Unlock Savings: The Complete Guide to LiFePO4 Batteries China (2025)

Introduction: Navigating the Global Market for lifepo4 batteries china

In the ever-evolving landscape of renewable energy solutions, sourcing LiFePO4 batteries from China presents both opportunities and challenges for international B2B buyers. With increasing global demand for sustainable energy storage options, businesses from Africa, South America, the Middle East, and Europe (including France and South Africa) are keen to tap into the vast potential of these batteries. However, navigating the complexities of the global market can be daunting, especially when it comes to ensuring quality, cost-effectiveness, and supplier reliability.

This comprehensive guide aims to demystify the process of sourcing LiFePO4 batteries from China. It covers a wide array of topics, including the different types of LiFePO4 batteries available, their diverse applications in various industries, and essential strategies for vetting suppliers. By addressing critical aspects such as pricing structures, shipping logistics, and regulatory compliance, this guide equips B2B buyers with the insights necessary for making informed purchasing decisions.

International buyers will find actionable insights tailored to their specific regional needs and market dynamics. Whether you’re looking to enhance your supply chain, improve product offerings, or simply understand the competitive landscape, this guide serves as a valuable resource. With a focus on empowering businesses to navigate the complexities of sourcing LiFePO4 batteries from China, it positions you to capitalize on this growing market and drive sustainable growth for your company.

Understanding lifepo4 batteries china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Lifepo4 Batteries | High energy density, long cycle life | Renewable energy storage, electric vehicles | Pros: Long lifespan, stable performance. Cons: Higher initial cost. |

| Prismatic Lifepo4 Batteries | Flat, rectangular shape, optimized for space efficiency | Consumer electronics, electric bikes | Pros: Space-saving design. Cons: Limited capacity compared to cylindrical types. |

| Cylindrical Lifepo4 Batteries | Robust design, excellent thermal management | Power tools, drones | Pros: High durability, good heat dissipation. Cons: Bulkier form factor. |

| Lithium Iron Phosphate Modules | Integrated systems with BMS, modular design | Large-scale energy storage, grid applications | Pros: Simplified installation. Cons: May require specialized knowledge for setup. |

| High-Temperature Lifepo4 Batteries | Enhanced performance in extreme conditions | Aerospace, industrial applications | Pros: Reliable in harsh environments. Cons: Limited availability and higher costs. |

What Are the Key Characteristics of Standard Lifepo4 Batteries?

Standard Lifepo4 batteries are renowned for their high energy density and long cycle life, making them an ideal choice for various applications. These batteries typically offer a nominal voltage of 3.2V per cell and can sustain over 2,000 charge cycles. B2B buyers should consider their applications in renewable energy storage systems and electric vehicles, where longevity and reliability are paramount. However, the higher initial investment can be a barrier for some businesses.

How Do Prismatic Lifepo4 Batteries Differ in Design and Application?

Prismatic Lifepo4 batteries feature a flat, rectangular design that optimizes space efficiency, making them suitable for applications where size is a constraint, such as in consumer electronics and electric bikes. These batteries can be stacked easily, allowing for compact battery packs. While they offer excellent space-saving benefits, their capacity may be limited compared to cylindrical alternatives. B2B buyers should weigh the trade-off between size and energy capacity when considering this type.

Why Choose Cylindrical Lifepo4 Batteries for Durability?

Cylindrical Lifepo4 batteries are characterized by their robust design and excellent thermal management capabilities. They are commonly used in power tools and drones due to their durability and ability to dissipate heat effectively. This design often leads to better performance in demanding environments. However, the bulkier form factor can be a disadvantage for applications with strict space requirements. Buyers should assess their specific needs for durability versus space constraints.

What Are the Benefits of Lithium Iron Phosphate Modules for Large-Scale Applications?

Lithium Iron Phosphate Modules represent an integrated solution that includes a Battery Management System (BMS) and a modular design, making them particularly suitable for large-scale energy storage and grid applications. These modules simplify installation and offer scalability for businesses looking to expand their energy capacity over time. However, they may require specialized knowledge for setup, which could be a consideration for B2B buyers without in-house expertise.

How Do High-Temperature Lifepo4 Batteries Perform in Extreme Conditions?

High-Temperature Lifepo4 batteries are specifically designed to perform reliably in extreme conditions, making them suitable for aerospace and industrial applications. They maintain efficiency and safety even at elevated temperatures, which is crucial for sectors that operate in harsh environments. However, their limited availability and higher costs can pose challenges for procurement. B2B buyers should evaluate their operational environments to determine if the investment is justified.

Related Video: Li-ion vs LiFePO4 Batteries: Advantages and Disadvantages

Key Industrial Applications of lifepo4 batteries china

| Industry/Sector | Specific Application of lifepo4 batteries china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Renewable Energy | Energy storage systems for solar and wind power | Efficient energy management and reduced costs | Ensure compatibility with existing systems and local regulations. |

| Electric Vehicles (EVs) | Powering electric buses and commercial vehicles | Lower operational costs and enhanced performance | Evaluate battery lifespan, charging infrastructure, and safety certifications. |

| Telecommunications | Backup power for telecom towers and data centers | Increased uptime and reliability of services | Assess capacity needs and integration with existing power solutions. |

| Industrial Equipment | Power supply for automated machinery and robotics | Improved productivity and reduced downtime | Confirm the battery’s discharge rates and operational temperature range. |

| Marine Applications | Energy storage for electric boats and vessels | Sustainable operation and reduced emissions | Investigate marine-grade certifications and environmental compliance. |

How Are Lifepo4 Batteries Used in Renewable Energy Applications?

In the renewable energy sector, lifepo4 batteries from China are pivotal for energy storage systems linked to solar and wind power installations. These batteries help in storing excess energy generated during peak production times, ensuring a stable energy supply during low generation periods. For international buyers, particularly those in Africa and South America, understanding local grid integration and energy regulations is essential for optimal deployment.

What Role Do Lifepo4 Batteries Play in Electric Vehicles?

Lifepo4 batteries are increasingly used in electric buses and commercial vehicles, significantly enhancing their performance and operational efficiency. These batteries provide a longer lifespan and faster charging capabilities compared to traditional lead-acid batteries. For B2B buyers in Europe and the Middle East, considerations such as battery lifecycle management and compatibility with existing EV infrastructure are crucial for maximizing investment returns.

Why Are Lifepo4 Batteries Important for Telecommunications?

In telecommunications, lifepo4 batteries serve as backup power sources for telecom towers and data centers, ensuring uninterrupted service during power outages. Their reliability and long cycle life reduce maintenance costs and enhance service reliability. Buyers from regions with unstable power supplies, like parts of Africa and South America, should prioritize sourcing batteries that meet specific capacity and integration requirements to safeguard their operations.

How Do Lifepo4 Batteries Enhance Industrial Equipment?

Lifepo4 batteries are integral to powering automated machinery and robotics in various industrial settings. These batteries offer high discharge rates and stability, which are critical for maintaining productivity and minimizing downtime. For international buyers, especially in Europe and the Middle East, it is vital to verify the operational temperature ranges and discharge characteristics to ensure compatibility with specific machinery.

What Are the Benefits of Lifepo4 Batteries in Marine Applications?

In marine applications, lifepo4 batteries provide energy storage for electric boats and vessels, promoting sustainable operation while reducing emissions. These batteries are designed to withstand harsh marine environments, making them suitable for various sea-going applications. B2B buyers should focus on sourcing marine-grade lifepo4 batteries that comply with environmental regulations and offer robust performance under marine conditions.

Related Video: China is Building Gravity Batteries

3 Common User Pain Points for ‘lifepo4 batteries china’ & Their Solutions

Scenario 1: Navigating Quality Concerns with Lifepo4 Batteries from China

The Problem: One of the primary challenges faced by B2B buyers, particularly in regions like Africa and South America, is the inconsistency in quality when sourcing Lifepo4 batteries from Chinese manufacturers. Many buyers have experienced receiving batteries that do not meet the specified capacity, performance standards, or safety regulations. This can lead to significant operational issues, including unexpected downtime, equipment damage, and financial losses. The fear of investing in subpar products often makes buyers hesitant to engage with suppliers, ultimately stifling business growth.

The Solution: To mitigate quality concerns, it is crucial for buyers to conduct thorough due diligence before finalizing any supplier agreements. Start by requesting product samples and conducting independent testing to verify performance claims. Additionally, consider partnering with suppliers who have established quality certifications, such as ISO 9001 or UL listing. Engaging third-party inspection services can also be beneficial; these agencies can perform on-site audits and ensure that the manufacturing processes adhere to international quality standards. By taking these proactive steps, buyers can reduce the risk of receiving inferior products and build long-term relationships with reputable suppliers.

Scenario 2: Understanding Regulatory Compliance for Lifepo4 Batteries

The Problem: B2B buyers in Europe and the Middle East often grapple with navigating the complex landscape of regulatory compliance associated with importing Lifepo4 batteries. Different regions have varying regulations regarding battery safety, recycling, and transportation. Failing to comply with these regulations can lead to severe penalties, product recalls, and damage to a company’s reputation. This complexity can deter potential buyers from entering the market or lead to costly mistakes.

The Solution: To ensure compliance, it is essential for buyers to familiarize themselves with the specific regulations governing Lifepo4 batteries in their target market. This can be achieved by consulting local regulatory bodies or industry associations that provide guidance on compliance issues. Furthermore, sourcing from suppliers who are well-versed in international regulations can simplify this process. Ask potential suppliers for documentation proving compliance with relevant standards, such as the European Union’s Battery Directive or the United Nations’ transport regulations. Regular training and updates on regulatory changes can also empower buyers to stay informed and proactive in their compliance efforts.

Scenario 3: Managing Supply Chain Disruptions in Lifepo4 Battery Procurement

The Problem: Supply chain disruptions can significantly impact B2B buyers’ ability to procure Lifepo4 batteries in a timely manner. Issues such as shipping delays, geopolitical tensions, or sudden increases in demand can lead to shortages, affecting operational efficiency and customer satisfaction. Buyers from regions like Africa may face additional challenges due to limited logistical infrastructure, making it harder to establish reliable supply chains with Chinese manufacturers.

The Solution: To effectively manage supply chain disruptions, buyers should diversify their supplier base to avoid dependency on a single source. Establishing relationships with multiple manufacturers can create a buffer against unforeseen disruptions. Additionally, implementing a just-in-time (JIT) inventory system can help manage stock levels more effectively, ensuring that you have enough batteries on hand without overcommitting resources. Collaborating with logistics experts who specialize in international shipping can also streamline the procurement process and provide real-time updates on shipment status. By taking these strategic steps, buyers can enhance their resilience against supply chain challenges and maintain a steady flow of Lifepo4 batteries.

Strategic Material Selection Guide for lifepo4 batteries china

When selecting materials for LiFePO4 batteries sourced from China, international B2B buyers must consider several common materials that significantly impact performance, durability, and cost. Below, we analyze four key materials used in the manufacturing of LiFePO4 batteries, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What are the Key Properties of Lithium Iron Phosphate (LiFePO4)?

Lithium Iron Phosphate (LiFePO4) is the primary cathode material used in LiFePO4 batteries. It exhibits excellent thermal stability, high safety, and a long cycle life. The temperature rating typically ranges from -20°C to 60°C, making it suitable for various climates. Its corrosion resistance is moderate, which is sufficient for most applications.

Pros & Cons: LiFePO4 offers high energy density and a long lifespan, making it a preferred choice for electric vehicles and renewable energy storage. However, its manufacturing process can be complex and costly, which may affect overall pricing.

Impact on Application: LiFePO4 is compatible with a wide range of applications, including electric vehicles and grid storage. Its stable performance under varying temperatures is crucial for regions with extreme weather conditions.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and JIS. Additionally, understanding local regulations regarding battery materials is essential, particularly in Europe, where stringent environmental regulations apply.

How Does Graphite Contribute to LiFePO4 Battery Performance?

Graphite is commonly used as the anode material in LiFePO4 batteries. Its key properties include excellent electrical conductivity and a high specific capacity, typically around 372 mAh/g. Graphite can withstand temperatures up to 60°C, but it has limited corrosion resistance.

Pros & Cons: The main advantage of graphite is its cost-effectiveness and high performance. However, its susceptibility to degradation over time can limit the battery’s lifespan, particularly in harsh environments.

Impact on Application: Graphite’s compatibility with various electrolytes makes it suitable for diverse applications, including consumer electronics and electric vehicles. However, its performance may degrade in high-temperature settings, which is a consideration for buyers in hotter regions like parts of Africa and the Middle East.

Considerations for International Buyers: Buyers should evaluate the sourcing of graphite, as it is often subject to geopolitical risks and supply chain disruptions. Compliance with local regulations regarding sourcing and environmental impact is also critical.

What Role Does Electrolyte Material Play in LiFePO4 Battery Efficiency?

The electrolyte in LiFePO4 batteries is typically a lithium salt dissolved in an organic solvent. Key properties include high ionic conductivity and a wide electrochemical window, which allows for efficient ion transport between the anode and cathode.

Pros & Cons: The main advantage of using high-quality electrolytes is improved battery performance and longevity. However, the cost of high-purity solvents can be significant, and improper handling can pose safety risks.

Impact on Application: The choice of electrolyte directly affects the battery’s efficiency and safety. In applications where rapid charging and discharging are critical, such as in electric vehicles, the right electrolyte choice can enhance performance.

Considerations for International Buyers: Buyers should ensure that the electrolyte materials meet safety and environmental standards, particularly in Europe, where regulations are stringent. Understanding the local market’s preferences for specific electrolyte compositions can also provide a competitive edge.

How Does the Separator Material Influence LiFePO4 Battery Safety?

The separator is a crucial component that prevents short circuits while allowing ionic movement. Common materials include polyethylene (PE) and polypropylene (PP), known for their thermal stability and chemical resistance.

Pros & Cons: The main advantage of using high-quality separators is enhanced safety and performance. However, lower-cost options may compromise battery safety and longevity.

Impact on Application: The separator’s performance is vital in high-drain applications, where efficiency and safety are paramount. In regions prone to high temperatures, selecting a separator with superior thermal stability is essential.

Considerations for International Buyers: Buyers should prioritize suppliers that adhere to international safety standards, such as UL and IEC. Additionally, understanding local preferences for separator materials can help in negotiating better terms with suppliers.

Summary Table of Material Selection for LiFePO4 Batteries

| Material | Typical Use Case for LiFePO4 Batteries China | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Lithium Iron Phosphate (LiFePO4) | Electric vehicles, renewable energy storage | High energy density, thermal stability | Complex manufacturing process | High |

| Graphite | Consumer electronics, electric vehicles | Cost-effective, high performance | Susceptible to degradation | Medium |

| Electrolyte | High-performance applications | Improved efficiency and longevity | High purity costs and handling risks | Medium |

| Separator | Safety-critical applications | Enhanced safety and performance | Lower-cost options may compromise safety | Medium |

This guide aims to empower international B2B buyers with actionable insights into material selection for LiFePO4 batteries from China, ensuring informed decisions that align with their specific regional needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for lifepo4 batteries china

What Are the Main Stages of Manufacturing LiFePO4 Batteries in China?

The manufacturing process of Lithium Iron Phosphate (LiFePO4) batteries is intricate and involves several critical stages. Understanding these stages helps B2B buyers make informed decisions when sourcing from Chinese manufacturers.

1. Material Preparation

The first step in LiFePO4 battery manufacturing involves sourcing and preparing raw materials. High-quality lithium iron phosphate powder is essential for optimal battery performance. Manufacturers typically procure raw materials from reputable suppliers, ensuring they meet industry standards. Additionally, the purity of materials is tested through various methods, including X-ray fluorescence (XRF) and scanning electron microscopy (SEM), to guarantee quality before proceeding.

2. Forming the Electrode

Once the materials are prepared, the next stage is forming the electrodes. This process includes mixing the LiFePO4 powder with conductive agents, such as carbon black, and a binder to form a slurry. The slurry is then coated onto aluminum or copper foils, depending on whether it’s the cathode or anode. This step is crucial as it directly influences the battery’s energy density and lifespan. Manufacturers often employ techniques like doctor blade coating or slot-die coating for uniform application.

3. Assembly of Cells

After the electrodes are formed, the assembly process begins. This involves stacking or winding the electrodes with separators to prevent short-circuiting. The assembly is conducted in a controlled environment to minimize contamination. Manufacturers may use automated machinery to enhance precision and efficiency during this stage. Attention to detail in this phase is vital, as improper assembly can lead to performance issues or safety hazards.

4. Finishing and Packaging

The final stage includes electrolyte filling, cell formation, and packaging. The cells are filled with electrolyte, which allows for ion movement. This is followed by an initial charge/discharge cycle to activate the cells, a process known as formation. Post-formation, the batteries undergo extensive testing before being packaged for shipping. Quality checks ensure that each battery meets the required specifications and performance metrics.

What Quality Assurance Standards Are Relevant for LiFePO4 Batteries?

Quality assurance is paramount in battery manufacturing, and adherence to international standards is essential for building trust with international B2B buyers. Understanding these standards can help buyers evaluate potential suppliers effectively.

ISO 9001 Certification

ISO 9001 is an internationally recognized standard that outlines the criteria for a quality management system. Manufacturers with ISO 9001 certification demonstrate their ability to consistently provide products that meet customer and regulatory requirements. Buyers should prioritize suppliers with this certification, as it indicates a commitment to quality and continuous improvement.

A stock image related to lifepo4 batteries china.

Industry-Specific Certifications (CE, UL, etc.)

In addition to ISO 9001, various industry-specific certifications are crucial for LiFePO4 batteries. The CE mark indicates compliance with European safety and environmental standards, while UL certification is vital for safety in North America. Understanding the specific certifications required in your region can help buyers ensure the batteries meet local regulations and safety standards.

How Do Manufacturers Ensure Quality Control Throughout the Process?

Quality control (QC) is integrated into every stage of the manufacturing process, with multiple checkpoints to ensure product integrity.

Incoming Quality Control (IQC)

IQC involves inspecting raw materials upon arrival at the manufacturing facility. This step is crucial for preventing defects in the final product. Manufacturers typically conduct tests for chemical composition and physical properties to verify that materials meet specified standards.

In-Process Quality Control (IPQC)

During the manufacturing process, IPQC is implemented to monitor each stage. This includes regular checks on electrode formation, assembly, and electrolyte filling. Techniques such as visual inspections, dimensional checks, and performance testing are employed to identify and rectify any issues before they escalate.

Final Quality Control (FQC)

FQC is conducted after the batteries are fully assembled and before they are shipped. This stage includes performance testing, cycle life assessments, and safety checks. Manufacturers may utilize advanced testing equipment to ensure that the batteries meet or exceed industry standards.

How Can B2B Buyers Verify Supplier Quality Control Measures?

To ensure the reliability of LiFePO4 batteries, B2B buyers must verify the quality control measures of potential suppliers. Here are actionable steps to do so:

Conduct Supplier Audits

Regular audits of suppliers can provide insights into their manufacturing processes and quality control practices. Buyers should consider on-site visits to evaluate the production environment, equipment, and adherence to safety standards. This also allows buyers to assess the suppliers’ commitment to quality.

Request Quality Control Reports

Buyers should request detailed QC reports from manufacturers, which outline the tests conducted at various stages of production. These reports should include data on material inspections, performance tests, and compliance with international standards. Transparent reporting indicates a supplier’s dedication to maintaining quality.

Engage Third-Party Inspection Services

Using third-party inspection services can provide an unbiased assessment of a manufacturer’s quality control processes. These services can conduct random checks and provide certification that the products meet specified standards. This step is particularly valuable for international buyers who may face language and regulatory barriers.

What Are the Nuances of Quality Control for International B2B Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality control when sourcing LiFePO4 batteries from China.

Understanding Regional Standards and Regulations

Buyers must familiarize themselves with regional regulations and standards that apply to batteries in their respective markets. For instance, European buyers should ensure compliance with RoHS and REACH directives, while Middle Eastern buyers might need to consider local safety certifications. This understanding helps buyers avoid compliance issues and potential financial losses.

Building Relationships with Suppliers

Establishing strong relationships with Chinese manufacturers can facilitate better communication regarding quality control practices. Buyers should engage in regular discussions about quality expectations and express their commitment to compliance. A collaborative approach can lead to improved product quality and responsiveness to buyer needs.

Monitoring Supply Chain Risks

International buyers should be vigilant about supply chain risks that can impact quality control. Political instability, logistical challenges, or changes in regulations can affect manufacturing processes. Implementing a robust risk management strategy can help mitigate these risks and ensure a steady supply of high-quality LiFePO4 batteries.

By understanding the manufacturing processes, quality assurance standards, and verification methods, international B2B buyers can make informed decisions and build successful partnerships with Chinese LiFePO4 battery manufacturers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘lifepo4 batteries china’

The following checklist is designed to assist international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, in sourcing LiFePO4 batteries from China. This step-by-step guide will help you navigate the complexities of international procurement, ensuring that you find a reliable supplier that meets your specific needs.

Step 1: Define Your Technical Specifications

Before you begin sourcing, it’s essential to have a clear understanding of your technical requirements. This includes the voltage, capacity, size, and intended application of the LiFePO4 batteries.

– Consider the end-use: Are they for electric vehicles, solar energy storage, or other applications?

– Compatibility: Ensure your specifications align with existing systems or products.

Step 2: Conduct Market Research on Suppliers

Market research is vital to identify potential suppliers in China. Use online platforms like Alibaba, Made-in-China, and Global Sources to find manufacturers.

– Look for specialization: Focus on suppliers that specifically produce LiFePO4 batteries rather than general battery manufacturers.

– Check reviews and ratings: User feedback can provide insights into the reliability and quality of the suppliers.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Assess manufacturing capabilities: Inquire about production capacity, technology used, and quality control processes.

– Visit their facilities if possible: A site visit can reveal much about their operational standards.

Step 4: Verify Supplier Certifications

Ensure that your chosen supplier meets international quality standards. Common certifications include ISO 9001 for quality management and CE for compliance with European health and safety standards.

– Request documentation: Ask for copies of certifications and check their validity.

– Understand local regulations: Different countries have varying requirements for battery imports, which can impact your sourcing decision.

Step 5: Request Samples for Testing

Before placing a bulk order, it’s essential to request samples of the batteries. Testing samples can help you assess performance, longevity, and compatibility with your systems.

– Conduct thorough testing: Evaluate the samples under real-world conditions that mimic your intended use.

– Feedback loop: Share your findings with the supplier to address any potential issues before full-scale production.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations to establish favorable terms and conditions. This includes pricing, payment methods, delivery timelines, and warranty policies.

– Be clear and firm: Clearly outline your expectations to avoid misunderstandings.

– Consider long-term partnerships: Discuss potential bulk order discounts or future collaboration opportunities.

Step 7: Establish Logistics and Shipping Arrangements

Finally, coordinate logistics to ensure timely delivery of your batteries. Work with your supplier to determine the most efficient shipping method, considering both cost and delivery times.

– Choose reliable freight forwarders: They can help navigate customs and ensure compliance with import regulations.

– Monitor shipment progress: Stay informed about your order status to address any delays proactively.

By following this structured checklist, you can streamline your sourcing process for LiFePO4 batteries from China, ensuring that you make informed decisions that align with your business needs and standards.

Comprehensive Cost and Pricing Analysis for lifepo4 batteries china Sourcing

What Are the Key Cost Components in Lifepo4 Battery Sourcing from China?

Understanding the cost structure is vital for international B2B buyers looking to source Lifepo4 batteries from China. The main cost components include:

-

Materials: The primary materials for Lifepo4 batteries include lithium iron phosphate (LiFePO4), lithium carbonate, and other chemical compounds. Prices of these raw materials fluctuate based on global supply and demand dynamics, so buyers should monitor market trends closely.

-

Labor: Labor costs in China can vary significantly by region. Typically, manufacturers in coastal cities may have higher labor costs than those in inland areas. However, the level of expertise required for battery production may necessitate skilled labor, which can increase costs.

-

Manufacturing Overhead: This encompasses utilities, rent, and equipment depreciation. Efficient manufacturers often optimize their overheads through automation, which can lower costs.

-

Tooling: Initial tooling costs can be substantial, particularly for custom battery designs. It’s essential to understand these costs upfront, especially if you require unique specifications.

-

Quality Control (QC): Rigorous QC measures ensure product reliability but can add to costs. Buyers should assess the QC processes of potential suppliers to ensure that they meet international standards.

-

Logistics: Freight charges, customs duties, and insurance are significant factors in the total cost. Buyers should factor in both the cost of shipping and the time it takes for delivery when negotiating contracts.

-

Margin: Suppliers will typically add a profit margin to their costs. Understanding the average margins in the industry can help buyers negotiate better pricing.

How Do Price Influencers Affect Lifepo4 Battery Costs?

Several factors influence the pricing of Lifepo4 batteries, which buyers should consider to make informed purchasing decisions:

-

Volume/MOQ: Minimum order quantities (MOQ) can dramatically affect pricing. Larger orders often qualify for bulk discounts, making it beneficial for buyers to consolidate purchases when feasible.

-

Specifications and Customization: Custom specifications, such as battery capacity or size, can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., ISO, CE) may lead to increased costs but can improve reliability and safety. It’s essential to weigh the cost against the potential benefits of quality assurance.

-

Supplier Factors: The reputation and experience of the supplier can impact pricing. Established suppliers with a proven track record may charge more but offer greater reliability.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can significantly affect pricing. Understanding terms like FOB (Free On Board) or CIF (Cost Insurance and Freight) can help buyers manage their total landed cost effectively.

What Are Effective Buyer Tips for Cost-Efficiency in Lifepo4 Battery Procurement?

Navigating the procurement landscape for Lifepo4 batteries requires strategic planning and negotiation skills. Here are some actionable tips:

-

Negotiate Terms and Pricing: Don’t hesitate to negotiate prices and payment terms. Building a strong relationship with suppliers can lead to better terms over time.

-

Evaluate Total Cost of Ownership (TCO): Beyond the purchase price, consider the TCO, which includes installation, maintenance, and potential warranty claims. A slightly higher upfront cost may result in lower overall expenses.

-

Understand Pricing Nuances: Be aware of regional pricing variances, particularly for buyers from Africa, South America, the Middle East, and Europe. Economic conditions and currency fluctuations can impact costs.

-

Conduct Supplier Audits: Before finalizing any deals, conduct audits of potential suppliers to assess their manufacturing capabilities and quality assurance processes. This can prevent costly mistakes later.

-

Stay Informed on Market Trends: Regularly research market trends and industry news. Staying informed can help you anticipate changes in material costs or supply chain disruptions.

Disclaimer

The prices discussed in this analysis are indicative and may vary based on specific supplier negotiations, market conditions, and logistical factors. Buyers should conduct thorough due diligence and obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing lifepo4 batteries china With Other Solutions

Introduction: What Are the Alternatives to Lifepo4 Batteries from China?

When considering battery solutions for industrial applications, especially in regions such as Africa, South America, the Middle East, and Europe, it’s essential to evaluate various options. Lithium Iron Phosphate (LiFePO4) batteries produced in China have gained popularity due to their stability and safety features. However, other battery technologies also exist that may better suit specific needs or budgets. This section compares LiFePO4 batteries from China with alternative solutions to provide international B2B buyers with actionable insights.

Comparison Table of Lifepo4 Batteries China and Alternatives

| Comparison Aspect | Lifepo4 Batteries China | Lead-Acid Batteries | Nickel-Metal Hydride (NiMH) Batteries |

|---|---|---|---|

| Performance | High cycle life (2000+ cycles) | Lower cycle life (300-500 cycles) | Moderate cycle life (500-1000 cycles) |

| Cost | Moderate initial cost; lower TCO | Low initial cost; higher TCO | Higher initial cost; moderate TCO |

| Ease of Implementation | Requires specialized handling | Easy to install and use | Moderate; requires specific charging equipment |

| Maintenance | Low maintenance; minimal upkeep | High maintenance; regular checks required | Moderate maintenance; periodic checks needed |

| Best Use Case | Renewable energy systems, electric vehicles | Backup power, automotive applications | Hybrid vehicles, portable electronics |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Lead-Acid Batteries?

Lead-acid batteries are one of the most traditional battery technologies. They are widely used due to their low initial cost and ease of availability. However, their shorter lifespan and higher total cost of ownership (TCO) make them less appealing for long-term projects. Maintenance is also a significant consideration, as lead-acid batteries require regular monitoring and electrolyte checks. They are best suited for applications where upfront costs are a priority and where regular maintenance is feasible.

How Do Nickel-Metal Hydride (NiMH) Batteries Compare?

Nickel-Metal Hydride (NiMH) batteries offer a middle ground between cost and performance. They provide a decent cycle life and are often used in hybrid vehicles and portable electronics. While they have a higher initial cost compared to lead-acid batteries, their moderate lifespan and performance can justify the investment in specific applications. Maintenance requirements are also less demanding than lead-acid batteries but still present a consideration for buyers. NiMH batteries are ideal for applications needing a balance between performance and cost without the complexities of lithium technologies.

Conclusion: How to Choose the Right Battery Solution for Your Needs

Selecting the right battery solution involves understanding your specific requirements, such as performance expectations, budget constraints, and maintenance capabilities. For projects focused on renewable energy or electric vehicles, Lifepo4 batteries from China might be the most effective choice due to their high cycle life and low maintenance needs. However, for applications with tight budgets or less demanding performance requirements, lead-acid or NiMH batteries could be more appropriate. By carefully evaluating each option against your operational needs and cost considerations, you can make an informed decision that aligns with your business objectives.

Essential Technical Properties and Trade Terminology for lifepo4 batteries china

What Are the Key Technical Properties of LiFePO4 Batteries?

When considering the procurement of LiFePO4 batteries from China, understanding their technical properties is essential for making informed purchasing decisions. Here are some critical specifications to keep in mind:

1. Energy Density

Energy density refers to the amount of energy stored per unit volume or weight. For LiFePO4 batteries, the energy density typically ranges from 90 to 160 Wh/kg. This property is crucial for B2B buyers as it directly impacts the battery’s performance in applications like electric vehicles and renewable energy storage. Higher energy density can lead to reduced weight and size, which is especially beneficial in industries where space is at a premium.

2. Cycle Life

Cycle life indicates the number of complete charge and discharge cycles a battery can undergo before its capacity significantly diminishes (usually defined as 80% of the original capacity). LiFePO4 batteries can achieve a cycle life of 2000 to 5000 cycles, making them a cost-effective choice over time. For B2B buyers, understanding cycle life is vital for evaluating long-term investments, particularly in applications that require frequent charging and discharging.

3. Thermal Stability

LiFePO4 batteries are known for their excellent thermal stability, which minimizes the risk of overheating and thermal runaway. This property is particularly important for buyers in regions with extreme temperatures, as it ensures safety and reliability. A battery that can withstand higher temperatures without compromising performance is a significant advantage in various industrial applications.

4. Charge/Discharge Rate

This specification indicates how quickly a battery can be charged and discharged, typically expressed in terms of C-rates. LiFePO4 batteries usually have a C-rate of 1C to 2C, meaning they can fully charge or discharge in one to two hours. For B2B buyers, understanding the charge/discharge rate is crucial for applications requiring rapid energy deployment, such as in emergency power supplies.

5. Internal Resistance

Internal resistance affects the efficiency of the battery during operation. Lower internal resistance leads to less energy loss in the form of heat, enhancing overall performance. For international buyers, particularly those in high-demand sectors, a battery with low internal resistance can lead to improved energy efficiency and cost savings in the long run.

What Are Common Trade Terminologies Related to LiFePO4 Batteries?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B market. Here are some common terms you should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of LiFePO4 batteries, working with an OEM allows buyers to source customized battery solutions that meet specific application needs. Understanding OEM relationships can help buyers ensure quality and compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for B2B buyers as it can affect inventory management and cash flow. Knowing the MOQ for LiFePO4 batteries can help businesses plan their purchases effectively, ensuring they meet both production and budgetary requirements.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products or services. For international buyers, submitting an RFQ for LiFePO4 batteries enables them to compare offers from different suppliers, ensuring they receive competitive pricing and terms.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is crucial for international transactions involving LiFePO4 batteries, as it clarifies who bears the risk and cost at various stages of the shipping process.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is essential for B2B buyers to effectively manage their supply chains and ensure timely project execution. For LiFePO4 batteries, lead times can vary based on customization and production schedules, making it a vital consideration in procurement planning.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of sourcing LiFePO4 batteries from China with greater confidence and clarity.

Navigating Market Dynamics and Sourcing Trends in the lifepo4 batteries china Sector

What Are the Key Market Trends Influencing the Lifepo4 Batteries Sector in China?

The global demand for lithium iron phosphate (LiFePO4) batteries is witnessing substantial growth, primarily driven by the increasing need for sustainable energy solutions and the proliferation of electric vehicles (EVs). International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are recognizing the potential of LiFePO4 batteries due to their safety, thermal stability, and longer lifecycle compared to traditional lithium-ion batteries.

Key trends shaping the sourcing landscape include advancements in battery technology, which enhance energy density and reduce costs. Additionally, the push for renewable energy sources has led to a surge in the integration of LiFePO4 batteries in solar energy systems. Countries like France and South Africa are investing heavily in green energy projects, creating a robust market for LiFePO4 batteries.

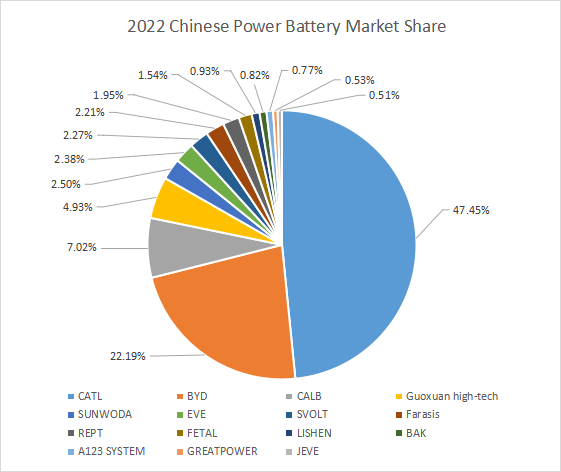

Moreover, Chinese manufacturers are increasingly adopting automation and AI in production processes, leading to improved quality control and faster turnaround times. This shift is particularly beneficial for international buyers who seek reliable suppliers capable of meeting large-scale demands swiftly. As a result, understanding the evolving market dynamics, including the competitive landscape among Chinese manufacturers, is crucial for international buyers looking to optimize their sourcing strategies.

How Does Sustainability Impact Sourcing Decisions for Lifepo4 Batteries?

Sustainability has become a cornerstone of sourcing strategies in the LiFePO4 battery sector. The environmental impact of battery production, including resource extraction and waste management, has led to heightened scrutiny from consumers and regulatory bodies alike. For B2B buyers, prioritizing ethical sourcing is not just a compliance issue but also a strategic advantage.

Ethical supply chains are increasingly being demanded by stakeholders, and suppliers that can demonstrate their commitment to sustainable practices are likely to gain a competitive edge. This includes sourcing raw materials from certified suppliers who adhere to environmental regulations and social responsibility standards. Certifications such as ISO 14001 for environmental management and the Responsible Minerals Initiative (RMI) are becoming essential for suppliers in the LiFePO4 battery space.

Furthermore, buyers should consider suppliers that utilize recycled materials or those that have implemented innovative technologies to reduce waste during production. By aligning with manufacturers who prioritize sustainability, international buyers can contribute to a circular economy while enhancing their brand reputation in markets that value green initiatives.

What Is the Historical Context of Lifepo4 Batteries in the Global Market?

The evolution of LiFePO4 batteries dates back to the early 1990s when they were first introduced as a safer alternative to traditional lithium-ion batteries. Initially, their high cost and lower energy density limited their application. However, advancements in technology and manufacturing processes have significantly improved their performance and affordability over the years.

By the mid-2000s, LiFePO4 batteries began gaining traction in various sectors, including renewable energy storage and electric vehicles, largely due to their safety profile and longevity. The Chinese market played a pivotal role in the global adoption of LiFePO4 technology, with numerous manufacturers emerging to meet rising demand. Today, China stands as a dominant player in the LiFePO4 battery market, exporting to regions including Africa, South America, the Middle East, and Europe.

A stock image related to lifepo4 batteries china.

Understanding this historical context is essential for B2B buyers as it highlights the trajectory of innovation and the current competitive landscape within the sector. It also emphasizes the importance of partnering with established suppliers who have a proven track record in quality and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of lifepo4 batteries china

-

How do I ensure the quality of LiFePO4 batteries sourced from China?

To ensure the quality of LiFePO4 batteries, it’s crucial to conduct thorough due diligence on potential suppliers. Request product samples and certifications, such as ISO 9001 and UN38.3, to verify compliance with international safety and quality standards. Additionally, consider visiting the manufacturing facility or employing third-party inspection services to assess production processes. Building a long-term relationship with suppliers can also facilitate better quality assurance practices. -

What are the key factors to consider when selecting a supplier for LiFePO4 batteries in China?

When selecting a supplier, evaluate their manufacturing capacity, experience in the industry, and customer reviews. Look for suppliers who specialize in LiFePO4 technology, as they are more likely to provide reliable products. It’s also essential to discuss their ability to meet your specific requirements, including customization options and minimum order quantities (MOQs). Communication and responsiveness can also indicate their commitment to customer service. -

What is the typical minimum order quantity (MOQ) for LiFePO4 batteries from Chinese suppliers?

The MOQ for LiFePO4 batteries can vary significantly between suppliers, typically ranging from 100 to 1,000 units. Smaller orders may be accepted, but they often come with higher per-unit costs. It’s advisable to negotiate MOQs based on your needs and explore options for bulk purchasing to reduce costs. Additionally, some suppliers may offer flexibility on MOQs if you establish a good relationship or commit to future orders. -

What payment terms should I expect when sourcing LiFePO4 batteries from China?

Payment terms can vary widely among suppliers, but common practices include a 30% deposit upfront with the balance due before shipping. Some suppliers may offer letters of credit or payment through platforms like Alibaba Trade Assurance for added security. Always clarify payment terms in your contract and consider negotiating terms that offer protection against potential risks, such as payment delays or product defects. -

How can I customize LiFePO4 batteries to meet my specific needs?

Most Chinese manufacturers offer customization options for LiFePO4 batteries, such as voltage, capacity, and packaging. When discussing customization, provide detailed specifications and any required certifications. It’s also beneficial to understand the lead times for custom orders, as they may differ from standard products. Establishing clear communication with your supplier will help ensure that your customization requirements are met effectively. -

What logistics considerations should I keep in mind when importing LiFePO4 batteries from China?

Logistics are crucial when importing batteries, especially due to regulations surrounding hazardous materials. Ensure your supplier provides proper packaging and documentation for shipping. Consider the shipping method (air or sea) based on cost and urgency, and work with freight forwarders experienced in battery shipments. Familiarize yourself with the import regulations in your country to avoid delays or additional fees upon arrival. -

What are the common certifications required for LiFePO4 batteries in international markets?

Common certifications for LiFePO4 batteries include CE, RoHS, UL, and UN38.3, which are essential for ensuring safety and compliance in international markets. Depending on your target region, additional certifications may be required. Always confirm that your supplier can provide these certifications, as they not only enhance the product’s credibility but also facilitate smoother customs clearance and market entry. -

How do I handle disputes or quality issues with my LiFePO4 battery supplier?

In the event of disputes or quality issues, first, communicate directly with your supplier to address the problem. Document all correspondence and maintain records of your agreements. If the issue remains unresolved, consider involving a third-party mediator or arbitration, as outlined in your contract. Establishing a clear return policy and warranty terms before placing an order can also provide a framework for resolving potential disputes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for lifepo4 batteries china

As the global demand for LiFePO4 batteries continues to surge, international B2B buyers must prioritize strategic sourcing to capitalize on the advantages offered by Chinese manufacturers. Key takeaways from this guide highlight the importance of understanding supply chain dynamics, the benefits of long-term partnerships, and the necessity of rigorous quality assessments. By aligning procurement strategies with the capabilities of Chinese suppliers, businesses from Africa, South America, the Middle East, and Europe can enhance their competitive edge in renewable energy and electric vehicle markets.

What should B2B buyers consider for future sourcing of LiFePO4 batteries? The outlook for this sector remains optimistic, driven by technological advancements and increased investment in sustainable energy solutions. International buyers are encouraged to explore innovative sourcing strategies, leveraging digital platforms to streamline procurement processes and improve transparency.

In conclusion, embracing a proactive approach to sourcing LiFePO4 batteries from China can lead to significant cost savings and operational efficiencies. By fostering strong relationships with reputable suppliers, businesses can not only secure quality products but also contribute to a more sustainable future. Now is the time to act—evaluate your sourcing strategies today to ensure a competitive advantage in the evolving global market.