Unlock Savings: The Complete Guide to Basketball Custom (2025)

Introduction: Navigating the Global Market for basketball custom

Navigating the global market for basketball custom products presents unique challenges for international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe. With an increasing demand for personalized sports equipment, sourcing high-quality, custom basketball products that meet both performance and aesthetic needs can be daunting. Buyers often grapple with issues such as supplier reliability, product quality, and competitive pricing, which can significantly impact their purchasing decisions.

This comprehensive guide delves into the multifaceted world of basketball custom products, covering various aspects such as types of customizations available, potential applications in different markets, and essential supplier vetting processes. Additionally, we will explore cost considerations and provide insights into negotiating favorable terms with suppliers.

By equipping international B2B buyers with actionable insights, this guide empowers you to make informed purchasing decisions. Whether you’re a team manager in Brazil seeking unique jersey designs or a distributor in Europe looking to expand your product line with custom basketball gear, our expert analysis will help you navigate this competitive landscape. Embrace the opportunity to enhance your offerings and meet the evolving demands of basketball enthusiasts globally.

Understanding basketball custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Team Jerseys | Unique designs, team colors, player names, and numbers. | Sports teams, schools, recreational leagues. | Pros: Boosts team identity; Cons: Higher costs. |

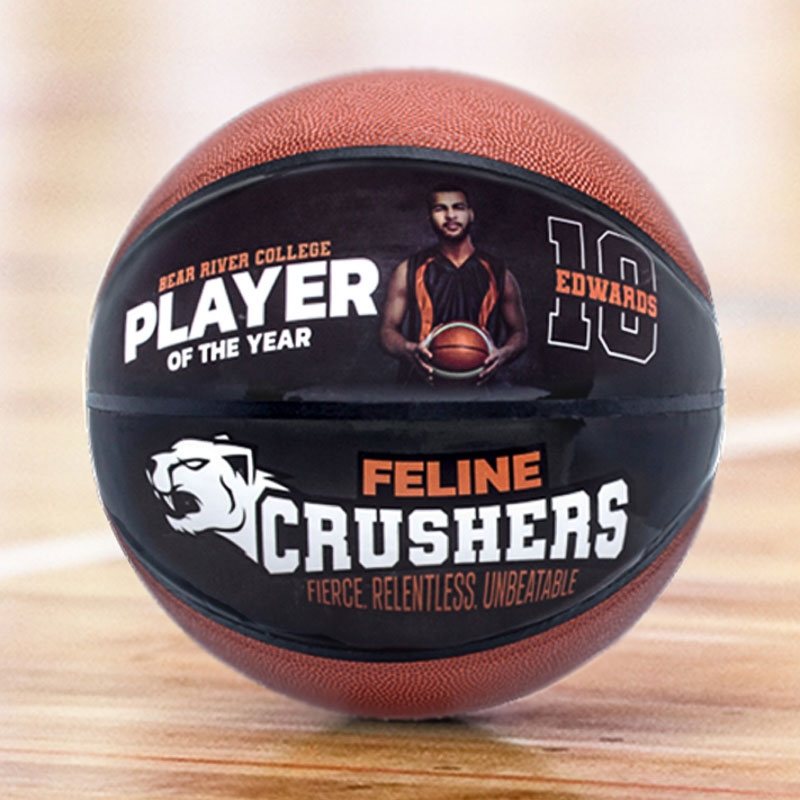

| Personalized Basketballs | Custom logos, colors, and sizes tailored to clients. | Promotional events, giveaways, branding. | Pros: Effective marketing tool; Cons: MOQ may apply. |

| Branded Sports Equipment | Includes custom hoops, nets, and training gear. | Schools, gyms, sports facilities. | Pros: Enhances facility branding; Cons: Longer lead times. |

| Custom Court Designs | Unique court layouts, logos, and color schemes. | Professional teams, recreational centers. | Pros: Distinctive appearance; Cons: High installation costs. |

| Specialty Apparel | Custom warm-ups, shorts, and accessories. | Teams, merchandise retailers. | Pros: Expands product range; Cons: Size and fit issues. |

What Are the Key Features of Custom Team Jerseys in B2B Basketball Purchases?

Custom team jerseys are a staple in the basketball industry, allowing teams to showcase their identity. These jerseys can be tailored with unique designs, team colors, and player names and numbers. For B2B buyers, especially schools and recreational leagues, investing in custom jerseys can enhance team spirit and visibility. While the initial costs may be higher than standard jerseys, the long-term benefits of team cohesion and brand recognition often outweigh these expenses.

How Do Personalized Basketballs Serve B2B Marketing Goals?

Personalized basketballs provide an excellent avenue for branding and marketing. Companies can customize basketballs with their logos, colors, and sizes, making them ideal for promotional events, giveaways, or corporate branding. For B2B buyers, these products serve as effective marketing tools that can enhance brand visibility. However, buyers should consider minimum order quantities (MOQ), which could impact budget and inventory management.

What Are the Benefits of Branded Sports Equipment for Facilities?

Branded sports equipment, including custom hoops, nets, and training gear, plays a significant role in enhancing the overall experience at sports facilities. Schools and gyms can use these products to reinforce their brand identity while providing quality equipment for athletes. The main advantage for B2B buyers is the ability to create a cohesive branding experience. However, longer lead times for custom orders can be a drawback, necessitating careful planning.

Why Are Custom Court Designs Important for Professional Teams?

Custom court designs offer professional teams a unique way to express their brand and create a memorable fan experience. By incorporating distinctive layouts, logos, and color schemes, teams can elevate their home court’s visual appeal. For B2B buyers, especially those managing recreational centers or professional teams, the investment can significantly enhance the facility’s attractiveness. However, buyers must be prepared for higher installation costs and maintenance considerations.

How Can Specialty Apparel Expand Product Offerings for Teams?

Specialty apparel, including custom warm-ups, shorts, and accessories, allows teams and merchandise retailers to expand their product range. This customization can cater to various team needs and preferences, ultimately driving sales and customer loyalty. For B2B buyers, the opportunity to offer a wider selection of gear can be a competitive advantage. However, considerations regarding size and fit issues should be made to ensure customer satisfaction.

Related Video: I Surprised Steph Curry With Custom Shoes

Key Industrial Applications of basketball custom

| Industry/Sector | Specific Application of basketball custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports Equipment | Custom basketballs for teams and leagues | Enhanced brand recognition and team cohesion | Quality control, customization options, delivery timelines |

| Event Management | Branded basketballs for promotional events | Increased engagement and brand visibility | Minimum order quantities, design capabilities, pricing |

| Education and Training | Custom training basketballs for schools and academies | Improved training outcomes and student engagement | Durability, safety standards, and compliance with educational regulations |

| Retail and Merchandising | Customized basketball merchandise for retail stores | Diverse product offerings and increased sales potential | Licensing agreements, inventory management, and market trends |

| Corporate Branding | Promotional basketballs for corporate events and giveaways | Strengthened brand loyalty and customer relations | Customization options, cost-effectiveness, and lead times |

How Are Custom Basketballs Used in Sports Equipment?

In the sports equipment sector, custom basketballs are integral for teams and leagues looking to establish a unique identity. These basketballs can be tailored with specific colors, logos, and designs that reflect team branding. This not only enhances brand recognition but also fosters team cohesion among players. For international buyers, especially in regions like Africa and South America, sourcing involves ensuring quality control and the availability of various customization options to meet unique regional preferences.

What Role Do Custom Basketballs Play in Event Management?

Custom basketballs serve as effective promotional tools during events. Organizations can use branded basketballs to engage participants and increase brand visibility. During sports events, giveaways featuring these custom products can create memorable experiences for attendees. For businesses in the Middle East and Europe, key sourcing considerations include minimum order quantities and the ability to create unique designs that resonate with local audiences, ensuring a successful promotional impact.

How Can Educational Institutions Benefit from Custom Training Basketballs?

Educational institutions utilize custom training basketballs to enhance their sports programs. These basketballs can be designed to meet specific training needs, such as size, weight, and grip, which can lead to improved training outcomes and student engagement. For buyers in Europe and South America, it is crucial to consider durability and safety standards, as well as compliance with educational regulations, when sourcing these products for schools and academies.

Why Are Customized Basketball Merchandise Important for Retail?

In the retail sector, customized basketball merchandise, including basketballs, can significantly diversify product offerings. By providing unique, branded items, retailers can attract more customers and increase sales potential. For international buyers, understanding market trends and managing inventory effectively are key sourcing considerations, ensuring that the merchandise aligns with consumer demand and local preferences.

How Can Corporations Use Custom Basketballs for Branding?

Corporate branding strategies often include promotional products like custom basketballs. These items can be used in corporate events or as giveaways to strengthen brand loyalty and customer relations. For B2B buyers, particularly in emerging markets, it is essential to evaluate customization options and cost-effectiveness, while also considering lead times to ensure timely delivery for events.

Related Video: Sci6 Q3 – Characteristics and Uses of Simple Machines

3 Common User Pain Points for ‘basketball custom’ & Their Solutions

Scenario 1: Customization Delays in Order Fulfillment

The Problem: One of the most significant challenges B2B buyers face when ordering custom basketball equipment is delays in the fulfillment process. Buyers, particularly from regions like Africa or South America, may experience long lead times due to production backlogs or shipping issues. This can be particularly damaging if the equipment is needed for a specific event, such as a tournament or school season. When buyers are counting on timely deliveries to meet their commitments, any delay can cause disruptions in their operations and potentially harm their reputation with clients or partners.

The Solution: To mitigate the risk of delays, B2B buyers should establish clear timelines with suppliers before placing orders. It’s crucial to set realistic expectations regarding production and shipping times, particularly when dealing with international suppliers. Additionally, buyers should consider sourcing from suppliers who offer expedited shipping options or have local warehouses in the region to shorten delivery times. Establishing a robust communication channel with the supplier can help buyers stay informed about the status of their order, allowing them to make contingency plans if necessary.

Scenario 2: Quality Inconsistencies in Custom Basketball Gear

The Problem: Quality inconsistency is another prevalent issue that B2B buyers encounter, especially when sourcing custom basketball gear from different manufacturers. Variations in materials, stitching, and overall craftsmanship can lead to dissatisfaction, particularly when products do not meet the expected standards or specifications. This situation is particularly critical for brands that rely on their reputation for quality in competitive markets across Europe and the Middle East.

The Solution: To ensure quality consistency, buyers should implement a thorough vetting process when selecting suppliers. This includes requesting samples of the basketball gear before placing bulk orders to assess quality firsthand. Establishing clear specifications and quality standards in the contract can also help set expectations. Additionally, buyers may benefit from creating a quality assurance checklist that suppliers must adhere to during production. Regular communication and site visits can further enhance oversight, ensuring that the products delivered align with the promised quality.

Scenario 3: Navigating Diverse Regulations for Custom Basketball Equipment

The Problem: B2B buyers must navigate a complex landscape of regulations when importing custom basketball equipment, which can vary significantly from one region to another. For instance, countries in Europe may have stringent safety and material regulations, while buyers in Africa might face different compliance requirements. Failing to adhere to these regulations can result in costly fines, delays at customs, or even the rejection of shipments, severely affecting business operations.

The Solution: To navigate these regulatory challenges, buyers should conduct thorough research on the import regulations in their target markets. Engaging with local legal or compliance experts can provide invaluable insights and ensure that all required documentation is in order before shipment. It’s also advisable to work with suppliers who are experienced in international trade and understand the regulatory landscape of the buyer’s home country. By fostering a partnership with suppliers who prioritize compliance, buyers can significantly reduce the risks associated with customs and ensure a smoother import process.

Strategic Material Selection Guide for basketball custom

What Are the Common Materials Used in Basketball Custom Manufacturing?

When selecting materials for basketball custom products, it is essential to understand the properties, advantages, and limitations of various options. Here, we analyze four commonly used materials: synthetic leather, rubber, polyester, and nylon.

How Does Synthetic Leather Perform in Basketball Custom Products?

Key Properties: Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers excellent durability and a high-quality feel. It can withstand varying temperatures and pressures, making it suitable for diverse playing conditions.

Pros & Cons: The primary advantage of synthetic leather is its durability and resistance to wear and tear. It is also easier to clean than natural leather. However, it can be more expensive than other materials and may not provide the same breathability as genuine leather, which could affect comfort during prolonged use.

Impact on Application: Synthetic leather is compatible with various media, including moisture and sweat, making it ideal for basketballs. Its non-porous nature also helps in maintaining the ball’s shape over time.

Considerations for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should ensure compliance with local regulations regarding synthetic materials. Common standards such as ASTM and REACH in Europe may apply, emphasizing the need for transparency in sourcing materials.

What Role Does Rubber Play in Basketball Custom Manufacturing?

Key Properties: Rubber is known for its high elasticity and resilience, which allows it to absorb shocks effectively. It performs well under different temperature ranges and has good abrasion resistance.

Pros & Cons: The key advantage of rubber is its cost-effectiveness and versatility, making it suitable for both indoor and outdoor basketballs. However, lower-quality rubber can degrade faster when exposed to UV light, leading to a shorter lifespan.

Impact on Application: Rubber’s flexibility makes it an excellent choice for the outer layer of basketballs, ensuring a good grip and bounce. It is also compatible with various playing surfaces, from hardwood to asphalt.

Considerations for International Buyers: Buyers should consider the quality of rubber used, as there are significant variations. Compliance with international standards like JIS for rubber materials is crucial, especially in regions with strict regulations.

Why is Polyester a Preferred Material for Basketball Custom Products?

Key Properties: Polyester is a synthetic fiber known for its strength and resistance to shrinking and stretching. It can withstand high temperatures and is resistant to mildew and abrasion.

Pros & Cons: The main advantage of polyester is its lightweight nature, making it ideal for basketball jerseys and uniforms. It is also cost-effective. However, polyester can retain odors and may not be as breathable as natural fibers, which could affect comfort during gameplay.

Impact on Application: Polyester is widely used in the manufacturing of basketball uniforms, offering durability and ease of maintenance. It is compatible with moisture-wicking treatments, enhancing player comfort.

Considerations for International Buyers: Buyers should ensure that polyester products meet local textile standards, such as those set by ASTM or ISO. Awareness of ethical sourcing and environmental impact is also increasingly important in regions like Europe.

How Does Nylon Compare in Basketball Custom Applications?

Key Properties: Nylon is a synthetic polymer known for its high tensile strength and elasticity. It performs well under stress and can resist wear and tear effectively.

Pros & Cons: The key advantage of nylon is its durability and lightweight nature, making it suitable for various basketball applications, including nets and straps. However, it can be more expensive than polyester and may absorb moisture, which could lead to discomfort.

Impact on Application: Nylon is often used in basketball nets and bags, providing excellent performance under dynamic conditions. Its compatibility with different media makes it versatile for various basketball-related products.

Considerations for International Buyers: International buyers should verify that nylon products comply with local regulations, especially in terms of chemical safety and environmental impact. Standards like DIN and ISO are relevant in Europe, while buyers in Africa and South America should be aware of local compliance requirements.

Summary Table of Material Selection for Basketball Custom Products

| Material | Typical Use Case for basketball custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Synthetic Leather | Basketballs, uniforms | High durability and quality feel | Higher cost, less breathability | High |

| Rubber | Outdoor basketballs | Cost-effective, versatile | Degrades under UV exposure | Low |

| Polyester | Jerseys, uniforms | Lightweight, durable | Retains odors, less breathable | Medium |

| Nylon | Nets, bags | High strength and elasticity | More expensive, moisture absorption | Medium |

This guide provides a comprehensive overview of material selection for basketball custom products, emphasizing the importance of understanding material properties and their implications for international B2B buyers.

In-depth Look: Manufacturing Processes and Quality Assurance for basketball custom

What Are the Typical Manufacturing Processes for Custom Basketballs?

The manufacturing of custom basketballs is a detailed process that involves several critical stages: material preparation, forming, assembly, and finishing. Each stage employs specific techniques that ensure the final product meets the quality and performance expectations of international buyers.

How Is Material Prepared for Custom Basketball Production?

The first step in the manufacturing process is material preparation. High-quality synthetic leather or rubber is typically chosen for the outer cover due to its durability and performance characteristics. During this stage, materials are cut into specific patterns that correspond to the design of the basketball.

Additionally, the bladder, which holds the air, is often made from latex or butyl rubber. The quality of these materials is crucial, as they affect both the feel and longevity of the basketball. B2B buyers should ensure that suppliers source materials from reputable manufacturers that comply with international standards, thus guaranteeing the performance of the final product.

What Techniques Are Used in Forming and Assembly?

Once the materials are prepared, the forming stage begins. This usually involves molding the outer cover over the bladder. Techniques such as compression molding or injection molding may be employed, depending on the design complexity and production volume.

After forming, the assembly process takes place. This includes stitching or bonding the panels together to create the final shape of the basketball. Advanced techniques, such as heat sealing, may be used to enhance durability and performance. During this phase, manufacturers must adhere to strict tolerances to ensure the basketballs meet specified standards.

What Are the Finishing Processes for Custom Basketballs?

The finishing stage is critical for aesthetics and performance. This may involve additional treatments such as surface texturing, which improves grip, and applying logos or custom designs. Quality assurance is vital here to ensure that all branding meets the client’s specifications without affecting the basketball’s performance.

What Quality Assurance Standards Are Relevant for Custom Basketball Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that the final product meets international standards. B2B buyers should be aware of various certifications and standards that pertain to custom basketballs.

Which International Standards Should B2B Buyers Consider?

ISO 9001 is a widely recognized standard for quality management systems. Manufacturers adhering to ISO 9001 demonstrate their commitment to consistent quality and customer satisfaction. Additionally, industry-specific certifications, such as CE marking in Europe, indicate compliance with health, safety, and environmental protection standards.

For sports equipment, manufacturers may also pursue certifications related to performance and safety, ensuring that the basketballs are suitable for professional play. Buyers should verify these certifications to ensure they are sourcing from compliant suppliers.

What Are the Key Quality Control Checkpoints in Basketball Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process, ensuring that defects are identified and rectified before the product reaches the market.

How Are QC Checkpoints Implemented?

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon delivery. Manufacturers should assess materials for defects or inconsistencies that could affect the final product.

-

In-Process Quality Control (IPQC): During the manufacturing stages, regular inspections and tests are conducted to ensure that each step adheres to established standards. This includes monitoring the molding and assembly processes.

-

Final Quality Control (FQC): Once production is complete, the basketballs undergo a final inspection. This includes tests for air retention, weight, and bounce characteristics, ensuring they meet specified performance criteria.

What Testing Methods Are Commonly Used in Custom Basketball Production?

Several testing methods are employed to evaluate the quality and performance of custom basketballs. These include:

- Pressure Testing: Ensures that the bladder maintains air pressure over time.

- Bounce Testing: Measures the height and consistency of the bounce, confirming that the basketball meets performance standards.

- Durability Testing: Involves subjecting the basketballs to wear-and-tear conditions to assess their longevity.

B2B buyers should inquire about the testing protocols used by manufacturers, as these directly impact the quality of the products.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Verification of a supplier’s quality control processes is essential for B2B buyers. Here are actionable steps to ensure that suppliers meet quality standards:

What Audit Procedures Should Be Followed?

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures firsthand. This can provide insight into the supplier’s capabilities and compliance with standards.

-

Requesting Quality Reports: Buyers should ask for detailed reports on quality inspections, including any issues encountered and how they were resolved. This transparency can foster trust and reliability.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased assessment of the manufacturing process and product quality. These services can verify compliance with international standards and provide additional assurance.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is crucial.

How Do Regional Standards Affect Quality Assurance?

Different regions may have varying standards and expectations regarding quality control. Buyers should familiarize themselves with local regulations, such as those enforced by the African Standards Organization or the Brazilian National Institute of Metrology, Quality and Technology (INMETRO).

Additionally, understanding the cultural differences in manufacturing practices can help buyers establish more effective communication with suppliers, ensuring that quality expectations are clearly defined and met.

Conclusion

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for custom basketballs is essential for B2B buyers. By focusing on material preparation, forming, assembly, finishing, and implementing robust quality control measures, buyers can ensure they are sourcing high-quality products that meet international standards. Engaging in audits, requesting quality reports, and utilizing third-party inspections are effective strategies for verifying supplier capabilities, ultimately leading to successful and reliable partnerships in the global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘basketball custom’

To ensure a successful procurement process for custom basketball products, international B2B buyers should follow a structured checklist. This guide outlines essential steps to help streamline sourcing, ensuring quality, compliance, and suitability for your specific needs.

Step 1: Define Your Technical Specifications

Clearly outline your requirements, including materials, sizes, designs, and performance features. This step is vital as it sets the foundation for all subsequent evaluations and communications with suppliers. Detailed specifications help avoid misunderstandings and ensure that the final product meets your expectations.

- Material Quality: Specify the type of fabric or leather needed.

- Design Elements: Include logos, colors, and any unique designs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers with a strong reputation and relevant experience in the custom basketball market. This step is crucial to ensure you partner with reliable manufacturers who can deliver high-quality products.

- Online Platforms: Utilize B2B marketplaces like Alibaba or Global Sources.

- Trade Shows: Attend industry-specific trade shows to meet suppliers and view samples.

Step 3: Evaluate Supplier Certifications

Before moving forward, verify the certifications of potential suppliers. This includes quality management systems (like ISO 9001) and compliance with safety standards. Certifications provide assurance that the supplier adheres to industry regulations and maintains a standard of quality.

- Request Documentation: Ask for copies of certifications and compliance reports.

- Check for Sustainability: Consider suppliers with eco-friendly certifications if sustainability is a priority.

Step 4: Request Samples

Always request samples of the custom basketball products before making a bulk order. This step allows you to assess the quality, craftsmanship, and adherence to your specifications.

- Quality Assessment: Examine the materials, stitching, and overall finish.

- Performance Testing: If possible, test the products for durability and performance in real conditions.

Step 5: Negotiate Pricing and Terms

Engage in negotiations regarding pricing, payment terms, and delivery schedules. This step is essential for establishing a mutually beneficial agreement and ensuring that your budget aligns with supplier offerings.

- Bulk Discounts: Inquire about pricing reductions for larger orders.

- Payment Methods: Discuss payment options, including letters of credit or escrow services for added security.

Step 6: Finalize Contracts

Once you’ve selected a supplier, draft a detailed contract outlining all agreed terms, including delivery timelines, quality expectations, and penalties for non-compliance. This contract serves as a legal safeguard for both parties.

- Legal Review: Consider having a legal expert review the contract to ensure all terms are clear and enforceable.

- Dispute Resolution: Include clauses for resolving potential disputes amicably.

Step 7: Plan for Logistics and Distribution

Finally, strategize the logistics of transporting the custom basketball products to your location. This step is crucial to ensure timely delivery and minimize additional costs.

- Shipping Options: Evaluate various shipping methods (air vs. sea) based on urgency and cost.

- Customs Regulations: Familiarize yourself with customs regulations in your country to avoid unexpected delays.

By following this comprehensive checklist, B2B buyers can effectively navigate the complexities of sourcing custom basketball products, ensuring they receive quality items that meet their specific needs.

Comprehensive Cost and Pricing Analysis for basketball custom Sourcing

When considering the costs associated with sourcing custom basketball products, it’s vital to understand the various components that contribute to the overall pricing structure. This analysis aims to provide actionable insights for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe.

What Are the Main Cost Components in Basketball Custom Sourcing?

-

Materials: The choice of materials is fundamental in determining the overall cost. High-quality leather or synthetic materials will increase the price but can enhance performance and durability. Buyers should evaluate the trade-off between cost and quality, especially when aiming for premium products.

-

Labor: Labor costs vary significantly by region. Countries with lower labor costs, such as those in Southeast Asia, may offer more competitive pricing. However, labor quality should not be compromised, as skilled craftsmanship is essential for producing high-quality basketballs.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. Understanding the supplier’s overhead can provide insight into their pricing strategy. Buyers should inquire about these costs to ensure they are not overpaying.

-

Tooling: Custom designs require specialized tooling, which can be a significant upfront cost. Buyers should consider whether they can negotiate tooling costs based on order volume or if they can share tooling with other buyers to mitigate expenses.

-

Quality Control (QC): Implementing rigorous QC processes is crucial to ensure product consistency and compliance with international standards. While this adds to the cost, it can prevent costly returns and reputational damage from defective products.

-

Logistics: Shipping and handling costs are often overlooked but can significantly affect total expenses. Factors such as shipping distance, mode of transportation, and import duties must be considered. Using Incoterms effectively can clarify responsibilities for shipping and help control costs.

-

Margin: Finally, the supplier’s margin is an essential component of the price. Understanding the market landscape can help buyers negotiate better terms and seek suppliers who offer competitive margins without compromising quality.

How Do Price Influencers Impact Custom Basketball Costs?

Several factors influence the pricing of custom basketballs:

-

Volume/MOQ: Higher order volumes often result in lower per-unit costs. Buyers should assess their current and future needs to leverage economies of scale effectively.

-

Specifications/Customization: Custom designs and specifications can significantly increase costs. Buyers should clearly define their requirements and seek suppliers who can accommodate these needs without excessive charges.

-

Quality/Certifications: Products that meet specific quality standards or certifications (such as ISO) may come at a premium. Buyers should consider the long-term benefits of investing in certified products, which can enhance brand reputation.

-

Supplier Factors: The supplier’s experience, reputation, and location can all impact pricing. Engaging with well-established suppliers may provide better reliability and quality assurance, justifying a potentially higher price.

-

Incoterms: Understanding different Incoterms can help buyers manage costs associated with shipping and logistics. Selecting the right terms can minimize unexpected expenses and clarify who bears risks during transport.

What Are the Best Buyer Tips for Negotiating Custom Basketball Prices?

-

Negotiate with Suppliers: Always engage in negotiations. Suppliers often have flexibility in pricing, especially for larger orders or long-term partnerships.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership rather than just the initial purchase price. Consider factors such as durability, warranty, and potential return on investment.

-

Understand Pricing Nuances: International B2B buyers should be aware of currency fluctuations and geopolitical factors that may affect pricing. Establishing contracts in a stable currency can mitigate risks.

-

Research Market Trends: Keeping abreast of market trends and competitor pricing can provide leverage in negotiations. Use this information to benchmark offers and make informed decisions.

Conclusion

In conclusion, a comprehensive understanding of the cost structure and pricing influences in custom basketball sourcing is essential for international B2B buyers. By considering the various components and employing strategic negotiation techniques, buyers can achieve favorable pricing while ensuring product quality and reliability. Always remember that indicative prices can vary based on market conditions, so maintaining flexibility and open communication with suppliers is critical.

Alternatives Analysis: Comparing basketball custom With Other Solutions

When considering the implementation of basketball custom solutions, it’s essential to evaluate alternative options available in the market. Different solutions can offer unique advantages and drawbacks, impacting performance, cost, and suitability for specific business needs. This analysis will compare basketball custom against two viable alternatives: generic basketball equipment and digital basketball training platforms.

Comparison Table

| Comparison Aspect | Basketball Custom | Generic Basketball Equipment | Digital Basketball Training Platforms |

|---|---|---|---|

| Performance | High-quality, tailored to user specifications | Standardized, variable quality | Interactive, data-driven insights |

| Cost | Higher initial investment | Generally lower cost | Subscription-based, scalable costs |

| Ease of Implementation | Requires planning and customization | Quick to procure and set up | User-friendly, minimal setup needed |

| Maintenance | May require specialized care | Standard maintenance practices | Regular updates and tech support |

| Best Use Case | Professional teams and leagues | Recreational use, schools | Training facilities, individual athletes |

How Does Basketball Custom Compare to Generic Basketball Equipment?

Pros: Basketball custom solutions are designed to meet the specific needs of a team or organization. They can enhance performance through tailored designs, such as size, materials, and features that align with a team’s play style. This customization can lead to a stronger team identity and improved player morale.

Cons: The initial investment for basketball custom can be significantly higher compared to generic equipment. Organizations may face longer lead times due to the design and production processes involved, which can delay implementation.

What Are the Advantages of Digital Basketball Training Platforms?

Pros: Digital basketball training platforms provide interactive training experiences that can analyze player performance through data. These platforms often include video analysis, performance tracking, and tailored training regimens, making them ideal for individual athletes or teams looking to enhance their skills in a measurable way. They are generally easy to implement and can be accessed remotely, allowing for flexible training schedules.

Cons: While digital platforms are cost-effective in the long run, they typically require a subscription fee, which can add up over time. Additionally, the effectiveness of these platforms depends heavily on user engagement and the willingness of players to adapt to technology-driven training.

Conclusion: How Should B2B Buyers Choose the Right Basketball Solution?

When selecting between basketball custom and its alternatives, B2B buyers should consider their specific goals, budget constraints, and the intended use of the equipment or service. For professional teams or organizations seeking to establish a strong identity and enhance performance, basketball custom may be the best option despite its higher costs and longer implementation times. Conversely, for schools or recreational leagues, generic basketball equipment may suffice for their needs. Lastly, for training facilities or individual athletes focused on skill development, digital basketball training platforms offer an innovative and engaging approach that can yield measurable results. Ultimately, the decision should align with the organization’s vision and operational requirements.

A stock image related to basketball custom.

Essential Technical Properties and Trade Terminology for basketball custom

What Are the Key Technical Properties for Custom Basketballs?

A stock image related to basketball custom.

Understanding the technical specifications of custom basketballs is crucial for international B2B buyers looking to ensure quality and performance. Here are some essential properties to consider:

-

Material Grade

The material used in basketballs typically includes rubber, synthetic leather, or composite materials. Each material has its unique properties affecting durability, grip, and performance. For example, rubber is often used for outdoor basketballs due to its toughness, while synthetic leather offers a better grip for indoor play. Choosing the right material grade can significantly impact the longevity and usability of the product. -

Weight Tolerance

Basketballs are generally manufactured to weigh between 567 to 650 grams. It is vital to specify weight tolerance, as deviations can affect gameplay and player performance. A consistent weight ensures that the balls behave predictably during play, which is essential for training and competitive events. -

Circumference Measurements

Standard basketball sizes vary, with a typical circumference of 29.5 inches for men’s basketballs and 28.5 inches for women’s. Custom orders may require specific size adjustments. Ensuring accurate circumference measurements is crucial for compliance with official regulations and optimal player performance. -

Bounce Height

The bounce height of a basketball is typically between 49 to 54 inches when dropped from a height of 6 feet. This property is essential for maintaining gameplay standards. Buyers should request bounce height specifications to ensure the basketballs meet the desired performance criteria for various playing surfaces. -

Durability Rating

Durability ratings indicate how well a basketball can withstand wear and tear. Factors like the type of material and construction methods influence this rating. A higher durability rating is particularly important for outdoor basketballs, which face harsher conditions. Buyers should inquire about the expected lifespan of the product to make informed purchasing decisions.

What Are the Common Trade Terms in Basketball Custom Orders?

Familiarizing yourself with industry jargon can streamline the purchasing process and enhance communication with suppliers. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of custom basketballs, an OEM can provide tailored designs and specifications according to the buyer’s requirements. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for B2B buyers to align their purchasing strategies with supplier capabilities, particularly when ordering custom basketballs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products or services. For international buyers, sending an RFQ for custom basketballs can facilitate better price negotiation and understanding of supplier offerings. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps in clarifying shipping responsibilities, risk management, and costs associated with transporting custom basketballs across borders. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until it is delivered. Understanding lead times is essential for planning inventory and ensuring that products are available when needed, especially for time-sensitive events or seasons.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing custom basketballs, ensuring they meet both quality standards and market demands.

Navigating Market Dynamics and Sourcing Trends in the basketball custom Sector

What Are the Current Market Dynamics and Key Trends in the Basketball Custom Sector?

The basketball custom sector is experiencing robust growth fueled by several global drivers, including the rising popularity of basketball in emerging markets and a growing trend toward personalization in sports apparel and equipment. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking customized solutions that cater to local tastes and cultural preferences. The integration of advanced technologies, such as 3D printing and digital design tools, is revolutionizing how manufacturers create bespoke basketball gear, enabling rapid prototyping and lower production costs.

Emerging B2B tech trends include the use of artificial intelligence for predictive analytics, which helps suppliers forecast demand more accurately. Additionally, e-commerce platforms are becoming essential for sourcing, providing buyers with access to a broader range of suppliers and products. This shift towards online marketplaces facilitates competitive pricing and enhances transparency in the sourcing process.

Sustainability is also a significant factor in the current market dynamics. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to environmental responsibility, making it essential for businesses in the basketball custom sector to adapt their practices accordingly. This evolution in sourcing trends not only helps businesses comply with regulatory standards but also aligns with the growing consumer demand for sustainable products.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in the Basketball Custom Sector?

The environmental impact of manufacturing processes in the basketball custom sector cannot be overlooked. As international B2B buyers increasingly recognize the importance of sustainability, they are looking for suppliers who prioritize ethical sourcing and sustainable practices. This includes using eco-friendly materials, such as organic cotton and recycled polyester, which significantly reduce the carbon footprint of products.

Moreover, establishing ethical supply chains is critical for maintaining brand integrity and customer loyalty. Buyers should seek out suppliers who hold certifications such as Global Organic Textile Standard (GOTS) or Fair Trade, as these credentials indicate a commitment to responsible production practices. Implementing a comprehensive supplier evaluation process can help buyers assess the sustainability credentials of potential partners, ensuring that their sourcing aligns with both ethical standards and consumer expectations.

Incorporating ‘green’ certifications and materials into product offerings not only caters to the growing demand for sustainable options but also differentiates businesses in a competitive marketplace. By prioritizing sustainability, B2B buyers can foster long-term relationships with suppliers and contribute positively to the environment, ultimately enhancing their brand reputation.

What Is the Brief Evolution of the Basketball Custom Sector?

The basketball custom sector has evolved significantly over the past few decades, transitioning from a niche market to a thriving global industry. Initially, customization was limited to basic modifications, such as name and number printing on jerseys. However, with advancements in technology, the scope of customization has expanded dramatically.

In the early 2000s, the introduction of digital printing and embroidery technologies allowed for more intricate designs and personalization options. This evolution coincided with the global rise of basketball as a popular sport, particularly in urban areas. In recent years, the emphasis on sustainability and ethical sourcing has further shaped the landscape of the basketball custom sector, pushing manufacturers to innovate in both product design and supply chain management.

As the sector continues to grow, international B2B buyers must stay informed about emerging trends and adapt their sourcing strategies to leverage opportunities in customization, sustainability, and technological advancements.

Frequently Asked Questions (FAQs) for B2B Buyers of basketball custom

-

How do I ensure quality when sourcing custom basketball products?

To ensure quality, start by vetting potential suppliers through thorough research. Request samples to assess material quality and craftsmanship before placing larger orders. Look for suppliers with certifications, such as ISO or other relevant quality standards. Additionally, consider visiting the manufacturing facility if possible or using third-party inspection services to verify quality during production. Establishing clear communication regarding quality expectations and specifications is also crucial to minimize misunderstandings. -

What are the best practices for negotiating prices with custom basketball suppliers?

When negotiating prices, research market rates and understand your supplier’s cost structure. Start with a competitive offer based on comparable products. Highlight your potential for long-term partnership and larger orders, which can incentivize suppliers to offer better pricing. Be transparent about your budget constraints while remaining flexible on terms such as payment schedules or delivery timelines. Building a positive relationship can lead to better pricing and terms in the long run. -

What is the minimum order quantity (MOQ) for custom basketballs?

Minimum order quantities (MOQs) for custom basketballs can vary significantly between suppliers. Typically, MOQs may range from 100 to 500 units, depending on the complexity of customization and production capabilities. Discuss your needs directly with potential suppliers, as many are willing to negotiate MOQs, especially for first-time buyers or long-term contracts. Keep in mind that larger orders often lead to lower per-unit costs, making it beneficial to plan your order strategically. -

What payment terms should I expect when ordering custom basketball products?

Payment terms can vary by supplier but typically include options like a deposit (20-50%) upfront and the balance upon delivery or prior to shipment. Some suppliers may offer payment through letters of credit, especially for international transactions, which can provide additional security. Always clarify payment methods and terms before finalizing contracts to avoid misunderstandings and ensure a smooth transaction process. -

How can I customize basketball products to meet specific market needs?

To customize basketball products effectively, engage in detailed discussions with your supplier about your target market’s preferences. Consider factors such as size, color, branding, and materials. Utilizing local insights can also guide your customization decisions. Many suppliers offer design services that can help you visualize your ideas, so take advantage of these resources. Additionally, be prepared to provide clear design specifications and any necessary logos or branding elements for optimal results. -

What logistics considerations should I keep in mind when importing custom basketballs?

Logistics for importing custom basketballs involve several key considerations. First, understand the shipping options available, including air freight for faster delivery or sea freight for cost-effectiveness. Factor in customs duties, taxes, and import regulations specific to your country. Collaborating with a reliable logistics provider can help streamline the process. Ensure you have all necessary documentation, such as invoices and shipping manifests, to avoid delays at customs. -

How do I assess a supplier’s reliability for custom basketball orders?

Assessing a supplier’s reliability involves checking references and reading reviews from other buyers. Look for suppliers with a proven track record in your specific product category. Additionally, evaluate their communication responsiveness and willingness to provide detailed information about their processes. It may also be helpful to request financial statements or certificates of good standing to ensure their stability. Engaging in trial orders can further gauge their reliability before committing to larger purchases. -

What are the common quality assurance practices for custom basketball manufacturing?

Common quality assurance practices in custom basketball manufacturing include regular inspections at different production stages, from raw materials to final products. Suppliers often implement quality control checklists to ensure adherence to specifications. Third-party quality assurance services can also be employed for unbiased evaluations. It’s essential to establish quality standards and protocols with your supplier upfront, including acceptable defect rates and processes for handling returns or replacements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for basketball custom

In today’s competitive basketball custom market, strategic sourcing has become essential for international B2B buyers looking to optimize their procurement processes. By focusing on long-term partnerships with reliable manufacturers, businesses can secure high-quality products that meet their specific needs while also benefiting from cost efficiencies. Understanding regional trends in Africa, South America, the Middle East, and Europe is crucial, as these markets present unique opportunities and challenges.

How can international buyers leverage strategic sourcing to enhance their business outcomes? By evaluating suppliers based on their production capabilities, quality control measures, and compliance with international standards, buyers can mitigate risks associated with sourcing. Additionally, fostering transparent communication with suppliers will lead to better negotiation outcomes and more favorable contract terms.

Looking ahead, the basketball custom industry is poised for growth, driven by increasing demand for personalized and innovative products. International B2B buyers are encouraged to embrace this trend by investing in strategic sourcing practices that not only streamline operations but also position them as leaders in their markets. Engage with suppliers today to explore customized solutions that can elevate your brand and meet the evolving needs of your customers.