Unlock Savings: The Ultimate Electric Motor Supplier Guide (2025)

Introduction: Navigating the Global Market for electric motor supplier

Navigating the global market for electric motor suppliers can be a daunting task for international B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe. With a plethora of options available, finding the right supplier that meets specific needs—whether it’s for industrial applications, automotive parts, or renewable energy solutions—poses significant challenges. This guide aims to streamline your sourcing process by providing a comprehensive overview of electric motor types, their diverse applications, and the critical factors involved in supplier vetting.

In this resource, we will delve into the various types of electric motors, including AC and DC motors, and their respective applications across different industries. We will also explore essential aspects of selecting a reliable supplier, such as evaluating technical specifications, understanding manufacturing capabilities, and assessing customer service practices. Furthermore, cost considerations will be discussed, empowering you to make informed purchasing decisions without compromising quality.

This guide is tailored specifically for B2B buyers from regions like Egypt and Vietnam, ensuring that it addresses the unique challenges and opportunities within these markets. By equipping you with actionable insights and best practices, we aim to enhance your ability to navigate this complex landscape and secure the most suitable electric motor suppliers for your business needs.

Understanding electric motor supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| AC Motors | Operate on alternating current; high efficiency | HVAC systems, industrial machinery | Pros: Cost-effective, reliable. Cons: Less torque at low speeds. |

| DC Motors | Operate on direct current; provide high torque | Electric vehicles, robotics | Pros: Excellent speed control. Cons: Maintenance can be higher. |

| Stepper Motors | Move in discrete steps; precise control | 3D printers, CNC machines | Pros: High precision, easy to control. Cons: Limited speed range. |

| Servo Motors | Feedback control for precise movement | Robotics, automation systems | Pros: High accuracy and performance. Cons: Can be more expensive. |

| Brushless Motors | No brushes; longer lifespan; higher efficiency | Electric bicycles, drones | Pros: Low maintenance, high efficiency. Cons: Higher initial costs. |

What Are AC Motors and Their B2B Applications?

AC motors are widely used in various industrial applications due to their efficiency and durability. They operate on alternating current, making them suitable for applications like HVAC systems and industrial machinery. When purchasing AC motors, buyers should consider factors such as power requirements, installation space, and compatibility with existing systems. While they are generally cost-effective and reliable, they may not provide sufficient torque at low speeds, which could be a drawback for certain applications.

How Do DC Motors Work and What Are Their Benefits?

DC motors are known for their ability to provide high torque and excellent speed control, making them ideal for applications such as electric vehicles and robotics. Their operation relies on direct current, which allows for easy manipulation of speed and torque. B2B buyers should assess the specific torque and speed requirements of their applications before purchasing. While they offer significant advantages in control, maintenance can be more demanding compared to AC motors, which is an important consideration for long-term operational costs.

Why Choose Stepper Motors for Precision Applications?

Stepper motors are designed to move in discrete steps, offering high precision and control. They are commonly used in applications like 3D printers and CNC machines, where accuracy is critical. When considering stepper motors, B2B buyers should evaluate the required precision levels and the complexity of control systems. While stepper motors excel in precision, they may have limitations in speed range, which could affect their suitability for high-speed applications.

What Are the Advantages of Servo Motors in Automation?

Servo motors are equipped with feedback control systems that allow for precise movement and positioning, making them essential in robotics and automation systems. Buyers should focus on the specific performance requirements of their applications, such as speed, torque, and accuracy. Although servo motors offer high performance and accuracy, they can come with a higher price tag, which is an important factor for budget-conscious buyers.

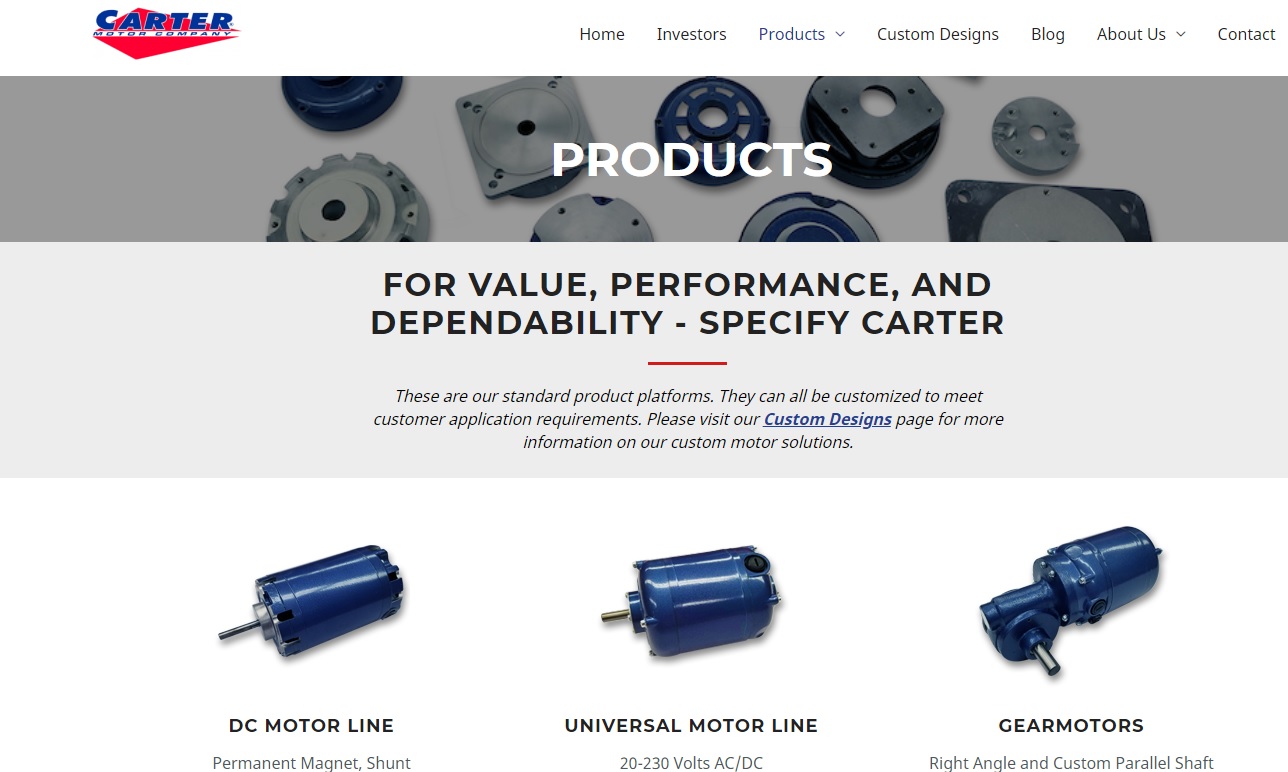

A stock image related to electric motor supplier.

Are Brushless Motors Worth the Investment?

Brushless motors eliminate the need for brushes, resulting in longer lifespans and higher efficiency. They are increasingly used in applications like electric bicycles and drones. When considering brushless motors, B2B buyers should evaluate their initial costs against long-term maintenance savings. While they provide significant advantages in efficiency and require less maintenance, the upfront investment can be higher compared to traditional motor types, making it essential to perform a cost-benefit analysis.

Related Video: Electric Motor Winding Types Comparison | Concentrated Winding vs Distributed Winding

Key Industrial Applications of electric motor supplier

| Industry/Sector | Specific Application of electric motor supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Electric motors in conveyor systems | Increased efficiency and reduced downtime | Reliability, power rating, and compatibility with existing systems |

| Agriculture | Electric motors for irrigation systems | Enhanced water management and energy savings | Weather resistance, power requirements, and ease of maintenance |

| Transportation | Electric motors in electric vehicles (EVs) | Lower operational costs and reduced environmental impact | Battery compatibility, motor efficiency, and regulatory compliance |

| Mining and Minerals | Electric motors for drilling and extraction equipment | Improved productivity and reduced labor costs | Durability, torque specifications, and sourcing of spare parts |

| HVAC Systems | Electric motors in heating, ventilation, and air conditioning (HVAC) systems | Optimized energy consumption and system reliability | Energy efficiency ratings, size, and integration capabilities |

How Are Electric Motors Used in Manufacturing Applications?

In manufacturing, electric motors are integral to conveyor systems, which facilitate the movement of materials and products throughout the production line. They help streamline operations, reducing manual labor and minimizing downtime due to mechanical failures. International B2B buyers should prioritize sourcing motors that offer high reliability and power ratings, ensuring compatibility with existing systems to maximize productivity.

What Role Do Electric Motors Play in Agriculture?

Electric motors are vital in agricultural settings, particularly in irrigation systems where they drive pumps to ensure consistent water supply. This application enhances water management, leading to significant energy savings and improved crop yields. Buyers from regions like Africa and South America should consider motors that are weather-resistant and meet specific power requirements, as these factors can greatly influence operational efficiency.

How Are Electric Motors Transforming Transportation?

In the transportation sector, electric motors are essential components of electric vehicles (EVs). They contribute to lower operational costs and a reduced carbon footprint, aligning with global sustainability goals. B2B buyers must focus on sourcing motors that are compatible with various battery technologies and efficient in terms of energy consumption, adhering to local regulatory standards, especially in Europe and the Middle East.

What Are the Benefits of Electric Motors in Mining and Minerals?

Electric motors are used in drilling and extraction equipment within the mining and minerals sector, significantly improving productivity and reducing labor costs. They provide the necessary power and torque for heavy-duty applications, making them indispensable in challenging environments. Buyers should seek durable motors with specific torque specifications and ensure the availability of spare parts to minimize downtime.

How Do Electric Motors Enhance HVAC Systems?

Electric motors are critical in heating, ventilation, and air conditioning (HVAC) systems, where they drive fans and compressors. These motors help optimize energy consumption and enhance system reliability, leading to lower operational costs. When sourcing motors for HVAC applications, buyers should pay attention to energy efficiency ratings, size compatibility, and the ability to integrate with existing systems for seamless operation.

Related Video: Electric Motor FACTORY – HOW IT’S MADE a Industrial Motor Assembly

3 Common User Pain Points for ‘electric motor supplier’ & Their Solutions

Scenario 1: Navigating Voltage Compatibility Issues

The Problem:

B2B buyers often encounter challenges when sourcing electric motors that are compatible with their existing systems, particularly when dealing with international suppliers. For instance, a manufacturer in South Africa may require motors that operate at 400V, while suppliers from Europe might primarily offer 230V models. This mismatch can lead to delays in production, increased costs due to the need for additional transformers or converters, and potential safety hazards if the equipment is improperly configured.

The Solution:

To effectively navigate voltage compatibility issues, buyers should begin by conducting a thorough analysis of their operational requirements, including voltage levels, phase types (single or three-phase), and frequency (Hz). When engaging with electric motor suppliers, clearly communicate these specifications upfront. Utilize platforms that allow for detailed filtering of suppliers based on voltage compatibility.

Additionally, consider partnering with local electrical engineers who understand regional electrical standards. They can provide insights into local practices and help negotiate with suppliers to ensure that the motors meet the required specifications. This proactive approach not only mitigates risks but also streamlines the sourcing process.

Scenario 2: Quality Assurance and Reliability Concerns

The Problem:

Quality assurance is a significant concern for B2B buyers in the electric motor sector, especially when sourcing from suppliers in regions with varying manufacturing standards. A buyer in Brazil may have previously experienced issues with motors that failed prematurely, leading to costly downtimes and repairs. Such experiences foster mistrust and raise questions about the reliability of suppliers, complicating future procurement efforts.

The Solution:

To address quality assurance concerns, buyers should implement a structured supplier evaluation process. This includes requesting certifications such as ISO 9001, which indicates adherence to quality management principles. Buyers can also demand product samples or trial orders before committing to larger purchases.

Conducting site visits to the supplier’s manufacturing facility can provide valuable insights into their quality control processes. Furthermore, building a long-term relationship with a few select suppliers can lead to better transparency regarding product quality and performance history. Engaging in open discussions about quality expectations and performance guarantees can also foster trust and accountability.

Scenario 3: Understanding Technical Specifications and Support

The Problem:

Many international B2B buyers lack the technical knowledge necessary to understand the intricate specifications of electric motors, which can lead to incorrect purchases and operational inefficiencies. For example, a buyer in Egypt might struggle to grasp the implications of torque ratings or efficiency classes, resulting in the acquisition of motors that do not meet their operational needs, thereby increasing operational costs and reducing productivity.

The Solution:

To overcome the knowledge gap in technical specifications, buyers should prioritize education and research. Engaging with suppliers who offer comprehensive technical support is crucial. Buyers should ask for detailed product documentation, including datasheets that explain motor characteristics, installation guidelines, and operational best practices.

Investing in training sessions or webinars hosted by suppliers can also significantly enhance understanding. Additionally, forming a collaborative network with other businesses in the same industry can provide insights and shared experiences regarding motor specifications. Utilizing online resources, forums, and technical articles can further augment this knowledge base, allowing buyers to make informed decisions when selecting electric motors.

Strategic Material Selection Guide for electric motor supplier

When selecting materials for electric motors, international B2B buyers must consider various factors that influence performance, cost, and compliance with regional standards. Here, we analyze four common materials used in electric motors, highlighting their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Copper in Electric Motors?

Copper is widely used in electric motor windings and connectors due to its excellent electrical conductivity and thermal properties. It typically has a temperature rating of up to 200°C and exhibits good corrosion resistance, making it suitable for various environments.

Pros and Cons: The primary advantage of copper is its high conductivity, which enhances motor efficiency and performance. However, copper is relatively expensive compared to alternatives like aluminum, and its manufacturing processes can be complex, involving precise winding techniques.

Impact on Application: Copper’s compatibility with high-temperature applications makes it ideal for motors used in industrial settings where heat generation is significant.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM B170 for copper wire and consider local sourcing options to mitigate costs. In regions like Europe, adherence to RoHS (Restriction of Hazardous Substances) regulations is also crucial.

How Does Aluminum Compare as a Material for Electric Motors?

Aluminum is often used in electric motor housings and rotor components due to its lightweight nature and decent conductivity, which is about 60% that of copper. It has a temperature rating of around 150°C and offers good corrosion resistance.

Pros and Cons: The lightweight characteristic of aluminum reduces the overall weight of the motor, enhancing efficiency in applications where weight is a critical factor. However, its lower conductivity compared to copper can lead to reduced performance in high-demand applications.

Impact on Application: Aluminum is suitable for motors that operate in humid or corrosive environments, making it a preferred choice in coastal regions.

Considerations for International Buyers: Buyers should be aware of the standards like ASTM B221 for aluminum extrusions and consider the availability of aluminum in local markets, particularly in Africa and South America, where supply chains may vary.

What Role Does Steel Play in Electric Motor Manufacturing?

Steel, particularly electrical steel, is essential for the magnetic components of electric motors. It has a high magnetic permeability and can withstand high temperatures, typically rated up to 250°C.

Pros and Cons: The key advantage of using electrical steel is its ability to enhance magnetic performance, which is crucial for efficient motor operation. However, steel can be heavier than other materials, potentially affecting the motor’s overall weight and efficiency.

Impact on Application: Steel is particularly beneficial in applications requiring high torque and power, such as industrial motors and heavy machinery.

Considerations for International Buyers: Compliance with standards like DIN EN 10106 for electrical steel is essential. Buyers should also consider local manufacturing capabilities to ensure timely delivery and cost-effectiveness.

Why Is Plastic Used in Electric Motor Components?

Plastics are increasingly used in non-load-bearing components of electric motors, such as insulation, housings, and fan blades. They offer excellent electrical insulation properties and can withstand temperatures up to 120°C.

Pros and Cons: The primary advantage of plastics is their lightweight nature and resistance to corrosion, which can extend the lifespan of motor components. However, plastics may not be suitable for high-temperature applications and can degrade over time under certain conditions.

Impact on Application: Plastics are ideal for smaller motors used in household appliances and consumer electronics where weight and insulation are critical.

Considerations for International Buyers: Buyers should ensure compliance with international plastics standards, such as ISO 9001, and assess the availability of high-quality plastics in their region, particularly in emerging markets.

Summary Table of Material Selection for Electric Motor Suppliers

| Material | Typical Use Case for electric motor supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Windings and connectors | High electrical conductivity | Higher cost and complex manufacturing | High |

| Aluminum | Housings and rotor components | Lightweight and good corrosion resistance | Lower conductivity than copper | Medium |

| Steel | Magnetic components | Enhanced magnetic performance | Heavier than alternatives | Medium |

| Plastic | Insulation and non-load-bearing components | Lightweight and corrosion-resistant | Not suitable for high-temperature use | Low |

A stock image related to electric motor supplier.

This strategic material selection guide provides international B2B buyers with essential insights into the materials used in electric motors, enabling informed decisions that align with performance requirements and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for electric motor supplier

What Are the Main Stages of Manufacturing Electric Motors?

The manufacturing process of electric motors involves several critical stages that ensure the final product meets performance and quality standards. Below are the key stages typically involved:

Material Preparation

The first step in the manufacturing process is the selection and preparation of raw materials. Common materials include:

- Copper for windings due to its excellent conductivity.

- Silicon steel for the stator and rotor cores, providing efficient magnetic properties.

- Insulating materials such as polymers for electrical insulation.

Once selected, these materials undergo rigorous quality checks to ensure they meet the required specifications. This may include chemical composition analysis and physical property testing.

Forming

After material preparation, the next stage is forming. This includes:

- Stamping: The silicon steel sheets are stamped into specific shapes for the stator and rotor.

- Winding: Copper wire is wound around the stator and rotor cores. This is often done using automated winding machines to maintain precision and reduce labor costs.

The forming stage is critical as it sets the foundation for the motor’s efficiency and performance.

Assembly

The assembly stage involves integrating all components to create the final product. Key steps include:

- Mounting the rotor within the stator.

- Connecting windings to the power supply and ensuring proper alignment.

- Incorporating bearings and other mechanical parts.

During assembly, manufacturers often employ automated systems to enhance precision and minimize human error.

Finishing

The final stage is finishing, which includes:

- Painting and coating: This protects against corrosion and enhances durability.

- Final assembly checks: Ensuring all parts are correctly installed and functioning.

Quality at this stage is crucial, as it affects the motor’s longevity and performance under various operating conditions.

What Quality Assurance Standards Should B2B Buyers Be Aware Of?

Quality assurance in electric motor manufacturing is governed by various international and industry-specific standards. Understanding these can help B2B buyers assess the credibility of suppliers.

International Standards

-

ISO 9001: This standard focuses on quality management systems and is widely adopted across industries. Suppliers who are ISO 9001 certified demonstrate their commitment to quality and continuous improvement.

-

ISO 14001: This standard pertains to environmental management systems. Suppliers adhering to this standard indicate a commitment to sustainable practices, which is increasingly important for global buyers.

Industry-Specific Certifications

-

CE Marking: Required for products sold in the European Economic Area, it indicates conformity with health, safety, and environmental protection standards.

-

API (American Petroleum Institute): For motors used in the oil and gas industry, API certifications ensure compliance with specific safety and performance standards.

What Are the Key Quality Control Checkpoints in Electric Motor Manufacturing?

Quality control (QC) is integral to the manufacturing process, ensuring that each motor meets stringent performance standards. Here are the primary QC checkpoints:

Incoming Quality Control (IQC)

This checkpoint occurs at the beginning of the manufacturing process. Incoming materials, such as copper and steel, undergo rigorous testing to verify that they meet predefined specifications. This may include:

- Visual inspections for defects.

- Dimensional checks to ensure materials are within tolerance levels.

- Material composition tests to confirm quality.

In-Process Quality Control (IPQC)

During the manufacturing process, continuous monitoring is essential. IPQC involves:

- Routine inspections at various stages, such as after winding and before assembly.

- Testing for electrical continuity to ensure windings are correctly done.

- Monitoring equipment settings to maintain consistency in production.

Final Quality Control (FQC)

Once the motors are assembled, FQC takes place. This involves:

- Functional testing to ensure the motor operates as expected under simulated conditions.

- Performance testing for efficiency and thermal characteristics.

- Visual inspections to check for cosmetic defects.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several proactive steps to ensure that their electric motor suppliers maintain high-quality standards:

Conducting Supplier Audits

Regular audits can provide insights into a supplier’s manufacturing processes and quality control systems. During an audit, buyers should evaluate:

- Compliance with international standards (e.g., ISO 9001).

- Documentation of QC processes and any deviation reports.

- Employee training programs related to quality assurance.

Requesting Quality Reports

Buyers should ask suppliers for detailed quality reports that outline:

- Testing methodologies employed during the manufacturing process.

- Results from recent quality tests and any corrective actions taken.

- Product traceability records to confirm that materials used in production meet quality standards.

Engaging Third-Party Inspection Services

Utilizing third-party inspection agencies can offer unbiased evaluations of a supplier’s quality control practices. These agencies can conduct:

- Random sampling of products for independent testing.

- Verification of certifications and compliance with international standards.

- Assessment of the supplier’s production environment to ensure it meets industry standards.

What Are the QC and Certification Nuances for International Buyers?

International B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should consider several nuances when dealing with quality control and certifications:

- Cultural Differences: Understanding regional business practices and quality expectations can enhance negotiations with suppliers.

- Regulatory Compliance: Different countries have varying regulations regarding electric motor imports. Buyers must ensure suppliers comply with local laws and standards.

- Language Barriers: Clear communication is vital. Buyers may need to engage translators or local representatives to facilitate effective discussions regarding quality and compliance.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when selecting electric motor suppliers, ensuring they choose partners that align with their quality and operational standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric motor supplier’

The following is a comprehensive guide designed to assist international B2B buyers in sourcing electric motors effectively. This checklist provides actionable insights to streamline the procurement process, ensuring that buyers from Africa, South America, the Middle East, and Europe can make informed decisions.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is crucial for a successful procurement process. Determine the type of electric motor needed based on factors such as voltage, power output, efficiency ratings, and application. This step ensures that you attract suppliers who can meet your specific needs, reducing the risk of compatibility issues later on.

- Consider specific applications: Identify whether you need AC or DC motors, and what torque and speed requirements must be met.

- Efficiency standards: Research energy efficiency ratings, as these can significantly impact long-term operational costs.

Step 2: Research Potential Suppliers

Conduct thorough research to create a shortlist of potential suppliers. Use industry directories, trade shows, and online platforms to identify manufacturers and distributors of electric motors.

- Look for industry reputation: Check reviews and testimonials from previous clients to gauge the reliability and quality of the suppliers.

- Geographical considerations: Take into account proximity to your location, as local suppliers may offer better support and faster delivery.

Step 3: Verify Supplier Certifications

Before engaging with suppliers, confirm that they hold relevant certifications and comply with industry standards. This verification step is vital to ensure that the motors meet safety, quality, and performance benchmarks.

- Check for ISO certifications: Look for suppliers with ISO 9001 or similar certifications to ensure quality management systems are in place.

- Regulatory compliance: Ensure the products meet local regulations and standards, which may differ significantly across regions.

Step 4: Request Detailed Quotes

Once you have identified potential suppliers, request detailed quotes that outline pricing, terms, and conditions. This step is essential for comparing costs and understanding the total financial commitment involved.

- Include all costs: Ensure quotes cover not only the price of the motors but also shipping, customs duties, and any potential tariffs.

- Payment terms: Clarify payment methods and timelines to avoid surprises later in the process.

Step 5: Evaluate Supplier Capabilities

Assess the capabilities of each supplier to ensure they can meet your production demands. This evaluation includes looking into their production capacity, lead times, and technological capabilities.

- Production scalability: Understand if the supplier can scale production if your demand increases in the future.

- Technology and innovation: Determine if the supplier invests in technology to improve efficiency and product quality.

Step 6: Conduct Site Visits or Virtual Inspections

If feasible, conduct site visits to potential suppliers to evaluate their operations firsthand. If travel is not possible, request virtual tours or video inspections.

- Operational assessment: Observe the manufacturing process, quality control measures, and overall facility conditions.

- Supplier relationships: Meeting suppliers in person can foster stronger relationships and better communication channels.

Step 7: Negotiate Terms and Finalize Contracts

After selecting a supplier, negotiate favorable terms and conditions to protect your interests. This final step is crucial for establishing a clear understanding of expectations and responsibilities.

- Contract specifics: Ensure the contract includes delivery schedules, warranty details, and service agreements.

- Contingency plans: Discuss what happens in case of delays or defects, ensuring both parties are clear on their obligations.

By following this step-by-step checklist, international B2B buyers can effectively source electric motors while minimizing risks and maximizing value.

Comprehensive Cost and Pricing Analysis for electric motor supplier Sourcing

What Are the Key Cost Components in Electric Motor Supplier Pricing?

Understanding the cost structure of electric motor suppliers is crucial for international B2B buyers. The pricing typically encompasses several key components:

-

Materials: This is often the largest portion of the cost. The choice of materials, such as copper for windings or high-grade steel for cores, directly impacts both quality and price. Sourcing materials from local suppliers can sometimes reduce costs, but it is essential to ensure that quality standards are met.

-

Labor: Labor costs vary significantly by region. In areas with higher wages, such as parts of Europe, expect increased production costs. Conversely, sourcing from regions with lower labor costs, like certain parts of South America or Africa, can provide savings. However, it’s crucial to evaluate the skill level of the labor force to ensure quality output.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, maintenance, and depreciation of equipment. A well-managed facility can minimize these costs, which can translate to better pricing for buyers.

-

Tooling: Initial tooling for custom or specialized electric motors can be a significant upfront investment. For large orders, this cost can be amortized over the production run, making it less impactful per unit.

-

Quality Control (QC): Ensuring that electric motors meet specified standards requires investment in quality assurance processes. This could include testing and certification, which can affect pricing but is essential for maintaining reliability and safety.

-

Logistics: Shipping and handling can be substantial, especially for international buyers. Factors such as distance, shipping mode (air vs. sea), and customs duties must be factored into the total cost.

-

Margin: Suppliers will add a profit margin to cover their expenses and risk. Understanding typical margins in the industry can help buyers gauge whether a supplier’s pricing is competitive.

How Do Price Influencers Affect Electric Motor Sourcing?

Several factors can influence the price of electric motors, which international buyers should consider:

-

Volume/MOQ: Larger orders often yield lower prices per unit due to economies of scale. Negotiating minimum order quantities (MOQs) can be beneficial, especially for companies looking to build long-term relationships with suppliers.

-

Specifications/Customization: Custom motors designed for specific applications will typically cost more than standard models. Clear communication of requirements can help manage expectations and costs.

-

Materials: The choice of raw materials can significantly affect pricing. Buyers should assess whether premium materials are necessary for their application or if more economical options suffice.

-

Quality/Certifications: Motors that meet international standards (like ISO or CE certifications) may come at a premium, but this often ensures greater reliability and safety. Buyers should weigh the cost against the potential risks of non-compliance.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record may charge more, but their products might save costs in the long run through durability and performance.

-

Incoterms: Understanding the agreed Incoterms (International Commercial Terms) is crucial, as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. This can significantly impact the total cost of acquisition.

What Are the Best Negotiation Tips for International B2B Buyers?

To maximize cost efficiency when sourcing electric motors, buyers should consider the following strategies:

-

Research and Benchmarking: Investigate typical pricing and practices within the industry to establish a baseline for negotiations.

-

Build Relationships: Establishing a good rapport with suppliers can lead to better pricing and terms. Long-term partnerships often yield more favorable conditions.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also operational costs, maintenance, and potential downtime. A slightly higher initial investment may result in lower TCO.

-

Be Transparent: Clearly communicate your needs and expectations with suppliers. This can lead to more tailored solutions and better pricing.

Disclaimer on Indicative Prices

Prices can fluctuate based on market conditions, currency exchange rates, and geopolitical factors. Buyers should seek updated quotations and consider the broader economic context when making purchasing decisions.

Alternatives Analysis: Comparing electric motor supplier With Other Solutions

Understanding Alternative Solutions to Electric Motor Suppliers

In the quest for optimal performance and efficiency in industrial applications, B2B buyers must consider various alternatives to traditional electric motor suppliers. Different technologies may offer unique advantages depending on specific operational needs, cost structures, and maintenance capabilities. This section compares electric motor suppliers with two viable alternatives: pneumatic systems and hydraulic systems, providing insights tailored for international buyers in Africa, South America, the Middle East, and Europe.

Comparison Table of Electric Motor Supplier and Alternatives

| Comparison Aspect | Electric Motor Supplier | Pneumatic Systems | Hydraulic Systems |

|---|---|---|---|

| Performance | High efficiency and torque | Good for rapid actuation | High power density and control |

| Cost | Moderate initial investment | Lower initial cost, but high operating costs | High initial investment, lower maintenance costs |

| Ease of Implementation | Requires electrical infrastructure | Simple installation, less space needed | More complex due to hydraulic lines |

| Maintenance | Regular checks and repairs needed | Relatively low maintenance | Regular fluid checks and system integrity inspections required |

| Best Use Case | Industrial automation, HVAC | Packaging, textile, and assembly lines | Heavy machinery, automotive applications |

What Are the Benefits and Drawbacks of Pneumatic Systems?

Pneumatic systems utilize compressed air to drive machinery, offering a lightweight and flexible solution. Their primary advantage is the lower initial cost compared to electric motors. They are particularly effective in applications requiring rapid movement and high-speed operation, such as assembly lines in manufacturing. However, the ongoing costs of compressed air generation can be substantial, and pneumatic systems may lack the precision and control offered by electric motors, making them less suitable for tasks requiring fine adjustments.

How Do Hydraulic Systems Compare to Electric Motors?

Hydraulic systems use fluid power to perform work and are known for their high power-to-weight ratio. They excel in applications requiring significant force and precision, such as in heavy machinery and construction equipment. While the initial investment can be high, the operational efficiency often leads to lower long-term maintenance costs. However, hydraulic systems can be more complex to implement and require regular maintenance to check for leaks and fluid integrity. This complexity may deter some buyers, particularly those in regions with limited access to hydraulic maintenance services.

Making the Right Choice: Which Solution Is Best for Your Business?

When selecting between electric motor suppliers and alternative solutions like pneumatic or hydraulic systems, international B2B buyers must evaluate their specific operational requirements. Consider factors such as performance needs, budget constraints, and the availability of maintenance services in your region. For instance, businesses focused on high-speed, low-cost operations may benefit more from pneumatic systems, while those requiring heavy lifting and precise control may find hydraulic systems more advantageous. Understanding these nuances will empower buyers to make informed decisions that align with their operational goals and financial capacities.

Essential Technical Properties and Trade Terminology for electric motor supplier

What Are the Key Technical Properties of Electric Motors?

When sourcing electric motors, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications:

-

Material Grade

– Definition: Material grade refers to the specific classification of materials used in the motor’s construction, such as copper for windings or steel for the casing.

– B2B Importance: Higher-grade materials typically enhance durability and performance, affecting the lifespan and efficiency of the motor. This is critical for businesses looking to minimize maintenance costs and downtime. -

Tolerance

– Definition: Tolerance indicates the permissible limit of variation in physical dimensions and specifications of the motor components.

– B2B Importance: Precise tolerances ensure that the motor operates smoothly without excess vibration or wear. This is particularly important for applications requiring high precision, such as in manufacturing and automation. -

Efficiency Rating

– Definition: Efficiency rating measures how effectively an electric motor converts electrical energy into mechanical energy, often expressed as a percentage.

– B2B Importance: Higher efficiency ratings reduce energy consumption, resulting in lower operational costs. For buyers in regions with high energy costs, selecting efficient motors can significantly impact the bottom line. -

Power Output

– Definition: Power output refers to the amount of mechanical power produced by the motor, usually measured in horsepower (HP) or kilowatts (kW).

– B2B Importance: Understanding power output is essential for ensuring that the motor meets the specific requirements of the intended application, whether it be in heavy machinery or smaller devices. -

Operating Temperature Range

– Definition: This property indicates the range of temperatures within which the motor can operate effectively.

– B2B Importance: Motors that can function in extreme temperatures are vital for applications in harsh environments, such as in mining or outdoor installations, ensuring reliability and longevity. -

Speed Control

– Definition: Speed control refers to the motor’s ability to operate at various speeds, often facilitated by variable frequency drives (VFDs).

– B2B Importance: Motors with adjustable speed settings offer flexibility in operations and can lead to energy savings, making them suitable for diverse industrial applications.

Which Trade Terminology Should International B2B Buyers Know?

Understanding trade terminology is essential for effective communication and negotiation in the electric motor supply chain. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: B2B buyers often engage with OEMs for custom solutions tailored to specific needs, ensuring compatibility with existing systems. -

MOQ (Minimum Order Quantity)

– Definition: MOQ refers to the smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ is vital for budgeting and inventory planning, particularly for small to medium-sized enterprises (SMEs) that may not require large quantities. -

RFQ (Request for Quotation)

– Definition: An RFQ is a formal document soliciting price quotes from suppliers for specific products or services.

– Relevance: Submitting an RFQ allows buyers to compare prices and terms from multiple suppliers, facilitating better negotiation and decision-making. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping goods.

– Relevance: Familiarity with Incoterms is crucial for understanding shipping costs, risks, and delivery responsibilities, especially for international transactions involving electric motors. -

Lead Time

– Definition: Lead time is the period between placing an order and receiving the product.

– Relevance: Understanding lead times helps buyers plan their operations, ensuring that they have the necessary equipment when needed without unnecessary delays. -

Warranty Period

– Definition: This refers to the duration during which the manufacturer guarantees the product against defects.

– Relevance: Knowing the warranty period is essential for assessing the risk associated with the investment in electric motors, providing assurance of support and service.

By grasping these technical properties and trade terminologies, B2B buyers can enhance their procurement processes, ensuring they make informed decisions that align with their operational needs and budget constraints.

Navigating Market Dynamics and Sourcing Trends in the electric motor supplier Sector

What Are the Current Market Dynamics and Key Trends in the Electric Motor Supplier Sector?

The electric motor supplier sector is experiencing significant transformation, driven by global demand for energy efficiency and sustainability. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking suppliers who can offer advanced technologies that enhance operational efficiency. The rise of Industry 4.0, characterized by automation and data exchange in manufacturing technologies, is a key driver reshaping this market. This has led to a surge in demand for smart electric motors that integrate IoT capabilities, enabling real-time monitoring and predictive maintenance.

Emerging trends also include a focus on lightweight materials and compact designs, which are crucial for applications in electric vehicles and renewable energy systems. The adoption of high-efficiency motors, compliant with international standards such as IE3 and IE4, is becoming a prerequisite for buyers aiming to reduce operational costs and carbon footprints. Additionally, as global supply chains continue to evolve, B2B buyers are looking for suppliers that can provide not only competitive pricing but also flexibility in production and delivery timelines.

How Can Sustainability and Ethical Sourcing Impact B2B Buying Decisions in the Electric Motor Sector?

Sustainability is no longer just a trend; it has become a critical factor influencing B2B purchasing decisions in the electric motor supplier sector. Buyers are increasingly aware of the environmental impacts associated with the production and disposal of electric motors. As such, they are prioritizing suppliers who demonstrate a commitment to sustainable practices, including the use of recyclable materials and energy-efficient manufacturing processes.

Ethical sourcing has also gained prominence, with buyers scrutinizing the entire supply chain for compliance with social and environmental standards. Certifications such as ISO 14001 (Environmental Management) and ISO 50001 (Energy Management) are becoming essential for suppliers to showcase their commitment to sustainability. Furthermore, the demand for ‘green’ motors, which utilize eco-friendly materials and technologies, is on the rise, particularly in markets that are heavily regulated regarding emissions and waste.

What Is the Historical Context of Electric Motor Suppliers Relevant for Today’s B2B Buyers?

The electric motor industry has evolved significantly over the past century, transitioning from simple mechanical devices to complex, high-efficiency systems integral to modern manufacturing and transportation. Initially, electric motors were primarily used in industrial applications; however, the advent of electric vehicles and renewable energy technologies has expanded their applications dramatically.

In the late 20th century, advancements in materials and technology led to the development of more compact and efficient motors, paving the way for their widespread use in consumer electronics and household appliances. Today, international B2B buyers are not only looking for suppliers with a strong historical foundation but also those who are adaptable to emerging technologies and market demands. Understanding this historical context helps buyers appreciate the innovation trajectory and the importance of selecting suppliers that can provide both reliability and cutting-edge solutions.

By leveraging insights into market dynamics, sustainability practices, and historical evolution, B2B buyers can make informed sourcing decisions that align with their operational goals and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of electric motor supplier

-

How do I choose the right electric motor supplier for my business needs?

When selecting an electric motor supplier, consider factors such as product quality, supplier reputation, and industry experience. Look for suppliers that specialize in your specific application, whether it’s for industrial machinery, automotive, or renewable energy. Additionally, verify certifications and compliance with international standards. Request samples and conduct a thorough evaluation of their motors to ensure they meet your specifications. Engaging in direct discussions can also provide insights into their technical support and customer service capabilities. -

What types of electric motors are available for industrial applications?

Electric motors come in various types suitable for different industrial applications, including AC motors, DC motors, stepper motors, and servo motors. AC motors are commonly used for their durability and efficiency, while DC motors are preferred for applications requiring variable speed. Stepper motors are ideal for precise positioning, and servo motors are used in applications demanding high performance and control. Assess your specific operational requirements, such as torque, speed, and power supply, to choose the right motor type. -

What factors should I consider when negotiating payment terms with a supplier?

When negotiating payment terms, consider your cash flow needs, the supplier’s payment policies, and any potential risks involved. Common terms include upfront payments, partial payments upon order confirmation, and balance upon delivery. Aim for terms that allow you to manage your cash flow effectively while ensuring the supplier is comfortable with the arrangement. Additionally, inquire about discounts for early payments or bulk orders, which can enhance your overall purchasing efficiency. -

What is the minimum order quantity (MOQ) when sourcing electric motors?

The minimum order quantity (MOQ) for electric motors can vary significantly between suppliers, often ranging from a few units to several hundred. Factors influencing MOQ include the type of motor, manufacturing processes, and the supplier’s production capabilities. It’s advisable to discuss your specific needs with potential suppliers to understand their MOQ and explore possibilities for smaller orders, especially if you are testing a new product line or entering a new market. -

How can I ensure quality assurance when sourcing electric motors from international suppliers?

To ensure quality assurance, establish clear specifications and standards before placing an order. Request documentation of certifications, quality control processes, and test results from the supplier. Consider conducting factory audits or inspections, if feasible, to assess the supplier’s manufacturing practices. Additionally, inquire about warranty policies and after-sales support to safeguard your investment and ensure that any issues can be promptly addressed. -

What logistics considerations should I keep in mind when importing electric motors?

When importing electric motors, consider shipping methods, transit times, and customs regulations. Evaluate the cost-effectiveness of air freight versus sea freight based on your delivery timelines and budget. Ensure that the supplier provides all necessary shipping documents, including invoices and certificates of origin, to facilitate smooth customs clearance. Additionally, factor in potential tariffs and duties applicable in your country to avoid unexpected costs upon arrival. -

What should I do if I encounter issues with my electric motor order?

If you face issues with your electric motor order, promptly contact your supplier to discuss the problem. Provide detailed information about the issue, including order numbers, product specifications, and any relevant documentation. Most reputable suppliers will have a process for handling complaints, returns, or replacements. It’s important to maintain clear communication and document all interactions to ensure a satisfactory resolution. -

How can I customize electric motors to meet my specific application requirements?

Customizing electric motors is often possible through discussions with your supplier. Specify your unique requirements, such as size, power rating, mounting options, or special features like encoders or gearboxes. Many suppliers offer engineering support to help design motors tailored to your application. Be prepared to provide detailed specifications and possibly engage in a prototyping phase to ensure the final product meets your expectations before mass production.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for electric motor supplier

What Are the Key Takeaways for Strategic Sourcing of Electric Motors?

Strategic sourcing is essential for international B2B buyers seeking reliable electric motor suppliers. By understanding market dynamics and regional demands, buyers can optimize their procurement strategies to enhance operational efficiency and cost-effectiveness. Key takeaways include the importance of assessing supplier capabilities, ensuring compliance with international standards, and fostering long-term partnerships that encourage innovation and sustainability.

How Can B2B Buyers in Africa, South America, the Middle East, and Europe Benefit from Strategic Sourcing?

In regions like Africa, South America, the Middle East, and Europe, the shift towards sustainable energy solutions is accelerating. Buyers should prioritize suppliers who demonstrate a commitment to environmentally friendly practices and technological advancements. This not only aligns with global sustainability goals but also positions businesses to capitalize on emerging markets and consumer trends.

What Should B2B Buyers Do Next?

As you embark on your sourcing journey, consider leveraging digital platforms for supplier discovery and evaluation. Engage in dialogue with potential partners to understand their value propositions and capabilities. The future is bright for those who strategically navigate the electric motor supply landscape, ensuring a competitive edge in an evolving market. Take action today to secure partnerships that drive innovation and operational excellence in your organization.