Unlock Savings: The Complete Guide to Hook Manufacturer (2025)

Introduction: Navigating the Global Market for hook manufacturer

Navigating the intricate landscape of the global market for hook manufacturers presents unique challenges for international B2B buyers. With a myriad of options available, sourcing the right hooks tailored to specific applications can be daunting. This guide aims to demystify the complexities of the hook manufacturing sector, covering essential aspects such as types of hooks, their diverse applications across industries, and effective supplier vetting processes. Additionally, we delve into cost considerations and quality standards that are crucial for informed purchasing decisions.

For buyers from Africa, South America, the Middle East, and Europe, including key markets like Saudi Arabia and Indonesia, this comprehensive resource is designed to empower you with actionable insights. By understanding the nuances of the hook manufacturing process, you can confidently navigate supplier negotiations and ensure you procure the best products that meet your operational needs.

Whether you’re looking for hooks for construction, fishing, or industrial applications, this guide will equip you with the knowledge to make strategic decisions that enhance your supply chain efficiency and drive business success. Explore the dynamic world of hook manufacturing with us and transform your sourcing strategy into a competitive advantage.

Understanding hook manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Industrial Hooks | Heavy-duty materials, high weight capacity | Construction, manufacturing, logistics | Pros: Durable, reliable for heavy loads. Cons: Bulkier, may require specialized equipment for handling. |

| Fishing Hooks | Various shapes and sizes, designed for specific fish types | Fishing equipment suppliers, outdoor retailers | Pros: Specialized designs improve catch rates. Cons: Limited to niche markets, seasonal demand fluctuations. |

| Decorative Hooks | Aesthetic designs, often made from lighter materials | Home decor, retail displays | Pros: Attractive, enhances product presentation. Cons: Less durable, not suitable for heavy applications. |

| Automotive Hooks | Engineered for specific vehicle models, high strength | Automotive manufacturers, repair shops | Pros: Tailored for performance, reliable. Cons: Higher cost due to specialization, limited interchangeability. |

| Custom Hooks | Tailored designs based on client specifications | Specialized industries, custom projects | Pros: Meets unique requirements, maximizes efficiency. Cons: Longer lead times, potentially higher costs. |

What are the Characteristics of Industrial Hooks?

Industrial hooks are typically made from heavy-duty materials like steel or reinforced polymers, designed to handle substantial weights. They are commonly used in construction, manufacturing, and logistics, where reliable lifting solutions are crucial. When considering an industrial hook purchase, buyers should evaluate the weight capacity, material durability, and compatibility with existing lifting equipment. These hooks are ideal for businesses that require robust solutions for heavy lifting and transportation.

How Do Fishing Hooks Differ in Design and Application?

Fishing hooks come in a variety of shapes, sizes, and materials, each designed for specific fish species and fishing techniques. They are primarily used by fishing equipment suppliers and outdoor retailers. B2B buyers should consider the type of fishing (freshwater vs. saltwater) and the species targeted when selecting fishing hooks. While they offer specialized designs that can enhance catch rates, they may face seasonal demand fluctuations, making it essential for buyers to plan their inventory accordingly.

What Makes Decorative Hooks Ideal for Retail Applications?

Decorative hooks are designed with aesthetics in mind, often made from lighter materials and featuring unique designs. They are commonly used in home decor and retail displays to enhance product presentation. Buyers should focus on the visual appeal and material quality when purchasing decorative hooks. While they can significantly improve the aesthetic of a display, their lower durability makes them unsuitable for heavy-duty applications, which is a critical consideration for businesses in retail environments.

How are Automotive Hooks Engineered for Specific Needs?

Automotive hooks are engineered for specific vehicle models, ensuring high strength and reliability. They are used by automotive manufacturers and repair shops where precise fit and performance are paramount. Buyers should assess the compatibility of hooks with various vehicle models and their strength ratings. Although automotive hooks can be more expensive due to their specialized nature, they offer tailored solutions that can enhance vehicle performance and safety.

Why Consider Custom Hooks for Unique Business Needs?

Custom hooks provide tailored designs based on specific client requirements, making them suitable for specialized industries and custom projects. B2B buyers should consider the intended application and the lead time for production when opting for custom hooks. While they can maximize efficiency and meet unique needs, the longer lead times and potentially higher costs can be a drawback for businesses with tight timelines or budget constraints.

Related Video: Heat Pump Thermostat O, B, and C Terminal Variations Explained

Key Industrial Applications of hook manufacturer

| Industry/Sector | Specific Application of Hook Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Lifting and Rigging Equipment | Enhances safety and efficiency in material handling | Compliance with safety standards and load capacity |

| Marine | Mooring and Anchoring Solutions | Provides stability and security for vessels | Corrosion resistance and material certification |

| Logistics and Warehousing | Cargo Handling and Storage Solutions | Optimizes space utilization and improves workflow | Durability under heavy loads and compatibility with existing systems |

| Agriculture | Equipment for Harvesting and Transporting Goods | Increases efficiency in farm operations | Adaptability to various agricultural machinery |

| Mining | Heavy-Duty Hooks for Material Transport | Ensures safe and reliable movement of materials | High tensile strength and resistance to wear and tear |

How is Hook Manufacturer Used in Construction?

In the construction industry, hook manufacturers supply lifting and rigging equipment that is vital for moving heavy materials. These hooks are used in cranes and hoists to lift beams, concrete blocks, and other heavy items. The primary challenge is ensuring safety and compliance with regulatory standards. International buyers from regions like Africa and the Middle East must consider load capacities, certifications, and the ability to withstand harsh environmental conditions when sourcing these products.

What Role Do Hooks Play in Marine Applications?

In marine applications, hooks are essential for mooring and anchoring vessels. They provide the necessary stability and security to keep ships in place against currents and winds. The main requirement for marine hooks is corrosion resistance due to constant exposure to saltwater. Buyers from South America and Europe should prioritize sourcing hooks made from high-grade materials that meet maritime standards to ensure longevity and reliability.

How Are Hooks Utilized in Logistics and Warehousing?

In logistics and warehousing, hooks are integral to cargo handling and storage solutions. They facilitate the efficient movement of goods, allowing for better space utilization and improved workflow. Buyers must consider the durability of hooks under heavy loads and their compatibility with existing equipment. International buyers should also assess the supply chain reliability of manufacturers to ensure timely delivery and consistent quality.

What Applications Exist for Hooks in Agriculture?

Agricultural operations utilize hooks for harvesting and transporting goods. These hooks are attached to machinery such as tractors and harvesters, allowing for the efficient movement of crops. The main challenge in agriculture is ensuring that the hooks can adapt to various machinery types and withstand the rigors of outdoor use. Buyers from Africa and South America should look for manufacturers that offer customizable solutions tailored to specific agricultural needs.

Why Are Heavy-Duty Hooks Important in Mining?

In the mining sector, heavy-duty hooks are crucial for the safe transport of materials. These hooks are designed to handle extreme loads and conditions, ensuring the reliable movement of ores and minerals. Key considerations for international buyers include the hooks’ tensile strength and resistance to wear and tear, as well as compliance with industry safety standards. Buyers from regions such as the Middle East should prioritize sourcing from manufacturers known for their robust quality control processes.

Related Video: Types Of Flowmeters And Their Industrial Applications.

3 Common User Pain Points for ‘hook manufacturer’ & Their Solutions

Scenario 1: Difficulty in Ensuring Quality Control in Hook Manufacturing

The Problem:

International B2B buyers often face significant challenges in maintaining quality control when sourcing hooks from manufacturers, especially when dealing with suppliers in different regions such as Africa or South America. The inconsistency in production standards can lead to defective products, which not only affects the buyer’s operations but can also result in costly returns and damaged reputations. For instance, a buyer from Europe might find that the hooks sourced from a South American manufacturer do not meet the necessary tensile strength specifications, leading to failures during critical applications.

The Solution:

To mitigate quality control issues, buyers should implement a comprehensive supplier evaluation process before finalizing contracts. This includes conducting thorough audits of the manufacturer’s facilities and production processes. Engaging third-party quality assurance firms to inspect products before shipment can also be beneficial. Furthermore, establishing clear quality benchmarks and specifications in the contract can prevent misunderstandings. It’s advisable to request samples and conduct performance tests in real-world applications to ensure the hooks meet the required standards. Building a strong relationship with the manufacturer can also foster better communication and proactive resolutions to quality concerns.

Scenario 2: Complicated Supply Chain Logistics for Hook Delivery

The Problem:

B2B buyers often encounter logistical challenges when sourcing hooks internationally. Delays in shipping, customs clearance issues, and inadequate inventory management can disrupt operations, particularly for businesses in the Middle East or Africa that depend on timely delivery for their projects. For example, a construction company in Saudi Arabia might experience project delays due to late arrivals of hooks needed for scaffolding, leading to financial losses and client dissatisfaction.

The Solution:

To streamline supply chain logistics, buyers should consider working with manufacturers who have a proven track record in efficient logistics management. Establishing a reliable communication channel with the manufacturer can facilitate updates on shipping schedules and potential delays. Additionally, using technology such as inventory management software can help track orders and optimize stock levels. Buyers should also explore local warehousing options or distributors who can hold inventory closer to their operations, reducing lead times. Forming partnerships with logistics companies that specialize in international shipping can further enhance reliability and efficiency.

Scenario 3: Lack of Customization Options for Specialized Applications

The Problem:

Many B2B buyers require hooks that meet specific industry standards or unique application needs. However, not all hook manufacturers offer customization, leaving buyers frustrated when they cannot source hooks tailored to their requirements. For instance, a company in Europe that manufactures custom machinery may need hooks that can withstand extreme temperatures and specific load capacities, but standard offerings from suppliers do not suffice.

The Solution:

To address the need for customized hooks, buyers should actively seek out manufacturers that specialize in custom solutions. Engaging in initial consultations with potential suppliers can help clarify customization capabilities and timelines. It’s essential to provide detailed specifications and possibly collaborate on design prototypes to ensure the final product meets all operational requirements. Additionally, leveraging local or regional manufacturers may lead to more flexibility in customization, as they might have the resources to accommodate unique requests. Establishing long-term partnerships with these manufacturers can also facilitate future customization needs as the buyer’s requirements evolve.

Strategic Material Selection Guide for hook manufacturer

What Are the Key Materials Used in Hook Manufacturing?

When selecting materials for hook manufacturing, it is essential to consider the specific requirements of the application, including environmental conditions and performance expectations. Below, we analyze four common materials: stainless steel, carbon steel, aluminum, and plastic. Each material has unique properties, advantages, and limitations that can significantly impact the performance and suitability of hooks for various applications.

How Does Stainless Steel Perform in Hook Manufacturing?

Key Properties: Stainless steel is known for its excellent corrosion resistance, high tensile strength, and ability to withstand extreme temperatures. It typically has a temperature rating of up to 800°C and can handle pressures up to 2000 psi, depending on the grade.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust and corrosion, making it ideal for marine and outdoor applications. However, it tends to be more expensive than other materials and can be challenging to machine, increasing manufacturing complexity.

Impact on Application: Stainless steel hooks are suitable for applications in corrosive environments, such as saltwater or chemical exposure. They are often used in fishing, marine equipment, and industrial applications requiring high strength.

Considerations for International Buyers: Buyers from regions like the Middle East and Europe should ensure compliance with standards such as ASTM A240 or DIN 17440 for stainless steel grades. Understanding local regulations regarding corrosion resistance can also be crucial.

What Are the Advantages of Carbon Steel Hooks?

Key Properties: Carbon steel offers high strength and hardness, making it suitable for heavy-duty applications. It typically has a lower corrosion resistance compared to stainless steel but can be treated with coatings to enhance durability.

Pros & Cons: The main advantage of carbon steel is its cost-effectiveness and ease of manufacturing. However, its susceptibility to rust and corrosion can limit its use in harsh environments unless adequately coated.

Impact on Application: Carbon steel hooks are commonly used in construction, automotive, and industrial applications where strength is paramount. They are often preferred for temporary applications due to their lower cost.

Considerations for International Buyers: Buyers in Africa and South America should be aware of local standards like ASTM A36 for structural steel. Coating options (e.g., galvanization) may also be essential to meet regional corrosion resistance requirements.

How Does Aluminum Compare in Hook Manufacturing?

Key Properties: Aluminum is lightweight and has good corrosion resistance, although it is not as strong as steel. It can withstand temperatures up to 400°C and is often anodized for enhanced durability.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, making it ideal for applications where weight is a concern. However, it has lower tensile strength compared to steel, which may limit its use in heavy-duty applications.

Impact on Application: Aluminum hooks are commonly used in recreational applications, such as camping and fishing, where weight savings are critical. They are also used in aerospace applications due to their lightweight properties.

Considerations for International Buyers: Buyers from Europe and the Middle East should consider compliance with standards like ASTM B221 for aluminum extrusions. Understanding the specific alloy grades suitable for their applications is also essential.

What Role Does Plastic Play in Hook Manufacturing?

Key Properties: Plastic hooks are lightweight, resistant to corrosion, and can be molded into various shapes. They typically have lower strength and temperature resistance compared to metals.

Pros & Cons: The main advantage of plastic is its versatility and low cost. However, plastic hooks may not be suitable for high-stress applications due to their lower mechanical properties.

Impact on Application: Plastic hooks are often used in household applications, such as hanging items or in low-load scenarios. They are also used in the food industry due to their non-corrosive nature.

Considerations for International Buyers: Buyers should ensure that the plastic materials meet food safety standards, especially in applications involving food handling. Compliance with relevant local regulations is crucial.

Summary Table of Material Selection for Hook Manufacturing

| Material | Typical Use Case for Hook Manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Marine and industrial applications | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Carbon Steel | Construction and automotive applications | Cost-effective and strong | Susceptible to rust unless coated | Medium |

| Aluminum | Recreational and aerospace applications | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

| Plastic | Household and low-load applications | Versatile and low cost | Not suitable for high-stress scenarios | Low |

This guide provides a detailed overview of material options for hook manufacturing, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for hook manufacturer

What Are the Main Stages in the Manufacturing Process of Hooks?

The manufacturing process for hooks involves several critical stages that ensure the final product meets both functional and aesthetic standards. Understanding these stages is crucial for B2B buyers, particularly those sourcing from regions like Africa, South America, the Middle East, and Europe.

-

Material Preparation: The process begins with selecting appropriate materials, typically stainless steel, carbon steel, or aluminum, depending on the intended use of the hooks. Buyers should ensure that the manufacturer uses high-grade materials that meet international standards. Before production, materials undergo inspection for quality, which may include checking for impurities and ensuring proper dimensions.

-

Forming: This stage involves shaping the raw materials into the desired hook form. Techniques such as forging, casting, and machining are commonly employed. Forging, for instance, enhances the strength of the hook by aligning the grain structure of the metal. Buyers should inquire about the specific techniques used, as this can significantly impact the durability of the hooks.

-

Assembly: After forming, hooks may require additional components, such as eyes or latches, which are assembled during this phase. This step may also involve welding or riveting parts together, depending on the hook design. Buyers should look for manufacturers that utilize automated assembly processes, as this often leads to higher precision and consistency.

-

Finishing: The final stage includes surface treatments such as polishing, coating, or galvanizing to enhance corrosion resistance and improve appearance. Finishing processes can significantly affect the hook’s longevity, especially in harsh environments. Buyers should verify that the manufacturer employs suitable finishing methods for their specific applications.

How Is Quality Assurance Implemented in Hook Manufacturing?

Quality assurance (QA) is a fundamental aspect of the manufacturing process, ensuring that the hooks produced meet both international standards and buyer expectations.

-

International Standards: Many hook manufacturers adhere to international standards like ISO 9001, which outlines requirements for a quality management system. Compliance with these standards indicates a commitment to quality and customer satisfaction. Additionally, industry-specific certifications such as CE marking for European markets or API standards for oil and gas applications are critical.

-

Quality Control Checkpoints: Implementing checkpoints throughout the manufacturing process is vital to maintaining product quality. Key checkpoints include:

– Incoming Quality Control (IQC): Inspects raw materials upon arrival to confirm they meet specified standards.

– In-Process Quality Control (IPQC): Monitors production processes to catch defects early, ensuring that any deviations are addressed immediately.

– Final Quality Control (FQC): Conducts thorough inspections of the finished products to ensure they meet all specifications before shipping. -

Common Testing Methods: Various testing methods are employed to assess the quality of hooks, including tensile strength tests, load tests, and corrosion resistance tests. Buyers should inquire about the specific tests conducted and the frequency of these tests to ensure the reliability of the products.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from diverse regions, verifying a supplier’s quality control processes is essential for ensuring product reliability and compliance with local regulations.

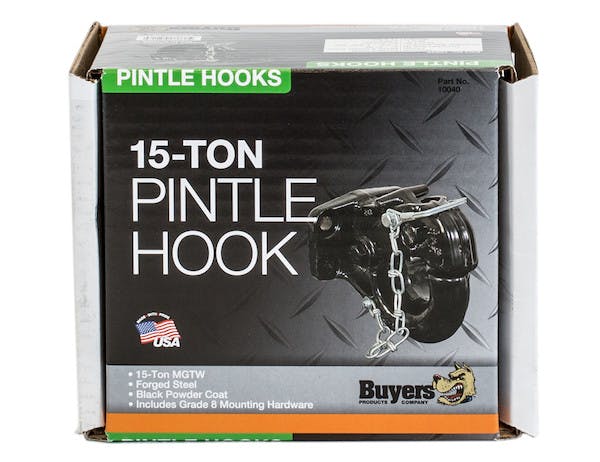

A stock image related to hook manufacturer.

-

Supplier Audits: Conducting on-site audits is one of the most effective ways to evaluate a manufacturer’s quality control processes. This allows buyers to see firsthand the production methods, QA protocols, and working conditions. It is advisable to create a checklist based on key quality criteria before the audit.

-

Reviewing Quality Reports: Manufacturers should be willing to provide quality reports that detail their QA processes, test results, and compliance with international standards. Buyers should request these documents regularly to stay informed about the quality status of the products.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s quality control measures. These services often conduct random checks and provide detailed reports that can help buyers make informed decisions.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

Understanding the nuances of quality control and certification is vital for international buyers, especially those operating in regions with varying regulatory standards.

-

Regional Compliance: Different regions have specific compliance requirements. For instance, hooks used in construction in Europe may need to meet stricter safety standards than those in other regions. Buyers should familiarize themselves with local regulations and ensure their suppliers can comply.

-

Documentation and Traceability: Maintaining thorough documentation of quality control processes and certifications is crucial. This documentation should include material traceability records, test results, and compliance certificates. Buyers should ensure that their suppliers can provide this documentation upon request.

-

Cultural Considerations: Cultural differences can impact communication and expectations regarding quality. B2B buyers should approach discussions about quality assurance with an understanding of these differences and be clear about their specific requirements.

Conclusion

Navigating the manufacturing processes and quality assurance protocols of hook manufacturers can be complex, particularly for international B2B buyers. By understanding the main stages of manufacturing, the importance of quality assurance, and how to verify supplier practices, buyers can make informed decisions that align with their quality expectations and operational needs. Engaging with suppliers who prioritize quality control and compliance with international standards will ultimately lead to better product reliability and customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hook manufacturer’

Introduction

Navigating the procurement process for hook manufacturing can be complex, especially for international B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe. This practical sourcing guide provides a step-by-step checklist to streamline your sourcing efforts and ensure you partner with the right manufacturers that meet your technical and business needs.

Step 1: Define Your Technical Specifications

Clearly articulating your technical requirements is the foundation of successful sourcing. This includes the type of hooks you need (e.g., fishing hooks, industrial hooks, etc.), material specifications, dimensions, and load-bearing capacities.

– Why It Matters: Precise specifications help potential suppliers understand your needs, reducing the risk of miscommunication and ensuring the final product meets your quality standards.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential hook manufacturers. Utilize online platforms, trade shows, and industry-specific directories to compile a list of candidates.

– What to Look For: Focus on suppliers with a solid reputation, positive customer reviews, and relevant industry experience. Pay attention to their geographical location, as proximity can affect shipping costs and lead times.

Step 3: Evaluate Supplier Certifications and Compliance

Before moving forward, verify that your shortlisted suppliers hold relevant certifications (ISO, CE, etc.) and comply with industry standards.

– Why It Matters: Compliance ensures that the manufacturer adheres to quality and safety standards, which is crucial for minimizing risks in your supply chain and ensuring product reliability.

Step 4: Request Samples for Quality Assessment

Ask for product samples from potential manufacturers to evaluate the quality of their hooks firsthand.

– What to Look For: Assess the craftsmanship, material quality, and adherence to your specifications. This step is vital to avoid future disappointments and ensure the product meets your expectations.

Step 5: Inquire About Production Capacity and Lead Times

Understanding a supplier’s production capabilities and lead times is essential for aligning with your business schedule.

– Why It Matters: Manufacturers with sufficient capacity can meet your order volumes without compromising quality, while clear lead times help you plan your inventory and avoid stockouts.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules.

– What to Consider: Ensure the terms are favorable and sustainable for both parties. Consider incorporating clauses for quality assurance, delivery timelines, and penalties for non-compliance to safeguard your investment.

Step 7: Establish Communication Protocols

Effective communication is key to a successful partnership. Establish clear channels for ongoing dialogue regarding order updates, quality issues, and logistics.

– Why It Matters: Open lines of communication foster transparency and trust, enabling quick resolutions to potential issues and ensuring that both parties are aligned throughout the procurement process.

By following this checklist, you can effectively navigate the complexities of sourcing hook manufacturers, ensuring that you select a reliable partner who meets your technical and operational requirements.

Comprehensive Cost and Pricing Analysis for hook manufacturer Sourcing

What Are the Key Cost Components in Hook Manufacturing?

Understanding the cost structure in hook manufacturing is crucial for international B2B buyers. The primary cost components include:

-

Materials: The type of materials used (e.g., stainless steel, carbon steel, or plastic) significantly impacts costs. High-quality materials not only ensure durability but also influence the price.

-

Labor: Labor costs vary by region and affect the overall pricing structure. Countries with lower labor costs may provide competitive pricing but may compromise on quality.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce these overhead costs.

-

Tooling: The initial setup cost for molds and tooling can be substantial, especially for custom designs. Buyers should inquire about these costs upfront.

-

Quality Control (QC): Implementing strict quality control measures can increase costs but is essential for ensuring product reliability and compliance with international standards.

-

Logistics: Shipping costs can vary widely based on location and Incoterms. It is vital to consider logistics in the total cost equation.

-

Margin: Manufacturers typically add a profit margin to cover their costs and ensure sustainability. This margin can vary based on market conditions and competition.

How Do Pricing Influencers Impact Hook Manufacturing Costs?

Several factors can influence pricing in hook manufacturing, including:

-

Volume/MOQ: Manufacturers often offer better pricing for larger orders due to economies of scale. Understanding minimum order quantities (MOQs) can help buyers negotiate better rates.

-

Specifications and Customization: Custom designs or specific material requirements can drive costs up. Buyers should be clear about their needs to avoid unexpected charges.

-

Material Quality and Certifications: Higher-quality materials and necessary certifications (like ISO or CE) typically increase costs. Buyers should assess whether these are essential for their application.

-

Supplier Factors: The reputation, reliability, and location of suppliers can affect pricing. Established suppliers may charge more but often provide better quality and service.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) will influence shipping costs and responsibilities, affecting the overall price.

What Are the Best Negotiation Tips for B2B Buyers?

To ensure cost efficiency when sourcing hooks, buyers should consider the following negotiation strategies:

-

Research Market Prices: Familiarizing yourself with market prices can empower negotiations. Seek quotes from multiple suppliers to understand the price range.

-

Discuss Volume Discounts: If your business requires regular purchases, negotiating volume discounts can lead to significant savings over time.

-

Evaluate Total Cost of Ownership: Consider not just the purchase price but also the costs associated with shipping, storage, and potential quality issues. A lower upfront cost may lead to higher total costs if the product requires frequent replacement.

-

Build Long-term Relationships: Cultivating strong relationships with suppliers can lead to better pricing and terms. Suppliers may be more willing to offer discounts or favorable terms to long-term clients.

What Pricing Nuances Should International Buyers Be Aware Of?

For international B2B buyers from Africa, South America, the Middle East, and Europe, several pricing nuances can impact sourcing decisions:

-

Currency Fluctuations: Exchange rates can significantly affect pricing. Buyers should consider this when negotiating contracts and pricing agreements.

-

Regulatory Compliance Costs: Import duties, tariffs, and compliance with local regulations can add to the total cost. Understanding these factors beforehand can prevent budget overruns.

-

Cultural Considerations: Different regions have varying negotiation styles and expectations. Being culturally aware can enhance communication and facilitate smoother negotiations.

Disclaimer on Indicative Prices

It is essential to note that prices for hook manufacturing can fluctuate based on market conditions, supplier changes, and material costs. Buyers should seek updated quotes and engage in thorough discussions with potential suppliers to ensure accurate pricing aligned with their needs.

Alternatives Analysis: Comparing hook manufacturer With Other Solutions

When considering the procurement of a hook manufacturer, it is essential to explore alternative solutions that can meet similar operational needs. Understanding the comparative advantages and disadvantages of each option can significantly influence a B2B buyer’s decision, especially in diverse markets across Africa, South America, the Middle East, and Europe.

| Comparison Aspect | Hook Manufacturer | Alternative 1: 3D Printed Hooks | Alternative 2: Off-the-Shelf Hook Solutions |

|---|---|---|---|

| Performance | High durability and load capacity | Variable, depends on material | Standardized performance, limited customization |

| Cost | Higher initial investment | Potentially lower, depending on design | Moderate, based on volume and materials used |

| Ease of Implementation | Requires specialized setup | Quick design and production | Readily available, minimal setup needed |

| Maintenance | Requires regular inspections | Minimal, depending on use | Standard maintenance procedures |

| Best Use Case | Heavy-duty applications | Prototyping and low-volume runs | General applications with no specific requirements |

What Are the Advantages and Disadvantages of 3D Printed Hooks?

3D printing has emerged as a versatile alternative for producing hooks. The primary advantage is the ability to create complex designs tailored to specific needs, making it an ideal choice for prototyping or low-volume production runs. However, the performance of 3D printed hooks can vary significantly based on the materials used (e.g., plastics vs. metals), potentially limiting their application in heavy-duty situations. Moreover, while the initial costs may be lower, the long-term durability could necessitate more frequent replacements, impacting overall cost-effectiveness.

How Do Off-the-Shelf Hook Solutions Compare?

Off-the-shelf hooks offer a straightforward solution for businesses requiring standard hooks for general applications. They are readily available and often come with established performance metrics, making them easy to implement. However, their limitations lie in customization; businesses with specific needs may find them inadequate. Additionally, while they are typically less expensive than custom solutions, the lack of tailored options may lead to inefficiencies in certain applications.

Conclusion: How Can B2B Buyers Choose the Right Hook Solution?

Selecting the right hook solution involves analyzing specific operational needs, budget constraints, and application requirements. For heavy-duty applications demanding high performance and durability, a hook manufacturer may be the most suitable choice despite the higher initial investment. Conversely, for businesses looking for flexibility and rapid prototyping, 3D printed hooks may offer significant advantages. Off-the-shelf solutions serve well in environments with standard needs but may lack the specific adaptations some businesses require. Ultimately, buyers should assess their unique circumstances and prioritize solutions that align with their operational goals and financial strategies.

Essential Technical Properties and Trade Terminology for hook manufacturer

What Are the Essential Technical Properties for Hook Manufacturers?

When sourcing hooks for industrial applications, understanding the technical specifications is crucial for ensuring product quality and suitability. Here are the key properties that international B2B buyers should consider:

-

Material Grade

– Hooks are typically made from various materials such as stainless steel, carbon steel, or aluminum. The material grade affects durability, corrosion resistance, and weight capacity. For example, stainless steel hooks are preferred for marine applications due to their resistance to rust and saltwater. -

Load Capacity

– This specification indicates the maximum weight a hook can safely handle without deformation or failure. Load capacity is critical for applications in construction, shipping, and logistics. Buyers should ensure the load capacity meets or exceeds the requirements of their specific use case to prevent accidents. -

Tolerance

– Tolerance refers to the permissible limit of variation in dimensions. A tight tolerance is essential for applications requiring precise fit and function, such as in machinery or safety systems. Buyers should inquire about tolerance levels to ensure compatibility with their existing systems. -

Finish Type

– The finish applied to hooks, such as powder coating, galvanization, or anodizing, influences both aesthetics and performance. Different finishes provide varying levels of corrosion resistance and grip. Understanding the finish type can help buyers select hooks suitable for specific environmental conditions. -

Size and Dimensions

– The size and dimensions of hooks must align with their intended application. Buyers should consider not only the hook size but also the opening width and overall length to ensure they fit within their operational parameters. -

Safety Factor

– The safety factor is the ratio of the maximum load a hook can support to the intended load. A higher safety factor provides an additional margin of safety, which is particularly important in critical applications. Buyers should verify the safety factor to ensure reliability and compliance with industry standards.

What Are Common Trade Terminology and Jargon in Hook Manufacturing?

Understanding industry terminology is vital for effective communication with suppliers and manufacturers. Here are some common terms that B2B buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of hooks, buyers may engage with OEMs to procure custom-designed hooks that meet specific operational requirements. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory and budget constraints. It can also affect pricing, as larger orders often attract bulk discounts. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing and terms for specific products. When sourcing hooks, submitting an RFQ can help buyers compare offers and negotiate better deals. -

Incoterms (International Commercial Terms)

– Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, risk transfer, and delivery. Familiarity with Incoterms can help B2B buyers understand their obligations and costs associated with importing hooks from overseas suppliers. -

Lead Time

– Lead time is the amount of time it takes from placing an order to receiving the product. For hooks, understanding lead times is crucial for project planning and ensuring timely delivery, especially in industries where delays can result in significant costs. -

Certification Standards

– Certifications, such as ISO or ASTM, indicate that products meet specific quality and safety standards. Buyers should prioritize suppliers who provide certifications to ensure compliance with industry regulations and enhance credibility.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when sourcing hooks, ultimately leading to better product selection and successful procurement strategies.

Navigating Market Dynamics and Sourcing Trends in the hook manufacturer Sector

What Are the Current Market Dynamics and Key Trends in the Hook Manufacturer Sector?

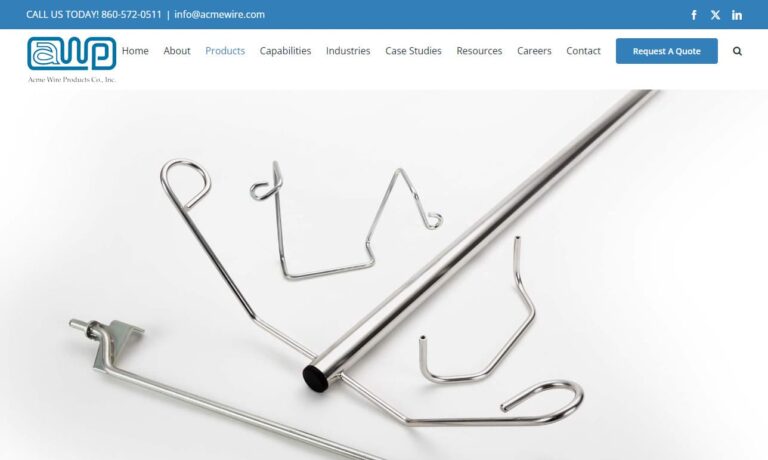

A stock image related to hook manufacturer.

The hook manufacturing sector is experiencing significant growth driven by various global factors. Key among these is the rising demand for durable and high-quality hooks across diverse industries such as construction, fishing, and logistics. The increasing emphasis on operational efficiency and safety standards has led to the adoption of advanced materials and manufacturing techniques. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions.

Emerging technologies are reshaping the hook manufacturing landscape. For instance, automation and smart manufacturing processes are enhancing production efficiency while reducing costs. Additionally, the integration of digital platforms for sourcing and procurement is becoming commonplace. Buyers are now leveraging e-commerce platforms and online marketplaces to access a wider range of suppliers and products, allowing for more competitive pricing and better negotiation terms.

Furthermore, geopolitical factors and trade policies are influencing sourcing trends. For instance, buyers in the Middle East may be affected by regional trade agreements, while those in Europe are navigating the complexities of post-Brexit trade regulations. Understanding these market dynamics is essential for B2B buyers to mitigate risks and seize opportunities in the hook manufacturing sector.

How Is Sustainability and Ethical Sourcing Influencing the Hook Manufacturing Sector?

Sustainability has emerged as a critical concern in the hook manufacturing industry. The environmental impact of manufacturing processes, including energy consumption and waste generation, has prompted buyers to prioritize sustainable sourcing practices. As international B2B buyers increasingly seek suppliers with environmentally friendly practices, the demand for ‘green’ certifications and materials is on the rise.

Ethical sourcing is also gaining traction, with many companies committed to ensuring that their supply chains are free from exploitation and adhere to fair labor practices. For buyers in Africa and South America, where economic disparities may be more pronounced, choosing suppliers who uphold ethical standards is not just a moral obligation but also a market differentiator. Suppliers with recognized certifications, such as ISO 14001 for environmental management or Fair Trade certification, can provide assurance to buyers that they are making responsible purchasing decisions.

Incorporating sustainability and ethical sourcing into procurement strategies can also enhance brand reputation and customer loyalty. As consumers become more environmentally conscious, businesses that prioritize these values are likely to attract a more discerning customer base.

What Is the Brief Evolution of the Hook Manufacturing Sector?

The hook manufacturing sector has evolved significantly over the past few decades. Initially dominated by traditional manufacturing techniques, the industry has undergone a transformation with the introduction of advanced materials and automated production processes. The adoption of steel and other durable materials has improved the performance and lifespan of hooks, catering to the evolving needs of various industries.

The globalization of trade has also played a pivotal role in this evolution, allowing manufacturers from different regions to access broader markets. Today, international B2B buyers can source hooks from diverse suppliers across the globe, leading to increased competition and innovation within the industry. As the sector continues to adapt to technological advancements and changing consumer demands, it remains essential for buyers to stay informed about market trends and sourcing options to ensure they are partnering with the right manufacturers.

Frequently Asked Questions (FAQs) for B2B Buyers of hook manufacturer

-

How do I choose the right hook manufacturer for my business?

Choosing the right hook manufacturer involves several factors. Start by assessing their industry experience and track record. Look for manufacturers that specialize in the type of hooks you need, whether for fishing, construction, or other applications. Request samples to evaluate quality and durability, and consider their production capacity to meet your demand. Finally, check customer reviews and testimonials to gauge reliability and service levels. -

What are the common minimum order quantities (MOQ) for hook manufacturers?

Minimum order quantities (MOQ) can vary widely among hook manufacturers. Generally, MOQs can range from a few hundred to several thousand units, depending on the type of hook and the manufacturer’s capabilities. If you are a smaller business, look for manufacturers willing to negotiate MOQs or those that offer a tiered pricing model where smaller orders are possible at a higher cost per unit. -

What customization options should I expect from a hook manufacturer?

Most reputable hook manufacturers offer a range of customization options. This can include variations in size, material, finish, and packaging. Discuss your specific requirements during initial communications, as many manufacturers can also accommodate branding or unique design features. Ensure that the manufacturer has the capability to produce prototypes before committing to a larger order. -

How do I vet potential hook manufacturers for quality assurance?

Vetting manufacturers for quality assurance involves several steps. First, request certifications such as ISO or other relevant quality standards. Conduct site visits if possible, or utilize third-party auditing services. Ask about their quality control processes, including inspections and testing methods, to ensure they meet your specifications. Finally, consider starting with a smaller order to evaluate their product quality firsthand before scaling up. -

What payment terms are typical when working with international hook manufacturers?

Payment terms can vary by manufacturer and region. Common practices include upfront payments, partial payments upon order confirmation, and the balance due before shipping. For international transactions, consider using secure payment methods such as letters of credit or escrow services to protect your investment. Always clarify terms in writing and ensure they align with your cash flow capabilities. -

What logistics considerations should I keep in mind when sourcing hooks internationally?

When sourcing hooks from international manufacturers, logistics play a crucial role in your supply chain. Evaluate shipping options, including air freight for speed or sea freight for cost-effectiveness. Factor in lead times, customs clearance, and potential tariffs that may apply to your imports. Collaborate with a reliable freight forwarder who can navigate the complexities of international shipping and help minimize delays. -

How can I ensure timely delivery from my hook manufacturer?

To ensure timely delivery, establish clear communication with your manufacturer about production timelines and shipping schedules. Include penalties or incentives in your contract to encourage adherence to deadlines. Regularly monitor the production process and maintain open lines of communication to address any potential delays proactively. Setting up a logistics plan that accounts for buffer time can also mitigate risks.

- What are the best practices for establishing a long-term relationship with a hook manufacturer?

Building a long-term relationship with a hook manufacturer involves consistent communication, transparency, and mutual respect. Start by setting clear expectations regarding quality, delivery, and payment terms. Regularly provide feedback and collaborate on product improvements. Attend trade shows or manufacturer visits to strengthen the partnership and foster trust. A reliable relationship can lead to better pricing, priority service, and enhanced product offerings over time.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for hook manufacturer

In today’s competitive landscape, strategic sourcing stands as a pivotal element for B2B buyers in the hook manufacturing industry. By leveraging strategic sourcing practices, businesses can optimize their supply chains, reduce costs, and enhance product quality. Key takeaways include the importance of establishing long-term relationships with suppliers, conducting thorough market research, and utilizing technology to streamline procurement processes.

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should prioritize sourcing from manufacturers that align with their operational needs and sustainability goals. This not only fosters trust but also ensures a steady supply of high-quality hooks that meet local market demands.

As the industry evolves, buyers are encouraged to stay informed about emerging trends and technologies that can enhance sourcing strategies. By adopting a proactive approach and embracing innovation, businesses can position themselves for success in the global marketplace.

Engage with reputable hook manufacturers today to explore how strategic sourcing can drive your business forward. The future is bright for those who invest in smart sourcing solutions that align with their growth objectives.