Unlock Savings: The Complete Guide to Electronic Industry China (2025)

Introduction: Navigating the Global Market for electronic industry china

In today’s fast-paced global economy, sourcing components from the electronic industry in China presents both opportunities and challenges for international B2B buyers. With the rapid advancements in technology and the increasing demand for electronic products, understanding the landscape of Chinese suppliers can significantly impact your business success. This guide aims to demystify the complexities of navigating the global market for electronic products, offering a comprehensive overview of various types of electronic components, their applications, and critical supplier vetting processes.

For businesses in Africa, South America, the Middle East, and Europe—regions characterized by diverse market needs and varying levels of technological infrastructure—making informed purchasing decisions is crucial. This guide will cover essential topics, including cost analysis, quality assurance, and logistics management, tailored to the unique challenges faced by buyers in these regions. By leveraging actionable insights and practical strategies, you will gain the confidence to engage with Chinese suppliers effectively, ensuring that your sourcing decisions align with your operational goals and budget constraints.

Whether you are looking to import consumer electronics, industrial components, or custom solutions, this guide will equip you with the knowledge needed to navigate the competitive landscape of the electronic industry in China. Prepare to transform your sourcing strategy and enhance your supply chain resilience in a dynamic global marketplace.

Understanding electronic industry china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Consumer Electronics | High-volume production, rapid innovation | Retail, e-commerce | Pros: Wide variety, competitive pricing. Cons: Market saturation, quality inconsistency. |

| Industrial Electronics | Tailored solutions for specific industries | Manufacturing, automation | Pros: High customization, robust performance. Cons: Longer lead times, higher costs. |

| Communication Equipment | Focus on connectivity and data transfer | Telecommunications, networking | Pros: Essential for modern infrastructure. Cons: Rapid technological changes, need for updates. |

| Automotive Electronics | Integration of electronics in vehicle systems | Automotive manufacturing, aftermarket parts | Pros: Growing market, high demand for innovation. Cons: Regulatory challenges, complexity in sourcing. |

| Medical Electronics | Compliance with strict regulations | Healthcare facilities, medical devices | Pros: High reliability, essential for patient care. Cons: High cost of compliance, limited suppliers. |

What Are the Characteristics of Consumer Electronics?

Consumer electronics are characterized by their mass production and rapid innovation cycles. This category includes products such as smartphones, laptops, and smart home devices. For B2B buyers, the suitability of consumer electronics lies in their ability to meet consumer demands and trends. When purchasing, it’s crucial to consider market saturation, as this can lead to price wars and quality inconsistencies. Buyers should focus on reliable suppliers who can provide consistent quality and support.

How Do Industrial Electronics Differ from Other Types?

Industrial electronics focus on providing tailored solutions for various sectors, including manufacturing and automation. These products are designed to withstand harsh environments and offer high reliability. B2B buyers in this segment should prioritize customization and robustness, as these factors can significantly impact operational efficiency. However, buyers must also be prepared for longer lead times and potentially higher costs, which are common in bespoke solutions.

What Is the Importance of Communication Equipment in B2B Transactions?

Communication equipment is vital for establishing connectivity and ensuring seamless data transfer. This category encompasses products like routers, switches, and telecommunications systems. B2B applications include telecommunications and networking, which are essential for modern business operations. While the demand for communication equipment is high, buyers must be mindful of rapid technological changes that may necessitate frequent updates and replacements. Selecting suppliers who stay ahead of tech trends can mitigate this risk.

How Is Automotive Electronics Evolving in the Market?

Automotive electronics are increasingly integrated into vehicle systems, driving innovation in the automotive industry. This type of electronics includes components used in safety systems, infotainment, and electric vehicles. B2B buyers in automotive manufacturing should look for suppliers who can provide cutting-edge technology to meet growing consumer demands. However, they must navigate regulatory challenges and the complexity of sourcing components, which can be daunting in this fast-evolving sector.

What Are the Key Considerations for Medical Electronics Purchases?

Medical electronics are defined by their compliance with strict regulations and the necessity for high reliability. This category includes devices used in healthcare facilities and for medical diagnostics. B2B buyers must ensure that suppliers adhere to regulatory standards, as non-compliance can have serious implications. Additionally, while the reliability of medical electronics is paramount, buyers should also be aware of the high costs associated with compliance and the limited number of qualified suppliers in the market.

Key Industrial Applications of electronic industry china

| Industry/Sector | Specific Application of electronic industry china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | Smart Home Devices | Enhanced customer engagement and convenience | Reliability, certification standards, and local support |

| Automotive | Electric Vehicle Components | Improved efficiency and sustainability | Quality assurance, compliance with international standards |

| Telecommunications | Network Infrastructure Components | Increased connectivity and data transmission speed | Scalability, compatibility with existing systems |

| Industrial Automation | Robotics and Automation Solutions | Enhanced productivity and reduced operational costs | Customization options, technical support, and integration |

| Healthcare Technology | Medical Devices and Equipment | Improved patient outcomes and operational efficiency | Regulatory compliance, service availability, and warranty |

How Are Smart Home Devices Benefiting Businesses in Africa and South America?

The electronic industry in China plays a pivotal role in the development of smart home devices, such as smart thermostats, security systems, and energy management tools. These products enhance customer engagement by providing convenience and energy savings, which are crucial in regions where energy costs can be high. For international B2B buyers, particularly from Africa and South America, sourcing reliable products with robust certification standards is essential to ensure quality and safety. Additionally, establishing a local support system can significantly enhance customer satisfaction and loyalty.

What Role Do Electric Vehicle Components Play in the Automotive Sector?

China’s electronic industry is instrumental in supplying electric vehicle (EV) components, such as batteries, control systems, and power electronics. These components are vital for improving the efficiency and sustainability of vehicles, which is increasingly important in regions like the Middle East and Europe, where environmental regulations are stringent. B2B buyers should focus on quality assurance and the compliance of products with international standards to mitigate risks associated with sourcing. Establishing relationships with manufacturers that offer after-sales support can also provide a competitive edge.

How Are Network Infrastructure Components Transforming Telecommunications?

In the telecommunications sector, network infrastructure components from China, including routers, switches, and fiber optics, are crucial for enhancing connectivity and data transmission speed. This is particularly beneficial in emerging markets in Africa and South America, where reliable communication networks are essential for business growth. Buyers should consider scalability and compatibility with existing systems when sourcing these components. Additionally, investing in suppliers that provide robust technical support can facilitate smoother implementation and operation.

Why Are Robotics and Automation Solutions Essential for Industrial Automation?

The electronic industry in China is at the forefront of providing robotics and automation solutions that significantly enhance productivity in various industries. By automating repetitive tasks, businesses can reduce operational costs and improve efficiency. This is especially relevant for international B2B buyers in sectors like manufacturing and logistics. When sourcing these solutions, it is crucial to evaluate customization options, as businesses often have unique operational requirements. Furthermore, ensuring that suppliers offer comprehensive technical support can help mitigate integration challenges.

How Are Medical Devices from China Impacting Healthcare Technology?

In the healthcare sector, electronic products from China, such as diagnostic equipment and monitoring devices, are transforming patient care. These innovations lead to improved patient outcomes and operational efficiency, which are critical in regions with limited healthcare resources. For B2B buyers, regulatory compliance is a primary consideration, as medical devices must meet stringent safety standards. Additionally, assessing the service availability and warranty options from suppliers can provide reassurance and reduce long-term operational risks.

Related Video: Types Of Flowmeters And Their Industrial Applications.

3 Common User Pain Points for ‘electronic industry china’ & Their Solutions

Scenario 1: Navigating Quality Assurance in Electronics Manufacturing

The Problem:

B2B buyers from regions like Africa and South America often face significant challenges in ensuring the quality of electronic components sourced from China. Many manufacturers may not adhere to international quality standards, leading to discrepancies in product performance. This can result in costly returns, damaged business reputations, and lost customer trust. Buyers may feel overwhelmed by the vast array of suppliers and the difficulty in assessing their credibility, especially when operating from a distance.

The Solution:

To overcome quality assurance issues, international buyers should adopt a comprehensive supplier evaluation process. Start by conducting thorough research on potential suppliers. Utilize platforms like Alibaba or Global Sources, and look for suppliers with verified certifications such as ISO 9001. Request samples before committing to large orders to evaluate product quality firsthand. Additionally, consider engaging third-party inspection services based in China. These services can conduct pre-shipment inspections to ensure that products meet your specifications and quality standards. Establishing clear communication regarding quality expectations and specifications in contracts can further safeguard against discrepancies.

Scenario 2: Overcoming Language and Cultural Barriers in B2B Transactions

The Problem:

Language and cultural differences pose significant hurdles for B2B buyers interacting with suppliers in China. Miscommunications can arise from language barriers, leading to misunderstandings about product specifications, pricing, and delivery timelines. This often results in delays, increased costs, and frustration for both parties. Buyers from the Middle East and Europe may particularly struggle with these challenges due to differing negotiation styles and business practices.

The Solution:

To bridge the communication gap, B2B buyers should consider hiring bilingual staff or partnering with local agents who understand both the language and cultural nuances. Additionally, investing in translation services for documents and contracts can prevent misunderstandings. When negotiating, be explicit about your expectations and preferred communication styles. Utilizing visual aids such as diagrams and photos can also help clarify complex product specifications. Establishing a relationship built on trust and transparency will facilitate smoother interactions and enhance the overall partnership.

Scenario 3: Managing Supply Chain Disruptions in the Electronics Sector

The Problem:

Supply chain disruptions are a common issue in the electronics industry, particularly for buyers sourcing components from China. Factors such as political instability, natural disasters, or global events like the COVID-19 pandemic can lead to delays in production and shipping, impacting a buyer’s ability to meet market demands. For B2B buyers in regions like South Africa and Egypt, these disruptions can result in inventory shortages and lost sales opportunities.

The Solution:

To mitigate the risks associated with supply chain disruptions, buyers should diversify their sourcing strategy. Rather than relying solely on a single supplier, consider establishing relationships with multiple suppliers across different regions within China. This approach can provide alternative options if one supplier faces challenges. Additionally, implementing a just-in-time inventory system can help manage stock levels more effectively, reducing the impact of delays. Regularly monitoring geopolitical developments and potential disruptions can also enable proactive planning. Building strong relationships with logistics partners can ensure more flexible and reliable shipping options, allowing for quicker adjustments when issues arise.

Strategic Material Selection Guide for electronic industry china

What Are the Key Materials Used in the Electronic Industry in China?

When sourcing materials for the electronic industry in China, international B2B buyers must consider various factors such as performance characteristics, cost, and compliance with international standards. Here, we analyze four common materials used in this sector: copper, aluminum, polyimide, and FR-4 (a type of fiberglass). Each material has distinct properties, advantages, and limitations that can significantly impact product performance and manufacturing processes.

How Does Copper Perform in Electronic Applications?

Copper is a fundamental material in the electronic industry, primarily used for wiring and circuit boards due to its excellent electrical conductivity. It boasts high thermal conductivity, making it suitable for heat dissipation in electronic devices. However, copper is susceptible to corrosion and oxidation, which can affect long-term reliability.

Pros & Cons: Copper is durable and widely available, but its higher cost compared to alternatives like aluminum can be a drawback for budget-conscious buyers. Additionally, the complexity of manufacturing processes can increase production time and costs.

Impact on Application: Copper is compatible with a variety of media, making it ideal for high-performance applications such as power distribution and signal transmission. Buyers should ensure that their suppliers adhere to standards such as ASTM B170 for copper wire.

What Advantages Does Aluminum Offer for Electronic Components?

Aluminum is increasingly popular in the electronic industry due to its lightweight nature and good electrical conductivity. It is often used in heat sinks and casings for electronic devices. Aluminum also offers excellent corrosion resistance, particularly when anodized, which prolongs the lifespan of components.

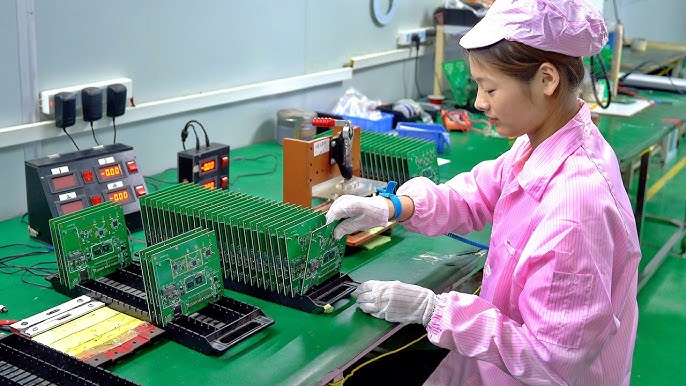

A stock image related to electronic industry china.

Pros & Cons: The primary advantage of aluminum is its cost-effectiveness and lower weight compared to copper. However, aluminum has a lower thermal conductivity than copper, which may limit its use in high-performance applications.

Impact on Application: Aluminum’s compatibility with various environmental conditions makes it suitable for outdoor electronic applications. Buyers should consider compliance with international standards such as JIS H 4000 for aluminum alloys.

Why Is Polyimide a Preferred Material for Flexible Circuits?

Polyimide is a high-performance polymer known for its thermal stability and flexibility, making it ideal for flexible circuits and high-temperature applications. It can withstand extreme temperatures, making it suitable for aerospace and automotive electronics.

Pros & Cons: Polyimide offers excellent dielectric properties and can be manufactured into thin films, which is advantageous for compact electronic designs. However, the cost of polyimide can be higher than traditional materials, and its manufacturing process is more complex.

Impact on Application: Polyimide’s unique properties allow it to be used in applications where space and weight are critical. Buyers should ensure compliance with standards such as ASTM D5207 for polyimide films.

How Does FR-4 Compare in Terms of Performance and Cost?

FR-4 is a composite material made from woven fiberglass cloth and epoxy resin, widely used in printed circuit boards (PCBs). It offers excellent electrical insulation and mechanical strength, making it a go-to choice for many electronic applications.

Pros & Cons: FR-4 is relatively inexpensive and easy to manufacture, making it a popular choice for mass production. However, it has limitations in terms of thermal performance compared to metals like copper and aluminum.

Impact on Application: FR-4 is suitable for a wide range of electronic applications, but its thermal limitations may restrict its use in high-power devices. Compliance with standards such as IPC-4101 is essential for ensuring quality.

Summary Table of Material Selection

| Material | Typical Use Case for electronic industry china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Wiring and circuit boards | Excellent electrical conductivity | Higher cost and corrosion issues | High |

| Aluminum | Heat sinks and casings | Lightweight and cost-effective | Lower thermal conductivity | Medium |

| Polyimide | Flexible circuits and high-temperature devices | High thermal stability and flexibility | Higher cost and complex manufacturing | High |

| FR-4 | Printed circuit boards (PCBs) | Inexpensive and easy to manufacture | Limited thermal performance | Low |

By understanding the properties and implications of these materials, international B2B buyers can make informed decisions that align with their specific needs and compliance requirements, ensuring successful sourcing and manufacturing processes in the electronic industry in China.

In-depth Look: Manufacturing Processes and Quality Assurance for electronic industry china

What Are the Key Stages in the Manufacturing Process of Electronics in China?

The manufacturing process for electronics in China is a multifaceted operation that typically involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is essential for ensuring that the final product meets the required specifications and quality standards.

-

Material Preparation: This initial stage involves sourcing and preparing raw materials, which can include metals, plastics, and electronic components. Suppliers often engage in stringent screening processes to ensure that materials meet industry standards. For B2B buyers, understanding the source and quality of materials is crucial, as it directly impacts the durability and reliability of the final product.

-

Forming: In this phase, raw materials are transformed into components through various techniques such as stamping, molding, and machining. Techniques like Surface Mount Technology (SMT) are prevalent in the electronics sector. Buyers should inquire about the technology and methods used, as advanced techniques can lead to better precision and reduced waste.

-

Assembly: The assembly stage involves integrating the formed components into a complete product. This often utilizes automated processes alongside manual labor, depending on the complexity of the product. Understanding the assembly line’s configuration can provide insights into the efficiency and scalability of production, which is particularly important for buyers looking to establish long-term partnerships.

-

Finishing: The final stage includes processes such as coating, printing, and packaging. This stage not only enhances the aesthetic appeal but also adds protective layers to the product. Buyers should verify the finishing techniques used, as they can affect the product’s longevity and marketability.

How Is Quality Assurance Managed in China’s Electronics Manufacturing?

Quality assurance (QA) is a cornerstone of electronics manufacturing in China, with numerous international and industry-specific standards guiding practices. Ensuring compliance with these standards helps maintain product integrity and customer satisfaction.

-

International Standards: Adhering to ISO 9001 standards is common in the Chinese electronics industry. This certification demonstrates a commitment to consistent quality management practices. B2B buyers should prioritize suppliers with this certification, as it indicates a structured approach to quality assurance.

-

Industry-Specific Standards: In addition to ISO certifications, compliance with regional standards such as CE (Conformité Européenne) for the European market and API (American Petroleum Institute) for specialized electronic components is crucial. These certifications ensure that products meet specific safety and performance criteria, which can vary by market.

What Are the Key Quality Control Checkpoints in Electronics Manufacturing?

Quality Control (QC) checkpoints are integral to maintaining high standards throughout the manufacturing process. The primary QC checkpoints include:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials and components before they enter the production line. By verifying the quality of materials at this stage, manufacturers can prevent defects from propagating through the production process.

-

In-Process Quality Control (IPQC): During manufacturing, IPQC involves continuous monitoring and inspection at various stages. This proactive approach allows for immediate corrective actions, minimizing waste and ensuring that products adhere to specifications.

-

Final Quality Control (FQC): At the end of the manufacturing process, FQC involves a comprehensive assessment of the final product. This includes functional testing, visual inspections, and compliance checks against specifications. Buyers should request detailed FQC reports to understand the final quality of products.

What Common Testing Methods Are Used in Electronics Quality Control?

Various testing methods are employed to ensure that electronic products meet the required standards. Common testing methods include:

- Functional Testing: Verifying that the product performs its intended functions correctly.

- Environmental Testing: Assessing how products withstand environmental factors such as temperature, humidity, and vibration.

- Electrical Testing: Ensuring that electrical components operate within specified voltage and current ranges.

B2B buyers should ask potential suppliers about their testing methodologies and request access to test reports to verify compliance with quality standards.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Verifying a supplier’s quality control processes is essential for B2B buyers looking to establish trust and ensure product quality. Here are effective strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the supplier’s manufacturing processes, QC checkpoints, and compliance with international standards. This hands-on approach provides valuable insights into the supplier’s operational integrity.

-

Quality Assurance Reports: Requesting detailed quality assurance reports, including IQC, IPQC, and FQC documentation, helps buyers assess the supplier’s commitment to quality. Reports should include metrics such as defect rates and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s QC processes. This is particularly important for international buyers who may not have the capacity for on-site inspections.

What Nuances Should International Buyers Consider Regarding Quality Control?

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of several nuances related to quality control:

-

Cultural Differences: Understanding the cultural context can influence communication and expectations regarding quality. Building relationships with suppliers can help bridge these gaps.

-

Regulatory Compliance: Different regions have varying compliance requirements. Buyers must ensure that products not only meet Chinese standards but also comply with regulations in their home markets.

-

Logistics and Supply Chain Risks: Quality control does not end at the factory. Buyers should consider the entire supply chain, including logistics, to mitigate risks associated with product damage during transport.

By understanding the manufacturing processes and quality assurance practices in China’s electronics industry, international B2B buyers can make informed decisions, ensuring they partner with reliable suppliers that meet their quality standards and market requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electronic industry china’

In the dynamic landscape of the electronic industry in China, international B2B buyers face unique challenges and opportunities. This step-by-step sourcing guide aims to streamline the procurement process by offering actionable insights tailored for buyers from Africa, South America, the Middle East, and Europe. By following this checklist, you can effectively navigate supplier selection, ensure quality, and mitigate risks.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the foundation of successful sourcing. Specify the product types, functionalities, and compliance standards required for your target market. This clarity helps suppliers understand your needs and reduces the risk of miscommunication.

- Consider including industry certifications, safety standards, and performance metrics.

- Prepare a detailed product requirement document to share with potential suppliers.

Step 2: Conduct Market Research on Suppliers

Before approaching suppliers, conduct thorough market research to identify reputable manufacturers in the electronic industry. Utilize platforms such as Alibaba, Made-in-China, or global trade directories to compile a list of potential suppliers.

- Look for reviews and ratings from previous buyers to gauge reliability.

- Pay attention to suppliers with a strong export track record, particularly with companies in your region.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website.

- Assess their production capacity, technology capabilities, and quality control processes.

- Schedule virtual meetings to discuss your needs and evaluate their communication skills.

Step 4: Verify Supplier Certifications

Ensure that your potential suppliers hold the necessary certifications that comply with international standards. This step is vital for maintaining product quality and ensuring safety.

- Check for ISO certifications, CE markings, or other relevant industry certifications.

- Request copies of these certifications and verify them through the issuing bodies.

Step 5: Request Samples for Quality Assurance

Before placing a bulk order, always request product samples. This allows you to assess the quality, functionality, and compatibility of the products with your requirements.

- Analyze the samples for durability, material quality, and performance.

- Use this opportunity to provide feedback to suppliers, which can improve the final product.

Step 6: Negotiate Payment Terms and Conditions

Establish clear payment terms and conditions to protect your investment. Understand the payment methods preferred by suppliers and negotiate terms that suit both parties.

- Consider using escrow services for large orders to mitigate risks.

- Clearly outline penalties for late deliveries or quality issues in your agreement.

Step 7: Plan for Logistics and Customs Clearance

Once the order is confirmed, plan for logistics, including shipping methods and customs clearance. Understanding these processes is crucial to avoid delays and unexpected costs.

- Research freight forwarders experienced in shipping electronic goods to your region.

- Prepare all necessary documentation for customs to ensure smooth clearance upon arrival.

By following these steps, B2B buyers can approach the sourcing process with confidence, ensuring a successful partnership with suppliers in the Chinese electronic industry. This structured approach not only mitigates risks but also fosters long-term business relationships.

Comprehensive Cost and Pricing Analysis for electronic industry china Sourcing

What Are the Key Cost Components in China’s Electronic Industry Sourcing?

When navigating the electronic industry in China, understanding the cost structure is crucial for international B2B buyers. The primary components of cost include:

-

Materials: The choice of materials significantly impacts the overall cost. Prices can vary based on market fluctuations, availability, and the specific materials required for your product. For example, high-grade metals or specialized components can drive costs higher.

-

Labor: Labor costs in China are generally lower than in many Western countries, but this can vary by region and skill level. Urban areas with specialized labor may command higher wages, while rural areas may offer more competitive rates.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment maintenance. Understanding these costs can help you negotiate better pricing.

-

Tooling: The initial investment in tooling can be significant, especially for customized products. It’s essential to factor in these costs when determining the overall pricing structure.

-

Quality Control (QC): Implementing stringent QC measures is vital to ensure product reliability. These costs should be included in your budget, particularly if you’re sourcing complex electronic components.

-

Logistics: Shipping costs can vary dramatically based on distance, shipping method, and the volume of goods. For international buyers, understanding Incoterms (International Commercial Terms) is critical, as they dictate who bears responsibility for shipping costs and risks.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on the supplier’s reputation, market demand, and the relationship you establish with them.

How Do Pricing Influencers Impact Your Sourcing Strategy?

Several factors can influence the pricing structure when sourcing electronics from China:

-

Volume/MOQ (Minimum Order Quantity): Ordering in larger quantities often results in lower per-unit costs. If your business can handle it, consider negotiating MOQs that align with your production needs.

-

Specifications and Customization: Customized products can incur higher costs due to the need for specialized materials or processes. Clearly defining your product specifications can help avoid unexpected expenses.

-

Material Quality and Certifications: Higher quality materials and recognized certifications (e.g., ISO, CE) can increase costs but are often necessary for compliance and market acceptance in regions like Europe and the Middle East.

-

Supplier Factors: The reputation and reliability of your supplier can significantly affect pricing. Established suppliers may charge more but often provide better quality assurance and service.

What Are Effective Tips for Negotiating Costs with Chinese Suppliers?

-

Emphasize Total Cost of Ownership (TCO): When evaluating suppliers, consider not just the initial price but the total cost of ownership, including shipping, duties, and potential warranty claims. This holistic approach can lead to better long-term savings.

-

Negotiate Terms: Don’t hesitate to discuss pricing, payment terms, and delivery schedules. Building a good relationship with your supplier can provide leverage in negotiations.

-

Stay Informed on Market Trends: Keeping abreast of global material prices and industry trends will equip you with the knowledge necessary to negotiate effectively.

-

Utilize Incoterms Wisely: Familiarize yourself with various Incoterms to understand the implications of shipping responsibilities and costs. For example, “CIF” (Cost, Insurance, and Freight) means the supplier covers shipping, which can influence your cost structure.

-

Consider Local Partnerships: Engaging with local agents or sourcing specialists can provide insights into the market and help you navigate negotiations more effectively.

Conclusion: Understanding Cost Nuances for International Buyers

International B2B buyers, especially from Africa, South America, the Middle East, and Europe, must approach sourcing from China with a clear understanding of the cost structure and pricing influencers. By focusing on the key cost components, leveraging pricing influencers, and employing effective negotiation strategies, buyers can optimize their sourcing decisions. Always remember that prices can vary significantly, so approach negotiations with a well-informed perspective. Prices mentioned are indicative and should be confirmed with suppliers for accuracy.

Alternatives Analysis: Comparing electronic industry china With Other Solutions

Understanding the Importance of Alternatives in the Electronic Industry

When evaluating options in the electronic industry, particularly for international B2B buyers, understanding alternatives to the dominant players, such as the electronic industry in China, is crucial. This analysis can help companies make informed decisions that align with their strategic goals, operational needs, and budget constraints. Below, we compare the electronic industry in China against two viable alternatives: the Indian electronics sector and localized manufacturing in Africa.

Comparison Table of Electronic Industry Options

| Comparison Aspect | Electronic Industry China | Indian Electronics Sector | Localized Manufacturing in Africa |

|---|---|---|---|

| Performance | High-volume production, established supply chains | Growing capacity, focus on innovation | Variable, often lower volume but increasing quality |

| Cost | Competitive pricing due to economies of scale | Generally lower than China, but rising | Higher due to lower economies of scale |

| Ease of Implementation | Established processes, but complex logistics for shipping | Easier for local sourcing; expanding infrastructure | May require significant setup and investment |

| Maintenance | Strong support networks, but remote service issues | Improving service support, local expertise growing | Local support may vary; skilled labor shortage |

| Best Use Case | High-demand consumer electronics, mass production | Niche markets, emerging technologies | Custom solutions for local needs, reducing lead times |

What Are the Advantages and Disadvantages of the Indian Electronics Sector?

A stock image related to electronic industry china.

The Indian electronics sector is rapidly evolving, characterized by a strong focus on innovation and increasing production capabilities. One of its main advantages is cost-effectiveness; labor costs are generally lower than in China, making it an attractive option for companies looking to minimize expenses. However, while the sector is growing, it may not yet match China in terms of volume and speed of production. Additionally, the logistics infrastructure, although improving, can still pose challenges for international shipping and distribution.

How Does Localized Manufacturing in Africa Compare?

Localized manufacturing in Africa presents a unique opportunity for B2B buyers looking to cater to specific regional needs. One significant advantage is the reduction of lead times and shipping costs, as products can be manufactured closer to the target market. Furthermore, this approach can enhance brand loyalty by supporting local economies. However, the main challenges include higher production costs and a potential lack of skilled labor, which can affect the quality and consistency of output. Companies may need to invest in training and development to build a capable workforce.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the right solution in the electronic industry requires a thorough understanding of each option’s strengths and weaknesses. For buyers from Africa, South America, the Middle East, and Europe, evaluating factors such as performance, cost, and ease of implementation is vital. If rapid scalability and established supply chains are paramount, the electronic industry in China remains a strong contender. However, if there is a focus on innovation or localization, the Indian electronics sector or localized manufacturing in Africa may offer compelling alternatives. Ultimately, aligning the choice with the company’s long-term strategic goals and operational capabilities will lead to the most beneficial outcome.

Essential Technical Properties and Trade Terminology for electronic industry china

What Are the Key Technical Properties in the Electronic Industry in China?

When engaging with suppliers in the Chinese electronic industry, understanding critical technical properties is essential for making informed purchasing decisions. Here are several key specifications that international B2B buyers should consider:

-

Material Grade

– Definition: Material grade refers to the quality and type of materials used in electronic components, such as metals, plastics, and semiconductors. Each grade has specific properties that determine durability, conductivity, and compatibility with other materials.

– B2B Importance: Knowing the material grade can significantly impact product performance and longevity. Buyers should ensure the material meets their specific industry standards, particularly in sectors like telecommunications or consumer electronics. -

Tolerance

– Definition: Tolerance defines the acceptable range of variation in a physical dimension of a component. It is critical for ensuring that parts fit together correctly and function as intended.

– B2B Importance: Tight tolerances are essential in applications where precision is crucial, such as in medical devices or aerospace technology. Understanding tolerance levels helps buyers avoid costly errors in assembly and operation. -

Electrical Specifications

– Definition: These include voltage ratings, current ratings, and power consumption metrics, which are vital for ensuring that components operate safely and efficiently within a circuit.

– B2B Importance: Buyers need to match these specifications with their application requirements to prevent failures. Mismatched electrical specifications can lead to product recalls or safety hazards. -

Thermal Properties

– Definition: Thermal properties refer to how materials respond to temperature changes, including thermal conductivity and thermal expansion coefficients.

– B2B Importance: Understanding these properties is crucial for applications that generate heat, such as processors and power supplies. Buyers must ensure that components can withstand operational temperatures without degrading. -

Reliability Ratings

– Definition: Reliability ratings indicate the expected lifespan and failure rates of electronic components under specified conditions.

– B2B Importance: High reliability ratings are particularly important in industries where equipment downtime can be costly. Buyers should seek components with proven performance records to minimize risks.

What Are Common Trade Terms in the Chinese Electronic Industry?

Familiarity with industry-specific terminology can facilitate smoother negotiations and transactions in the Chinese electronic market. Here are some common trade terms to understand:

-

OEM (Original Equipment Manufacturer)

– Definition: OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. This term often pertains to custom products made to a buyer’s specifications.

– Importance: Understanding OEM relationships allows buyers to leverage manufacturers’ expertise while ensuring that products meet their specific needs. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell. This figure varies between manufacturers and can affect pricing and inventory strategies.

– Importance: Buyers should negotiate MOQs that align with their demand forecasts to avoid overstocking or stockouts, which can disrupt operations. -

RFQ (Request for Quotation)

– Definition: An RFQ is a formal request sent to suppliers asking for pricing and terms on specific products or services.

– Importance: Using RFQs can streamline the procurement process and ensure that buyers receive competitive offers, enabling better budget management. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs.

– Importance: Familiarity with Incoterms helps buyers understand their obligations and costs, minimizing disputes and ensuring smoother logistics. -

Lead Time

– Definition: Lead time refers to the total time taken from placing an order to receiving the goods. It includes manufacturing, shipping, and customs clearance times.

– Importance: Understanding lead times is crucial for inventory planning and maintaining supply chain efficiency, especially when dealing with international suppliers.

By grasping these essential technical properties and trade terms, B2B buyers from Africa, South America, the Middle East, and Europe can enhance their procurement strategies and foster successful partnerships within the Chinese electronic industry.

Navigating Market Dynamics and Sourcing Trends in the electronic industry china Sector

What Are the Current Market Dynamics and Key Trends in the Chinese Electronics Industry?

The Chinese electronics industry remains a global powerhouse, driven by rapid technological advancements and an expanding consumer base. A significant trend is the shift towards smart and connected devices, propelled by the Internet of Things (IoT) and 5G technology. For international B2B buyers from Africa, South America, the Middle East, and Europe, this trend presents opportunities to source innovative products that cater to evolving consumer demands. Notably, the adoption of artificial intelligence (AI) in manufacturing processes is enhancing efficiency and reducing costs, making it an attractive sourcing option for buyers looking to optimize their supply chains.

Another critical dynamic is the diversification of sourcing strategies. International buyers are increasingly looking beyond traditional suppliers to mitigate risks associated with geopolitical tensions and supply chain disruptions. This trend is particularly relevant for regions like Africa and South America, where establishing strong partnerships with Chinese manufacturers can unlock access to high-quality components at competitive prices. Additionally, sustainability is becoming a priority, with buyers seeking suppliers who prioritize environmentally friendly practices and materials. This shift towards sustainable sourcing is not only a response to regulatory pressures but also a reflection of changing consumer preferences.

How Can Sustainability and Ethical Sourcing Impact B2B Relationships in the Electronics Sector?

The environmental impact of electronics manufacturing is significant, making sustainability and ethical sourcing crucial considerations for B2B buyers. The electronics industry is often associated with e-waste and resource depletion; therefore, buyers from Africa, South America, the Middle East, and Europe must prioritize suppliers who demonstrate a commitment to sustainable practices. This includes using recycled materials, minimizing energy consumption during production, and implementing waste reduction strategies.

Ethical supply chains are increasingly important, as consumers and regulators alike demand transparency and accountability. Buyers should look for manufacturers that hold certifications such as ISO 14001 for environmental management and R2 for responsible recycling practices. Furthermore, sourcing from companies that adhere to fair labor practices not only enhances corporate reputation but also mitigates risks associated with supply chain disruptions. By choosing suppliers who prioritize sustainability and ethics, B2B buyers can foster long-term relationships that contribute positively to both their brand image and the environment.

How Has the Chinese Electronics Industry Evolved to Meet Global B2B Needs?

The evolution of the Chinese electronics industry has been marked by a transition from low-cost manufacturing to high-value innovation. Initially, the focus was primarily on mass production to meet global demand; however, as technology advanced, manufacturers began investing in research and development. This shift has allowed China to emerge as a leader in cutting-edge technologies, such as semiconductors, renewable energy solutions, and advanced telecommunications equipment.

In response to global B2B needs, Chinese manufacturers have increasingly adopted international quality standards, enhancing their competitiveness in the global market. This evolution is particularly beneficial for international buyers, as it ensures access to high-quality products that meet stringent requirements. As the industry continues to adapt and innovate, buyers can leverage these advancements to enhance their own offerings and stay ahead in an increasingly competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of electronic industry china

-

How do I identify reliable suppliers in China’s electronic industry?

To identify reliable suppliers, start by researching potential partners through reputable platforms like Alibaba, Global Sources, or Made-in-China. Look for suppliers with verified certifications, positive customer reviews, and a proven track record. Engage in direct communication to assess their responsiveness and willingness to provide documentation, such as quality certifications and business licenses. Additionally, consider visiting trade shows in China, which can offer firsthand insights into supplier capabilities and allow for face-to-face interactions. -

What are the common payment terms when sourcing electronics from China?

Payment terms can vary significantly among suppliers, but common practices include a 30% deposit upfront and the remaining 70% before shipment. Some suppliers may offer payment through secure methods like PayPal or letters of credit, which can protect your interests. It’s crucial to clarify payment terms early in negotiations and ensure they are documented in your contract. Be cautious of suppliers demanding full payment upfront, as this can increase the risk of fraud. -

What is the minimum order quantity (MOQ) for electronic products from Chinese suppliers?

The MOQ can vary widely depending on the product type and supplier. While some manufacturers may have a low MOQ of 50 to 100 units, others may require orders in the thousands. Always inquire about MOQs during your initial discussions, and don’t hesitate to negotiate, especially if you are a first-time buyer. For smaller orders, consider working with suppliers that specialize in smaller batch production or those who offer dropshipping services. -

How can I ensure product quality when sourcing electronics from China?

To ensure product quality, request samples before placing a large order. This allows you to evaluate the product against your specifications. Additionally, consider implementing third-party quality assurance (QA) inspections during production and before shipment. Establish clear quality standards in your contract and maintain open communication with your supplier throughout the manufacturing process. Utilizing inspection services in China can provide an extra layer of security. -

What are the logistics considerations for importing electronics from China?

When importing electronics, consider freight options such as sea, air, or rail transport, depending on your budget and time constraints. Engage with a reliable freight forwarder to navigate customs regulations and ensure all necessary documentation, such as bills of lading and invoices, is in order. Additionally, factor in potential tariffs and duties that may apply to your shipments. Understanding the logistics landscape can help you optimize costs and delivery timelines. -

How can I customize electronic products sourced from China?

Most Chinese manufacturers are open to customization, whether it involves altering specifications, branding, or packaging. To initiate the customization process, provide clear and detailed requirements to your supplier, including drawings or prototypes if possible. Be prepared for potential minimum order quantities that may apply to customized products. Effective communication is key; ensure you establish timelines and confirm adjustments through prototypes before final production. -

What are the legal considerations when sourcing electronics from China?

When sourcing from China, it’s essential to be aware of intellectual property rights and ensure that your supplier respects them. Conduct due diligence on patents and trademarks related to your products to avoid infringement. Additionally, ensure your contracts include clauses regarding dispute resolution and compliance with international trade regulations. Consulting with a legal professional specializing in international trade can provide valuable guidance. -

How do I handle disputes with Chinese suppliers?

Disputes can arise for various reasons, including quality issues or delivery delays. To handle disputes effectively, maintain open lines of communication with your supplier to address issues promptly. Document all correspondence and agreements to support your case. If necessary, refer to the terms outlined in your contract for dispute resolution procedures. For significant disputes, consider mediation or arbitration as a cost-effective alternative to litigation.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for electronic industry china

As the electronic industry in China continues to evolve, international B2B buyers must leverage strategic sourcing to navigate this complex landscape effectively. The insights gleaned from market trends, such as the rise of sustainable practices and the increasing importance of supply chain resilience, underscore the need for buyers to adopt a proactive approach. By aligning sourcing strategies with local market dynamics in Africa, South America, the Middle East, and Europe, businesses can optimize costs while enhancing product quality and innovation.

How can international buyers capitalize on China’s electronic market potential? By establishing robust partnerships with reliable suppliers and investing in technology-driven solutions, businesses can ensure a competitive edge. Additionally, fostering transparency and communication throughout the supply chain will mitigate risks associated with geopolitical fluctuations and market volatility.

Looking ahead, the potential for growth in the electronic industry remains significant. Buyers are encouraged to explore new opportunities and stay informed about emerging trends. Embracing strategic sourcing not only facilitates better decision-making but also positions companies for long-term success. Now is the time to act—evaluate your sourcing strategies and engage with Chinese suppliers to harness the full potential of this dynamic market.