Unlock Savings: The Complete Guide to Crusher Manufacturers (2025)

Introduction: Navigating the Global Market for crusher manufacturer

In today’s global economy, sourcing the right crusher manufacturer can be a daunting task for international B2B buyers. The challenge lies not only in identifying quality suppliers but also in understanding the diverse types of crushers available and their specific applications in various industries. This guide aims to demystify the complexities of the crusher manufacturing sector, providing a comprehensive overview that covers everything from the different types of crushers, such as jaw, cone, and impact crushers, to their applications in sectors like construction, mining, and recycling.

International buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Kenya and Thailand, will find actionable insights tailored to their unique market needs. This guide will empower you to make informed purchasing decisions by offering strategies for effective supplier vetting, understanding cost structures, and recognizing critical factors that influence quality and reliability.

Whether you’re looking to expand your operations, upgrade your equipment, or optimize your supply chain, this resource serves as a crucial tool to navigate the global market for crusher manufacturers. With a focus on practical advice and industry best practices, you’ll be well-equipped to tackle the challenges of sourcing and procurement in this competitive landscape.

Understanding crusher manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Jaw Crushers | High compressive strength, simple design | Mining, construction, recycling | Pros: Versatile, easy maintenance. Cons: Limited to soft to medium materials. |

| Cone Crushers | Adjustable settings, efficient in secondary crushing | Aggregate production, mining | Pros: High reduction ratio, suitable for hard materials. Cons: Higher operational costs. |

| Impact Crushers | High-speed rotor, produces high-quality aggregate | Construction, demolition, recycling | Pros: Excellent for shaping materials. Cons: Can be less efficient on harder materials. |

| Gyratory Crushers | Large capacity, continuous operation | Large-scale mining, quarrying | Pros: Very efficient for large volumes. Cons: Requires significant investment and space. |

| Mobile Crushers | Portable, flexible configuration | On-site crushing, recycling | Pros: Versatile and space-saving. Cons: May compromise on capacity compared to stationary models. |

What Are the Characteristics of Jaw Crushers for B2B Buyers?

Jaw crushers are characterized by their high compressive strength and straightforward design, making them suitable for a variety of materials. They excel in primary crushing applications, particularly in mining and construction. For B2B buyers, the key consideration is maintenance ease and versatility, allowing for adaptability in different operational environments. However, they are generally limited to soft and medium-hard materials, which may restrict their applicability in certain sectors.

How Do Cone Crushers Serve International B2B Markets?

Cone crushers are known for their adjustable settings and high efficiency in secondary crushing applications. Their design allows for a high reduction ratio, making them particularly effective for hard materials. B2B buyers should consider the operational costs associated with cone crushers, as they can be higher than other types. However, the investment is often justified due to their performance in aggregate production and mining operations.

What Advantages Do Impact Crushers Offer for B2B Applications?

Impact crushers utilize a high-speed rotor to produce high-quality aggregate, making them ideal for construction and demolition projects. They are particularly effective at shaping materials, which is crucial for producing specific aggregate sizes. B2B buyers must weigh the benefits of excellent material shaping against the potential inefficiency when dealing with harder materials. This makes them a solid choice for projects requiring versatility and quality.

In What Situations Are Gyratory Crushers Most Effective for B2B Buyers?

Gyratory crushers are distinguished by their large capacity and ability to operate continuously, making them suitable for large-scale mining and quarrying operations. They provide significant efficiency when processing high volumes of materials. For B2B buyers, the key considerations include the need for substantial investment and adequate space for installation. Their efficiency in handling large quantities can outweigh these concerns for businesses focused on high-output operations.

How Do Mobile Crushers Fit into the Needs of B2B Buyers?

Mobile crushers offer portability and flexible configurations, making them ideal for on-site crushing and recycling applications. Their ability to adapt to various environments is a significant advantage for B2B buyers who require versatility. However, buyers should be aware that mobile crushers may compromise on capacity compared to stationary models. This trade-off is essential for businesses that prioritize mobility and the ability to process materials directly at the job site.

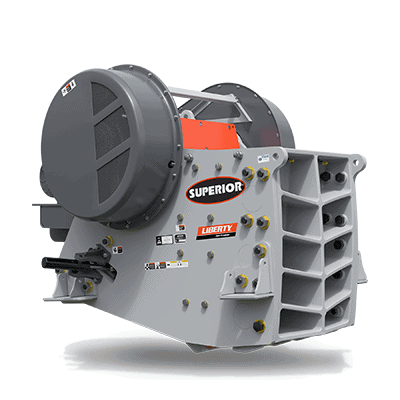

A stock image related to crusher manufacturer.

Related Video: Setting up and Running a Stone Crusher Plant Made Easy and Economical by CPC Ranchi

Key Industrial Applications of crusher manufacturer

| Industry/Sector | Specific Application of crusher manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Mining and Minerals | Crushing ores and minerals for extraction | Enhances material recovery and reduces processing costs | Reliability, maintenance support, and local service availability |

| Construction and Demolition | Aggregate production for concrete and roadworks | Provides high-quality materials, ensuring structural integrity | Compliance with local regulations and quality standards |

| Recycling | Processing waste materials and scrap metals | Promotes sustainability and reduces landfill costs | Equipment versatility and efficiency in handling diverse materials |

| Agriculture | Crushing agricultural waste for bioenergy | Supports waste management and sustainable energy production | Customization options and adaptability to various crop types |

| Chemical Manufacturing | Size reduction of raw materials for chemical processes | Improves process efficiency and product quality | Material compatibility and safety features in design |

How is Crusher Manufacturer Used in Mining and Minerals?

In the mining and minerals sector, crusher manufacturers provide essential equipment for crushing ores and minerals to facilitate extraction. These crushers are designed to handle large volumes of material, increasing the efficiency of the mining process. For international buyers, especially in Africa and South America, sourcing reliable and durable crushers is critical to minimize downtime and enhance material recovery rates. Buyers should consider the local availability of spare parts and maintenance services when evaluating suppliers.

What are the Applications of Crushers in Construction and Demolition?

In construction and demolition, crushers play a vital role in producing aggregates for concrete and roadworks. By converting large debris into manageable sizes, these machines ensure that the resulting materials meet quality standards for structural integrity. B2B buyers from regions such as Europe and the Middle East should prioritize crushers that comply with local regulations and offer consistent performance. Additionally, the ability to produce various aggregate sizes can be a significant advantage in diverse construction projects.

How Do Crushers Support Recycling Initiatives?

Crushers are instrumental in the recycling industry, where they process waste materials and scrap metals. By reducing the size of these materials, crushers facilitate easier handling and transportation, promoting sustainability and reducing landfill costs. International buyers, particularly in developing regions, should seek equipment that offers versatility and efficiency in handling a wide range of materials. Understanding the specific recycling needs of their local market will help buyers choose the most suitable crushing solutions.

What Role Do Crushers Play in Agriculture?

In agriculture, crushers are used to crush agricultural waste, making it suitable for bioenergy production. This process not only helps manage waste but also contributes to sustainable energy solutions. Buyers from regions with significant agricultural activities, such as Africa and South America, should look for crushers that can be customized to handle various crop types efficiently. The adaptability of the equipment to different agricultural waste materials is a crucial consideration for effective sourcing.

How are Crushers Utilized in Chemical Manufacturing?

In chemical manufacturing, crushers are employed for size reduction of raw materials, which is critical for optimizing chemical processes. By ensuring that materials are of the appropriate size, crushers enhance process efficiency and improve the quality of the final products. For international B2B buyers, particularly from Europe and the Middle East, sourcing crushers that are compatible with specific materials and designed with safety features is essential. Buyers should also consider the supplier’s experience in the chemical sector to ensure reliable performance.

Related Video: FANUC Industrial Robots | AUDI Case Study

3 Common User Pain Points for ‘crusher manufacturer’ & Their Solutions

Scenario 1: High Maintenance Costs for Crushers

The Problem:

B2B buyers often face significant operational challenges when it comes to the maintenance of crushers. This is particularly true for companies in harsh environments, such as those found in parts of Africa and the Middle East, where dust and debris can lead to frequent breakdowns. High maintenance costs not only impact profitability but can also cause project delays and loss of productivity. Buyers may find themselves dealing with unexpected repairs that strain budgets and disrupt production schedules.

The Solution:

To mitigate high maintenance costs, buyers should focus on selecting crushers designed for durability and ease of maintenance. When sourcing crushers, prioritize manufacturers that offer robust after-sales support and readily available spare parts. This will ensure that maintenance can be performed quickly and efficiently. Additionally, consider investing in predictive maintenance technologies that utilize sensors and IoT (Internet of Things) devices to monitor equipment condition in real-time. By adopting a proactive maintenance strategy, companies can reduce unplanned downtimes and extend the lifespan of their crushers.

Scenario 2: Inadequate Crusher Performance for Specific Materials

The Problem:

Another common pain point for international B2B buyers is the inability of crushers to perform effectively with specific materials, such as harder rocks or recycled aggregates. This can be particularly problematic in regions like South America, where the geological composition varies significantly. Buyers may invest in a crusher that underperforms, resulting in lower output quality and increased wear on the equipment.

The Solution:

To address performance issues, buyers should conduct thorough material analysis before purchasing a crusher. Engage with manufacturers who can provide customized solutions tailored to the specific materials you intend to process. Understanding the crushing requirements—such as hardness, moisture content, and particle size—will enable buyers to select the right type of crusher (e.g., jaw, cone, or impact). Additionally, consider trialing equipment through rental programs or demos to evaluate performance before making a significant investment. This approach will ensure that the chosen equipment meets your operational needs effectively.

Scenario 3: Limited Availability of Local Support and Spare Parts

The Problem:

For B2B buyers in regions like Africa and parts of Europe, one significant concern is the limited availability of local support and spare parts for crushers. This can lead to extended downtimes when repairs are needed, as sourcing parts from international suppliers can be time-consuming and costly. Buyers often find themselves grappling with the logistical challenges of importing parts, which can further exacerbate operational inefficiencies.

The Solution:

To overcome this challenge, buyers should prioritize partnering with manufacturers that have a strong presence in their region or offer local distribution networks. Research the manufacturer’s supply chain capabilities to ensure that spare parts are readily available. Additionally, consider establishing a relationship with local service providers who can assist with maintenance and repairs. Some manufacturers may offer training programs for local technicians, empowering them to perform basic repairs and maintenance on-site. By fostering local partnerships and ensuring access to parts, companies can significantly reduce downtime and enhance operational efficiency.

Strategic Material Selection Guide for crusher manufacturer

When selecting materials for crushers, it is crucial for international B2B buyers to consider the properties and performance characteristics of various materials. The choice of material can significantly impact the efficiency, durability, and overall cost-effectiveness of the equipment. Below are analyses of four common materials used in the manufacture of crushers, focusing on their key properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Steel in Crusher Manufacturing?

Steel is one of the most widely used materials in crusher manufacturing due to its excellent mechanical properties. It typically offers high tensile strength and toughness, making it suitable for handling heavy loads and impact forces. Steel can withstand elevated temperatures and pressures, which is essential in high-performance applications. Additionally, various grades of steel can provide different levels of corrosion resistance, depending on the alloying elements used.

Pros & Cons:

– Pros: High durability, good impact resistance, and relatively low cost.

– Cons: Prone to corrosion if not properly treated, which can lead to maintenance challenges.

Impact on Application:

Steel is compatible with a variety of media, including rocks and minerals, making it suitable for diverse crushing applications. However, its susceptibility to corrosion can limit its use in environments with high moisture or corrosive materials.

Considerations for International Buyers:

Buyers should ensure that the steel used complies with international standards such as ASTM or DIN. Additionally, local sourcing may reduce costs and improve supply chain efficiency.

How Does High-Performance Alloy Steel Enhance Crusher Efficiency?

High-performance alloy steel is engineered to provide enhanced strength and wear resistance compared to standard steel. This material often includes elements such as chromium, molybdenum, and nickel, which improve its hardness and toughness. High-performance alloy steel is particularly effective in high-impact and high-abrasion applications.

Pros & Cons:

– Pros: Superior wear resistance and longer service life.

– Cons: Higher manufacturing complexity and cost.

Impact on Application:

This material is ideal for crushing abrasive materials like granite and basalt, where traditional steel might wear out quickly. The enhanced properties allow for more extended operational periods without the need for frequent replacements.

Considerations for International Buyers:

Buyers should consider the availability of high-performance alloy steel in their regions and whether local suppliers can meet the necessary standards for quality assurance.

What Role Does Cast Iron Play in Crusher Manufacturing?

Cast iron is another common material used in the manufacturing of crushers, particularly for components such as frames and housings. It is known for its excellent castability and wear resistance. Cast iron can handle high compressive loads, making it suitable for stationary equipment.

Pros & Cons:

– Pros: Good wear resistance and cost-effective for large components.

– Cons: Brittle nature can lead to cracking under impact.

Impact on Application:

Cast iron is well-suited for applications involving less abrasive materials. However, its brittleness may limit its use in high-impact scenarios.

Considerations for International Buyers:

Buyers should assess the local availability of cast iron and ensure compliance with relevant standards, as variations in quality can affect performance.

Why is Rubber Important for Crusher Applications?

Rubber is often used in specific components of crushers, such as liners and dampeners, due to its excellent shock absorption and flexibility. It can effectively reduce noise and vibration, which is beneficial in urban or sensitive environments.

Pros & Cons:

– Pros: Excellent shock absorption and reduced wear on metal components.

– Cons: Limited temperature and chemical resistance compared to metals.

Impact on Application:

Rubber is particularly effective in applications where vibration reduction is crucial, such as mobile crushers. However, it may not be suitable for extremely high-temperature environments.

Considerations for International Buyers:

Buyers should ensure that the rubber used meets the necessary specifications for temperature and chemical exposure, particularly in regions with extreme climates.

Summary Table of Material Selection for Crusher Manufacturing

| Material | Typical Use Case for crusher manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | General-purpose crushers | High durability and low cost | Prone to corrosion | Low |

| High-Performance Alloy Steel | High-impact and abrasive applications | Superior wear resistance | Higher manufacturing complexity | High |

| Cast Iron | Frames and housings | Good wear resistance | Brittle nature under impact | Med |

| Rubber | Liners and dampeners | Excellent shock absorption | Limited temperature resistance | Med |

By understanding the properties and implications of these materials, international B2B buyers can make informed decisions that align with their operational needs and local market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for crusher manufacturer

What are the Main Stages of the Manufacturing Process for Crushers?

The manufacturing process for crushers typically involves several key stages: material preparation, forming, assembly, and finishing. Understanding these stages is critical for international B2B buyers looking to ensure product quality and reliability.

-

Material Preparation: The first stage involves selecting high-grade raw materials, such as steel alloys, that meet industry specifications. Suppliers should provide documentation verifying the material’s origin and compliance with international standards. Proper material preparation is crucial for the durability and performance of the crushers.

-

Forming Techniques: This stage includes techniques such as casting, forging, and machining. Casting is often used for complex shapes, while forging provides strength through compressive forces. Machining further refines the components to meet precise specifications. B2B buyers should inquire about the specific techniques used and how they impact the final product’s performance.

-

Assembly: The assembly process involves integrating various components, including the crusher frame, jaws, and drive mechanisms. This step requires skilled labor and precise alignment to ensure optimal performance. Buyers should look for manufacturers that utilize automated assembly techniques, as this can enhance consistency and reduce human error.

-

Finishing: The final stage involves surface treatments such as painting, coating, or heat treatment to enhance corrosion resistance and longevity. It is essential for buyers to understand the finishing processes employed and how they contribute to the overall lifespan of the equipment.

How is Quality Assurance Implemented in Crusher Manufacturing?

Quality assurance (QA) is a vital aspect of the manufacturing process, ensuring that products meet specified standards and customer expectations. For B2B buyers, understanding these QA processes can be the difference between a successful purchase and costly operational failures.

-

International Standards: Many manufacturers adhere to internationally recognized standards such as ISO 9001, which focuses on quality management systems. Compliance with ISO certifications indicates that a manufacturer has established processes for continuous improvement and customer satisfaction.

-

Industry-Specific Certifications: Depending on the application, crushers may also need to comply with industry-specific certifications such as CE marking for the European market or API standards for oil and gas applications. Buyers should verify that their suppliers have the necessary certifications relevant to their region and industry.

-

Quality Control Checkpoints: Implementing quality control checkpoints throughout the manufacturing process is essential. Key checkpoints include:

– Incoming Quality Control (IQC): Assessing the quality of raw materials upon arrival.

– In-Process Quality Control (IPQC): Monitoring the manufacturing processes to catch defects early.

– Final Quality Control (FQC): Conducting a thorough inspection of the finished product before shipment. -

Common Testing Methods: Various testing methods are employed to ensure product reliability, including tensile strength tests, hardness tests, and non-destructive testing (NDT). Buyers should ask for test reports and certifications to validate the manufacturer’s claims regarding product quality.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial to mitigate risks associated with procurement.

-

Conducting Supplier Audits: Regular audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. Audits should assess compliance with relevant standards, the effectiveness of QA processes, and overall operational efficiency.

-

Requesting Quality Reports: Buyers should not hesitate to request detailed quality reports from suppliers. These reports should include data on manufacturing processes, quality control measures, and results from any testing performed. A transparent supplier will readily provide this information.

-

Utilizing Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of a manufacturer’s quality assurance practices. These services can perform checks at various stages of the production process, providing an additional layer of assurance for buyers.

-

Understanding Certification Nuances: Different regions may have varying requirements for certifications and quality assurance. Buyers from Africa, South America, the Middle East, and Europe should familiarize themselves with local regulations and standards to ensure compliance and avoid any legal or operational issues.

What Should Buyers Consider Regarding Quality Control and Certifications?

When sourcing crushers, B2B buyers need to consider several factors related to quality control and certifications to ensure they are making informed purchasing decisions.

-

Regional Standards and Compliance: Buyers must be aware of the specific standards applicable in their regions. For example, EU buyers need to ensure that products meet CE standards, while buyers in the Middle East may need to comply with local regulations. Understanding these requirements can prevent costly delays and penalties.

-

Supplier Reputation and Track Record: Researching a supplier’s reputation in the industry can provide insights into their reliability and quality control practices. Look for testimonials, case studies, and reviews from other B2B buyers to gauge their experience with the supplier.

-

Long-Term Support and Warranty: Quality assurance doesn’t end at the point of sale. Buyers should inquire about the supplier’s warranty policies and post-purchase support. A solid warranty indicates confidence in the product’s quality and can provide peace of mind for buyers.

-

Continuous Improvement Practices: Manufacturers committed to continuous improvement will regularly update their processes and technologies. Buyers should look for suppliers that invest in research and development, which can lead to enhanced product performance and longevity.

A stock image related to crusher manufacturer.

By understanding these aspects of the manufacturing processes and quality assurance for crushers, international B2B buyers can make more informed decisions, ensuring they procure reliable and high-quality equipment that meets their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘crusher manufacturer’

Introduction

Navigating the procurement process for a crusher manufacturer can be complex, especially for international B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe. This step-by-step checklist provides actionable insights to streamline your sourcing process, ensuring you select a supplier that meets your operational needs and quality standards.

Step 1: Define Your Technical Specifications

Before you start reaching out to suppliers, it’s essential to have a clear understanding of your technical requirements. Consider factors such as material types, processing capacity, and desired output size.

- Material Compatibility: Ensure the crusher can handle the materials specific to your industry, whether it’s limestone, granite, or recycled materials.

- Capacity Needs: Identify the production volume you require to avoid over- or under-investing in equipment.

Step 2: Research Potential Suppliers

Start with thorough research to identify potential suppliers that specialize in crushers. Utilize online platforms, trade shows, and industry publications to gather a list of manufacturers.

- Industry Experience: Look for suppliers with proven experience in your specific market or material type.

- Geographical Considerations: Consider suppliers that have a presence or partnerships in your region, as this can facilitate easier communication and logistics.

Step 3: Evaluate Supplier Certifications and Compliance

Verify that potential suppliers possess the necessary certifications and compliance with international standards. This step is critical to ensure quality and reliability.

- ISO Certification: Check for ISO 9001 certification, which indicates a commitment to quality management systems.

- Safety Standards: Ensure compliance with relevant safety and environmental regulations, which can vary by region.

Step 4: Request Detailed Proposals and Quotes

After narrowing down your list, request detailed proposals and quotations from each supplier. This will help you compare offerings comprehensively.

- Cost Breakdown: Look for transparency in pricing, including equipment costs, shipping, and any additional fees.

- Delivery Timelines: Ensure the supplier can meet your delivery timelines to avoid disruptions in your operations.

Step 5: Assess After-Sales Support and Warranty Terms

A reliable supplier should offer robust after-sales support and clear warranty terms. This is crucial for minimizing downtime and addressing potential issues.

- Technical Support: Inquire about the availability of technical support and training for your staff.

- Warranty Coverage: Understand what the warranty covers, including parts and labor, to protect your investment.

Step 6: Check References and Reviews

Before finalizing your decision, seek references from other clients who have purchased from the supplier. This step can provide invaluable insights into their reliability and service quality.

- Client Testimonials: Look for feedback on their performance, particularly regarding product quality and customer service.

- Industry Reputation: Research any reviews or case studies that highlight the supplier’s standing in the market.

Step 7: Finalize the Contract and Terms of Agreement

Once you’ve selected a supplier, ensure that all terms are clearly outlined in a contract. This protects both parties and sets clear expectations.

- Payment Terms: Clarify payment schedules and methods to avoid future disputes.

- Delivery and Installation: Define responsibilities for shipping and installation to ensure a smooth transition.

By following this comprehensive sourcing checklist, international B2B buyers can effectively navigate the complexities of procuring a crusher manufacturer, ensuring a strategic fit for their operational needs.

Comprehensive Cost and Pricing Analysis for crusher manufacturer Sourcing

What Are the Key Cost Components in Crusher Manufacturing?

Understanding the cost structure of crusher manufacturing is crucial for B2B buyers looking to source efficiently. The primary cost components include:

-

Materials: The choice of raw materials significantly impacts the total cost. High-quality steel or specialized alloys may be required for durability, which can increase material costs. Buyers should consider sourcing from local suppliers to mitigate import costs.

-

Labor: Labor costs vary by region, influenced by local wage rates and the skill level of the workforce. Countries with high labor costs may necessitate automated solutions, which can affect the upfront investment but may yield savings over time.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and facility costs. Buyers should assess how manufacturers allocate these costs, as it can vary widely depending on operational efficiency.

-

Tooling: Custom tooling for specific crusher designs can be a significant expense. Buyers should inquire about tooling costs and whether they are included in the quoted price or charged separately.

-

Quality Control (QC): Ensuring product quality can involve additional costs. Manufacturers who implement stringent QC processes may charge higher prices but offer better reliability and lower risk of defects.

-

Logistics: Transportation costs can vary based on the distance from the manufacturer to the buyer. Understanding local logistics options can help optimize shipping costs.

-

Margin: Manufacturer margins can differ based on market positioning, brand reputation, and the level of competition. It’s essential for buyers to understand these margins as they will directly impact final pricing.

How Do Price Influencers Affect Crusher Manufacturing Costs?

Several factors influence the pricing of crushers, and understanding these can aid in negotiation:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk can significantly reduce unit costs. Buyers should negotiate MOQs that align with their operational needs to maximize savings.

-

Specifications and Customization: Customized crushers tailored to specific needs can incur higher costs. Buyers should weigh the benefits of customization against standard options.

-

Materials Quality and Certifications: Crushers made from higher-grade materials or those that comply with specific certifications (like ISO standards) may come at a premium. Buyers should ensure that the quality justifies the price.

-

Supplier Factors: The reputation and reliability of the supplier can also influence pricing. Established suppliers with a track record may charge more, but they often provide better service and product reliability.

-

Incoterms: Understanding the agreed terms of shipment (e.g., FOB, CIF) is critical, as they dictate who bears the costs and risks at various points in the shipping process. This knowledge can aid in budgeting and risk management.

What Buyer Tips Can Enhance Cost-Efficiency in Crusher Sourcing?

International buyers, especially from Africa, South America, the Middle East, and Europe, should consider several strategies:

-

Effective Negotiation: Leverage multiple quotes from different manufacturers to strengthen your negotiating position. Highlighting your potential for future orders can also incentivize suppliers to provide better pricing.

-

Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, operational efficiency, and lifespan when evaluating cost. A higher upfront investment might lead to lower operating costs.

-

Pricing Nuances for International Purchases: Be aware of potential tariffs, taxes, and currency fluctuations that can affect final costs. Engaging with local experts or consultants can provide insights into these factors.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better terms, discounts, and priority service. Regular communication and feedback can foster trust and collaboration.

-

Market Research: Stay informed about market trends, material costs, and technological advancements in the crusher manufacturing sector. This knowledge will enhance your purchasing decisions and negotiation strategies.

Disclaimer on Pricing

Prices in the crusher manufacturing sector are subject to fluctuation based on market conditions, material costs, and geopolitical factors. It is advisable for buyers to conduct thorough research and obtain updated quotes before making purchasing decisions.

Alternatives Analysis: Comparing crusher manufacturer With Other Solutions

Exploring Alternatives to Traditional Crusher Manufacturers for B2B Buyers

In the competitive landscape of industrial machinery, particularly for crushing solutions, B2B buyers often seek alternatives to traditional crusher manufacturers. Understanding these alternatives can help businesses in Africa, South America, the Middle East, and Europe make informed decisions based on performance, cost, and specific operational needs. Below, we compare traditional crusher manufacturers with two viable alternatives: mobile crushing plants and impact crushers.

| Comparison Aspect | Crusher Manufacturer | Mobile Crushing Plant | Impact Crusher |

|---|---|---|---|

| Performance | High throughput; suitable for large-scale operations | Flexible capacity; good for varying site conditions | High efficiency; excels in producing fine materials |

| Cost | Higher initial investment; long-term durability | Moderate cost; potential savings on transport | Lower upfront cost; may require more maintenance |

| Ease of Implementation | Requires permanent installation and setup | Quick deployment; can be moved easily between sites | Simple installation; minimal site preparation |

| Maintenance | Regular upkeep needed; parts can be costly | Lower maintenance due to modular design | Requires frequent checks and part replacements |

| Best Use Case | Large mining and aggregate operations | Construction sites needing flexibility | Recycling and smaller-scale aggregate production |

What are the Benefits and Drawbacks of Mobile Crushing Plants?

Mobile crushing plants offer significant advantages in terms of flexibility and mobility. They can be easily transported to various job sites, making them ideal for construction projects that require frequent location changes. Additionally, their modular design often leads to lower maintenance costs. However, they may not match the throughput of traditional crushers, making them less suitable for large-scale operations.

How Do Impact Crushers Compare in Terms of Efficiency?

Impact crushers are designed to produce high-quality output with a focus on fine materials. Their operational efficiency makes them a preferred choice for recycling and smaller-scale aggregate production. While they come with a lower initial investment compared to traditional crushers, they do require more frequent maintenance, which can lead to increased operational costs over time. Therefore, businesses should evaluate their production needs carefully when considering this option.

How Can B2B Buyers Decide on the Right Crushing Solution?

When selecting the right crushing solution, B2B buyers should consider several factors, including the scale of operations, budget constraints, and maintenance capabilities. For companies in regions like Africa and South America, where logistics may pose challenges, mobile crushing plants can provide the flexibility needed for diverse projects. Conversely, for those engaged in large-scale mining or aggregate production, a traditional crusher might be the best fit due to its high performance and durability.

Ultimately, the choice between a traditional crusher manufacturer, mobile crushing plants, or impact crushers depends on the specific operational requirements and strategic goals of the business. By carefully analyzing these alternatives, buyers can optimize their investment and ensure efficient operations.

Essential Technical Properties and Trade Terminology for crusher manufacturer

What Are the Key Technical Properties to Consider When Sourcing Crushers?

When sourcing crushers, understanding the technical specifications is crucial for making informed purchasing decisions. Here are some essential properties to consider:

-

Material Grade

– The material grade of the crusher components significantly influences durability and performance. Common materials include high manganese steel for wear parts and alloy steel for structural components. Selecting the right material can enhance the longevity of the machinery, reducing downtime and maintenance costs. -

Crushing Capacity

– This specification indicates the maximum amount of material that a crusher can process in a given timeframe, usually measured in tons per hour (TPH). Understanding the crushing capacity is vital for buyers to ensure that the equipment meets their production needs without overloading or underutilizing the machine. -

Tolerance Levels

– Tolerance levels refer to the permissible limits of variation in dimensions of the crusher parts. High tolerance levels can ensure better fit and function of components, leading to improved operational efficiency. For B2B buyers, recognizing the importance of tolerance can prevent costly repairs and enhance the overall reliability of the equipment. -

Power Requirements

– Power requirements, typically expressed in kilowatts (KW), dictate the energy needs of the crusher. Buyers should assess their existing power infrastructure to ensure compatibility with the new equipment, as mismatched power requirements can lead to inefficiencies or additional costs in energy consumption. -

Weight and Dimensions

– The weight and dimensions of the crusher are essential for logistical considerations, especially regarding shipping and installation. Understanding these specifications helps buyers evaluate site suitability and transportation costs, particularly in regions with challenging infrastructure. -

Maintenance Intervals

– Knowing the recommended maintenance intervals for the crusher can aid in scheduling and budgeting for maintenance activities. Regular maintenance is essential for optimal performance and can significantly extend the lifespan of the equipment.

What Are Common Trade Terms Used in the Crusher Manufacturing Industry?

Understanding industry jargon is essential for effective communication and negotiation. Here are some key terms that every B2B buyer should know:

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. In the context of crushers, sourcing from an OEM can ensure that buyers receive high-quality, compatible components that meet industry standards. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest quantity of goods that a supplier is willing to sell. Understanding MOQ is crucial for buyers to assess their purchasing power and inventory management, especially when entering new markets or sourcing from international suppliers. -

RFQ (Request for Quotation)

– An RFQ is a document that buyers send to suppliers to request pricing and availability for specific products or services. Crafting a clear RFQ can streamline the procurement process and ensure that buyers receive accurate and comparable quotes. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce. They outline the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers manage risks and understand their obligations in cross-border trade. -

Lead Time

– Lead time refers to the time taken from placing an order until the product is delivered. For B2B buyers, understanding lead times is essential for project planning and ensuring that production schedules are met, particularly in industries with tight deadlines. -

Warranty and Service Agreements

– Warranty terms and service agreements define the conditions under which repairs or replacements will be made. Buyers should carefully review these terms to safeguard their investment and ensure that they have adequate support in case of equipment failure.

By understanding these technical properties and trade terminology, international B2B buyers can make more informed decisions when sourcing crushers, ensuring that they choose the right equipment for their operational needs while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the crusher manufacturer Sector

What Are the Key Market Dynamics and Trends Impacting the Crusher Manufacturer Sector?

The global crusher manufacturing sector is witnessing significant transformations driven by various market dynamics. One of the most notable trends is the increasing demand for sustainable and efficient crushing solutions. As industries across Africa, South America, the Middle East, and Europe focus on reducing their carbon footprints, manufacturers are innovating to produce energy-efficient and environmentally friendly equipment. In particular, the push towards automation and smart technology integration is reshaping the market landscape, allowing for enhanced operational efficiency and data-driven decision-making.

Emerging technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) are becoming integral in optimizing the performance of crushing equipment. For international B2B buyers, understanding these technological advancements is crucial for making informed purchasing decisions. Furthermore, supply chain diversification is gaining traction, especially in regions like Africa and South America, where buyers are increasingly looking to source materials and equipment locally to mitigate risks associated with global supply chain disruptions.

Additionally, fluctuating commodity prices and geopolitical factors are influencing sourcing trends. Buyers need to stay informed about these fluctuations, as they can significantly impact procurement strategies. Engaging with suppliers who can provide real-time data and insights into market conditions will be essential for navigating these complexities.

How Can Sustainability and Ethical Sourcing Influence Your Purchasing Decisions in the Crusher Manufacturing Sector?

Sustainability and ethical sourcing are becoming paramount in the crusher manufacturing sector. The environmental impact of mining and material processing has raised concerns, prompting buyers to prioritize suppliers who adhere to responsible practices. This shift not only aligns with global sustainability goals but also enhances brand reputation and customer loyalty.

International B2B buyers should seek manufacturers that demonstrate a commitment to sustainability through certifications such as ISO 14001 for environmental management and adherence to the Global Reporting Initiative (GRI) standards. Additionally, opting for suppliers that utilize recycled materials or eco-friendly manufacturing processes can significantly reduce the overall environmental footprint of operations.

In regions like the Middle East and Europe, where regulatory frameworks around sustainability are becoming stricter, aligning procurement strategies with ethical sourcing practices will not only ensure compliance but also unlock potential market opportunities. Buyers should conduct thorough due diligence to assess the sustainability credentials of potential suppliers, ensuring that their sourcing decisions contribute positively to environmental stewardship.

What Is the Historical Context of the Crusher Manufacturing Sector?

The crusher manufacturing sector has evolved significantly over the past few decades, reflecting broader technological advancements and changing market demands. Initially, crushers were predominantly mechanical devices, primarily used in mining and construction. However, with the advent of advanced materials and engineering techniques, the industry has seen a shift towards more sophisticated equipment that not only enhances productivity but also prioritizes safety and efficiency.

The rise of globalization has further transformed the sector, enabling manufacturers to tap into new markets and innovate based on diverse customer needs. As a result, today’s crushers are more versatile, capable of handling a wider range of materials and applications, from aggregates to recycling processes. This historical evolution underscores the importance of staying updated with industry trends and technological advancements for B2B buyers looking to make strategic sourcing decisions in the current landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of crusher manufacturer

-

How do I select the right crusher manufacturer for my business needs?

Choosing the right crusher manufacturer involves assessing your specific requirements such as the type of material to be processed, production capacity, and operational environment. Start by researching manufacturers with a strong reputation in your region, focusing on those that offer robust customer support and a proven track record. Request case studies or references from similar industries. Additionally, consider manufacturers that provide customization options, as this may significantly enhance efficiency and productivity for your specific application. -

What are the most common types of crushers available for international buyers?

International buyers typically encounter several types of crushers, including jaw crushers, cone crushers, impact crushers, and vertical shaft impactors (VSIs). Each type serves different purposes: jaw crushers are ideal for primary crushing, while cone crushers are better suited for secondary or tertiary applications. Understanding the characteristics and functionalities of each type can help you choose the right equipment based on your operational needs and material specifications. -

What are the typical minimum order quantities (MOQ) for crushers?

Minimum order quantities can vary significantly among manufacturers, depending on the type of crusher and the level of customization required. Generally, MOQs for crushers range from one unit for standard models to several units for specialized or custom-built machines. It’s crucial to discuss your needs with the manufacturer to understand their MOQ policy and whether they offer flexibility for smaller orders, especially for international buyers who may be testing the market. -

What payment terms should I expect when purchasing crushers internationally?

Payment terms can vary widely among manufacturers. Common options include full payment upfront, a deposit followed by the balance upon delivery, or financing arrangements. International buyers should seek clarity on the payment methods accepted (e.g., bank transfers, letters of credit) and ensure that the terms align with their financial capabilities. Additionally, consider negotiating terms that protect your investment, such as escrow services or partial payments linked to delivery milestones. -

How do I ensure quality assurance when sourcing crushers?

Quality assurance is critical in the procurement of industrial equipment like crushers. Start by verifying the manufacturer’s certifications, such as ISO standards, which indicate adherence to quality management systems. Request detailed product specifications, and consider visiting the manufacturing facility if possible. Additionally, ask for sample testing or trial runs to evaluate performance. Establishing clear communication about quality expectations and inspection processes will also enhance trust in the supplier relationship. -

What logistics considerations should I keep in mind when importing crushers?

When importing crushers, logistics plays a crucial role in ensuring timely delivery and compliance with regulations. Assess the manufacturer’s shipping capabilities, including the ability to handle customs clearance and provide necessary documentation. Plan for potential delays due to customs or transportation challenges, especially in regions with complex logistics networks. Additionally, consider the total landed cost, including shipping, insurance, and taxes, to avoid surprises that could impact your budget. -

How can I customize my crusher to better suit my operational needs?

Customization options for crushers often include adjustments to the size, design, and materials used in construction. Discuss your specific operational requirements with the manufacturer, such as desired output size, feed type, or special features like automated controls. Some manufacturers also offer modular designs that allow you to upgrade components later, providing flexibility as your operations evolve. Ensure that any customization is backed by adequate support and warranty provisions. -

What support and maintenance services should I expect from a crusher manufacturer?

Reputable crusher manufacturers typically offer comprehensive support and maintenance services, which are crucial for ensuring the longevity and efficiency of your equipment. Look for manufacturers that provide installation assistance, operator training, and ongoing technical support. Warranty terms should also be clear, covering parts and labor for a reasonable period. Additionally, inquire about spare parts availability and service contracts that can help minimize downtime and reduce overall maintenance costs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for crusher manufacturer

What Are the Key Takeaways for International B2B Buyers in the Crusher Manufacturing Sector?

Strategic sourcing in the crusher manufacturing industry is not just about acquiring equipment; it’s about building long-term partnerships that drive value and innovation. B2B buyers should prioritize suppliers that demonstrate a commitment to quality, sustainability, and technological advancements. Understanding the specific needs of your region—be it in Africa, South America, the Middle East, or Europe—can significantly enhance the effectiveness of your sourcing strategy.

How Can B2B Buyers Leverage Strategic Sourcing for Competitive Advantage?

By implementing a strategic sourcing approach, buyers can optimize procurement costs while ensuring access to the latest technology and reliable support services. This is particularly crucial in regions experiencing rapid infrastructure development, where demand for efficient and durable crushing equipment is on the rise.

What Is the Future Outlook for the Crusher Manufacturing Industry?

As the global economy evolves, the crusher manufacturing sector is poised for growth, driven by advancements in automation and sustainability. B2B buyers are encouraged to stay informed about emerging technologies and trends that could influence their sourcing decisions. Engaging with suppliers who align with future market needs will be essential for maintaining a competitive edge.

In conclusion, as you navigate the complexities of the crusher manufacturing landscape, leverage strategic sourcing to build resilient supply chains. The future is bright for those who adapt and innovate—now is the time to forge partnerships that will secure your position in the market.