting in strong and functional parts. This technology is commonly employed in industries such as aerospace and medical devices, where durability is paramount. The absence of support structures during printing is a significant advantage, allowing for complex geometries. However, buyers should consider the higher costs associated with SLS printers and materials, as well as longer print times compared to other methods.

What are the Advantages of Digital Light Processing (DLP)?

Digital Light Processing (DLP) offers a faster alternative to SLA by using a digital light projector to cure resin. This technology excels in producing high-detail parts suitable for jewelry and dental applications. B2B buyers benefit from the speed of DLP printing, which can significantly reduce lead times. However, the range of materials is more limited compared to FDM, and buyers must consider the trade-offs between speed, detail, and material options.

What Makes Multi-Jet Fusion (MJF) a Competitive Choice?

Multi-Jet Fusion (MJF) is a cutting-edge technology that applies a binding agent to powdered materials using inkjet technology, resulting in fast production of functional parts. MJF is particularly effective for end-use applications across various industries. While it offers excellent mechanical properties and rapid production speeds, B2B buyers should be mindful of the initial setup costs and the need for specialized equipment. This technology is ideal for businesses looking to scale up production while maintaining quality.

Related Video: Digital printing and embroidery expo

Key Industrial Applications of 3d printing china

| Industry/Sector | Specific Application of 3D Printing China | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Rapid prototyping of aircraft components | Reduces development time and costs, enhances design flexibility | Quality certifications, material specifications, lead times |

| Healthcare | Customized prosthetics and implants | Improved patient outcomes, personalized solutions | Regulatory compliance, material biocompatibility, production scale |

| Automotive | Tooling and jigs for assembly lines | Increased production efficiency, reduced waste | Durability of materials, precision requirements, supplier reliability |

| Consumer Goods | Custom product designs for niche markets | Enhanced brand differentiation, faster time-to-market | Design capabilities, minimum order quantities, logistics |

| Architecture and Construction | Scale models and architectural prototypes | Facilitates client presentations, better project visualization | Material selection, printing technology, turnaround time |

How is 3D Printing Used in Aerospace Applications?

In the aerospace industry, 3D printing from China is revolutionizing the production of aircraft components through rapid prototyping. This technology allows manufacturers to create lightweight, complex parts that traditional methods cannot achieve. By utilizing additive manufacturing, companies can significantly reduce development time and costs while enhancing design flexibility. International buyers should ensure that suppliers possess the necessary quality certifications and understand material specifications to meet stringent aerospace standards.

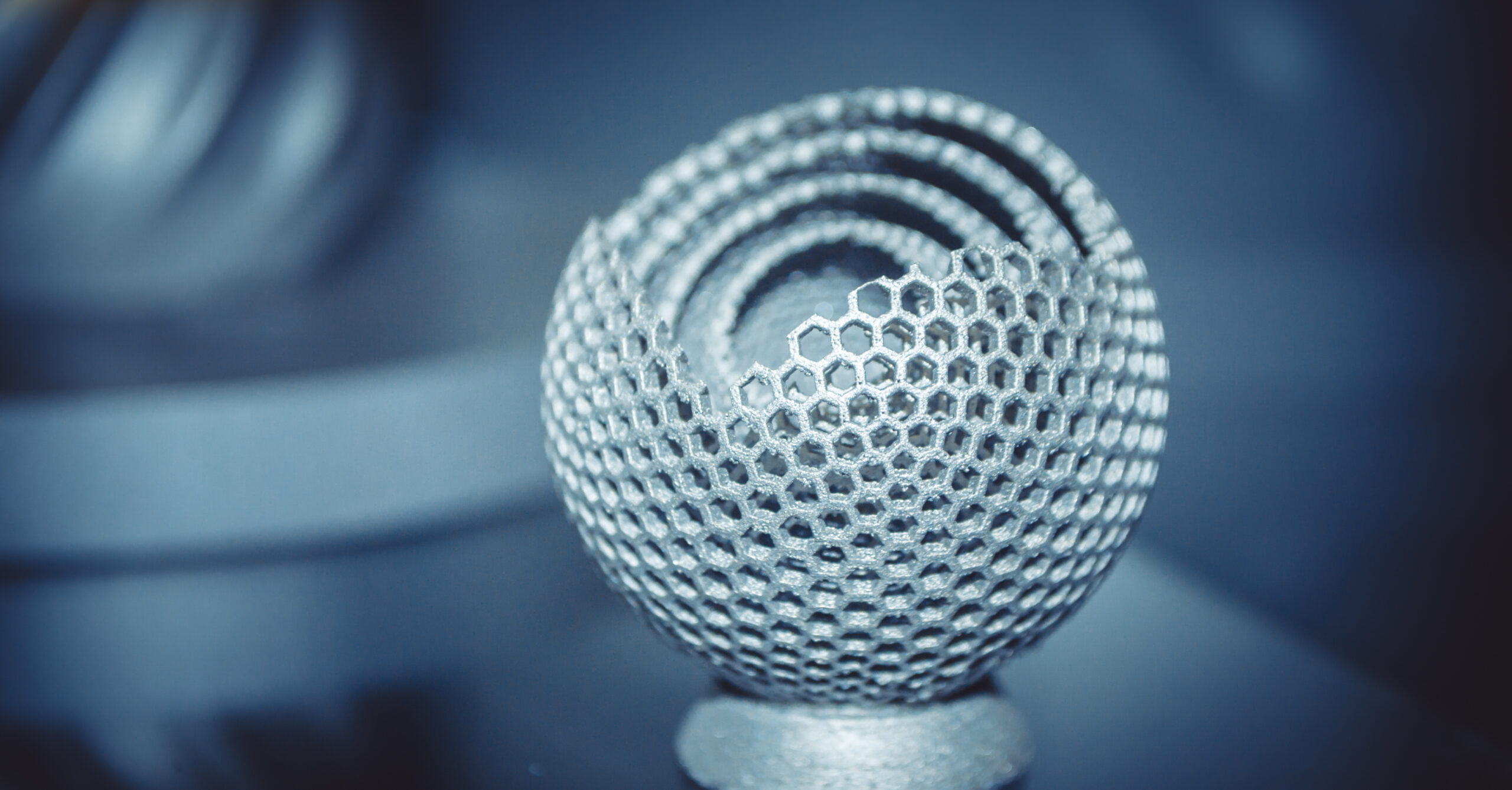

A stock image related to 3d printing china.

What Role Does 3D Printing Play in Healthcare?

Healthcare applications of 3D printing include the production of customized prosthetics and implants tailored to individual patient needs. This personalization leads to improved patient outcomes and satisfaction. The ability to quickly produce these items allows for faster surgical procedures and recovery times. For international buyers, especially from regions like Africa and South America, sourcing from manufacturers that comply with regulatory standards and use biocompatible materials is essential to ensure safety and effectiveness.

How is 3D Printing Enhancing the Automotive Industry?

In the automotive sector, 3D printing is increasingly being used for tooling and jigs in assembly lines. This application enhances production efficiency by allowing manufacturers to create precise tools that reduce assembly times and minimize waste. By adopting this technology, companies can respond more swiftly to market demands and innovate faster. Buyers should focus on the durability of the materials used and the precision of the printing process when selecting suppliers in China.

What are the Benefits of Custom 3D Printed Consumer Goods?

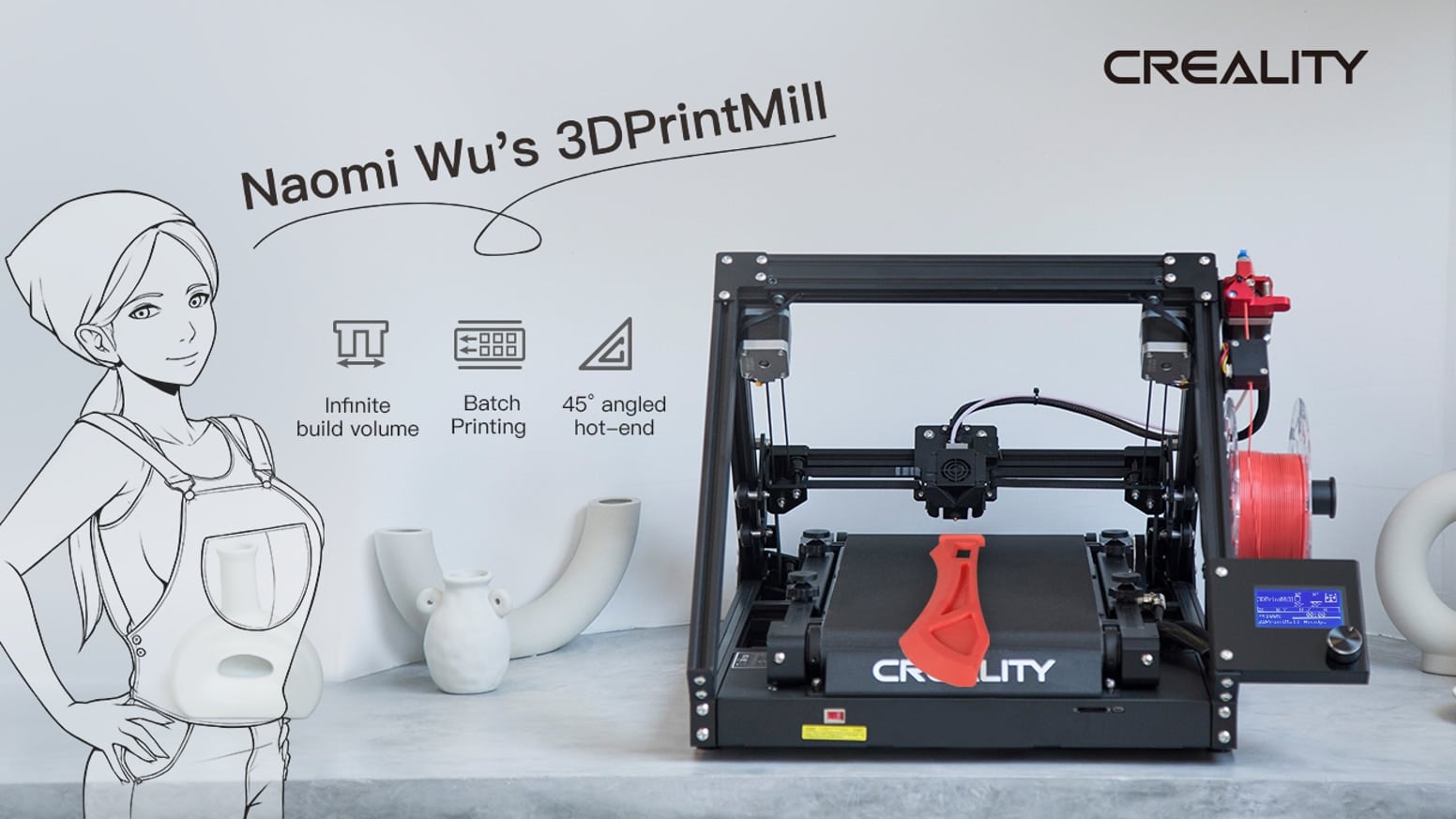

A stock image related to 3d printing china.

3D printing is enabling brands in the consumer goods sector to design and produce custom products tailored to niche markets. This capability not only enhances brand differentiation but also accelerates the time-to-market for new products. International buyers should consider the design capabilities of their suppliers, minimum order quantities, and logistical aspects to ensure a smooth supply chain process.

How is 3D Printing Transforming Architecture and Construction?

In architecture and construction, 3D printing is used to create scale models and architectural prototypes that facilitate client presentations and project visualization. This technology allows architects to demonstrate complex designs more effectively, leading to better client engagement and approval processes. Buyers should evaluate material selection, the type of printing technology used, and turnaround times to ensure that their projects are completed on schedule and to the desired specifications.

Related Video: Stereolithography (SLA) 3D Printing Explained: Guide to Resin 3D Printers

3 Common User Pain Points for ‘3d printing china’ & Their Solutions

Scenario 1: Ensuring Quality Control in 3D Printing from China

The Problem:

B2B buyers often face challenges with quality assurance when sourcing 3D printed products from China. Due to vast geographical distances and cultural differences, maintaining consistent quality can be difficult. Buyers may receive products that do not meet their specifications or quality standards, leading to increased costs from returns, rework, or project delays. This problem is particularly acute for industries like aerospace or healthcare, where precision and material integrity are critical.

The Solution:

To tackle quality control issues, it is vital to establish clear, detailed specifications before initiating any orders. Utilize standards such as ISO or ASTM relevant to your industry to communicate expectations effectively. Furthermore, consider conducting due diligence by visiting the manufacturing facilities or hiring third-party quality inspectors to verify production processes. Implementing a robust communication plan throughout the production cycle, including regular updates and samples, can help ensure that the final products align with your quality requirements. Additionally, engaging in a trial run with small batch orders can allow you to assess quality before committing to larger quantities.

Scenario 2: Navigating Intellectual Property Concerns in 3D Printing

The Problem:

International B2B buyers frequently worry about intellectual property (IP) theft when dealing with manufacturers in China. Concerns around the unauthorized reproduction of designs can deter companies from pursuing innovative projects, particularly in sectors like automotive or consumer goods, where proprietary designs are crucial for competitive advantage. The lack of strong IP protections can result in significant financial losses if designs are copied and produced by competitors.

The Solution:

To mitigate IP risks, it is essential to establish clear legal agreements that outline ownership of designs and the consequences of infringement. Consider using non-disclosure agreements (NDAs) and intellectual property agreements that are enforceable in both your country and China. Additionally, working with legal experts familiar with Chinese laws can help navigate potential pitfalls. It is advisable to register patents or trademarks in China before sharing sensitive information. Building a trusted relationship with manufacturers who have a reputation for respecting IP rights can also provide additional peace of mind.

Scenario 3: Managing Lead Times and Production Delays in 3D Printing

The Problem:

Lead times and unexpected delays are common pain points for B2B buyers engaging with 3D printing services in China. Factors such as production scheduling, shipping logistics, and local holidays can significantly impact delivery schedules, leading to disruptions in supply chains and project timelines. This unpredictability can be particularly challenging for businesses that rely on just-in-time manufacturing practices.

The Solution:

To effectively manage lead times, buyers should implement a detailed project timeline that includes buffer periods for potential delays. Communicating openly with your supplier about your timeline can encourage them to prioritize your order. Use project management tools to track progress and set milestones that align with your production schedule. Additionally, consider diversifying your supplier base by identifying multiple manufacturers capable of meeting your needs. This strategy can provide flexibility and options in case one supplier faces delays. Finally, maintaining a close relationship with logistics partners can help in anticipating and resolving shipping issues before they impact your operations.

Strategic Material Selection Guide for 3d printing china

What Are the Key Properties of Common Materials Used in 3D Printing in China?

When selecting materials for 3D printing, it is crucial to understand their properties and how they align with specific application requirements. Below, we analyze four common materials used in 3D printing in China, focusing on their properties, advantages and disadvantages, and considerations for international B2B buyers.

How Do PLA and ABS Compare for 3D Printing Applications?

PLA (Polylactic Acid)

PLA is a biodegradable thermoplastic derived from renewable resources like corn starch. It has a low melting point (around 180-220°C) and excellent printability.

- Key Properties: Good tensile strength, low warping, and a glossy finish.

- Pros: Environmentally friendly, easy to print, and minimal odor during printing.

- Cons: Lower heat resistance (around 60°C), making it unsuitable for high-temperature applications.

- Impact on Application: Ideal for prototypes, educational models, and decorative items but not for functional parts exposed to heat.

- Considerations for Buyers: Compliance with environmental regulations is essential, especially in Europe, where sustainability is increasingly prioritized. Buyers should also check for ASTM compliance for material quality.

ABS (Acrylonitrile Butadiene Styrene)

ABS is a widely used thermoplastic known for its toughness and impact resistance.

- Key Properties: High temperature resistance (up to 100°C), good chemical resistance, and excellent durability.

- Pros: Strong and flexible, suitable for functional parts and automotive applications.

- Cons: Requires a heated bed to prevent warping and emits fumes during printing, necessitating good ventilation.

- Impact on Application: Preferred for functional prototypes, mechanical components, and consumer products.

- Considerations for Buyers: Buyers must ensure compliance with safety standards, particularly in the automotive and consumer goods sectors.

What Are the Advantages of Using Nylon in 3D Printing?

Nylon

Nylon is a versatile polyamide known for its strength and flexibility.

- Key Properties: Excellent tensile strength, good abrasion resistance, and flexibility.

- Pros: Highly durable and suitable for parts that require strength and flexibility, such as gears and mechanical components.

- Cons: Hygroscopic (absorbs moisture), which can affect print quality and requires careful storage.

- Impact on Application: Ideal for functional parts in engineering and manufacturing.

- Considerations for Buyers: Buyers from humid regions (like parts of Africa and South America) must consider moisture control during storage and printing. Compliance with industry standards such as DIN or JIS is also critical.

How Does TPU Enhance 3D Printing Capabilities?

TPU (Thermoplastic Polyurethane)

TPU is a flexible material known for its rubber-like properties.

- Key Properties: High elasticity, excellent wear resistance, and good chemical resistance.

- Pros: Ideal for applications requiring flexibility and durability, such as seals and gaskets.

- Cons: More challenging to print due to its flexibility, requiring precise settings and adjustments.

- Impact on Application: Suitable for products that need to withstand bending and stretching.

- Considerations for Buyers: Buyers should be aware of the specific printing requirements and ensure that their equipment is compatible with TPU. Compliance with relevant safety standards is also important.

Summary Table of Materials for 3D Printing in China

| Material | Typical Use Case for 3D Printing China | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PLA | Prototypes, educational models, decorative items | Environmentally friendly | Low heat resistance | Low |

| ABS | Functional prototypes, automotive parts | Strong and flexible | Requires heated bed | Medium |

| Nylon | Functional parts, mechanical components | Highly durable | Hygroscopic, moisture-sensitive | Medium |

| TPU | Flexible products like seals and gaskets | Excellent elasticity | Challenging to print | High |

This guide provides a comprehensive overview of common materials used in 3D printing in China, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 3d printing china

What Are the Key Stages in the 3D Printing Manufacturing Process in China?

The manufacturing process for 3D printing in China involves several critical stages that ensure quality and efficiency. Understanding these stages can help international B2B buyers make informed decisions when sourcing from Chinese manufacturers.

-

Material Preparation

Material selection is foundational in 3D printing. Common materials include thermoplastics, metals, ceramics, and composites. Suppliers must ensure that materials meet specific industry standards and are appropriate for the intended application. Buyers should inquire about the sourcing and quality of these materials to avoid subpar products. -

Forming

The forming stage involves the actual 3D printing process, which can utilize various technologies such as Fused Deposition Modeling (FDM), Stereolithography (SLA), or Selective Laser Sintering (SLS). Each technology has its own advantages and is chosen based on the desired properties of the final product. Buyers should assess the technology used by the supplier, as it impacts production speed, finish quality, and material compatibility. -

Assembly

For products that require multiple parts, the assembly stage is crucial. This may involve additional machining or joining techniques to create a final product that meets specifications. Understanding the assembly capabilities of your supplier can lead to better negotiation on lead times and costs. -

Finishing

The finishing stage enhances the aesthetic and functional properties of the printed parts. Techniques may include sanding, painting, or applying coatings. Buyers should consider the finishing processes available and how they align with their product requirements.

How Is Quality Assurance Managed in 3D Printing in China?

Quality assurance (QA) is paramount in ensuring that the final products meet both international standards and customer expectations. Here are the essential aspects of quality assurance in the 3D printing sector:

-

Adherence to International Standards

Manufacturers in China often comply with international standards such as ISO 9001, which focuses on quality management systems. Industry-specific certifications like CE for products sold in Europe or API for oil and gas components are also important. Buyers should request evidence of these certifications as part of their supplier evaluation process. -

Quality Control Checkpoints

The quality control process typically includes three major checkpoints:

– Incoming Quality Control (IQC): Inspection of raw materials and components before production begins.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to catch issues early.

– Final Quality Control (FQC): A thorough inspection of finished products before shipping to ensure they meet specifications. -

Testing Methods Used in Quality Control

Common testing methods include dimensional checks, mechanical property testing, and surface finish assessments. Non-destructive testing methods such as ultrasonic or X-ray testing may also be employed, depending on the product’s application. Buyers should inquire about the specific testing procedures used by suppliers.

How Can B2B Buyers Verify Supplier Quality Control in China?

For international B2B buyers, ensuring the quality of products sourced from China requires due diligence. Here are actionable strategies:

-

Conduct Supplier Audits

Regular audits of suppliers can provide insights into their manufacturing processes and quality control practices. Buyers should consider conducting both initial audits and ongoing assessments to ensure compliance with quality standards. -

Request Quality Reports

Suppliers should provide detailed quality reports that outline test results, compliance with standards, and any quality issues encountered during production. These reports can serve as a basis for evaluating the supplier’s quality assurance capabilities. -

Utilize Third-Party Inspection Services

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s operations and products. These services can perform inspections at various stages, ensuring adherence to specifications before products are shipped.

What Are the Quality Control Nuances for International Buyers from Africa, South America, the Middle East, and Europe?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control when sourcing from China:

-

Understanding Regional Regulations

Different regions may have unique regulations that impact product compliance. Buyers should familiarize themselves with these regulations and ensure that their suppliers can meet them. -

Cultural and Language Considerations

Effective communication is vital. Language barriers and cultural differences may lead to misunderstandings regarding quality expectations. Buyers should establish clear communication channels and consider hiring local representatives who understand both the local context and the supplier’s processes. -

Building Long-Term Relationships

Developing a long-term relationship with suppliers can lead to better quality control over time. Suppliers who understand their clients’ needs are more likely to prioritize quality and adhere to specifications.

In conclusion, understanding the manufacturing processes and quality assurance practices in 3D printing in China is essential for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing, while ensuring robust quality control measures, buyers can enhance their sourcing strategies and mitigate risks associated with product quality.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3d printing china’

In the rapidly evolving landscape of 3D printing, international B2B buyers, especially from Africa, South America, the Middle East, and Europe, must adopt a strategic approach to sourcing from China. This practical sourcing guide outlines essential steps to streamline the procurement process, ensuring that buyers make informed decisions and secure quality products.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is the first step in the sourcing process. This includes determining the materials, dimensions, and tolerances required for your 3D printing projects. Providing detailed specifications helps suppliers understand your needs and reduces the risk of miscommunication or subpar products.

- Materials: Specify the types of materials (e.g., PLA, ABS, nylon) you want to use.

- Design Files: Ensure you have the correct CAD files ready for production.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers in China. Utilize online platforms like Alibaba, Made-in-China, and global trade directories to compile a list of candidates. Assess their reputation through reviews and ratings to ensure they align with your business standards.

- Supplier Background: Look for established companies with a proven track record.

- Industry Experience: Focus on suppliers with experience in your specific industry to ensure they understand your requirements.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it is crucial to evaluate them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This step is vital to verify their capabilities and reliability.

- Certifications: Check for ISO certifications or other relevant industry standards.

- Production Capacity: Ensure they can meet your volume needs without compromising quality.

Step 4: Request Samples

Always request samples before placing a bulk order. This allows you to assess the quality of the 3D-printed products and evaluate the supplier’s workmanship. Testing samples can save you from costly mistakes later on.

- Quality Check: Inspect the samples for defects and adherence to your specifications.

- Performance Testing: If applicable, conduct performance tests to ensure the materials meet your requirements.

Step 5: Negotiate Terms and Conditions

Once you have selected a supplier, negotiate the terms and conditions of the agreement. This includes pricing, payment terms, delivery schedules, and warranty options. Clear agreements can help mitigate risks and ensure a smooth transaction.

- Payment Methods: Discuss payment options, including deposits and full payments.

- Lead Times: Confirm lead times to align with your project timelines.

Step 6: Establish Clear Communication Channels

Establishing effective communication channels is critical for successful sourcing. Regular updates and open lines of communication can help address any issues promptly and ensure that the project stays on track.

- Preferred Platforms: Agree on communication platforms (e.g., email, WhatsApp, video calls).

- Point of Contact: Designate a point of contact on both sides to streamline communication.

Step 7: Monitor Production and Quality Control

Once production begins, actively monitor the process to ensure adherence to specifications. Implement a quality control system that includes regular inspections and reporting to catch any issues early.

- Site Visits: If feasible, consider visiting the production facility to oversee operations.

- Regular Updates: Request progress updates and photos from the supplier to stay informed.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing 3D printing services from China, ensuring they select the right supplier and receive high-quality products that meet their specifications.

Comprehensive Cost and Pricing Analysis for 3d printing china Sourcing

What Are the Key Cost Components in 3D Printing Sourcing from China?

When sourcing 3D printing services from China, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly affects the overall cost. Common materials like PLA and ABS are relatively inexpensive, while advanced materials like nylon or metal can considerably increase costs. Buyers should evaluate the material requirements against their budget.

-

Labor: Labor costs in China are generally lower than in many Western countries. However, skilled labor for operating advanced 3D printing machines can command higher wages. Understanding the skill level required for specific projects is crucial in assessing labor costs.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses associated with running the manufacturing facility. Overhead costs can vary significantly between suppliers, impacting the final pricing.

-

Tooling: If your project requires custom tooling, this will incur additional costs. Tooling is particularly important for large volume orders or specialized designs, and it’s essential to factor this into your budget.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes is a necessity that can add to costs. Suppliers may charge for additional inspections or certifications, particularly for industries with strict compliance standards.

-

Logistics: Shipping costs, customs duties, and insurance play a crucial role in the total cost. The choice of shipping method (air vs. sea) will affect delivery times and costs, which are critical for timely product launches.

-

Supplier Margin: Finally, the supplier’s profit margin will be included in the pricing. This can vary based on the supplier’s reputation, the complexity of the project, and the volume of business they anticipate.

How Do Price Influencers Affect 3D Printing Costs?

Several factors influence pricing when sourcing 3D printing services from China:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically reduce the unit cost due to economies of scale. Negotiating for better pricing on larger orders can be beneficial for B2B buyers.

-

Specifications and Customization: Custom designs or specific tolerances can increase costs. Clear communication of design specifications can help manage expectations and costs.

-

Materials and Quality Certifications: Certain materials come with additional costs, and certifications (like ISO or ASTM) can also influence pricing. Buyers should verify if certifications are necessary for their products.

-

Supplier Factors: The supplier’s experience, technological capabilities, and reputation can significantly affect pricing. Established suppliers may charge more but often deliver higher quality.

-

Incoterms: The terms of shipping and delivery, defined by Incoterms, can also impact costs. Understanding whether costs are inclusive or exclusive of shipping can help in budgeting accurately.

What Are the Best Negotiation Tips for International Buyers?

Negotiating effectively can lead to significant cost savings. Here are some actionable tips for international B2B buyers:

-

Research and Compare: Gather quotes from multiple suppliers to understand market pricing. This information can empower you during negotiations.

-

Discuss Volume Discounts: If you anticipate future orders, discussing potential volume discounts can be beneficial. Suppliers are often willing to negotiate lower prices for guaranteed repeat business.

-

Clarify Costs Upfront: Ensure you understand all cost components, including shipping and handling, to avoid surprises later. A detailed breakdown can help in negotiations.

-

Total Cost of Ownership (TCO): Consider the TCO beyond the initial purchase price. Factors like quality, durability, and maintenance can influence the long-term cost-effectiveness of your purchase.

-

Be Aware of Pricing Nuances: Understand that prices may fluctuate based on currency exchange rates, raw material availability, and market demand. Keep this in mind when finalizing contracts.

What Are the Pricing Nuances for Buyers from Africa, South America, the Middle East, and Europe?

Buyers from regions like Africa, South America, the Middle East, and Europe need to consider additional factors:

-

Currency Fluctuations: Be mindful of currency exchange rates when negotiating prices. Consider locking in prices when favorable rates are available.

-

Import Tariffs and Duties: Different countries have varying import tariffs that can affect the total cost. Researching these tariffs can prevent unexpected expenses.

-

Logistical Challenges: Shipping routes and logistics can vary greatly by region, impacting delivery times and costs. Understanding local logistics will aid in planning.

-

Cultural Differences in Negotiation: Each region has its own negotiation styles. Understanding these cultural nuances can foster better supplier relationships and enhance negotiation outcomes.

Disclaimer on Indicative Prices

It is important to note that the prices discussed in this analysis are indicative and may vary based on specific project requirements, supplier negotiations, and market conditions. Always seek formal quotes from suppliers to ascertain accurate pricing.

Alternatives Analysis: Comparing 3d printing china With Other Solutions

In the evolving landscape of manufacturing technologies, international B2B buyers need to explore various alternatives to ‘3D Printing China’ to find the most suitable solution for their operational needs. This section provides a comparative analysis of ‘3D Printing China’ against two viable alternatives: traditional manufacturing methods and additive manufacturing from local suppliers. Each option presents unique advantages and disadvantages, depending on specific business requirements.

Comparison Table of 3D Printing China and Alternatives

| Comparison Aspect | 3D Printing China | Traditional Manufacturing | Local Additive Manufacturing |

|---|---|---|---|

| Performance | High precision, complex geometries | Limited by tooling and molds | Varies by technology used |

| Cost | Competitive for small batches | Economies of scale reduce cost | Higher than mass production |

| Ease of Implementation | Quick prototyping, longer lead times for large runs | Longer setup times | Moderate, depends on local capabilities |

| Maintenance | Low, but requires skilled operators | Moderate, dependent on machinery | Low, but specialized training may be needed |

| Best Use Case | Custom parts, low-volume production | High-volume, low-complexity products | Custom and low-volume runs, local market responsiveness |

What Are the Pros and Cons of Traditional Manufacturing Compared to 3D Printing China?

Traditional Manufacturing: This method excels in producing large volumes of standardized parts at a reduced unit cost. However, it often requires significant upfront investment in tooling and molds, making it less flexible for custom orders. While traditional manufacturing can be efficient for high-volume production, it lacks the adaptability and design freedom that 3D printing provides. For businesses focused on mass production with consistent quality, traditional manufacturing remains a viable choice.

How Does Local Additive Manufacturing Stand Against 3D Printing China?

Local Additive Manufacturing: This alternative leverages similar technology to 3D printing but emphasizes sourcing from local suppliers. The primary advantage is reduced shipping costs and faster turnaround times due to proximity. However, local additive manufacturing may have varying levels of technology and expertise, which can impact quality and consistency. While it offers competitive pricing for small batches, businesses should assess the capabilities of local providers to ensure they meet design and quality standards.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the right manufacturing solution involves understanding your specific business needs, such as production volume, customization requirements, and budget constraints. If your operations demand high customization and rapid prototyping, ‘3D Printing China’ may be the ideal choice. Conversely, for high-volume production, traditional manufacturing could provide the best value. Local additive manufacturing stands out for businesses prioritizing quick delivery and local support. B2B buyers should conduct a thorough evaluation of each alternative, considering factors such as performance, cost, and ease of implementation, to make an informed decision that aligns with their strategic objectives.

Essential Technical Properties and Trade Terminology for 3d printing china

What Are the Essential Technical Properties for 3D Printing in China?

When engaging with 3D printing suppliers in China, understanding the technical properties of materials and processes is crucial for international B2B buyers. Here are some key specifications that can significantly affect product quality and manufacturing efficiency:

1. Material Grade: Why Is It Important?

Material grade refers to the specific type of material used in 3D printing, such as PLA, ABS, or Nylon. Each material has distinct properties like strength, flexibility, and thermal resistance. For buyers, selecting the right material grade impacts the durability and functionality of the final product, making it essential to communicate specific material requirements to suppliers.

2. Tolerance: How Does It Affect Product Precision?

Tolerance defines the permissible limits of variation in a physical dimension. In 3D printing, tighter tolerances (e.g., ±0.1mm) lead to higher precision and better fit for parts, which is vital in industries like aerospace and automotive. Understanding and specifying tolerance levels ensures that the produced parts meet design specifications and function correctly in their intended applications.

3. Layer Height: What Role Does It Play in Quality?

Layer height is a critical factor in determining the surface finish and detail of a 3D printed object. A smaller layer height results in finer details but increases production time. For B2B buyers, balancing layer height against production speed and cost is essential to achieve the desired quality without compromising efficiency.

4. Build Volume: Why Is It a Key Consideration?

Build volume refers to the maximum size of an object that can be printed in a single run. Understanding build volume is crucial for B2B buyers as it affects the overall design and assembly of parts. If a product exceeds the machine’s build volume, it may require multiple prints and post-processing, impacting lead times and costs.

5. Print Speed: How Does It Impact Production?

Print speed is the rate at which a 3D printer can produce an item. Faster print speeds can reduce production time, but may compromise detail and surface finish. Buyers must consider their timelines and the acceptable quality levels when discussing print speeds with suppliers.

6. Surface Finish: What Is Its Importance in Aesthetics?

Surface finish refers to the smoothness or texture of a printed part’s exterior. A high-quality surface finish can enhance the aesthetic appeal of a product and reduce the need for extensive post-processing. Buyers should specify surface finish requirements to ensure that the final product meets branding and usability standards.

What Trade Terms Should B2B Buyers Understand When Sourcing from China?

Navigating the 3D printing landscape in China involves familiarizing oneself with specific trade terminology. Here are some essential terms that can help facilitate smoother transactions:

1. What Is an OEM (Original Equipment Manufacturer)?

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of 3D printing, understanding OEM relationships helps buyers identify suppliers capable of producing custom designs and parts that meet specific brand requirements.

2. What Does MOQ (Minimum Order Quantity) Mean?

MOQ is the minimum quantity of a product that a supplier is willing to sell. For B2B buyers, understanding MOQ is crucial for budgeting and inventory management. Suppliers in China often have varying MOQs based on the material and complexity of the print, so confirming this upfront can prevent unexpected costs.

3. How to Use RFQ (Request for Quotation) Effectively?

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. Crafting a detailed RFQ that includes material specifications, quantities, and desired lead times can help buyers receive accurate and competitive pricing, ensuring better negotiation outcomes.

4. What Are Incoterms and Why Are They Important?

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations, manage risks, and negotiate better shipping terms with Chinese suppliers.

5. What Does Lead Time Refer To in 3D Printing?

Lead time is the period from the placement of an order to the delivery of the product. For B2B buyers, understanding lead time is critical for planning and meeting project deadlines. Clear communication about lead times with suppliers can prevent delays and ensure timely product availability.

By mastering these technical properties and trade terms, international B2B buyers can better navigate the complexities of sourcing 3D printing services from China, ensuring successful partnerships and high-quality outcomes.

Navigating Market Dynamics and Sourcing Trends in the 3d printing china Sector

What Are the Current Market Dynamics and Key Trends in the 3D Printing Sector in China?

The 3D printing sector in China is experiencing rapid growth, propelled by advancements in technology and increasing demand from various industries, including aerospace, automotive, healthcare, and consumer goods. The global drivers behind this trend include the need for rapid prototyping, customization, and the reduction of manufacturing costs. For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for effective sourcing decisions.

Emerging technologies such as metal 3D printing and bioprinting are gaining traction, offering new avenues for product development and innovation. Additionally, the integration of artificial intelligence and machine learning into 3D printing processes is enhancing efficiency and precision. Buyers should be aware of the importance of collaborating with suppliers who are at the forefront of these technological advancements to leverage the benefits of improved production capabilities.

Furthermore, the Chinese government’s supportive policies and investments in R&D are fostering a conducive environment for growth. International buyers should keep an eye on the evolving landscape, as local manufacturers are increasingly capable of meeting global standards and expectations. Engaging with reliable suppliers who can offer the latest technologies and innovations will be key to staying competitive in the market.

How Important Is Sustainability and Ethical Sourcing in the 3D Printing Industry?

Sustainability is becoming a significant factor in the decision-making process for B2B buyers in the 3D printing sector. The environmental impact of traditional manufacturing processes has raised concerns, leading to a shift towards more sustainable practices. For international buyers, particularly those in Africa, South America, the Middle East, and Europe, sourcing from suppliers who prioritize ethical practices is essential.

Buyers should look for suppliers that utilize eco-friendly materials and possess certifications such as ISO 14001, which demonstrates a commitment to environmental management. The use of biodegradable filaments and recycled materials in 3D printing not only reduces waste but also aligns with the growing consumer demand for sustainable products.

Moreover, ethical sourcing practices contribute to a company’s brand reputation and can lead to increased customer loyalty. Buyers can enhance their value proposition by ensuring that their suppliers follow sustainable practices throughout the supply chain. This focus on sustainability not only mitigates risks but also opens new market opportunities, particularly in regions where environmental concerns are paramount.

What Is the Brief Evolution of 3D Printing in China and Its Significance for B2B Buyers?

The evolution of 3D printing in China can be traced back to the early 2000s when the technology was primarily used for prototyping. Over the years, it has transformed into a comprehensive manufacturing solution, with applications across various sectors. Significant investments from both the government and private enterprises have propelled China to the forefront of the global 3D printing market.

This evolution is crucial for B2B buyers as it signifies a shift towards more innovative and efficient manufacturing solutions. China’s rapid advancements in 3D printing technologies present unique opportunities for international buyers to access cutting-edge products and services. By understanding this historical context, buyers can better appreciate the potential advantages of engaging with Chinese suppliers who are leading the charge in 3D printing innovation.

Frequently Asked Questions (FAQs) for B2B Buyers of 3d printing china

- How do I find reliable 3D printing suppliers in China?

To find reliable 3D printing suppliers in China, start by utilizing platforms such as Alibaba, Made-in-China, or Global Sources. Look for suppliers with verified credentials and positive reviews. It’s also beneficial to request samples of their work to assess quality firsthand. Engage in direct communication to gauge their responsiveness and willingness to customize your orders. Additionally, consider attending industry trade shows in China to meet suppliers in person and build trust.

-

What are the common customization options available for 3D printing in China?

Most 3D printing suppliers in China offer a wide range of customization options, including material selection (like PLA, ABS, or resin), size, color, and design specifications. Some suppliers may also provide post-processing services such as painting, polishing, or assembly. When discussing customization, be clear about your requirements and ask for a prototype or sample to ensure the final product meets your expectations. -

What is the minimum order quantity (MOQ) for 3D printing services in China?

The minimum order quantity (MOQ) for 3D printing services can vary significantly based on the supplier and the complexity of the project. Some suppliers may accept single-item orders, while others might require a MOQ of 50 to 100 pieces. Always confirm the MOQ during your initial discussions, as larger orders often lead to reduced per-unit costs and better negotiation opportunities. -

What payment terms should I expect when sourcing 3D printing from China?

Payment terms for sourcing 3D printing services from China typically involve a deposit (usually 30-50%) upfront, with the balance due before shipment. Some suppliers may offer flexible payment options, including letter of credit or PayPal for smaller transactions. Ensure you discuss and agree on payment terms in advance, and consider using escrow services for added security in transactions.

-

How can I ensure quality assurance in my 3D printing orders from China?

To ensure quality assurance in your 3D printing orders, establish clear quality criteria before production begins. Request detailed specifications, including material certifications and production techniques. It’s also advisable to conduct regular communication with your supplier throughout the production process. If possible, consider hiring a third-party inspection service to verify product quality before shipment. -

What are the logistics considerations for shipping 3D printed products from China?

When shipping 3D printed products from China, consider factors such as shipping methods (air freight vs. sea freight), customs clearance, and delivery times. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments. Ensure your supplier provides all necessary documentation for customs, and be aware of any import duties or taxes applicable in your country. -

How do I handle communication barriers with Chinese suppliers?

To effectively handle communication barriers with Chinese suppliers, use clear and concise language, avoiding jargon and idioms. Utilize translation tools if necessary, and consider hiring a local intermediary or sourcing agent who speaks both English and Mandarin. Establishing regular check-ins via email or video calls can also help maintain a clear line of communication and prevent misunderstandings.

- What are the trends in 3D printing technology that I should be aware of?

Stay informed about emerging trends in 3D printing technology, such as advancements in materials (like bioplastics), speed improvements in printing processes, and the integration of AI in design optimization. Understanding these trends can help you make informed decisions about which technologies to adopt for your business. Additionally, consider how these innovations might enhance your product offerings or production efficiency.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 3d printing china

In the dynamic landscape of 3D printing in China, international B2B buyers are presented with unique opportunities for strategic sourcing that can enhance their operational efficiencies and product offerings. Key takeaways include the importance of establishing robust relationships with reliable suppliers, understanding the technological advancements in 3D printing, and leveraging China’s manufacturing capabilities to reduce costs while maintaining quality.

Strategic sourcing is not merely a procurement tactic; it is a holistic approach that allows companies to align their sourcing strategies with broader business goals. By focusing on long-term partnerships and innovation, buyers can tap into China’s vast resources and expertise, ensuring they remain competitive in their respective markets.

As we look to the future, the potential for 3D printing in diverse sectors such as automotive, healthcare, and consumer goods is immense. For businesses in Africa, South America, the Middle East, and Europe, the time to act is now. Engage with Chinese manufacturers, explore collaborative opportunities, and harness the power of 3D printing to propel your business forward. The journey toward innovation begins with a strategic sourcing plan—take the first step today.