Unlock Savings: The Complete RFID Custom Guide (2025)

Introduction: Navigating the Global Market for rfid custom

In an increasingly interconnected world, sourcing RFID custom solutions can present a formidable challenge for international B2B buyers, especially in diverse markets such as Africa, South America, the Middle East, and Europe. The rapid evolution of RFID technology, combined with varying regional regulations and supplier capabilities, complicates the decision-making process. This guide is designed to streamline your journey, providing essential insights into the types of RFID custom products available, their applications across various industries, and strategies for effective supplier vetting.

Understanding the landscape of RFID custom solutions is crucial for optimizing supply chain efficiency, enhancing inventory management, and improving overall operational effectiveness. This comprehensive resource delves into the nuances of sourcing, including the cost implications of different RFID technologies, the importance of compatibility with existing systems, and the potential for scalability as your business grows.

By addressing common concerns and providing actionable insights, this guide empowers B2B buyers to make informed purchasing decisions that align with their organizational goals. Whether you are in Brazil seeking innovative tracking solutions or in Saudi Arabia looking to enhance logistics operations, our curated information will help you navigate the global market for RFID custom products with confidence. Equip yourself with the knowledge needed to leverage RFID technology effectively, ensuring that your investments yield tangible results in your respective markets.

Understanding rfid custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Passive RFID Tags | No internal power source; rely on reader signals | Inventory management, asset tracking | Pros: Cost-effective, long lifespan. Cons: Limited range, slower read speeds. |

| Active RFID Tags | Battery-powered; longer read range | Real-time tracking, high-value asset management | Pros: Extended range, real-time data. Cons: Higher cost, battery maintenance required. |

| Semi-Passive RFID Tags | Battery-assisted; combines features of passive and active | Cold chain monitoring, temperature-sensitive goods | Pros: Improved read range, battery life. Cons: More expensive than passive tags. |

| NFC (Near Field Communication) | Short-range communication; requires close proximity | Retail payments, access control | Pros: Secure, user-friendly. Cons: Limited range, not suitable for bulk tracking. |

| RFID Inlays | Thin, flexible tags embedded in packaging | Retail, logistics, and supply chain | Pros: Space-saving, versatile. Cons: May require specialized readers. |

What Are the Key Characteristics of Passive RFID Tags?

Passive RFID tags are characterized by their lack of an internal power source. Instead, they harvest energy from the electromagnetic field generated by RFID readers. This makes them a cost-effective solution for various applications, particularly in inventory management and asset tracking. For B2B buyers, the longevity and low cost of these tags are significant advantages; however, they are limited in range and read speed, which can affect efficiency in high-demand environments.

How Do Active RFID Tags Differ from Other Types?

Active RFID tags contain their own power source, allowing them to transmit signals over longer distances. This feature makes them ideal for real-time tracking of high-value assets, such as shipping containers and expensive machinery. B2B buyers should consider the initial investment and ongoing battery maintenance when opting for active tags. While they provide extensive data and range, their higher cost may not be justifiable for all applications, particularly for smaller enterprises.

When Should You Consider Semi-Passive RFID Tags?

Semi-passive RFID tags combine the best features of passive and active tags. They utilize a battery to power their internal circuits, enhancing their read range while still relying on external readers for communication. This type is particularly useful in cold chain monitoring and for temperature-sensitive goods. For B2B buyers, the balance of improved functionality and moderate cost makes semi-passive tags an attractive option, although they are generally more expensive than passive tags.

What Are the Advantages of Using NFC Technology?

NFC technology operates on a short-range communication principle, requiring devices to be in close proximity to interact. This makes NFC suitable for applications like retail payments and access control systems. B2B buyers should weigh the benefits of security and user-friendliness against the limited range and suitability for bulk tracking. While NFC can enhance customer experiences, its application is more niche compared to broader RFID solutions.

How Do RFID Inlays Benefit B2B Supply Chains?

RFID inlays are thin, flexible tags that can be embedded into various packaging materials. Their space-saving design makes them particularly suitable for retail and logistics applications. For B2B buyers, the versatility of RFID inlays can streamline operations, although they may require specialized readers for optimal functionality. While they offer innovative tracking solutions, the need for compatible technology can be a consideration in the purchasing decision.

Related Video: How RFID Works? and How to Design RFID Chips?

Key Industrial Applications of rfid custom

| Industry/Sector | Specific Application of rfid custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Inventory Management and Loss Prevention | Enhanced inventory accuracy and reduced shrinkage rates | Compatibility with existing systems and scalability |

| Logistics and Supply Chain | Asset Tracking and Management | Improved visibility and reduced operational costs | Durability of tags and integration with tracking software |

| Healthcare | Patient Tracking and Medication Management | Increased patient safety and streamlined operations | Compliance with health regulations and data security |

| Manufacturing | Production Line Monitoring and Quality Control | Enhanced efficiency and reduced downtime | Customization options and real-time data capabilities |

| Agriculture | Livestock and Crop Management | Optimized resource management and increased yield | Environmental resilience of RFID tags and reader range |

How is RFID Custom Used in Retail for Inventory Management?

In the retail sector, RFID custom technology is revolutionizing inventory management by enabling real-time tracking of stock levels. Retailers can quickly scan products, ensuring accurate inventory counts and significantly reducing shrinkage due to theft or misplacement. For B2B buyers in regions like South America and Africa, sourcing RFID solutions that integrate seamlessly with existing Point of Sale (POS) systems is crucial. Additionally, the ability to customize tags for various product types can enhance operational efficiency and customer satisfaction.

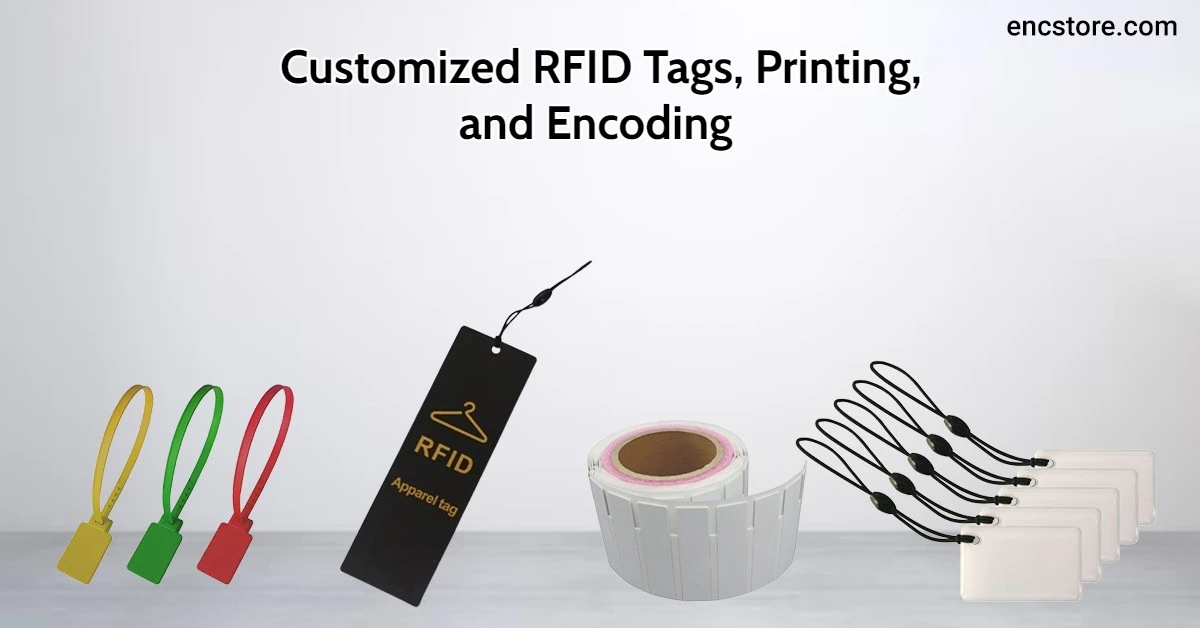

A stock image related to rfid custom.

What are the Benefits of RFID Custom in Logistics and Supply Chain Management?

Within logistics and supply chain management, RFID custom applications facilitate asset tracking, ensuring that goods are monitored throughout the supply chain. This technology provides businesses with improved visibility, allowing for better inventory control and reduced operational costs. For international buyers, particularly in the Middle East and Europe, it’s essential to consider the durability of RFID tags and their ability to withstand various environmental conditions. Integration with existing tracking software is also a key factor in maximizing the benefits of RFID technology.

How Does RFID Custom Enhance Patient Safety in Healthcare?

In healthcare, RFID custom solutions are essential for patient tracking and medication management. These systems help ensure that patients receive the correct medications at the right times, thereby increasing overall safety and operational efficiency. For B2B buyers in Africa and Europe, compliance with health regulations and data security standards is paramount when sourcing RFID solutions. Customizable features that cater to specific healthcare environments can also provide significant advantages in enhancing patient care.

In What Ways Does RFID Custom Improve Manufacturing Efficiency?

Manufacturing industries leverage RFID custom technology for production line monitoring and quality control. By tracking components in real-time, manufacturers can identify bottlenecks and reduce downtime, leading to enhanced efficiency. For international buyers, particularly from Brazil and Saudi Arabia, it’s important to evaluate the customization options available to meet unique production needs and ensure that the RFID system can provide real-time data capabilities that align with their operational goals.

How Can Agriculture Benefit from RFID Custom Solutions?

In agriculture, RFID custom applications are used for livestock and crop management, enabling farmers to optimize resource usage and increase yield. By tracking livestock movements and monitoring crop conditions, agricultural businesses can make informed decisions that enhance productivity. For B2B buyers in South America and Africa, sourcing RFID solutions that are resilient to environmental factors such as moisture and temperature variations is critical. Additionally, considering the range of RFID readers can help ensure comprehensive coverage across large agricultural areas.

Related Video: RFID Technology Explained

3 Common User Pain Points for ‘rfid custom’ & Their Solutions

Scenario 1: Ineffective Inventory Tracking Leading to Losses

The Problem: Many B2B buyers, especially in industries like retail and logistics across Africa and South America, face challenges with inventory management. Traditional tracking methods can be error-prone and labor-intensive, leading to discrepancies in stock levels. This not only results in lost sales due to stockouts but also increases carrying costs when excess inventory accumulates. The inability to efficiently track inventory in real-time can severely impact operational efficiency and customer satisfaction.

The Solution: Implementing custom RFID solutions can significantly enhance inventory tracking accuracy. Buyers should start by identifying specific inventory management needs and selecting RFID tags that can withstand environmental conditions, such as moisture and temperature fluctuations. For instance, tags designed for cold storage are essential for businesses in the food industry. Additionally, integrating RFID with inventory management software will provide real-time data analytics, allowing businesses to adjust stock levels dynamically. Regular training for staff on using RFID technology will further ensure seamless operation and minimize errors.

Scenario 2: High Initial Costs and ROI Concerns

The Problem: In regions like the Middle East and Europe, many businesses hesitate to invest in RFID technology due to concerns about high initial costs and uncertain return on investment (ROI). This is particularly true for small to medium-sized enterprises (SMEs) that may not have substantial capital reserves. The fear of investing in a technology that may not deliver immediate benefits can prevent these businesses from adopting RFID, thereby missing out on its long-term advantages.

The Solution: To mitigate these concerns, B2B buyers should conduct a thorough cost-benefit analysis before implementation. Start by evaluating the specific processes RFID can improve, such as reducing labor costs or minimizing stock discrepancies. It’s also advisable to consider phased implementation—starting with a pilot program to assess effectiveness before a full rollout. Partnering with RFID vendors that offer financing options or scalable solutions can also help manage initial costs. Additionally, establishing clear KPIs (Key Performance Indicators) to measure the impact of RFID on operations will assist in justifying the investment over time.

Scenario 3: Integration Challenges with Existing Systems

The Problem: A common pain point for international B2B buyers is the integration of RFID systems with existing IT infrastructure. Many companies, particularly in sectors like manufacturing and logistics, rely on legacy systems that may not support new technologies. This can lead to data silos, where information from RFID systems does not communicate with other business functions, resulting in inefficiencies and increased operational costs.

The Solution: To address integration challenges, buyers should prioritize working with RFID vendors who offer comprehensive support and customization services. It’s essential to assess the compatibility of RFID solutions with existing software and hardware systems. Buyers can also consider middleware solutions that facilitate communication between RFID systems and legacy platforms. Engaging IT specialists early in the planning process can help design a seamless integration strategy. Moreover, fostering a culture of collaboration between IT and operational teams will ensure that all stakeholders are aligned and can contribute to a smoother transition to RFID technology.

Strategic Material Selection Guide for rfid custom

What Are the Common Materials Used in RFID Custom Applications?

In the realm of RFID custom solutions, the selection of materials plays a critical role in determining the performance, durability, and application suitability of the products. Here, we will analyze four common materials used in RFID tags and readers, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Polypropylene Impact RFID Custom Solutions?

Key Properties: Polypropylene is a thermoplastic polymer known for its excellent chemical resistance, lightweight nature, and good thermal stability. It can withstand temperatures up to 100°C, making it suitable for various environments.

Pros & Cons: The primary advantage of polypropylene is its low cost and ease of manufacturing, which allows for high-volume production. However, it has lower durability compared to other materials, particularly in harsh environments, and may not perform well under extreme temperatures or pressures.

Impact on Application: Polypropylene is often used in applications where chemical exposure is limited, such as retail inventory management. Its compatibility with various printing technologies allows for easy customization.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local regulations regarding plastic materials, as well as consider the environmental impact of polypropylene, which may be scrutinized in certain markets.

What Role Does PVC Play in RFID Custom Manufacturing?

Key Properties: Polyvinyl chloride (PVC) is a versatile plastic known for its rigidity and excellent moisture resistance. It can function effectively in temperatures ranging from -10°C to 60°C.

Pros & Cons: PVC is durable and cost-effective, making it a popular choice for RFID tags used in logistics and asset tracking. However, it can be less environmentally friendly due to the release of harmful chemicals during production and disposal.

Impact on Application: PVC is particularly suitable for applications requiring waterproofing, such as in outdoor environments or supply chain management. Its robustness ensures reliable performance in various conditions.

Considerations for International Buyers: Buyers in the Middle East and Europe should be aware of compliance with environmental regulations, such as REACH in the EU, which governs the use of hazardous substances. Understanding local standards is crucial for successful market entry.

How Does Metal Affect RFID Custom Solutions?

Key Properties: Metals, such as aluminum and stainless steel, provide exceptional durability and resistance to extreme temperatures and pressures. They can withstand harsh environmental conditions, making them ideal for industrial applications.

Pros & Cons: The primary advantage of metal RFID tags is their longevity and reliability in challenging environments. However, they are generally more expensive and may require specialized manufacturing processes, increasing lead times.

Impact on Application: Metal tags are commonly used in asset tracking, particularly in industries like manufacturing and transportation, where exposure to harsh conditions is prevalent.

Considerations for International Buyers: Buyers from regions like Saudi Arabia and Brazil must consider the metallurgical standards and certifications required for their specific industry applications, ensuring compliance with local regulations.

What Are the Benefits of Silicone in RFID Custom Solutions?

Key Properties: Silicone is a flexible material known for its high-temperature resistance and excellent durability. It can operate effectively in temperatures ranging from -50°C to 200°C.

Pros & Cons: Silicone’s flexibility allows for the creation of RFID tags that can be integrated into various surfaces and shapes. However, it is generally more expensive than other materials and may not be suitable for high-volume production due to manufacturing complexities.

Impact on Application: Silicone is particularly beneficial in medical or high-tech applications where flexibility and biocompatibility are essential.

Considerations for International Buyers: Buyers in Europe and the Middle East should be aware of medical device regulations and standards when using silicone in RFID applications, ensuring compliance with relevant health and safety guidelines.

Summary Table of Material Selection for RFID Custom Applications

| Material | Typical Use Case for rfid custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | Retail inventory management | Low cost and easy to manufacture | Lower durability in harsh conditions | Low |

| PVC | Logistics and asset tracking | Durable and moisture-resistant | Environmental concerns | Low |

| Metal | Industrial asset tracking | Exceptional durability | Higher cost and manufacturing complexity | High |

| Silicone | Medical and high-tech applications | Flexibility and high-temperature resistance | Higher cost and complex manufacturing | Med |

This strategic material selection guide provides international B2B buyers with the insights needed to make informed decisions regarding RFID custom solutions, ensuring that they choose the right materials for their specific applications and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for rfid custom

What Are the Key Stages in the Manufacturing Process of RFID Custom Solutions?

The manufacturing process for RFID custom solutions is intricate, involving several key stages to ensure high-quality outcomes. Understanding these stages will help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: What Materials Are Used in RFID Manufacturing?

The first stage involves selecting and preparing materials suitable for RFID tags and systems. Common materials include:

- Silicon Chips: The core of RFID technology, these chips process and store data.

- Antennas: Made from copper or aluminum, antennas enable communication between the RFID reader and the tag.

- Substrates: Plastic, paper, or metal materials that house the RFID components. The choice of substrate affects durability and application suitability.

Proper material preparation ensures that components meet technical specifications and performance standards.

Forming: How Are RFID Components Shaped and Assembled?

In the forming stage, the prepared materials are shaped into their final forms through various techniques:

- Die-Cutting: This method allows for precise cutting of substrates to create tags of various shapes and sizes.

- Injection Molding: Used for creating durable housings that protect internal components, especially in harsh environments.

- Printing: Advanced printing technologies are utilized for embedding circuitry onto substrates and adding branding or identification marks.

Each technique has its advantages, and the choice largely depends on the intended use of the RFID solution.

Assembly: What Are the Key Steps in RFID Assembly?

The assembly stage combines all components to create the final product. Key steps include:

- Chip Attachment: Silicon chips are affixed to antennas using adhesives or soldering techniques.

- Encapsulation: This involves sealing the RFID assembly in protective casings to safeguard against environmental factors.

- Integration: For complex systems, integrating RFID tags with software and hardware components is crucial for functionality.

Effective assembly processes ensure that RFID tags are reliable and ready for deployment.

Finishing: How Is Quality Enhanced in the Final Stage?

The finishing stage involves additional processes to enhance the quality of RFID solutions:

- Surface Treatment: Techniques like coating or laminating are applied to improve durability and resistance to wear and tear.

- Labeling: Final products are labeled with important information such as serial numbers, barcodes, or QR codes for tracking purposes.

Finishing touches are essential for ensuring that RFID products meet industry standards and customer expectations.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance (QA) is a critical aspect of the RFID manufacturing process. International standards and industry-specific regulations ensure that products meet safety, reliability, and performance criteria.

Which International Standards Are Relevant for RFID Custom Solutions?

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements. B2B buyers should confirm that their suppliers hold ISO 9001 certification.

- CE Marking: Common in Europe, CE marking indicates compliance with health, safety, and environmental protection standards. It is crucial for products intended for the European market.

- API Standards: In sectors like oil and gas, adhering to API standards is essential for RFID solutions used in tracking and asset management.

Understanding these standards can guide buyers in selecting reputable suppliers.

What Are the Key Quality Control Checkpoints in RFID Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process to ensure product integrity:

- Incoming Quality Control (IQC): At this stage, raw materials are inspected for compliance with specifications before they are used in production.

- In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are conducted to identify any defects or deviations from quality standards.

- Final Quality Control (FQC): The final product undergoes thorough testing to ensure it meets all specifications and standards before shipping.

Implementing these QC checkpoints can significantly reduce the risk of defects in the final product.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying the quality control processes of suppliers is essential for ensuring reliable RFID solutions. Here are some actionable steps:

What Audit Methods Can Be Used to Assess Supplier Quality?

- Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturer’s processes, facilities, and adherence to quality standards. This firsthand assessment provides insights into their operational capabilities.

- Requesting Quality Reports: Suppliers should provide documentation related to their quality control processes, including test results and compliance certifications. Reviewing these reports can help buyers assess the reliability of the supplier.

Are Third-Party Inspections a Good Option for Ensuring Quality?

Utilizing third-party inspection services is an effective way for buyers to verify the quality of RFID products. These independent inspectors can evaluate the manufacturing processes, conduct tests, and confirm compliance with industry standards. This step adds an extra layer of confidence for B2B buyers, especially when sourcing from international markets.

What Specific QC Considerations Should International Buyers Keep in Mind?

When sourcing RFID custom solutions from suppliers in Africa, South America, the Middle East, and Europe, buyers should be aware of several nuances:

- Cultural and Regulatory Differences: Different regions may have varying quality standards and regulatory requirements. Understanding these differences is vital for ensuring compliance and successful market entry.

- Communication and Transparency: Establishing clear communication channels with suppliers can help mitigate misunderstandings related to quality expectations and product specifications.

- Logistics and Supply Chain Considerations: Quality assurance also extends to logistics. Buyers should assess how suppliers manage shipping, handling, and storage to prevent damage or loss of quality during transit.

By focusing on these areas, B2B buyers can make informed decisions and ensure that they partner with manufacturers capable of delivering high-quality RFID solutions tailored to their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rfid custom’

The procurement of RFID custom solutions is a strategic decision that can significantly enhance operational efficiency. This step-by-step checklist is designed to guide international B2B buyers from regions such as Africa, South America, the Middle East, and Europe in navigating the sourcing process effectively.

Step 1: Define Your Technical Specifications

Understanding your specific needs is crucial before engaging suppliers. Clearly outline the technical specifications of the RFID custom solutions you require, such as frequency, range, data storage capacity, and compatibility with existing systems. This step ensures that you communicate your requirements effectively and helps suppliers to provide tailored solutions.

Step 2: Conduct Market Research

Invest time in researching the current RFID market landscape. Identify trends, technologies, and innovative solutions that align with your business goals. Look into suppliers’ market presence, product offerings, and customer feedback to gain insights into their reliability and performance. This knowledge can empower you to make informed decisions.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Evaluate their experience with RFID custom solutions and ask for examples of past projects that demonstrate their capabilities. Don’t just rely on their website; conduct thorough due diligence to ensure they meet your expectations.

Step 4: Verify Supplier Certifications and Compliance

Compliance with international standards is vital when sourcing RFID solutions. Verify that potential suppliers hold relevant certifications such as ISO, CE, or FCC, which signify their adherence to quality and safety regulations. This step mitigates risks associated with sourcing from non-compliant suppliers, ensuring that your investment is protected.

Step 5: Request Samples and Prototypes

Before finalizing your order, request samples or prototypes of the RFID custom solutions. This allows you to assess the quality, functionality, and compatibility of the products with your systems. Testing samples can also help you identify any potential issues that may arise during implementation, saving you time and resources in the long run.

Step 6: Negotiate Terms and Conditions

Engage in discussions with suppliers to negotiate favorable terms and conditions. Consider aspects such as pricing, payment terms, delivery timelines, and warranty provisions. Clear agreements can prevent misunderstandings and ensure that both parties are aligned on expectations and deliverables.

Step 7: Establish a Communication Plan

Effective communication is essential for a successful sourcing process. Establish a clear communication plan with your chosen supplier, detailing how you will exchange information, track progress, and address any issues that arise. Regular check-ins and updates can foster a collaborative relationship, ensuring that your project stays on track.

By following this comprehensive checklist, B2B buyers can streamline the sourcing process for RFID custom solutions, ensuring that they make informed decisions that align with their operational needs and business objectives.

Comprehensive Cost and Pricing Analysis for rfid custom Sourcing

What Are the Key Components of Cost in RFID Custom Sourcing?

Understanding the cost structure of RFID custom sourcing is crucial for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. The main components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality materials may have a higher upfront cost but can lead to lower failure rates and longer lifespans, ultimately reducing the Total Cost of Ownership (TCO).

-

Labor: Labor costs vary by region and can influence the pricing of RFID solutions. Countries with lower labor costs may offer competitive pricing, but it’s essential to ensure that quality is not compromised.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and administrative expenses. These costs are typically factored into the pricing and can vary widely based on the supplier’s location.

-

Tooling: Custom RFID solutions often require specific tooling, which can lead to significant upfront costs. Buyers should inquire about tooling costs and whether they are included in the quoted price.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and compliance with international standards. Suppliers that prioritize QC may charge higher prices, but this investment can prevent costly issues down the line.

-

Logistics: Shipping and handling costs can vary based on the distance from the supplier to the buyer, as well as the chosen shipping method. Incoterms will also play a crucial role in determining who bears these costs.

-

Margin: Suppliers will include a profit margin in their pricing. Understanding typical margins within the RFID industry can help buyers gauge whether a quote is reasonable.

How Do Volume and Customization Affect RFID Pricing?

The volume of your order can significantly influence pricing. Most suppliers have Minimum Order Quantities (MOQs) that determine the base price per unit. Larger orders can lead to economies of scale, reducing the per-unit cost.

Customization is another critical factor. Highly specialized RFID solutions require more resources and time to produce, which can increase costs. Buyers should clearly define their specifications and explore whether a more standardized solution could meet their needs while remaining cost-effective.

What External Factors Influence RFID Pricing for International Buyers?

-

Quality and Certifications: The level of quality and any necessary certifications can affect pricing. Suppliers with higher certifications may charge more but offer greater reliability, which is essential for industries like healthcare and logistics.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Established suppliers with a track record of delivering quality solutions may charge a premium, but this can be justified by lower risks.

-

Incoterms: Understanding Incoterms is vital for international transactions. They define the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs, impacting the overall cost structure.

What Are Effective Negotiation and Cost-Efficiency Strategies for Buyers?

International B2B buyers should adopt a strategic approach to negotiation. Here are actionable tips:

-

Research: Familiarize yourself with market prices and supplier capabilities. This knowledge can empower you during negotiations.

-

Long-Term Relationships: Building strong relationships with suppliers can lead to better pricing and terms over time. Consider establishing partnerships that go beyond single transactions.

-

Assess Total Cost of Ownership: Look beyond the initial purchase price. Evaluate the TCO, including maintenance, operational costs, and potential downtime, to make informed decisions.

-

Flexibility in Specifications: If possible, consider flexibility in your specifications to enable suppliers to offer more cost-effective solutions.

-

Understand Regional Variations: Be aware of how local economic conditions in regions like Africa, South America, the Middle East, and Europe can affect pricing and availability.

What Should Buyers Keep in Mind Regarding Indicative Prices?

It’s important to remember that prices for RFID custom solutions can fluctuate based on market conditions, supplier availability, and raw material costs. Always request detailed quotes and be prepared for potential changes in pricing, especially in volatile markets. By understanding the cost structure and engaging effectively with suppliers, buyers can make informed decisions that align with their business goals.

Alternatives Analysis: Comparing rfid custom With Other Solutions

Understanding the Importance of Alternatives in B2B Solutions

When considering the implementation of RFID custom technology, it’s essential for international B2B buyers to explore viable alternatives that may also meet their operational needs. This comparative analysis aims to provide insights into how RFID custom stacks up against other solutions, particularly for businesses in diverse regions such as Africa, South America, the Middle East, and Europe. By evaluating performance, cost, ease of implementation, maintenance, and best use cases, buyers can make more informed decisions tailored to their specific requirements.

Comparison Table of RFID Custom and Alternative Solutions

| Comparison Aspect | Rfid Custom | Alternative 1: Barcode Systems | Alternative 2: NFC Technology |

|---|---|---|---|

| Performance | High accuracy and speed | Moderate accuracy, slower than RFID | High accuracy for short-range use |

| Cost | Higher initial investment | Lower initial cost | Moderate cost, but requires additional infrastructure |

| Ease of Implementation | Requires technical setup | Easy to implement | Moderate, requires NFC-enabled devices |

| Maintenance | Low maintenance, but needs updates | Minimal maintenance | Low maintenance, but tech-dependent |

| Best Use Case | High-volume inventory management | Retail environments | Payment systems and access control |

In-Depth Analysis of Alternatives

What Are the Advantages and Disadvantages of Barcode Systems?

Barcode systems are widely used in retail and inventory management due to their lower initial costs and ease of implementation. They require minimal technical expertise and can be deployed quickly, making them an attractive option for smaller businesses or those just beginning to automate their processes. However, their performance can lag behind RFID custom solutions, especially in environments where speed and accuracy are critical. Barcodes require line-of-sight scanning and are less effective in high-volume scenarios, which can lead to delays and potential errors.

How Does NFC Technology Compare to RFID Custom?

NFC (Near Field Communication) technology offers high accuracy for transactions and is particularly effective for payment systems and access control. It facilitates seamless communication between devices when they are in close proximity, making it user-friendly for mobile applications. However, NFC is limited to short-range interactions, which can hinder its effectiveness in large-scale inventory management compared to RFID custom solutions. Additionally, NFC requires specialized devices, which can add to the overall implementation costs.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the appropriate technology hinges on understanding your specific operational requirements and constraints. For businesses focused on high-volume inventory management, RFID custom may provide the best performance despite its higher cost and implementation complexity. Conversely, for smaller businesses or those in retail environments, barcode systems might offer a more cost-effective and straightforward solution. If the focus is on secure transactions and access control, NFC could be the most suitable alternative.

Ultimately, the decision should be based on a comprehensive evaluation of each solution’s performance capabilities, costs, and alignment with your business objectives. Engaging with technology providers to assess tailored offerings can also help in making a well-informed choice that meets both current and future needs.

Essential Technical Properties and Trade Terminology for rfid custom

What Are the Key Technical Properties of RFID Custom Solutions?

When evaluating RFID custom solutions, understanding specific technical properties is crucial for making informed purchasing decisions. Here are some essential specifications that international B2B buyers should consider:

-

Material Grade

The material grade of RFID tags and components significantly impacts durability and performance. Common materials include PVC, PET, and silicone, each offering different levels of resistance to environmental factors like moisture and temperature. Selecting the right material is vital for applications exposed to harsh conditions, ensuring longevity and reliability. -

Operating Frequency

RFID systems operate at different frequencies: Low Frequency (LF), High Frequency (HF), and Ultra High Frequency (UHF). Each frequency has its advantages and limitations, affecting read range and data transfer speed. For instance, UHF tags can provide longer read distances, making them suitable for inventory management in large warehouses. Understanding the frequency requirements of your application can optimize performance and efficiency. -

Tolerance and Accuracy

Tolerance refers to the allowable deviation in dimensions during manufacturing, which is critical for ensuring that RFID tags fit seamlessly into your existing systems. Accuracy relates to the precision of data capture and read reliability. High tolerance and accuracy are essential for applications that require real-time tracking and data integrity, such as supply chain management. -

Read Range

Read range defines the distance at which an RFID tag can be successfully read by a reader. Factors like the type of tag, reader power, and environmental conditions affect this range. Buyers should assess their operational needs to determine the appropriate read range, ensuring that the RFID solution can meet the demands of their application, whether it be asset tracking or personnel management. -

Memory Capacity

The memory capacity of RFID tags varies widely, influencing the amount of data that can be stored and transmitted. Tags with higher memory can hold more information, which is particularly beneficial for complex inventory management systems where detailed item information is necessary. Understanding the memory requirements based on your data needs is key to selecting the right RFID solution.

What Are Common Trade Terms in RFID Custom Solutions?

Familiarity with industry terminology is essential for effective communication and negotiation in the RFID sector. Here are some commonly used terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the RFID industry, working with an OEM can provide access to customized solutions tailored to specific needs. Buyers should evaluate OEM partnerships to ensure product quality and reliability. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management. Buyers should negotiate MOQ based on their projected usage to avoid overstocking or running short on critical components. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to invite them to bid on specific products or services. In the context of RFID, an RFQ helps buyers obtain competitive pricing and terms. Crafting a detailed RFQ can lead to better supplier responses and more favorable deals. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is essential for understanding shipping costs and risk management in international RFID procurement. -

Lead Time

Lead time refers to the time taken from placing an order until the goods are delivered. It’s crucial for project planning and inventory control. Buyers should inquire about lead times to ensure timely delivery aligns with operational schedules, especially in fast-paced industries.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions in their RFID custom solutions procurement, leading to improved operational efficiency and better ROI.

Navigating Market Dynamics and Sourcing Trends in the rfid custom Sector

What Are the Current Market Dynamics and Key Trends in the RFID Custom Sector?

The RFID custom sector is experiencing dynamic shifts driven by technological advancements and changing consumer expectations. Key global drivers include the increasing demand for automation and real-time data analytics across various industries, such as retail, logistics, and healthcare. This demand is particularly pronounced in emerging markets in Africa and South America, where businesses are adopting RFID technologies to enhance supply chain efficiency and inventory management.

Additionally, the integration of Internet of Things (IoT) capabilities with RFID systems is fostering innovation. B2B buyers from regions like the Middle East and Europe are particularly keen on solutions that offer seamless connectivity and data exchange. Furthermore, the rise of e-commerce is compelling businesses to rethink their inventory management strategies, leading to increased investment in RFID custom solutions that provide visibility and traceability throughout the supply chain.

Emerging trends also include a shift towards customizable RFID solutions, allowing businesses to tailor systems to their specific operational needs. This trend is beneficial for international B2B buyers who seek to optimize their processes while ensuring scalability. In conclusion, understanding these market dynamics is crucial for B2B buyers looking to make informed sourcing decisions in the RFID custom sector.

How Does Sustainability and Ethical Sourcing Impact RFID Custom Solutions?

As businesses increasingly prioritize sustainability, the RFID custom sector is adapting to meet these demands. Environmental impact is becoming a crucial consideration, with many organizations seeking to minimize waste and energy consumption in their operations. For B2B buyers, sourcing RFID solutions from manufacturers that prioritize eco-friendly practices is not only ethically responsible but also enhances brand reputation.

The importance of ethical supply chains cannot be overstated. Buyers are encouraged to inquire about the sourcing of materials used in RFID tags and readers. Options such as biodegradable plastics or recyclable components are becoming more prevalent, reflecting a commitment to sustainability. Moreover, certifications like ISO 14001 for environmental management systems can serve as indicators of a supplier’s commitment to sustainable practices.

Investing in ‘green’ RFID custom solutions can lead to long-term cost savings and improved operational efficiency. By prioritizing sustainability, international B2B buyers can align their sourcing strategies with global trends towards environmental stewardship, thereby enhancing their competitive edge in the market.

What Is the Evolution of RFID Technology and Its Relevance to B2B Buyers?

The evolution of RFID technology began in the mid-20th century, primarily used for military applications. However, its commercial adoption surged in the late 1990s and early 2000s, driven by the retail sector’s need for efficient inventory management. Today, RFID custom solutions have expanded beyond simple tracking applications, now incorporating advanced features such as real-time data analytics and integration with IoT devices.

For B2B buyers, understanding this evolution is essential, as it highlights the technology’s adaptability to various industries and applications. The ongoing advancements in RFID technology promise even greater efficiencies and capabilities. Buyers should stay informed about emerging technologies and trends that can enhance their operational strategies, ensuring they leverage the full potential of RFID custom solutions in their businesses.

Frequently Asked Questions (FAQs) for B2B Buyers of rfid custom

-

How do I choose the right RFID custom solution for my business needs?

Choosing the right RFID custom solution involves assessing your specific operational requirements, such as the type of items you need to track, the environment they will be in, and the scale of your operations. Engage with multiple suppliers to discuss your needs and ask for case studies or references from similar industries. Ensure that the solution you select offers scalability and compatibility with existing systems. Consider factors like read range, durability, and ease of integration to ensure the solution aligns with your long-term goals. -

What are the key factors to consider when vetting RFID custom suppliers?

When vetting RFID custom suppliers, prioritize their industry experience and expertise. Look for suppliers with a proven track record in delivering similar projects, as well as certifications that demonstrate quality compliance, such as ISO standards. Evaluate their customer service and support capabilities, as ongoing assistance is crucial for successful implementation. Don’t hesitate to request samples or prototypes to assess product quality firsthand. Additionally, consider their manufacturing capabilities and lead times to ensure they can meet your demands. -

What is the minimum order quantity (MOQ) for RFID custom solutions?

The minimum order quantity (MOQ) for RFID custom solutions can vary significantly based on the supplier and the complexity of the customization required. Typically, MOQs can range from a few hundred to several thousand units. Discussing your specific needs with potential suppliers can sometimes lead to flexibility, especially if you’re willing to negotiate on price or delivery timelines. Be sure to clarify any bulk order discounts that may be available, as this can significantly impact your overall procurement costs. -

What payment terms should I expect when sourcing RFID custom products internationally?

Payment terms for international RFID custom products can vary widely depending on the supplier and your relationship with them. Common terms include upfront payments, partial payments upon order confirmation, and final payments upon delivery. It’s advisable to negotiate terms that offer you protection, such as letters of credit or escrow services. Always ensure that the payment method you choose is secure and consider the impact of currency exchange rates on your overall costs. -

How can I ensure quality assurance (QA) for my RFID custom products?

To ensure quality assurance for your RFID custom products, establish clear specifications and standards before placing an order. Request documentation from suppliers that outlines their QA processes, including testing procedures and compliance with industry standards. Consider implementing a third-party inspection service to verify product quality prior to shipment. Maintaining open communication with your supplier throughout the production process can also help address any potential issues early. -

What logistics considerations should I keep in mind when importing RFID custom products?

When importing RFID custom products, logistics considerations include shipping methods, customs regulations, and lead times. Evaluate whether air freight or sea freight is more suitable based on your urgency and budget. Familiarize yourself with the customs requirements of your destination country, including any tariffs or duties that may apply. Partnering with a logistics provider experienced in handling international shipments can streamline the process and help avoid delays.

A stock image related to rfid custom.

-

How do I handle potential language barriers when sourcing RFID products internationally?

Handling language barriers when sourcing RFID products internationally can be approached by using clear and simple language in all communications. Utilizing professional translation services for critical documents can help ensure accuracy. Consider establishing a local contact or representative who can facilitate communication and clarify any misunderstandings. Additionally, many suppliers may have staff fluent in English or other major languages, so inquire about language capabilities during your supplier vetting process. -

What are the common challenges faced in the RFID custom sourcing process and how can I overcome them?

Common challenges in the RFID custom sourcing process include miscommunication, quality discrepancies, and unexpected delays. To overcome these issues, invest time in thorough supplier vetting and establish clear communication channels. Utilize project management tools to track progress and set milestones. Build strong relationships with your suppliers based on transparency and collaboration, which can foster better problem-solving when challenges arise. Regularly review performance metrics to identify areas for improvement.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for rfid custom

In navigating the dynamic landscape of RFID custom solutions, international B2B buyers must prioritize strategic sourcing as a cornerstone of their procurement strategy. The key takeaways from this guide emphasize the importance of understanding local market conditions, leveraging supplier relationships, and embracing innovative technologies. By aligning sourcing practices with the unique needs of their industries, businesses in regions such as Africa, South America, the Middle East, and Europe can enhance operational efficiency and drive significant cost savings.

What are the benefits of strategic sourcing in RFID custom solutions? Strategic sourcing not only helps in identifying reliable suppliers but also fosters long-term partnerships that can lead to tailored solutions and improved service delivery. It enables companies to adapt to market changes swiftly, ensuring they remain competitive in a global marketplace.

Looking ahead, the future of RFID custom solutions is promising, driven by advancements in technology and increasing demand for data-driven decision-making. Buyers are encouraged to take proactive steps in their sourcing strategies, exploring new partnerships and investing in innovative RFID technologies that align with their business goals. As the industry evolves, staying informed and adaptable will be crucial for sustained success.